Abstract

Fondant is a saturated sugar solution which is a paste- or cream-like heterogeneous system consisting of a solid phase (saccharose crystals), a liquid phase (saturated saccharose solution and glucose/invert sugar) and a gaseous phase. Fondant is used as a filling material and as a coating material for pastry, confectionery and chocolate products. Therefore, mechanical properties are important for both machinability and sensory properties of the fondant. In the present study, the invertase enzyme was added at different concentrations (0.1–0.5%) to investigate its effect on the textural and rheological properties of the fondant during the storage period as well as on the sugar composition. After the first week of storage, the hardness of the control sample decreased from the initial value of 221.1–69.24 g and 48.22 g for the addition of 0.1 and 0.5% enzyme. G′ and G″ values of the fondant decreased by treatment with invertase enzyme. The positive effect of the invertase addition to fondant was also perceived in sensory evaluation. Therefore, using invertase enzyme enabled the product having desired quality characteristics. The results of the present study highlighted that invertase enzyme can be used to soften the product improving the sensory characteristics and machinability and reducing or eliminating the crystallization of sucrose which negatively affects the quality parameters. Depending on the intended purpose of the fondant, the invertase concentration can be optimized.

Keywords: Confectionery, Fondant, Rheology, Texture, Enzyme

Introduction

Confectionery products are sugar-based products widely consumed by people of all ages especially children throughout the world. Candy products are generally classified as crystalline candies (rock candy, fondant and fudge) and amorphous or noncrystalline candies (caramel, taffies, brittles, marshmallows and gumdrops) (Vaclavik and Christian 2014). The crystalline candies can be subdivided into 2 types: (i) with sugar crystals perceived by tongue and (ii) with sugar crystals not perceived by tongue.

Fondant is a product where sugar is in crystalline form with a size of crystal that can not be sensed by tongue. Regarding physicochemical approach, fondant is a heterogenous system composed of a solid phase (sucrose crystals with different shapes), a liquid phase (saturated sucrose solution including glucose syrup or invert sugar) and a gaseous phase (air bubbles incorporated into the product during manufacturing process) (Bratu et al. 2007). Fondant consists of approximately 60% sucrose and 20% glucose syrup. As in most of the candy products, glucose syrup and sucrose are together due to several factors: (i) glucose syrup prevents or retards the crystallization of sucrose which is important for maintaining textural properties, (ii) glucose syrup enables the machinability of candy paste, (iii) prevention of the microbial growth since a production with a solid content lower than 75% is a suitable media for yeast and mold growth and this concentration can not be achieved by using only sucrose; therefore, glucose syrup having greater solubility than sucrose is used in the candy formulation (Jackson and Howling 1999). Sucrose/glucose syrup concentration used in the fondant formulation and production process are critical factors of the quality parameters of the products. The production process of the fondant includes cooking, cooling, crystallization and packaging. Produced fondant can be re-used after melting. In this circumstances, preservatives and flavor compounds can be added into formulation. By this ways, fondant can be used for many different confectionery products such as fondant with caramel or various flavors. In addition, fondant can be also used as a filling or coating material for pastry products, cakes and chocolates (Varzakas et al. 2012). In the literature, there are very limited studies about fondant (Nummer et al. 2012) or confectionery products. The study carried out by Schmidt et al. (Schmidt et al. 2018) is one of them and investigated the thermo-mechanical properties of soft candies. Therefore, such studies about confectionery products are important for the candy industry to improve the quality of the product or efficiency of processes.

Hard structure of fondant can restrict its machinability (Hartel et al. 2017) and eating quality. In order to soften the fondant, invertase is added to the formulation. Invertase is obtained from yeasts especially Saccharomyces cerevisiae (Kulshrestha et al. 2013). Invertase activity results in formation of invert sugar consisting of monosaccharides d-glucose and d-fructose, by hydrolysis of α-1,4-glycosidic bonds of sucrose (Mobini-Dehkordi et al. 2008). Invert syrup has many applications in the food industry due to its sweetener characteristics than sucrose (approximately 1.5 times higher), higher solubility and hygroscopic nature (Aranda et al. 2006; Santana de Almeida et al. 2005). Therefore, it is used in the formulation of chocolate-coated soft-centered sweeteners, candy products, fondants and after-dinner mints as humectants (Oyedeji et al. 2017). The activity of invertase depends on invertase concentration, water amount, pH and temperature (Hartel et al. 2017). The aim of the manuscript was to investigate the effect of using invertase enzyme in fondant formulation at different concentrations (0.1, 0.2, 0.3 and 0.5%) on the change in textural and rheological properties of fondants with respect to end of the storage period (1st, 2nd and 4th week).

Materials and methods

Materials

Sucrose, glucose syrup and invertase were used in the manufacturing of fondant. Standart glucose, fructose and sucrose used in sugar analyses were purchased from Sigma Aldrich (Milwaukee, USA).

