Abstract

Background

Air-purifying, tight-fitting facepieces are examples of respiratory protective equipment and are worn to protect workers from potentially harmful particulate and vapors. Research shows that the presence of facial hair on users' face significantly reduces the efficacy of these devices. This article sets out to establish if an acceptable seal could be achieved between facial hair and the facepiece. The team also created and investigated a low-cost “pressure testing” method for assessing the efficacy of a seal to be used during the early design process for a facepiece designed to overcome the facial hair issue.

Methods

Nine new designs for face mask seals were prototyped as flat samples. A researcher developed a test rig, and a test protocol was used to evaluate the efficacy of the new seal designs against facial hair. Six of the seal designs were also tested using a version of the conventional fit test. The results were compared with those of the researcher-developed test to look for a correlation between the two test methods.

Results

None of the seals performed any better against facial hair than a typical, commercially available facepiece. The pressure testing method devised by the researchers performed well but was not as robust as the fit factor testing.

Conclusion

The results show that sealing against facial hair is extremely problematic unless an excessive force is applied to the facepiece's seal area pushing it against the face. The means of pressure testing devised by the researchers could be seen as a low-cost technique to be used at the early stages of a the design process, before fit testing is viable.

Keywords: Facepiece design facial hair, Respirator design facial hair, RPE design facial hair

1. Introduction

The type of tight-fitting facepiece respirators considered for this article is the elastomeric half-mask respirator (EHR), the filtering or “air purifying” type which the Occupational Safety and Health Administration (OSHA) describe as “respirators that use filters, cartridges, or canisters to remove contaminants from the air you breathe.” The OSHA goes on to state that tight-fitting respirators need a tight seal between the respirator and the face and/or neck of the respirator user for it to work properly. If the respirator's seal leaks, contaminated air will be pulled into the facepiece and can be breathed in; therefore, anything that interferes with the respirator seal is not permitted when using this type of respirator. This could include facial hair [1].

The ability of a respirator to prevent inward leakage of harmful particulate or vapor when fitted to a user's face is commonly assessed by analyzing the fit factor. The fit factor is obtained during a Fit test and is measured using a piece of equipment called a fit tester (commonly a PortaCount machine manufactured by TSI). Respiratory Protective Assessment Ltd. states on its website that describe the fit factor as a ratio of the concentration of challenge aerosol outside a respirator to the concentration of aerosol that leaks into the respirator through the face seal. They go on to describe the PortaCount machine: “[It] works by measuring the concentration of microscopic dust particles in the ambient air and then measuring the concentration of those dust particles that leak into the respirator. The ratio of these two concentrations is called the fit factor. The high-efficiency particulate absorbing (HEPA) filter cartridges stop essentially all the particles, so anything that gets into the mask must come out through the face seal” [2].

This article looks at a means of addressing the problem of the loss of performance of EHRs when worn by users with facial hair because of the poor seal between face and EHR.

Frost and Harding of the Health and Safety Laboratory compiled a report in 2015 entitled “The effect of wearer stubble on the protection given by Filtering FacepiecesClass 3 (FFP3) and Half Masks.’ In the report, they articulate that tests have previously been carried out which demonstrate that facial hair is detrimental to the protection given by reusable facepieces, and they go on to convey that the current guidance advising that wearers of masks must be clean-shaven in the area of the mask seal is justified [3].

In the UK, Control of substances hazardous to health, Approved Code of Practice (COSH ACOP) paragraph 7 line 160 is clear on the issue of facial hair when using respiratory protective equipment (RPE), affirming “the proper training and supervision of employees in its use. This will include wearers being clean-shaven in the area of the face seal when using tight-fitting RPE” [4].

This advice, although justified, does not take into account that some men will refuse to shave on religious grounds or for other personal reasons. Some men may not shave frequently enough to gain the maximum level of protection from an EHR, or some men may just be negligent with regard to shaving to ensure that they gain optimum protection from an EHR.

Stobbe et al. [5] declared that the effect of facial hair on the quality of fit obtained while wearing a tight-fitting respirator has been and continues to be a controversial subject.

In particular, this article investigates whether a good seal can be achieved between an EHR and a face with facial hair. It also investigates an alternative method of prototyping the EHR seal surface and measuring the effectiveness of the seal against inward leakage when compared with the conventional fit-test approach.

The development of a new EHR to overcome the issue of facial hair is a design problem with many challenges. In addition to the problem of creating a seal against the hirsute face, the design of a facepiece that fits as many face types as possible is in itself a considerable design challenge. Results of a study conducted by Oestenstad et al [6] in 2010 indicate that respirator leakage is strongly affected by nose and chin leaks, that gender is a factor influencing the way a respirator fits, and that consideration should be given to nasal dimensions when defining a respirator test panel and selecting a respirator for an individual wearer.

The work of Lee et al. [7] in analyzing the key facial dimensions for the design of a half mask for Korean air force pilots offers a robust source of anthropometric data which could be used to accurately design a new half mask using computer-aided design. However, the issue of how to ensure this new mask would be fitted properly against inward leakage on any face when analyzing its performance against facial hair remains. It is important that no other factors such as a leak around the nose section should hinder the research. Therefore, the methods used in the research are focused only on obtaining a seal against facial hair in a flat plane. If the means of making a good seal against facial hair can be established, then a further exercise in converting this technology into an actual functioning face mask prototype will be undertaken.

When talking about how the mask seals against the face, Lei et al. [8] discuss contact behavior as being a function of the seal area and the straps and that other areas of the respirator can be neglected. This has influenced this research where only the seal area is considered. For the tests in the research, the straps have also been removed and replaced by weights to give a uniform force onto the seal area.

Lei et al. [8] look at alternative ways of developing a respirator to cut costs and shorten time to market. They look at a means of developing a mask using computerized modeled heads and masks, mapping the pressure applied around the seal area using finite element analysis (FEA). They compare and contrast this to using physical model heads and masks to check the accuracy of their technique. This article suggests a physical way of developing and testing new mask seals in a low-cost way versus the conventional way of creating a physical working mask prototype and fit testing it with human test subjects. The fact that the seals in this research are flat means that the results can focus on the interface between the face and seal area without the added complication of facial geometry.

The first part of this project was to assess if a seal could be achieved against the facial hair before the design of a finished mask could be addressed. This led the research team to pose two research questions:

-

1.

Can an acceptable seal be achieved between a facepiece and face with facial hair?

-

2.

Can an alternative low-cost testing method be developed for testing potential seal designs, which does not involve incorporating the seal into a finished mask worn by a human test subject?

The researchers proposed an alternative method of testing measuring seal effectiveness (how well a seal prevents inward leakage). The new test was to assess how well a seal could hold air pressure. A specially designed test rig comprising a cup, with a proposed new seal design fitted at its open end, was pushed against facial hair. Both negative and positive air pressures were applied into the cup via an air tube, and the resulting internal air pressure measured. The hypothesis was there would be a strong correlation between a seal that could hold a reasonable amount of air pressure and a seal that would ultimately perform well in a fit test. Following the tests developed by the researchers, the seals designed for this research also underwent a modified “fit test” at an independent laboratory, and the results were compared to prove or disprove the hypothesis that a strong correlation would exist between a seal that could hold a reasonable amount of air pressure and a seal that would ultimately perform well in a conventional fit test.

Another barrier to reducing the cost and time in developing a new EHR is the availability of very soft, good-quality elastomers for simulation by rapid prototyping techniques.

In a recent white paper, the low-volume/rapid manufacturing company Protolabs stated “Device developers have a number of plastic, metal and liquid silicone rubber materials, in various grades, available to them during prototyping and low-volume production, and each provides different properties and application opportunities” [9].

This is certainly true, but for this project, the researchers felt that they pushed the limits of soft materials for rapid prototyping; the softest polymer material that could be obtained for the samples was a vacuum cast silicone with a hardness of shore A 10. To address this, the researchers experimented with non-Newtonian fluids to mimic extremely soft elastomers that cannot be easily prototyped.

2. Materials and methods

Because of the challenges associated with designing a prototype mask to fit the complex geometries of the human face, the researchers based their research around creating a range of 9 flat seal designs, performance of which in creating a seal against facial hair could initially be tested in a flat form on a specially designed test rig. This test rig would measure how well the seals could hold air pressure. If one or more of the flat seal designs demonstrate good sealing qualities, the researchers plan to develop them into a fully working prototype EHR masks in future stages of the project.

