Abstract

One of the main challenges facing Ethiopia today is to ensure food security for its highly increasing population growth. Although the country's production is much lower than the national demand, there are high post-harvest food losses. Among several causes at different levels, absence of infrastructure plays a critical role in quantitative and qualitative losses of mainly fruit, vegetable, root and tuber crops. This study was initiated to investigate impact of two different production areas having different road access on qualitative and quantitative loss of potato tuber in extended storage time. Load tracking approach was used by simulating existing postharvest handling and storage practice of potato tuber in the study area. Quantitative post-harvest loss assessment along the supply chains, qualitative loss and shelf life estimation at retail market were investigated using standard methods. Results showed that more mechanical damages and seepage loss were observed in case of poor road quality and transportation. During extended storage time (30 days) at ambient environment, potato tubers transported from Dedo to Jimma resulted in high average weight loss (17.9 ± 0.9%), significant loss in firmness (7.0 ± 0.6N in average) and average vitamin C content of 9.20 ± 0.05mg/100g as compared to tubers transported from Seka to Jimma market. This implies that, lack of good road access and transportation facility contributed for more external mechanical damages and internal injuries which will critically enhance rate of degradation of tubers in later stages of storage.

Keywords: Agriculture, Food science, Potato tuber, Post-harvest handling, Storage, Quantitative and qualitative loss

1. Introduction

Potatoes are the third most important food crop in the world after rice and wheat and the leading vegetable crop in area of production and productivity worldwide (ICP, 2016). More than a billion people consume potatoes and global potato production was 376.83 million metric tons in 2016 (FAOSTAT, 2017) and is projected to reach more than 400 million tonnes by 2020 (Scott et al., 2000). Potato production is expanding strongly in many developing countries accounting for more than half of the global harvest (Scott and Suarez, 2012).

In Ethiopia, root and tuber crops are the third largest national food commodity, after maize and wheat, in terms of production (Country STAT Ethiopia 2018; Emana and Nigussie, 2011). However, production of potato tuber is constrained by pre-harvest factors and postharvest losses, which in turn limit the volumes of good quality, produce reaching consumers. Although increasing production is one aspect of fulfilling food demand, failure to reduce postharvest loss reduces the availability of food crops and income that could be generated by selling these crops. According to FAO (2013) losses of starchy roots at different stages of supply chain is among the top ten food losses occurred worldwide. The most important factor leading to high losses is the perishable nature of the crops, which expose them easily to damage during post-harvest handling steps (FAO G 2011). Reduction of Postharvest losses is reported as a critical component of ensuring future global food security (Aulakh et al., 2013). Therefore, to sustain food and nutrition security, food availability needs to be increased via reduction of quantitative and qualitative losses after harvest (Aulakh et al., 2013).

So far, different attempts have been made to come up with an appropriate agronomic and pre-harvest management to increase potato tuber productivity in Ethiopia (Worku et al., 2013; Gebru et al., 2017; Kolech et al., 2015; Diro, 2016). However, Very few studies have been attempted to assess the extent of losses at different stages and all of them are survey based works and they are subjective (Tadesse et al., 2018; Emana and Nigussie, 2011; Urge et al., 2015). It is therefore, important that objectively evaluating the post-harvest quantitative and qualitative loss be given as much attention as production practices. Reducing post-harvest losses instead of increasing food production is not only making food available to consumers, it also save scarce resources and reduce environmental pollution due to intensive farming (Zorya et al., 2011). Therefore, reducing post-harvest losses seems much better and rapid option to make more foods available without increasing burden on the natural resources (Hodges et al., 2011).

Availability of good infrastructures play significant role to minimize after harvest losses of horticultural commodities. In developing countries challenges like lack of recommended harvesting practices and tools, poor road and transportation access as well as absence of low temperature storage make it difficult to extend shelf life of products and maintain desired quality. This study aimed to investigate impact of road quality and access for transportation on shelf life and quality of potato tuber during storage time at retailers' market storage condition.

In study area, farmers transport potato tuber to urban within two days after harvested since demand for potato is particularly high in the Jimma town where it is processed into value added products such as chips and French fries. From the production field the tuber undergo series of post-harvest handling stages and storage before they reach to the consumers. Each handling stage results into some losses of the tubers and leads decrease in food availability. These kinds of food losses are critical importance in food insecure countries like Ethiopia. However, no extensive study has been done to identify and quantify the extent of post-harvest losses due to mishandling practices during harvesting and handling practices in the study area. Therefore it becomes inevitable to identify the operations and channels where losses are considerable. This could lead to device technology in future for these operations and channels and will lead towards post-harvest reduction of potato tubers.

