Abstract

Over the last decades, the fabrication of three-dimensional (3D) tissues has become commonplace in tissue engineering and regenerative medicine. However, conventional 3D fabrication techniques such as scaffolding, microengineering, and fiber and cell sheet engineering are limited in their capacity to fabricate complex tissue constructs with the required precision and controllability that is needed to replicate biologically relevant tissues. To this end, 3D bioprinting offers great versatility to fabricate biomimetic volumetric tissues that are structurally and functionally relevant. It enables precise control of the composition, spatial distribution, and architecture of bioprinted constructs facilitating the recapitulation of the delicate shape and structure of targeted organs and tissues. Here we systematically review the history of bioprinting and the most recent advances in instrumentation and methods. We then focus on the requirements for bioinks and cells to achieve optimal fabrication of biomimetic constructs. We next discuss emerging evolutions and future directions of bioprinting such as freeform, high-resolution, multi-material, and four-dimensional bioprinting. Finally, we present the translational potential of bioprinting and bioprinted tissues of various categories and conclude by exemplifying commercially available bioprinting platforms.

Keywords: 3D bioprinting, additive manufacturing, bioink, tissue engineering, regenerative medicine

Graphical Abstract

Recent advances in translating 3D bioprinting to the clinics are reviewed, including developments in bioprinting strategies, innovations in bioinks for bioprinting, advances in bioprinting of complex architectures, and translational potential of bioprinted tissue-like structures. Commercially available bioprinting platforms are briefly discussed towards the end.

1. Introduction

Tissue engineering aims to generate and utilize biomimetic tissue or organ substitutes to replace, repair, or augment those damaged by injuries or diseases.[1] The native tissues are typically sophisticated in terms of cellular population, extracellular matrix (ECM) composition, variety of growth factors and bioactive agents, as well as spatial organization of all these different components in an orchestrated manner.[2–4] No tissue is composed of only a single cell type. For example, the skin contains layered keratinocytes and fibroblasts, which have a protective function, while the function of melanocytes is to give color;[5, 6] the heart beats upon contraction of cardiomyocytes initiated by pacemaker cells lying in the Purkinje fibers;[6–8] the liver functions based primarily on hepatocytes but other non-parenchymal cells, such as biliary epithelial cells, hepatic stellate cells, and Kupffer cells are also indispensable;[6, 9, 10] and the brain contains billions of neurons surrounded by astrocytes to provide nutrients and glial cells to modulate the immunity.[6] These various cell types are tightly connected by a plethora of ECM molecules in specific spatial arrangements. This allows the cells to interact in the right context with strong coordination mediated by the presence of residing or diffusive growth factors, hormones, and additional bioactive molecules.[2, 3, 11] Moreover, blood vessels are another critical component of almost all functional tissues. These perfusable networks function to transport nutrients, oxygen, and bioactive agents across different organs or sections of a tissue, and remove metabolic wastes such as acids and carbon dioxide to maintain the homeostasis of the human body.[12, 13] Without an interconnected vascular network, tissues cannot survive on their own.

To date, many strategies have been developed to engineer functional tissues, such as three-dimensional (3D) scaffolding,[2, 14] microengineering based on self-assembly,[15, 16] fiber engineering,[17] scaffold-free cell sheet engineering,[18] and others.[3, 4] Scaffolds, made from materials including hydrogels and biodegradable polymers, can be processed into 3D volumes of desired structures, architectures, and shapes to allow seeded cells to attach, proliferate, migrate, and differentiate.[2, 19] Microscale building units, including blocks with complementary shapes or surface chemistry (e.g., DNA sequences and hydrophilicity, respectively), can self-assemble into bulk volumes resembling the properties of the target tissues.[16, 20] Cell-laden fibers may also be used as building units and assembled into hierarchical structures through weaving, knitting, braiding, and spooling.[17, 21] Scaffold-free cell sheet engineering relies on stacking of thin sheets of cells to assume the desired 3D tissue constructs.[18] Although these strategies all possess their own advantages, none of them have been able to achieve reproducible fabrication of volumetric tissue constructs at high spatial precision and controllability.

Three-dimensional bioprinting is a recently developed biofabrication technology capable of addressing such a challenge by providing unprecedented accuracy and precision in patterning biomaterials and cells in a 3D volume in a highly reproducible manner empowered by a programmed robotic fabrication mechanisms.[9, 22–24] To date, a variety of bioprinting strategies have been proposed and executed, including those based on stereolithography, extrusion, and droplets, for engineering different types of tissue substitutes and models of interest. This review systematically discusses the history of bioprinting and its recent advancements in both instrumentation and methods. Subsequently, it provides a detailed discussion on the requirements for a selection of bioinks to achieve optimal bioprinting of biomimetic constructs. We next summarize the trends and directions in future development of bioprinting including freeform, high-resolution, multi-material, and four-dimensional (4D) bioprinting. Finally, we conclude with the translational potential of bioprinting technologies and illustrate exiting commercial bioprinting platforms that are possibly capable of meeting such a need.

2. Bioprinting Strategies

Additive manufacturing techniques in conjunction with biomaterials and cells enable rapid fabrication of 3D biomimetic structures for applications in tissue engineering and regenerative medicine. Over the past decade, a variety of strategies for 3D bioprinting have been developed (Figure 1), each with their own unique advantages and limitations (Table 1). In this section, we will discuss these 3D bioprinting strategies, their working principles, as well as advantages/disadvantages and suitability for different applications.

Figure 1.

Schematic representations of the different strategies currently used in 3D bioprinting. (A) Stereolithography-based bioprinting based on DMD. (B) Inkjet bioprinting using (left) thermal or (right) piezoelectric actuation. (C) Laser-assisted bioprinting. (D) Extrusion-based bioprinting strategies. From left to right: pressure-based (illustrated without valve), piston-based, and screw based. (E) EBB.

Table 1:

Overview of advantages and disadvantages of different bioprinting techniques.

| 3D Bioprinting Technique | Advantages | Disadvantages |

|---|---|---|

| Stereolithography | - Simultaneous crosslinking of the whole 2D layer avoids need of X-Y movement - High cell viability (>85%) - High variety of printable bioinks - High resolution of bioprinting (~1 μm) |

- Crosslinking requires transparent and photosensitive bioink limiting choice of additives and cell density (108 cells mL−1) - Comparatively complex system |

| Inkjet Bioprinting | - Simple bioprinting method - Low cost - Applicability of multi-material bioprinting - High resolution (~30 μm) - High cell viability (80–90%) |

- Limited to low cell density (<106 cells mL−1) - Limited to bioinks with viscosity of 3.5–12 mPa·s |

| Laser-assisted Bioprinting | - High cell viability (>95%) - Variety of printable bioinks with viscosity of 1–300 mPa·s |

- Limited to low cell density (<106 cells mL−1) - Complex system - Comparatively high costs |

| Extrusion-based Bioprinting | - Printability of highly viscous bioinks (30–6×107 mPa·s) - Printability of high cell densities (including cell spheroids) - Applicability of multi-material bioprinting - Comparatively simple bioprinting process |

- Relatively low printing speed - Low-to-medium resolution highly dependent on setup - Moderate cell viability (40–80%) dependent on setup |

| Electrospinning-based Bioprinting | - High resolution (<1 μm) - Optimal for the fabrication of scaffolds |

- Not possible to directly bioprint cell-laden constructs - Complex system - High costs |

2.1. Stereolithography

The initial demonstration of stereolithography for additive manufacturing could be dated back to 1986 when Charles W. Hull initially described the process of creating 3D objects by selectively transform the physical state of a fluid to a solid in a reservoir, through layer-by-layer photocrosslinking.[25] In medicine, stereolithography was first used to create models for reconstructive head surgery, where researchers were able to produce highly accurate and detailed models of the cranium.[26] Stereolithography bioprinters are based on the concept to selectively solidify a (cell-laden) bioink using photo-polymerization in a layer-by-layer process controlled by a moveable stage along the z-axis (Figure 1A). In stereolithography, a two-dimensional (2D) pattern of interest is projected onto the bioink reservoir, allowing for the generation of complex 3D structures without the need of a printhead that travels in x-y direction. This feature results in a higher bioprinting speed in comparison with other nozzle-based bioprinters. The selective crosslinking of bioink by light results in no shear stress to cells, enabling these bioprinters to achieve a high cell viability (>85%).[27] One major disadvantage of this system is the necessity of the liquid to be transparent with limited scattering; otherwise light would not be able to uniformly pass the material resulting in a non-uniform crosslinking. Due to this requirement, cell density within the bioink is limited to approximately 108 cells mL−1.[27] Despite this disadvantage, stereolithography has drawn the interest of several research fields as a result of its capacity to bioprint structures rapidly without applying shear forces to cells and with high resolution (~1 μm).[28, 29] The detailed advantages of stereolithography as well as recent studies to print biomimetic tissues will be further discussed in Section 5.1.2.