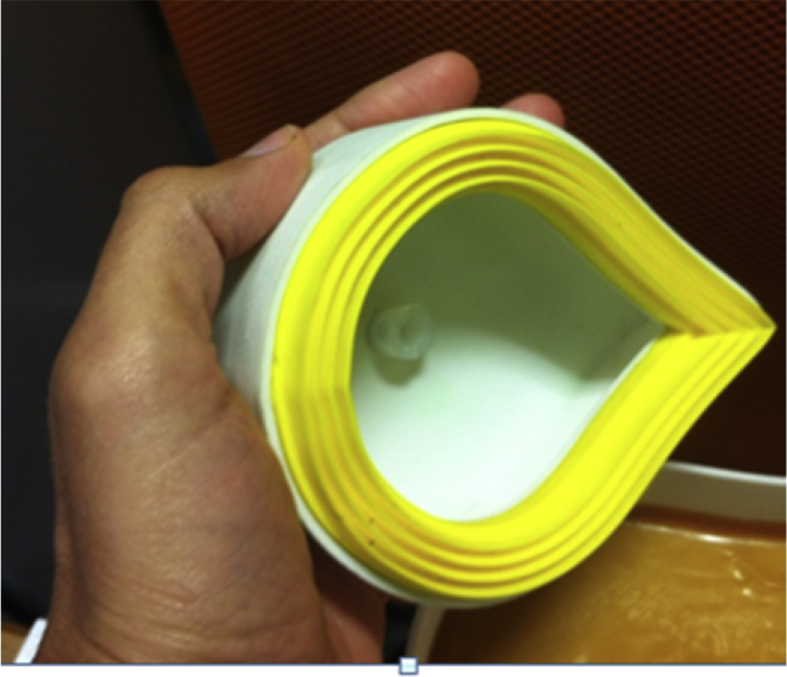

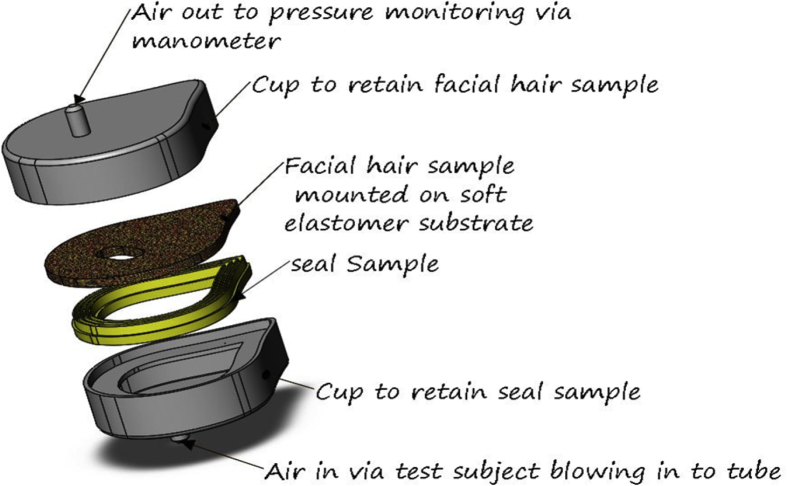

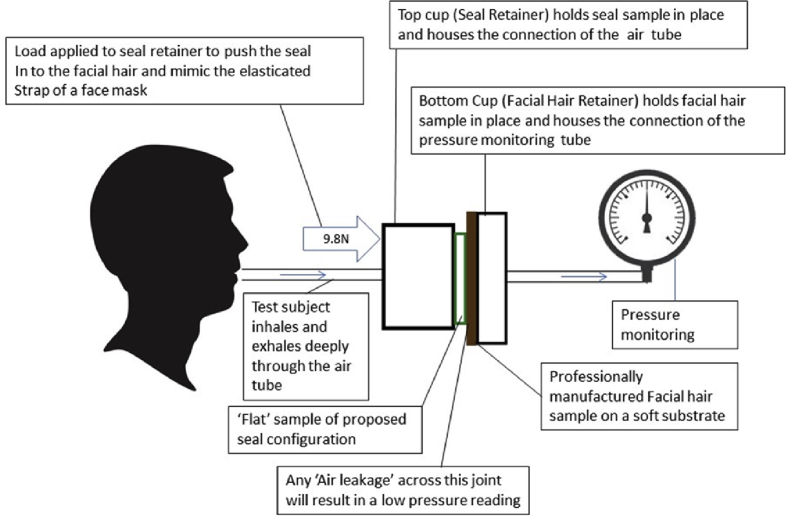

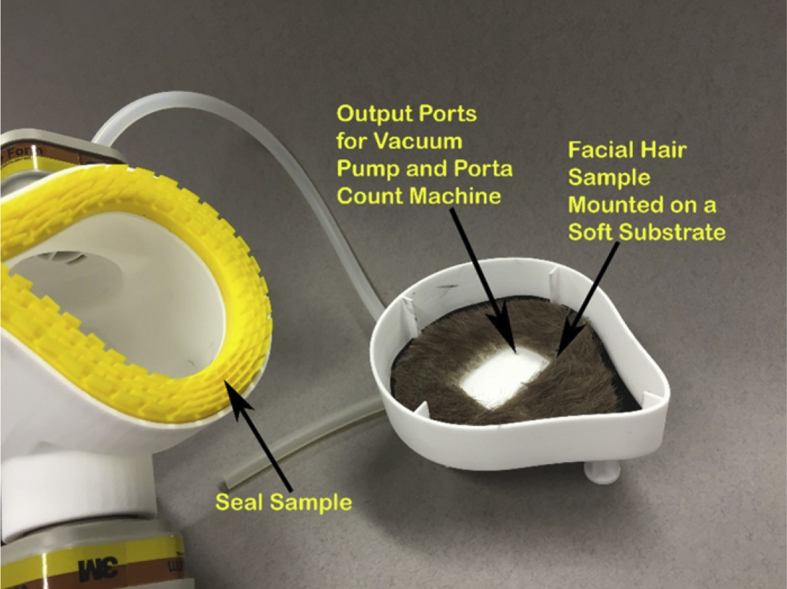

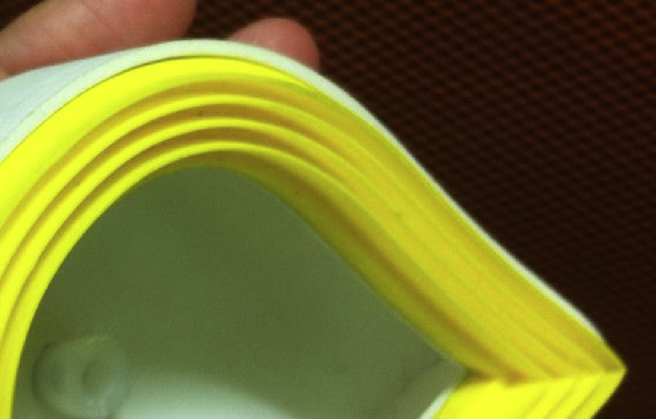

The flat seal samples developed for the research were made up of different materials with various surface features, each representing a potential new seal surface for an EHR facepiece. A teardrop shape was decided upon to mimic a section through an EHR mask at the point where it covers the mouth and nose (See Fig. 1). The specially designed test rig comprises a chamber made up of two half cups: the bottom cup (Fig. 3) houses a flat surface with a professionally made facial hair sample mounted on a soft substrate. This part of the test rig simulates a bearded or unshaven human face, the opposing top cup (Fig. 2) houses one of the new seal samples on its perimeter edge. The two cups are then

Fig. 1.

CAD image of an example of one of the flat seal samples. This particular sample has soft ribs that are designed to penetrate through the facial hair as much as possible while still remaining comfortable for the wearer. Brought together, which creates a chamber with the flat seal sample pressed against the simulated facial hair surface at the joint of the two halves. Air can then be introduced to the closed chamber via a tube to assess how well the seal maintains air pressure inside the chamber. A corresponding tube is connected to the chamber to take pressure readings.

Fig. 3.

Bottom cup, housing facial hair sample mounted on a soft substrate.

Fig. 2.

Top cup, housing seal sample.

This “pressure testing” method was the technique developed by the researchers to assess the efficacy of the seals. Following on from the pressure testing, the seals were tested using a modified version of the conventional fit test. (No human test subject was used.) The results from each testing method could then be compared and analyzed to assess if the pressure testing method was viable.

The nature of the test apparatus is discussed further in the Testing Method section.

Two approaches were used in the design of the flat seal samples. The first approach was to create samples using very soft “gel-like” materials that are soft enough to envelop the facial hair, allowing a seal to be made with the skin beneath it. The second approach was to create features on the surface of the seal that would either embed themselves between the facial hair, to create a seal with the skin, or nestle into the hair, working in conjunction with it to create a secondary filter effect that would not allow particulate through, keeping inward leakage within acceptable limits.

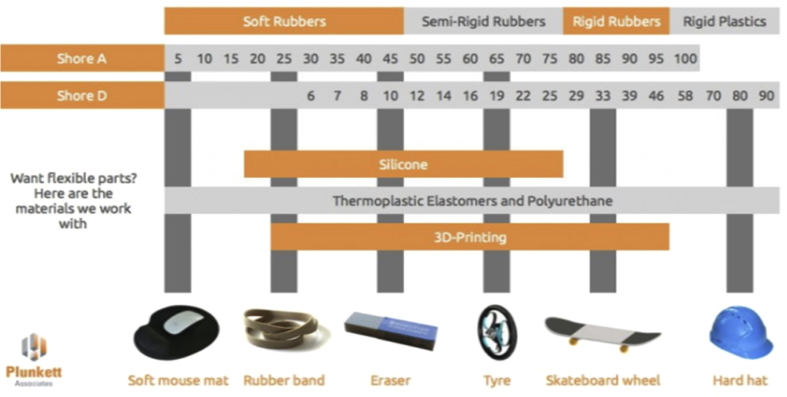

Some of the new seal ideas were based on using very soft elastomeric materials. Accurately prototyping products in materials of this type has been a challenging aspect of product design for many years, but advancements in three-dimensional (3D) printing materials and rapid prototyping techniques have greatly aided this process. Fig. 4 shows a table from a low-volume/rapid manufacturing company, stating the shore hardness levels that can be achieved using various prototyping/manufacturing techniques.

Fig. 4.

Shore Hardness Comparison Chart showing the softness that can be achieved using low-volume manufacturing and rapid prototyping techniques—Chart taken from the website of Plunket associates an established UK prototyping and low-volume manufacturing consultancy [10].

As a very soft elastomer may have the capability to envelop the facial hair and seal against the skin, the researchers were keen to investigate elastomeric materials that are softer than those readily available for prototyping or low-volume manufacture. Softer materials could be specified for an injection molded production facepiece using materials such as styrene-ethylene-butylene-styrene (commonly known as SEBS), but these are not easy to prototype without significant tooling investment. To accommodate this, the researchers crafted two seal samples from non-Newtonian fluids: one utilizes a child's “slime” toy which was molded into correct shape (seal 3), and the second was a material composed of psyllium husk, a powdered fiber, which when mixed with water and heated forms a non-Newtonian fluid. The more the solution is heated and cooled, the firmer the material becomes (seal 9). This solution was taken through a number of heating and cooling cycles until the material had a hardness close to that of a very soft SEBS material. The hardness was based on a sample of SEBS that the researchers had received from a specialist polymer supplier and had tested its hardness using a durometer.

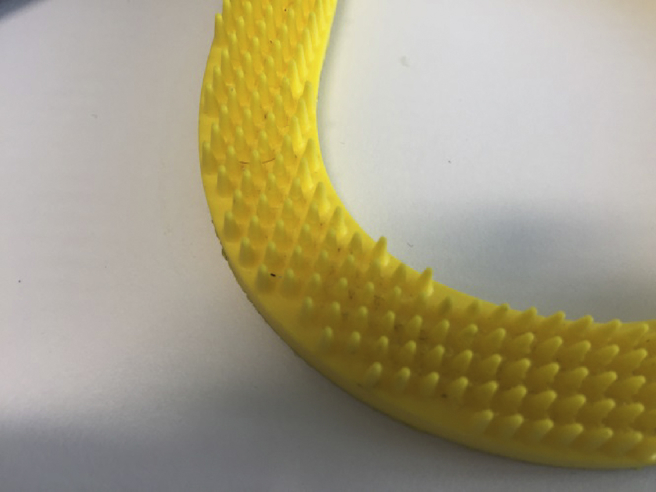

The 9 different seal designs that were used in the study are described in the following list:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2.1. Testing the new flat seal designs to assess their efficacy in sealing against facial hair testing method 1

