Abstract

In order to meet stringent fuel sulfur limits, ships are increasingly utilizing new fuels or, alternatively, scrubbers to reduce sulfur emissions from the combustion of sulfur-rich heavy fuel oil. The effects of these methods on particle emissions are important, because particle emissions from shipping traffic are known to have both climatic and health effects. In this study, the effects of lower sulfur level liquid fuels, natural gas (NG), and exhaust scrubbers on particulate mass (PM) and nonvolatile particle number (PN greater than 23 nm) emissions were studied by measurements in laboratory tests and in use. The fuel change to lower sulfur level fuels or to NG and the use of scrubbers significantly decreased the PM emissions. However, this was not directly linked with nonvolatile PN emission reduction, which should be taken into consideration when discussing the health effects of emitted particles. The lowest PM and PN emissions were measured when utilizing NG as fuel, indicating that the use of NG could be one way to comply with up-coming regulations for inland waterway vessels. Low PN levels were associated with low elemental carbon. However, a simultaneously observed methane slip should be taken into consideration when evaluating the climatic impacts of NG-fueled engines.

Introduction

Shipping is a very efficient way of transporting goods, and currently the majority of global trade volume is transported by sea. Although significant reductions in emissions of terrestrial vehicle engines have been achieved because of a series of environmental regulations and subsequent implementation of emission control techniques over the years, marine vessel emissions have not been thoroughly addressed. As a result, their relative contribution to air pollution has increased during recent years.1

Container ships, bulk carriers, and oil tankers, with slow-speed 2-stroke engines, consumed approximately 74% of all marine fuels in 2015, whereas ships having medium-speed 4-stroke engines (like most cruise ships) consumed approximately 23%.2 However, compared to containers and cargo vessels, cruise ship routes are generally nearer to coastlines, and these ships may spend more time at anchor or berthing, which can have a significant effect on local air quality.

Around 15% of global anthropogenic NOx and 5–8% of global SOx emissions can be attributed to shipping operations.3−5 In response, the International Maritime Organization (IMO) has introduced specific regulations to reduce shipping emissions of both pollutants. NOx limits have been set at a global level with Tier I and II standards, whereas lower limits are applicable to ships constructed after 2016 (Tier III) in NOx emission control areas (NECA). Tier III leads to an increase in the use of emission control devices, the most important of which is selective catalytic reduction (SCR). The SCR system utilizes a catalyst and externally fed ammonia to reduce NOx emissions. Catalysts in ship applications are usually vanadium-based, and an aqueous solution of urea is utilized as a source of ammonia (see, for example refs (6 and 7)).

In order to address SOx emissions, a global cap in fuel sulfur content (FSC) of marine fuels has been set at 0.5% m/m by 2020, compared to earlier permitted FSC levels of up to 3.5% m/m. In SOx emission control areas (SECA), the FSC is further limited to 0.1%. Higher sulfur levels are applicable only if an on-board sulfur scrubber is used. Different types of SOx scrubbers use fresh water (closed loop), seawater (open loop), a hybrid technology (either fresh or seawater), or dry removal agents. Alternatively, distillate fuels (ISO 8217), alcohols and biofuels, or gaseous fuels, primarily liquefied natural gas (LNG) with inherently low FSC, may be used for compliance with sulfur regulations. Of the distillate fuels, marine gas oil (MGO, free from residual fuel) is primarily used in marine engines with displacement less than 5 L per cylinder, whereas marine diesel oil (MDO, may have traces of residual fuel) is typically used in engines with greater than 5 L per cylinder. In addition, low sulfur residual marine fuel oils (also called hybrid fuels) may be utilized in ships operating in SECAs.

The IMO has not defined explicit emission limits for PM, despite its environmental and health implications. Shipping PM emissions are important especially in Asia, with China having 7 of the 10 largest ports in the world in terms of volume of transported goods.8 Liu et al.9 recently showed that during ship plume-influenced periods, shipping emissions contributed up to 20–30% of total PM2.5 within tens of kilometers of the coastal and riverside Shanghai regions. Chen et al.10 estimated that the contribution of shipping emissions to ambient PM2.5 concentrations over the urban area of Qingdao could exceed 20%. Corbett et al.5 estimated that on a global scale, shipping-related PM emissions are annually responsible for approximately 60 000 premature deaths related to cardiopulmonary and lung cancer diseases. Sofiev et al.11 recently estimated that total premature mortality due to shipping is much higher, and that even low-sulfur marine fuels still account for approximately 250 000 deaths annually. SOx regulations also have an implicit impact on PM, because they lead to decreased particulate sulfate emissions. A recent study by Sofiev et al.11 showed that low-sulfur fuels may provide pollution health benefits but with a climate trade-off, because the reduction in sulfate in PM decreases the climatic cooling effects of the exhaust aerosol. Although sulfate aerosol has a cooling effect, absorbent black carbon (BC) emissions warm the atmosphere and are not explicitly dependent on the FSC.12 BC deposition on ice and subsequent albedo change is especially important in the Arctic area, which has recently experienced an increase in shipping activity.13

The existing evidence discussed above suggests that global shipping PM emissions have a clear effect on climate, air pollution, and public health. PM emission levels are also significantly influenced by regulations addressing other pollutants. The present study provides evidence on how different options enabling ships to operate within SECAs affect the PM emissions of marine engines. The options examined include lower sulfur level fuels (liquid and gaseous) as well as on-board scrubbers. Both the PM and nonvolatile PN emissions are studied in experiments conducted on board two different ships and in a marine engine laboratory.

Experimental Section

Engines in Laboratory

Experiments with low-sulfur liquid fuels and natural gas were conducted in a marine engine laboratory. The first engine was a Wärtsilä Vasa 4R32, a four-cylinder medium-speed 4-stroke marine engine that was retrofitted to enable operation with natural gas in dual fuel (DF) mode. In this mode, a small quantity of liquid fuel is first injected to pilot combustion, which is then sustained by delivery of the main quantity of natural gas. The maximum power of this engine was 1400 kW. The engine was modified to run on natural gas in 2016, using state-of-the-art components of current commercial natural gas marine engines. The modification of the engine included, for example, installing gas admission valves on the cylinder heads and replacing the cylinder heads as well as the liners, pistons, camshaft, and turbocharger. In addition, the engine control system was updated and a pilot fuel line with a high-pressure pilot fuel pump was added. This engine was tested with the 40% and 85% loads that are considered representative of in-harbor maneuvering and open-seas operation, respectively. Emissions of PM and PN were also characterized from a second DF engine on the test bed. This was a 2017 production series Wärtsilä 20DF (medium speed, 4-stroke engine), which is of similar size to the 4R32 engine and delivers a maximum power output of 1000 kW.

