Abstract

During chia oil extraction a by-product, the partially-deoiled chia flour is obtained. This product has highly desirable characteristics. It has a high content of protein, dietary fiber and a high antioxidant power. The partially-deoiled chia meal (PDCF) was extracted, characterized and utilized to formulate a popular baked product (muffins). The effect of the PDCF on its physicochemical, microstructural, sensory, nutritional and antioxidant properties were evaluated. Muffins supplemented with the chia by-product had improved nutritional properties (higher protein, fiber, polyphenols content, and higher antioxidant capacities). The sensory properties of the muffins made with up to 5% were not significantly changed. The use of a partially-deoiled chia meal in functional food development could add value to the food chain value with economic/social benefits. Some changes in the quality were observed but the use of a 5% of partially-deoiled chia flour could be proposed without significantly affecting the overall quality of the product.

Keywords: Chia, Functional ingredients, Muffins, Antioxidant properties

Introduction

The popularity of baked products such as bread, muffins, biscuits, cakes and pastries has increased significantly (Goswami et al. 2015). Bakery products have good acceptance among consumers. Thus, they can be considered acceptable vehicles for nutrient supplementation and functional food product development. Muffins are very convenient (ready-to eat) products especially preferred by children mainly because of their sweet taste and soft texture.

Salvia hispanica L. seeds are one of the best natural sources of poly-unsaturated fatty acid (PUFA) α-linolenic [ALA; 18:3 (n − 3)] showing a highly beneficial ω − 3/ω − 6 fatty acid proportion (Menga et al., 2017). The oil content of chia seeds ranges 30–35% and the protein content is between 19 and 27% similar to that present in lentil (23%), pea (25%) and chickpea (21%) (Olivos-Lugo et al. 2010), with a very good balance of essential aminoacids, especially methionine and cysteine (Menga et al. 2017). In addition, the dietary fiber content is significant and ranges between 34 and 50%, higher than the described for flax seeds (Sandoval-Oliveros and Paredes-López 2013), which may potentiate the use of chia in the production of functional foods. Chia seeds contain antioxidants derived from caffeic acid, such as rosmarinic acid, danshensu, and its glycosides (Oliveira-Alves et al. 2017), but also contains flavonoids such as kaempferol and quercetin (Capitani et al. 2012). Antioxidant activity is one of the most studied properties in foods. Many authors believe antioxidants are of paramount importance in the protection against oxidative damage of cells and tissues, having an important role in the prevention of many diseases related with the oxidation stress, such as cancer, cardiovascular diseases, and diabetes (Dias et al. 2017).

A by-product, with high content of fiber, protein, and antioxidants, remains after oil is extracted from chia seeds. Despite the good nutritional value of this by-product, it is usually used as animal feed, a low value product. The meal (partially-deoiled chia flour-PDCF) could be utilized as a potential source for adding value in traditional cereal-based products by enhancing the nutritional and antioxidant capacity of properties of them. The objective of this study was to evaluate the effect of this by-product on the nutritional, technological, and quality characteristics of wheat muffins.

Experimental

Materials

Commercial cake flour (Triticum aestivum), eggs, sugar, sunflower oil, whole milk, baking powder, vanilla extract, and chia seeds (Salvia hispanica L.) were obtained from local markets. All chemicals acquired were of analytical grade.

Processing of chia seeds to obtain the by-product (partially-deoiled chia flour)

Chia seeds were first conditioned to 9.5% moisture content, 48 h before the extraction process, in air-tight bags, with distilled water. For a better homogenization, bags were shaken every 20 min. Hydrated chia seeds were heated at 60 °C/20 min and screw pressed in a Komet (Model CA 59 G, IBG Monforts, Germany) at 20 rpm and with a 5 mm of restriction die. The by-product obtained was milled in a coffee grinder and sieved (0.25 mm). This ground residue is called PDCF (Aranibar et al. 2018).

PDCF composition

PDCF was analyzed for oil content, protein, and ash content according to official methods of the AACC (2000).

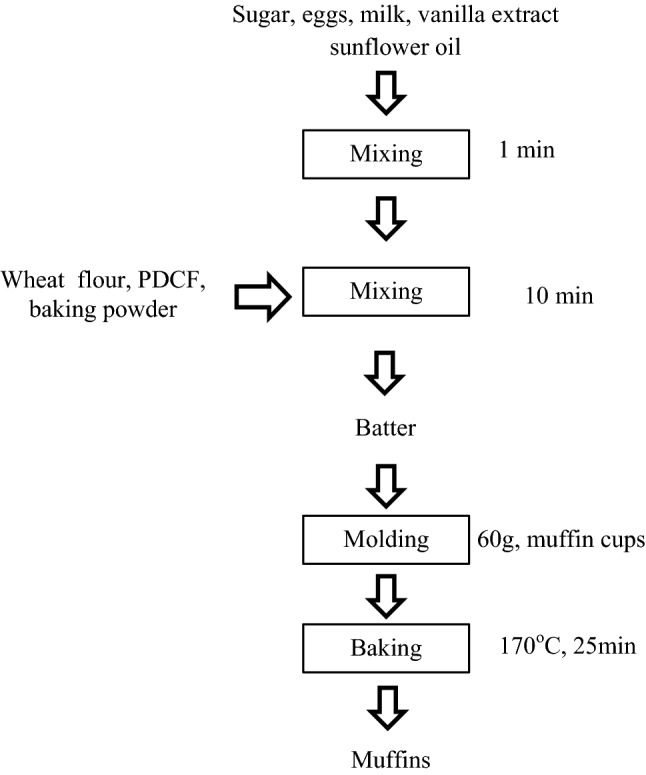

Muffins manufacturing process

A standardized laboratory process (Fig. 1) was used to manufacture muffins.

