Abstract

Filtering facepiece respirators (FFRs) are commonly worn by first responders, first receivers and other exposed groups to protect against exposure to airborne particles, including those originated by combustion. Most of these FFRs are NIOSH-certified (e.g., N95-type) based on the performance testing of their filters against charge-equilibrated aerosol challenges, e.g., NaCl. However, it has not been examined if the filtration data obtained with the NaCl-challenged FFR filters adequately represent the protection against real aerosol hazards such as combustion particles. A filter sample of N95 FFR mounted on a specially designed holder was challenged with NaCl particles and three combustion aerosols generated in a test chamber by burning wood, paper and plastic. The concentrations upstream (Cup) and downstream (Cdown) of the filter were measured with a TSI P-Trak condensation particle counter and a Grimm Nanocheck particle spectrometer. Penetration was determined as (Cdown/Cup) ×100%. Four test conditions were chosen to represent inhalation flows of 15, 30, 55 and 85 L/min. Results showed that the penetration values of combustion particles were significantly higher than those of the “model” NaCl particles (p < 0.05), raising a concern about applicability of the N95 filters performance obtained with the NaCl aerosol challenge to protection against combustion particles. Aerosol type, inhalation flow rate and particle size were significant (p < 0.05) factors affecting the performance of the N95 FFR filter. In contrast to N95 filters, the penetration of combustion particles through R95 and P95 FFR filters (were tested in addition to N95) were not significantly higher than that obtained with NaCl particles. The findings were attributed to several effects, including the degradation of an N95 filter due to hydrophobic organic components generated into the air by combustion. Their interaction with fibers is anticipated to be similar to those involving “oily” particles. The findings of this study suggest that the efficiency of N95 respirator filters obtained with the NaCl aerosol challenge may not accurately predict (and rather overestimate) the filter efficiency against combustion particles.

Keywords: combustion particles, N95, filtering facepiece respirator, penetration

INTRODUCTION

First responders and first receivers as well as some other groups of workers are often exposed to airborne particles containing hazardous materials which may cause various respiratory illnesses. (1) For example, studies have shown that the first receivers who responded to the collapse of the World Trade Center have substantial loss in pulmonary function and increasing risk for developing a number of cancers. (2, 3)

Combustion process can generate a large amount of particles and gases that are known or anticipated to be harmful to both the environment and the health. (4) Of particular importance is the combustion of ultrafine/nano-scale particles (<100 nm in size), (5,6) which can penetrate deep into the lung; once deposited, some of these particles may cross the air-blood barrier and accumulate in other organs. (7) Workers exposed to the combustion particles may be at risk for developing respiratory and cardiovascular problems. (8,9) Characteristics such as particle size, shape, charge, surface area, chemical properties, and solubility may attribute to the particle toxicity and health effects. (10)

The NIOSH-certified filtering facepiece respirators (FFRs), e.g., N95-type devices, are commonly used in the workplace to protect against hazardous aerosols, including those generated by combustion. (11) The certification is based on the performance testing of the respirator filters against charge-equilibrated aerosol challenges such as NaCl. (12) However, the question is whether the performance data obtained with NaCl particles adequately represent the protection characteristics of these filters against real aerosol hazards.

Numerous studies have been performed to determine the filter efficiency of the FFRs against specific aerosols.(13–16) One study conducted with two N99 and one N95 filters challenged with three viral aerosols and NaCl at inhalation flow rates of 30, 85, and 150 L/min, revealed that the filter penetration of the virions did not exceed that of the NaCl particles, suggesting that the NIOSH certification test generated adequate data for modeling the filter penetration of similarly sized virions.(13) In another study, which tested the efficiency of N95 FFRs against silver and NaCl particles of 20 – 30 nm at 85 L/min, the investigators found that aerosol type had no significant effect on the penetration values. (14) The penetration of combustion particles through FFR has been addressed only in a few investigations. He, et al.(17,18) tested an elastomeric half-mask equipped with P100 filters using particles generated by combustion of wood, paper, and plastic; it was found that the aerosol type significantly affected the filter penetration. To our knowledge, no similar investigation has been conducted with N95, P95, R95, and other filters commonly used in the field.

The aim of this study was to investigate the penetration of aerosol particles produced by combustion of wood, paper and plastic through an N95 FFR filter and compare the data to the penetration of charge-equilibrated NaCl “model” particles. In addition to the challenge aerosol type, factors such as inhalation flow rate and particle size were also investigated. The R95 and P95 filters were also tested to help interpret the findings obtained with the N95 filter challenged with combustion particles.