2.1.1. Pressure testing of seals using the researcher-developed method

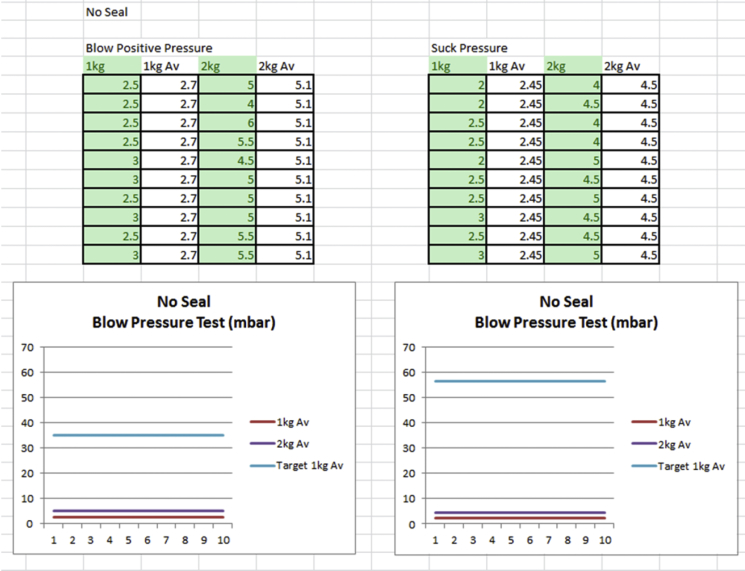

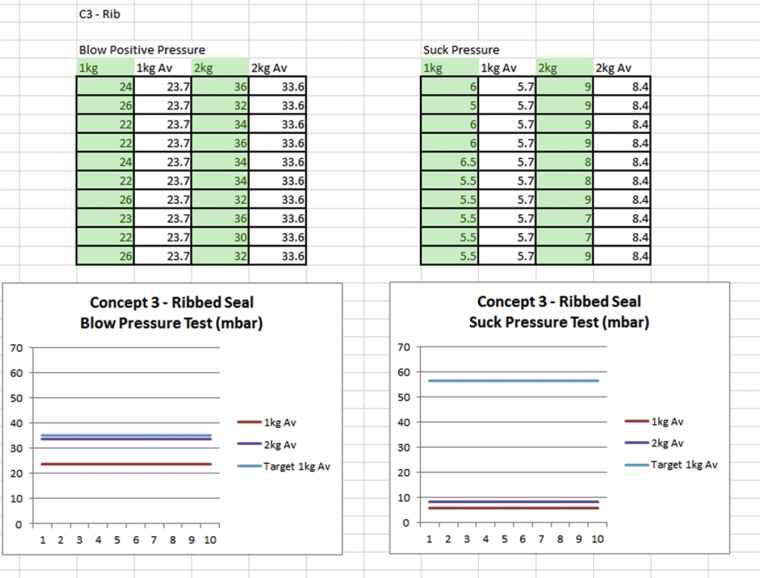

Each seal design was tested using the pressure method developed by the researchers. This measured how well each seal could maintain air pressure.

A silicone tube was fitted to each of the two test rig cups, and both were checked for leaks. One tube was connected to a manometer to measure pressure, and the other tube was to allow the chamber to be breathed through by a human test subject.

When the test subject both inhaled and exhaled deeply into the tube, the chamber is pressurized and the pressure reading was shown on the manometer. The higher the pressure reading, the better the sealing properties of the seal sample.

The test rig was securely mounted in the horizontal plane, and a weight was placed on the cup containing the seal sample to mimic the elastic straps pulling the facepiece on to the face. A round of tests were conducted with a 1-kg weight being used to represent 9.81 N of force pulling the mask onto the face, followed by a second round of tests with a 2-kg weight representing 18.62 N of force pulling the mask onto the face. The rationale for this can be found in the following section—Setting a benchmark for the pressure testing.

A human test subject inhaled into the test rig (creating a negative pressure inside the rig) ten separate times, with the pressure readings for each attempt being recorded. In addition to this, the test subject also exhaled, blowing as hard as he or she could to study if there was any difference in the seal properties under positive pressure. Again, this was performed ten times with the results recorded. For each attempt, the test subject was asked to exhale/inhale to his or her full extent to a count of five seconds. The positive pressure test was of interest because if the seal of a mask breaks during exhalation, then there is an opportunity for particulate or vapor to enter the mask. The researchers were also keen to investigate if some of the new seal designs actually improved their seal performance under positive pressure.

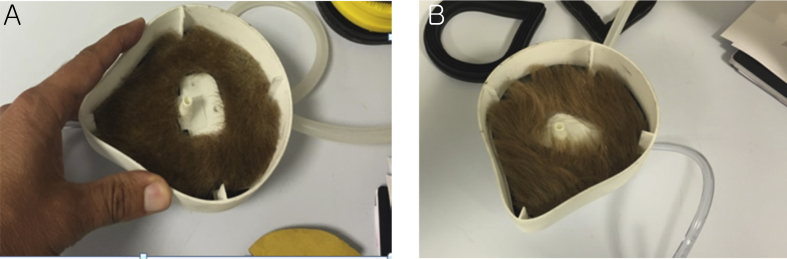

Two facial hair samples were used for the research, a short-beard sample and a long-beard sample. These can be seen in Fig. 7. Each facial hair sample was tested with each seal sample ten times as described previously

Fig. 7.

Two facial hair samples. (A) Short beard. (B) Long beard. These were produced by a toupee maker and mounted on a soft elastomer substrate. They were then bonded to the base of the test rig to ensure a good seal.

An exploded view of the manufactured parts for the test rig can be seen in Fig. 5, a more schematic view of the test rig can be seen in Fig. 6, and an image of the rig in use can be seen in Fig. 8

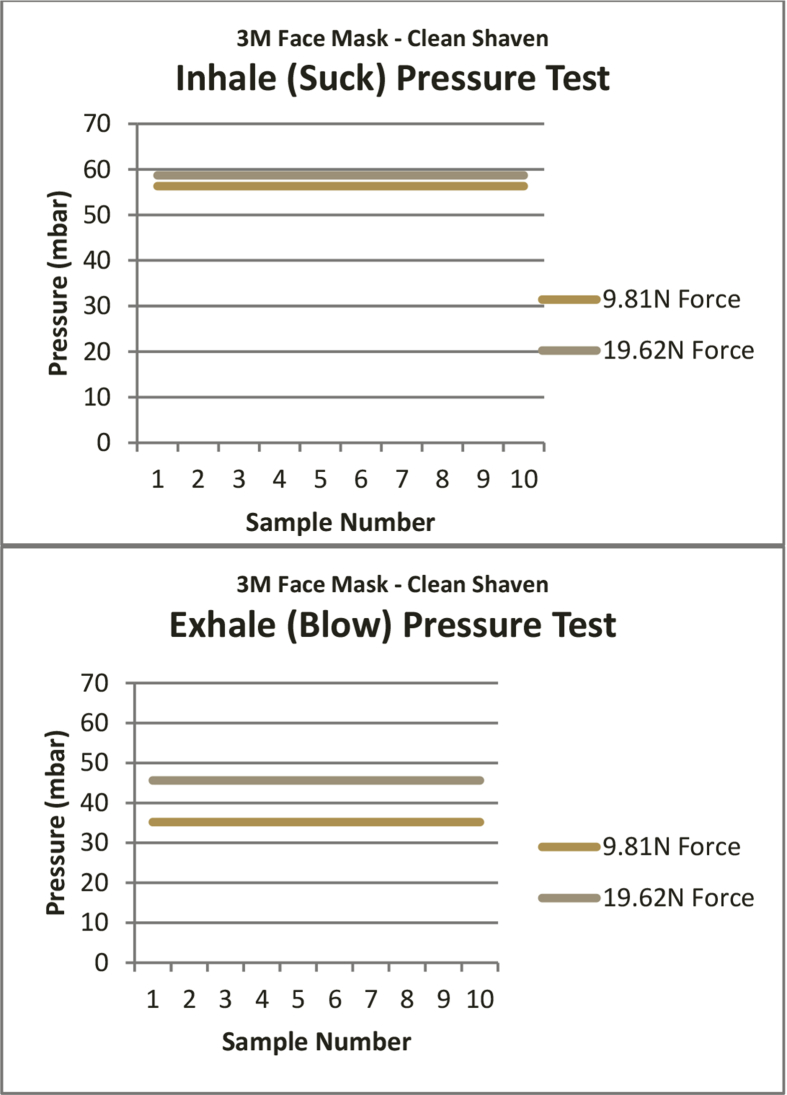

Fig. 9.

Images of benchmark pressure testing for a standard readily available facepiece.

Fig. 10.

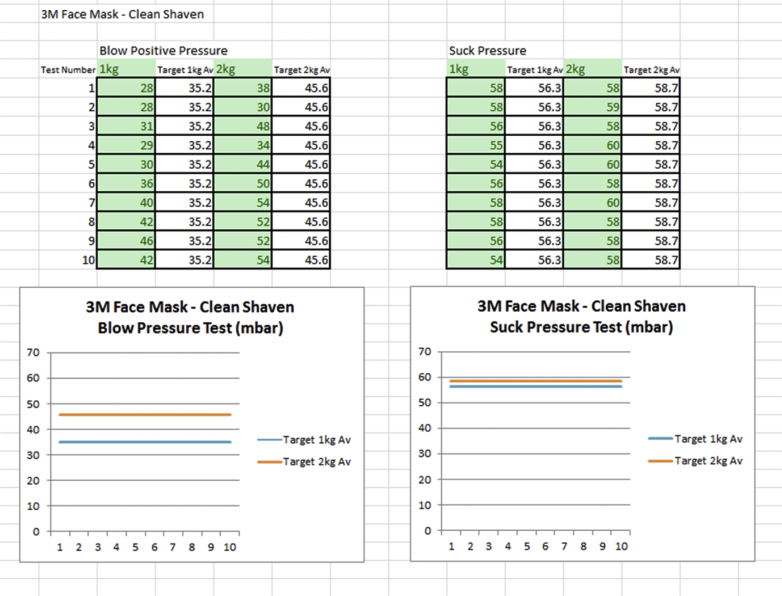

Results of benchmark testing to establish pressure sealing qualities of a typical commercially available facepiece worn by a clean-shaven test subject.

Fig. 5.

CAD model of the test rig, developed for pressure testing of the seals (the test rig is used with a cup retaining the seal sample on top). CAD, computer-aided design.

Fig. 6.

Schematic showing the principle of the test rig, developed for pressure testing of the seals.

Fig. 8.

Test subject performing initial tests using the test rig. (1-kg weight fitted to the test rig to represent 9.81-N force.)

2.2. Setting a benchmark for the pressure testing

Before initial pressure testing could begin, it was important to obtain a benchmark for the pressure sealing properties of a typical, commercially available EHR facepiece. For this, a facepiece from 3M, (a mask manufacturer and global science based technology company) was purchased. Its filter and exhaust ports were blanked off, and the internal chamber was connected to the manometer via a silicone tube. A spring balance was used to pull the mask onto a clean-shaven test subject's face. A force of 9.81 N was deemed to be comfortable; anything above this became little uncomfortable, and as the force approached 19.62 N, the test subject reported levels of discomfort that could not be endured for more than a few seconds. The test subject blew into the mask to his full extent; he also inhaled to his full extent (both to a count of five seconds). It was observed that when the test subject inhaled, there was an improvement in the pressure readings due to the mask being sucked onto the face. This exercise was repeated ten times, and the pressure inside the facepiece was recorded on each attempt. The results were then plotted, and a line of best fit was drawn to gain an average pressure reading inside the facepiece.

For testing of the new flat seal samples, a force of 9.81 N was simulated by placing a 1-kg weight on the upper cup of the test rig chamber. A second set of readings was also taken with a 2-kg weight on the test rig. This would simulate a force of 19.62 N pulling the mask onto the face. Despite this force being deemed excessive for the mask to be a comfortable fit, the research team was keen to learn how much the sealing properties of each seal design would improve as more force was exerted onto it, pushing it into the facial hair sample (see Fig. 8).