Fig. 1.

Muffins manufacturing process

Formulations included cake wheat flour (100 g), whole eggs (80.8 g), granulated sugar (67.8 g), sunflower oil (48.5 g), whole milk (19.4 g), baking powder (6.5 g), and vanilla extract (0.3 g). A tabletop blender (Peabody SMARTCHEF PE-BMP 19R, China) was used for mixing. An electric oven (PAUNA Beta 21 IPA, Buenos Aires Argentina) was used for baking. Different proportions of PDCF (0, 2.5, 5.0, and 10%, respectively, weight flour basis) were utilized to manufacture muffins with PDCF.

Pasting properties of blends

The pasting properties of blends of wheat flour with 0, 2.5, 5, 10% PDCF were evaluated using a Rapid Visco Analyzer (RVA series 4500, Perten instruments, Suecia). Viscosity profiles were recorded by mixing 3.5 g of wheat flour, PDCF or blends (14% moisture basis) with 25 mL distilled water. Heating and cooling cycles were used (50 °C for 1 min, heated to 95 °C at 9.4 °C/min, held at 95 °C for 2.5 min, cooling from 95 to 50 °C at 11.8 °C/min and holding at 50 °C for 2 min). RVA parameters were obtained from RVA profiles.

Apparent viscosity of the batters

Apparent viscosity was measured using a rotational viscosimeter FungiLab (model: VISCOLEAD ADV R 100). A model R7 spindle and a rotational speed of 50 rpm was used. The spindle was immersed and centered into the batters. The viscosity value (expressed as mPas = cP) was obtained in triplicate.

Physical characteristics of muffins

After baking, muffins were cooled for 4 h at room temperature on a wire grid. Afterwards, muffins were weighed, packed and stored for 14 days. Muffin height was measured from the bottom part of the muffin to the highest part using a vernier calliper. Muffin volume was determined by the rapeseed displacement method (AACC 2000). Specific volumes were calculated by dividing volume by weight and expressing the results as milliliters per gram.

Muffins crust and crumb color was evaluated using a colorimeter (KONICA MINOLTA Sensing, Inc), using the CIE Lab color space: L* (luminosity), a* (red-green) and b* (yellow-blue). A whiteness value (WV) and a color difference value (ΔE) was calculated using methods described in Hsu et al. (2003).

The textural parameters (Texture Profile Analysis) of the muffins were derived using an INSTRON Texturometer (Model 3342, Norwood, MA, USA) according to methods described in Bourne (2002).

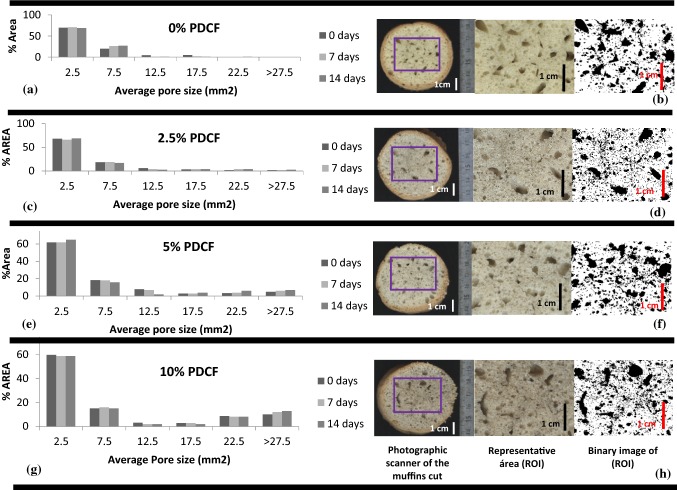

Evaluation of muffin’s crumb structure

The crumb’s structure (distribution of air cells) was studied by image analysis (Fig. 2). A photographic scanner (HP Scanjet G3010, Palo Alto CA, USA) of the muffins cut transversely (2.5 cm) was used to acquire images. Images in JPEG file format were analyzed with the Image-J2 image analysis program (Rueden et al. 2017). A representative area (ROI) of equal size was selected manually for all muffins. The color image was converted to an 8-bit image and analyzed in grayscale (0 black for empty spaces, 255 white for walls of crumb pores). The segmentation of the image (conversion to binary image) was done by the program by automatic selection of the threshold value. The following parameters were obtained from the analysis of the images: area occupied by pores (%), average of pore size (mm2), perimeter, and circularity (1 = maximum circularity, 0 = without circularity). Also, the distribution of pore size was extracted.

Fig. 2.

Pore size distribution (left) derived analyses of muffins images (right); a 0% PDCF muffin stored for 0, 7, and 14 days; b images of 0% PDCF muffin at day 0; c 2.5% PDCF muffin stored for 0, 7, and 14 days; d images of 2.5% PDCF muffin at day 0; e 5% PDCF muffin stored for 0, 7, and 14 days; f images of 5% PDCF muffin at day 0; g 10% PDCF muffin stored for 0, 7, and 14 days; h images of 10% PDCF muffin at day 0

Nutritional and antioxidant evaluation of muffins

Protein and ash content was measured by the official methods of the AACC (2000). TDF was quantified by using a Total Dietary Fiber Assay Kit (number K-TDFR-100) from Megazyme Inc. based on official method of the AOAC (2016).