2.2. Inkjet bioprinting

Inkjet bioprinting was initially developed in 2003 and officially patented in 2006.[30] It is based on conventional 2D inkjet printers, where the ink is replaced with a bioink and the paper switched to an x-y-z controllable platform allowing for 3D manufacturing of objects. The bioink deposition is based on temporal deformation of the internal space within the extruder, through which the bioink flows, due to piezoelectric actuation or digitized thermal actuation (Figure 1B). This deformation allows for droplet-wise dispensing of liquid onto the collection platform, and the build-up of layers in the z-direction eventually leads to generation of a 3D object. The major advantage of inkjet bioprinting lies in the simplicity of the system and relatively low costs.[27, 31] Several printheads can further work in parallel allowing for rapid fabrication at high resolution (~30 μm).[27, 30, 32] In addition, this technique results in a relatively high cell viability of 80–90%.[27, 31] However, inkjet bioprinting also displays several disadvantages such as a relatively low cell density (<106 cells mL−1) that can be used for bioprinting as well as the capacity to only print bioinks with viscosities in a range of around 3.5–12 mPa·s.[27, 30, 31, 33] The relatively high resolution of the system of approximately 30 μm, as well as the capacity to use multiple printheads make inkjet bioprinting attractive for multiple applications. Cui and co-workers described an inkjet bioprinter, which was able to deposit 8 materials and simultaneously crosslink the bioprinted structures for studies on bone and cartilage.[32] They successfully developed a platform to achieve mechanically strong bone and cartilage constructs using poly(ethylene glycol) (PEG)-dimethacrylate (PEGDMA) and gelatin methacryloyl (GelMA), and encapsulated human mesenchymal stem cells (MSCs). Huang and co-workers successfully bioprinted bifurcated vascular structures using inkjet bioprinting with a controlled and uniform diameter of the channels.[34] Recently, Jung and co-workers developed a bioprinting process based on a combination of inkjet bioprinting with a spray-coating technique.[35] They demonstrated the versatility of their technique by the rapid fabrication of hydrogel constructs with various sizes and materials including alginate, cellulose, fibrinogen, or GelMA. Bioprinted human dermal fibroblasts in the constructs displayed high proliferation and activity as well as cell-specific characteristics such as extensive collagen I deposition. Their novel approach showed that inkjet bioprinting can be used to bioprint larger-scale constructs consisting of various materials for applications in tissue engineering.

2.3. Laser-assisted bioprinting

Laser-assisted bioprinting is based on laser direct-write or laser-induced forward transfer.[36] The first appearance of laser-assisted bioprinting applied to tissue engineering was on a publication by Duocastella and co-workers in 2007, describing the bioprinting of a microarray of droplets, laying the foundation for the use of this method in biomedical applications.[37] Platforms using this technique typically consist of three layers from top to bottom: an energy-absorbing layer, a donor layer, and a layer of bioink (Figure 1C). The crucial part of the system is a donor layer that responds to an applied laser beam. Attached on top of this donor layer is an energy-absorbing layer (e.g., titanium or gold). At the bottom, a thin layer of bioink is suspended for bioprinting. When a selective laser beam is applied to desired sites of the energy-absorbing layer, the corresponding locations of the donor layer underneath is vaporized, creating a high-pressure bubble at this interface. This pressure causes impelling of the bioink, resulting in a droplet falling onto the collection platform. By controlling the z-stage of the collector, a 3D construct is eventually formed. Laser-assisted bioprinting has the advantage that cells are not directly exposed to high shear stress. In fact, during the bioprinting process there is no contact between the dispenser and the bioink. As a result, this bioprinting method leads to a high cell viability (>95%) and is able to also deposit highly viscous materials (1–300 mPa·s).[33] One of the major problem with this system is the high cost due to the requirement of a high-resolution and intensity laser diode. With the drop-wise bioprinting mechanism, the cell density achievable by this method is similar to that of inkjet bioprinting (<106 cells mL−1), which has limited its applications to a certain extent.[27] Guillemot and co-workers successfully bioprinted MSCs with a high viability and at a high resolution using a high-throughput laser-assisted bioprinting.[38] Additionally, they developed a system that could achieve cell-level resolution (10 μm) at a very high speed (5 kHz) of bioprinting.[39] In summary, laser-assisted bioprinting shows a good potential based on contactless deposition at fast speeds. However, because due to high costs and the fact that not all parameters are completely optimized and understood, laser-assisted bioprinting is still relatively immature for the fabrication of 3D tissue constructs.

2.4. Extrusion-based bioprinting

The basic mechanism of extrusion-based 3D printing for tissue engineering applications was first applied by Hutmacher and co-workers back in 2002.[40] They created scaffolds made from poly(ε-caprolactone) (PCL) using an extrusion-based design with two rollers combined with a heating system to deliver melted material. Over the last years, the process of extrusion-based 3D printing rapidly developed and its application soon extended to 3D bioprinting. Several different systems have been developed for extrusion-based bioprinting (Figure 1D); among them, two main working principles have displayed high performance in tissue engineering applications: pneumatic- and mechanical-driven fluid dispensing systems. Pneumatic systems can be either valve-free or valve-based.[41] Valve-free systems, on the one hand, are easier to manufacture and are therefore most commonly used in bioprinting. Whereas valve-based systems, on the other hand, have several advantages in terms of control over pressure and pulse frequencies, enabling high precision of material deposition and resulting in high-resolution bioprinting. Mechanical systems are mainly controlled by a piston or by a screw. Piston-based systems allow for direct control over the bioink deposition onto the platform. Screw-driven systems are preferable for bioinks with higher viscosities due to the better spatial control. However, due to larger pressure drops at the nozzle exit, screw-driven systems can be harmful for cells.[41, 42] In comparison with other aforementioned platforms, extrusion-based bioprinting possesses several advantages, including the capacity of depositing high-viscosity bioinks (30 mPa·s to >6×107 mPa·s) as well as large cell densities (>108 cells mL−1 up to cell spheroids).[27, 33] Moreover, extrusion-based bioprinting systems can continuously extrude bioinks without interruptions. In most applications, this is preferable in comparison to dropwise methods considering the requirement for the integrity of bioprinted tissue constructs. On the other hand, the bioprinting speed is relatively slow to build up a 3D structure and the resolution is strongly dependent on different components such as the nozzle size. Studies have also shown that cell viability after extrusion-based bioprinting is usually moderate at around 40–80% due to high shear stresses experienced by cells during the extrusion process.[27] Nevertheless, extrusion-based bioprinting has thus far been one of the most widely adopted forms of bioprinting due to its relative simplicity in instrumentation.

2.5. Electrospinning-based bioprinting (EBB)

Electrospinning is a simple and versatile method to produce nano- and microscale fibers using various materials including polymers, ceramics, and composites.[43, 44] This method uses an electrical force to rapidly stretch a charged polymer solution/melt jet coupled with solvent evaporation/solidification and subsequent collection of filaments into a fibrous mat.[45] Due to the small diameter of electrospun fibers achievable by this technique, electrospinning has been recently modified and employed as an emerging method to improve the resolution of current bioprinting platforms. The setup usually consists of an x-y-z robotic stage combined with a conventional electrospinning equipment set, including a solution or melt polymer extrusion system based on a syringe pump or pneumatic regulator and a high-voltage power supply (Figure 1E). Electrospinning allows the bioprinting to be controlled in either a continuous or discontinuous manner.[46–49]

One major disadvantage in electrospinning is the chaotic whipping of the charged jet resulting in unstable fibers and constructs.[46] Up to now, the main strategy to deposit electrospun ultrafine fibers in a controllable manner is utilizing a stable liquid jet region, namely near-field electrospinning (NFES), electrospinning writing, and direct writing, all of which will be further referred to in this section as EBB.[46, 50, 51] One of the main characteristics of EBB is the shorter collecting distance (usually between 500 μm and 3 mm), while the collecting distance of conventional electrospinning ranges from a few centimeters to 30 cm.[44, 52] The applied voltage is also lower when compared with conventional electrospinning, but it significantly varies depending on the type of bioprinting.