1.1. Significance of the study

In order to device alternative solutions to reduce losses, it is necessary to identify major causes of losses, critical loss points and extents of losses. This study provides substantial information about impact of two different production areas having different road access on qualitative and quantitative loss of potato tuber in extended storage time. The study also provides critical loss points and extents of losses at each supply chain from farm to retailer storage conditions. Thus, the information generated from this study are valuable impute for producers, regulatory bodies, stockholders, policy makers and etc. to help them to analyze about the existing scenario of potato postharvest handling and transportation practices and enable them to devise a strategy for its handling and transportation improvement. This could lead to development of technology for these operations and channels and results post-harvest reduction of potato tubers.

2. Material and methods

2.1. Description of study areas and transportation facility

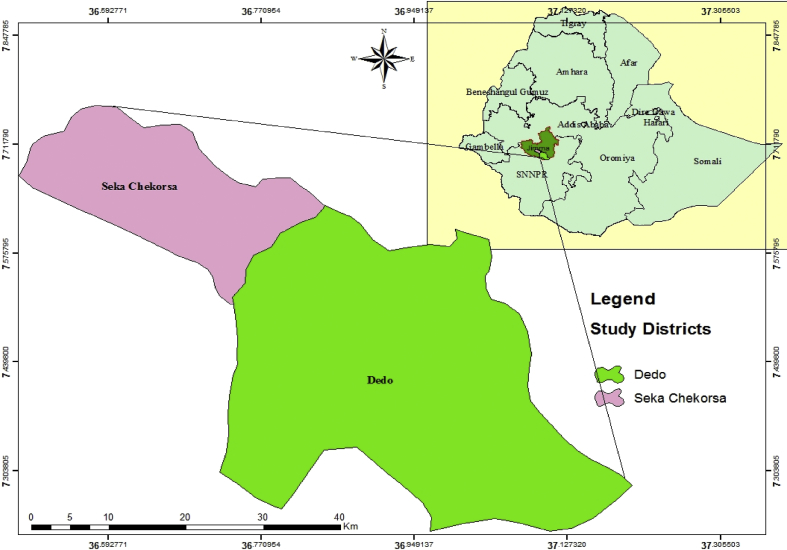

The study was conducted in Jimma zone of Oromia Regional State, Ethiopia. The load trucking FAO (2011) approach was used to determine losses at different stages of supply chain from harvesting to retail marketing of Jimma town. Two districts (Fig. 1) as per their production capacity were purposively selected from districts of Jimma zone. Dedo district is 18 km away from Jimma town and located off road (gravel surface) of main asphalt and characterized by poor road condition and access for good transportation facilities. Tubers are commonly transported from farmers household to Dedo district using draught animals back (donkeys, horses and mules) and then from district to Jimma town on top of public transportation bus which involves relatively mishandling practices. However, Seka district is 20 km far from Jimma town retail market but located in good road access area with good transportation facility as compared to Dedo. Retailer storage and quality evaluation studies were made in Jimma University College of Agriculture and Veterinary Medicine.

Fig. 1.

Geographical location of the study districts.

2.2. Sampling methods

To select the study area, preliminary information was gathered from Zonal Agriculture office and an attempt was made to select representative Peasant Associations (PAs) and individual farm from where samples were collected. Three stage sampling procedure were employed to select specific potato producer farm. First, by employing purposive sampling method, two major potato producing districts (Dedo and Seka) with different infrastructure for transportation were selected. In the second stage, by using simple random sampling technique three PAs were selected from the districts. Finally three representative farms were selected from each peasant associations to assess harvesting and post-harvesting losses of potato using load trucking approach. Tubers collected from different farms of the two districts are local varieties widely grown by farmers (Irish potato). An attempt was made to control all factors that can impact post-harvest losses of the tuber except handling practices and transportation. Important agronomic and management practices including variety, application of fertilizer, weeding, hoeing, and earthing up were implemented uniformly for all farms from where sample were collected. During transportation uniform packaging materials and weight of tubers were used by simulating existing transportation system in the study area. For all quantitative and qualitative variables, five replicated sample were collected from each farms and therefore there were 30 total experimental units.

2.3. Quantitative post-harvest loss assessment along the supply chains

Load trucking approach was applied to get quantitative post-harvest losses at different harvesting and post-harvesting operation along supply chains. From each selected farm, potato tubers were harvested from two square meter land following similar harvesting practice used by farmers. After harvesting the amount of left over tubers were collected to estimate the amount of loss incurred during harvesting due to incomplete harvesting.

It was expected that mechanical injury during harvesting, big size packing materials, overloading of the product and bump road have a significant impact on produce quality. To measure the impact of these mishandling practices, samples bags were taken and traced following similar practices used by farmers, local collectors and traders to transport their produce to final destination market (Jimma market). At each supply chain stage loss quantification was made on the basis of sorting and weighing those damaged/cut and rotten potatoes separately as well as considering physiological weight loss.

2.4. Qualitative loss and shelf life estimation at retail market

To get broader understanding on the cumulative effect of improper handling practices from harvest to retail level on the quality of potato, similar storage conditions with actual retail market store in Jimma was made. The potatoes were then stored for one month (the maximum storage period in retail market of Jimma town) and different analyses were carried out at 5 days intervals.

