Abstract

Given their durability and long‐term stability, self‐healable hydrogels have, in the past few years, emerged as promising replacements for the many brittle hydrogels currently being used in preclinical or clinical trials. To this end, the incompatibility between hydrogel toughness and rapid self‐healing remains unaddressed, and therefore most of the self‐healable hydrogels still face serious challenges within the dynamic and mechanically demanding environment of human organs/tissues. Furthermore, depending on the target tissue, the self‐healing hydrogels must comply with a wide range of properties including electrical, biological, and mechanical. Notably, the incorporation of nanomaterials into double‐network hydrogels is showing great promise as a feasible way to generate self‐healable hydrogels with the above‐mentioned attributes. Here, the recent progress in the development of multifunctional and self‐healable hydrogels for various tissue engineering applications is discussed in detail. Their potential applications within the rapidly expanding areas of bioelectronic hydrogels, cyborganics, and soft robotics are further highlighted.

Keywords: cyborganics, nanocomposite hydrogels, nanomaterials, self‐healing hydrogels, tissue engineering

1. Introduction

In recent years, tissue engineering has emerged as a promising technology to grow organs from scratch,1, 2, 3 replicate biological mechanisms of various diseases,4, 5, 6, 7 address tissue‐related ailments8, 9, 10, 11, 12 and enable life extension in the growing aging population.13, 14 So far, most of the tissue engineering approaches has relied on the encapsulation of stem cells within native‐like and highly porous biomaterials;15, 16, 17, 18, 19, 20, 21, 22 or scaffolds as the tissue engineers prefer to say. The scaffold‐based biomaterials enable encapsulated cells to spread and reorganize into tissue‐like architectures, while permitting sufficient nutrient and waste material exchange with the surrounding environment.

Of the many scaffolding biomaterials currently utilized for tissue engineering applications, hydrogels are among the most promising ones. Hydrogels are composed of polymeric networks that are capable of absorbing and retaining high amount of water.19, 23 Hydrogels are also tunable (both physically and chemically), are injectable, and have been used over the years for tissue engineering and various drug delivery applications.24, 25, 26, 27, 28 However, as one of the fascinating properties of natural tissues is their ability to self‐heal after minor injuries, to truly recapitulate the physical properties of native tissues, such human‐made biomaterials also need to spontaneously heal and regenerate injuries inflicted on them. This inherent ability of native tissues to regenerate on demand has initiated enormous motivation to develop intelligent hydrogels with similar self‐repair mechanisms.

In spite of their many similarities to the extracellular matrix (ECM) of the native tissues, self‐healable hydrogels still face several shortcomings, which limits their specific application for replacement of electrically active and elastic tissues (Figure 1 ).29, 30, 31, 32 For example, current self‐healable hydrogels are typically nonconductive and exhibit significantly lower fracture energies (<10 J m−2)33 than that of cartilage,33 skin,34 tendon,35 and muscle tissues36 (kJ m−2 regime). Conventional hydrogels implanted within the load‐bearing and dynamic environments of the human body are thus inclined to acquire some minor defects. These microcracks gradually propagate and grow in size and will ultimately lead to failure of the material if they are not repaired in due time. Moreover, in case of cell‐encapsulated hydrogels, cells are prone to rapid migration and interface pulling, and will eventually disrupt the structural integrity of the hydrogel matrix due to traction forces. Therefore, to achieve optimal implant lifetime, it will be necessary to engineer mechanically tough hydrogels with the ability to quickly remedy material defects.37, 38, 39, 40, 41, 42, 43

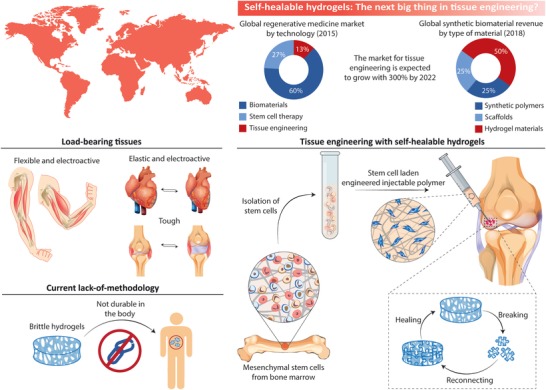

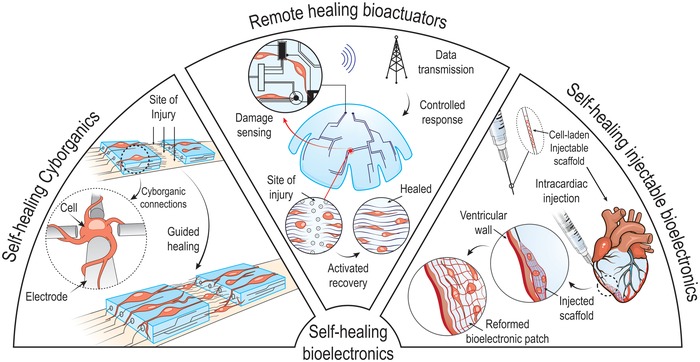

Figure 1.

Human organs are made of elastic, tough, and electroactive tissues, which can spontaneously heal. The microenvironment within most tissues is also highly dynamic and load‐bearing. Tissue engineering hydrogels, therefore, need to heal on command and incorporate the same mechanical and electrical properties as those found in natural tissues. Injectability is also a sought‐after property, as injectable hydrogels can be used to deliver stem cells to the target tissue in a minimally invasive manner.

Although the literature on self‐healing hydrogels is growing fast, only a few practical applications for these biomaterials exist in tissue engineering; this is because most self‐healable hydrogels do not match with the above‐described electromechanical milieu of the body (Figure 1). Moreover, the long‐standing incompatibility between hydrogel toughness and rapid self‐repair has not yet been fully addressed. To address this unmet need, nanomaterials are rapidly emerging as an exciting approach to develop self‐healable and multifunctional hydrogels through one‐step strategies that are based on simple mixing procedures (Figure 2 ).

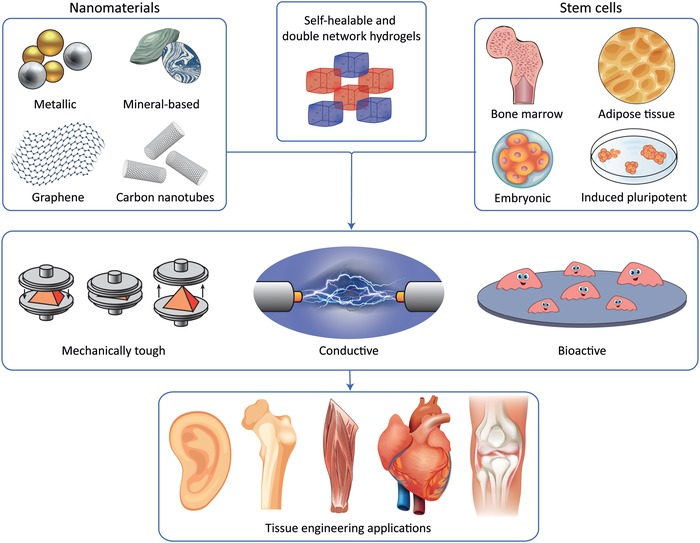

Figure 2.

Nanoreinforcement can be used to generate multifunctional hydrogels that blend in with electrically and mechanically active tissues. With the right combination of nanoreinforcer and hydrogel polymer, it is possible to manufacture mechanically tough, electrically conductive, and bioactive tissue engineering systems for organ regeneration.

In this review article, we discuss the unexplored and enormous possibilities of self‐healable hydrogels in tissue/organ regeneration and repair. We will mainly focus on the synergy between hydrogel toughness and dynamic self‐repair, as we believe this unique combination will ultimately induce a paradigm shift in the field of hydrogel‐based tissue engineering. Additionally, we will also highlight the emerging area of self‐healable hydrogels made through nanoreinforcement and review the many recent impressive applications of these systems in tissue engineering. Finally, we will review the application of self‐healable hydrogels in cyborganics, soft robotics, and bioelectronics, since these fields will rise in the coming decades and define an entire new frontier in health sciences.

2. Self‐Healing mechanisms

Self‐healable hydrogels rely on one common principle involving a so‐called mobile phase, which enables crack closure through a combination of mass transfer and reconnection of broken links within the hydrogel matrix. The reconnection within this matrix is typically mediated by either noncovalent or covalent bonds (Figure 3 ). The noncovalent interactions are based on weak sacrificial links such as ionic,44 hydrogen,45 or hydrophobic bonds,46 while the chemical bonds are based on dynamic covalent bonds and metal coordination bonds.47, 48, 49, 50, 51, 52 The combination of the above‐mentioned covalent and noncovalent bonds has also recently been used to generate mechanically tough and elastic double‐network hydrogels with rapid self‐repair properties.53, 54, 55 In this section, we will highlight the key mechanisms behind the repairing properties of such self‐healable hydrogels (Figure 3). Specifically, we have divided this section into three independent subsections, the first two dealing with self‐healing mechanisms based on either noncovalent or covalent bonds, and the last section on the working principle behind double‐network hydrogels.

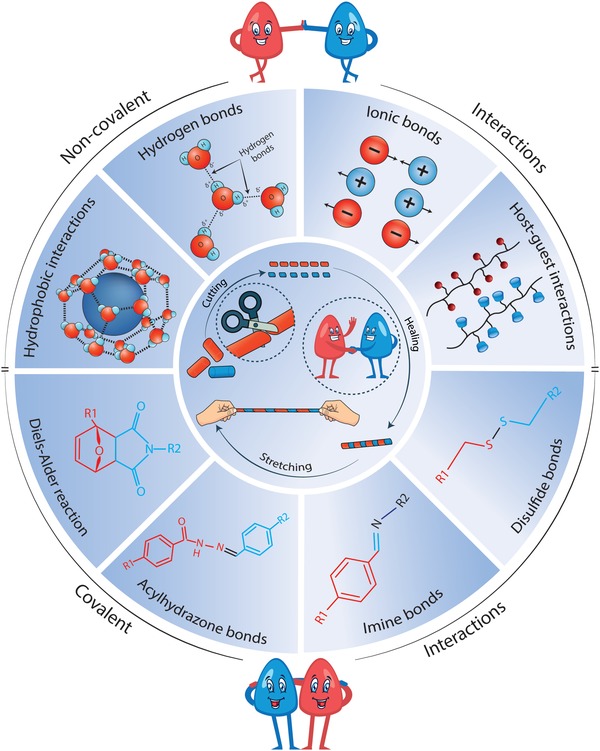

Figure 3.

The various chemical and noncovalent interactions behind self‐healable hydrogels are highlighted here.