Production of fondant

For the production process of fondant, 60% sugar, 21.25% glucose and 18.75% water were mixed, cooked to 170 °C and cooled to 65 °C which is the optimum temperature of invertase. After adding invertase, fondant samples were poured into a rectangular plate including 2 × 1 × 1 gaps and cooled to room temperature and used for analyses.

Sugar analyses

A quantity of 0.25 g of each standard sugar (fructose, glucose, sucrose) was weighed into a 10 mL volumetric flask. Volumes of 4 mL of deionized water and 2.5 mL of methanol were added and the mixture was allowed to stand in an ultrasonic bath for 5 min. Then the final volume of 10 mL was reached with deionized water. Appropriate calibration standards were prepared using water: methanol (75:25, v/v) solution.

The extraction method described AOAC (2010) with some modifications was used. A volume of 1 mL of the sample was taken into a 10 mL volumetric flask and 5 mL of deionized water was added and the mixture was left in the ultrasonic bath for 10 min and then deionized water was added to a 10 mL volume. The solution was injected into HPLC using filtration through 0.45 μm filter.

Levels of fructose, glucose and sucrose in samples were determined by high-performance liquid chromatography (HPLC) by refractive index detection method. HPLC conditions described by DIN 10758 (1997) with some modifications were used. HPLC system was a Shimadzu LC 20AT pump with a Shimadzu: Refractive Index (RI) detector (Shimadzu Corporation, Kyoto, Japan). HPLC conditions were given as follows; Column: Merck LiChroCART NH2, 5 μm, 4.6 × 250 mm, mobile phase Asetonitrile:Water, 80:20; v/v, Column Temperature: 25 °C, injection volume: 10 µl, flow rate: 2 mL/min and analysis time: 20 min.

Rheology analyses

Dynamic oscillatory measurements were carried out by using the stress and temperature controlled rotational rheometer (Antonpaar MCR 302, Austria) equipped with a parallel plate of diameter 25 mm (PP25). Storage modulus (G′), loss modulus (G″), and complex modulus (G*) were determined as viscoelastic properties of fondant samples. The parameter tanδ, the ratio between the loss and storage modulus of a rheological system (G″/G′), was also determined (Pajin et al. 2013). Linear viscoelastic region was detected as 0.01% by amplitude sweep test. The measurement conditions were defined for angular frequency within the interval of 0.1–10 rad/s under the constant shear stress of 1 Pa at 25 °C. Calculation of the model parameters which are intercepts (K′, K′′ and K*), and slopes (n′, n′′ and n*) were performed according to Yoo and Rao (1996) and the following equations were used:

| 1 |

| 2 |

| 3 |

Textural analyses

Hardness and stickness parameters were measured by using TA.XT2 Plus Texture Analyzer (SMS, UK) equipped with 5 kg load cell. Each fondant samples were cut into 2 × 1 × 1 cm as a rectangular solid and compressed under a cylindrical probe (P/5) with 25% strain level at 2 mm/s test speed.

Sensory analyses

Ten panelists (7 women, 3 men), ranging in age from 27 to 42 years who were informed about the samples carried out the sensory analysis of the fondant samples. Every week same panelists evaluated the samples. The two pieces of each samples were served and labeled with three-digit codes. The panelists used spring water to clean their palates before testing next sample. The sensory attributes of fondant samples including appearance, odour, taste, texture and overall acceptability were evaluated using a 9-point hedonic scale from 1 (dislike extremely) to 9 (like extremely).

Statistical analyses

The results were analysed by using one-way ANOVA with the JMP ver.6 software (SAS Institute, Inc. 2005) and Student t test was used to compare the means at a significance level of 0.05.

Results and discussion

Effect of invertase enzyme on sugar composition of fondant

Sugar composition (sucrose, fructose and glucose) of the fondants prepared with/without invertase enzyme is presented in Table 1. Sucrose and glucose were present in control sample produced without enzyme addition and their concentration was found to be 57.36 and 3.54%, respectively. Sucrose was added to fondant formulation as 60% and the findings indicated that there were approximately 2.64% loss in sucrose concentration, which might have resulted from production process where some sucrose can degrade due to applied heat. In addition, hard structure of fondant can interfere with extraction of sucrose from fondant since penetration of water into the interior for dissolving of sucrose is difficult. Low amounts of glucose and fructose found can be due to the glucose syrup, including maltose and dextrose, used in the formulation. Regarding the analyzes performed 1 week after the addition of enzyme, it can be concluded that enzyme activity is sufficient for hydrolyzing almost all of the sucrose All the fondant samples manufactured with invertase enzyme at different concentration had sucrose content lower than detection limit. An increase in the amount of glucose and fructose was observed parallel to the decrease in sucrose, implying that as expected sucrose was converted to glucose and fructose by the invertase activity. As can be seen from the results, added enzyme amounts stretched for completely degradation of sucrose. Fructose and glucose concentration of the fondant changed between 32.00–35.40% and 35.55–37.75%, respectively. Generally, enzyme concentration and storage period did not significantly affect fructose and glucose amount present in the fondant (p > 0.05). According to the usage aim and desired quality characteristics of the fondant, lower enzyme can be added to the formulation depending on the storage time in order to converting ratio of the sucrose to glucose and fructose.