2.4.1. Percentage weight loss

One hundred kilogram of the tuber was taken and weight loss was determined by weighing the initial weight of the tubers and at 5 days interval during storage period using digital balance (TWIII, USA). The difference between initial and final potato tuber weight was considered as weight loss during that storage interval and then the percent weight loss were calculated as:

2.4.2. Loss in firmness (Newton)

Firmness of the potato tuber was measured by destructive or invasive method using texture analyzer (TA-XT plus 40555, UK). Samples were subjected to a puncture test at a constant speed of 2 mm/sec, using a 2 mm diameter round stainless steel probe. Then the maximum force (N) required to penetrate the sample to 5 mm depth was recorded and used as measure of loss of textural or firmness of the tubers. Three tubers were taken and three measurements were made at a time on each tuber at different locations and the results were averaged (Siddiqui et al., 2015).

2.4.3. Vitamin C determination

Ascorbic acid content was determined using the 2, 6-dichlorophenolindophenol dye titrimetric method (AOAC, 2002).

2.4.4. Shelf/Storage life index

Storage life determination was made following the methods indicated in Garg et al. (2008). Twenty four tubers of each location at each supply chain were randomly selected and evaluated. During storage the tubers were removed at the first deterioration mark (showing visible deterioration and became unmarketable). The removal of tubers was carried out until the last tubers became unmarketable. The shelf life index, accounting both the number of tubers possessing marketability and length of storage, was calculated using the following equation.

Where, ni is the number of marketable roots on ith day; ni+1 is the number of marketable roots on (i+1) th day; N is the total number of roots under observation; di is the number of days after storage.

2.5. Statistical analysis

Statistical analysis was carried out using Minitab version 16 Software and analysis of variance (ANOVA) to determine the significance differences in quantitative, qualitative loss and shelf life estimation of the samples. Differences between the sample means were conducted using Tukey's test at α = 0.05 level for parameters showed significant difference.

3. Results and discussion

3.1. Quantitative postharvest loss along supply chains

The quantitative post-harvest losses of potato tubers at different supply chain stages due to poor harvesting practices (leftovers and mechanically damaged) and losses incurred during transportation from farm to market places are presented in Table 1. The result showed that, there was a significant difference (p < 0.05) among locations and stage of supply chain. The average potato tuber yield per hectare in the study area was estimated to be 15ton and all percentage loss indicated in Table 1 is derived from 15ton yield per hectare.

Table 1.

Quantitative post-harvest losses (%) of potato root at production and different supply chain stage locations in districts of Jimma zone.

| Districts | Peasant Association | Supply chain stages |

Total loss |

|||

|---|---|---|---|---|---|---|

| Left over after harvesting (%) | Damage during harvesting (%) | Transportation loss (%) | Weight (kg) | Percent (%) | ||

| Dedo | Debele | 3.2 ± 0.2NS | 6.0 ± 0. 3c | 2.7 ± 0.1a | 11.90 | 1,785 |

| Kusaye | 4.5 ± 0.1NS | 10.0 ± 0.4a | 1.6 ± 0.1ab | 16.06 | 2,409 | |

| Quno | 3.7 ± 0.2NS | 3.3 ± 0.3d | 2.4 ± 0.2a | 9.40 | 1,416 | |

| Average loss (%) | 3.8 ± 0.4 | 6 ± 2 | 2.2 ± 0.3 | 12.45 | 1,870 | |

| Seka | Deboyaya | 5.7 ± 0.3NS | 2.8 ± 0.2d | 0.4 ± 0.3c | 8.84 | 1,326 |

| Atro Sufa | 4.7 ± 0.3NS | 9.2 ± 0.3ab | 0.9 ± 0.2bc | 14.80 | 2,220 | |

| Wekito Medalu | 3.1 ± 0.1NS | 6.80 ± 0.07bc | 1.6 ± 0.2b | 11.48 | 1,722 | |

| Average loss (%) | 4.5 ± 0.7 | 6 ± 2 | 1.0 ± 0.3 | 11.7 | 1,756 | |

| Total loss (%) | 24.84 | 38.04 | 9.6 | 72.48 | 10,878 | |

| Average loss per hectare (%) | 4.1 ± 0.2 | 6.3 ± 0.3 | 1.6 ± 0.2 | 12.08 | 1,813 | |

Notes: NS = non-significant, Results are mean values of triplicate determination and means with the different letters across the column are significantly different (p < 0.05).