Extraction of phenolic compounds

Baked muffins were lyophilized, grounded (coffee grinder) and defatted with hexane (1:2.5 w/v, 25 min). One gram of powder was extracted with 10 mL of acetone/water (70:30) for 7 h at room temperature in darkness. Samples were centrifuged at 5000×g (30 min), the supernatant decanted, and used for further analysis. Samples were prepared in triplicate.

Total polyphenol content (TPC)

TPC of extracts was measured by the Folin–Ciocalteu method (Orthofer and Lamuelas-Raventos 1999). Results are expressed in mg of gallic acid equivalents (GA) per 100 g of sample. All samples were analyzed in triplicate.

Antioxidant capacity determination

Antioxidant capacity was measured by two chemical methods: the ferric reducing ability of plasma assay (FRAP), to evaluate the reducing power and the ABTS·+ radical cation decolorization assay to assess de radical scavenging activity. FRAP assay was performed according to Benzie and Strain (1996). The ABTS was analyzed as reported by Fares et al. (2010). Results of FRAP and ABTS are expressed in mg TE/100 g of samples. All samples were analyzed in triplicate.

Sensory evaluation of muffins

Forty-three adults (23–50 years-old semi-trained panelists) participated in the sensory evaluation of muffins. Samples were evaluated for the degree of liking for colour, flavour, aroma, texture/firmness, and overall appearance. Rating were collected using a 9-hedonic scale where 1 = extremely dislike and 9 = extremely like. This study was approved by the University Institutional Review Board.

Statistical analyses

Differences were analyzed comparing average data values according to the Fisher test (ANOVA) at p < 0.05 of significance level. A DGC comparison test was performed to reveal differences between means. Tests were performed using InfoStat Software (Di Rienzo et al. 2002).

Results and discussion

Characterization of the PDCF

The proximate composition (mean ± SD) of the PDCF exhibited a high content of protein (27.7 ± 0.18%), total dietary fiber (59.73 ± 7.75%), ash (5.62 ± 0.15%), total polyphenols (221.20 ± 2.25 mg GA/100 g), and antioxidant activity (FRAP, 0.70 ± 0.03 mmol Trolox eq./100 g; ABTS, 0.47 ± 0.02 mmol Trolox eq./100 g). Also, the PDCF had a high content of ω − 3 (6850 ± 0.95 mg/100 g) fatty acids and a high ω − 3/ω − 6 proportion (3.17 ratio). Other authors who have evaluated chia proximate composition also demonstrated that chia is a good source of these components (Coelho et al. 2015; Marineli et al. 2014). The PDCF obtained in this study is a potential food ingredient that could be used to improve the nutritional quality and antioxidant capacity of baked products.

Effect of PDCF on viscosity of muffins batter

Apparent viscosity

Apparent viscosities (ApV) of batters made with PDCF are shown in Table 1. It was observed that as the proportion of PDCF increased in the batter the ApV increased. The ApV of the batters almost doubled with 2.5% and 5% of PDCF, and increased 3.2 times with the addition of 10% of the chia residue. This data show that the addition of PDCF increases the viscosity of the batters. This important physical property is related to the final quality of an aerated baked product. The incorporation and retention of air, the stability of the bubble and the generation of convection flow in the batter during cooking depend on the initial viscosity of batter and the evolution of the net viscosity during heating (Martínez-Cervera et al. 2012). Muffins have a typical porous structure with a spongy texture and high volume. The incorporation of dietary fiber (PDCF is a material with a high content of fiber) in baked sweet products is associated with an increase in the viscosity of the batter (Martínez-Cervera et al. 2012). This increase in viscosity is related to the high ability of fiber to bind water (Struck et al. 2016). Shaabani et al. (2018) mentioned that for the production of high quality muffins a high viscosity of the batter is important because a sufficiently high viscosity of the batter could maintain the air bubbles in the batter. Low viscosity batters may lead to insufficient formation of air cells.

Table 1.

Viscosity and pasting properties of PDCF and flour blends and batters

| % of PDCF (flour base) | ApV (mPa) | BD (cP) | FV (cP) | SB (cP) | PT (min) | PT° (C°) | PV (Cp) |

|---|---|---|---|---|---|---|---|

| 0 | 16446.26 ± 4.98a | 1359 ± 2.6a | 3494 ± 0.4a | 1642 ± 0.7a | 6 ± 0.0a | 66 ± 0.6a | 3211 ± 0.3a |

| 2.5 | 30426.33 ± 10.39b | 1401 ± 0.4a | 3375 ± 0.2b | 1634 ± 0.7a | 5 ± 0.0b | 64 ± 0.5b | 3142 ± 0.3a |

| 5 | 32554.00 ± 9.09b | 1487 ± 3.6a | 3398 ± 0.2b | 1679 ± 0.3b | 5 ± 0.0b | 63 ± 0.0b | 3206 ± 1.4a |

| 10 | 52886.67 ± 9.35c | 1754 ± 14.5a | 3333 ± 0.8b | 1763 ± 0.6c | 5 ± 0.1c | 63 ± 0.6b | 3424 ± 6.9a |

| 100 | *** | 545 ± 9.9b | 1195 ± 86.6c | 310 ± 144.2d | 2 ± 0.8d | 50 ± 0.2c | 1430 ± 65.0b |

Different letters within same column means statistical significant difference (p < 0.05)

PV peak viscosity, BD breakdown, FV final viscosity, SB set back, PT peak time, PT pasting temperature, ApV batter apparent viscosity

***Not possible to measure

Pasting properties of WF and PDCF blends

Pasting properties of the different blends used in this study were obtained using the Rapid Visco Analyzer (RVA) profiles and are summarized in Table 1. The PDCF alone (100% PDCF, Table 1) has a significantly lower viscosity at all times during the test when compared to the sample with flour only (0% PDCF sample, Table 1) since peak, average, and final viscosity are statistically significantly lower. RVA profile of the PDCF alone is basically (data not shown) a flat slow viscosity changing curve. This signals that the components of the PDCF alone do not behave on the RVA as cereals do, probably due to the fact that the chia seed and its corresponding PDCF does not have the same chemical composition than starchy cereals blends (we tested starch absence in PDCF by a negative reaction to the Lugol Test). García-Salcedo et al. (2018) did not find starch by chemical and X-ray analyses.