Table 1.

Influence of invertase enzyme on sugar composition of fondant

| Enzyme con. (%) | Storage time (week) | Sucrose (%) | Fructose (%) | Glucose (%) |

|---|---|---|---|---|

| 0.0 | 0 | 57.36 ± 1.08 | – | 3.54 ± 0.23 |

| 0.1 | 1 | – | 32.00 ± 1.13 | 35.55 ± 0.49 |

| 2 | – | 32.97 ± 0.33 | 36.35 ± 0.35 | |

| 4 | – | 34.10 ± 0.42 | 37.00 ± 0.14 | |

| 0.2 | 1 | – | 32.75 ± 0.21 | 35.40 ± 0.42 |

| 2 | – | 32.35 ± 1.48 | 36.55 ± 1.63 | |

| 4 | – | 34.35 ± 1.06 | 37.35 ± 0.64 | |

| 0.3 | 1 | – | 33.15 ± 0.92 | 36.50 ± 0.57 |

| 2 | – | 33.10 ± 0.71 | 36.55 ± 0.49 | |

| 4 | – | 34.75 ± 0.78 | 36.90 ± 0.14 | |

| 0.5 | 1 | – | 34.15 ± 0.07 | 36.60 ± 0.57 |

| 2 | – | 34.35 ± 0.21 | 37.15 ± 0.35 | |

| 4 | – | 35.40 ± 0.57 | 37.75 ± 0.21 |

Effect of invertase enzyme on rheological properties of fondant

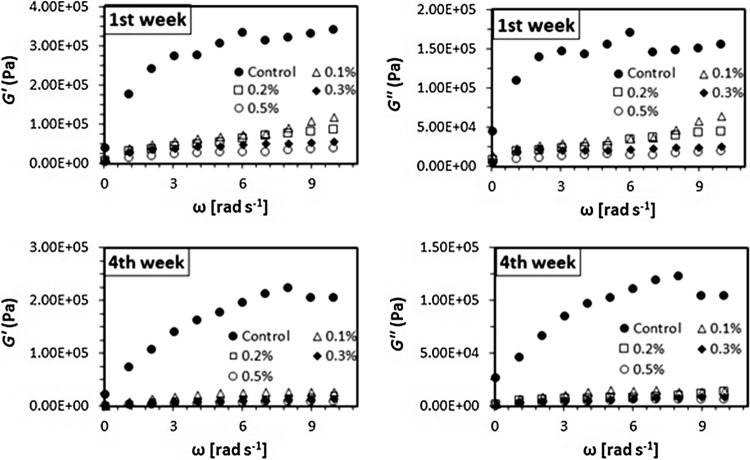

Viscoelastic properties of fondant samples, change in storage modulus (G′) and loss modulus (G″) as a function of angular frequency values were determined. Figure 1 shows the general behavior of G′ and G″ with respect to angular frequency for all the fondant samples at 1st week of storage. At low frequency values, G″ was higher than G′, indicating crystallization or drying or dehumidification phenomena taking place during storage period, all of them affect textural and rheological properties of the fondant samples. Frequency-based parameters give information about storage stability of the samples in terms of textural or rheological parameters. Variation of G′ and G″ depending on frequency indicated that structural characteristics of the fondant changed, which can be also understood from textural characteristics of the samples with respect to storage period. Change of G′ and G″ as a function of angular frequency was modelled with power-law model and the corresponding parameters are tabulated in Table 2. R2 values of all the established model were found to be higher than 0.80, indicating that the relation between dependent and independent parameters can be expressed by using these models. Generally, except for the samples produced with addition of 0.3 and 0.5% invertase at 2nd and 4th weeks, K’ values were higher than K’’, showing solid-like nature of the fondant. K’, K’’ and K* values decreased due to treatment of the fondant with invertase enzyme, which is in accordance with the hardness parameter.

Fig. 1.

Change in G′ and G″ of the fondant samples with as a function of angular frequency

Table 2.