As indicated in Table 1, in average 12.08 % (1.8 ton) of the tubers were lost per hectare along the supply chain stages. This indicated that in average only 87.92% (13.2 ton out of estimated average 15 tons per hectare yield) of the tubers were delivered to the final consumer. About 4.14% (621kg) tuber per hectare in average was ultimately lost in the field without harvested and 6.34% (951kg) due to mechanical damaged during harvesting. During harvesting estimated loss is about 10.48% of total harvest. This loss is mainly caused because of lack of sufficient labor force, use of traditional harvesting tools like hand hoe and traditional plow used for preparation of the land. No improved potato tuber harvester is used in the districts due its inability. Considering this volume of loss, harvesting stage can be considered as one of the critical loss points and needs consideration to improve the practice through training and use of recommended potato harvesting tools. The significant difference observed between peasant associations during harvesting could be due to difference in awareness of farmers. Seka district farmers commonly have better consultation with agriculture extension personnel and produce tubers for market as a cash crop introduced less loss.

There is also a loss during transportation of tubers from farmer's field to destination markets. Tubers commonly packed in polypropylene bags (50 kg capacity) and transported using draught animals (donkeys, mules and horses) and public transportation bus. Estimated loss during transportation is about 1.6% (240kg) per total yield transported to market. Major observed cause for the losses is mechanical damages induced due to over packing, rough handling, transportation over bump roads and inappropriate loading and unloading. It was observed that heavy bags were badly dragged and dropped and resulted in splitting and bruising of tubers.

The contribution of infrastructure to minimize after harvest losses of agricultural products is critical. For instance, when study districts are considered, higher transportation loss was incurred in sample transported from dedo district in comparison with Seka. Road from Dedo to Jimma market is gravel road with poor quality as compared to smooth Asphalt road from Seka to Jimma. Additionally, in appropriate packing, handling and over filling of sacks used to transport tubers in poor road quality critically induce mechanical damages. Overfilling of bags mainly associated with transportation cost and tax. Both market taxation and transportation costs are based on number of bags than actual weight of tuber. Similar result also indicated in Misener et al. (1989), who reported that harvesting injury and subsequent handling influence post-storage marketability of potato tubers. Thiele et al. (2009) report also concluded that potato quantities losses in the marketing chain were high due to miss treatment during harvesting and subsequent post-harvest handling.

3.2. Qualitative postharvest loss and shelf-life estimation at retail market

3.2.1. Weight loss

Once tubers purchased by retailers in Jimma market can be stored up to 3–4 weeks based upon volume of tubers purchased and market opportunities available. Table 2 shows percentage weight loss of potato as affected by locations and days in storage.

Table 2.

Changes in weight losses (%) potato tuber sampled from different areas during storage at retailers storage condition*.

| District | Locations (PA) | Storage time (days) |

||||||

|---|---|---|---|---|---|---|---|---|

| 0 | 5 | 10 | 15 | 20 | 25 | 30 | ||

| Dedo | Debele | 0 | 3.9 ± 0.9a | 4.5 ± 0.1ab | 6.6 ± 0.2ab | 9.7 ± 0.4b | 15±1b | 16±1b |

| Kusaye | 0 | 3.1 ± 0.7a | 5.5 ± 0.5ab | 7.6 ± 0.5ab | 11.6 ± 0.5a | 16.4 ± 0.9a | 19±1a | |

| Quno | 0 | 3.0 ± 0.7a | 6.4 ± 0.2a | 8.5 ± 0.1a | 11.2 ± 0.3a | 13.1 ± 0.8c | 19±1a | |

| Average | 3.3 ± 0.3 | 5.5 ± 0.6 | 7.5 ± 0.6 | 10.7 ± 0.5 | 15 ± 1 | 17.9 ± 0.9 | ||

| Seka | Deboyaya | 0 | 2.7 ± 0.4b | 4.1 ± 0.7b | 5.5 ± 0.1b | 8.1 ± 0.3c | 13.1 ± 0.4c | 14.1 ± 0.3c |

| Atro Sufa | 0 | 2.8 ± 0.6b | 4.2 ± 0.8b | 6.5 ± 0.4b | 9.1 ± 0.5b | 14.7 ± 0.7b | 16±1bc | |

| Wekito Medalu | 0 | 2.2 ± 0.2b | 4.6 ± 0.4ab | 7.5 ± 0.3ab | 9.7 ± 0.2b | 14.7 ± 0.8b | 17±1b | |

| Average | 2.7 ± 0.2 | 4.3 ± 0.1 | 6.5 ± 0.6 | 9.0 ± 0.4 | 14.2 ± 0.5 | 15.3 ± 0.6 | ||

Notes: *retailers store tubers at ambient temperature without any protection at market place under shade condition, Results are mean values of triplicate determination and means with the different letters across the column are significantly different (p < 0.05).