Engines and Scrubbers on Board

Emission measurements were also made on board two ships during regular cruising conditions. A modern cruise ship equipped with SCR and a hybrid sulfur scrubber was first tested. The hybrid scrubber used closed loop scrubbing during harbor operation, whereas seawater scrubbing was used on the open sea. PM and PN emissions were measured from two main engines (E1 and E2) at constant engine loads of 40% and 75%. Both engines were medium-speed, 4-stroke, modern engines. For E1, the measurements were made upstream (engine outlet) and downstream of the scrubber. The E2 engine was equipped with the SCR placed upstream of the scrubber, so the measurement points were downstream of the scrubber and downstream of the SCR, before the scrubber. The second ship was a RoPax vessel (built for freight vehicle transport along with passenger accommodation) equipped with a diesel oxidation catalyst (DOC) and an open loop seawater-operating scrubber. PM and PN from one of its main engines (a medium-speed, 4-stroke engine, E3) were measured upstream of the scrubber (thus downstream of the DOC) and downstream of the scrubber. The ship operated normally, and the engine load varied during the cruise mainly in the range of 63–66% of maximum load. A schematic layout of all tested engines and related after-treatment is presented in the Supporting Information (Figure S1).

Fuels

Table 1 contains the main specifications of all liquid fuels used in the measurement campaigns. Two different liquid fuels (MDO and MGO) were used in the laboratory experiments with the Wärtsilä Vasa 4R32 engine when operated in liquid-fuel mode. The MDO had an FSC of 0.0822% and thus fulfilled the SECA requirements (limit 0.1% S), whereas the MGO was of even higher quality (on-road diesel quality, EN 590), with a very low sulfur level. High-quality MGO with a very low sulfur level is not widely utilized in ships today, but it was selected here based more on its role as a pilot in DF mode. In DF mode, the main fuel was compressed natural gas (CNG) and the pilot injection was with MGO according to the engine manufacturer’s instruction. The CNG had a high methane content (volumetric composition: 96.4% methane, 2.3% ethane, 0.35% propane, 0.15% other hydrocarbons, 0.57% nitrogen, and 0.21% carbon dioxide). In DF mode, the pilot fuel quantity was adjusted to 1.2% and 3.8% of the total fuel mass flow for 85% and 40% loads, respectively. LNG was used as the main fuel in the 20DF engine, because there was no natural gas distribution system available for that engine. The LNG used contained 90% methane and approximately 9% ethane. MGO was also used as pilot in this case, with an amount of approximately 2% of the total fuel mass flow for 75% engine load.

Table 1. Main Specifications of Liquid Fuels Used in the Measurement Campaigns.

| parameter | unit | MGO <0.001% S | MDO <0.1% S | HFO <0.7% S | MGO <0.1% S | HFO <2% S |

|---|---|---|---|---|---|---|

| use | engine test bed | cruise ship | RoPax | |||

| engine | 4R32 and 20DF | 4R32 | E1 and E2 | E2 | E3 | |

| density (15 °C) | kg/m3 | 836 | 879 | 873 | 873 | 984 |

| viscosity (40 °C) | mm2/s | 2.94 | 4.07 | 886 | 3.87 | 625 |

| heating value, lower | MJ/kg | 42.8 | 42.2 | 40.8 | 42.0 | 40.5 |

| flash point | °C | 66 | 78 | 146 | 81 | 109 |

| sulfur | mg/kg | 6.1 | 822 | 6520 | 780 | 18600 |

| ash | % (m/m) | <0.005 | <0.005 | <0.005 | <0.005 | 0.165 |

| carbon | % (m/m) | 86.2 | 87.4 | 87.7 | 87.9 | 86.6 |

| hydrogen | % (m/m) | 13.9 | 12.5 | 11.5 | 12.8 | 10.7 |

| nitrogen | mg/kg | 40.6 | 367 | 2490 | 5400 | |

| Ni | mg/kg | <0.50 | <0.50 | 12.4 | <0.50 | 21.1 |

| V | mg/kg | <0.50 | <0.50 | 17.2 | <0.50 | 110 |

The cruise ship, equipped with a scrubber to meet SECA requirements, operated on heavy-fuel oil (HFO) with 0.65% sulfur content as a fuel (in all its engines). For comparison, the E2 engine was also operated on 0.10% FSC MGO for a period of 9 h with 40% load to conduct emission measurements. The RoPax ship operated on 1.9% FSC HFO.

Sampling and Analysis

Exhaust PM was sampled according to the ISO Standard 8178-1:2006, using an AVL Smart Sampler (or with a consistent in-house sampling system which was utilized in the case of the RoPax ship) that draws up and dilutes a sample of the exhaust flow. This is also the method specified for PM emissions sampling from inland waterway vessels in the EU, the only category of vessels for which PM regulations exist. According to this standard, PM is quantified as the mass of any material collected on a filter after diluting exhaust gas with clean, filtered air to a temperature greater than 42 °C and less than or equal to 52 °C, as measured at a point immediately upstream of the filter. The standard also defines a minimum dilution ratio of 4:1, but no maximum, before PM sampling is conducted. A schematic figure of the PM sampling system can be found in the Supporting Information (Figure S2). Smart Sampler and the in-house sampling system both had a flow-based control system for the dilution ratio. The correct filter temperature was achieved by heating the dilution air and placing the filter holders inside a heated cabinet. In the post scrubber measurements, a heated measurement probe and heated transfer line were utilized prior to the dilution tunnel.