MATERIALS AND METHODS

Tested Filters

Filter samples taken from a widely used N95 FFR model (8110S, 3M Corp., MN, USA) were tested in this study. This filter has an electrically charged layer – a feature which makes it more efficient. (19,20) To further investigate the interaction between this filter medium and the combustion aerosol particles, R95 (8247, 3M Corp., MN, USA) and P95 FFRs (64420 R20, Jackson safety, GA, USA) filter samples were also tested (in contrast to the N-type, which stands for not resistant to oil degradation), the R- and P-types represent “resistant to oil degradation” and “oil proof”, respectively. (16)

Challenge Aerosols

Three types of combustion particles, including wood, paper and plastic, were generated in a test chamber by burning a wood stick (24 cm long and 0.4 cm diameter, 1.9 ± 0.5 g), a sheet of paper (23 × 24 cm brown multifold paper towel, 2.1 ± 0.2 g), and a plastic straw (19 cm long and 0.5 cm diameter, 0.6 ± 0.01 g), respectively, using the protocol described elsewhere. (6) The burning materials were held by a caliper with a water-filled basin right under it, and were ignited by a lighter. The measurement was started 15 min (= time zero) after the complete burning of each material to allow the particles to reach a uniform concentration inside the test chamber. Based on our previous findings, (17,18) we expected that the concentration of wood combustion particles would be 160,000 – 200,000 particles/cm3 at time zero; the “initial” particle concentrations for paper and plastic were expected to range from 280,000 to 330,000 particles/cm3. These concentration levels are within the measurement capabilities of the aerosol instruments utilized in this study (see below).

The sodium chlorite particles were aerosolized using a particle generator (Model 8026, TSI Inc., MN, USA) containing NaCl solution with a concentration of 0.02 g/ml. The generated particles, primarily 20 to 500 nm, were charge-equilibrated before challenging the filters by passing the aerosol through a 85Kr electrical charge equilibrator (Model 3054, TSI Inc., MN, USA) placed between the generator and the filter sample holder. The generator produced a stable concentration (±17%) of NaCl particles at a level of about 160,000 particles/cm3.

It is acknowledged that in this study design we charge-equilibrated NaCl particles but not combustion particles. The former was done to follow conventional filter testing protocols … while the combustion particles were not subjected to the same procedure in order to better simulate the field conditions.

Experimental Design

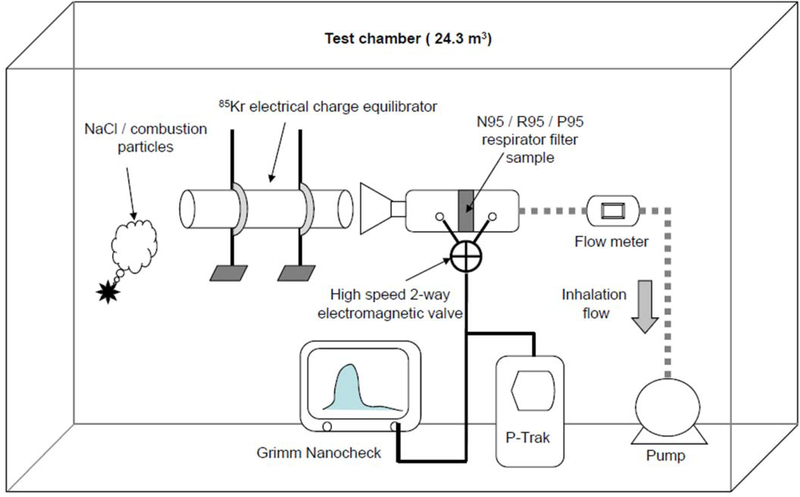

The experiments were conducted in a room-sized test chamber (volume = 24.3 m3). The experimental setup is shown in Figure 1. The tested filter sample with a surface area of 45.34 cm2 (about a quarter of the whole respirator area) was mounted on a specially designed holder and challenged with one of the four aerosols. The sampling probes were placed upstream and downstream of the filter sample at the flow centerline. A high speed 2-way electromagnetic valve was placed between the sampling probes and the measurement devices to allow an operator to switch between the upstream and downstream measurements. The holder was connected to an air sampling pump (SP-280, Air Diagnostics and Engineering Inc., ME, USA) producing a constant inhalation air flow (Q). A mass flow meter (4050, TSI Inc., MN, USA) with a range of 0 – 300 L/min was placed between the pump and the holder to monitor the flow rate. Four inhalation flow rates (QSample) of 3.75, 7.50, 13.8, and 21.3 L/min were applied on the filter samples. With the sample areas (ASample) selected, these allowed matching the air face velocity through the filter sample and the whole respirator at inhalation flows (QRespirator) of 15, 30, 55 and 85 L/min, respectively (see Table I). The latter simulate low, moderate, high, and strenuous workload, respectively. (21,22) During the testing, the concentrations of each challenge aerosol were measured upstream (Cup) and downstream (Cdown) of the tested filter with a P-Trak condensation particle counter (8525, TSI Inc., Shoreview, MN, USA) operating within a size range of 20 to >1000 nm and a particle size spectrometer (Grimm Technologies, Inc., Ainring, Germany) consisting of a Nanocheck (Model 1320).and an optical particle counter (OPC) (Model 1.108). We focused primarily on the size range of 20–150 nm since our earlier experiments showed that 90% of combustion particles were in this range. (17) The corresponding mean sizes for the selected channels were 26, 35, 46, 60, 80, 105 and 139 nm. Additionally, larger particles (up to 900 nm) were measured using the Grimm OPC, which allowed comparing the size-integrated (total) concentrations obtained with the Grimm particle size spectrometer and the P-Trak.