Textural properties of fondant samples

| Enzyme con. (%) | Storage time (week) | Hardness (g) | Stickness (g) |

|---|---|---|---|

| Control | 1 | 203.2 ± 22.8Ab | 53.2 ± 4.6Ab |

| 2 | 214.9 ± 11.6Ab | 56.9 ± 3.5Ab | |

| 4 | 380.9 ± 19.8Aa | 76.1 ± 2.3Aa | |

| 0.1% | 1 | 86.9 ± 15.3Ba | 25.1 ± 2.4BCa |

| 2 | 85.6 ± 4.7Ba | 24.5 ± 2.3Ca | |

| 4 | 93.8 ± 4.9Ba | 25.3 ± 0.7BCa | |

| 0.2% | 1 | 62.8 ± 1.0Cb | 27.6 ± 5.1Ba |

| 2 | 66.9 ± 3.7Cb | 30.5 ± 3.4Ba | |

| 4 | 87.9 ± 6.3Ba | 31.7 ± 1.8Ba | |

| 0.3% | 1 | 46.5 ± 5.2Ca | 17.6 ± 2.9 Da |

| 2 | 50.4 ± 1.4Db | 16.8 ± 0.6 Da | |

| 4 | 68.1 ± 10.8BCb | 22.5 ± 4.2Ca | |

| 0.5% | 1 | 42.1 ± 2.3Ca | 19.6 ± 1.3CDb |

| 2 | 52.8 ± 8.3Db | 20.4 ± 2.1CDab | |

| 4 | 74.4 ± 3.1Cc | 26.6 ± 4.8BCa |

A, B, C, DDifferent superscript uppercase letters show significant differences between concentration at the same storage time

a, b, cDifferent superscript lowercase letters show significant differences between storage periods for the samples including equal amount of invertase

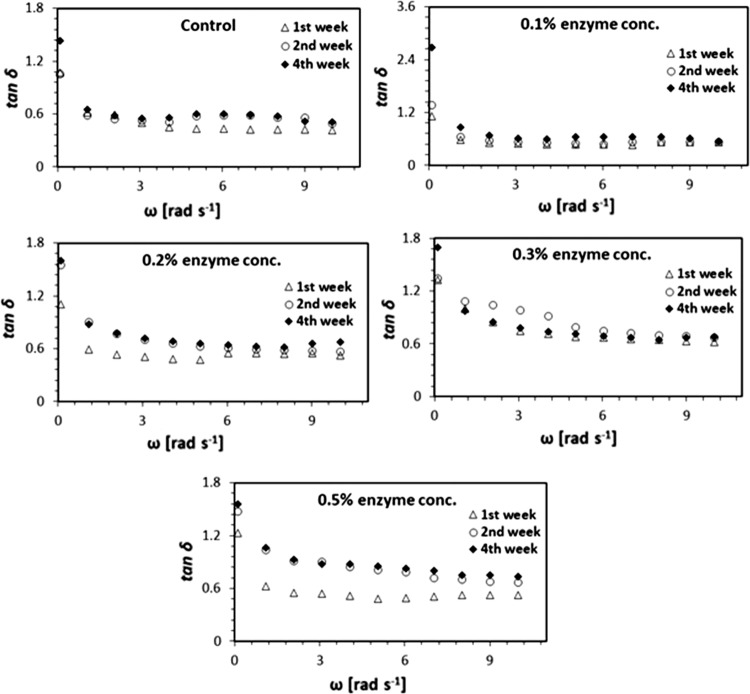

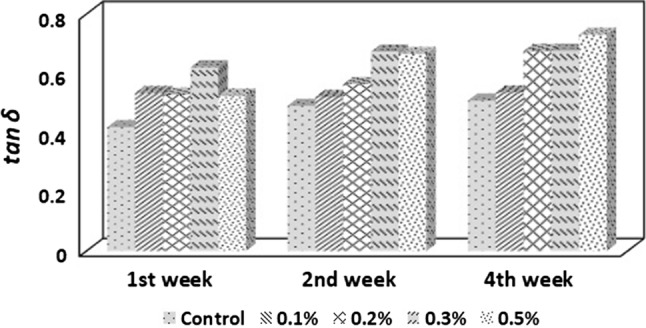

Addition of invertase resulted in decreasing G′ and G″, also implying softening of the fondant as a result of enzyme activity. G′ is correlated with the firmness/consistency of the jellies structure determined by textural analyses (Garrido et al. 2015). As mentioned above, the aim of the present study is to soften the fondant products by using invertase. Therefore, among rheological parameters, G′, G″, complex modulus (G*) and complex viscosity (η*), tan δ (equal to G″/G′) parameter was taken into consideration since this value can give information about behavior of material, solid-like or liquid-like (Gunasekaran and Ak 2000). In other words, regarding this study, it can represent fluidity characteristics of the fondant. Alteration of tan δ based on angular frequency is shown in Fig. 2 for all the samples at different storage periods. As it can be seen from the results, except for the 0.1 rad/s, since they have tan δ lower than unit, all the sample indicated solid-like behavior. Generally, invertase enzyme usage caused to increase in tan δ magnitude, indicating also that fluidity of the fondant increased. In order to clearly observe the softening effect of invertase, tan δ values of the fondant samples at 10 rad/s was compared in Fig. 3. As it can be seen, it increased with enzyme treatment, indicating the softening effect of the invertase.

Fig. 2.