In general, EBB can be classified as solution electrospinning-based bioprinting (SEBB) and melt electrospinning-based bioprinting (MEBB). The applied voltage of SEBB is a few hundred volts, while the counterpart of MEBB is approximately 10 kV. SEBB, on the one hand, can bioprint fibers in the range of nanometers with a smallest diameter reported of 16.2 nm; however, this technique has not yet been proven in biological applications.[47] MEBB, on the other hand, can deposit fibers in the range of 650 nm to 980 nm in a highly controlled manner, making it suitable for the fabrication of high-resolution scaffolds for cell attachment and long term culture.[50] Detailed discussions can be found in Section 5.2.

3. Design of Functional Bioinks for Bioprinting

Bioinks are one of the most important aspects for successful 3D bioprinting of engineered tissue and organ constructs. They form the backbone of almost every 3D-bioprinted construct.[53, 54–57] In general, bioinks should possess excellent mechanical and biological properties, defining printability and biocompatibility of the bioink. Printability indicates the suitability of a bioink to fabricate stable 3D constructs with high structural integrity and fidelity whereas biocompatibility indicates that the bioink is cell-friendly and supports cell adhesion, proliferation, and spreading.[29] Hereby cells can be seeded on or encapsulated into bioprinted constructs to promote specific tissue growth. Especially in the fabrication of larger-scale biomimetic tissues, the choice of the proper bioink is crucial for the success of bioprinting. The bioink needs to maintain the structure of a bioprinted construct of a larger size, promote cell growth, spreading, and interaction throughout the whole construct, as well as support maturation into respective tissues.

Over the last decades, several naturally derived and synthetic biopolymer-based hydrogels have proven to be promising candidates to serve as bioinks for bioprinting applications. Bioinks that have been extensively investigated include alginate, fibrinogen, gelatin, collagen, chitosan, agarose, pluronics, hyaluronic acid (HA), GelMA, PEG, and decellularized ECM (dECM).[57] These bioinks are ion-sensitive, photosensitive, thermosensitive, enzyme-sensitive, or pH-responsive so that they can be easily gelled to form solid 3D constructs before, during, and/or after bioprinting.

Among all, alginate is perhaps one of the most frequently used bioinks in bioprinting for medical applications and tissue engineering. Its viscous properties, combined with the comparatively simple crosslinking mechanism using calcium chloride (CaCl2), make it an attractive hydrogel for bioprinting applications.[56, 58] The main disadvantage of alginate is its chemical structure that usually does not allow cell adhesion. To induce cell adhesion and biological activity, alginate needs to be blended with other natural polymers such as gelatin-based materials, collagen, or fibrinogen.[59, 60] Gelatin and GelMA are other hydrogels that are widely used in bioprinting applications due to their excellent cell compatibility and mechanical properties.[61] A disadvantage of using GelMA is the requirement of a photoinitiator that allows for crosslinking and solidification of bioprinted constructs. At higher concentrations these initiators can be toxic to cells, which limits the use to low concentrations of photoinitiator.[59]

Similar to gelatin, HA can be modified to create a printable bioink usable for cell-laden constructs. These supramolecular HA-based hydrogels are especially attractive due to their tunable characteristics and mechanical properties.[62] Hydrogels based on dECM are attracting increasing interest for the use as bioinks due to their naturally given biocompatibility, tissue specificity, and ease to formulate into usable bioinks.[63] Different from hydrogels that can be directly used as cell-laden bioinks are hydrogels that mainly act as supporting or sacrificial layers, such as pluronics or gelatin.[64] In general, over the last decades, the research on bioinks for bioprinting has been rapidly growing and new combinations and modified bioinks are developed constantly to achieve improved mechanical and biological properties for application in tissue engineering and regenerative medicine. This chapter briefly reviews the recent progress of functional bioinks and their applications in 3D bioprinting of specific tissues/organs, which are of particular interest in the fabrication of clinically relevant biomimetic tissue constructs. More systematic discussions on bioinks can be accessed elsewhere.[29, 55, 57, 65]

3.1. Mechanical properties of bioinks

The fabrication of complex 3D functional structures in bioprinting requires accurate layer-by-layer placement and/or solidification of the bioink. During this process, the bioprinted layers need to sustain their shape and hold their previously defined 3D structure. Furthermore, cells loaded in the bioinks should not be negatively influenced by the bioprinting process in terms of viability and performance.[23, 66, 67] To achieve this goal, it is crucial to take into consideration the rheological properties of the bioinks, the mechanical effects on encapsulated cells, and the function of bioprinted tissues.

As discussed in the previous section, the most commonly used method in bioprinting is extrusion-based deposition of a bioink through a printhead onto a collector in conjunction with a rapid phase transition of the bioink into a solid-like material.[67] Here, the bioink should fulfill different requirements such as a viscosity that is low enough to allow extrusion through the printhead while avoiding high shear rates on laden cells, but high enough to hold a 3D shape after extrusion. Because of these requirements, hydrogels with shear-thinning properties came into focus of many bioprinting applications. Shear-thinning hydrogels display low viscosities when high shear stress is applied to the materials and regain their original viscosities after the shear stress is removed.[22, 68] Based on their optimal shear-thinning properties, bioinks based on alginate or GelMA have been widely applied.[69]

Moreover, several research has focused on the hybridization of these bioinks with nanomaterials to achieve improved performances. For example, Gaharwar and co-workers indicated that nanoclay particles in a GelMA-based bioink could increase its shear-thinning properties (Figure 2A).[70] In their study, it was shown that the mechanical properties of GelMA could be fine-tuned by addition of nanoparticles of different sizes and concentrations. Nanoclay addition resulted in a 4-fold increase in the compressive modulus and a 10-fold increase in the peak tensile stress at 90% strain. The energy absorbed during deformation (90% cyclic compression) of the GelMA/nanoclay hydrogel was 6-fold higher than that of pure GelMA. Such a bioink can be used to bioprint hydrogel constructs that are highly elastic under high compressive strains. They demonstrated that nanoclay could increase the mechanical properties of bioprinted constructs from biopolymer solution-based bioinks and did not decrease their biocompatibility.

Figure 2.

Bioprinting of strong hydrogel constructs with polymer-nanoclay composite bioinks. (A) Bioprinting of GelMA enriched with nanosilicate to achieve rigid complex structures. Reproduced with permission from ref.[70]. (B) Various 3D constructs bioprinted with a PEG-alginate-nanoclay hydrogel (from left to right: hollow cube, hemisphere, pyramid, twisted bundle, ear shape and nose shape). (C) Bioprinted PEG-alginate-nanoclay mesh undergoing repeated uniaxial stretching and recovering to its original shape. (D) Bioprinted PEG-alginate-nanoclay pyramid undergoing repeated compressions and recovering to its original shape. Reproduced with permission from ref.[81]. (E) Human L3 vertebrae bioprinted with various concentrations of MeHA in the bioink. Reproduced with permission from ref.[83].

Another strategy to fine-tune the properties of bioinks is a change of bioprinting conditions such as maintaining a relatively high temperature during extrusion that could decrease viscosities of certain bioinks and contribute to easier extrusion of the materials.[71, 72] For instance, Dubruel and co-workers demonstrated that the viscosity of GelMA would sharply decrease from 10 Pa.s to 0.01 Pa.s when the bioprinting temperature increased from 20 °C to 37 °C.[71] Furthermore, the concentration of GelMA and the density of loaded cells have additional impacts on the viscosity of the bioink. They indicated that an elevated concentration of GelMA caused an increase in the viscosity whereas a higher cell density lowered the viscosity of the bioink. Fu and co-workers systemically investigated the influence of the processing parameters such as air pressure, feed rate, and bioprinting distance on the printability of biomaterials.[72] It was found that a higher pressure resulted in a higher feeding rate and a larger volume of bioink being deposited at one location, consequently increasing the line width of the bioprinted structure. The same effect could be seen by slowing the moving speed of the printhead. Conversely, a slower feeding rate and/or higher bioprinting speed could decrease the line width. A different approach to optimize the bioprinting conditions is to reduce the time between material extrusion and phase transition through in situ crosslinking of the bioinks, which decreases the possibility of the structure to collapse. For instance, Khademhosseini and co-workers leveraged a coaxial extrusion printhead to bioprint a low-viscosity bioink consisting of alginate and GelMA.[69] With this extrusion system, they were able to extrude a continuous filament of alginate/GelMA that was surrounded by a solution of CaCl2. At the tip of the coaxial printhead, the bioink underwent rapid phase transition due to the fact that alginate would undergo an instantaneous physical gelation when exposed to calcium ions. Using this method, they bioprinted microfibrous 3D structures at good resolution with a single fiber diameter of down to 100 μm.