FIGURE 1.

Experimental set-up (85Kr electrical charge equilibrator was used only when generating NaCl particles)

Table I.

Inhalation Flow Rates of the Filter Samples

| QRespirator (L/min) | VRespirator (cm/s) | QSample (L/min) = QRespirator (Asample/ARespirator)1 |

|---|---|---|

| 15 | 1.62 | 3.75 |

| 30 | 3.25 | 7.50 |

| 55 | 5.95 | 13.8 |

| 85 | 9.20 | 21.3 |

The adjustment was made to keep VRespirator = VSample.

The size specific particle penetration values (Pdp) were determined for these sizes as

| (1) |

The total particle penetration (Ptotal) was determined from the P-Trak data as

| (2) |

The P-Trak was chosen for the total count because it has the same operating principle as a PortaCount respirator fit testing apparatus (8038, TSI Inc., Shoreview, MN, USA) which is utilized for evaluating the fit factor of FFRs.

Data Analysis

Statistical data analysis was performed using SAS version 9.3 (SAS Institute Inc., Cary, NC, USA). Two way analysis of variance (ANOVA) was conducted to study the effects of inhalation flow rate, challenge aerosol type, and their interaction on the Ptotal. T-test was used to evaluate the differences between NaCl and three combustion particles. One-way ANOVA was performed to study the effect of particle size. P-values less than 0.05 were considered significant.

RESULTS AND DISCUSSION

Total Particle Penetration (Ptotal)

The total particle penetration (Ptotal) obtained for the N95 FFR filter samples challenged with four tested aerosols is presented in Figure 2. Combustion particles penetrated more readily, with the penetration values significantly higher than those of “model” NaCl particles (p < 0.05) regardless of the inhalation flow rates. At QRespirator = 85 L/min, the flow rate condition under which the respirators are tested for NIOSH certification, the Ptotal of NaCl was at least 50% lower than that of combustion particles. One possible explanation could be the difference in shape, density, charge, surface properties and possibly other characteristics between the combustion particles and NaCl particles. Further investigation was undertaken to understand how these differences may affect the outcome (described below). It is noted, however, that although the N95 filters did not provide the same filtration efficiency against combustion particles as they did for NaCl, their collection efficiency was still above 95% (none of Ptotal exceeded 5%), which is acceptable for the N95 filters.