Initial pasting temperature (PT, Table 1) was lower for all samples with PDCF. The lower indicate some “easiness” of the paste to increase viscosity as it is heated. Since PDCF does not have starch in its composition some other components may be exerting this effect. Perhaps the solubilization of fiber-soluble components may be responsible for this behavior. There was not a statistical significant difference in peak viscosity (PV, Table 1) nor in the breakdown of the paste (BD, Table 1) with the increased proportions of the PDCF in the blend.

Effect of PDCF on technological quality of muffins

The effect of the incorporation of PDCF on colour, physical properties, and moisture content is shown in Table 2 (upper part). Crust and crumb colour were evaluated. Crust colour results show that the L* parameter decreases as the proportion of the PDCF in the muffin increased. This indicates a slightly darkening effect on crust color. Color differences (ΔE*, respect to muffin with 0% PDCF) ranged between 3.4 (5% PDCF) and 5.9 (10% PDCF). The higher the value of ΔE the greater the deviation compared to the original color (0% PDCF). A ΔE greater than 3.0 indicates a significant detectable colour difference for the human eye (Martínez-Cervera et al. 2012). Regarding crumb color (Table 2) the data also indicates that crumbs become darker as the proportions of PDCF increases since L* decreases and the whiteness value (WV) decreases (Table 2). ΔE values were very high (above 10) which as mentioned before means a very detectable difference in colour by human eye. Overall, the effect of adding PDCF to muffins is the darkening of the product (crust and crumb). Similar results have been obtained by other authors (Marchetti et al. 2018; Sharma et al. 2016).

Table 2.

Effect of PDCF addition and of storage on physical characteristics of muffins

| %PDCF | Days | Crust color | Crumb color | Weight (g) | Height (cm) | Volume (ml) | Specific volume (ml/g) | Moisture (%) | Firmness (N) | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L* | ∆E | WV | L* | ∆E | WV | ||||||||

| Effect of PDCF addition | |||||||||||||

| 0.0 | 0 | 58.8a | – | 42.8a | 80.5a | – | 67.2a | 52.4a | 5.35a | 138.57a | 2.65a | 23.14a | 17.11a |

| 2.5 | 0 | 56.8b | 4.07a | 43.0a | 69.9b | 11.1a | 63.1b | 52.3a | 5.28a | 127.15b | 2.44b | 22.68a | 19.49b |

| 5.0 | 0 | 56.9b | 3.36b | 43.8a | 66.2c | 12.1a | 60.5c | 52.7a | 5.19b | 126.89b | 2.41b | 23.62a | 21.61c |

| 10.0 | 0 | 55.4c | 5.88c | 44.5b | 58.7d | 10.9a | 54.59d | 52.9a | 5.14b | 125.94b | 2.38b | 23.99b | 21.57c |

| Effect of storage | |||||||||||||

| 0.0 | 0 | 58.8ª | 0.0a | 42.9a | 80.5a | 0.0a | 67.2a | 52.4a | 5.35a | 138.57 | 2.65a | 23.14a | 17.11a |

| 7 | 58.6a | 1.6b | 42.3a | 77.65b | 1.8b | 67.2a | 52.3a | 5.37a | 127.15 | 2.38b | 19.5b | 31.61b | |

| 14 | 58.4a | 2.5b | 42.9a | 78.68b | 1.2 | 69.0b | 52.1a | 5.37a | 126.89 | 2.14c | 19.46b | 33.51b | |

| 2.5 | 0 | 56.8a | 0.0a | 43.0a | 69.9a | 0.0a | 63.1c | 52.3a | 5.28a | 127.15 | 2.44b | 22.68a | 19.49a |

| 7 | 55.5a | 1.1b | 42.8a | 69.5a | 1.2b | 62.2c | 52.1b | 5.18b | 126.89 | 2.40b | 18.91b | 35.9b | |

| 14 | 56.1a | 0.9b | 43.1a | 71.37a | 2.0c | 67.0a | 52.1b | 5.13b | 125.94 | 2.22c | 18.8b | 40.02c | |

| 5.0 | 0 | 56.9a | 0.0a | 43.9a | 66.20a | 0.0a | 60.5d | 52.7c | 5.19b | 126.89 | 2.41b | 23.62a | 21.61d |

| 7 | 56.3a | 1.2b | 44.8b | 67.44a | 1.7b | 61.4d | 52.7c | 5.07c | 125.94 | 2.39b | 19.55b | 39.43e | |

| 14 | 56.4a | 1.4b | 44.1a | 66.57a | 1.7b | 64.0e | 52.6c | 5.11b | 117.42 | 2.23c | 19.51b | 43.74f | |

| 10.0 | 0 | 55.4a | 0.0a | 44.5a | 58.73a | 0.0a | 54.59f | 52.9d | 5.14b | 125.94 | 2.38b | 23.99a | 21.57d |

| 7 | 54.2a | 1.0b | 44.4a | 61.42a | 3.4b | 58.5 g | 52.9d | 5.03c | 125.08 | 2.37b | 19.06b | 40.12e | |

| 14 | 54.7a | 1.2b | 44.5a | 61.57a | 3.7b | 59.3 h | 52.8d | 4.99d | 119.33 | 2.26c | 18.84c | 46.76 g | |