Potato tubers sampled and stored from different districts showed significant difference (p < 0.05) in percent weight loss. This might be associated with the way tubers were harvested and transported to Jimma market. Tubers experienced harsh handling and transportation, in case of Dedo district exhibited more postharvest loss during storage as compared to tubers from Seka district where better road and transportation access available. It is apparent that, weight loss of tubers increase with storage time but high percentage loss was observed when tubers stored for more than 20 days. After 30 days of storage, 14.14–18.82% weight losses were observed and also critically affect the quality of tubers marketed. Moisture migration and rotting are the two major factors contributed for storage related losses due to lack of recommended low temperature-high relative humidity storage condition. This finding is in line with the work of Tigist et al. (2013) who reported that, moisture is lost during storage due to respiration and transpiration and resulted in physiological weight loss. The work in Kenya by Kaguongo et al. (2014) also reported similar observation on storage related losses. Storage at retailers' level can also be considered as one of the hot spots for high postharvest loss of the tubers, Therefore construction and use of recommended tuber storage structures with efficient marketing strategies can be alternative recommendations to minimize storage associated losses.

3.2.2. Loss in firmness of tubers

Texture is one of the sensorial properties commonly considered by consumers to purchase tubers. Loss in texture of tubers commonly associated with loss of moisture and degradation of cell wall of tissue of tubers. Tubers with loosen texture are less liked and purchased by buyers. Texture of tubers is objectively expressed by measuring firmness of tubers. Table 3 shows the values for firmness of the potato tubers as affected by harvest locations and storage time.

Table 3.

Changes in firmness (Newton) of potato tubers sampled from different locations during 30 days storage at retailers storage condition*.

| District | Locations (PA) | Storage time (days) |

||||||

|---|---|---|---|---|---|---|---|---|

| 0 | 5 | 10 | 15 | 20 | 25 | 30 | ||

| Dedo | Debele | 14.8 ± 0.5a | 10.49 ± 0.07b | 10.37 ± 0.18b | 10.2 ± 0.1b | 10.08 ± 0.08b | 8.7 ± 0.1b | 8.08 ± 0.06b |

| Kusaye | 11.3 ± 0.2a | 9.09 ± 0.16b | 9.0 ± 0.1c | 8.71 ± 0.06c | 8.67 ± 0.04bc | 7.1 ± 0.2bc | 6.7 ± 0.4c | |

| Quno | 13.5 ± 0.7a | 10.2 ± 0.3b | 8.8 ± 0.3c | 7.8 ± 0.4c | 7.8 ± 0.2c | 6.3 ± 0.2c | 6.3 ± 0.1c | |

| Average | 13 ± 1 | 9.9 ± 0.4 | 9.5 ± 0.6 | 9.0 ± 0.7 | 8.8 ± 0.7 | 7.4 ± 0.7 | 7.0 ± 0.6 | |

| Seka | Deboyaya | 10.9 ± 0.1a | 10.45 ± 0.09b | 10.2 ± 0.1b | 10.2 ± 0.3b | 10.1 ± 0.2b | 8.7 ± 0.1b | 8.4 ± 0.2b |

| Atro Sufa | 10.25 ± 0.05a | 9.03 ± 0.04b | 8.8 ± 0.1c | 8.7 ± 0.3c | 8.7 ± 0.2bc | 8.1 ± 0.4b | 7.8 ± 0.2bc | |

| Wekito Medalu | 13.5 ± 0.7a | 12.0 ± 0.4a | 11.9 ± 0.3a | 11.8 ± 0.5a | 11.8 ± 0.1a | 10.2 ± 0.7a | 9.9 ± 0.1a | |

| Average | 12 ± 1 | 10.5 ± 0.2 | 10.3 ± 0.9 | 10.2 ± 0.9 | 10.2 ± 0.9 | 9.0 ± 0.6 | 8.7 ± 0.6 | |

Notes: *retailers store tubers at ambient temperature without any protection at market place under shade condition, Results are mean values of triplicate determination and means with the different letters across the column are significantly different (p < 0.05).

The firmness showed a decreasing pattern in all samples with the advancement of the storage period. For samples collected and stored from different farms of Dedo district showed a 40.8–53.6% loss in firmness after 30 days storage. However, samples collected from Seka district exhibited a 23.6–26.2% loss in firmness after 30 days storage. Likewise association of poor transportation facility for weight loss, loss in firmness of tubers during storage was also significantly high for samples collected from Dedo district. Cumulative effect of negligence in handling, loading, unloading, poor transportation facility could contribute for observed change in firmness between the two districts. In similar manner Siddiqui et al. (2011) reported that as firmness lost, wilting and wrinkling happens due to moisture loss from the commodities. Accordingly higher amount of weight loss is a sign of loosing firmness as observed in this study, which is in line with the findings of Tigist et al. (2013). Regardless of location difference, an apparent decrease in firmness also expected during storage of tubers and might be due to increase in metabolic and enzymatic activities responsible for starch and cell wall degradation (Page et al., 2008).

3.2.3. Vitamin C contents

Traditional methods in harvesting and postharvest handling practices and poor infrastructure not only enhance quantitative losses but also it has effects on qualitative parameters. Vitamin C is one of sensitive vitamins significantly affected during postharvest life of tuber crops. It is commonly used as an indicator vitamin to understand nature of post-harvest handling practices. Less vitamin loss associated with good postharvest harvest handling practices results better quality product. Table 4 shows the values for vitamin C contents of the potato as affected by locations and storage duration.