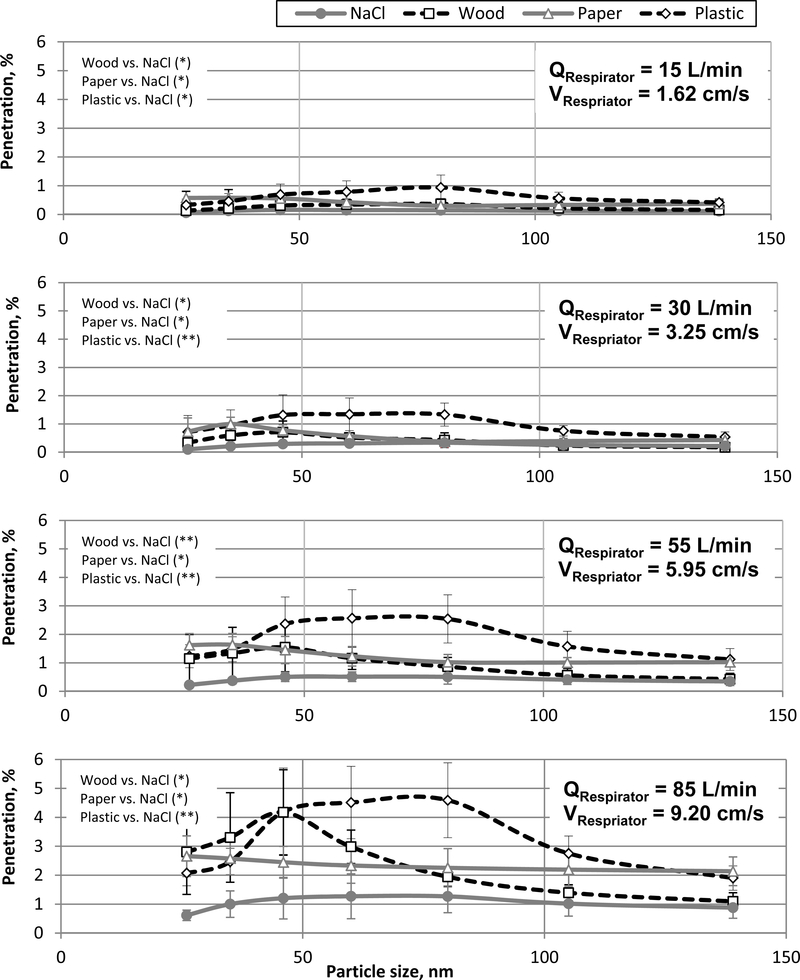

FIGURE 2.

Total particle penetration values (measured using a P-Trak) for an N95 FFR filter samples challenged with three combustion aerosols (wood, paper, and plastic) and NaCl particles under different inhalation flow rates (QRespirator). [The error bars were obtained from five to six replicates; Symbols “*” and “**” indicate significant differences (“*”: p < 0.05; “**”: p < 0.01) when comparing the NaCl to the combustion particles]

For the three combustion materials, the penetration of plastic particles was the highest, followed by paper and wood. This finding is consistent with our previous studies, which were conducted using elastomeric half-mask with P100 filters. (6,18)

The results obtained with the P-Trak were in agreement with the size-integrated data generated by the Grimm spectrometer in a range of 25 to 900 nm. No significant difference (p >0.05) was observed between the total particle penetration obtained with the two aerosol measurement devices.

ANOVA Results on the Effect of Challenge Aerosol

A two-way ANOVA with interaction showed that the type of the challenge aerosol has a strong significant effect on the performance of the N95 filter (p < 0.0001) (see Table II). Further analysis was undertaken using a pair-wise multiple comparison to assess the significance of the penetration difference when each challenge aerosol was compared with the other three challenge aerosols. As seen from Table III, all the differences were significant (p ˂ 0.05).

Table II.

Effects of the Aerosol Type and Inhalation Flow Rate on Ptotal (Two-way ANOVA with Interaction)

| Source | DF | SS | MS | F-Value | p-value |

|---|---|---|---|---|---|

| Aerosol type | 3 | 8.08 | 2.69 | 48.65 | < 0.0001 |

| Inhalation flow rate | 3 | 35.34 | 11.78 | 212.84 | < 0.0001 |

| Inhalation flow rate* Aerosol type | 9 | 3.44 | 0.38 | 6.91 | < 0.0001 |

DF: degree of freedom; SS: sum of squares; MS: mean square

TABLE III.

Pairwise Comparisons of Ptotal for Challenge Aerosol Types (ANOVA with Post-hoc Pair-wise Comparisons)

| Aerosol type | Aerosol type | Estimate | SE | DF | T-value | p-value |

|---|---|---|---|---|---|---|

| NaCl | Wood | −0.40 | 0.096 | 32 | −4.16 | 0.0013 |

| NaCl | Paper | −0.72 | 0.096 | 32 | −7.54 | < 0.0001 |

| NaCl | Plastic | −1.11 | 0.096 | 32 | −11.60 | < 0.0001 |

| Paper | Plastic | −0.39 | 0.096 | 32 | −4.06 | 0.0018 |

| Paper | Wood | 0.32 | 0.096 | 32 | 3.37 | 0.0117 |

| Plastic | Wood | 0.71 | 0.096 | 32 | 7.44 | < 0.0001 |

Estimate: the difference in mean penetration values between the selected two materials; SE: standard error; DF: degree of freedom

ANOVA Results on the Effect of Inhalation Flow Rate

The total particle penetration increased with increasing constant flow rate. This could be explained by particle capture mechanisms, which are primarily diffusion and electrical charge interaction. These mechanisms are affected by the face velocity of the air flow, with higher face velocity resulting in a shorter residence time and, consequently, higher penetration level.

As shown in Table II, inhalation flow rate was a significant factor affecting Ptotal (p < 0.0001). The interaction between the challenge aerosol and the inhalation flow rate had also a strong significance (p < 0.0001). Pair-wise comparison (Table IV) revealed that the differences among the data series of four flow rates were significant except the data series obtained at 15 and 30 L/min. One possible reason is that the flow rate increment (the interval between 15 and 30 L/min is only 15 L/min) is not large enough to significantly reduce the penetration levels.