*Samples with different letter within each column represent statistically significant (p < 0.05) differences (within each block of effect of PDCF addition or effect of storage)

In regard to other physical characteristics, it was found that the addition of PDCF had no effect on muffin weight (Table 2). However, muffin height, volume, weight loss during baking, and firmness were all affected by the incorporation of PDCF (Table 2). The height of a muffin is one of the most desirable characteristics (Sharma et al. 2016). The height of PDCF muffins decreased as the PDCF proportion increased. Kaur and Kaur (2018) explained that this decrease in height is attributed to smaller size of air cells and to the poor ability to retain air bubbles by the muffin batter and the limited stability of the gas cells due to the dilution of gluten.

Texture/firmness of the crumb is one of the most important factors in measuring the quality of bakery products as an important indicator of freshness, aging and quality for the consumer. Consumers prefer muffins with an airy and tender crumb. A loss of the desired texture results in a noticeable decrease in the shelf life of the product. The texture profile analysis (TPA) performed on muffins demonstrated that the incorporation of PDCF significantly (p < 0.05) affected the crumb texture (firmness, Table 2). Crumbs of muffins with added PDCF tend to be firmer (higher values of firmness). No statistical significant differences (p < 0.05) were found on adhesiveness, springiness and gumminess (data not shown). Studies related to the texture of muffins with the incorporation of flaxseeds have demonstrated an increase in the firmness as well (Kaur and Kaur 2018). They believed that the hardening of fiber-enriched muffins could be attributed to the dilution of gluten after fiber incorporation. In addition, Martínez-Cervera et al. (2012) mentioned that fiber would cause an increase in water absorption with a consequent decrease in final volume and the consequent increase in hardness. A decrease in volume and specific volume was also observed in our results (Table 2).

Effect on storage of muffins

The data regarding changes in physical properties of muffins during storage is shown in Table 2 (lower part). The results demonstrated a loss of moisture during storage from 23.14 to 19.50% for control muffins, from 22.68 to 18.91% for 2.5% PDCF, 23.62 to 19.55% for 5% PDCF muffins, and 23.99–19.06% for 10% PDCF muffins. At the same time it was observed a significant decrease of specific volume (inverse of density). Aging in baking products is related to two basic processes that occur in the crumb; one is a process of intrinsic increase in hardness of the alveolar wall material of gas cells, and the other is the macroscopic moisture migration from the central zones of the crumb to the drier regions of the crust (Fennema 1996). The density of baked products refers the porosity, softness and lightness, that’s why the preservation of the muffin’s sponginess during storage is an attribute appreciated by consumers.

The results of color parameters (L*, ΔE* and WV) of crust and crumb of muffins stored for 14 days are reported also in Table 2. The luminosity (L*) of the crust of the muffins did not change significantly during storage (Table 2; lower part) for each of the muffins sample (control, 2.5, 5, and 10% PDCF). The whiteness value (WV) also remained unchanged. These results, taken as a whole, shows that crust color do not change significantly during storage.

Regarding color crumb (Table 2) it was observed that for the control muffin (0% PDCF) the L* decreased during storage indicating a darkening effect of storage. However this darkening effect may not be appreciated by the human eye since the ΔE values were below 3. Samples with PDCF (2.5, 5.0, and 10% of PDCF) did not show changes in L* values during the 14 day period of storage. ΔE values for the 10% PDCF muffins were above 3. Table 2 shows the firmness obtained on muffins with 0, 2.5, 5 and 10% PDCF during storage. The firmness of the crumb increased gradually and significantly in all samples, the longer the storage time is, the hardener the crumb is. Bartolozzo et al. (2015) observed an increase in hardness values of control muffins during storage. Besbes et al. (2014) suggested that the increase in crumb firmness was related to the moisture distribution between the crumb and crust. They also found that firmness in bread increases during aging due to structural changes in amylopectin within the swollen and gelatinized granules. However, it must be pointed out that several additional factors could influence aging of muffins. We could observe that muffins lost moisture during storage and that hardness increased, so this loss (or redistribution) could contribute to hardening crumbs.

Structure of muffins

The area occupied by pores increased (data not shown) statistically and significantly from 22% (0% PDCF) to 31% (2.5% PDCF), to 35% (5% PDCF) and 45% (10% PDCF). Basically, total pore area (empty area occupied by pores) more than doubled with the addition of 10% PDCF. Also, average pore size increased statistically from 0.40 to 0.73 mm2 (10% PDCF) meaning that pores were bigger as PDCF content increased. No statistically significant differences were observed in circularity values (0.76–0.77) in any of the samples while the perimeter value decreased from 3.33 mm (control) to 2.82 for samples containing 10% PDCF (only the control-0% PDCF muffins had statistically and significantly higher values of perimeter). Overall, these results indicate that the effect of adding PDCF, a complex material made of protein, fiber, and lipids, is to increase the pore area and the average pore area. Marchetti et al. (2018) found that the addition of a pecan nut expeller led to an increase of average pore size. Also, Sciammaro et al. (2018) found that the greatest area occupied by pores was for muffins containing higher amounts of a flour of Prosopis alba.