Because the dilution ratio variation can result in significant changes in PM,14,15 the dilution ratio was kept constant during the measurements, in addition to what the standard prescribed. We selected a DR of 10:1, which already significantly decreases the sensitivity of semivolatile material condensation while at the same time minimizing sampling duration. This is also in the same range as used for exhaust PM of on-road vehicles16 and provides a common reference for comparing vehicle and vessel PM levels. Samples were collected on TX40HI20-WW filters (Ø 47 mm), with collection times ranging from 5 to 30 min. Measurements were repeated five times for each measurement point.

The concentrations of sulfate, organic carbon (OC), and elemental carbon (EC) were analyzed from the PM filter samples. Sulfate concentration was determined by electrophoresis from water and isopropanol mixture extracts. The OC/EC samples were collected on quartz filters, and the analysis was performed by the thermal-optical method.17 Sunset Laboratories Inc.’s OC/EC analyzer mode 4L was used, and following ref (18), the EUSAAR2 temperature program was applied.

The PN measurement method used in this study originates from the Particle Measurement Programme (PMP) work and considers only nonvolatile particles with a diameter greater than 23 nm. This method is also mandated by the upcoming Stage V regulation for inland waterway vessels in 2020, which requires compliance with a nonvolatile PN limit. A Dekati Engine Exhaust Diluter (DEED) was used for PN sample conditioning in the current study. The system consists of two ejector diluters, providing a total dilution ratio of 100:1 in the case of NG fuel and 1000:1 in the case of diesel fuels, and an evaporation tube between the two dilution units (see Figure S1 in the Supporting Information). The temperature of the first ejector was ∼200 °C, and the temperature at the outlet of the DEED unit was below 35 °C. PN>23nm concentrations were determined with an Airmodus A23 Condensation Particle Counter (CPC). The DR setting in the case of nonvolatile PN sampling is much less critical than in the case of PM mass because of the elimination of condensation dynamics in the former case. The relatively high DR, which is recommended for road vehicles, was also adopted in this study to decrease coagulation dynamics and the corresponding PN concentration sensitivity to residence time before counting.19 The DR setting would be even less relevant if nonvolatile PM rather than PN was to be characterized, as in the case of jet exhaust sampling, where DRs as low as 10 are being implemented.20

The concentrations of NOx (NO and NO2) in exhaust emissions were measured with a chemiluminescence detector (CLD), and carbon monoxide (CO) and carbon dioxide (CO2) were measured with a nondispersive infrared (NDIR) analyzer. Light hydrocarbon components were speciated with a gas chromatograph when natural gas was used as a fuel. A flame ionization detector (FID) was utilized in some of the tests to measure the total hydrocarbon (THC) content in the exhaust. Concentrations of sulfur dioxide (SO2) and water were measured with Fourier transform infrared spectroscopy (FTIR).

Results and Discussion

PM and PN Emissions

Liquid Fuels

HFO was the fuel of choice for the majority of shipping operations before the global sulfur cap enforcement. In addition to high FSC, this fuel may contain large amounts of metals, such as V and Ni, and other ash components, compared to distillate fuels that contain practically no metals or ash (Table 1). Earlier experiments performed on the same Vasa 4R32 engine used in the current study demonstrated that marine engine PM emissions depend heavily on fuel quality. At 75% load, PM decreased from 850 mg/kWh, when using 2.5% FSC HFO, to 280 mg/kWh with 1% FSC HFO,12 and down to 60 mg/kWh when using a light fuel oil (similar to MGO in the present study).14

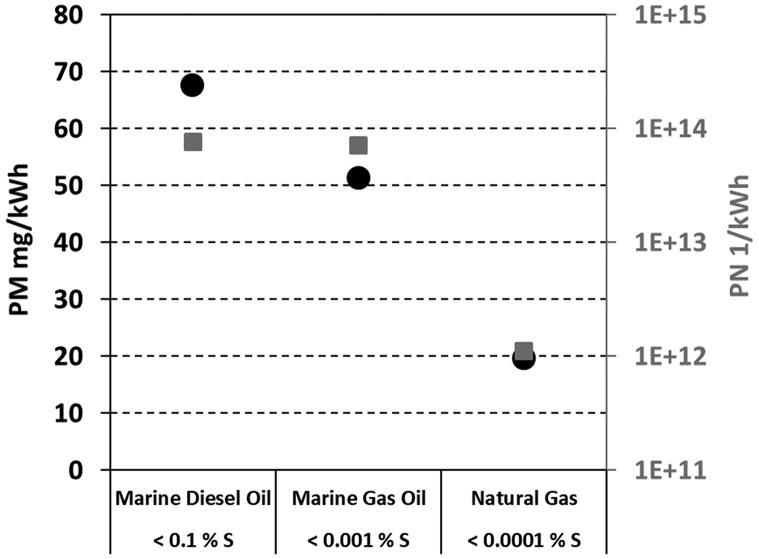

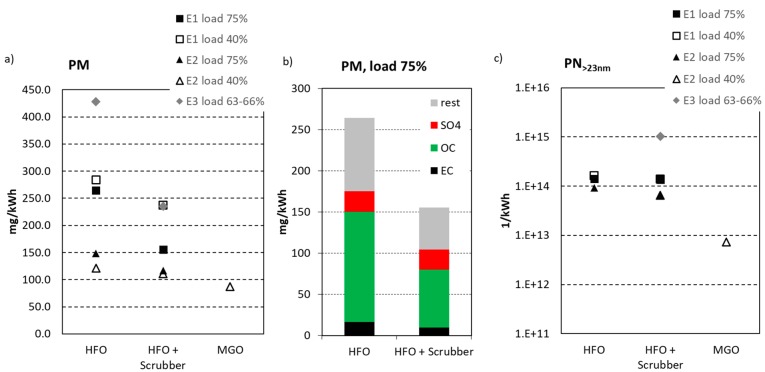

The present results confirm previous evidence. Figure 1a presents PM emissions of the two laboratory engines fueled with NG, MDO, and MGO on the test bed. PM with MGO at 85% load was at a level similar to what has been measured previously at 75% load.14 Earlier evidence using HFO has shown that sulfate and associated water comprise more than half of total PM.12,21 With the lighter fuels used in the present study, sulfate accounted for only a minor fraction of total PM (Figure 1b); even in the case of MDO, the sulfate comprised only 4% of the total PM in the 85% load case. EC (18–19% of total PM) and OC (60–63% of PM) comprised the majority of PM for MDO and MGO. The “rest” PM fractions were calculated by subtracting the EC, OC, and sulfate amounts from the total PM. This rest fraction was not further specified in the present study, but typically it comprises water as well as fuel and lube-derived ash.