TABLE IV.

Pairwise Comparisons of Ptotal for Inhalation Flow Rates (ANOVA with Post-hoc Pair-wise Comparisons)

| Inhalation flow rate, QRespirator | Inhalation flow rate, QRespirator | Estimate | SE | DF | T-value | p-value |

|---|---|---|---|---|---|---|

| 15 | 30 | −0.12 | 0.096 | 32 | −1.29 | 0.2056 |

| 15 | 55 | −0.83 | 0.096 | 32 | −8.63 | < 0.0001 |

| 15 | 85 | −2.16 | 0.096 | 32 | −22.49 | < 0.0001 |

| 30 | 55 | −0.70 | 0.096 | 32 | −7.34 | < 0.0001 |

| 30 | 85 | −2.04 | 0.096 | 32 | −21.20 | < 0.0001 |

| 55 | 85 | −1.33 | 0.096 | 32 | −13.86 | < 0.0001 |

Estimate: the difference in mean penetration values between the selected two inhalation flow rates; SE: standard error; DF: degree of freedom

Size-Selective Particle Penetration (Pdp)

The size-selective particle penetration values determined by Grimm Nanocheck are presented in Figure 3. While retrieving the particle size distribution data across the entire operational size range of this spectrometer, we found that, based on the aerosol type, 97–99% (by number) of combustion particles generated were within the selected range of 20 to about 150 nm. The figures represent four challenge aerosols and four inhalation flow rates.

FIGURE 3.

Size-selective particle penetration values for N95 FFR filter samples challenged with three combustion particles (wood, paper, and plastic) and NaCl particles. Each point represents the average value of five to six replicates. Symbols “*” and “**” indicate significant differences (“*”: p < 0.05; “**”: p < 0.01) when comparing the NaCl to the combustion particles.

Increasing the inhalation flow resulted in an increase in Pdp values for all the tested combustion particles as well as NaCl particles, which is consistent with the results of previous studies conducted with N95 FFRs. (14, 23) The results of paired t-test showed that the difference between each paired flow rate was also significant (p < 0.05).

All three combustion particles featured significantly higher penetration values than NaCl regardless of the particle size and flow rate (p < 0.05). One-way ANOVA revealed that the particle size had a significant effect on the penetration of combustion particles (p < 0.05) while not being a significant factor (p > 0.05) for NaCl. In contrast, our earlier study on the efficiency of an N95 FFR against NaCl particles under cyclic flows with mean inspiratory flows (MIFs) of 15, 30, 55 and 85 L/min [conducted using a Nano-ID (NPS500, Naneum, Canterbury, UK)] showed that the effect of particle size was significant. (20) An important difference between these investigations is an instrument deployed for aerosol measurement. The sensitivity of the Grimm spectrometer (used in the present study) is not as high as that of the Nano-ID (used in the quoted study) at low penetration levels observed with NaCl. This may be, at least partially, a reason for ANOVA not yielding the penetration dependency on size. The disagreement can also be attributed to differences in the experimental design and flow regime used in these two studies. E.g., in the quoted investigation, cyclic flow regime was applied on a manikin headform wearing the N95 FFRs while in the present effort a constant flow regime was applied on the N95 FFR filters. In the cyclic regime, the returned clean air (exhalation) dilutes the aerosol inside the respirator. This “cleaning” effect is different for different particle sizes. Furthermore, some particles present inside the respirator cavity may deposit on the inner surface of the filter or move out through the filter and faceseal leakage during exhalation. These effects are also anticipated to be particle size dependent.

The most penetrating particle size (MPPS) varied depending on the aerosol type. For example, the curves obtained for NaCl were almost flat with a barely visible peak at about 70 nm; the penetration of wood steadily increased until the particle size reached 46 nm, then the Pdp started to decrease; the curves for paper were relatively flat reaching a small peak at 35 nm; the MPPS values for plastic particles were in the range of 46–80 nm. Overall, the MPPS for the tested N95 FFR filter against combustion particles was observed in the size range of 35 – 105 nm, which is consistent with the results of earlier studies reporting the MPPS values below 100 nm for the N95 FFRs. (23–25) The MPPS is also dependent on the tested filter type. In one study that included a half-mask respirator with P100 filters, the MPPS for plastic particles fell in the range of 120 –140 nm, while the MPPS for wood and paper was difficult to identify since the penetration curves were close-to-flat. (17)