2.1. Noncovalent Interactions

This section focuses on self‐healable hydrogels made from noncovalent crosslinks including hydrogen bonds,53, 56, 57, 58, 59, 60 host–guest interactions,61, 62, 63 ionic bonds,64 and hydrophobic interactions.65, 66, 67 Although the listed interactions can generate hydrogels that display rapid healing time and good self‐healing efficiency, these attributes come at the cost of inelasticity and mechanical weakness. In the following subsections, we describe the pros and cons of each of these interaction schemes from a mechanical‐point‐of‐view and provide possible solutions that could remedy their current shortcomings.

2.2. Hydrogen Bonds

Hydrogen bonds are among the most common noncovalent interactions found in nature. For instance, it is hydrogen bonds that keep complementary strands of DNA together in their unique helix structure,68 and they are also a key player in water's many solvent properties (Figure 3).69 They also play a determining role in the secondary and tertiary structure of folded proteins70 and the properties of various solid polymers such as cellulose and wool.71, 72

Hydrogen bonds occur when the positive hydrogen atom establishes an electrostatic link with electronegative acceptor atoms such as oxygen, nitrogen, or fluoride.73 The strength of the hydrogen bonds depends mostly on the negative charge of the acceptor atom and can thus vary greatly depending on the atom in question and the pH value of the solvent in which the bonding occurs. Examples of hydrogen bonds are those formed between two hydroxyl groups (OH···OH), between carboxyl and amide groups (NH···O=C), and between hydrogen and fluorine (H···F). The bonding strength of hydrogen bonds varies greatly, from 0.25 to 15 kcal mol−1, with the weakest being those formed with fluorine and the strongest those that incorporate hydroxyl or amide groups.73

Even though a hydrogen bond is several times weaker than ionic (100–1000 kcal mol−1) and covalent bonds (35–240 kcal mol−1),74 they still contribute significantly to the mechanical properties of hydrogels, when a lot of them are present within the hydrogel matrix. Moreover, the association and dissociation of hydrogen bonds occur rapidly; typically on sub‐picosecond to picosecond time scales.75, 76, 77 This property is a governing factor behind the rapid healing time seen in repairable hydrogels based on hydrogen bonds. For these reasons, hydrogen bonds have been exploited in the manufacture of numerous self‐healable hydrogels, the most prominent of these being those using poly(vinyl alcohol),53, 56 ureidopyrimidinone (UPy),57, 58, 59, 60 and polyacrylamide (PAM);53, 78 with the hydrogen bonds being mediated by either hydroxyl or amide groups. However, due to their weakness, hydrogen bonds need to be combined with other stronger bonds to yield self‐healable hydrogels with the desired combination of mechanical strength and fast healing time. We will return to cover this important point in Section 2.4., when discussing how double‐network hydrogels work and what they do.

2.2.1. Hydrophobic Interactions

Hydrophobic interactions are perhaps as important as hydrogen bonds when it comes down to protein folding, the properties of solid polymers, and the interaction between molecules in different solvents.79 However, hydrophobic interactions are slightly stronger than hydrogen bonds and easier to control; as they can be fine‐tuned by varying the shape of the hydrophobes and the number of hydrophobic moieties on them. Hydrophobic interactions occur because of the formation of a clathrate cage around the hydrophobe, which is an ice‐like cage structure of water molecules formed through hydrogen bonds among the water molecules (Figure 3).80 This highly ordered arrangement leads to entropy decrease and constitutes an unstable configuration, which easily breaks when two hydrophobes come close enough to one another to enable the formation of hydrophobe–hydrophobe assemblies, and the subsequent release of trapped water between the two. The highly adhesive force between two hydrophobes is thus caused by a physically driven increase in entropy, which is also a governing factor behind the highly reversible nature of hydrophobic interactions.79

Some different hydrophobic schemes based on 1) host–guest interactions,61, 62, 63 2) micelles,81, 82 and 3) hydrophobic moieties65, 66, 67 have been used over the years to generate self‐healable hydrogels. Self‐healable micelle‐based hydrogels are generated by incorporating amphiphilic polymers and surfactants into the hydrogel. The self‐healing mechanisms of such hydrogels are attributed to the cyclic dissociation and reassociation of the micelles. The self‐repair mechanisms underlying hydrogels that incorporate hydrophobic moieties, on the other hand, arise from reversible interactions between such moieties. Host–guest interactions are more complicated and, in most cases, are ruled by the conjugation of cyclodextrin—a molecule that consists of a lipophilic inner cavity and a hydrophilic outer surface—onto the hydrogel backbone.61 To this end, cyclodextrin can enable a so‐called host–guest interaction with hydrophobic guest molecules, as they can become restrained within its lipophilic inner cavity due to hydrophobic interactions. One important concern of the above‐mentioned self‐healable hydrogels is the possible low water‐uptake caused by the presence of hydrophobic regions within the hydrogel matrix. However, numerous studies have shown that this does not need to be the case when hydrophilic regions outbalance the number of hydrophobic moieties in the hydrogel matrix.81, 83, 84

2.2.2. Ionic Bonds

As an alternative strategy, ionic bonds can also be used to develop self‐healable hydrogels via reversible electrostatic interactions between oppositely charged moieties. Such interactions can happen between oppositely charged polymers or through ionic bridges between same charged polymers mediated by oppositely charged ions.85, 86, 87 A common example of the later is alginate hydrogels made from negatively charged alginate pre‐polymers that crosslink into a hydrogel through divalent ions; typically calcium.88, 89 A less common but yet highly promising approach is to use electrostatic interactions between charged nanomaterials and the hydrogel backbone, as this approach can add a range of additional properties to the system in question because of the multifunctional attributes of nanomaterials.8, 90, 91, 92 For instance, nanomaterials are known for their ability to dissipate energy within hydrogels, and can, therefore, increase the toughness and durability of hydrogels significantly.93 Although ionically bonded hydrogels are simple, as they are manufactured by one‐step‐mixing procedures, their inelasticity and brittleness are major drawbacks. One avenue to overcome the shortcomings of ionically crosslinked hydrogels is blending them with a covalently cross‐linkable polymer to yield a double‐network hydrogel consisting of interpenetrating and adaptable polymeric networks.94, 95

2.3. Covalent Interactions

In addition to the noncovalent self‐healing mechanisms discussed in the previous section, covalent binding schemes in the form of chelation and dynamic covalent bonds can also be used to generate self‐healable hydrogels. In this section, we will focus on the chemistry of these with special focus on dynamic covalent bonds made from imine, disulfide, boronate ester, acylhydrazone, and Diels–Alder reactions (Figure 3).

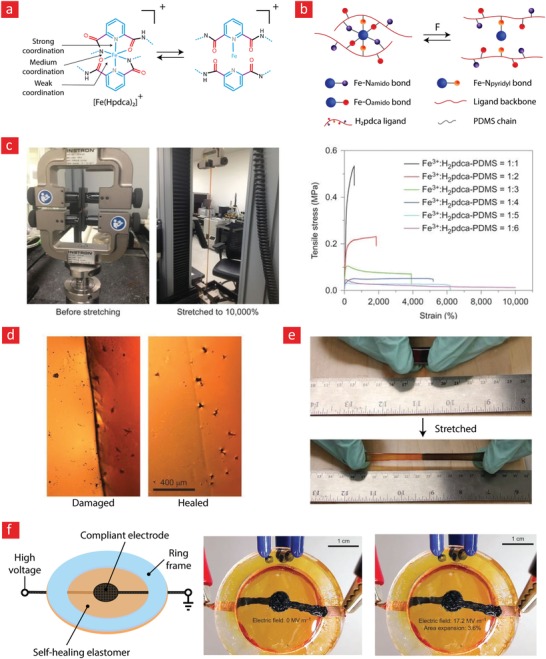

2.3.1. Chelation

Chelation can be described as a number of coordinate bonds between ligands (organic molecules) and one positively charged transition‐metal ion.96 Notably, the transition metal ion is surrounded by the ligands to yield highly complex lattice structures. Each ligand can donate electrons to the metal ion; two or more electrons from each ligand are typically donated to the metal. The bonding is thus essentially a covalent bond involving two electrons from the same atom instead of one electron from each atom, which is the typical case in standard covalent bonds. However, due to the lattice structure of these metal complexes and the many donor atoms involved, the binding energy of the complexes is typically stronger than covalent bonds.97, 98 But what makes chelation unique in comparison to covalent bonds is the fact that they can display high adhesivity, elasticity, and reversibility at the same time. For this reason, chelation can be used to yield highly adhesive, elastic, and self‐healable materials. A prime example of this can be found in nature in the form of the sticky feet of mussels, which in recent years have been linked to chelation between Fe+3 and catechol ligands.99 Indeed, the binding strength of catechol‐Fe+3 can reach 33 kcal mol−1 and catechol can form reversible bonds with titanium interfaces with a bond strength of 800 pN, which is almost 40% of the bonding strength between silicon and carbon.100 This gives an idea of some of the incredible features of chelation complexes, and why they have constituted an integral component in many self‐healable hydrogels.48, 101, 102

2.3.2. Dynamic Covalent Bonds

Dynamic covalent bonds are unique because of their ability to reconnect without physical stimuli, which is in contrast to standard covalent bonds. Dynamic covalent bonds, therefore, combine the stability of covalent bonds and reversibility of noncovalent interactions into a potent healing force that works entirely on its own. The general principle behind such dynamic bonds is the presence of an equilibrium phase between various fates from the same reaction process. Under certain conditions, one of the fates is more stable and dominates over the others. However, a return to the original compounds followed by a reversion to another outcome is still possible, which makes such reactions highly dynamic.103, 104 As such, these are highly sought out in the field of chemistry, but their numbers are relatively few compared to conventional covalent reactions. Nevertheless, various self‐healable hydrogels have been produced over the years through dynamic covalent crosslinks, with imine bonds being the most widely used. Thus, we will first focus on the chemistry of these bonds and their usefulness for self‐healing.