Change in tan δ values of the fondant samples with as a function of angular frequency

Fig. 3.

Effect of invertase enzyme on the tan δ values of the fondant samples at 10 rad/s

Effect of invertase enzyme on textural properties of fondant

The influence of invertase enzyme on the textural properties of the fondant is shown in Table 3. Among textural parameters, hardness and stickness (adhesiveness) were evaluated for fondant samples. Hardness is a required force to perform the targeted activity such as penetrating into required gap, breaking the sample etc. Regarding sensory aspects, it represents the force necessary to compress the sample between molars during first bite (Garrido et al. 2015). Hardness value is also important for machinability of the sample as well as sensory characteristics of the sample. Therefore, fondant structure can be modified by the invertase to achieve the product with desired quality. Hardness value of the control fondant was found to be 203.19 g at 1st week of the storage. Hardness value of the control sample increased from 203.19 to 380.91 g after 4 week storage, which might have resulted from moisture loss and recrystallization of small crystals, meaning that the crystals grow over time and become larger (Hartel et al. 2017) giving rise to increasing hardness value of the fondant. In the candy production, condensation process of the solutes from saturated solution occurs (Zhang et al. 2015) which can be desirable or undesirable depending on the product type. Crystallization process takes place slowly and controlling of it is very difficult (Patel and Murthy 2011; Raghavan et al. 2001). Therefore, the ingredients such as glycose syrup is used with sucrose to control crystallization of sucrose as well as providing required solid content for microbial safety. If the crystallization is not eliminated, in a short time candy is converted to form which can not be consumed due to a very hard structure, interfering with chewiness of the candy.

Table 3.

Power-law model parameters for angular frequency (ω) versus storage modulus (G′), loss modulus (G″) and complex modulus (G*) parameters

| Enzyme con. (%) | Time (week) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| K′ (Pa) | n′ | R 2 | K″ (Pa) | n″ | R 2 | K* (Pa) | n * | R 2 | ||

| Control | 1 | 107010Aa | 0.52Aa | 0.9690 | 78155Aa | 0.35Aa | 0.8755 | 136456Aa | 0.46Aa | 0.9557 |

| 2 | 48017Ac | 0.55Ca | 0.9739 | 33463Ac | 0.38Ba | 0.9151 | 60104Ac | 0.50Ba | 0.9638 | |

| 4 | 70778Ab | 0.53Ca | 0.9483 | 53388Ab | 0.35 Da | 0.8066 | 91538Ab | 0.46Ca | 0.9180 | |

| 0.1% | 1 | 34490Ba | 0.47Bb | 0.9799 | 23052Ba | 0.31Ab | 0.8462 | 42661Ba | 0.41Ab | 0.9616 |

| 2 | 10988Bb | 0.70ABa | 0.9618 | 9625Bb | 0.45Ba | 0.9482 | 16200Bb | 0.56Ba | 0.9428 | |

| 4 | 7615Bb | 0.63Bab | 0.9747 | 6430Bb | 0.41Ca | 0.9240 | 10384Bb | 0.54Ba | 0.9707 | |

| 0.2% | 1 | 24258Ca | 0.53Ab | 0.9718 | 17090Ca | 0.36Aa | 0.8998 | 30578Ca | 0.47Ab | 0.9628 |

| 2 | 8556BCbb | 0.64BCa | 0.9622 | 7775BCb | 0.39Ba | 0.9142 | 12101BCb | 0.53Bab | 0.9602 | |

| 4 | 4227Cb | 0.67Ba | 0.9932 | 3938Cc | 0.46Ca | 0.9799 | 5994Cb | 0.57Ba | 0.9934 | |

| 0.3% | 1 | 21326CDa | 0.46Bb | 0.9512 | 13714CDa | 0.29Ab | 0.8808 | 25800CDa | 0.41Ab | 0.9462 |

| 2 | 3712CDb | 0.79Aa | 0.9832 | 3959CDb | 0.58Aa | 0.9464 | 5612CDb | 0.68Aa | 0.9757 | |

| 4 | 2596Cb | 0.73Aa | 0.9946 | 2680Db | 0.52Ba | 0.9914 | 3852Db | 0.62Aa | 0.9960 | |

| 0.5% | 1 | 11602 Da | 0.53Ab | 0.9799 | 8212 Da | 0.34Ab | 0.9628 | 14639 Da | 0.46Ab | 0.9800 |

| 2 | 2493Db | 0.77ABa | 0.9953 | 2607Db | 0.60Aa | 0.9842 | 3678Db | 0.68Aa | 0.9927 | |

| 4 | 1639Cb | 0.76Aa | 0.9909 | 1855Db | 0.58Aa | 0.9825 | 2535Eb | 0.66Aa | 0.9905 | |

A, B, C, D, EDifferent superscript uppercase letters show significant differences between concentration at the same storage time

a, b, cDifferent superscript lowercase letters show significant differences between storage periods for the samples including equal amount of invertase