2.3. Testing method 2

2.3.1. Fit testing of seals to obtain a fit factor—using a conventional measure for how well the seals prevent inward leakage

Following on from the pressure testing of the seal sample designs, the researchers were keen to compare their test results with a more conventional measure for testing the effectiveness of an EHR face mask seal. The test decided upon was a fit test using a TSI PortaCount machine. This test provides a fit factor which compares the amount of particulate inside a respirator face mask vs the particulate outside the mask, thus giving an indication of the amount of inward leakage that has taken place in the mask. The researcher's hypothesis was that seals which performed well in the pressure tests should also perform well in the fit test. The tests were carried out at an independent testing laboratory (ITL).

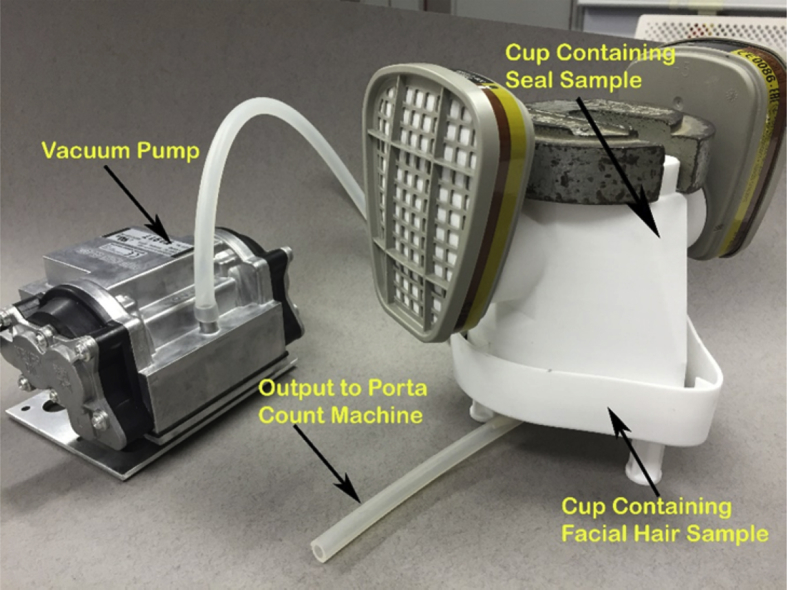

Fit testing typically involves measuring challenge aerosol that leaks inside a respirator worn by a human test subject breathing through the filters. As the flat seals used for this research eliminate the possibility of using a human test subject, the test rig had to be modified to suit fit testing.

This was done by the addition of two typical filters on the upper cup (the upper cup houses the seal sample) and two connection ports on the lower cup (the lower cup houses the facial hair sample). One port would be connected to an air pump, which would draw air through the filters into the test rig chamber (simulating inhalation), and the second port would be connected to the PortaCount machine, measuring particulate. Any inward leakage would be between the mating faces of the seal sample and facial hair sample. (See Fig. 11, Fig. 12, Fig. 13 for details of the modified test rig.)

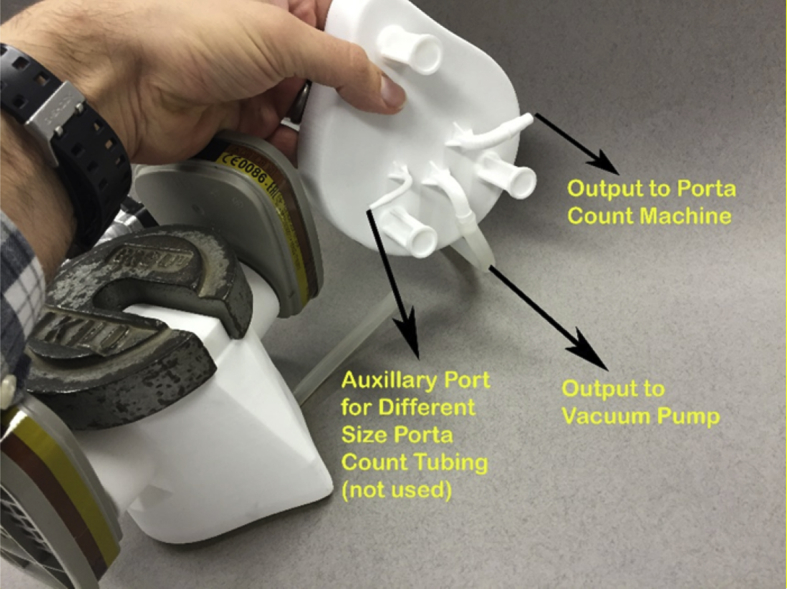

Fig. 11.

Image showing the test chamber developed for fit factor testing of flat seal samples at the ITL. ITL, independent testing laboratory.

Fig. 12.

Image showing the internals of the test chamber developed for fit factor testing of flat seal samples at the ITL. ITL, independent testing laboratory.

Fig. 13.

Image showing underside of the lower hair cup.

Again, a 1-kg load was placed on the upper cup to press the seal down into the facial hair sample to mimic the straps of the mask pulling it onto the face. The 2-kg load tests were omitted from the fit factor testing because of budget constraints.

2.4. ITL for fit testing of flat seals

The test rig described previously was inspected by an ITL. Different filters were supplied and fitted by the ITL (with the same connection fitting). This was to suit their testing regime. (See Fig. 16).

Fig. 16.

New filters presented by the ITL, note standardized fitting detail.

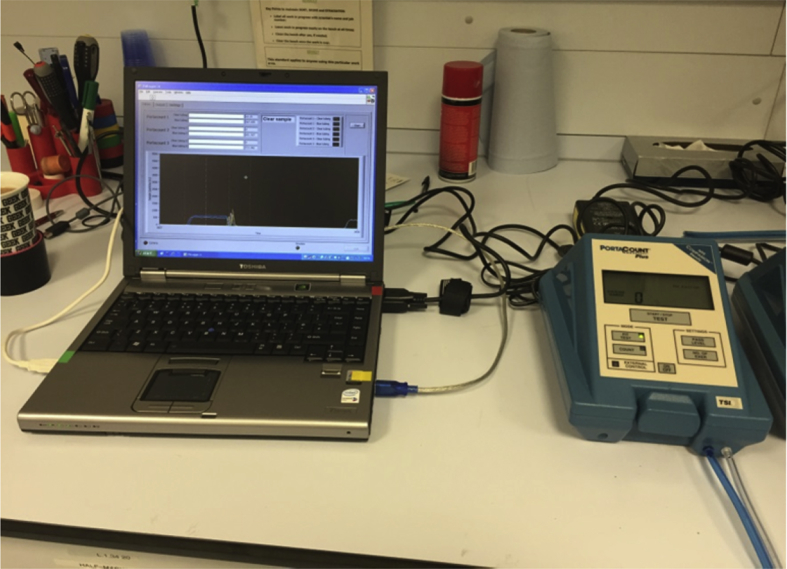

The test chamber was then connected to the PortaCount machine at the ITL along with the mains-operated vacuum pump (see Fig. 14, Fig. 15).

Fig. 14.

The PortaCount machine and PC running dedicated software at the ITL.

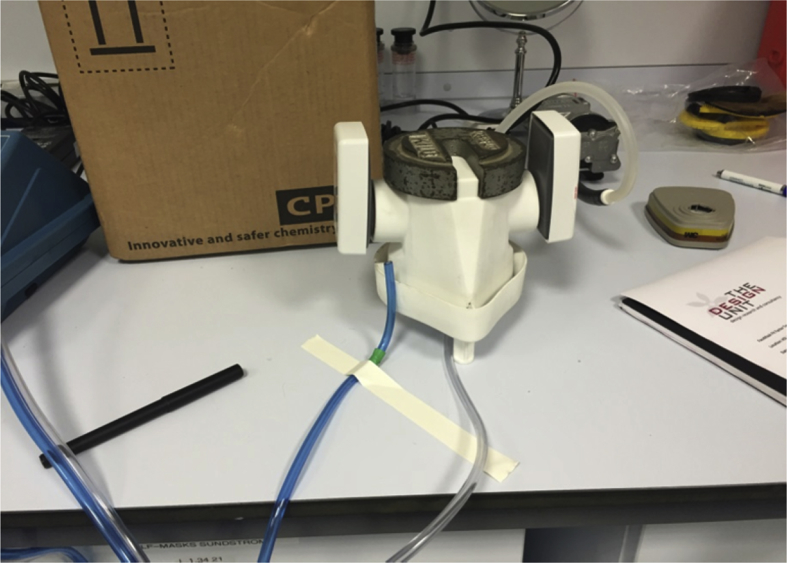

Fig. 15.

The test rig connected to the PortaCount machine: the blue tube measures particulate outside the test rig chamber, the clear tube at the front of the test chamber measures the test chamber inside and is connected to the PortaCount machine, and the clear tube at the rear end of the photograph is connected to the vacuum pump which draws air through the filters and into the test chamber.

2.4.1. Testing regime

Before tests on the seal samples commenced, a comparison check reading was taken, a fit factor calculated for the test rig with no seal sample in place, and the vacuum pump switched off. See Table 1.

Table 1.

Fit factor comparison check results (for test rig with no seal fitted)

| Mask not fitted comparison check | |||

|---|---|---|---|

| Test 1 | Test 2 | Test 3 | |

| In mask | 601 | 594 | 592 |

| Out mask | 624 | 621 | 602 |

| Fit factor | 1.03827 | 1.045455 | 1.016892 |

This format was used for all seal tests. The sample was tested with the vacuum pump switched off and the vacuum pump switched on. Three tests were carried out for each sample. The “In mask” row denotes the measurement of particulate inside the test rig chamber, and the “Out mask” row represents the measurement of particulate outside the test chamber. A fit factor is calculated as a ratio of these two figures. With no seal fitted, the measurements both inside and outside of the test chamber are similar, giving a fit factor of close to 1 (as expected). The minimum allowable fit factor for the type of facepiece considered for this article is 100 in the UK [11].

Each seal sample was tested with the short-beard and long-beard test pieces. A 1-kg weight was used to represent 9.81-N force, pushing the facepiece onto the face. The application of 2-kg load was eliminated for the fit tests because of cost, time constraints, and the fact that such a force would not be applied to the facepiece in “real world.” The non-Newtonian fluid seals (3 and 9) and the blue malleable elastomeric foam seal (7) were deemed to be too uncomfortable against the skin. Both materials, particularly the non-Newtonian fluid, have a slimy, almost wet feel to them. It was also observed that the non-Newtonian fluid could leave a residue on the facial hair when removed. Because of this, coupled with cost constraints, these samples were not taken forward for fit testing. Shinn [12] discussed that comfort of the facepiece is important. If the facepiece does not fit comfortably, the user may not wear the mask and he or she could get distracted or may need to take additional breaks.