The mechanical properties of the bioink to achieve optimal printability and capability to form a 3D construct is not the only requirement necessary to be suitable for bioprinting applications. An inevitable consideration is also the mechanical effects on loaded cells during the extrusion process. It is well-documented that the mechanical stress has a profound influence on cell survival and function.[73] However, in bioprinting little is known regarding the mechanical effects on laden cells and most reports are still controversial. Khalil and Sun indicated that, when the shear stress applied to cells changed from 100 kPa to 1150 kPa, the viability percentage of rat heart endothelial cells could range from 76% to 83% and there was no statistically significant difference.[74] In contrast, Heilshorn and co-workers further investigated the mechanical influence on cell viability during the extrusion process.[75] They found that the mechanical force applied on cells during extrusion through the nozzle had an adverse effect on cell viability. In particular, the extensional flow induced by the sharp change in cross-sectional diameter from syringe to nozzle, rather than the pressure drop and shear stress, was the main cause of acute cell death. Recently, Fischer and co-workers precisely controlled the shear stress at the nozzle site during the bioprinting process and investigated the effects of different levels of shear stress on the viability and proliferation of mesenchymal stem cells (MSCs).[76] They showed that loaded cells could be bioprinted without side effects under a threshold of shear stress. However, high shear stresses would affect cell viability during the bioprinting process and furthermore induce long-term alterations in the proliferation of the surviving cells. For this reason, hydrogels with shear-thinning properties are often used, as the low shear stress during extrusion favors cell survival and functionality.[77]

However, the mechanical properties of bioinks do not solely affect laden cells in a negative way. These properties may also have a profound positive influence on cell maturation and development and form a crucial factor in obtaining biomimetic tissues for regenerative medicine. For some tissues such as articular cartilages and muscles, the mechanical properties of bioprinted constructs are of utmost importance. Nevertheless, bioinks based on a single hydrogel or a blend of two comparably soft hydrogels such as alginate and GelMA are often too weak to be used for bioprinting of musculoskeletal tissues.[68, 78]

To overcome the limitations of commonly used bioinks, two strategies have been developed recently. The first one is the hybrid bioprinting strategy, in which a reinforcing component is combined with a bioink providing the necessary mechanical support.[79, 80] For instance, Malda, Hutmacher, and co-workers 3D-printed high-porosity melt-electrospun PCL fiber scaffolds through EBB to mechanically reinforce GelMA hydrogels resulting in bioprinted constructs that, in terms of mechanical properties, closely resembled those of healthy articular cartilage.[80] Moreover, human chondrocytes embedded in the composites were viable and maintained their cell-specific functions. The second strategy is based on composite bioinks consisting of an intertwined hybrid network providing the necessary mechanical properties.[70, 81, 82] Zhao and co-workers reported a bioink of alginate-PEG-nanoclay for 3D bioprinting of highly stretchable and tough hydrogel structures (Figure 2B).[81] Alginate and PEG polymers were ionically and covalently crosslinked by calcium ions and UV exposure, respectively. As the hydrogels are deformed, alginate chains are detached from the ionic crosslinks so that mechanical energy is dissipated. Once the hydrogels are relaxed from deformation, they regain their original configurations since the covalently crosslinked PEG network retains the elasticity of the hydrogels. Over time, the ionic crosslinks of the alginate network can reform within both deformed and relaxed hydrogels. More complex tough 3D hydrogel structures could be bioprinted through controlling the viscosity of the solution with nanoclay addition. The bioprinted constructs could bear high stress in both tension and compression. A bioprinted grid was uniaxially stretched to 300% of its length and relaxed to its initial state (Figure 2C). A bioprinted pyramid underwent 99% compressive strain and recovered 97% of its original height after unloading in 5 mins (Figure 2D). The constructs achieved a high toughness of above 1,500 J m−2. The high viability of human embryonic kidney (HEK) cells seeded on the hydrogel constructs demonstrated that the alginate-PEG-nanoclay bioink was not only printable to form tough structures but also suitable for long-term cell cultures.

Alternatively, Alblas and co-workers described the 3D bioprinting of cell-laden constructs for bone tissue engineering using a modified bioink consisting of methacrylated HA (MeHA).[83] They were able to induce osteogenic differentiation of incorporated MSCs solely based on the mechanical properties of the bioink without the need for additional osteogenic stimuli. Incorporated cells displayed a viability of ~64.4% after culturing for 21 days, proving the biocompatibility of the bioink. Osteogenic differentiation was measured by quantification of calcium deposition by MSCs. They were able to show a concentration-dependent response based on the used MeHA polymer concentration (Figure 2E). Wei and co-workers more recently developed an alginate-polyvinyl alcohol (PVA)-hydroxyapatite bioink for 3D bioprinting of a scaffold that was relevant for bone tissue engineering.[84] Their bioink presented optimal rheological and biological properties for bioprinting of bone-like scaffolds encapsulating MC3T3-E1 preosteoblasts. The bioprinted constructs were stable for a duration of 14 days and encapsulated cells displayed high viability as well as osteogenic differentiation throughout the entire constructs.

In summary, the mechanical properties of the used bioink are crucial for the formation of 3D constructs. Not only do the mechanical properties have influence on the bioprinting properties and the rigidity of the final construct, but they also directly influence cell behavior and activity, including viability and differentiation. However, it remains to be understood in how far the mechanical properties of, in particular, bioinks with high toughness might impede cell proliferation and other crucial aspects of cell behaviors. Bioprinted constructs with high toughness, as aforementioned, are often based on dense polymer networks or rely on additives, which could have a direct effect on cell responses, such as proliferation, or on cell phenotypes. To fully prove the applicability of such hydrogels in the fabrication of biologically relevant tissues, it is crucial to investigate these characteristics in the future.

3.2. Biological properties of bioinks

Besides the passive influence of the bioink on laden cells based on mechanical forces, the bioink can also have direct influences on cell viability and behavior. Therefore, the biological properties and the biocompatibility of the bioink are crucial to ensure the generation of target tissues. Numerous bioinks have been used in bioprinting applications that can be loaded with cells to achieve cell-laden bioprinted constructs. The different advantages and disadvantages of specific bioinks in terms of their biological properties were reviewed extensively elsewhere.[29, 54, 57, 65] This section focuses solely on one specific source of highly biocompatible bioinks, which has been of particular interest for its use in bioprinting, i.e., dECM bioinks. In the body, ECM is excreted by resident cells to shape the microenvironment (“niche”) for optimal cell survival, adhesion, spreading, proliferation, migration, differentiation, as well as tissue formation and repair.[85] ECM can be harvested from a variety of allogeneic or xenogeneic tissue sources, including dermis, urinary bladder, small intestine, mesothelium, pericardium, and heart valves, and from several different species.[86]

Various studies show that such decellularized scaffolds can partly mimic the microenvironments in native tissues or organs.[81, 87, 88] For example, Zheng, Himmelfarb, and co-workers found that hydrogels could be derived from the human kidney cortex. Compared with normal kidney tissue, such kidney ECM (K-ECM) hydrogels contained a majority of native matrix proteins, such as collagen IV, laminin, and heparan sulfate proteoglycan and their isoforms.[89] Increasing evidence proved that such ECMs can provide niches that mimic their respective natural microenvironments of the body. Jin and co-workers recently reported that liver-derived ECM (L-ECM) from porcine origin could promote the differentiation of rat MSCs to hepatic cells.[88] Moreover, they found L-ECM could provide a microenvironment that contained many protein signals, which when in contact with exogenous additives (Mn2+), could lead to fibrosis through different integrin pathways.