Figure 1.

(a) PM and (c) nonvolatile PN>23nm emissions measured from 40% load mode and 85% load mode with the 4R32 DF engine utilizing MDO, MGO, and NG fuels and from 75% load with the 20DF engine utilizing MGO and LNG fuels (marked load 75% p). Error bars show the standard deviation of a minimum of five measurements. (b) PM composition of exhaust of the 4R32 DF engine fueled with MDO, MGO, and NG at 85% load.

The particle emission results also show that the MGO produced 17–25% less PM than the MDO, but without any measurable effects on PN>23nm (see Figure 1c). Other studies (e.g., refs (21−24)) concluded that liquid fuel change has the potential to decrease particle emissions from ships, although they also concluded that such reductions are not only due to FSC reduction. Additionally, even if reduced sulfur content of the fuel efficiently reduced the PM emission, the BC emissions were not necessarily reduced.12 Khan et al.22 and Zetterdahl et al.23 both compared emissions of HFO (higher S) to a lower sulfur level fuel. They both observed significant reductions in PM mass when changing to lower sulfur content fuel. Zetterdahl et al. observed 67% reduction in PM mass and smaller average particle size when changing to low sulfur level fuel, but the total particle number was found to be on similar levels for both fuels. In the present study, we also showed a PM decrease with fuel sulfur decrease, although no difference was found in the PN level.

Effect of Engine Load

Engine load was found to affect the work-specific PM emissions for the laboratory engine 4R32. PM emissions at low load (40%) were higher than when the load was increased, with all of the fuels used. Emission rates at low load were also more variable than at higher load, as indicated by the error bars in Figure 1a. In DF operation, the quantity of liquid fuel used per unit of energy was higher at low load (3.8% of main fuel) compared to high load (1.2% of main fuel), which may have contributed to the higher energy-specific PM emissions at low load. Marine engines are generally optimized for loads in the 75–90% range, which is the typical operation range for open-seas sailing. In ports, low loads are required for maneuvering and for berthing. Although in-port emissions make only a small contribution to the total emissions of any vessel, they are important for local air quality and associated health effects on populations in the vicinity of ports.25 This means that any future regulation initiatives on PM emissions control from ships will require that emissions are also regulated at low-load operation.

Natural Gas

DF operation (with NG as main fuel) resulted in the lowest PM levels for both engines, at a level 63–69% lower than the MGO and 72–75% lower than the MDO. When shifting to DF operation, only traces of EC were observed and OC accounted for 83% of PM (Figure 1b). The impact of NG use was actually magnified when nonvolatile PN>23nm was considered, with PN levels 98–99% lower than when using liquid fuels (Figure 1c). Particles in this size range are often assumed to represent the soot mode that accounts for the major part of EC. The observed low PN>23nm for NG is consistent with the very low levels of EC measured for this particular fuel. The low soot emissions with NG also explain why changes in the load when in DF mode (85% load compared to 40% load with the 4R32 engine, Figure 1c) had practically no effect on the nonvolatile particle number, which is different from what is observed with liquid fuels.

Differences under DF mode are observed when comparing the retrofitted engine with the production-series engines; the latter were significantly lower in terms of both PM and PN>23nm emissions than the retrofitted engine. In addition to the impact of engine design, load level, and NG composition differences between the two engines, the lubricating oil might be a significant contributor to the observed differences, as observed in previous studies.26−29 The two engines operated with lubricating oils of different specifications and, presumably, different consumption rates, although lubrication oil consumption was not measured in any of the engines. There were also differences in the pilot fuel amounts (i.e., 2% pilot fuel injection at 75% load of the production series engines compared to the 1.2% ratio used at 85% load of the retrofitted engine), but these do not provide an explanation for the observed lower PN>23nm emissions of the production engine.

PN>23nm Discussion

The level of PN>23nm emissions from marine engines is important in view of the upcoming EU regulations for inland waterway vessels. The Stage V regulation, applicable from 2020 on, has introduced the requirement of PN>23nm remaining below 1012 kWh–1 over a testing procedure involving several steady-state modes and weighing factors. Although we have not tested the complete range of conditions required by the regulation, the orders of magnitude of PN collected are indicative of the potential of different technology options.

PN>23nm emissions were well beyond the limit with all of the tested liquid fuels, almost 2 orders of magnitude or higher than the limit, with both engines tested. The retrofitted engine (with NG as the main fuel) produced 1.1 × 1012 kWh–1 and 1.0 × 1012 kWh–1 at 85% and 40% load, respectively, thus being within the range of regulatory requirements. The PN>23nm emissions of the production-series engine at 75% load with LNG was 1.3 × 1011 kWh–1, which was actually much lower than the limit (1012 kWh–1). These results indicate that the use of natural gas as a fuel for marine and inland waterway vessels could be one way to comply with upcoming regulations. The low nonvolatile PN>23nm level is also associated with low EC concentration (seen Figure 1). This strongly indicates that the regulation of PN>23nm may also be effective in controlling EC (and, correspondingly, BC) emissions of vessels and may thus contribute to decreasing the shipping impact on climate forcing. Figure 1c shows that light liquid fuel effects on PN>23nm were more marginal.

The observations related to fuel effects on PN>23nm emissions in this study refer to nonvolatile particles above 23 nm in size and could be different if smaller particles and/or semivolatile particles were included in the analysis. Anderson et al.28 studied total particle emissions from an LNG-powered ship and also observed that LNG resulted in significantly lower PN numbers than when MGO was used. However, they also found that a significant fraction of particles were in the sub-23 nm size range. Alanen et al.29 observed a remarkable amount of sub-23 nm nanoparticles with diameters down to only a few nanometers when using NG. Marine exhaust PN conclusions should therefore be observed carefully in relation to the particle population to which they refer.