3. Results

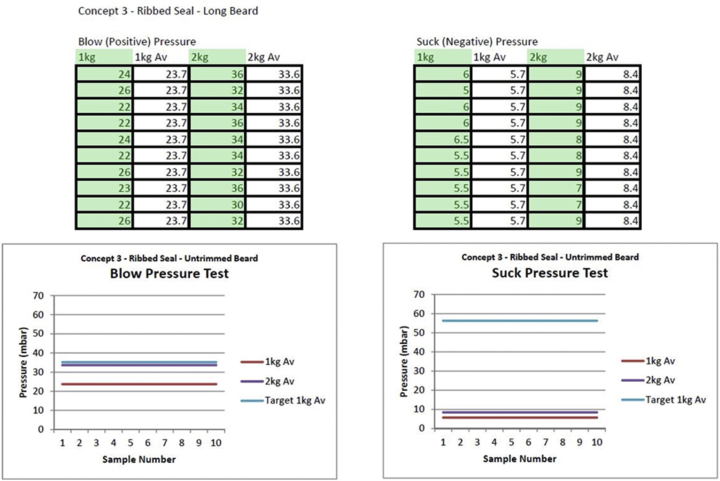

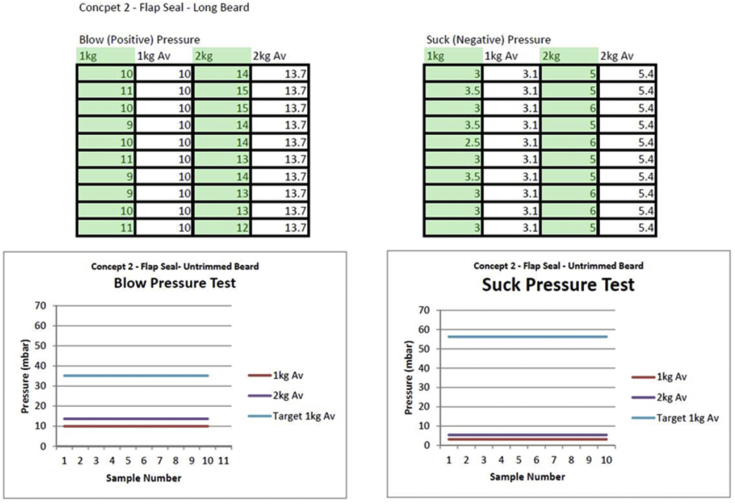

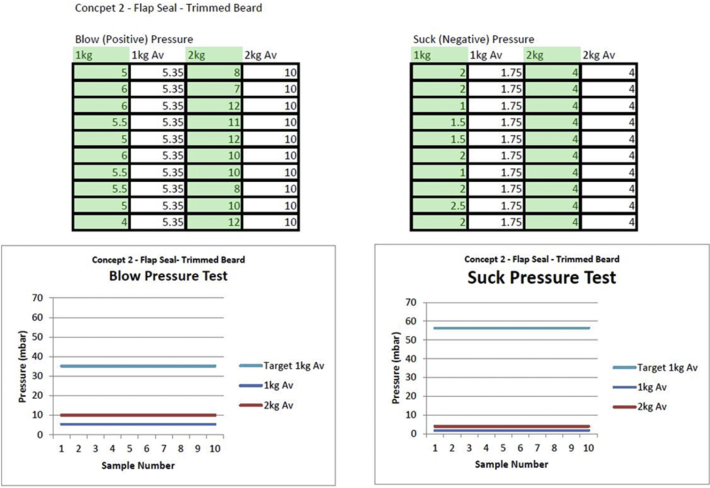

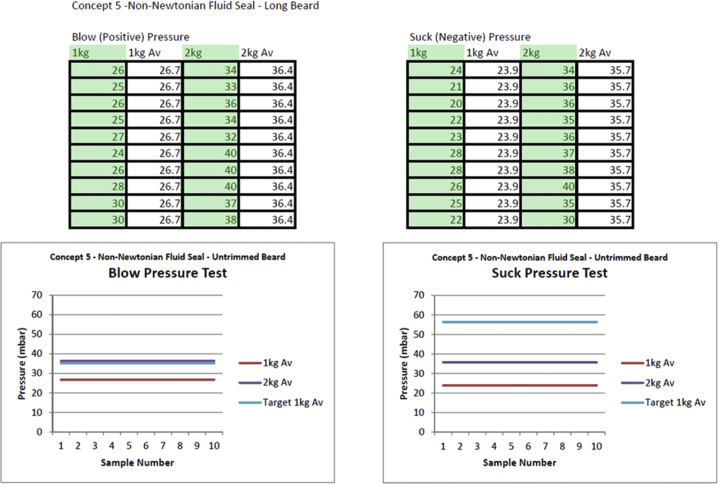

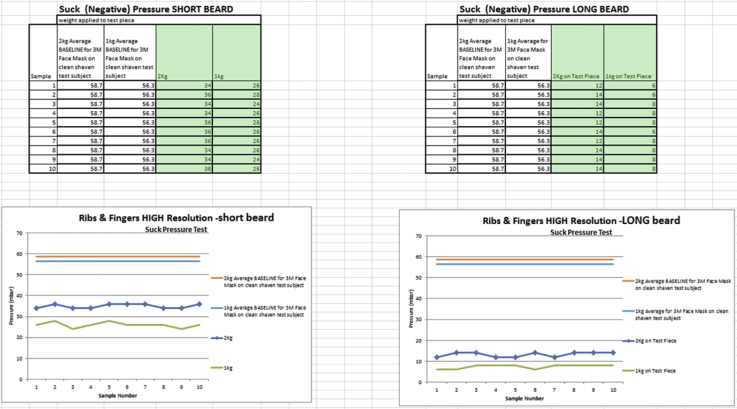

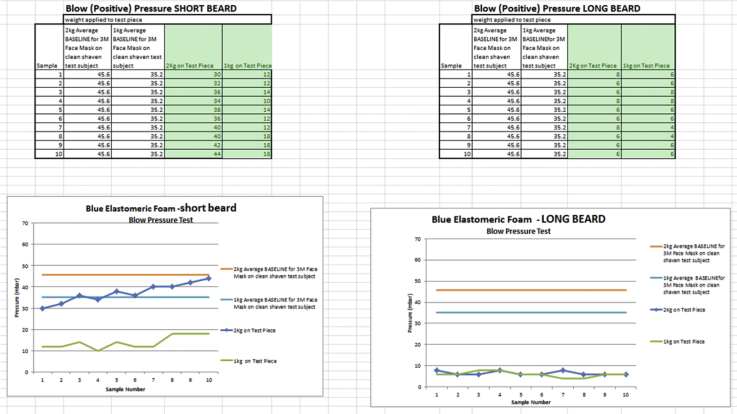

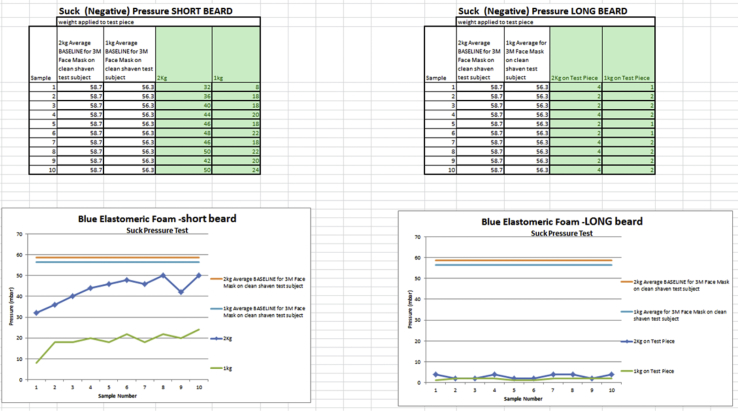

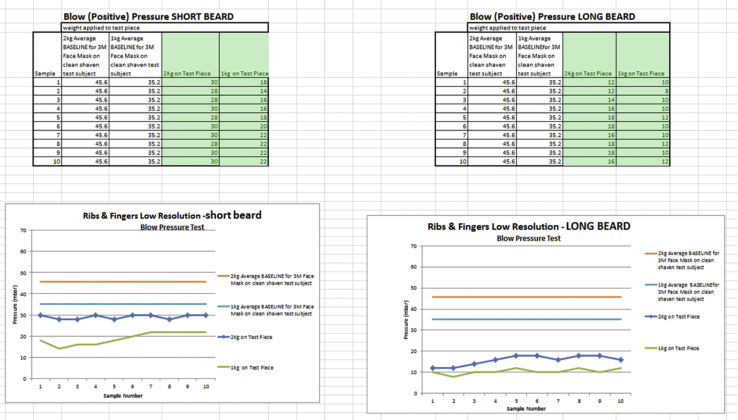

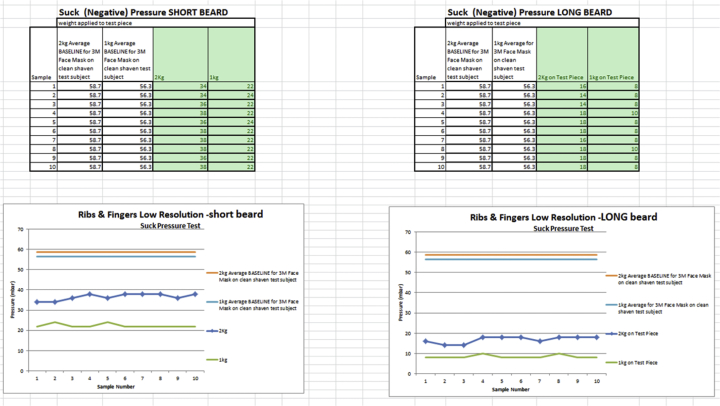

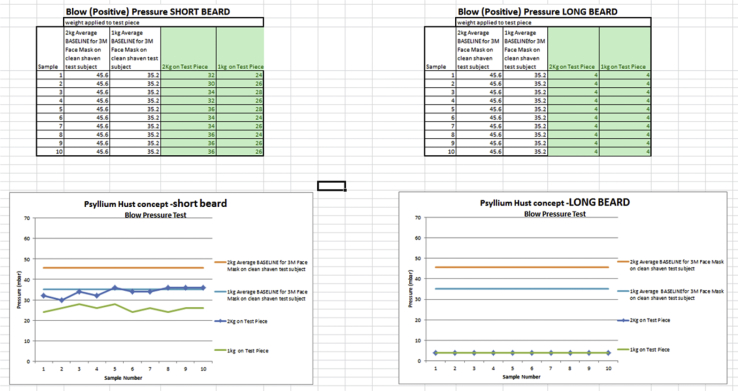

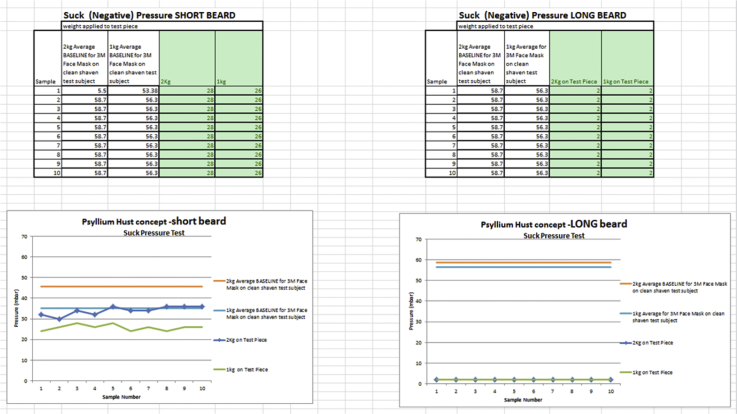

3.1. Result 1: Researcher-developed pressure tests

Table 2 shows the maximum pressure reading achieved for each seal sample. A total of eight readings are given for each seal sample test. The following readings were taken with a 1-kg load pushing the seal on to the facial hair sample: long-beard inhale reading, long-beard exhale reading, short-beard inhale reading, short-beard exhale reading.