Recently, it was demonstrated that dECM obtained from different tissues could serve as promising bioinks for 3D bioprinting (Figure 3A).[63, 81, 90] Cho and co-workers developed novel tissue-specific dECM bioinks, based on adipose, cartilage, and heart tissues. Tissue-specific cells could proliferate for at least 14 days in such tissue-specific bioinks.[63] The dECMs were solubilized to obtain a final concentration of 3 w/v.%. The acidic solubilized dECM solution was then adjusted to physiological pH for encapsulating cells while maintaining the temperature below 10 °C. These cell-laden dECM bioinks could be deposited through an extrusion nozzle, and then undergo gelation at physiological temperature to maintain the generated 3D structures. Rheological studies indicated that the three types of dECM-based bioinks had shear-thinning properties resulting in good printability. In addition, the gelation kinetics affirmed that these bioinks started immediate gelation at 15 °C and formed a stable crosslinked hydrogel at 37 °C within 30 min, avoiding the need of any harsh crosslinking conditions or gelatin additives. Cartilage-derived dECM (C-dECM), heart-derived dECM (H-dECM), and adipose-derived dECM (A-dECM) bioinks were used to 3D-bioprint respective tissue constructs (Figure 3B - 3D). The bioprinted and gelled multi-layered grids remained stable on the deposited position during a culture period without disintegration for over 14 days. In addition, Cho and co-workers managed to improve their dECM bioinks with vitamin B2-induced UV crosslinking and thermal gelation to induce solidification.[91] They displayed differentiation of cardiac progenitor cells in a bioprinted cardiomyogenic tissue with increased cell viability and proliferation over a duration of 23 days in culture.

Figure 3.

Bioprinting of tissue constructs with tissue-specific dECM bioinks. (A) Schematic representation of the bioprinting process using dECM bioinks. (B-D) Multi-layered tissue constructs were bioprinted with (B) cardiac-specific dECM bioink and representative microscopic image, (C) cartilage-specific dECM bioink and representative SEM image, and (D) adipose-specific dECM bioink and representative microscopic image. Reproduced with permission from ref.[63]. (E) Schematic representation of a bioprinted pre-vascularized stem cell patch using dECM bioink and supporting PCL. (F) Photograph of implanted cardiac dECM/PCL patch. (G) Cardiomyogenesis and neovascularization of the pre-vascularized stem cell patch. Reproduced with permission from ref.[92]. (H) SEM images of native porcine Achilles tendon and dECM obtained from the same tissue. (I) Collagen type I immunostaining of native and dECM tendon tissues. Reproduced with permission from ref.[93].

More recently, Kim, Cho, and co-workers successfully tackled the problem of cardiac repair.[92] They bioprinted stem cell-laden dECM multi-material patches that were able to promote direct cell-to-cell interaction and differentiation (Figure 3E and 3F). The patches displayed high vascularization and tissue matrix formation after implantation into Balb/c mice indicating their functionality in vivo. They showed enhanced cardiac function, reduced cardiac hypotrophy and fibrosis, increased migration from patch structure to the diseased area, as well as neo-muscle and capillary formation (Figure 3G). Their study suggested the applicability of dECM bioinks in in vivo situations. Furthermore, Koc and co-workers demonstrated the applicability of decellularized tendons in bioprinting applications, while drastically reducing the gelation time of their bioprinted constructs in comparison to previous methods (Figure 3H and 3I).[93] By applying an aspiration-extrusion method, where a dECM pre-gel obtained from bovine Achilles tendon gelled in a glass capillary and subsequently extruded, they were able to reduce the gelation time of their dECM bioink down to 6 min compared to 30 min gelation time using conventional protocols. The rapid gelation of their dECM bioink allows for the bioprinting of structures with high shape fidelity avoiding the need of a supporting structure. Encapsulated NIH/3T3 fibroblasts showed high viability as well as lineage-specific morphology.

In general, dECMs are auspicious candidate biomaterials for use as bioinks that are capable of providing optimized microenvironments conducive to the growth of specific tissues including but are not limited to cartilage, heart, adipose, and liver tissues.

3.3. Electrical properties of bioinks

In the last decade, 3D printing technologies have been widely employed to fabricate electronic circuits and devices.[94] The traditional manufacturing strategies of electronic devices are complex and cost-intensive, produce high amounts of waste, and are not environmental-friendly with multi-stage processes of photolithography/electron beam lithography, metal deposition, and lift-off. Meanwhile, the huge demand in electronic devices market also results in a strong need for low-cost, simple, and highly efficient technologies as alternatives for device fabrication.[95] To this end, 3D printing becomes a promising strategy to fabricate electronic devices that can easily achieve automated large-scale fabrication of electronics with high resolution (down to 20 μm).[96]

By the use of a conductive bioink, 3D bioprinting can also be applied in tissue engineering and regenerative medicine for the fabrication of bioelectronics and conductive tissues, such as heart tissues and spinal cord.[97, 98] For the design of a bioink that is suitable for the fabrication of bioelectronics, it is necessary to include a conductive material into the bioink to ensure high electrical conductivity. It is well-known that higher concentrations of nanomaterials produce better conductivity at the same bioink volume.[97] On the other hand, non-conductive materials can also significantly determine the conductivity of devices, which serve as organic polymeric stabilizers or adhesion promoters in the bioinks. Consequently, the electrical contact between conductive materials depends on these different aspects, which determines the electrical performance of bioprinted devices and tissues.

In general, the conductive material included into the bioink can be nanoparticles, polymers, or organometallic compounds.[99] Here, we focus on conductive nanomaterial-based bioinks, such as those based on metal nanoparticles, graphene, and carbon nanotubes (CNTs). Metal-based bioinks provide good electrical conductivity based on highly conductive metals, such as gold, silver, aluminum, or copper. In recent decades, gold in particular, has been widely used in regenerative medicine and drug delivery for its superior biocompatibility.[100] Shin, Khademhosseini, and co-workers incorporated gold nanorods into a GelMA-based bioink with the aim to bioprint cardiac tissue constructs.[101] They demonstrated that the encapsulation of nanorods did not significantly influence the viscosity of the bioink allowing for co-encapsulation of cells with a high density into the bioink resulting in rapid bioprinting of cell-laden constructs with a cell viability of approximately 70%. The encapsulation of gold nanorods caused an improved electrical propagation between cardiac cells and an advanced functionality of the bioprinted constructs. Their research demonstrated that bioprinted constructs with encapsulated gold nanostructures might offer a novel treatment for affected areas in the heart after myocardial infarction as well as applications in the engineering of electrogenic tissues such as the spinal cord, brain, or skeletal muscles.

Additional interesting components for conductive bioinks are carbon-based materials, such as graphene and CNTs. Graphene-based bioinks usually consist of pristine graphene (PG) or graphene oxide (GO). Although both materials would form suitable bioinks, the application of PG-based bioinks is strongly limited by the low dispersability of PG in aqueous media, resulting in final concentrations ranging from only 0.002–0.1 wt.% in the bioinks.[102] GO on the other hand, which is mainly produced by oxidation of graphene, shows excellent dispersability in water.[103] Dispersions of stable GO in the bioinks usually achieve final concentrations ranging from 0.1–1.0 wt.%, making it a suitable material for the use in bioprinting of conductive materials.[104] Hersam, Shah, and co-workers have reported the use of graphene-bioinks to 3D-bioprint functional cardiac and spinal cord tissues (Figure 4A).[105] The encapsulation of graphene did not influence the printability of their bioink in a negative way, and allowed for rapid bioprinting of free-standing anisotropic microstructures (Figure 4B). The extrusion shear forces facilitated reorientation and alignment of microflakes along the flow direction. The gross effect was a filament microstructure with graphene flakes aligned along the fibers. In vitro biological properties were determined by statically seeding of MSCs onto the 3D-bioprinted scaffolds. They found that, over a duration of 2 weeks, graphene-PLG scaffolds supported MSC growth and proliferation. The 3D-bioprinted constructs showed high electrical conductivity, flexibility, and biocompatibility. Furthermore, they were biodegradable and neurogenically active. Recently, Hsu and co-workers were able to successfully confirm the functionality of such GO-based bioinks for the fabrication of neural tissue constructs by encapsulation of GO into a waterborne biodegradable polyurethane-based bioink.[106] Encapsulated neural stem cells (NSCs) presented a high viability (>65%) and functionality after bioprinting. Furthermore, they confirmed the differentiation of NSCs by an increased gene expression of neural tissue specific markers such as β-tubulin, glial fibrillary acidic protein (GFAP), and microtubule-associated protein 2 (MAP2). Their research proved the application of GO-based bioinks in neural tissue engineering.