The famous German chemist, Hugo Schiff, discovered imine bonds in 1864 and imine‐based compounds are therefore also commonly referred to as “Schiff's bases.”105 An imine bond essentially involves a reaction between an aldehyde and a primary amine with the generation of a water molecule; and is considered a strong covalent bond (150 kcal mol−1)106 that can occur both at neutral and acidic pH values. In this reaction, the amine nitrogen (a nucleophile) attacks the electrophile carbonyl atom in the aldehyde to yield a double nitrogen–carbon bond. If the water molecule is not removed, this reaction can still go back through hydrolysis and, therefore, under certain conditions, a dynamic equilibrium is possible. Since imine bonds involve an amine group, they are frequently used to turn amino‐rich polymers, such as chitosan and polyacrylamide, into self‐healable hydrogels by combining them with other aldehyde‐functionalized polymers, such as oxidized alginate and hyaluronic acid (HA), as described in Section 3.50, 107

Acylhydrazone bonds are very close relatives of imine bonds, as they are synthesized by reacting a hydrazine with an aldehyde group;108, 109 typically through a condensation reaction.50, 110 Acylhydrazone bonds can be spontaneously formed under physiological conditions; albeit at a significantly slower rate than under acidic environments.111, 112 However, recent studies have shown that this bonding scheme can be used to yield self‐healable hydrogels with a crosslinking time that makes them amenable as injectable hydrogel carriers for stem cells.50, 113 In one of these studies, a self‐healable polyethylene glycol (PEG) hydrogel was developed through a condensation reaction between two PEG macromers; one functionalized with benzaldehyde and the other with an aldehyde. This system could self‐assemble rapidly under physiological conditions and provided a viable environment for encapsulated muscle cells.113

Another dynamic covalent bond type used in self‐healable hydrogels, although a bit weaker than imine bonds (50 kcal mol−1),106 is disulfide bonds. They are essentially based on thiol/disulfide dynamic exchange reactions, in which the thiol groups needs to be oxidized.114, 115 The reaction is, therefore, highly sensitive to the pH value and needs the involvement of an oxidation agent, which can make some of the manufacturing protocols for such hydrogels cytotoxic for cells. For these reasons, thiol‐based hydrogels with self‐healing capacity are not stable in physiological tissues due to the presence of reducing agents such as glutathione, which is found in most tissues in the body.116, 117, 118 These are, therefore, not the preferred choice for the design and development of self‐healable hydrogels.

The combination of diols and boronic acid can also yield reversible covalent links in the form of boronate esters.52, 119 However, the stability of this reaction is highly pH sensitive and the resultant self‐healing efficiency and mechanical properties of such systems are therefore sensitive to pH changes. Indeed, the formation of diol‐boronic acid links only happens at pH values greater than or equal to the pKa value of boronic acid; which is typically greater than 8 pKa.120, 121 From a tissue engineer's point‐of‐view, this can be a disadvantage, as most tissues in the human body operate at neutral pH and the fact that cells perish at pH values above 8. However, in a recent study, it was shown that the combination of PEG–phenylboronic acid macromonomers with PEG–diol macromonomers could yield injectable hydrogels with sufficient self‐healing efficiency and mechanical properties at neutral pH.122 In another recent study, a self‐healing hydrogel was formed using intramolecular interactions between 2‐acrylamidophenylboronic acid (2APBA) moieties. This hydrogel could self‐heal at both neutral and acidic pH values and is thus suitable for tissue engineering applications.51 These studies, taken together, have demonstrated that, despite the highly pH‐sensitive nature of boronate esters, they can be used to develop self‐healable hydrogels that are compatible with tissues and cells.

In addition to the above‐mentioned reactions, Diels–Alder reactions have also been rapidly adopted by scientists in the field to yield self‐healable hydrogels. Diels–Alder reactions are considered click reactions, which are widely recognized for their ability to yield outstanding reaction specificity through simple synthesis procedures typically done in water and with no offensive byproducts.123 In simple terms, a Diels–Alder reaction is a reaction between a conjugated diene and a dienophile, typically an alkene or alkyne.124 Such reactions are essentially electrocyclic reactions that involve π electrons from the HOMO and LUMO molecular orbitals of diene and the dienophile, respectively. To this end, to enable the reaction to proceed optimally, it is important that there is an energy‐band overlap between the two molecular orbitals.124 Diels–Alder reactions are also thermoreversible, meaning that they break at elevated temperatures—typically above 100 °C—and can reform again once the temperature is lowered. This process is cyclic and, therefore, enables the manufacture of materials that can break and heal indefinitely by applying the appropriate thermal healing procedure.125, 126, 127 This is interesting but, unfortunately, also implies that the self‐healing potential of conventional Diels–Alder bonds is not fit for use in tissue engineering. However, some recent studies have shown that it is possible to generate Diels–Alder‐based self‐healable hydrogels that can solidify and self‐heal under physiological conditions.128, 129 The family of Diels–Alder reactions, therefore, has promise for delivering injectable and self‐healable hydrogels that can crosslink autonomously within the target tissue, if prepared correctly.

2.4. Double‐Network Hydrogels

An on‐going challenge in the design and development of hydrogels is the conflict between strength, toughness, and high water content (>90 wt%). Given that strong materials tend to be brittle, softer materials usually tougher, and highly hydrated materials weak, this challenge is difficult to overcome.130, 131 Another challenge in the field is to combine fast self‐healing kinetics with hydrogel strength, as mechanically strong hydrogels are typically achieved by increasing the polymer concentration and the number of crosslinks within the hydrogel matrix. The latter, unfortunately, reduces the mass transfer into the crack site and, therefore, significantly increases the healing time.

Double‐network hydrogels address all of these challenges by combining a strong and rigid network with a much weaker network that is typically made from reversible crosslinks (Figure 4 ).94, 95, 132, 133, 134 Hydrogels made in this manner have demonstrated some amazing properties, including high elastic modulus (0.1–1.0 MPa), strength (1–10 MPa), stretchability (1000–2000%), and toughness (100–10 000 J m−2).94, 132 Notably, double‐network hydrogels can be used to develop mechanically strong hydrogels with rapid self‐healing properties using much lower polymer concentrations than their single‐network counterparts.63, 102 Indeed, the mechanical properties that double‐network hydrogels display are highly sought‐out attributes in the field, as they resemble those of conventional rubbers (1000 J m−2) and load‐bearing cartilage tissues (100–9000 J m−2);94, 132 while being tougher than commercially available hydrogels, which are notoriously weak and brittle (0.1–10 J m−2) and, therefore, unable to resist the cyclic forces that tissues such as muscle, bone, heart, and cartilage endure during daily routine activities.94, 132

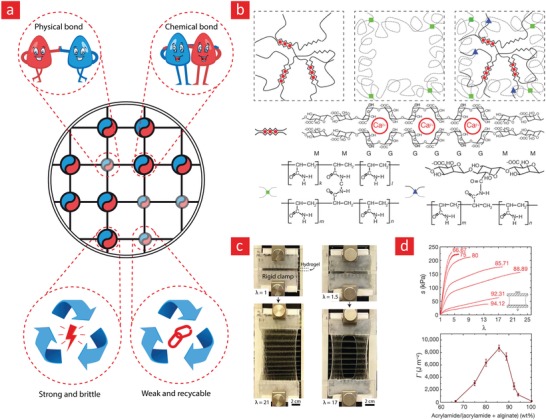

Figure 4.

A brief depiction of the concept behind double‐network hydrogels and what they can do. The working principle behind double‐network hydrogels is essentially based on a combination of weak reversible bonds and strong irreversible bonds. Together these can yield tough and highly extendible hydrogels due to the dissipation mechanism embedded in the reversible bonds. a) A prime example of systems like this was given in a recent publication in nature letter that was based on b) ionically bonded alginate (reversible) and covalently bonded polyacrylamide (irreversible) polymers. c) This hydrogel could stretch up to 21‐times its original length and d) exhibited a toughness value around 10 000 J m−2. Reproduced with permission.94 Copyright 2012, Macmillan Publishers Ltd.

The toughening mechanism of double‐network hydrogels stems from the presence of strong irreversible and weak reversible bonds within the hydrogel matrix. The weak bonds can reform again and thus limits the amount of stress accumulation within the matrix, as these bonds can undergo many destruction–reconnection cycles. In simple terms, one can therefore attribute the amazing mechanical properties of double‐network hydrogels to a rigid skeleton that keeps the system intact, and sacrificial bonds that enable energy dissipation, delaying the onset of critical stress accumulation.94, 132, 133, 134 This mechanism is similar to the mechanism used by the body to toughen bone,135 and by engineers to generate structural materials that are both strong and tough at the same time.130

In a recent study, a double‐network hydrogel made from a covalently crosslinked polyacrylamide and ionically crosslinked alginate network displayed some interesting properties, as this system could stretch up to 2000% of its original length with a toughness value that could reach 9000 J m−2 (Figure 4).94 The authors speculated that the reversible ionic bonds enabled an energy dissipation scheme that could keep going as the hydrogel stretched, leading to the reported combination of high toughness, strength, and elasticity. The working principle behind double‐network hydrogels therefore presents an exciting avenue to remedy the inherent mechanical weakness of hydrogen‐bonded self‐healable hydrogels;53, 136, 137 and as we will see in Sections 3 and 4, this combination can generate self‐healable hydrogels that could transform the world of tissue engineering if they can be translated into the clinic.

2.5. Outlook and Future Opportunities

In conclusion, a wide selection of reversible bonds is currently available for the design and development of self‐healable hydrogels. However, neither the physical nor the chemical bonds can, on their own, address the many requirements for self‐healable tissue engineering hydrogels. These requirements include high toughness, mechanical strength, high water content, injectability, elasticity, and fast self‐healing kinetics. Nevertheless, the combination of physical and chemical bonds in the form of double‐network hydrogels can address this current lack‐of‐methodology in the field, as evident from recent publications in Nature Letters94 and Nature Materials.134 In the authors' opinion, this area of research is still ripe for investigation, and a successful outcome to this end could yield the next gold standard in implantable materials for tissue engineering applications. One avenue that might open the field even further is the development of a double‐network hydrogel with well‐defined matrix architecture. Indeed, some recent studies have shown that by aligning polymers138, 139 or nanomaterials140, 141 within hydrogels, it is possible to significantly improve mechanical integrity without increasing the polymer concentration or the crosslinking density. We, therefore, anticipate that this unique combination can result in self‐healable hydrogels with mechanical properties that might match that of skeletal tissues, without compromising the self‐healing or water retention properties. On a more fundamental level, we envision that other dynamic covalent bonds could be used to further improve the state‐of‐the‐art in the emerging area of self‐healable tissue engineering hydrogels. For instance, dynamic covalent bonds, such as those based on amide and ester exchange reactions,142 could—together with weak hydrogen bonds—yield some exciting double‐network hydrogels for the field.

3. Polymers for Self‐Healing Hydrogels

One of the most important components in hydrogels, are polymers, that can be united into water friendly 3D environments for cells to attach, grow, and differentiate within.143 The logical way to obtain self‐healing hydrogels is, therefore, by altering these essential building blocks. This is typically accomplished by incorporating the aforementioned self‐healing mechanisms into the polymeric hydrogel backbone through various nontoxic and nonhazardous chemical modifications.

The healing capacity of polymeric hydrogels is typically accessed by monitoring the rejoining of two broken pieces by either optical or scanning electron microscopy (SEM). Another more precise quantification of the healing capacity includes mechanical characterization of the ultimate tensile strength and Young's modulus of the hydrogels before and after the healing process. The healing efficiency is then defined as the ratio of the modulus or tensile strength of the healed and unbroken hydrogels. Finally, it is also possible to use rheology to gain a detailed picture of both the healing efficiency and healing time by monitoring the real‐time changes in storage and loss modulus during the healing process.