Scrubbers on Board

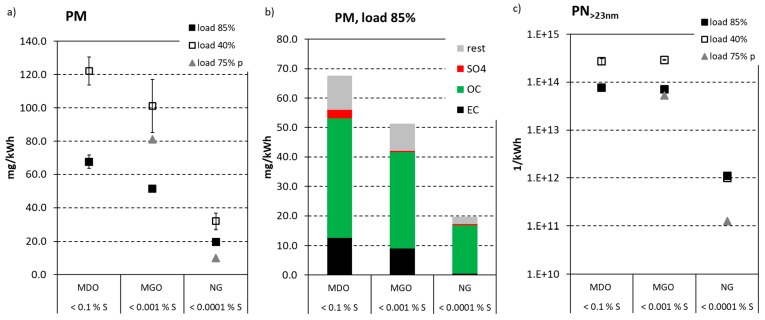

The results of PM and PN>23nm measurements conducted on board the two different ships are presented in Figure 2. The PM level from the E3 engine (RoPax ship) during regular vessel operation with the engine load varying between 63% and 66% was the highest. In this case, the FSC of the HFO used was significantly higher than that of the HFO used on the cruise ship (engines E1 and E2). Operation of the scrubber was found to decrease the PM level by 21–45% in the high load cases (E1, E2, and E3, loads 63–66% and 75%) and 8–17% at low load (40%, E1 and E2). The PM composition analysis (Figure 2b) showed that the organic carbon was reduced by the scrubber. Interestingly, sulfate aerosol was at the same level both upstream and downstream of the scrubber, whereas EC seemed to be decreased by passage over the scrubber. The “rest” part of PM (consisting typically of sulfate-associated water and ash) was almost halved by the scrubber.

Figure 2.

(a) PM and (c) nonvolatile PN>23nm emissions measured on board two different ships (i.e., engines E1 and E2 on a cruise ship and E3 on a RoPax). (b) PM composition from measurements made on engine E1 at 75% load. Note: In the case of engine E3, the HFO differed from the HFO utilized with engines E2 and E1 (see Table 1).

The impact of the scrubber on PM emitted from the E1 and E2 engines was different, despite the fact that both engines were on the same ship and utilizing the same scrubber. One reason for this is that sampling from the E2 was conducted downstream of the SCR to which the engine was connected. First, the SCR by itself was most probably having a positive impact on PM emissions. The SCR system has been shown to have an impact on PM, for example, by decreasing the organic fraction.6 The additional benefit that the scrubber can offer is therefore lower than the improvement it offers over engine-out PM emissions.

Even though PM clearly decreased over the scrubber, its effect on the nonvolatile PN was less clear. In the case of E1, the PM decrease was 41% in 75% load mode, whereas there was practically no change in the PN>23nm level. On the other hand, in the case of E2 and 75% load, the PM decrease was 21% and the PN>23nm decrease was observed to be 30%. However, bearing in mind that the standard deviation for PN measurements made in the laboratory (with MDO fuel) was ±15–18%, this PN decrease is considered to be minor.

Use of MGO in engine E2 led to lower PM and PN>23nm concentrations than were observed downstream of the scrubber with HFO fuel. However, this is only one example (one MGO fuel, one engine, and one load mode) and cannot be presented as a general conclusion.

Fridell and Salo30 also studied the particle emissions from a marine engine equipped with a scrubber (open-loop wet scrubber using seawater). They found the total number of particles to be reduced by 92% in the scrubber, while the solid fraction was reduced by 48%. The PM was also significantly decreased; that is, about 75% of the total PM was captured by the scrubber. These are all higher reduction values than in the present study, and there might be several reasons for this, for example, differences in engines, fuels, and/or scrubbers. Moreover, one big difference is the particle measurement method. Fridell and Salo measured the PN with an engine exhaust particle sizer with a size range of 5.6–560 nm therefore also covering particles below 23 nm size, which were not measured in the present study. Several studies performed with liquid fuels report particle size distributions from marine engines suggesting that a share of nonvolatile PN resides below the 23 nm level.28,31−33 In addition to the PN 23 nm limit, the results of Ntziachristos et al.14,21 show that even when conducted following the ISO 8178 protocol, the dilution system can have a significant effect on the measured PM result. At minimum, the dilution ratio range allowed should be more strictly defined in order to obtain comparable results.

To the authors’ knowledge, the standard PM and nonvolatile PN measurement methods were utilized for the first time in the present study in studying ship emissions with different fuels and after-treatment systems. Furthermore, the dilution conditions were strictly controlled in order to make comparison of the results of different measurement campaigns possible both on board and in engine laboratories.

Gaseous Exhaust Emissions

Liquid Fuels and Natural Gas

With the laboratory engine (4R32), gaseous emissions were also studied (Table 2). Lower levels of NOx were measured with NG compared to MGO or MDO. This was most probably due to the homogeneous premixing of the gas with air and the lower combustion temperature of NG (in lean burn conditions). As expected, no SO2 was detected in the exhaust gas when utilizing either NG or MGO (<0.001% S). The assumption that all the sulfur in fuel and lubricating oil ends up in SO2 in the exhaust results in below 2 ppm in the MGO case and even less in the NG case. With the FTIR, it is possible to measure accurately only levels above 2 ppm.

Table 2. Gaseous Emissions Measured from the Marine Laboratory Engine 4R32a.

| fuel | load (%) | NOx (g/kWh) | SO2 (g/kWh) | CO2 (g/kWh) | CO (g/kWh) | THC (g/kWh) | CH4 (g/kWh) | C2H6 (g/kWh) | C3H8 (g/kWh) |

|---|---|---|---|---|---|---|---|---|---|

| natural gas | 85 | 2.7 | bd | 420.0 | 1.7 | – | 5.6 | 0.24 | 0.05 |

| 40 | 3.6 | bd | 484.3 | 3.8 | – | 13.8 | 0.62 | 0.05 | |

| MGO | 85 | 9.0 | bd | 582.2 | 0.3 | 0.4 | bd | bd | bd |

| 40 | 10.1 | bd | 645.8 | 0.8 | 0.5 | bd | bd | bd | |

| MDO | 85 | 10.0 | 0.31 | 611.1 | 0.4 | 0.3 | bd | bd | bd |

| 40 | 11.2 | 0.35 | 639.1 | 0.8 | 0.4 | bd | bd | bd |

bd, below detection limit; −, no measurement. The detection limit for CH4 was 10 ppm, and for C2H6, C3H8, and SO2, the detection limit was 2 ppm.