Table 4.

Changes in vitamin C contents (mg/100g) of potato tubers sampled from different locations during 30 days storage at retailers store conditions.

| District | Locations (PA) | Storage time (days) |

||||||

|---|---|---|---|---|---|---|---|---|

| 0 | 5 | 10 | 15 | 20 | 25 | 30 | ||

| Dedo | Debele | 12.0 ± 0.5NS | 11.7 ± 0.5NS | 11.4 ± 0.5NS | 10.4 ± 0.5b | 9.7 ± 0.5b | 9.6 ± 0.5b | 9.1 ± 1.3b |

| Kusaye | 12.0 ± 0.1NS | 11.6 ± 0.7NS | 11.1 ± 0.7NS | 10.2 ± 0.1b | 9.3 ± 0.6b | 9.4 ± 0.1b | 9.2 ± 1.2b | |

| Quno | 12.9 ± 0.4NS | 11.93 ± 0.05NS | 11.46 ± 0.05NS | 10.3 ± 0.4b | 9.70 ± 0.03b | 9.3 ± 0.4b | 9.3 ± 0.6b | |

| Average | 12.5 ± 0.4 | 11.8 ± 0.2 | 11.3 ± 0.2 | 10.30 ± 0.05 | 9.5 ± 0.2 | 9.4 ± 0.03 | 9.20 ± 0.05 | |

| Seka | Deboyaya | 11.7 ± 0.5NS | 11.7 ± 0.5NS | 11.4 ± 0.5NS | 11.03 ± 0.09a | 10.8 ± 0.4a | 10.4 ± 0.5a | 10.5 ± 0.5a |

| Atro Sufa | 11.7 ± 0.1NS | 11.7 ± 0.1NS | 11.1 ± 0.7NS | 10.2 ± 0.2b | 10.2 ± 0.2a | 10.2 ± 0.1a | 10.1 ± 0.1a | |

| Wekito Medalu | 12.0 ± 0.4NS | 11.6 ± 0.4NS | 11.47 ± 0.05NS | 11.3 ± 0.1a | 10.2 ± 0.4a | 10.1 ± 0.4a | 10.1 ± 0.4a | |

| Average | 11.8 ± 0.1 | 11.70 ± 0.02 | 11.3 ± 0.1 | 11.20 ± 0.07 | 10.4 ± 0.2 | 10.20 ± 0.07 | 10.2 ± 0.1 | |

Notes: NS=non-significant, *retailers store tubers at ambient temperature without any protection at market place under shade condition, Results are mean values of triplicate determination and means with the different letters across the column are significantly different (p < 0.05).

There was a significant difference (p < 0.05) in vitamin C contents during storage due to location from where the samples were collected starting from 20 days of storage. The tubers from all locations underwent to storage of 30 days, showed decreasing trend of vitamin C contents with the storage duration. Generally, the maximum vitamin C loss (23.64–27.91%) was incurred in sample transported from Dedo district at the end of the storage period. The maximum vitamin C loss (10.28–16.45%) was incurred in sample collected from Seka district at the end of the storage period. High percentage of vitamin C loss in case of Dedo district could be due to the fact that Vitamin C is most sensitive to damage when the product is subjected to unfavorable handling and transportation in case of Dedo. Furthermore the loss is enhanced by extended storage period and physical damage (bruising and internal injury) introduced during handling practices (Lee and Kader, 2000). Results in this study are in line with the work of Moretti et al. (1998) who reported that bruising significantly affected the chemical composition of pericarp and locular tissues of tomato fruit. Vitamin C content was about 15% lower in bruised locular tissue than unbruised fruit. Lee and Kader (2000) also reported that, losses in vitamin C occur when vegetables are severely cut or shredded, as in the case of cabbage, lettuce, carrots, and other vegetables sold as salad mixes.