Figure 4.

Bioprinting of tissue constructs using bioinks with high conductivity and favorable bioelectronics properties. (A) Schematic showing the preparation of PLG-graphene conductive bioink and fabrication of tissue constructs by 3D printing. (B) (Left) Schematic of the extrusion of a bioink containing 60% grapheme and 40% PLG displaying how shear forces at the nozzle tip could result in graphene flake alignment. (Right) SEM images of the printed partially aligned grapheme flakes. Reproduced with permission from ref.[105]. (C) Schematic diagram of the bioprinting process for 3D electrically conductive constructs using DNA/HA-coated CNT bionks. (D) Cast GelMA constructs containing 3D-bioprinted CNT microfibers. (E) Immunostaining for sarcomeric α-actinin (green), nuclei (blue), and Cx43 (red) of cardiomyocytes encapsulated in the GelMA hydrogels containing bioprinted CNT microfibers 10 days post-bioprinting. Reproduced with permission from ref.[113]. (F) A 3D-printed wearable sensor for finger gesture recognition. Reproduced with permission from ref.[116].

CNT is another excellent conductive nanomaterial to formulate conductive bioinks. However, the hydrophobicity of CNT limits their application in bioprinting, as they tend to rapidly aggregate in aqueous solutions making it challenging to obtain a homogenous distribution of CNTs in the bioink.[99] Nevertheless, there are different strategies to obtain homogenous CNT bioinks based on the use of i) organic solvents without dispersants,[107, 108] ii) aqueous media with dispersants,[108, 109] and iii) chemical modification with a functional group.[108, 110] The production of CNT-based bioinks using organic solvents without dispersant usually results in low concentrations of CNT (<0.1 g L−1). To solve this problem, aqueous dispersants (e.g., Triton X-100 and sodium dodecyl sulfate [SDS]) have been used to obtain bioinks with high concentrations of CNTs.[111] Subsequent ultrasonication is additionally applied to prepare homogeneous CNT bioinks. The typical concentration of these CNT bioinks ranged from 0.01–10 g L−1.[112] As an example, Khademhosseini and co-workers tackled the problem of a proper CNT dispersion using bio-surfactants such as DNA, HA, and GelMA (Figure 4C and 4D). [113] They were able to create a bioink with high conductivity and biocompatibility. Cardiac fibroblasts seeded on top of this structure displayed a high viability of 90% and performance demonstrating the potential of CNT-based bioinks in bioprinting applications (Figure 4E). In addition, CNT-based bioinks also show promising performance in 4D bioprinting as indicated by Gou, Leng, and co-workers.[114] They coated CNT sheets with the shape-memory polymer Veriflex®. After application of an electric current (0.09 A) they observed the bending of the sheets into a “U” shape, which could rapidly be reversed within 2 min after release of the electrical current. Their research demonstrated the suitability of CNT-based bioinks for the use in 4D bioprinting applications.

Besides the application in bioprinting tissue-like constructs, 3D-printed electronic devices based on conductive inks can also be used for various applications in the field of medicine such as fabricating smart sensors or novel conductors. For example, 3D-printed electronic devices were used for measurement and stimulation of on a Langendorff-perfused rabbit heart, including electrocardiography (ECG), Si strain gauge, inorganic light-emitting diodes (LEDs), as well as pH and temperature sensors.[115] These elastic membrane-based sensors could easily achieve the multi-parameter analysis of the heart, which is difficult for conventional 2D sensors. Moreover, other groups developed a printed wearable sensor on the impedance changes of printed devices that could be used for the finger gesture recognition based (Figure 4F).[116] Recently, Kim and co-workers developed an ink for 3D printing of lithium batteries based on conductive silver nanowires (AgNWs) with a proven conductivity of 103 S/cm, which is 10 times higher compared to carbon-based conductors, and therefore especially applicable for batteries.[117] By combining the AgNW ink with cellulose, they achieved the necessary mechanical properties to successfully print 3D constructs. Although their approaches are not yet applicable for tissue engineering applications, printing highly conductive materials might have high potential for applications in regenerative medicine such as the development of smart pacemakers and sensors for interfacing with engineered tissues.[118]

Summarizing, 3D bioprinting with conductive bioinks is a promising technique to provide efficient, fast, and low-cost fabrication of bioelectronics as well as the fabrication of conductive tissue constructs for the application in tissue engineering and regenerative.

4. Cell Sources for Bioprinting

Bioprinting is generally defined as the “use of 3D printing technology with materials that incorporate viable living cells”, and therefore, it is clear that one of the essential parts of bioprinting is the cells used in the process.[119] The combination of the chosen bioprinting technique, the designed bioink, and the cell source determines whether bioprinting of a viable construct is successful or not. On the one hand, the bioprinting technique should allow the fabrication of 3D constructs with minimum damage to cells, while the bioink should possess certain properties to provide an optimal microenvironment for the cells. On the other hand, the cells should be derived from a suitable source that matches the specific application of bioprinting.

Several sources of cells are available for bioprinting, ranging from MSCs from different origins to patient-derived cells (Figure 5A). MSCs are a widely used in bioprinting applications. Although these cells can be derived from different sources, which will be discussed later on, most commonly the term MSC refers to stem cells derived from the bone marrow.[120] These multipotent stem cells generally differentiate into mesodermal lineages such as osteocytes, adipocytes, and chondrocytes as well as possessing the capacity to differentiate into ectodermal cells (e.g., neurocytes) and endodermal cells (e.g., hepatocytes).[120] Due to this wide range of differentiation possibilities, MSCs are a prominent source for the fabrication of various tissue types. Święszkowski and co-workers used cell-laden bioinks consisting of either GelMA, chondroitin sulfate amino ethyl methacrylate (CS-AEMA), or MeHA emulating the natural ECM properties, in combination with MSCs to bioprint 3D cell-laden constructs.[121] They observed high cell viability, chondrogenic differentiation, as well as high robustness of the obtained constructs, indicating the capability of their construct for the use as neocartilage. A similar approach was adopted by Cui and co-workers, who cultured MSCs on a 3D-bioprinted scaffold to investigate the importance of nuclear receptor subfamily 2 group F member 2 (NR2F2).[122] This factor plays a crucial role in the regulation of mesoderm-derived tissues on chondrogenesis. Fisher and co-workers successfully demonstrated the application of MSCs for bone tissue engineering.[123] They showed high cell spreading and survival as well as enhanced osteogenic differentiation of MSCs, supported by collagen type I in the used bioink. Khademhosseini, Annabi, and co-workers adopted MSCs to develop a large-scale bone construct with high structural fidelity, improved cell viability, and osteogenic differentiation as well as perfusable blood vessel-like microchannels within the construct.[124] Other than MSCs derived from bone marrow, cells originating from adipose tissue, termed as adipose-derived stem cells (ASCs), are also used in bioprinting applications and have shown a high potential.[125] Butcher and co-workers demonstrated a higher resistance of ASCs to increasing photoinitiator concentrations, which is known to negatively influence cell survival in bioprinted constructs, in comparison to aortic valve sinus smooth muscle cells (SMCs), resulting in higher cell survival.[126] This study demonstrated the robustness of these stem cells and their strong potential for bioprinting applications. Gruene and co-workers confirmed this by using ASCs for the fabrication of 3D tissue grafts for adipogenic differentiation based on laser-assisted bioprinting.[127]

Figure 5.