Compared to diesel fuels the CO2 emission was lower with NG use, which is because NG is mainly composed of methane, with a higher hydrogen-to-carbon (H/C) ratio compared to diesel. The carbon monoxide and hydrocarbon emissions, on the other hand, were higher with the NG compared to diesel fuels. These results are in line with those of other studies.28,34−36 CO and hydrocarbon emission levels were found to depend largely on engine load; higher levels were measured at lower loads of 40%.

Because natural gas is mainly composed of methane, one could expect to have some methane emissions if small quantities of gas escape from the combustion process. This was found to be true in the present study. In addition to methane, smaller quantities of ethane and propane were also found from the engine exhaust when running on natural gas (see Table 2). No methane, ethane, or propane were detected from the engine exhaust when running on MGO or MDO. However, the measured total hydrocarbon emission was 0.3–0.5 g/kWh when running on MGO and MDO, probably consisting only of longer chain hydrocarbon components.

Because methane is a greenhouse gas, its emissions should be minimized. The methane emission levels measured in the present study were relatively high, and it should be noted that these might not be typical values for the modern DF engines in production today. The measured methane levels were also higher than previously measured on board an LNG ship.28 The difference between these two studies could be due to the different engine sizes. The engine on board was a 7600 kW engine with a larger cylinder and lower speed, meaning that there was more time for the combustion compared to the engine of the present study. In addition, the combustion chamber design was probably different, resulting in differences in the NG amounts escaping the cylinder. According to refs (37 and 38), methane emissions could be reduced, for example, by better fuel mixing conditions, by improvements in combustion chamber design, and by reducing crevices. One option could also be the use of oxidation catalysts, but further research is needed to solve the long-term performance of methane catalysts.

Natural gas is a flexible and cost-effective way to support the decarbonization of transport and to tackle air quality issues. The low levels of PM and PN measured in the present study also support the use of NG. However, as shown in the study, there is also a challenge with methane slip, which needs to be solved in order not to compromise the climate benefit gained from the CO2 decrease. If available, biogas would be one possible attractive fuel in future marine engines aiming to reduce greenhouse gas emissions by 50% by 2050, as presented recently by IMO.

Scrubbers on Board

The NOx levels were found to be significantly lower with the E2 engine than with the E1 engine of the same ship (or E3 in the other ship) (Table 3). The E2 engine was equipped with SCR, which explains this difference. The somewhat higher CO levels from the E2 engine could also be influenced by the SCR, because CO has been found to increase in SCR-equipped applications because of thermal decomposition of urea and/or partial oxidation of HC compounds over the catalyst.39

Table 3. Gaseous Emissions Measured on Board Downstream of Scrubbers and with MGO without a Scrubber.

| ship | fuel | engine and after-treatment | load (%) | NOx (g/kWh) | SO2 (g/kWh) | CO2 (g/kWh) | CO (g/kWh) |

|---|---|---|---|---|---|---|---|

| cruise | HFO | E1 + scrubber | 75 | 11.4 | 0.033 | 620 | 0.34 |

| 40 | 19.5 | 0.019 | 653 | 0.61 | |||

| cruise | HFO | E2 + SCR + scrubber | 75 | 1.2 | 0.006 | 627 | 0.56 |

| 40 | 5 | 0.013 | 650 | 0.94 | |||

| cruise | MGO | E2 + SCR | 40 | 4.3 | 0.327 | 647 | 1.44 |

| RoPax | HFO | E3 + scrubber | 63–66 | 15 | 0.07 | 544 | 0.16 |

The SO2 level measured from engine E2 with MGO fuel (fulfilling the SECA limitations with 780 ppm of S level) was 0.327 g/kWh at 40% engine load. In the same mode, the SO2 level measured downstream of the scrubber (HFO fuel) was remarkably lower, resulting in a level of 0.013 g/kWh (see Table 3). Furthermore, in the case of the E3 engine, a very low level of SO2 of 0.07 g/kWh was observed downstream of the scrubber when utilizing HFO with FSC of 1.9%. As a reference, FSC should be well below 0.02% in order to maintain the theoretical SO2 output below 0.07 g/kWh, meaning an SO2 level 2 orders of magnitude lower compared to the 1.9% S HFO fuel utilization (without any scrubber). The theoretical value is based on the assumption that all the sulfur from the fuel ends up as SO2 in the exhaust. These results confirm that the scrubber was working effectively in decreasing the SOx level, as intended. The lower PM levels measured with scrubbers in the present study also favor the utilization of scrubbers, but the effect of a scrubber on PN was not straightforward. With the growing trend in utilization of scrubbers, further studies are needed to clarify their effects on particle number and size, especially when discussing the health impacts of ship emissions.

Acknowledgments

This study was part of several projects: HERE, SEA-EFFECTS BC, and INTENS, funded by Business Finland and several Finnish companies, and Hercules-2 with funding from the European Union’s Horizon 2020 research and innovation programme under Grant Agreement No. 634135.

Supporting Information Available

The Supporting Information is available free of charge on the ACS Publications website at DOI: 10.1021/acs.est.8b05555.

Schematic of the layout of all engines tested on the engine test bed and on board (Figure S1) and PM measurement system according to ISO8178:2006 and the “PMP” PN (nonvolatiles >23) measurement system (Figure S2) (PDF)

The authors declare no competing financial interest.

This article published February 28, 2019 with an error in the abstract artwork. The correct file published March 6, 2019.

Supplementary Material

References

- Viana M.; Hammingh P.; Colette A.; Querol X.; Degraeuwe B.; de Vlieger I.; van Aardenne J. Impact of Maritime Transport Emissions on Coastal Air Quality in Europe. Atmos. Environ. 2014, 90, 96–105. 10.1016/j.atmosenv.2014.03.046. [DOI] [Google Scholar]

- Comer B.; Olmer N.; Mao X.; Roy B.; Rutherford D. A. N.. Black Carbon Emissions and Fuel Use in Global Shipping, 2015; 2017.