Regarding the fondants manufactured with invertase, it is seen that enzyme addition significantly reduced the hardness value (p < 0.05). The hardness of the control sample decreased from the initial value of 203.19 g to 86.93 g, 62.83 g, 46.54 g and 42.05 g for the addition of 0.1, 0.2, 0.3 and 0.5% enzyme, respectively. As it can be seen, the level of softness increased with enzyme concentration, which can be resulted from enzyme addition to formulation as a solution. Therefore, increasing the moisture content by water access can result in reduction of hardness value. The results indicated that use of enzyme significantly softened the product by reducing the hardness value to almost one-third or more (p < 0.05). Glucose and fructose are formed as a result of breaking down of sucrose by consuming one mole of water for each sucrose mole (Silver and Karel 1981). The softening effect of the invertase is resulted from the reduction of the sucrose crystallinity (Ergun et al. 2010). After 1 week of storage, the hardness value of the fondant product increased as in the control sample. As mentioned for control sample, there might be two factors for increasing the hardness value: (i) Crystallisation of sugars and (ii) drying of samples. Sucrose was not found in the enzyme-including sample due to the enzyme activation. Therefore, crystallization of different sugars present in the glycose syrup can occur. The findings about textural results indicated that softening of fondant is possible by using the invertase enzyme, which can be applied for the eating quality of fondant. Depending on the usage target of the fondant, the amount of invertase can be optimized. For the product where fondant is utilized as a filling material such as chocolate coated fondant, a hard structure provide an advantage during the coating process to protect the fondant shape against mechanical forces applied during process. After coating, softening can be required to enable the chewiness of the product, which improve sensory characteristics; therefore, consumer acceptability. In addition, the crystallization of sucrose up to undesirable level can be eliminated by using invertase.

The other textural parameter calculated from the time versus force curve is the stickness which is the force required to pull the probe away from the sample (Bourne 2002). Considering sensory characteristics, it represents the attraction forces between food surface and surface of the tongue, teeth and palate (Garrido et al. 2015). Therefore, this parameter is also crucial for both sensory properties and production process of the fondant where a tailing problem can be observed during depositing step. The stickiness of the control sample decreased from the initial value of 53.2 g to 25.1 g, 27.6 g, 17.6 g and 19.6 g after 1 week for the addition of 0.1, 0.2, 0.3 and 0.5% enzyme, respectively. Generally, storage time did not significantly effect on stickiness value (p > 0.05). A significant decrease was observed in the stickness value when the fondant sample was treated with invertase enzyme and it increased with the storage period of the fondant. Depending on the optimum sensory characteristics of the fondant, the added amount of enzyme should be optimized considering the textural characteristics of the sample.

Effect of invertase enzyme on sensory properties of fondant

The results of sensory analysis of the fondant samples are presented in Table 4. Panelists evaluated the fondant samples according to appearance, odour, taste, texture and overall acceptability. As shown in Table 4, in contrast to the texture and overall acceptability scores, the invertase addition did not significantly affect the appearance and odour scores of the samples (p < 0.05). There were not any significant differences in taste scores of the samples at 1st and 2nd week, however decreasing at 4th week compared to the previous weeks scores. The control samples had the lowest texture and overall acceptability scores at every week. Whereas samples produced with the addition of 0.2% invertase received the higher texture score compared to others at 1st and 2nd week, samples with 0.3% and 0.5% invertase were evaluated as better than 0.2% at 4th week. When considering the texture properties of the fondant samples, it can be seen that the hardness value of the samples produced with the addition of 0.3% and 0.5% invertase at 4th week were similar to samples with 0.2% invertase at 2nd week. The differences were not observed in overall acceptability scores of the samples produced with 0.3% and 0.5% invertase depending on the storage time. Comparing the control samples to samples produced with invertase enzyme, it can be concluded that the invertase treatment to fondant had a positive effect on the sensory properties.

Table 4.

Sensory properties of fondant samples

| Enzyme con. (%) | Storage time (week) | Appearance | Odour | Taste | Texture | Overall acceptability |

|---|---|---|---|---|---|---|

| Control | 1 | 6.9 ± 0.74Aa | 6.4 ± 0.70ABa | 6.6 ± 0.52Aa | 4.5 ± 0.74 Da | 4.7 ± 0.67Ca |

| 2 | 6.4 ± 0.70Aa | 6.8 ± 0.63Aa | 6.3 ± 0.82Aa | 4.6 ± 0.52 Da | 4.3 ± 0.82Ca | |

| 4 | 6.5 ± 0.53Aa | 5.5 ± 1.08Ab | 4.6 ± 1.43Bb | 3.9 ± 1.2Ca | 3.2 ± 0.79Cb | |

| 0.1% | 1 | 6.9 ± 0.73Aa | 6.1 ± 0.74ABa | 6.9 ± 0.57Aa | 6.6 ± 0.52Ba | 6.4 ± 0.70Ba |