Cell sources for bioprinting. (A) Schematic overview of most common cell types used for bioprinting applications. (B) Bright-field and fluorescence images of multi-cellular constructs fabricated using inkjet bioprinting containing BAECs (green-labeled), human AFSCs (blue-labeled), and canine SMCs (red-labeled). (C) Microscopic image of microstructure of the multi-cellular construct. (D) Gross view of the multi-cellular construct 2 weeks after implantation in a mouse model. Reproduced with permission from ref.[128]. (E) Fluorescence and bright-field images of labeled iPSC-derived hepatocytes in green and a mixture of HUVECs and ASCs in red forming characteristic hepatic hexagon structures bioprinted by stereolithography. Reproduced with permission from ref.[135]. (F) Self-organized embryoids from iPSCs bioprinted in a supporting hydrogel matrix consisting of alginate, chitosan, and agarose (from left to right: 0 min, 350 min, 890 min and 1290 min. (G) Immunofluorescence staining in 3D-bioprinted embryoids of MAP2, GFAP, and GABA expressions as well as depth coding along z-axis from 0–47 μm. Reproduced with permission from ref.[136]. (H) Confocal images of a bioprinted blood vessel after long-term perfusion in a thick tissue construct. HUVECs appear in red and HNDFs in green. (I) Confocal microscope image of a 1 cm-thick vascularized osteogenic tissue construct containing HUVECs, HNDFs, and hMSCs. Reproduced with permission from ref.[140].

Besides MSCs and ASCs, Atala and co-workers further suggested that amniotic fluid-derived stem cells (AFSCs), a relatively new source of stem cells with wider availability, are also suitable for 3D bioprinting applications.[128] These multipotent cells possess a high capacity to differentiate into cell types from all three germ layers and can be maintained for long durations (up to approximately 250 population doublings) in vitro.[129] The same group successfully bioprinted a complex heterogeneous tissue construct containing human AFSCs, canine SMCs, and bovine aortic endothelial cells (BAECs) using inkjet bioprinting (Figure 5B). They mixed the cell sources with CaCl2 solution as crosslinking agent and deposited the mixture in an alginate-collagen bath. The final construct showed proper differentiation of AFSCs into the osteogenic lineage supported by vascularization from BAECs (Figure 5C and 5D). In addition, for 3D bioprinting that specifically aims to generate tissues from the spinal cord or from the brain, NSCs are a broadly used source to fabricate these tissues. NSCs are multipotent stem cells that especially generate neurons and glial cells of the nervous system,[130] facilitating bioprinting of functional nerve tissues. The topic will be discussed in a later section of this review addressing the 3D bioprinting of neural tissues.

Although the use of multipotent stem cells is widely applied and accepted in 3D bioprinting, their limitation to only differentiate into specific tissues might reduce overall capacity of bioprinting. Therefore, the use of pluripotent stem cells offers a superior cell source for bioprinting as these cells have the capacity to differentiate into almost every cell type in the human body.[131] Sun and co-workers demonstrated the applicability of pluripotent stem cells by bioprinting mouse embryonic stem cells (ESCs) into 3D constructs.[132] They observed high viability of cells (~90%) and proliferation after bioprinting. Moreover, these ESCs formed uniform embryoid bodies (EBs) after 7 days of culture mimicking the early stages of embryogenesis. Their bioprinted construct might find good application in drug screening and might bring a better understanding of biological processes behind embryonic development. Shu and co-workers further showed the high performance of ESCs by incorporating them into an alginate-based hydrogel with the aim to fabricate a 3D mini-liver.[133] They successfully differentiated ESCs into hepatocyte-like cells, which they confirmed by measuring a constant albumin secretion, reaching its peak at 21 days after bioprinting with an amount of approximately 2.5 ng mL−1. Their work demonstrated the use of ESCs for the fabrication of complex organ structures to achieve regenerative medicine. Nevertheless, the use of ESCs especially in the case of human ESCs in research is raising ethical and political controversies. This is due to facts that ESCs can only be derived from the inner cell mass of a blastocyst, an early-stage pre-implantation embryo.[134]

Fortunately, with the advances in stem cell biology over the last decades, the use of pluripotent stem cells in tissue engineering is no longer limited to ESCs but has also expanded to the use of induced pluripotent stem cells (iPSCs). To this end, Chen and co-workers were able to successfully bioprint an in vitro 3D hepatic model by combining iPSC-derived hepatic progenitor cells with human umbilical vascular endothelial cells (HUVECs) and ASCs in a rapid 3D bioprinting process (Figure 5E).[135] They revealed enhanced morphological organization, expression of liver-specific genes, increased metabolic product secretion, and enhanced cytochrome P450 induction. Their model might form a crucial step towards personalized early drug screening as well as improving the knowledge of liver pathophysiology. Recently, Wallace, Crook, and co-workers described a 3D-bioprinted platform for the differentiation of iPSCs into self-organizing embryoids comprising cells of endoderm, mesoderm, and ectoderm lineages or into homogenous neural tissues containing functional migrating neurons and neuroglia.[136] They managed to fabricate a fully 3D-bioprinted structure that was able to support iPSC differentiation for culture as well as expansion (Figure 5F and 5G).

Besides the use of multi- or pluripotent stem cells, fully differentiated cells have also been used in bioprinting applications. Naturally, in this case, the choice of an appropriate cell source is highly dependent on and selective for anticipated tissue as these cells do not possess the ability to differentiate into diverse tissues. Yang and co-workers fabricated gradient structures to obtain constructs with high physiological similarity.[137] They combined chondrocytes and collagen type II-containing bioinks with a gradient concentration of collagen to obtain zonal cartilage. This work is a step towards bioprinted constructs with a similar natural physiology. Another approach demonstrated the applications of bioprinting in drug screening. Nguyen and co-workers developed a 3D-bioprinted liver tissue containing patient-derived hepatocytes to investigate the effects of drug-induced liver injury.[138] They proved that the 3D-bioprinted construct formed a better model for testing drugs compared to a 2D model when insulted by Trovafloxacin. The clear cytotoxic effect, which they observed, could not be assessed using commonly used pre-clinical models mainly based on in vitro monolayer cultures of primary human hepatocytes, due to a rapid loss of their functions and activity in these cultures.[139]

Another step towards the fabrication of complex tissues that mimic the physiological properties of their native counterparts is the combination of several types of cells harvested from different cell sources. As an example, Lewis and co-workers successfully created a thick (~1 cm) and vascularized tissue construct that allowed perfusion for up to 6 weeks.[140] This construct consisted of MSCs and human neonatal dermal fibroblasts (DNFs) combined with HUVECS (Figure 5H and 5I). This work proved that it was possible to combine different types of cells from different cell sources to obtain a complex tissue construct through bioprinting.

It is clear that selection of the right cell source is an important step towards successful bioprinting of tissue constructs. Depending on the desired tissue types, cells should be chosen accordingly and provided with the optimal microenvironment allowing them to proliferate, spread, and if necessary, differentiate. Stem cells demonstrate a high potential to be used for the fabrication of patient-specific constructs, and in combination with gradient-like structures, complex architecture, and other relevant cell types, they together promise a great potential for the translation of 3D bioprinting into the clinics.

5. Emerging Evolutions in Bioprinting

To obtain biomimetic human tissues for translational applications, not only the choices of the proper bioprinting technique, bioink, and cell source are crucial, but it is also desirable to integrate these elements into newer 3D bioprinting strategies to further broaden the applications of bioprinting. Several different approaches have emerged over the past years that could potentially overcome the limitations of current bioprinting strategies, resulting in innovations that set milestones for further developments in this area. These innovations range from freeform bioprinting that addresses the challenges of gravity in conventional extrusion bioprinting and microfluidic bioprinting to obtain perfusable hollow vascular structures, to 4D bioprinting techniques taking bioprinting to the next dimension. In this section, we provide a detailed discussion on recent evolutions that have broadened the applications of bioprinting in achieving the fabrication of biomimetic tissue constructs.

5.1. Bioprinting of complex architectures

The human body consists of numerous complex structures ranging from the hepatic lobule in the liver and the delicate network of bronchi, arteries, and veins in the lung to the complex neural network in the brain.[141, 142] To achieve biomimetic tissues, mimicking the in vivo counterparts in both architecture and function is crucial. To this end, 3D bioprinting is a promising technique as it enables the design of complex structures based on computer-aided design (CAD) models as well as allows that designs to be directly digitized from medical images of the human tissues by for example, magnetic resonance imaging (MRI).[143] Recently, several studies addressed the challenge to bioprint complex structures to mimic human tissues, which are described in detail in this subsection.