Interpretation of Data Obtained for an N95 Filter. Testing of R95 and P95 Filters

Generally, combustion particles, which are electrically charged, should be collected more efficiently by the N95 filter fibers than the charge-equilibrated (quazi-neutralized) NaCl particles. Thus, it was surprising to observe that the combustion particles penetrated through an N95 FFR filter significantly more readily than the “model” NaCl. We hypothesized that the “reverse” trend seen in our experiments can be, at least partially, attributed to the following. The combustion particles (as well as vapors originated when burning different materials) contain hydrophobic molecules (or hydrophobic portions of molecules). E.g., the plastic combustion has been shown to emit hydrophobic organic compounds. (26) In this regard, having properties similar to oil particles (and in presence of “oily” vapors), the combustion particles may degrade an “electret” filter (media used for FFRs not resistant to oil, e.g. N95), if deposited on its fibers, (27–28) thus increasing the aerosol penetration. This may be associated with the charge neutralization during the filter collection, (27) dielectric shielding of fibers and ionic conduction. (28)

An additional experiment was conducted to examine the above interpretation. In contrast to the N95 filter type, the filters of R95 and P95 FFRs are designed to protect against oily particles; therefore, we repeated the particle penetration experiments using these two types of filters. We anticipated that since R95 and P95 filters are resistant to degradation associated with oil aerosols, we should observe no significant difference in penetration of combustion particles and NaCl particles, which would support our hypothesis.

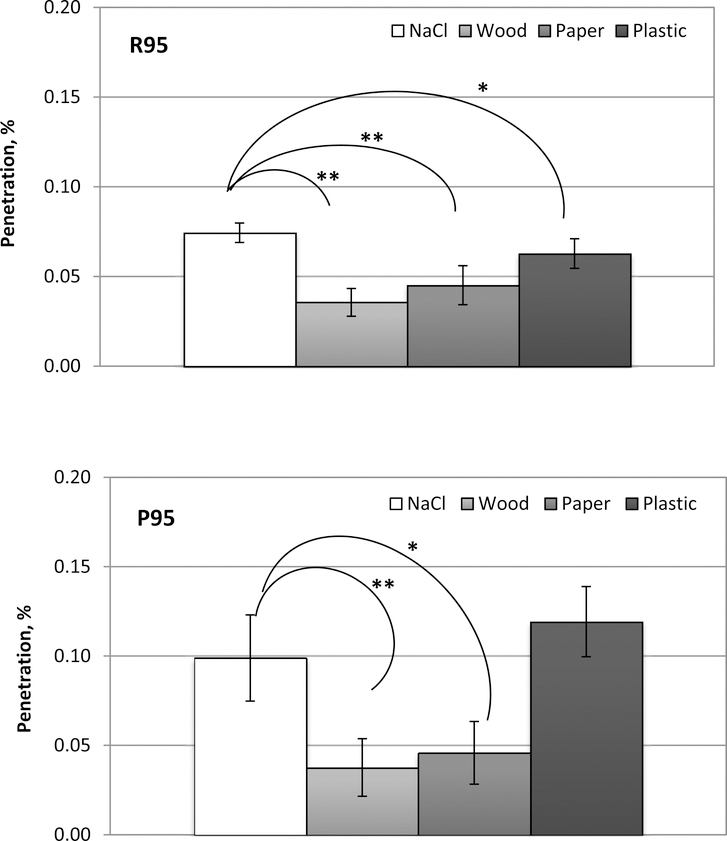

As shown in Figure 4, the penetration values through R95 and P95 were extremely low as compared to N95, with the total particle penetration being below 0.15% for all the tested materials at QRespirator= 85 L/min. This finding is consistent with other studies. (16, 17, 28, 29)

FIGURE 4.

Total particle penetration values (result of P-Trak) for R95 and P95 FFR filter samples challenged with three combustion particles (wood, paper, and plastic) and NaCl particles under the inhalation flow rate (QRespirator) of 85 L/min.

Remarkably, for R95 and P95filters, the penetration levels of combustion particles were not higher than that of NaCl. We believe it is because, unlike an N95, these two filters were “non-degradable” or “less degradable” which supports our above interpretation of the effect of particle type. Furthermore, opposite to the test results obtained with an N95 filter, the R- and P-type filters allowed penetrating fewer combustion particles than NaCl particles in most experimental conditions (with an exception of plastic particles penetrating through a P95 filter) (p < 0.05). Unlike NaCl aerosol that passed the electrical charge equilibrator, combustion particles carried some electric charges, which enhanced their deposition on fibers. The net charge is not expected to be substantial though because the freshly-generated particles were allowed to interact with air ions for 15 minutes before the measurement began, which should have led to their partial neutralization. The charge neutralization rate of combustion particles is unknown, which is a limiting factor for our data interpretation involving the particle charge. In any case, because of their design, the R- and P-type filters were not subjected to substantial degradation due to exposure to combustion aerosols – the phenomenon caused the “reverse” trend for the N95 filter.