Histograms of pore size distribution are shown in Fig. 2. These histograms clearly show that the presence of PDCF increases the proportion of pores of higher average pore size. This effect is seen as an increase in the “height” of those bars on the right side of the histograms (higher mean pore size) and the reduction of the “height” of those bars on the left side of the histograms (lower mean pore size). This indicates that PDCF produces a more open structure with big empty pores instead of many small pores.

The effect of storage on muffin structure is not quite clear from data shown on Fig. 2. However, and although not statistically significant, some changes can be deduced. It seems that the proportion of pores of small area size seem to decrease as muffins are stored for 14 days while the proportion of pores of higher area size seem to increase as storage progress.

The changes in pore size distribution seen in Fig. 2 relate to the changes in texture observed as firmness (Table 2). Firmness increased as the percentage of PDCF increased in the muffin formulation (upper part of Table 2). Also, inclusion of PDCF in muffins led to products with less height, less volume, and less specific volume (overall, a denser and firmer product). At the same time an increase in mean pore area was observed with the increase in PDCF content. Previous investigations (Sharma et al. 2016; Kaur and Kaur 2018) related to the texture of muffins with the incorporation of fiber form different sources have demonstrated an increase in the firmness as well. According to Kaur and Kaur 2018 the hardening of fiber-enriched muffins could be attributed to the dilution of gluten after fiber incorporation. Fiber could cause an increase in water absorption with a consequent decrease in final volume and the consequent increase in hardness (Martínez-Cervera et al. 2012). Also, it is possible that the increase in firmness could be the result of fiber interacting with water and forming a gel with bonds that strengthen the matrix network resulting in a firmer and gummier crumb.

Effect of PDCF on nutritional quality and sensory properties of muffins

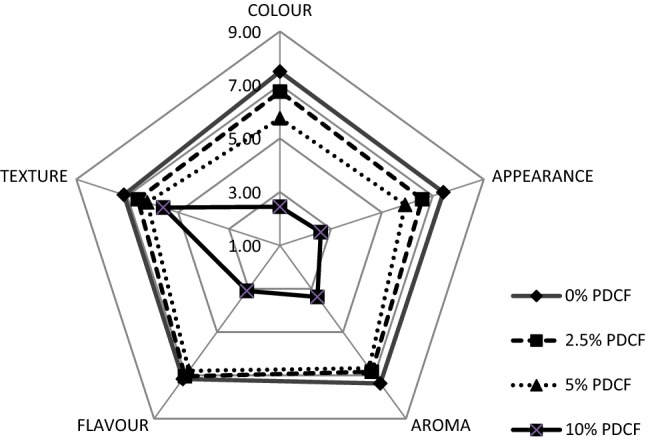

Sensory characteristics of muffins

Figure 3 is a graphical representation of the results obtained when muffins were evaluated by semi-trained panelists. Star plots are a useful way to display multivariate observations with an arbitrary number of variables (Chambers et al. 2018). Sensorial evaluation is certainly a multivariate evaluation in which colour, aroma, appearance, flavour, and texture (mouthfeel) were evaluated on the same sample. In a star graphs, the data length of a spoke is proportional to the magnitude of one of each of the variables evaluated from the sample. Since panelists evaluated 5 variables (colour, aroma, appearance, flavor, and texture) a 5-star (5-spokes) graph is produced. Star graphs are useful because they allow to spot easily clustering or outliers samples. By looking at Fig. 3 it is easy to see that as the content of PDCF increases the evaluation of the sensorial properties tend to receive less punctuation, since as the content of PDCF increased, the “contour” evaluation (formed by joining the point evaluations of all 5 spokes of the star) tend to move towards the center of the star while the sample control “contour” rest on the outer part of the star.

Fig. 3.

Sensory evaluation of muffins with 0, 2.5, 5, and 10% of added PDCF

It is important to notice that, interestingly, up to a 5% of PDCF the evaluation of all samples on all the sensory attribute (variables) tend to cluster meaning there is not much difference in liking as evaluated by panelists. However, the 10% PDCF sample is clearly differentiated from the rest since it de-clusters or strongly separates from the others (in regard to colour, flavor, appearance, and aroma). However, with respect to the texture (evaluated by mouthfeel) all sample clusters around the same point indicating that the content of PDCF did not affect the evaluation of texture by panelists.

Nutritional and antioxidant properties of muffins

Table 3 shows different nutritional properties evaluated on muffins containing different proportions of PDCF. As the content of PDCF increased muffins had significantly higher content of ash, proteins and total dietary fiber (TDF). The results in Table 3 also showed that the addition of PDCF increased the total phenolic content when compared to the control muffin. Antioxidant properties also changed as a result of adding PDCF. At 5% and above both FRAP and ABTS antioxidant numbers were statistically significant. Our results are consistent with those obtained by other researchers (Coelho and Salas-Mellado 2015; Mesías et al. 2016), who also observed an increase in the nutritional properties and the antioxidant properties of breads, biscuits and cupcakes with the addition of chia’s fibers.

Table 3.