- Viana M.; Hammingh P.; Colette A.; Querol X.; Degraeuwe B.; de Vlieger I.; van Aardenne J. Impact of Maritime Transport Emissions on Coastal Air Quality in Europe. Atmos. Environ. 2014, 90, 96–105. 10.1016/j.atmosenv.2014.03.046. [DOI] [Google Scholar]

- Eyring V.; Kohler H. W.; van Aardenne J.; Lauer A. Emissions from International Shipping: 1. The Last 50 Years. J. Geophys. Res. 2005, 110, 1–12. 10.1029/2004JD005619. [DOI] [Google Scholar]

- Corbett J. J.; Winebrake J. J.; Green E. H.; Kasibhatla P.; Eyring V.; Lauer A. Mortality from Ship Emissions: A Global Assessment. Environ. Sci. Technol. 2007, 41 (24), 8512–8518. 10.1021/es071686z. [DOI] [PubMed] [Google Scholar]

- Lehtoranta K.; Vesala H.; Koponen P.; Korhonen S. Selective Catalytic Reduction Operation with Heavy Fuel Oil: NO X NH 3 and Particle Emissions. Environ. Sci. Technol. 2015, 49 (7), 4735–4741. 10.1021/es506185x. [DOI] [PubMed] [Google Scholar]

- Magnusson M.; Fridell E.; Ingelsten H. H. The Influence of Sulfur Dioxide and Water on the Performance of a Marine SCR Catalyst. Appl. Catal., B 2012, 111–112, 20–26. 10.1016/j.apcatb.2011.09.010. [DOI] [Google Scholar]

- Zhang Y.; Yang X.; Brown R.; Yang L.; Morawska L.; Ristovski Z.; Fu Q.; Huang C. Shipping Emissions and Their Impacts on Air Quality in China. Sci. Total Environ. 2017, 581–582, 186–198. 10.1016/j.scitotenv.2016.12.098. [DOI] [PubMed] [Google Scholar]

- Liu Z.; Lu X.; Feng J.; Fan Q.; Zhang Y.; Yang X. Influence of Ship Emissions on Urban Air Quality: A Comprehensive Study Using Highly Time-Resolved Online Measurements and Numerical Simulation in Shanghai. Environ. Sci. Technol. 2017, 51 (1), 202–211. 10.1021/acs.est.6b03834. [DOI] [PubMed] [Google Scholar]

- Chen D.; Wang X.; Nelson P.; Li Y.; Zhao N.; Zhao Y.; Lang J.; Zhou Y.; Guo X. Ship Emission Inventory and Its Impact on the PM2.5 Air Pollution in Qingdao Port, North China. Atmos. Environ. 2017, 166, 351–361. 10.1016/j.atmosenv.2017.07.021. [DOI] [Google Scholar]

- Sofiev M.; Winebrake J. J.; Johansson L.; Carr E. W.; Prank M.; Soares J.; Vira J.; Kouznetsov R.; Jalkanen J.-P.; Corbett J. J. Cleaner Fuels for Ships Provide Public Health Benefits with Climate Tradeoffs. Nat. Commun. 2018, 9 (1), 406. 10.1038/s41467-017-02774-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Aakko-Saksa P.; Murtonen T.; Vesala H.; Koponen P.; Nyyssönen S.; Puustinen H.; Lehtoranta K.; Timonen H.; Teinilä K.; Karjalainen P.; et al. Black Carbon Measurements Using Different Marine Fuels. 28th CIMAC World Congress; 2016; Paper 068.

- Winther M.; Christensen J.; Plejdrup M.; Ravn E.; Eriksson O.; Kristensen H. Emission Inventories for Ships in the Arctic Based on Satellite Sampled AIS Data. Atmos. Environ. 2014, 91, 1–14. 10.1016/j.atmosenv.2014.03.006. [DOI] [Google Scholar]

- Ntziachristos L.; Saukko E.; Rönkkö T.; Lehtoranta K.; Timonen H.; Hillamo R.; Keskinen J.. Impact of Sampling Conditions and Procedure on Particulate Matter Emissions from a Marine Diesel Engine. 28th CIMAC World Congress; 2016; Paper 165.

- Ristimaki J.; Hellen G.; Lappi M.. Chemical and Physical Characterization of Exhaust Particulate Matter from a Marine Medium Speed Diesel Engine. 26th CIMAC World Congress; 2010; Paper 73.

- Giechaskiel B.; Maricq M.; Ntziachristos L.; Dardiotis C.; Wang X.; Axmann H.; Bergmann A.; Schindler W. Review of Motor Vehicle Particulate Emissions Sampling and Measurement: From Smoke and Filter Mass to Particle Number. J. Aerosol Sci. 2014, 67, 48–86. 10.1016/j.jaerosci.2013.09.003. [DOI] [Google Scholar]

- Birch M. E.; Cary R. A. Elemental Carbon-Based Method for Monitoring Occupational Exposures to Particulate Diesel Exhaust. Aerosol Sci. Technol. 1996, 25 (3), 221–241. 10.1080/02786829608965393. [DOI] [PubMed] [Google Scholar]

- Aakko-Saksa P.; Koponen P.; Aurela M.; Vesala H.; Piimäkorpi P.; Murtonen T.; Sippula O.; Koponen H.; Karjalainen P.; Kuittinen N.; et al. Considerations in Analysing Elemental Carbon from Marine Engine Exhaust Using Residual, Distillate and Biofuels. J. Aerosol Sci. 2018, 126, 191–204. 10.1016/j.jaerosci.2018.09.005. [DOI] [Google Scholar]

- Isella L.; Giechaskiel B.; Drossinos Y. Diesel-Exhaust Aerosol Dynamics from the Tailpipe to the Dilution Tunnel. J. Aerosol Sci. 2008, 39 (9), 737–758. 10.1016/j.jaerosci.2008.04.006. [DOI] [Google Scholar]

- Brem B. T.; Durdina L.; Siegerist F.; Beyerle P.; Bruderer K.; Rindlisbacher T.; Rocci-Denis S.; Andac M. G.; Zelina J.; Penanhoat O.; et al. Effects of Fuel Aromatic Content on Nonvolatile Particulate Emissions of an In-Production Aircraft Gas Turbine. Environ. Sci. Technol. 2015, 49 (22), 13149–13157. 10.1021/acs.est.5b04167. [DOI] [PubMed] [Google Scholar]