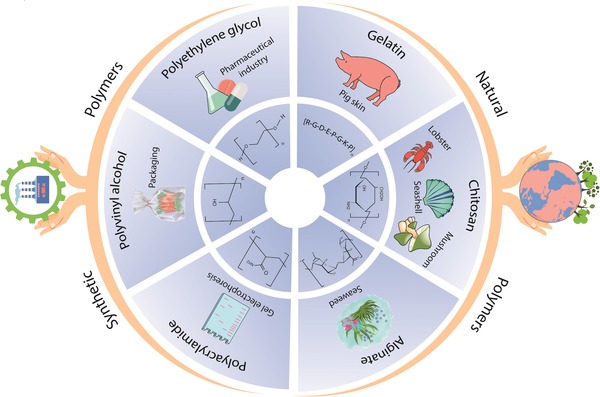

Self‐healing hydrogels have so far been made from either natural or synthetic polymers (Figure 5 ). The natural polymers are for the most part polysaccharide‐based polymers, such as alginate, chitosan, and HA. The synthetic polymer systems, on the other hand, are based on polymers such as polyethylene glycol, poly(acrylic acid), poly(vinyl alcohol), and polyacrylamide. These polymers provide certain advantages and disadvantages and abandoning one in favor of another typically involves some trade‐offs. For example, the natural polymers are typically more biocompatible, as polymers such as gelatin and chitosan are famed for their cell attachment properties,144, 145, 146, 147, 148 while poly(vinyl alcohol) and polyacrylamide typically yield stronger and more elastic hydrogels at the cost of reduced biofriendliness. In the following subsections, we will review these polymers as potential candidates for self‐healing hydrogels in the field of tissue engineering.

Figure 5.

The various synthetic and natural polymers used to generate self‐healable hydrogels are highlighted here.

3.1. Natural Polymers

Over the centuries, natural materials have been a great source of inspiration for materials scientists and physicians; noteworthy examples in this regard are silk‐based sutures149 and cellulose‐based building materials.150, 151 In recent years, biomedical engineers have also started to tap into natural sources to develop even better biomaterials. Because one of the prime‐ingredients in native tissues is HA—a polysaccharide—the focus has for the most part been directed toward polysaccharides, such as alginate, pectin, and chitosan, which can be procured from natural sources. These naturally derived polymers are cheaper than HA and less immunogenic than, for instance, gelatin. The focus of this section is, therefore, directed toward alginate and chitosan‐based self‐healable hydrogels, however, we will also briefly highlight some of the emerging trends in self‐healable hydrogels made from gelatin and HA.

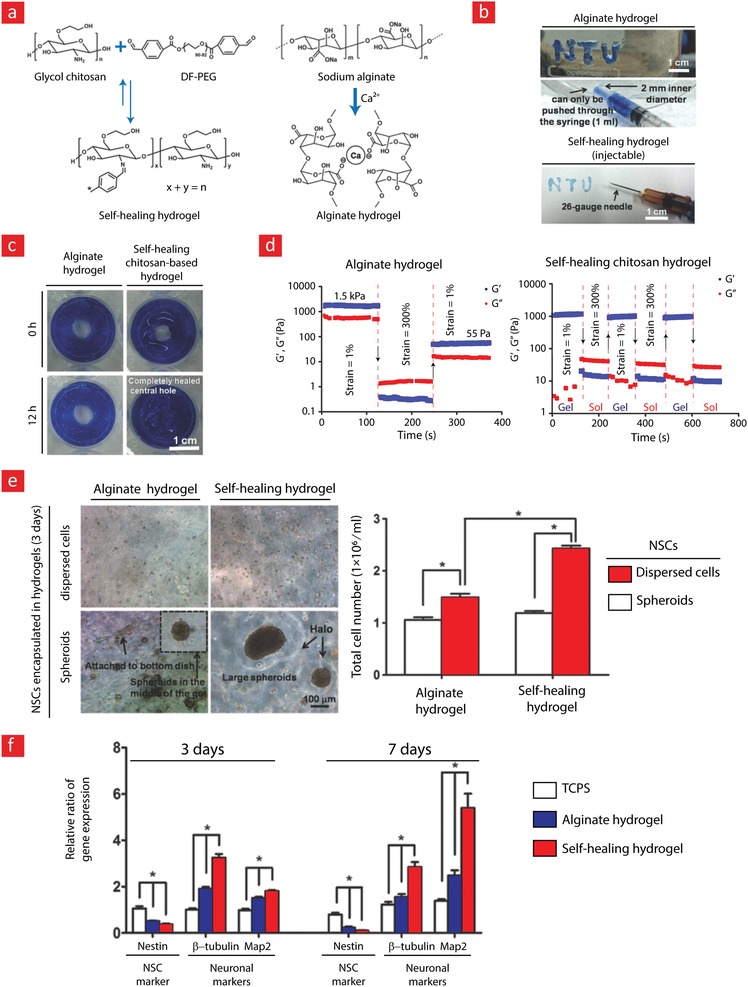

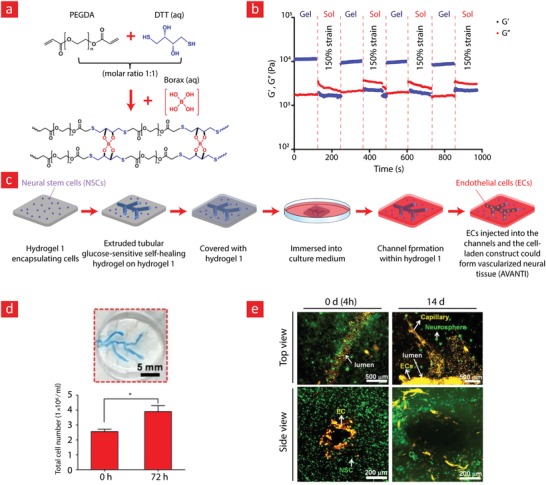

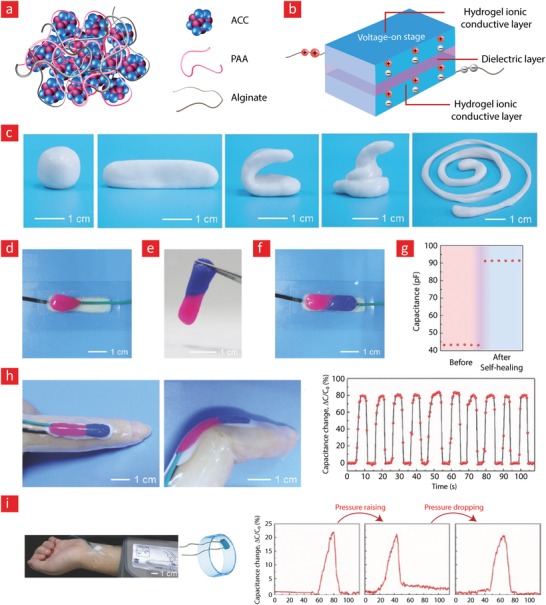

3.1.1. Alginate

Alginates are naturally occurring polysaccharides typically retrieved from marine algae and brown seaweed.152 Because of their good biocompatibility, exceptional water retention, and tunable gelation properties, alginates have been extensively studied as soft scaffolds in various tissue engineering applications, and as microcapsules for delivery of drugs.153, 154, 155, 156, 157 However, alginate‐based hydrogels are brittle and mechanically unstable, which significantly limits their use in many biomaterial applications.89 One approach to remedy this is by making self‐healing alginate hydrogels with the capacity to spontaneously self‐repair in the event of mechanical damages.

Recently, a variety of methods have been applied to generate self‐healing alginate hydrogels; something that has enticed much attention in the field of biomaterial science.50, 158, 159 These methods include various chemical methods to incorporate dynamical covalent bonds into the polymeric backbone of alginate50, 159 and through the concept of host–guest interactions.158 For instance, in a recent study, the noncovalent interaction between a host [β‐cyclodextrin grafted alginate (alg‐g‐CD)] and a guest (Pluronic F108) was shown to facilitate a fast healing performance alongside desirable thermoresponsive gelling properties and negligible cytotoxicity.158 As alginates contain functional hydroxyl groups, which are transformable into aldehyde groups, dynamical imine bonds arising from the interaction between aldehyde groups and amines have also become a central theme in the development of self‐healable alginate hydrogels.50, 159 As an example of this feasibility, Wei et al. used chitosan (amine rich) and oxidized alginate (aldehyde rich) to yield a mechanically robust hydrogel with excellent self‐healing ability (up to 95% healing efficiency) and good cytocompatibility, as tested through encapsulation with 3T3 fibroblast cells.50 The hydrogel developed in this study was an engineering masterpiece as it achieved the rare union between high self‐healing efficiency and high mechanical strength, while still keeping the hydrogel biocompatibility intact. Such hydrogels will assist scientists to carve new avenues in the field of tissue engineering, which we anticipate will enable the manufacture of scaffolds with the ability to integrate with native tissue over sustainable periods. Along the same line, a hydrogel composed of dopamine‐grafted oxidized sodium alginate (OSA‐DA) and PAM, showed efficient self‐healing ability (80% mechanical recovery in 6 h), high tensile strength (0.109 MPa), and ultrastretchability (2550%). Remarkably, due to plenty of catechol groups on the OSA‐DA chains, the hydrogel possessed unique cell affinity (NIH‐3T3 fibroblasts) and tissue adhesiveness. Furthermore, the in vivo rat experiment showed that this hydrogel could promote tissue regeneration and accelerate the process of wound healing.160

Quite often multicomponents are utilized to construct hydrogels with self‐healing ability and the resulting hydrogel systems often exhibit batch‐to‐batch dependent inconsistent results, problems in multicomponent mixings, and involve unpredictable cross‐talk between the added components. To this end, Hong et al., developed a “single polymeric component,” based on alginate‐boronic acid (alginate‐BA) to overcome the aforementioned problems.161 This stretchable hydrogel showed efficient self‐healing performance (up to 98% healing efficiency), owing to reversible inter‐ and intramolecular interactions. In addition, subcutaneous implantation of this hydrogel under mice skin showed inflammatory response at day 3 which mostly disappeared on day 7, indicating the low toxicity of the hydrogel.