Nutritional and antioxidant properties of muffins with 0, 2.5%, 5% and 10% of PDCF

| Percentage of PDCF (flour base) | ||||

|---|---|---|---|---|

| 0% | 2.5% | 5% | 10% | |

| Moisture content (%) | 23.14 ± 2.01a | 22.68 ± 1.64a | 23.62 ± 1.29a | 23.99 ± 1.23a |

| Ash (%) | 1.65 ± 0.01a | 1.65 ± 0.03a | 1.74 ± 0.02b | 1.83 ± 0.01c |

| Fat (%) | 23.79 ± 0.68a | 22.72 ± 0.69a | 22.66 ± 1.24a | 22.52 ± 0.99ª |

| Protein (%) | 8.37 ± 0.47a | 9.36 ± 0.48b | 9.38 ± 0.74b | 9.70 ± 0.33b |

| TDF (%) | 0.748 ± 0.19a | 0.831 ± 0.12a | 0.927 ± 0.05b | 1.098 ± 0.63b |

| FOLIN-PT (mg GA/100 g) | 31.69 ± 4.16a | 38.90 ± 1.95b | 41.28 ± 4.09b | 56.78 ± 2.15c |

| ABTS-AOA (mg TE/100 g) | 931.56 ± 13.1a | 962.85 ± 0.96a | 1227.09 ± 9.96b | 1475.32 ± 3.04b |

| FRAP (mg TE/100 g) | 11.84 ± 2.95a | 21.34 ± 4.78a | 49.49 ± 2.05b | 79.13 ± 3.06b |

TDF total dietary fiber, FOLIN-PT total polyphenols by Folin method, GA gallic acid, AOA antioxidant activity, FRAP ferric reducing antioxidant power, TE trolox equivalent

Samples with different letter within each file represent statistically significant (p < 0.05) differences

Conclusion

The results of this study indicated that a by-product of the chia oil extraction process, the partially-deoiled chia flour, had high protein, high dietary fiber and antioxidant capacity, and could be a good nutritional and functional ingredient to be used in wheat flour baked products. Additionally, utilization of this product in food formulations could add value to the agri-food chain. Although some changes in the quality of the products were observed, a safe usage of 5% of partially-deoiled chia flour could be proposed in muffins without significantly affecting its technological, quality, and sensory properties.

Acknowledgements

This work was supported by Secretaria de Ciencia y Tecnología (Universidad Nacional de Córdoba) (Res. 455-18) and Consejo Nacional de Investigaciones Científicas y Técnicas (CONICET) (P-UE 2016).

Compliance with ethical standards

Conflict of interest

The authors declare that they have no conflict of interests.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- AACC . Approved methods of the American Association of Cereal Chemists. 10. St. Paul: American Association of Cereal Chemists; 2000. [Google Scholar]

- AOAC . Official methods of analysis of the AOAC international. 20. USA: AOAC; 2016. [Google Scholar]

- Aranibar C, Pigni NB, Martinez M, Aguirre A, Ribotta P, Wunderlin D, Borneo R. Utilization of a partially-deoiled chia flour to improve the nutritional and antioxidant properties of wheat pasta. LWT Food Sci Technol. 2018;89:381–387. doi: 10.1016/j.lwt.2017.11.003. [DOI] [Google Scholar]

- Bartolozzo J, Borneo R, Aguirre A. Effect of triticale-based edible coating on muffin quality maintenance during storage. J Food Meas Charact. 2015;10:88–95. doi: 10.1007/s11694-015-9280-1. [DOI] [Google Scholar]

- Benzie IF, Strain JJ. The ferric reducing ability of plasma (FRAP) as a measure of “antioxidant power”: the FRAP assay. Anal Biochem. 1996;239(1):70–76. doi: 10.1006/abio.1996.0292. [DOI] [PubMed] [Google Scholar]

- Besbes E, Jury V, Monteau JY, Le Bail A. Effect of baking conditions and storage with crust on the moisture profile, local textural properties and staling kinetics of pan bread. LWT Food Sci Technol. 2014;58:658–666. doi: 10.1016/j.lwt.2014.02.037. [DOI] [Google Scholar]

- Bourne M. Food texture and viscosity: concept and measurement. 2. London: Academic Press; 2002. [Google Scholar]

- Capitani MI, Spotorno V, Nolasco SM, Tomás MC. Physicochemical and functional characterization of by-products from chia (Salvia hispanica L.) seeds of Argentina. LWT Food Sci Technol. 2012;45(1):94–102. doi: 10.1016/j.lwt.2011.07.012. [DOI] [Google Scholar]

- Chambers J, Cleveland WS, Kleiner B, Tukey P. Graphical methods for data analysis. New York: CRC Press; 2018. [Google Scholar]

- Coelho MS, Salas-Mellado MDLM. Effects of substituting chia (Salvia hispanica L.) flour or seeds for wheat flour on the quality of the bread. LWT Food Sci Technol. 2015;60:729–736. doi: 10.1016/j.lwt.2014.10.033. [DOI] [Google Scholar]

- Di Rienzo JA, Guzmán AW, Casanoves F. A multiple-comparisons method based on the distribution of the root node distance of a binary tree. J Agric Biol Environ Stat. 2002;7:129–142. doi: 10.1198/10857110260141193. [DOI] [Google Scholar]

- Dias TR, Alves MG, Casal S, Oliveira PF, Silva BM. Promising potential of dietary (poly)phenolic compounds in the prevention and treatment of diabetes mellitus. Curr Med Chem. 2017;24(4):334–354. doi: 10.2174/0929867323666160905150419. [DOI] [PubMed] [Google Scholar]

- Fares C, Platani C, Bianao A, Menga V. Effect of processing and cooking on phenolic acid profile and antioxidant capacity of durum wheat pasta enriched with debranning fractions of wheat. Food Chem. 2010;119:1023–1029. doi: 10.1016/j.foodchem.2009.08.006. [DOI] [Google Scholar]