- Ntziachristos L.; Saukko E.; Lehtoranta K.; Rönkkö T.; Timonen H.; Simonen P.; Karjalainen P.; Keskinen J. Particle Emissions Characterization from a Medium-Speed Marine Diesel Engine with Two Fuels at Different Sampling Conditions. Fuel 2016, 186, 456–465. 10.1016/j.fuel.2016.08.091. [DOI] [Google Scholar]

- Khan M. Y.; Giordano M.; Gutierrez J.; Welch W. A.; Asa-Awuku A.; Miller J. W.; Cocker D. R. Benefits of Two Mitigation Strategies for Container Vessels: Cleaner Engines and Cleaner Fuels. Environ. Sci. Technol. 2012, 46 (9), 5049–5056. 10.1021/es2043646. [DOI] [PubMed] [Google Scholar]

- Zetterdahl M.; Moldanová J.; Pei X.; Pathak R. K.; Demirdjian B. Impact of the 0.1% Fuel Sulfur Content Limit in SECA on Particle and Gaseous Emissions from Marine Vessels. Atmos. Environ. 2016, 145, 338–345. 10.1016/j.atmosenv.2016.09.022. [DOI] [Google Scholar]

- Winnes H.; Fridell E. Emissions of NOX and Particles from Manoeuvring Ships. Transp. Res. Part D Transp. Environ. 2010, 15 (4), 204–211. 10.1016/j.trd.2010.02.003. [DOI] [Google Scholar]

- Cooper D. A. Exhaust Emissions from Ships at Berth. Atmos. Environ. 2003, 37 (27), 3817–3830. 10.1016/S1352-2310(03)00446-1. [DOI] [Google Scholar]

- Jayaratne E. R.; Meyer N. K.; Ristovski Z. D.; Morawska L. Volatile Properties of Particles Emitted by Compressed Natural Gas and Diesel Buses during Steady-State and Transient Driving Modes. Environ. Sci. Technol. 2012, 46 (1), 196–203. 10.1021/es2026856. [DOI] [PubMed] [Google Scholar]

- Bullock D. S.; Olfert J. S. Size, Volatility, and Effective Density of Particulate Emissions from a Homogeneous Charge Compression Ignition Engine Using Compressed Natural Gas. J. Aerosol Sci. 2014, 75, 1–8. 10.1016/j.jaerosci.2014.04.005. [DOI] [Google Scholar]

- Anderson M.; Salo K.; Fridell E. Particle- and Gaseous Emissions from an LNG Powered Ship. Environ. Sci. Technol. 2015, 49 (20), 12568–12575. 10.1021/acs.est.5b02678. [DOI] [PubMed] [Google Scholar]

- Alanen J.; Saukko E.; Lehtoranta K.; Murtonen T.; Timonen H.; Hillamo R.; Karjalainen P.; Kuuluvainen H.; Harra J.; Keskinen J.; et al. The Formation and Physical Properties of the Particle Emissions from a Natural Gas Engine. Fuel 2015, 162, 155–161. 10.1016/j.fuel.2015.09.003. [DOI] [Google Scholar]

- Fridell E.; Salo K. Measurements of Abatement of Particles and Exhaust Gases in a Marine Gas Scrubber. Proc. Inst. Mech. Eng. Part M J. Eng. Marit. Environ. 2016, 230 (1), 154–162. 10.1177/1475090214543716. [DOI] [Google Scholar]

- Kasper A.; Aufdenblatten S.; Forss A.; Mohr M.; Burtscher H. Particulate Emissions from a Low-Speed Marine Diesel Engine. Aerosol Sci. Technol. 2007, 41 (1), 24–32. 10.1080/02786820601055392. [DOI] [Google Scholar]

- Pirjola L.; Pajunoja A.; Walden J.; Jalkanen J.-P.; Rönkkö T.; Kousa A.; Koskentalo T. Mobile Measurements of Ship Emissions in Two Harbour Areas in Finland. Atmos. Meas. Tech. 2014, 7 (1), 149–161. 10.5194/amt-7-149-2014. [DOI] [Google Scholar]

- Amanatidis S.; Ntziachristos L.; Karjalainen P.; Saukko E.; Simonen P.; Kuittinen N.; Aakko-Saksa P.; Timonen H.; Rönkkö T.; Keskinen J. Comparative Performance of a Thermal Denuder and a Catalytic Stripper in Sampling Laboratory and Marine Exhaust Aerosols. Aerosol Sci. Technol. 2018, 52 (4), 420–432. 10.1080/02786826.2017.1422236. [DOI] [Google Scholar]

- Hesterberg T. W.; Lapin C. A.; Bunn W. B. A Comparison of Emissions from Vehicles Fueled with Diesel or Compressed Natural Gas. Environ. Sci. Technol. 2008, 42 (17), 6437–6445. 10.1021/es071718i. [DOI] [PubMed] [Google Scholar]

- Liu J.; Yang F.; Wang H.; Ouyang M.; Hao S. Effects of Pilot Fuel Quantity on the Emissions Characteristics of a CNG/diesel Dual Fuel Engine with Optimized Pilot Injection Timing. Appl. Energy 2013, 110, 201–206. 10.1016/j.apenergy.2013.03.024. [DOI] [Google Scholar]

- Lehtoranta K.; Murtonen T.; Vesala H.; Koponen P.; Alanen J.; Simonen P.; Rönkkö T.; Timonen H.; Saarikoski S.; Maunula T.; et al. Natural Gas Engine Emission Reduction by Catalysts. Emiss. Control Sci. Technol. 2017, 3 (2), 142–152. 10.1007/s40825-016-0057-8. [DOI] [Google Scholar]

- Järvi A.Methane Slip Reduction in Wärtsilä Lean Burn Gas Engines. 26th CIMAC World Congress; 2010; Paper 106.

- Hiltner J.; Loetz A.; Fiveland S.. Unburned Hydrocarbon Emissions from Lean Burn Natural Gas Engines - Sources and Solutions. 28th CIMAC World Congress; 2016; Paper 032.

- Lehtoranta K.; Turunen R.; Vesala H.; Nyyssoenen S.; Soikkeli N.; Esselstroem L.. Testing SCR in High Sulphur Application. 27th CIMAC World Congress; 2013; Paper 107.

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.