3.1.2. Chitosan

Chitosan is a positively charged and amino‐rich polysaccharide typically derived from the exoskeleton of shellfish and possesses similar structural characteristics as glycosaminoglycan (GAG); one of the major components of the ECM.162, 163 Due to its similarities with the native ECM, chitosan is also biocompatible, biodegradable, and hydrophilic, which makes it an ideal 3D microenvironment for cell encapsulation. For these reasons, chitosan has frequently been used as a scaffolding material for tissue engineering144, 164, 165 and various cell delivery therapies.166, 167, 168 As chitosan is rich in amino groups, the ideal pathway for generating self‐healing hydrogels with chitosan is through dynamic covalent imine/enamine bonds.43, 50, 107, 169, 170 To this end, a recent study by Huang et al. used an enamine bonding between carboxymethyl chitosan (CMC) and an aldehyde functionalized polyethylene glycol polymer (PEG‐BA) to develop a self‐healing hydrogel (Figure 6 ).43 The two polymers formed a stable hydrogel film after 5 min with a good storage modulus (3.2 kPa) and a healing efficiency ranging from 80% to 94% at physiological temperature (37 °C), depending on the healing time (6–12 h). Encapsulation studies with fibroblast cells demonstrated excellent cell viability for up to 7 d, indicative of chitosan's potential as a regenerative milieu for tissue engineering applications. In a similar vein, chitosan and cellulose acetoacetate were mixed to endow a hydrogel with good self‐healing ability on account of dynamic enamine bonding between aldehyde groups of the functionalized cellulose and amino groups of chitosan.169 Specifically, the broken gels were able to heal after 40 min at 37 °C in physiological conditions. Despite increasing usage of chitosan in self‐healing hydrogels, low water solubility of this polymer at physiological pH can be problematic for its application in tissue engineering. To this end, Khan et al. synthesized a water‐soluble derivative of chitosan by grafting l‐glutamic acid onto its backbone (chit‐glu). Subsequent mixing with benzaldehyde‐terminated 4‐arm poly(ethylene glycol) (PEG‐BA) led to fast formation (<60 s) of a gel, based on imine bonds. The prepared hydrogels were shown to be injectable and self‐healing, and the healed hydrogels fully recovered their initial elastic modulus in a compression test. Most remarkably, human fibroblast cell lines (WI‐38) cultured on top of the hydrogel were viable and capable of proliferating.171

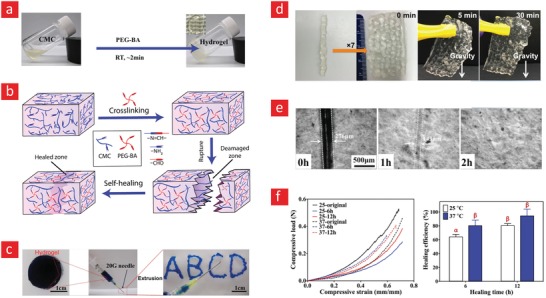

Figure 6.

A mechanically strong and self‐healable carboxymethyl–chitosan (CMC) hydrogel based on Shiff‐base bonds. a) The gel formation is shown here along with b) the chemical mechanism behind its self‐healing properties. c,d) The self‐healing properties of the CMC hydrogel. e) The mechanical properties of the as‐prepared hydrogel and those that were allowed to heal for 6 and 12 h. f) The healing efficiencies (the compressive load ratio of as‐prepared and healed samples) at 25 °C and 37 °C are shown here; there were no significant differences between bars with the same letters. Adapted with permission.43 Copyright 2016, Wiley‐VCH.

Noncovalent interactions based on hydrogen bonds172, 173 and hydrophobic forces174 have also been utilized to fabricate self‐healable chitosan hydrogels. For instance, a pH‐sensitive hydrogel made from hydrogen‐bonded chitosan (CS) and polyvinyl alcohol (PVA) was capable of completely healing itself after 1 h and showed good cytocompatibility with HeLa cells.175 In a similar study, a multilayered polyelectrolyte composite film comprised of CS and polyacrylic acid (PAA) was demonstrated to pose excellent self‐healing ability at low PH values.172 In another study, hydrophobic interactions were used to develop a chitosan‐based self‐healable hydrogel.176 Specifically, in this study, chitosan was modified with the hydrophobic compound—ferrocene—to enable self‐healing through hydrophobic interactions between adjacent ferrocene sites. This hydrogel was also highly stimuli‐responsive and could be triggered to deliver small molecules and biologics by changing the pH value. In the authors' opinion, stimuli‐responsive and self‐healable hydrogels are ideal for on‐demand delivery of tissue growth factors and stem cells to injury sites in the body and could potentially change the course of the field of tissue engineering.

3.1.3. Hyaluronic Acid

HA is a nonsulfated glycosaminoglycan that is found in ECM of vertebrate tissues,177 and is a suitable tissue engineering polymer due to its ability to bind cell surface receptors such as CD44, as well as its involvement in regulating cell differentiation and proliferation.178 In addition, the presence of reactive carboxylic groups on HA enables various chemical functionalization schemes for further downstream applications.179 Nonetheless, similar to other hydrogels made from naturally derived polymers, HA‐based hydrogels are susceptible to mechanical disruption, and accordingly, a variety of methods have been applied to develop self‐healable and durable HA hydrogels. These methods include the use of chemical bonds such as Diels–Alder and acylhydrazone bonds180 or noncovalent interactions such as guest–host interactions38, 181, 182, 183, 184 and hydrogen bonds.45 For instance, a recent study has used a combination of Diels–Alder and acylhydrazone bonds to make a self‐healing hydrogel (healing after 3 h) with good mechanical property (storage modulus of 18 kPa) from a mixture of oxidized furan–HA, furan–adipic dihydrazide‐functionalized HA, and dimaleimide–PEG.180 Specifically, Diels–Alder click chemistry between furan and maleimide was utilized to give the hydrogel matrix its mechanical integrity, while the self‐healing mechanism was built into the system via reversible acylhydrazone bonds between acylhydrazine and the aldehyde groups present on the oxidized furan–HA backbone. Most remarkably, this hydrogel showed great adhesion to native cartilage tissue (adhesive strength of ≈10 kPa), owing to the aldehyde‐amine Schiff‐base reaction. Based on a similar principle, a hydrogel composed of hydrazide‐modified HA (HA‐HYD) and aldehyde‐modified HA (HA‐ALD), exhibited fast self‐healing (healing after 10 min) with 100% healing efficiency.185 Additionally, 3T3 fibroblast cells encapsulated within the hydrogel demonstrated high cell viability (after 14 d of culture) in accordance with a high biocompatibility.

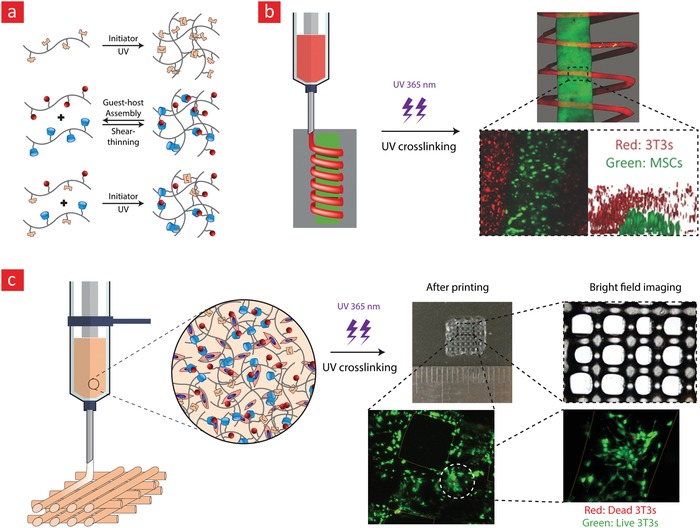

With regard to self‐healable hydrogels generated through physical crosslinking, a series of milestone studies from Jason Burdick's laboratory are worthy of mentioning.38, 181, 182, 183, 184 In most of these studies, guest–host interactions between adamantine(guest)–HA and β‐cyclodextrin(host)–HA were used to develop self‐healable hydrogels, which at the same time also were suitable for printing 3D scaffolds due to their shear‐thinning properties.38, 182, 186, 187, 188 In some of these studies, a methacrylated HA precursor polymer was added to the system for stabilizing the finalized scaffolds through UV‐crosslinking of the methacrylate groups (covalent bonding).38, 182, 188 Specifically, the authors used this method to generate highly complex 3D scaffolds into which 3T3 fibroblast cells were encapsulated in a viable state for up to 5 d of culture (Figure 7 ).188 In the authors' opinion, the combination of 3D printing and self‐healable hydrogel inks can pave the way for 3D‐printed tissue engineering constructs with the capacity to heal in the same way that natural tissues do within the human body. To this end, the authors also envision that the addition of shape memory properties to such constructs could enable the delivery of scaffolds with complex architectures using a noninvasive syringe injection methodology. We will revisit injectable scaffolds with shape memory and self‐healing capacity in Section 6.3.

Figure 7.

A self‐healable and printable HA‐hydrogel based on host‐guest interactions. a) The chemistry behind the self‐healing mechanism. b) A depiction of the cell‐laden hydrogel patterns with helical features, which were generated through extrusion printing. c) The team also used the extrusion printing technique to generate a grid‐like 3D construct consisting of 3T3 cells, which displayed high viability. Adapted with permission.188 Copyright 2016, American Chemical Society.

3.1.4. Gelatin

Gelatin is a natural protein that is derived from the denaturation of collagen via hydrolysis.189, 190 Consequently, gelatin retains the bioactive sequences of collagen (such as an arginine–glycine–aspartic acid peptide), while exhibiting limited antigenicity.191 Gelatin has numerous advantages making it an exciting biopolymer for tissue engineering and regenerative medicine.148, 192, 193, 194 This includes biocompatibility, biodegradability, cost effectiveness, and ease of modification.190, 191, 192 Yet, gelatin undergoes gel–sol transition at body temperature, which emphasizes the importance of chemical cross‐linking of gelatin‐based hydrogels for tissue engineering applications.195 Because gelatin contains aromatic residues in its backbone (e.g., tryptophan, phenylalanine, and tyrosine), the most logical method for developing self‐healable gelatin is through guest–host interactions.196 In a noteworthy example, Feng et al. used the guest‐host interactions between aromatic residues (guest) of gelatin and photo‐crosslinkable acrylate β‐cyclodextrin (Ac‐β‐CD) (host) to institute a highly stretchable (failure strain above 400%) hydrogel with quick healing ability (5 min) and good biocompatibility, as tested through encapsulation with human mesenchymal stem cells (hMSCs).197 The reversible nature of guest–host crosslinks made this hydrogel injectable and allowed infiltration and migration of hMSCs into the hydrogels without comprising the structural integrity of the hydrogel matrix. Most importantly, in vivo implantation of the hydrogel into rat calvarial bone defect led to enhanced tissue deposition in the defect, which was correlated with the ability of the hydrogel to recruit endogenous osteoblastic cells as the reversible crosslinks within the gel enabled cell migration without disrupting its mechanical integrity. As it was described in Section 2.4, double‐network hydrogels are another approach to produce self‐healing hydrogels. Along these line, gelatin methacrylate (GelMA) was used in conjugation with tannic acid (TA) to institute a self‐healing hydrogel with adhesive properties.198 The double‐network hydrogel in this study was comprised of precrosslinked GelMA hydrogel accompanied with TA as a multifunctional hydrogen bond provider. The resulting hydrogel showed significant increase in ultimate stress (4.3‐fold), compressive modulus (2.5‐fold), and elongation (sixfold), when compared to pristine GelMA hydrogel. Furthermore, the GelMA‐TA hydrogel generated sufficient adhesiveness to various surfaces (rubber, plastic, metal, glass, and porcine skin) corresponding with the TA content in the hydrogel.