Other possible mechanisms that may explain the differences in penetration of combustion and NaCl particles through an N95 filter include the formation of loose agglomerates on the fibers, neutralization or reduction of charge occurring on fiber due to deposition of oppositely charged particles, as well as chemical reaction. (30)

CONCLUSIONS

Performance of the N95 FFR filter was significantly affected by the aerosol type and inhalation flow rate. The penetration of combustion particles through an N95 respirator filter was significantly higher than that of the “model” NaCl particles (p < 0.05), raising a concern about applicability of the N95 filters performance obtained with the NaCl aerosol challenge to protection against combustion particles. The findings were attributed to several effects, including the degradation of an N95 filter due to hydrophobic organic components originated in the air during combustion. Their interaction with fibers is anticipated to be similar to those involving “oily” particles. Additional experiments with oil-resistant and oil-proof FFR filters supported our explanation. The total penetration increased with an increasing flow rate regardless of particle types. Particle size was also found to be a significant factor on the penetration of combustion particles. The findings of this study suggest that the efficiency of N95 respirator filters obtained with the NaCl aerosol challenge may not accurately predict (and rather overestimate) the filter efficiency against combustion particles.

ACKNOWLEDGEMENT

This research was supported by the Targeted Research Training (TRT) program in the University of Cincinnati Education and Research Center (Grant T42-OH008432) and NIOSH Contract 200-2013-M-56581. The authors are grateful for this support.

REFERENCES

- 1.Lioy PJ, Weisel CP, Millette JR, Eisenreich S, Vallero D, Offenberg J, et al. : Characterization of the dust/smoke aerosol that settled east of the World Trade Center (WTC) in lower Manhattan after the collapse of the WTC 11 September 2001. Environ. Health Perspect, 110(7):707–714 (2002). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 2.Banauch GI, Hall C, Weiden M et al. Pulmonary function after exposure to the World Trade Center collapse in the New York City Fire Department. Am. J. Respir. Crit. Care Med, 174:312–319 (2006). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.Aldrich TK, Gustave J, Hall CB, Cohen HW, Webber MP, Zeig-Owens R, Cosenza K, Christodoulou V, Glass L, Al-Othman F, Weiden MD, Prezant DJ: Lung function in rescue workers at the world trade center after 7 years. N Engl. J. Med, 362 (14): 1263–1272 (2010). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Morawska L, Zhang J: Combustion sources of particles. 1. Health relevance and source signatures. Chemosphere. 49:1045–1058 (2002). [DOI] [PubMed] [Google Scholar]

- 5.NIOSH Approaches to safe nanotechnology, An information exchange with NIOSH. http://www.cdc.gov/niosh/topics/nanotech/safenano/(2006).

- 6.He X, Grinshpun SA, Reponen T, McKay R, Bergman MS, Zhuang Z: Effects of breathing frequency and flow rate on the total inward leakage of an elastomeric half-mask donned on an advanced manikin headform. Ann. Occup. Hyg, 58(2):182–194 (2014). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Kreyling WG, Hirn S, Schleh C: Nanoparticles in the lung. Nature Biotech, 28:1275–1276 (2010). [DOI] [PubMed] [Google Scholar]

- 8.Timonen KL, Vanninen E, de Hartog J, IbaldMulli A, Brunekreef B, Gold DR et al. : Effects of ultrafing and fine particulate and gaseous air pollution on cardiac autonomic control in subjects with coronary artery disease: the ULTRA study. J. Expos. Sci. Environ. Epidemiol, 16(4):332–341 (2005). [DOI] [PubMed] [Google Scholar]

- 9.Schwartz J, Dockery DW, Neas LM: Is daily mortality associated specifically with fine particles? J. Air Waste Manag. Assoc.,46(10):927–939 (1996). [PubMed] [Google Scholar]

- 10.Shaffer RE, Rengasamy S: Respiratory protection against airborne nanoparticles: a review. J. Nanopart. Res, 11:1661–1672 (2009). [Google Scholar]

- 11.BLS/NIOSH. Respirator usage in private sector firms, 2001. U.S. Department of Labor, Bureau of Labor Statistics/U.S. Department of Health and Human Services, Public Health Services, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health. [Google Scholar]

- 12.National Institute for Occupational Safety and Health (NIOSH): Respiratory protective devices: final rules and notices. Federal Register 60(110): 30335–30393 (1995). [Google Scholar]