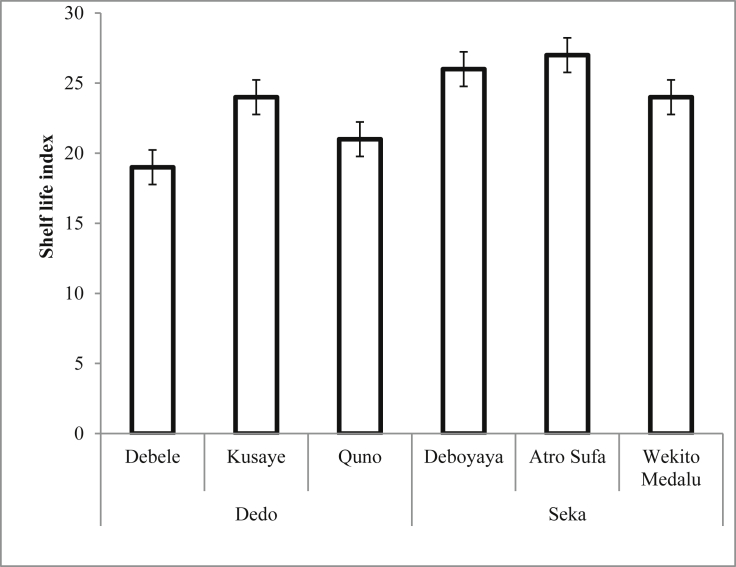

3.2.4. Shelf life index

The shelf life index presents the average storage life of roots collected from different locations varied significantly (p < 0.05). Generally the tubers collected from peasant association of Seka district showed higher shelf life index as compared to Dedo district (Fig. 2).

Fig. 2.

Shelf life index of potato roots sampled from different locations under retails storage conditions.

Sample collected from Atro Sufa peasant association had the highest shelf life index from Seka district. The shelf life index presented could be correlated with other quality attributes as the shelf life extension is a cumulative effect of maintaining different quality attributes. The loss of quality parameters which are influenced by mechanical damage suffered during harvest, handling and transportation and physiologic tuber condition influence considerably the tuber shelf life. Mechanical damage could facilitate invasion and development of microorganisms that cause tuber illnesses and rottenness. Moreover, the physical damage causes a tuber stress condition and lead to an increment in potato tuber respiration activity and hence increases the weight loss. The loss in quantities and quality of potato tuber correlated with that of shelf life index of the tuber. That means the tuber that exhibits the lowest loss has the highest shelf life index. The present results were similar with the studies of Penchaiya et al. (2006) who reported that shelf life of fruits was extended with gentle handling during post-harvest stage.

4. Conclusion

Although the Ethiopian production is much lower than the national demand, there are high post-harvest food losses due to different reasons. Understanding major causes and critical loss points are important inputs to recommend relevant solutions to minimize losses. In the study two different districts of Jimma zone having different road quality and transportation access were compared to evaluate postharvest loss of potato tuber from harvesting to nearby local market transportation as well as storage. Average harvest and transportation related losses of 12.45 and 11.7 % were estimated in Dedo and Seka districts respectively. In extended storage evaluation of tubers, relatively higher loss in moisture content, firmness and vitamin C contents were observed from tubers harvested, transported and stored from Dedo district than Seka. This implies that, tubers produced, transported and stored from where there is poor road quality and less access for transportation prone to qualitative and quantitative losses with lower shelf life index even in 20 km distance. Therefore, tubers from such production areas are better to be sold in short period of time than stored for extended period since they are highly prone to after harvest losses.

Declarations

Author contribution statement

Chala G Kuyu: Conceived and designed the experiments; Performed the experiments; Analyzed and interpreted the data; Contributed reagents, materials, analysis tools or data; Wrote the paper.

Yetenayet Tola: Conceived and designed the experiments; Analyzed and interpreted the data; Contributed reagents, materials, analysis tools or data; Wrote the paper.

Gemechu G Abdi: Performed the experiments.

Funding statement

This work was supported by Jimma University College of Agriculture and Veterinary Medicine, Ethiopia.

Competing interest statement

The authors declare no conflict of interest.

Additional information

No additional information is available for this paper.

References

- AOAC International . sixteenth ed. Vol. II. AOAC International; Rockville, MD: 2002. (Official Methods of Analysis of the Association of Official Analytical Chemists (AOAC)). [Google Scholar]

- Aulakh J., Regmi A., Fulton J., Alexander C. Agricultural and Applied Economics Association Annual Meeting, August 4–6. 2013. Food losses: developing a consistent global estimation framework. [Google Scholar]

- Diro S. Ambo University; 2016. Assessment of the Effect of Plant Density on Yield of Irrigated Potato and Analysis of Input Supply Chains at Adea Berga District of West Shoa Zone, Oromia. Doctoral dissertation. [Google Scholar]

- Emana B., Nigussie M. International Potato Center (CIP-Ethiopia); Addis Ababa, Ethiopia: 2011. Potato Value Chain Analysis and Development in Ethiopia. [Google Scholar]

- Ethiopia C. 2018. Production Quantity of Major Agricultural National Commodities.http://countrystat.org/home.aspx?c=ETHandp=ke [Google Scholar]

- FAO G . 2011. Global Food Losses and Food Waste–Extent, Causes and Prevention. SAVE FOOD: an Initiative on Food Loss and Waste Reduction. [Google Scholar]

- FAO . 2013. Food Wastage Footprint Impacts on Natural Resources. Summary report, Rome. [Google Scholar]

- FAOSTAT. 2017. http://faostat.fao.org/site/339/default.aspx Available at. [Google Scholar]

- Garg N., Cheema D.S., Dhatt A.S. Genetics of yield, quality and shelf life characteristics in tomato under normal and late planting conditions. Euphytica. 2008;159(2):275–288. [Google Scholar]