- Fennema O. Food chemistry. 3. New York: CRC Press; 1996. [Google Scholar]

- García-Salcedo ÁJ, Torres-Vargas OL, del Real A, Contreras-Jiménez B, Rodriguez-Garcia ME. Pasting, viscoelastic, and physicochemical properties of chia (Salvia hispanica L.) flour and mucilage. Food Struct. 2018;16:59–66. doi: 10.1016/j.foostr.2018.03.004. [DOI] [Google Scholar]

- Goswami D, Gupta RK, Mridula D, Sharma M, Tyagi SK. Barnyard millet based muffins: physical, textural and sensory properties. LWT Food Sci Technol. 2015;64:374–380. doi: 10.1016/j.lwt.2015.05.060. [DOI] [Google Scholar]

- Hsu C, Chen W, Weng Y, Tseng C. Chemical composition, physical properties, and antioxidant activities of yam flours as affected by different drying methods. Food Chem. 2003;83(85):92. [Google Scholar]

- Kaur R, Kaur M. Microstructural, physicochemical, antioxidant, textural and quality characteristics of wheat mu ffi ns as in fl uenced by partial replacement with ground fl axseed. LWT Food Sci Technol. 2018;91:278–285. doi: 10.1016/j.lwt.2018.01.059. [DOI] [Google Scholar]

- Marchetti L, Califano AN, Andrés SC. Partial replacement of wheat flour by pecan nut expeller meal on bakery products. Effect on muffins quality. LWT Food Sci Technol. 2018;95:85–91. doi: 10.1016/j.lwt.2018.04.050. [DOI] [Google Scholar]

- Marineli RDS, Morales ÉA, Lenquiste SA, Godoy AT, Eberlin MN, Maróstica MR. Chemical characterization and antioxidant potential of Chilean chia seeds and oil (Salvia hispanica L.) LWT Food Sci Technol. 2014;59:1–7. doi: 10.1016/j.lwt.2014.04.014. [DOI] [Google Scholar]

- Martínez-Cervera S, Sanz T, Salvador A, Fiszman SM. Rheological, textural and sensorial properties of low-sucrose muffins reformulated with sucralose/polydextrose. LWT Food Sci Technol. 2012;45:213–220. doi: 10.1016/j.lwt.2011.08.001. [DOI] [Google Scholar]

- Menga V, Amato M, Phillips TD, Angelino D, Morreale F, Fares C. Gluten-free pasta incorporating chia (Salvia hispanica L.) as thickening agent: an approach to naturally improve the nutritional profile and the in vitro carbohydrate digestibility. Food Chem. 2017;221:1954–1961. doi: 10.1016/j.foodchem.2016.11.151. [DOI] [PubMed] [Google Scholar]

- Mesías M, Holgado F, Márquez-Ruiz G, Morales FJ. Risk/benefit considerations of a new formulation of wheat-based biscuit supplemented with different amounts of chia flour. LWT Food Sci Technol. 2016;73:528–535. doi: 10.1016/j.lwt.2016.06.056. [DOI] [Google Scholar]

- Oliveira-Alves SC, Vendramini-Costa DB, Betim Cazarin CB, Maróstica Júnior MR, Borges Ferreira JP, Silva AB, Bronze MR. Characterization of phenolic compounds in chia (Salvia hispanica L.) seeds, fiber flour and oil. Food Chem. 2017;232:295–305. doi: 10.1016/j.foodchem.2017.04.002. [DOI] [PubMed] [Google Scholar]

- Olivos-Lugo BL, Valdivia-López MÁ, Tecante A. Thermal and physicochemical properties and nutritional value of the protein fraction of mexican chia seed (Salvia hispanica L.) Food Sci Technol Int. 2010;16:89–96. doi: 10.1177/1082013209353087. [DOI] [PubMed] [Google Scholar]

- Orthofer R, Lamuelas-Raventos RM. Analysis of total phenols and other oxidation substrates and antioxidants by means of Folin–Ciocalteau reagents. Methods Enzymol. 1999;29:152–178. [Google Scholar]

- Rueden CT, Schindelin J, Hiner MC, et al. Image J2: ImageJ for the next generation of scientific image data. BMC Bioinform. 2017;18:529. doi: 10.1186/s12859-017-1934-z. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Sandoval-Oliveros MR, Paredes-López O. Isolation and characterization of proteins from chia seeds (Salvia hispanica L.) J Agric Food Chem. 2013;61(1):193–201. doi: 10.1021/jf3034978. [DOI] [PubMed] [Google Scholar]

- Sciammaro LP, Ferrero C, Puppo MC. Gluten-free baked muffins developed with Prosopis alba flour. LWT Food Sci Technol. 2018;98:568–576. doi: 10.1016/j.lwt.2018.09.045. [DOI] [Google Scholar]

- Shaabani S, Saeid M, Kiami M, Zahra ED. The efect of chickpea protein isolate in combination with transglutaminase and xanthan on the physcal and rheological characteristics of gluten free muffin and batter based on millet flour. LWT Food Sci Technol. 2018 [Google Scholar]

- Sharma S, Singh N, Katyal M. Effect of gelatinized-retrograded and extruded starches on characteristics of cookies, muffins and noodles. J Food Sci Technol. 2016;53:2482–2491. doi: 10.1007/s13197-016-2234-8. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Struck S, Gundel L, Zahn S, Rohm H. Fiber enriched reduced sugar muffins made from iso-viscous batters. LWT Food Sci Technol. 2016;65:32–38. doi: 10.1016/j.lwt.2015.07.053. [DOI] [Google Scholar]