Table 2.

Results from pressure testing of seals

| Sample name | Load on sample inhale/exhale | Short-beard maximum pressure reading (mbar) | Long-beard maximum pressure reading (mbar) | Target maximum pressure for a EHR mask fitted to a clean-shaven user—test (mbar) |

|---|---|---|---|---|

| No seal fitted to the test rig (calibration) | 1 kg Inhale | 3 | N/A | 58 |

| 1 kg Exhale | 6 | N/A | 46 | |

| 2 kg Inhale | 3 | N/A | 59 | |

| 2 kg Exhale | 5 | N/A | 54 | |

|

1 kg Inhale | 6.5 | 6.5 | 58 |

| 1 kg Exhale | 26 | 26 | 46 | |

| 2 kg Inhale | 9 | 9 | 59 | |

| 2 kg Exhale | 36 | 36 | 54 | |

|

1 kg Inhale | 1 | 3.5 | 58 |

| 1 kg Exhale | 20 | 11 | 46 | |

| 2 kg Inhale | 1.6 | 6 | 59 | |

| 2 kg Exhale | 21 | 15 | 54 | |

|

1 kg Inhale | 60 | 28 | 58 |

| 1 kg Exhale | 36 | 30 | 46 | |

| 2 kg Inhale | 60 | 40 | 59 | |

| 2 kg Exhale | 56 | 40 | 54 | |

|

1 kg Inhale | 14 | 9.5 | 58 |

| 1 kg Exhale | 14 | 34 | 46 | |

| 2 kg Inhale | 24 | 16 | 59 | |

| 2 kg Exhale | 23 | 42 | 54 | |

|

1 kg Inhale | 28 | 8 | 58 |

| 1 kg Exhale | 24 | 8 | 46 | |

| 2 kg Inhale | 36 | 14 | 59 | |

| 2 kg Exhale | 34 | 14 | 54 | |

|

1 kg Inhale | 0.5 | 1 | 58 |

| 1 kg Exhale | 2.5 | 20 | 46 | |

| 2 kg Inhale | 0.5 | 1.5 | 59 | |

| 2 kg Exhale | 4 | 25 | 54 | |

|

1 kg Inhale | 24 | 2 | 58 |

| 1 kg Exhale | 18 | 8 | 46 | |

| 2 kg Inhale | 50 | 4 | 59 | |

| 2 kg Exhale | 44 | 8 | 54 | |

|

1 kg Inhale | 24 | 10 | 58 |

| 1 kg Exhale | 22 | 12 | 46 | |

| 2 kg Inhale | 38 | 18 | 59 | |

| 2 kg Exhale | 30 | 18 | 54 | |

|

1 kg Inhale | 26 | 2 | 58 |

| 1 kg Exhale | 28 | 4 | 46 | |

| 2 kg Inhale | 28 | 2 | 59 | |

| 2 kg Exhale | 36 | 4 | 54 |

EHR, elastomeric half-mask respirator.

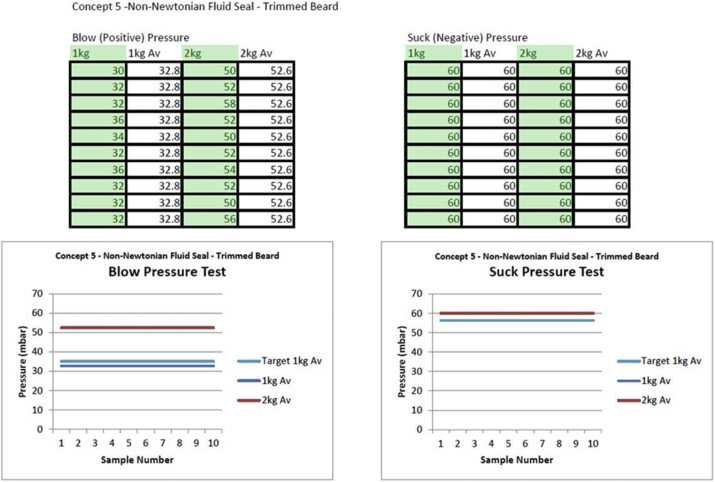

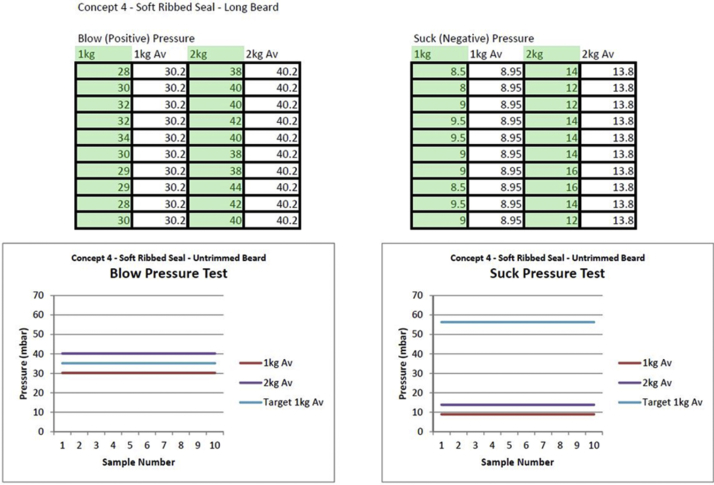

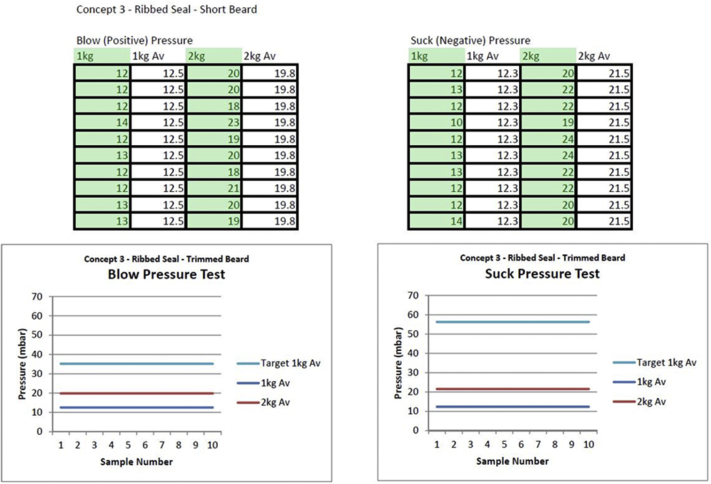

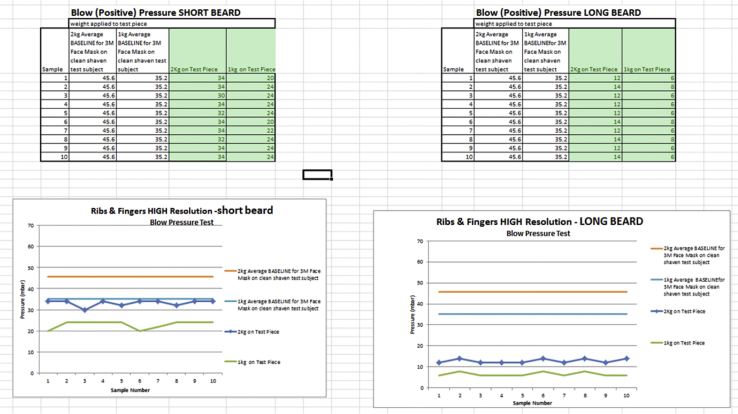

The same four readings were taken with a 2-kg load pushing the seal onto the facial hair sample (hence 8 readings in total). Full tables and graphical results can be seen in Appendix A. Each seal was tested 10 times, and the readings shown are the best achieved from the 10 attempts

3.2. Summary for initial flat seal pressure testing—researcher-devised test

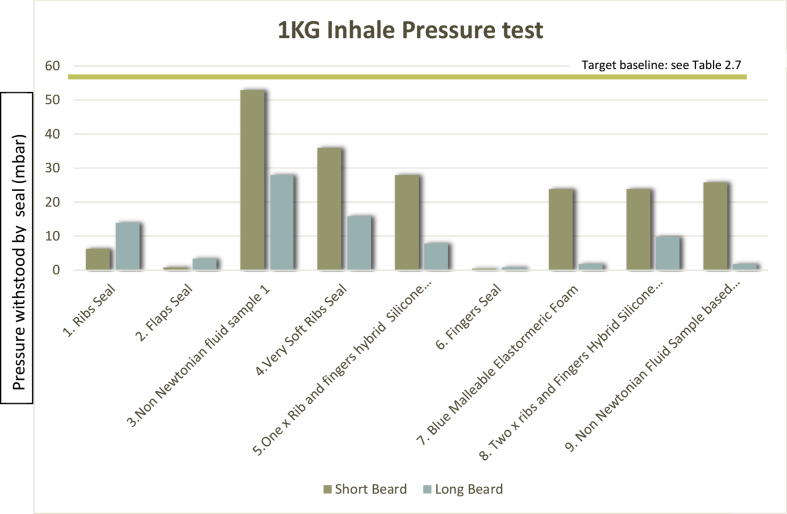

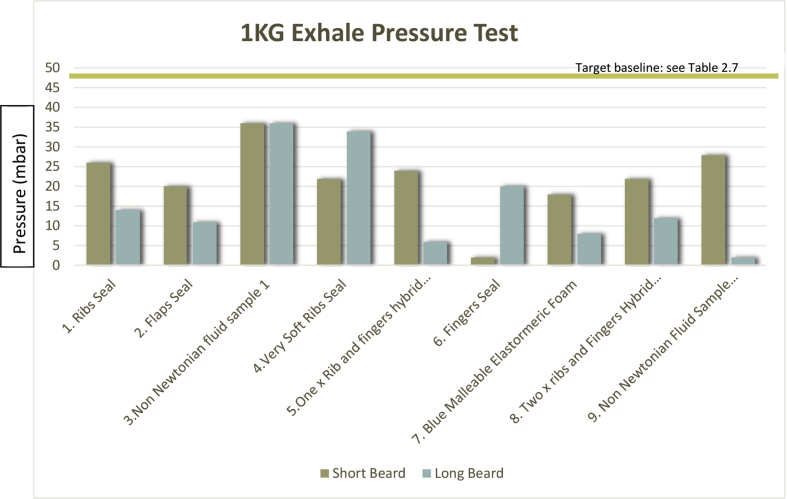

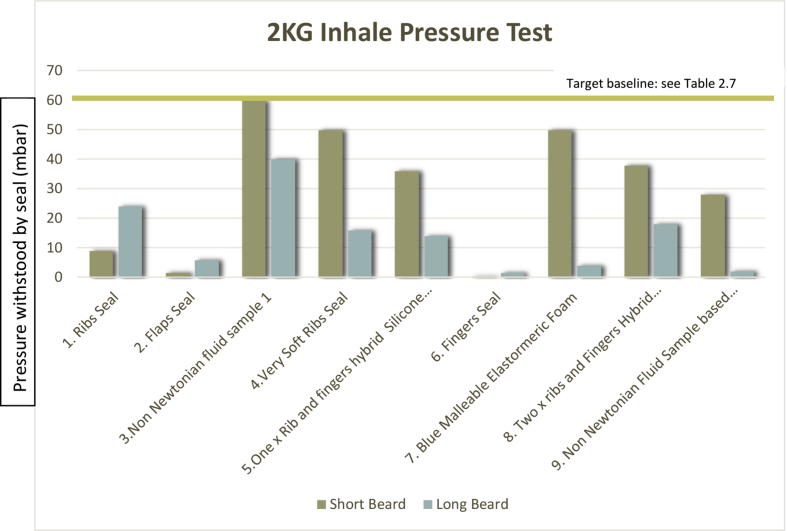

Unfortunately, none of the samples reached the desired benchmark sealing qualities of a commercially available half mask on a clean-shaven test subject (see the baseline of Fig. 17, Fig. 18, Fig. 19, Fig. 20). When the weight, pushing the seal into the facial hair sample, was increased to 2 kg, there was a marked improvement for Seal No 3: Non-Newtonian fluid seal 1. However, it still did not meet the minimum sealing requirements for a long beard. Second, the force that would be required on the face to make a good seal renders this material unusable [12].