3.2. Synthetic Polymers

Synthetic polymers have played an integral part in the technological revolution, which have been witnessed in modern times. This is in part due their chemical inertness, strong elastic modulus, flexibility, and ease of custom modification.199, 200 However, some synthetic polymers are highly toxic to humans, not biodegradable, and biologically inert, and thus not suitable for tissue engineering applications.201 Furthermore, many synthetic polymers are oil based, which is a great disadvantage, as the global oil supplies are expected to become greatly exhausted in the near future. Nevertheless, synthetic polymers offer a range of exciting properties that one has to consider when engineering self‐healing hydrogels. As was noted in the previous section, the natural‐based polymeric hydrogels are typically not stretchable, do not offer instant self‐healing, and are mechanically weak. Their synthetic counterparts can address all of these shortcomings, and we will, therefore, highlight their recent uses in the field of self‐healable tissue engineering hydrogels. In particular, we will mainly focus on self‐healable hydrogels made from polyethylene glycol, poly(acrylamide), and poly(vinyl alcohol) under conditions that make them amenable to tissue engineering applications (Figure 5).

3.2.1. Polyethylene Glycol

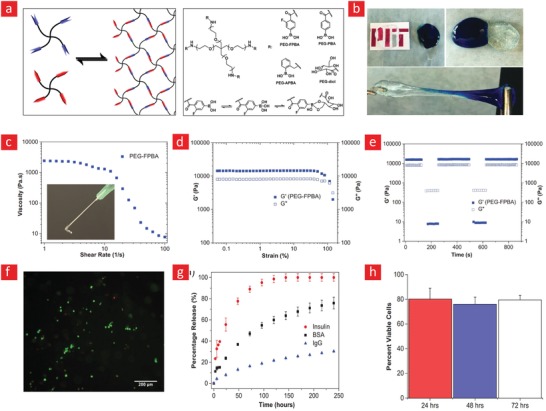

PEG has been cemented as one of the most imperative hydrophilic polymers for biomedical applications thanks to desirable characteristics such as good biocompatibility, nonimmunogenicity, and versatile physical properties.23, 202, 203 The widespread recognition that PEG has garnered over the years has made it the first choice for most engineers attempting to develop self‐healing hydrogels. This is evident from the many studies published on the preparation of self‐healable PEG hydrogels.57, 101, 122, 128, 204, 205, 206 Examples include hydrogels with repair mechanisms based on borate esters,122, 206 Diels–Alder reactions,128 imine bonds,205, 207 hydrogen bonds,57, 204 and hydrophobic forces.84 Especially, a series of landmark achievements, wherein borate esters were used to impart good self‐healing efficiency and high mechanical stability are worthwhile mentioning.122, 206 In these milestone studies, the authors develop self‐healable hydrogels that were elastic and could reach high storage modulus values (up to 10 kPa) without rupturing. For instance, a team led by Robert Langer and Daniel G. Anderson managed by using boronate ester bonds between a four‐arm PEG–phenylboronic acid (three different PEG–phenylboronic acid derivatives: PEG–FPBA, PEG–PBA, and PEG–APBA) and four‐armed PEG–diol macromonomers, to develop a stretchable hydrogel with instant healing properties (Figure 8 ).122 Moreover, this hydrogel displayed shear‐thinning properties and could thus be used as an injectable and self‐healable hydrogel carrier for stem cell therapy. However, to this end, it is pivotal that the hydrogel carrier can sustain viable cells over longer periods. The team validated this by encapsulating fibroblast cells within the hydrogel and demonstrated that the cells remained viable for up to 72 h with viability of around 80%. This team also examined the potential of this system for the targeted delivery of both biologics and cells to possible target sites in the body with promising results.

Figure 8.

A stimuli‐responsive and self‐healable PEG‐hydrogel based on phenyl–boronic acid–cis–diol binding. a) The chemistry behind the self‐healing mechanism. b) Photographic images showing the self‐healing properties of the hydrogel. c) In addition to its self‐healing properties, this hydrogel was also shear‐thinning. d) Strain amplitude sweep and the associated e) step‐strain measurements of the PEG‐hydrogel to elucidate its self‐recovery properties. f) The viability of cells within the self‐healable hydrogels was ≈80% and remained at this level for up to 72 h. g) The release profiles of insulin, BSA, and IgG at different time‐points and h) cell viability at different time points are shown here. Adapted with permission.122 Copyright 2016, Wiley‐VCH.

In another series of experiments, self‐healable PEG‐based hydrogels were synthesized by functionalizing telechelic difunctional PEG (DF‐PEG) with two aldehyde end groups through esterification of the hydroxyl groups on PEG and mixing the DF‐PEG with an aminated polymer such as chitosan205 or polyethylenimine (PEI).207 The combination of DF‐PEG and PEI resulted in an exciting hydrogel that could stretch up to 400% and recover fully to its original state. Moreover, once broken, it could instantly self‐heal and withstand extensive stretching without rupturing. However, one drawback of this study is the use of PEI, a molecule that can be toxic to cells at high doses.208 Along the same lines, a hydrogel comprised of dialdehyde‐functionalized polyethylene glycol (DF‐PEG) and agarose–ethylenediamine conjugate (AG–NH2) showed fast self‐healing (after 5 min) and exhibited higher yield stress (≈ 2000 Pa) when compared to pure agarose (126 Pa) or agarose–PEG hydrogels (315 Pa).209 This hydrogel demonstrated excellent adhesion to porcine skin and after being applied on the incision of the skin, it was able to withstand a bursting pressure that was even bigger than the arterial blood pressure (120 mmHg), indicating the capability of the hydrogels to assist in wound healing. Furthermore, human umbilical vein endothelial cells (HUVEC) in contact with the hydrogel extracts demonstrated high cellular viability (>80%), indicating low cytotoxicity of the hydrogels. Most importantly, hydrogels showed remarkable hemostatic capability after being applied to a rabbit liver incision immediately, in contrast with conventional sterile gauze.

Another way of preparing self‐healing PEG hydrogels is through thiol‐ene interactions, where the PEG alkene (or alkyne) reacts with a thiolated polymer to establish a self‐healing polymeric network.210, 211, 212 To this end, Macdougall et al. developed a self‐healing hydrogel from a mixture of four‐arm PEG alkyne and difunctional linear PEG thiol, yet this hydrogel suffered from low compressive strength and stretchability.212 In an attempt to address these shortcomings the same group developed interpenetrating networks (IPN) by incorporating a range of unfunctionalized natural polymers (alginate, chitosan, gelatin, heparin, or hyaluronic acid) into the hydrogel. Accordingly, PEG/alginate and PEG/gelatin systems showed higher compressive strength, tensile strength, and stretch‐ability when compared to control PEG hydrogel. The observed properties were attributed to existence of a secondary electrostatic loose network that complemented the efficient nucleophilic thiol‐ene cross‐linking chemistry. Most remarkably, human mesenchymal stem cells encapsulated in PEG/alginate hydrogels showed higher cell viability after 72 h (95%) when compared to that of PEG‐alone systems (77%), which implied PEG/Alginate provided a cytocompatible matrix that supports cell growth.

Recently, UPy has also been shown to be a promising tool for making self‐healable PEG hydrogels owing to hydrogen‐bond‐assisted dimerization of the UPy moieties.57 Notably, PEG oligomers were functionalized with UPy and immersed in a buffered solution, in which they began to solidify into stable hydrogels through hydrogen bonding mediated by UPy. As this system was injectable, it was used for further down‐stream studies to examine its ability to deliver bone morphogenetic protein 7 (BMP‐7) into kidney tissue via a minimally invasive injection method. Therefore, this UPy‐based approach could potentially lead to significant clinical break‐through discoveries in the foreseeable future.

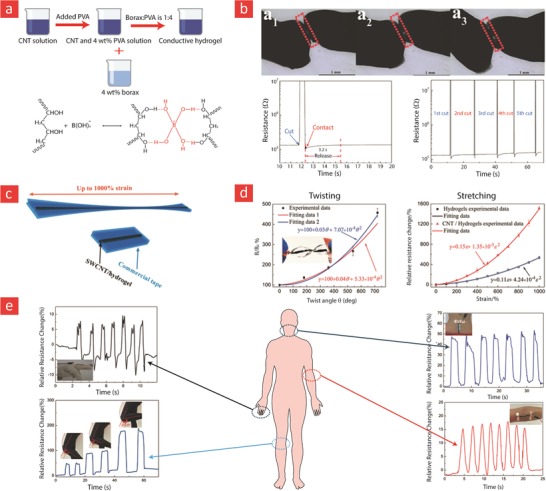

3.2.2. Poly(vinyl alcohol)

Another synthetic, biocompatible, non‐toxic and water‐soluble polymer—PVA—has also been employed in numerous biomedical applications ranging from contact lenses to scaffolds and various drug delivery platforms.152, 213, 214, 215 PVA is unique because of its many hydroxyl groups, which, together with its high water retention properties, makes it an ideal candidate for self‐healing hydrogels. Accordingly, over the years, several PVA‐based self‐healing systems have emerged, in which the healing mechanism was based on reversible hydrogen bonds.63, 216, 217, 218 In one such example, a double‐network hydrogel consisting of PVA and PEG was combined to yield an exceptionally tough hydrogel that could reach an ultimate tensile strength of almost 1.3 MPa while exhibiting shape memory and self‐healing properties.219 The secret behind the many amazing properties of this PVA–PEG system stemmed mainly from the presence of weak reversible hydrogen bonds between PVA polymers that yielded deformability, and strong chemical crosslinks between PEG polymers that could keep the system intact in high strain regimes and, thus, enable a return to its original shape. Even though a plethora of seal‐healable hydrogels have been presented to the field of biomaterial science, this combination of high material toughness and self‐healing ability is rather unusual, as high stiffness typically goes hand‐in‐hand with strong and stable intermolecular bonds, which conflict with the unstable and highly dynamic links behind self‐healable systems. Similarly, a hydrogel blend made from PVA, borax, and nanofibrillated cellulose resulted in a reinforced self‐healable hydrogel with improved mechanical properties as a result of reversible interchain hydrogen bonding between PVA and the nanocellulose, and strong boronate ester links mediated among the PVA polymers by borax.220 In a similar vein, a mixture of PVA and 2APBA yielded a hydrogel that exhibited self‐healing ability not only in PBS but also in a culture media (with or without the serum).221 Moreover, encapsulated fibroblast cells (CCL‐151) or breast cancer cells (MDA‐MB‐231) exhibited good viability over the course of 7 d, indicating cytocompatibility of the materials. More remarkably, the self‐healing ability of this hydrogel was successfully used to create a dynamic coculture system by separately encapsulating fibroblast cells and breast cancer cells in the hydrogel pieces and subsequently connecting them. In our opinion, this study holds much value as it can inspire researchers to create more complex culture environments for probing dynamic cell−cell and cell−matrix interactions.