| 2 | 6.7 ± 0.67Aa | 6.1 ± 1.20Aa | 6.4 ± 0.84Aa | 5.4 ± 0.52Cb | 5.5 ± 0.97Bb | |

| 4 | 6.6 ± 0.69Aa | 5.6 ± 1.26Aa | 4.8 ± 1.03ABb | 5.2 ± 0.79Bb | 5.1 ± 1.20Bb | |

| 0.2% | 1 | 6.8 ± 0.63Aa | 6.1 ± 0.74ABa | 6.6 ± 0.84Aa | 7.2 ± 0.63Aa | 7.1 ± 0.88Aa |

| 2 | 6.6 ± 0.52Aa | 6.3 ± 0.82Aa | 6.2 ± 0.92Aab | 6.9 ± 0.74Aa | 7.4 ± 0.52Aa | |

| 4 | 6.7 ± 0.67Aa | 6.1 ± 0.74Aa | 5.4 ± 1.07ABb | 5.4 ± 0.97Bb | 5.3 ± 1.06Bb | |

| 0.3% | 1 | 7.1 ± 0.57Aa | 5.9 ± 0.74Ba | 6.8 ± 0.63Aa | 5.80 ± 0.63Ca | 6.7 ± 0.67ABa |

| 2 | 6.7 ± 0.70Aa | 6.6 ± 0.70Aa | 6.4 ± 0.84Aab | 5.9 ± 0.57BCa | 6.1 ± 0.57Ba | |

| 4 | 6.7 ± 0.67Aa | 6.0 ± 1.15Aa | 5.7 ± 1.34Ab | 6.3 ± 1.16Aa | 6.6 ± 0.97Aa | |

| 0.5% | 1 | 6.8 ± 0.63Aa | 6.7 ± 0.95Aa | 6.7 ± 0.48Aa | 6.3 ± 0.67BCab | 6.6 ± 0.70ABa |

| 2 | 6.6 ± 0.70Aa | 6.6 ± 0.84Aa | 6.4 ± 0.84Aab | 6.1 ± 0.57Bb | 6.0 ± 0.67Ba | |

| 4 | 6.6 ± 0.70Aa | 6.4 ± 0.97Aa | 5.8 ± 0.92Ab | 6.8 ± 0.79Aa | 6.7 ± 0.95Aa |

A, B, C, DDifferent superscript uppercase letters show significant differences between concentration at the same storage time

a, b, cDifferent superscript lowercase letters show significant differences between storage periods for the samples including equal amount of invertase

Conclusion

Fondant is a crystallized confectionery type which is directly consumed or used as a filling or coating material. Fondant is comprised of sucrose and glucose/invert syrup. Designing of mechanical properties of the fondant depending on the usage aim is required to achieve the end product with desired quality characteristics. It is desired to be maintained shape of the fondant against forces applied during process for coating fondant with chocolate, as well as chewiness quality of the product. Therefore, the investigation of the effect of invertase use on the quality characteristics of the fondant was studied in the present study. The results showed that invertase treatment dramatically effects on the quality characteristics of fondant even in the low concentration such as 0.1%. The hardness and storage (G′) and loss (G″) modulus of the fondant sample decreased with enzyme addition resulting in the production of the fondant with softer structure. Generally, K′ values were higher than K″, showing solid-like nature of the fondant. The invertase treatment to the fondant resulted the decreasing of K′, K″ and K* values, which is in accordance with the hardness parameter. The invertase enzyme usage caused to increase in tan δ magnitude, indicating also that fluidity of the fondant increased. The sensory analyses results also showed the positive effect of the addition of invertase on fondant samples. The sucrose crystallization of such confectioneries can be a problem for the quality of the product because it adversely affects the chewiness of the fondant since the crystallization produced the sample hardening, which can be eliminated by the treatment of the product with invertase. The amount of the invertase should be optimized to manufacture the product with the required characteristics.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- AOAC (2010) International official methods of analysis. Fructose, Glucose, lactose, maltose, and sucrose in milk chocolate, liquid chromatographic method. Sec. 980.13

- Aranda C, Robledo A, Loera O, Contreras-Esquivel JC, Rodríguez R, Aguilar CN. Fungal invertase expression in solid-state fermentation. Food Technol Biotechnol. 2006;44(2):229–233. [Google Scholar]

- Bourne MC. Principles of objective texture measurement. In: Taylor SL, editor. Food texture and viscosity: concept and measurement. San Diego: Academic Press; 2002. pp. 182–186. [Google Scholar]

- Bratu MG, Stoica A, Mihail B (2007) The influence of additives on preparing the fondant. The annals of ‘Valahia University of Targoviste, pp 5–9