- 13.Eninger RM, Honda T, Adhikari A, Heinonen-Tanski H, Reponen T, Grinshpun SA: Filter performance of N99 and N95 facepiece respirator against viruses and ultrafine particles. Ann. Occup. Hyg, 52(5):385–396 (2008). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 14.Rengasamy S, King WP, Eimer BC, Shaffer RE: Filtration performance of NIOSH-approved N95 and P100 filtering facepiece respirators against 4 to 30 nanometer-size nanoparticles. J. Occup. Environ. Hyg, 5:556–564 (2008). [DOI] [PubMed] [Google Scholar]

- 15.Moyer ES, Bergman MS: Electrostatic N-95 respirator filter media efficiency degradation resulting from intermittent sodium chloride aerosol exposure. Appl. Occup. Environ. Hyg, 15(8):600–608 (2000). [DOI] [PubMed] [Google Scholar]

- 16.Martin SB, Moyer ES: Electrostatic respirator filter media: filter efficiency and most penetrating particle size effects. Appl. Occup. Environ. Hyg, 15(8):609–617 (2000). [DOI] [PubMed] [Google Scholar]

- 17.He X, Grinshpun SA, Reponen T: Laboratory evaluation of the particle size effect on the performance of an elastomeric half-mask respirator against ultrafine combustion particles. Ann. Occup. Hyg, 57(7):884–897 (2013). [DOI] [PubMed] [Google Scholar]

- 18.He X, Yermakov M, Reponen T, McKay R, James K, Grinshpun SA: Manikin-based performance evaluation of elastomeric respirators against combustion particles. J. Occup. Environ. Hyg, 10:203–212 (2013). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 19.He X, Reponen T, McKay R, Grinshpun SA: How does breathing frequency affect the performance of an N95 filtering facepiece respirator and a surgical mask against surrogates of viral particles? J. Occup. Environ. Hyg, 11:178–185 (2014). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 20.He X, Reponen T, McKay R, Grinshpun SA: Effect of particle size on the performance of an N95 filtering facepiece respirator and a surgical mask at various breathing conditions, Aerosol Sci. and Tech, 47:1180–1187 (2013). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 21.Sherwood L: Fundamentals of Physiology: a human perspective, 3rd ed. Belmont, Calif.: Brooks/Cole, Thomson Learning, 2006. p.380. [Google Scholar]

- 22.Tortora GJ, and Anagnostakos NP: Principles of Anatomy and Physiology, 6th ed. New York: Harper-Collins, 1990. p.707. [Google Scholar]

- 23.Balazy A, Toivola M, Reponen T, Podgorski A, Zimmer A, and Grinshpun SA: Manikin-based performance evaluation of N95 filtering facepiece respirators challenged with nanoparticles. Ann. Occup. Hyg, 50:259–269 (2006). [DOI] [PubMed] [Google Scholar]

- 24.Huang SH, Chen CW, Chang CP, Lai CY, Chen CC: Penetration of 4.5 nm to aerosol particles through fibrous filters. J. Aerosol. Sci, 38:719–727 (2007). [Google Scholar]

- 25.Rengasamy S, Eimer BC, Shaffer RE: Comparison of nanoparticle filtration performance of NIOSH-approved and CE-marked particulate filtering facepiece respirators. Ann. Occup. Hyg, 53:117–128 (2009). [DOI] [PubMed] [Google Scholar]

- 26.Teuten EL, Rowland SJ, Galloway TS, Thompson RC: Potential for plastic to transport hydrophobic contaminants. Environ. Sci. Technol, 41(22):7759–7764 (2007). [DOI] [PubMed] [Google Scholar]

- 27.Biermann AH, Lum B, Bergman.: Evaluation of permanently charged electrofibrous filters. Proceedings of the 17th Department of Energy Nuclear Air Cleaning Conference Denver, CO; pp.523–547. (1982). [Google Scholar]

- 28.Tennal KB, Mazumder MK, Siag A, Reddy RN: Effect of loading with an oil aerosol on the collection efficiency of an electrets filter. Particulate Sci. Technol, 9:19–29 (1991). [Google Scholar]

- 29.Lee BU, Yermakov M, Grinshpun SA: Filtering efficiency of N95- and R95-type facepiece respirators, dust-mist facepiece respirators, and surgical masks operating in unipolarly ionized indoor air environments. Aero. Air Quality, 5(3):27–40 (2005). [Google Scholar]

- 30.Barrett LW, Rousseau AD: Aerosol loading performance of electrets filter media. Am. Ind. Hyg. Assoc. J, 59:532–539 (1998). [Google Scholar]