Another challenge in the field of biomaterial science is the design and development of materials with high stiffness but fast molecular dynamics to yield a hydrogel that can quickly heal itself. To address this challenge, a recent study combined highly crystalline nanocellulose with PVA to generate a promising hydrogel for tissue engineering applications. Specifically, this self‐healable hydrogel was composed of hard, modified cellulose nanocrystals and soft, polymeric PVA domains crosslinked by dynamic host–guest interactions brought about by cucurbit[8]uril (CB[8]).63 This combination resulted in a mechanically strong hydrogel that could heal rapidly (within few seconds). From our viewpoint, such systems that address the conflict between strength and fast molecular dynamics could lead to new resilient biomaterials with the capacity to mend defects within load‐bearing tissues, such as cartilage and bone, as they can readily heal possible small fractures arising from the cyclic stretches and compressions imposed on natural bone and cartilage tissues.

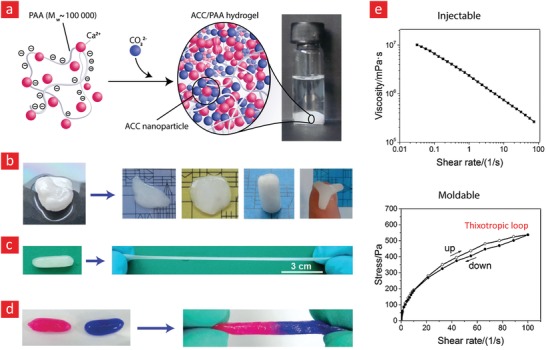

3.2.3. Poly(acrylic acid)/Poly(acryl amide)

Another class of synthetic self‐healing hydrogels—albeit less used—are those made from acrylate‐based polymers, especially acrylic acid and acrylamide. These hydrogels are special because of their good water absorption capacity and high density of functional chemical groups, such as carboxylic acid and amine groups, which in combination with their nontoxicity, makes them ideal to use for many biomedical applications.222, 223, 224, 225 Over the years, acrylate‐based self‐healable hydrogels have, for the most part been generated through hydrophobic interactions derived from either host‐gust interactions or micelles entrapped within the hydrogels.81, 82, 226, 227

In particular, the incorporation of micelles into poly(acrylic acid)/poly (acrylamide) hydrogels has proven a versatile pathway to produce self‐healable hydrogels with desirable attributes, such as high extensibility, elastic modulus, and toughness. A common approach to this end is the spontaneous polymerization of stearyl methacrylate (C18) into micelles within hydrophobically modified acrylic acid/acrylamide hydrogels in the presence of either of the surfactants; cetyltrimethylammonium bromide (CTAB) or sodium dodecyl sulfate (SDS).81, 82, 226 A key example of this methodology can be found in a recent study by Gulyuz et al.,81 wherein a poly(acrylic acid) hydrogel encapsulated with C18‐based micelles was developed. This self‐healable hydrogel could stretch up to 800% of its original length before it broke and displayed a high tensile strength in the range of 0.7–1.7 MPa. Similarly, the copolymerization of N,N‐dimethylacrylamide (DMA) and stearyl methacrylate (C18) in the company of SDS led to a poly(acrylamide)‐based hydrogel with self‐healing properties arising from the incorporation of C18/SDS‐based micelles within it.82 This hydrogel was extremely stretchable (broke at 4200% strain), displayed shape memory behavior, and could heal itself. However, one disadvantage of using the above‐mentioned methodology is the long hydrogel self‐healing duration; typically ranging from 20 to 60 min.

Another way of preparing self‐healing poly(acrylamide) hydrogels is through host‐guest interactions, in which the amine groups on the polymer backbone are functionalized with a host—cyclodextrin—and a hydrophobic and aliphatic guest molecule (n‐butyl acrylate, adamantane, and ferrocene).61, 62 Kakuta et al. embraced this approach to develop a self‐healable hydrogel based on a adamantine–ferrocene host molecule, which could immediately mend itself after rupturing, however, the self‐healing efficiency in terms of the adhesion strength between the rejoined pieces was relatively low, and it took up to 24 h to reach the prerupture adhesion strength.61 In another study, researchers attempted to develop a double‐network hydrogel by using host–guest interactions, between isocyanatoethyl acrylate modified with β‐cyclodextrin (host; β‐CD‐AOI2) and 2‐(2‐(2‐(2‐(adamantyl‐1‐oxy)ethoxy)ethoxy)ethoxy)ethanol acrylate (Guest; A‐TEG‐Ad), accompanied by a second covalent bonding between acrylate groups (achieved by UV‐initiated polymerization).228 The resulting hydrogel showed fatigue resistance and resistance to slicing because of the combination of host–guest interactions and covalent bonds in the hydrogel networks. Furthermore, in a strain sweep test (1% strain–1000% strain–1% strain), these hydrogels fully recovered their initial storage modulus even after the hydrogel had undergone several cycles. Most significantly, mouse bone marrow stromal cells (mBMSCs) or myeloid‐derived suppressor cells (MDSCs) cultured in the presence of the hydrogel extracts had a proliferation rate consistent with that of the positive control group, indicating their good cell compatibility. Most recently, the same group used a similar composition except they added GelMA to the recipe to benefit from its excellent biocompatibility.229 The resulting hydrogel exhibited superior mechanical properties compared to pristine GelMA and was able to completely heal itself after 1 h. Owing to shear‐thinning properties of this hydrogel, it was successfully 3D printed into a multilayer scaffold and mouse bone marrow stem cells (mBMSCs) cultured on top of these scaffolds were shown to be viable and proliferating after 7 d of culture. Furthermore, subcutaneous implantation of this hydrogel on the backs of nude mice (for 40 d) revealed that the scaffolds were completely integrated with the autogenous tissue of the nude mice, and new subcutaneous muscle tissues and blood vessels were formed in their pores with no immunological rejection occurred. These results suggested that these self‐healing scaffolds had favorable bioactivity and histocompatibility, making them useful in biomedical applications.

Hydrogen bonds are another alternative interaction scheme, which has been explored extensively over the years to develop self‐healable acrylic acid/acrylamide hydrogels.53, 60, 230 In one such study, acrylic acid and acrylamide were mixed in the company of glycogen to polymerize into a hydrogel through hydrogen bonds between carboxyl groups and hydroxyl groups in glycogen. This hydrogel could completely heal itself at neutral pH after 12 h while exhibiting shear modulus values as high as 1000 kPa and a swelling ratio that could reach 3500% after ≈ 500 min of swelling in water.230 The combination of self‐healing capacity at neutral pH together with high mechanical strength makes this system interesting, as many of the self‐healing hydrogels reconnect in nonphysiologically conditions and display low elastic modulus values. Based on the same concept, a double‐network hydrogel composed of poly(acrylamide‐co‐acrylic acid) (PAM‐co‐PAA) and PVA was generated via copolymerization and hydrogen bonds between the carboxyl groups of PVA and acrylamide groups of acrylamide. Moreover, the PVA polymeric backbone was made highly crystalline through a well‐established freeze/thawing procedure. Overall, this double‐network hydrogel could stretch up to almost 600% and reach 1230 kPa in tensile strength before breakage. The authors speculated that these formidable mechanical properties arose from the combination of weak reversible hydrogen bonds and the rigid crystalline PVA domains.53

3.3. Others

Other self‐healable hydrogels based on peptides,231, 232, 233, 234, 235 mussel‐inspired proteins,47, 48, 101, 236, 237 conductive polymers,85, 233, 238, 239, 240, 241, 242, 243, 244, 245 and zwitterionic polymers,246, 247, 248, 249 have also gained acceptance in the field. Peptide‐based hydrogels with self‐healing properties have been described elsewhere in detail, and the interested reader is referred to these recent reviews on this topic.231, 250 In this section, we will instead focus on conductive, mussel‐inspired and zwitterionic self‐healable hydrogels.

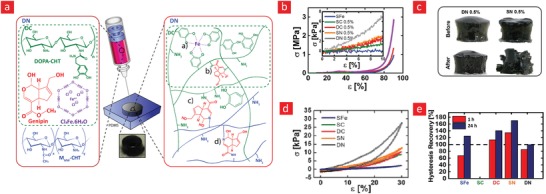

The working mechanism behind most mussel‐inspired hydrogels stems from metal chelating cross‐links between positively charged Fe+3 ions and negatively charged catechol molecules.48, 101, 102, 237 In simple terms, the polymer in question is functionalized with negatively charged catechol groups—typically in the form of 3,4‐dihydroxyphenylalanine (DOPA)—which then crosslinks into a hydrogel through sacrificial bonds mediated by metal‐catechol coordination. These bonds are stronger than hydrogen bonds yet sufficiently weaker than covalent bonds to enable dynamic binding schemes and, ultimately, good self‐healing properties. A recent forerunner toward such Fe+3–DOPA‐mediated hydrogels was based on a DOPA‐chitosan (DOPA‐CHT) derivative, which could spontaneously crosslink into a double‐network hydrogel in the presence of Cl3Fe.6H2O (metal–ligand coordinate) and genipin (covalent) (Figure 9 ).102 This bioinspired hydrogel displayed a range of interesting properties including: i) a high compressive strength in the MPa range, ii) good cytocompatibility and iii) fast self‐healing time ranging from 8 to 15 min. In addition, the mussel‐inspired hydrogel was injectable and could easily recover from repeated cyclic loadings. For these reasons, this is an ideal hydrogel carrier for stem cell therapies targeted against load‐bearing tissues, such as bone and cartilage.

Figure 9.