- Gebru H., Mohammed A., Dechassa N., Belew D. Assessment of production practices of smallholder potato (Solanum tuberosum L.) farmers in Wolaita zone, southern Ethiopia. Agric. Food Secur. 2017;6(1):31. [Google Scholar]

- Hodges R.J., Buzby J.C., Bennett B. Postharvest losses and waste in developed and less developed countries: opportunities to improve resource use. J. Agric. Sci. 2011;149:37–45. [Google Scholar]

- International Potato Center . 2016. Potato Facts and Figures.http://cipotato.org/potato/facts/ [Google Scholar]

- Kaguongo Wachira, Maingi Gladys, Giencke Sigrid. Deutsche Gesellschaft für Internationale Zusammenarbeit (GIZ) GmbH; 2014. Post-harvest Losses in Potato Value Chains in Kenya: Analysis and Recommendations for Reduction Strategies. [Google Scholar]

- Kolech S.A., Halseth D., De Jong W., Perry K., Wolfe D., Tiruneh F.M., Schulz S. Potato variety diversity, determinants and implications for potato breeding strategy in Ethiopia. Am. J. Potato Res. 2015;92(5):551–566. [Google Scholar]

- Lee S.K., Kader A.A. Pre-harvest and post-harvest factors influencing vitamin C content of horticultural crops. Postharvest Biol. Technol. 2000;20(3):207–220. [Google Scholar]

- Misener G.C., McLeod J.R., Walsh C.F. Effect of potato harvesting injury on post-storage marketability. Can. Agric. Eng. 1989;1:7–10. [Google Scholar]

- Moretti C.L., Sargent S.A., Huber D.J., Calbo A.G., Puschmann R. Chemical composition and physical properties of pericarp, locule, and placental tissues of tomatoes with internal bruising. J. Am. Soc. Hortic. Sci. 1998;123(4):656–660. [Google Scholar]

- Page D., Marty I., Bouchet J.P., Gouble B., Causse M. Isolation of genes potentially related to fruit quality by subtractive selective hybridization in tomato. Postharvest Biol. Technol. 2008;50:117–124. [Google Scholar]

- Penchaiya P., Jansasithorn R., Kanlavanarat S. IV International Conference on Managing Quality in Chains-The Integrated View on Fruits and Vegetables Quality 712. 2006. Effect of 1-mcp on physiological changes in mango Nam Dokmai; pp. 717–722. [Google Scholar]

- Scott G., Suarez V. The rise of Asia as the center of global potato production and some implications for industry. Pot. J. 2012;39(1):1–22. [Google Scholar]

- Scott G., Rosegrant M., Ringler C. IFPRI (International Food Policy Research Institute) and CIP; Washington, D.C.: 2000. Roots and Tubers for the 21st century: Trends, Projections, and Policy Options. Food, Agriculture, and the Environment Discussion Paper 31. [Google Scholar]

- Siddiqui M.W., Bhattacharjya A., Chakraborty I., Dhua R.S. 2011. 6-Benzylaminopurine Improves Shelf Life, Organoleptic Quality and Healthpromoting Compounds of Fresh-Cut Broccoli Florets. [Google Scholar]

- Siddiqui M.W., Chakraborty I., Mishra P., Hazra P., Ayala-Zavala J.F. Postharvest physicochemical changes in mutant (dg, og c, and rin) and non-mutant tomatoes. Acta Physiol. Plant. 2015;37(1):1728. [Google Scholar]

- Tadesse B., Bakala F., Mariam L.W. Assessment of postharvest loss along potato value chain: the case of Sheka Zone, southwest Ethiopia. Agric. Food Secur. 2018;7(1):18. [Google Scholar]

- Thiele G., Lynam J., Lemaga B., Low J. International Potato Centre (CIP); Lima, Peru: 2009. Challenge Theme Paper 4: Sweet Potato Value Chains. [Google Scholar]

- Tigist M., Workneh T.S., Woldetsadik K. Effects of variety on the quality of tomato stored under ambient conditions. J. Food Sci. Technol. 2013;50(3):477–486. doi: 10.1007/s13197-011-0378-0. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Urge M., Negeri M., Selvaraj T., Gebresenbet G. 2015. Assessment of Post-harvest Losses of Ware Potatoes (Solanum tuberosum l.) in Chelia and Jeldu Districts of West Shewa, Ethiopia. [Google Scholar]

- Worku A., Tsegaw T., Mengistu F. 2013. Yield and Yield Components of Potato Cultivars as Influenced by Period of Seed Tuber Storage at Adet. Seed Potato Tuber Production and Dissemination. [Google Scholar]

- Zorya S., Morgan N., Diaz Rios L., Hodges R., Bennett B., Stathers T., Mwebaze P., Lamb J. 2011. Missing Food: the Case of Postharvest Grain Losses in Sub-saharan Africa. [Google Scholar]