Fig. 17.

Bar chart showing the results of the pressure tests with a 1-kg load pressing the seal into the facial hair sample (test subject inhaling).

Fig. 18.

Bar chart showing the results of the pressure test with a 1-kg load pressing the seal into the facial hair sample (test subject exhaling).

Fig. 19.

Bar chart showing the results of the pressure test with a 2-kg load pressing the seal into the facial hair sample (test subject inhaling).

Fig. 20.

Bar chart showing the results of the pressure test with a 2-kg load pressing the seal into the facial hair sample (test subject exhaling).

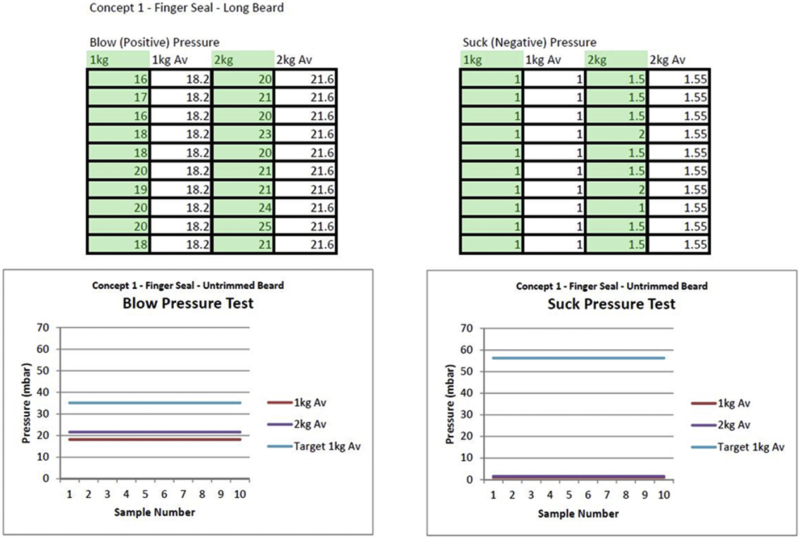

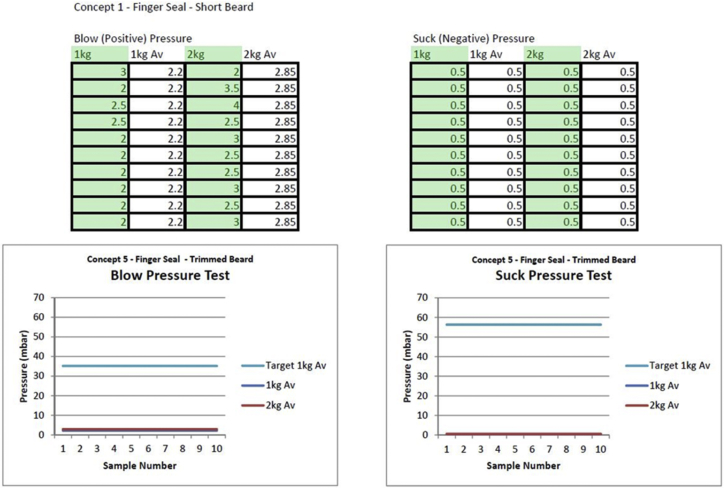

3.3. Results for fit testing

Each seal sample was tested 3 times with both long-beard and short-beard facial hair samples. Three readings were taken with the air pump switched off, and 3 readings taken with the air pump running, drawing air into the test rig chamber through the filters to mimic inhalation. Table 3 shows the best fit factor result for each sample for both long and short facial hair with the pump switched on and off. The minimum acceptable fit factor is 100 [11]. A full set of results for all tests can be seen in Appendix B.

Table 3.

Results from fit factor testing

| Seal design | Short beard |

Long beard |

||

|---|---|---|---|---|

| Best fit factor with no pump | Best fit factor with pump | Best fit factor with no pump | Best fit factor with pump | |

|

5.64 | 1.37 | 5.74 | 1.89 |

|

1.61 | 1.68 | 1.59 | 1.39 |

|

N/A | N/A | N/A | N/A |

|

9.81 | 3.19 | 18.5 | 3.82 |

|

4.56 | 2.73 | 5.42 | 2.43 |

|

1.56 | 1.21 | 1.53 | 1.39 |

|

N/A | N/A | N/A | N/A |

|

5.16 | 2.18 | 6.82 | 2.93 |

|

N/A | N/A | N/A | N/A |

3.4. Summary of fit testing

The fit factor results for all of the seal samples are very poor. As stipulated previously, the pass mark for a half mask in the UK is a minimum fit factor of 100 [11]. The best fit factors achieved during these tests, with the vacuum pump running, were 3.2 for the short beard and 3.8 for the long beard. This was achieved with the soft ribs sample (Seal 4). It is therefore conclusive that none of the samples demonstrated any potential for further development into 3D and to be incorporated into a mask.

3.5. Comparing the pressure test results with the conventional fit test results

After completion of the testing for both pressure testing and fit testing, the research team was in a position to compare the two techniques to ascertain if there is a direct correlation between the performance of the seals under both testing methods (as would be reasonably expected).

As the non-Newtonian fluid seal design (3 and 9) and the blue malleable elastomeric foam seal design (7) were not fit tested, they cannot be compared.

On the fit tests, the air pump only draws air through the filters and exhausts through its own exhaust port, and it does not mimic exhalation; therefore, only the results for “1 kg inhale” on the pressure tests can be reasonably compared with those of the fit tests. Two-kilogram tests were omitted from the fit testing.

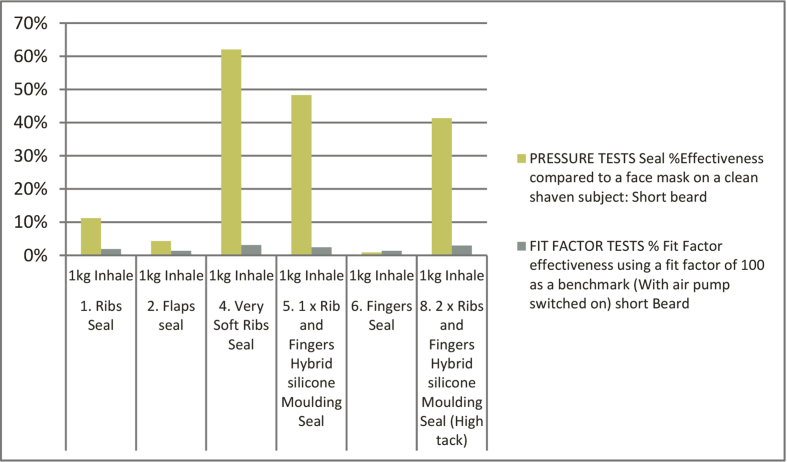

3.6. Devising a metric for seal effectiveness for comparison

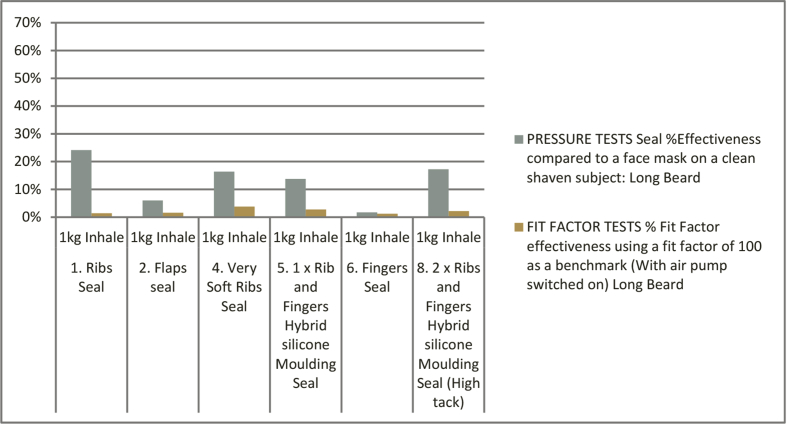

The metric that has been used for comparison is the percentage effectiveness when measured against a benchmark. In the case of the pressure testing of the seals, the benchmark is the pressure measured inside a commercially available mask when tested with a clean-shaven test subject (Fig. 17, Fig. 18, Fig. 19, Fig. 20). This was 58 mbar. The results for the “1 kg inhale” pressure tests for each flat seal are plotted against what percentage of this figure they achieved when tested. For the fit tests, the target fit factor was 100 (the minimum fit factor permitted in the UK). The results for the fit factor are therefore plotted against the percentage they achieved off a fit factor of 100.

The results for both pressure tests and fit factor tests are then plotted together on a bar chart. Although the juxtaposition of both percentages is not a fair comparison, it allows us to graphically ascertain whether the best-/worst-performing seals in the pressure tests are also the best-/worst-performing seals in the fit tests. Fig. 21, Fig. 22 show the comparison results for fit factor tests vs “1 kg inhale” pressure tests for both short- and long-beard samples, respectively.

Fig. 21.

Comparison of pressure test seal performance vs fit factor test performance (short beard).

Fig. 22.

Comparison of pressure test seal performance vs conventional fit test performance (long beard).

4. Discussion

As stated, the testing of flat seals using both pressure testing by the researchers and fit testing at the ITL has not yielded any promising results despite a wide range of different approaches being tried. If excess force is applied to the seal medium to press it against the facial hair, then a reasonable seal may be achieved, but this is not comfortable and therefore not viable, as it would cause extreme discomfort to the user of any mask containing this seal, with comfort being deemed as an important factor in mask design [13]. The seal materials that present the best seal properties under excess force also happen to be the ones that users would be unlikely to adopt because of their unpleasant feeling against the skin (such as the non-Newtonian fluid sample 3). The research team has considered that it may be possible that the properties of such materials could be replicated using elastomers such as SEBS. However, after discussions with suppliers of such materials, it became apparent that extreme quantities of plasticizers (in this case, oil) would be required. This would give the SEBS a wet, slimy feel similar to that of the non-Newtonian fluid. This could potentially irritate the skin. David et al. [13] state, “A plasticizer is a substance the addition of which to another material makes that material softer and more flexible. Most often plasticizers are materials which, when added to a polymer, cause an increase in the flexibility and workability”.