A tough, durable, and self‐healable chitosan–dopamine–hydrogel based on chelation. a) The chemistry behind the self‐healable hydrogel. DN indicates a double‐network hydrogel made from dopamine–chitosan (DOPA–CHT) and medium molecular weight chitosan (MM w‐CHT), while DC indicates a double crosslinked DOPA–CHT hydrogel made through genipin (crosslinks the amine group in CHT) and Fe3 (mediates coordination bonds between catechol groups). b) Compressive stress–strain curves of DOPA–CHT hydrogels that are solely crosslinked through Fe3+ (SFe) or through the addition of 0.5% genipin (SC 0.5%). SN (0.5%) and DN (0.5%) indicate single‐network DOPA‐CHT hydrogel with 0.5% genipin and double‐network hydrogel with 0.5% genipin, respectively. c) The self‐healing properties of DN 0.5% and SN 0.5% hydrogels are shown. d) Cyclic stress–strain curves and e) their associated hysteresis recovery. Adapted with permission.102 Copyright 2017, Wiley‐VCH.

Mussel‐inspired hydrogels with self‐healing capacity have also been generated under metal‐free conditions by using catecholamine‐3,4‐dihydroxyphenethylamine (dopamine) instead of DOPA. These hydrogels typically obtain their self‐healing properties from noncovalent interactions between aromatic rings, hydrogen bonds, and via imine bonds mediated by the NH2‐groups in polydopamine. An elegant solution toward such hydrogels was recently reported, wherein gelatin was functionalized with aldehyde groups and mixed with polydopamine under metal‐free condition (via sodium periodate) to generate an injectable, moldable, self‐healable hydrogel with fast recovery time, good self‐healing efficiency (95%), and a good adhesiveness (10–40 kPa).237 Such properties were an outcome of a complicated cross‐linking scheme comprised of hydrogen bonds in combination with imine and π–π interactions.

Another remarkable concept in the field is the development of electrically conductive and self‐healable hydrogels—as many tissues in the body—such as heart, muscle, and brain tissues are electroactive, and therefore need to be matched with similar electroactive biomaterials to yield good biointegration.93 Despite extensive studies on the design and development of self‐healable hydrogels, only a few studies have attempted to capture other properties, such as electrical conductivity. An elegant forerunner toward this goal has been based on polypyrrole‐based hydrogels; as polypyrrole is a highly conductive yet biocompatible polymer.85, 233, 238, 239, 240, 241

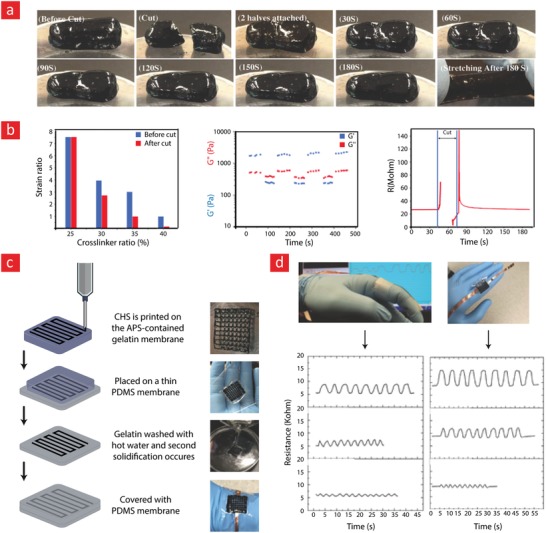

To this end, Darabi et al.85 generated a conductive, injectable, and self‐healing hydrogel by decorating chitosan with pyrrole and mixing it with acrylic acid monomers in the presence of Fe+3 and N,N˝‐methylenebis‐acrylamide (MBA) crosslinkers (Figure 10 ). These components altogether generated a double‐network hydrogel compromised of reversible ionic interactions between carboxylic groups on poly(acrylic acid) and amine groups on polypyrrole mediated by Fe+3, and irreversible covalent bonds between neighboring poly(acrylic acid) chains mediated by MBA. The combination of reversible and irreversible bonds resulted in a highly conductive hydrogel that could stretch up to 1500% and which could self‐heal its electrical and mechanical properties after just 1–2 min. Specifically, the mechanical healing efficiency was complete (100%), whereas the electrical healing efficiency saturated at 96% after 1 min.

Figure 10.

A conductive and self‐healable hydrogel made from chitosan (CSH), poly (acrylic acid) (PAA), and polypyrrole (PPY) based on electrostatic interactions. a) The self‐healing properties of the resulting hydrogel are displayed. b) The mechanical and electrical self‐healing efficiency of the hydrogel. c) Schematic depicting the preparation of the wearable sensor. d) The 3D printed wearable sensor could detect human‐body motions by measuring the associated resistance variation. Adapted with permission.85 Copyright 2017, Wiley‐VCH.

Another series of milestone concepts recently pursued is the development of electrically conductive, thermoplastic, moldable, and self‐healing hydrogels by mixing polypyrrole with agarose.240, 251 The polypyrrole makes the system conductive, while the agarose gel imposes self‐healing properties onto the system as the gelation of agarose is thermally reversible. This system could, therefore, heal itself through both external heat and near‐infrared light because of reversible liquidation and gelation in response to thermal stimuli. Moreover, the authors managed to adhere this conductive gel directly on the human skin for human motion detection and demonstrated that the system could yield an electrical circuit that could self‐heal via external heat or near‐infrared light stimuli.240, 251

Most recently, a new class of self‐healing hydrogels based on zwitterionic polymers have emerged— taking the field by storm owing to their unique biocompatible attributes. These polymers contain a balanced pairs of cationic and anionic groups, and mimic the phospholipids comprising the membranes of native cells or the mixed‐charge surfaces of many proteins.246 In fact, the positive and negative charges of the overall neutral zwitterionic molecules make a high dipole moment and such strong dipolarity endows excellent adhesion of zwitterionic hydrogels to many surfaces through ion–dipole or dipole–dipole interactions.252 Furthermore, the association of zwitterionic polymers can provide physical cross‐linking to enhance the mechanical properties of hydrogels. Most remarkably, zwitterions can assist the ion transportation along the highly dipolarized skeleton to promote ion conduction, which endows zwitterion hydrogels with good conductivity.253 Despite such great properties, most zwitterionic hydrogels are mechanically weak, hence researchers have incorporated other functionalities into them to make them self‐healable. In a noteworthy study, researchers utilized two different types of zwitterionic monomers, carboxybetaine acrylamide monomers with either one‐carbon (PCB‐1) or two‐carbon (PCB‐2) spacing between the charged groups, and separately cross‐linked them using carboxybetaine diacrylamide.246 Both hydrogels exhibited self‐healing behaviors in a strain sweep test (1% strain–300% strain‐1% strain), owing to ionic and hydrogen bonds between polymeric chains. Yet, PCB‐2 hydrogels demonstrated higher storage modulus compared to PCB‐1 hydrogels, which was attributed to stronger hydrogen bonds in PCB‐2 hydrogels. Additionally, both hydrogels were injectably and human embryonic kidney cells (HEK‐293T cells) encapsulated in these hydrogels retained a high cell viability even after being injected through a 28‐gauge needle. Additionally, hMSCs encapsulated in these hydrogels had greater population expansion over 14 d than that of cells in standard flask culture. Notably, hMSCs encapsulated in the hydrogels maintained their multipotency after 28 d of culture, while half the population of flask‐cultured hMSCs lost their multipotency. This phenomenon was shown to be a result of ROS‐scavenging capacity of zwitterionic hydrogels, which in turn causes stem cells favoring self‐renewal and mitigating nonspecific differentiation. In summary, this hydrogel presented a promising new platform for a wide variety of clinical applications requiring biocompatible injectable materials.

Another approach to make zwitterionic‐based self‐healing hydrogels is by modification of these polymers with boronic acid to allow formation of boron ester bonds. Along these lines, a group of researchers used a zwitterionic monomer (2‐methacryloyloxyethyl phosphorylcholine; MPC) and copolymerized it with a benzoxaborole‐containing monomer (5‐methacrylamido‐1,2‐benzoxaborole) to yield the PMB hydrogel. Separately, they have also copolymerized the MPC monomer with a glucose‐containing monomer (2‐gluconamidoethyl methacrylamide) to make the PMG hydrogel. Accordingly, mixture of PMB and PMG resulted in the formation of a hydrogel (PMBG) that showed fast self‐healing (after 20 s) owing to boron–ester bonds between the boronic acid (on PMB backbone) and hydroxyl groups (on PMG). The resulting PMBG hydrogels was injectable and showed pH‐responsive behavior due to the nature of boron–ester bonds. Additionally, both normal skin fibroblast cells (NSFB) and cancerous HeLa cells treated with the gel extracts maintained a high level of cell viability (>80%).247 Similarly, the same group copolymerized the MPC monomer with catechol‐containing monomer (dopamine methacrylamide; DMA) to yield poly (MPC‐co‐DMA) and, mixed it with poly (MPC‐co‐DMA) to facilitate a rapidly self‐healing hydrogel (after 1 min) with pH‐responsive behavior.248

3.4. Outlook and Future Opportunities

In summary, the synthetic polymers give rise to stronger self‐healable hydrogels with faster self‐healing kinetics than their natural counterparts. However, this is accompanied by much lower biocompatibility and potential adverse reactions within the body. The incorporation of cell adhesive motifs, such as RGD peptides, into the polymeric backbone of synthetic hydrogels, could potentially address some of these issues by enhancing the spreading, proliferation, and differentiation of encapsulated cells into mature tissues. The combination of a synthetic and natural polymer also offers the interesting possibility of generating a hydrogel that taps into the positive properties of both realms.

As the field advances, we anticipate that other sophisticated polymers grown inside bacteria—through recombinant technology—will grab the attention of scientists in the field, as this methodology can enable highly customized routes toward the generation of polymers with even better self‐healing efficiency and mechanical properties. Although attempts have already been made to introduce this technology into the field, most of these hydrogels have been weak (typically below 5 kPa) and, for the most part, intended to be used as injectable stem cell carriers that could mechanically shield the cells during the injection phase and retain them within the target site in a postinjection scenario.231 We, therefore, conjecture that further research into this area could yield some exciting self‐healable hydrogels for the field of tissue engineering.

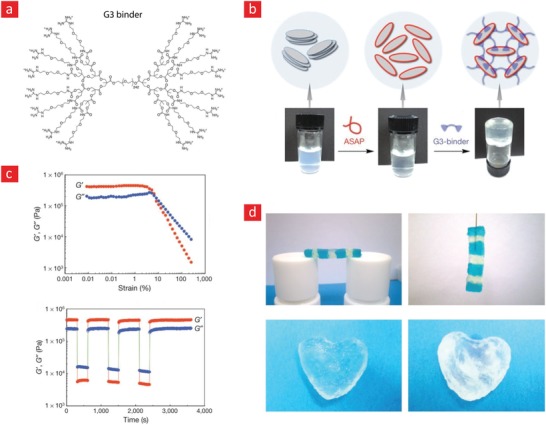

4. Nanomaterial‐Based Self‐Healing Hydrogels