- Ergun R, Lietha R, Hartel R. Moisture and shelf life in sugar confections. Crit Rev Food Sci Nutr. 2010;50:162–192. doi: 10.1080/10408390802248833. [DOI] [PubMed] [Google Scholar]

- Garrido JI, Lozano JE, Genovese DB. Effect of formulation variables on rheology, texture, colour, and acceptability of apple jelly: modelling and optimization. LWT-Food Sci Technol. 2015;62:325–332. doi: 10.1016/j.lwt.2014.07.010. [DOI] [Google Scholar]

- Gunasekaran S, Ak MM. Dynamic oscillatory shear testing of foods—selected applications. Trends Food Sci Technol. 2000;11:115–127. doi: 10.1016/S0924-2244(00)00058-3. [DOI] [Google Scholar]

- Hartel RW, Joachim H, Hofberger R. Confectionery science and technology. Berlin: Springer; 2017. [Google Scholar]

- Jackson EB, Howling D (1999) Glucose syrups and starch hydrolysates. In: Sugar confectionery manufacture, 2nd edn. Aspen Publishers, Gaithersburg, MD

- Kulshrestha S, Tyagi P, Sindhi V, Yadavilli KS. Invertase and its applications–a brief review. J Pharm Res. 2013;7:792–797. [Google Scholar]

- Mobini-Dehkordi M, Nahvi I, Zarkesh-Esfahani H, Ghaedi K, Tavassoli M, Akada R. Isolation of a novel mutant strain of Saccharomyces cerevisiae by an ethyl methane sulfonate-induced mutagenesis approach as a high producer of bioethanol. J Biosci Bioeng. 2008;105:403–408. doi: 10.1263/jbb.105.403. [DOI] [PubMed] [Google Scholar]

- Nummer B, Shrestha S, Smith J. Survival of Salmonella in a high sugar, low water-activity, peanut butter flavored candy fondant. Food Control. 2012;27:184–187. doi: 10.1016/j.foodcont.2011.11.037. [DOI] [Google Scholar]

- Oyedeji O, Bakare MK, Adewale IO, Olutiola PO, Omoboye OO. Optimized production and characterization of thermostable invertase from Aspergillus niger IBK1, using pineapple peel as alternate substrate. Biocatal Agric Biotechnol. 2017;9:218–223. doi: 10.1016/j.bcab.2017.01.001. [DOI] [Google Scholar]

- Pajin B, Dokić L, Zarić D, Šoronja-Simović D, Lončarević I, Nikolić I. Crystallization and rheological properties of soya milk chocolate produced in a ball mill. J Food Eng. 2013;114:70–74. doi: 10.1016/j.jfoodeng.2012.06.024. [DOI] [Google Scholar]

- Patel S, Murthy Z. Anti-solvent sonocrystallisation of lactose. Chem Process Eng. 2011;32:379–389. doi: 10.2478/v10176-011-0030-6. [DOI] [Google Scholar]

- Raghavan S, Ristic R, Sheen D, Sherwood J. The bulk crystallization of α-lactose monohydrate from aqueous solution. J Pharm Sci. 2001;90:823–832. doi: 10.1002/jps.1036. [DOI] [PubMed] [Google Scholar]

- Santana de Almeida AC, Costa de Araújo L, Mendes Costa A, Moraes de Abreu CA, de Andrade Gomes, Lima MA, Palha PF, de Los Angeles M. Sucrose hydrolysis catalyzed by auto-immobilized invertase into intact cells of Cladosporium cladosporioides. Electron J Biotechnol. 2005;8:54–62. [Google Scholar]

- Schmidt C, Bornmann R, Schuldt S, Schneider Y, Rohm H. Thermo-mechanical properties of soft candy: application of time-temperature superposition to mimic response at high deformation rates. Food Biophys. 2018;13:11–17. doi: 10.1007/s11483-017-9506-3. [DOI] [Google Scholar]

- Silver M, Karel M. The behavior of invertase in model systems at low moisture contents. J Food Biochem. 1981;5:283–311. doi: 10.1111/j.1745-4514.1981.tb00680.x. [DOI] [Google Scholar]

- Vaclavik VA, Christian EW. Essentials of food science. 14. New York: Springer; 2014. [Google Scholar]

- Varzakas T, Labropoulos A, Anestis S. Sweeteners: nutritional aspects, applications, and production technology. Boca Raton: CRC Press; 2012. [Google Scholar]

- Yoo B, Rao M. Creep and dynamic rheological behavior of tomato concentrates: effect of concentration and finisher screen size. J Texture Stud. 1996;27:51–459. doi: 10.1111/j.1745-4603.1996.tb00087.x. [DOI] [Google Scholar]

- Zhang Z, Sun DW, Zhu Z, Cheng L. Enhancement of crystallization processes by power ultrasound: current state-of-the-art and research advances. Compr Rev Food Sci Food Saf. 2015;14:303–316. doi: 10.1111/1541-4337.12132. [DOI] [Google Scholar]