The results between pressure testing and fit factor testing show some correlation in that the better performing seals in the pressure tests have better fit factors (as expected), but there is no clear pattern. Seal 6 actually scored marginally better in the fit factor test than it did in the pressure tests; however, because the fit factor results are so low, it is difficult to make a true comparison.

The performance of each seal also differs in performance between the long and short beard, and the results for the long facial hair tests are universally poor, with only small differences between each test.

The research team concluded that sealing against the hair is extremely difficult to achieve. One might expect it is easier to seal against a short beard or stubble, but our research shows that this cannot be done without excess force being applied to the surface of the seal to pull it up against the face. While as a research exercise, it would be interesting to continue looking at different designs of seal and different materials; the researchers are sceptical that sealing against the hair can be viably achieved. There would also be significant costs in continuing this research because of design time, seal manufacturing costs, and time at third-party facilities that would be unlikely to yield positive results.

The pressure testing technique devised for use in this study did not prove as rigorous as fit testing; it did however prove a useful indicator of seal efficacy, and it could be used as a low-cost tool when developing new seal materials/designs, providing an early indication of the potential of a concept before committing further investment to it.

Conflict of interest

The authors declare no conflict of interest. This research was funded by a private company. That commissioned the researchers to undertake the project. The company has given express permission for the details of the research to be published. Details of the company can be shared upon request to the authors.

Appendix A. : Result tables and graphs from pressure testing

Appendix B. Result tables from fit testing

Ribs and fingers—high definiton:

Short beard

| No pump | Test 1 | Test 2 | Test 3 | Pump | Test 1 | Test 2 | Test 3 |

|---|---|---|---|---|---|---|---|

| In mask | 159 | 142 | 151 | In mask | 253 | 256 | 258 |

| Out mask | 623 | 647 | 621 | Out mask | 690 | 683 | 696 |

| Fit factor | 3.918239 | 4.556338 | 4.112583 | Fit factor | 2.727273 | 2.667969 | 2.697674 |

Long beard

| No pump | Test 1 | Test 2 | Test 3 | Pump | Test 1 | Test 2 | Test 3 |

|---|---|---|---|---|---|---|---|

| In mask | 276 | 184 | 195 | In mask | 413 | 410 | 416 |

| Out mask | 1012 | 998 | 996 | Out mask | 986 | 996 | 993 |

| Fit factor | 3.666667 | 5.423913 | 5.107692 | Fit factor | 2.387409 | 2.429268 | 2.387019 |

Ribs and fingers—low definition/tacky:

Short beard

| No pump | Test 1 | Test 2 | Test 3 | Pump | Test 1 | Test 2 | Test 3 |

|---|---|---|---|---|---|---|---|

| In mask | 121 | 129 | 131 | In mask | 304 | 303 | 312 |

| Out mask | 624 | 625 | 649 | Out mask | 662 | 660 | 663 |

| Fit factor | 5.157025 | 4.844961 | 4.954198 | Fit factor | 2.177632 | 2.178218 | 2.125 |

Long beard

| No pump | Test 1 | Test 2 | Test 3 | Pump | Test 1 | Test 2 | Test 3 |

|---|---|---|---|---|---|---|---|

| In mask | 189 | 154 | 154 | In mask | 354 | 357 | 357 |

| Out mask | 1067 | 1051 | 1047 | Out mask | 1036 | 1017 | 1026 |

| Fit factor | 5.645503 | 6.824675 | 6.798701 | Fit factor | 2.926554 | 2.84873 | 2.87395 |

Continuous ribs—soft

Short beard

| No pump | Test 1 | Test 2 | Test 3 | Pump | Test 1 | Test 2 | Test 3 |

|---|---|---|---|---|---|---|---|

| In mask | 86 | 72 | 70 | In mask | 226 | 221 | 223 |

| Out mask | 653 | 671 | 687 | Out mask | 707 | 707 | 707 |

| Fit factor | 7.593023 | 9.319444 | 9.814286 | Fit factor | 3.128319 | 3.199095 | 3.170404 |

Long beard

| No pump | Test 1 | Test 2 | Test 3 | Pump | Test 1 | Test 2 | Test 3 |

|---|---|---|---|---|---|---|---|

| In mask | 99 | 62 | 61 | In mask | 301 | 318 | 309 |

| Out mask | 1134 | 1126 | 1129 | Out mask | 1151 | 1165 | 1147 |

| Fit factor | 11.45455 | 18.16129 | 18.5082 | Fit factor | 3.82392 | 3.663522 | 3.711974 |

Continuous ribs—firm

Short beard

| No pump | Test 1 | Test 2 | Test 3 | Pump | Test 1 | Test 2 | Test 3 |

|---|---|---|---|---|---|---|---|

| In mask | 124 | 137 | 153 | In mask | 539 | 549 | 554 |

| Out mask | 699 | 678 | 704 | Out mask | 744 | 750 | 723 |

| Fit factor | 5.637097 | 4.948905 | 4.601307 | Fit factor | 1.380334 | 1.36612 | 1.305054 |

Long beard

| No pump | Test 1 | Test 2 | Test 3 | Pump | Test 1 | Test 2 | Test 3 |

|---|---|---|---|---|---|---|---|

| In mask | 205 | 199 | 202 | In mask | 576 | 585 | 572 |

| Out mask | 1142 | 1143 | 1104 | Out mask | 1091 | 1080 | 1081 |

| Fit factor | 5.570732 | 5.743719 | 5.465347 | Fit factor | 1.894097 | 1.846154 | 1.88986 |

Fingers

Short beard

| No pump | Test 1 | Test 2 | Test 3 | Pump | Test 1 | Test 2 | Test 3 |

|---|---|---|---|---|---|---|---|

| In mask | 505 | 475 | 485 | In mask | 663 | 699 | 710 |

| Out mask | 741 | 743 | 746 | Out mask | 803 | 846 | 862 |

| Fit factor | 1.467327 | 1.564211 | 1.538144 | Fit factor | 1.211161 | 1.2103 | 1.214085 |

Long beard

| No pump | Test 1 | Test 2 | Test 3 | Pump | Test 1 | Test 2 | Test 3 |

|---|---|---|---|---|---|---|---|

| In mask | 742 | 749 | 744 | In mask | 830 | 827 | 837 |

| Out mask | 1061 | 1093 | 1139 | Out mask | 1144 | 1146 | 1144 |

| Fit factor | 1.429919 | 1.459279 | 1.530914 | Fit factor | 1.378313 | 1.385732 | 1.366786 |

Flaps

Short beard

| No pump | Test 1 | Test 2 | Test 3 | Pump | Test 1 | Test 2 | Test 3 |

|---|---|---|---|---|---|---|---|

| In mask | 579 | 566 | 574 | In mask | 573 | 573 | 578 |

| Out mask | 924 | 911 | 913 | Out mask | 951 | 961 | 933 |

| Fit factor | 1.595855 | 1.609541 | 1.590592 | Fit factor | 1.659686 | 1.677138 | 1.614187 |

Long beard

| No pump | Test 1 | Test 2 | Test 3 | Pump | Test 1 | Test 2 | Test 3 |

|---|---|---|---|---|---|---|---|

| In mask | 607 | 577 | 596 | In mask | 741 | 744 | 756 |

| Out mask | 952 | 919 | 979 | Out mask | 1002 | 1037 | 1023 |

| Fit factor | 1.568369 | 1.592721 | 1.642617 | Fit factor | 1.352227 | 1.393817 | 1.353175 |

References

- 1.United States Department of Labor Occupational Safety and Health Administration [Internet] – Respirator types. [cited 2017 Aug 22]. Available from: https://www.osha.gov/video/respiratory_protection/resptypes_transcript.html.

- 2.http://www.face-fit.co.uk/fit-testing-with-the-portacount.asp. [Accessed 6 August 2017].

- 3.Frost S., Harding A.H. HSE Books; 2015. The effect of wearer stubble on the protection given by filtering facepieces class 3 (FFP3) and half masks RR1052 research report; pp. i–iii. [Google Scholar]

- 4.Health, Safety Executive L.5. 6th ed. HSE Books; 2013. The control of substances hazardous to Health regulations 2002 (as amended) approved code of practice and guidance; p. 41. ISBN 978 0 7176 6582 2. [Google Scholar]

- 5.Stobbe T.J., Daroza R.A., Watkins M.A. Facial hair and respirator fit: a review of the literature. Am Ind Hyg Assoc J. 1988;49(4):199. doi: 10.1080/15298668891379594. [DOI] [PubMed] [Google Scholar]

- 6.Oestenstad R.K., Dillion H.K., Perkins L.L. Distribution of face seal leak sites on a half-mask respirator and their association with facial dimensions. Am Ind Hyg Assoc J. 04/06/2010:285–290. doi: 10.1080/15298669091369664. [DOI] [PubMed] [Google Scholar]

- 7.Lee Wonsup, Jeong Jeongrim, Park Jangwoon, Jeon Eunjin, Kim Heeeun, Jung Daehan, Park Seikwon, You Heecheon. Analysis of the facial measurements of Korean Air Force pilots for oxygen mask design. Ergonomics. 2013;56(9):1451–1464. doi: 10.1080/00140139.2013.816376. [DOI] [PubMed] [Google Scholar]

- 8.Lei Zhipeng, Yang Jingzhou (James), Zhuang Ziqing. Headform and N95 filtering facepiece respirator interaction: contact pressure simulation and validation. J Occup Environ Hyg. 2012;9(1):46–58. doi: 10.1080/15459624.2011.635130. [DOI] [PubMed] [Google Scholar]

- 9.Protolabs Ltd. [Internet] Prototyping and low-volume production for the medical industry. [cited 2017 Aug 23]. Available at: https://www.protolabs.co.uk/media/751803/uk_med_wp_uk.pdf. [Accessed 23 August 2017] 17:50.

- 10.Plunket Associates [Internet] Flexible and rubber prototype and production parts. What are the options?. [cited 2017 Aug 23]. Available at: https://www.plunkettassociates.co.uk/materials/flexible.php.

- 11.Clayton M., Vaughan N. Fit for purpose? The role of fit testing in respiratory protection. Ann Occup Hyg. 1 October 2005;49(7):545–548. doi: 10.1093/annhyg/mei046. [DOI] [PubMed] [Google Scholar]

- 12.Shinn S. Vol. 76. Chilitons Industrial Safetey and Hygiene News; 9/29/2011. A tight and comfortable seal-the result you want from respirator fit testing. [Google Scholar]

- 13.David F., Cadogan D.F., Howick C.J. John Wiley & Sons, Inc.; 2000. Plasticizers, kirk-othmer encyclopedia of chemical technology; p. 1. ISBN: 9780471238966. [Google Scholar]