5.1.1. Freeform bioprinting

One major limitation with conventional bioprinting lies in their inadequacy to deposit discrete layers that are not mechanically supported by those underneath.[144] As a consequence, a new class of 3D bioprinting techniques has been developed that permits direct extrusion of hydrogel bioinks into self-healing support hydrogels. This allows for the fabrication of discrete patterns in the volumetric space over relatively large scales and constructs with complex architectures. By design, either the deposited patterns in the hydrogel matrices can be sacrificially removed, leaving desired cavities in the 3D space, or the support matrices may be washed off to retain the bioprinted 3D structures. For example, Burdick and co-workers developed bioinks and support hydrogels based on supramolecular assembly through a guest-host system.[144] Due to non-covalent bonding of the guest-host molecules, splitting of the bonds could be achieved when an external stimulus, such as shear stress (in the case of the bioinks) or deformation (in the case of the support matrices), was applied. However, they could rapidly self-heal upon removal of the stimulus. Especially, the supramolecular hydrogels that were prepared based on modification of HA with either adamantine (Ad, guest) or β-cyclodextrin (β-CD, host) (Ad-HA and CD-HA) displayed promising performance. The intermolecular guest-host bonds between Ad and β-CD rendered the modified HA the capability to self-assemble upon mixing, which allowed for direct embedded bioprinting of 3D tissue architectures (Figure 6A). Using such a technique, supramolecular filaments with varying diameters could be deposited in the support hydrogel by adjusting the nozzle size, the volume of extruded bioinks, or the physical properties of hydrogels. The guest-host writing further enabled bioprinting of discrete 3D structures not achievable by standard methods, such as the bioprinting of a spiral structure surrounding a cylinder in the center (Figure 6B - 6E). Significantly, these supramolecular hydrogels could also be designed to possess a secondary moiety that facilitates covalent crosslinking on demand to stabilize bioprinted 3D structures. The same group introduced photocrosslinkable methacrylate groups into the Ad-HA (Ad-MeHA) and CD-HA (CD-MeHA), which could be used as either bioinks or support matrices, to selectively stabilize one of these two components. For example, bifurcated microchannels were fabricated by extruding Ad-HA/CD-HA bioink into the Ad-MeHA/CD-MeHA support matrix. UV-crosslinking of the support matrix permanently stabilized the construct and subsequent vacuum removal of the bioink formed hollow, perfusable channels. On the contrary, by using Ad-MeHA/CD-MeHA as bioink and extrusion into a non-crosslinkable support matrix, complex and crosslinkable 3D constructs were fabricated and retrieved by dissolving of the support matrix. The method was reported to exert no negative effects on embedded cells.

Figure 6.

Freeform embedded bioprinting of different shapes and constructs. (A) Schematic showing extrusion of a supramolecular HA-Ad guest bioink into a HA-CD host matrix. (B) Rhodamine-labeled filaments extruded into a fluorescein-labeled support hydrogel from using different needle gauges. (C) Confocal images of a filament of a fluorescein-labeled bioink and then a continuous spiral of a second, rhodamine-labeled bioink extruded into an unlabeled support hydrogel. (D) Confocal images of discrete pockets of a rhodamine-labeled bioink extruded into an unlabeled support hydrogel. (E) Confocal images of mesenchymal stem cells (green) printed within a bioink into a support hydrogel containing NIH/3T3 fibroblasts (red). Reproduced with ref.[144]. (F) Model and bioprinted structure of a human right coronary arterial based on a 3D MRI image with perfusable structure. (G) Model of a human femur and printed design with alginate bioink after removal from the support hydrogel. (H, I) Bioprinted scaffolds with complex internal and external architectures based on 3D imaging data from whole organs for (H) brain and (I) heart. Reproduced with permission from ref.[145]. (J) Thin-shell octopus bioprinted in different designs and a model of a Russian doll with several layers bioprinted in the support hydrogel. (K) A continuous network of hollow vessels with features spanning several orders of magnitude in diameter and aspect ratio. Reproduced with permission from ref.[146].

Similarly, Feinberg and co-workers used a suspension of gelatin microparticles with shear-thinning properties as a support matrix to enable direct deposition of bioinks in complex 3D structures.[145] After bioprinting, the thermosensitive gelatin support matrix could be selectively dissolved by elevating the temperature to 37 °C to retrieve bioprinted biomimetic tissues. With this technique, they were able to produce complex structures ranging from vascular and bone constructs to brain and heart models (Figure 6F - 6I). Angelini and co-workers adopted a similar idea by using a soft granular gel made from micrometer-sized soft hydrogel particles as support matrix that smoothly transited between fluid- and solid-like states.[146] The medium was fluidized under locally applied low shear stresses permitting direct writing of the bioinks, and rapidly re-solidified when the stresses were released, allowing for continuous bioprinting of complex 3D shapes (Figure 6J and 6K). Through subsequent removal of the support hydrogel the constructs could be retrieved after bioprinting. In a recent approach, Huang and co-workers took advantage of the physical crosslinking mechanism of alginate by Ca2+.[147] They designed an approach to fabricate 3D alginate structures based on a granular hydrogel support material-enabled two-step gelation process. The first step was based on the extrusion of an alginate-gelatin bioink into a 0.8 w/v.% Carbopol hydrogel environment, which allowed the freeform fabrication of constructs without the necessity to immediately crosslink the bioink. This step avoided clogging of the nozzle as well as allowing the different layers to easily fuse into a single construct. Gelatin in the bioink served as a sacrificial layer, which was thermally gelled after extrusion into the Carbopol environment (first gelation process). After removal from the Carbopol environment, gelatin was melted and diffused away while alginate was crosslinked in a CaCl2 bath (second gelation process).

5.1.2. Stereolithographic bioprinting

While conventional stereolithography typically suffers from the use of static patterns and low bioprinting speeds, in recent years this technique has undergone significant developments towards its use for rapid, dynamic patterning of biomaterials to achieve constructs with complex architecture. The dynamic photopatterning in stereolithography can be achieved by using a digital micromirror device (DMD). A DMD consists of millions of micro-sized mirrors, which can be individually tilted to allow for the formation of controllable patterns during the photocrosslinking processes of consecutive layers, thus enabling rapid fabrication of complex 3D structures. Chen, Khademhosseini, and co-workers observed enhanced cell proliferation and uniform cell distribution of HUVECs in DMD-fabricated GelMA scaffolds (Figure 7A).[148] Furthermore, they showed that the cells maintained their endothelial phenotype, demonstrating the biological functionality of the scaffolds using DMD-based stereolithography bioprinting. At the same time, Chen, Zhang, and co-workers verified the performance of this method by the rapid fabrication of microwells of 150–200 μm in diameter with different surface topographies to study the interactions between cells and their microenvironment.[149] They demonstrated different geometric guidance of HUVECs and NIH/3T3 fibroblasts with bioprinted scaffolds containing 15 w/v.% GelMA and 20 w/v.% PEGDMA (Figure 7B). Zhang and co-workers bioprinted nanocomposite matrices in different shapes to investigate bone metastasis of breast cancer (Figure 7C).[150] They compared MDA-MB-231 breast cancer cells with a high potential of metastasis with MCF-7 breast cancer cells possessing a low capacity of metastasis, in a PEG-diacrylate (PEGDA)-based bioink embedded with hydroxyapatite nanoparticles to mimic the human bone. They successfully created a 3D platform to investigate bone metastasis of breast cancer cells with an improved performance compared to 2D cultures.

Figure 7.

Stereolithography-based bioprinting. (A) Confocal images of HUVECs spreading on bioprinted scaffolds. Reproduced with permission from ref.[148]. (B) SEM images of PEGDA microwells of different shapes. Reproduced with permission from ref.[149]. (C) Confocal images of MDA-MB-231 cells on 3D-bioprinted bone matrices of different shapes, stained for phalloidin (red) and nuclei (blue). Reproduced with permission from ref.[150]. (D) Confocal fluorescence image of encapsulated NIH/3T3 fibroblasts in a bioprinted GelMA scaffold showing cell spreading and active cell-material interactions. Reproduced with permission from ref.[151]. (E) Bioprinted hybrid construct with HUVECs incorporated into a collagen hydrogel surrounded by a PEGDA scaffold. Reproduced with permission from ref.[152].

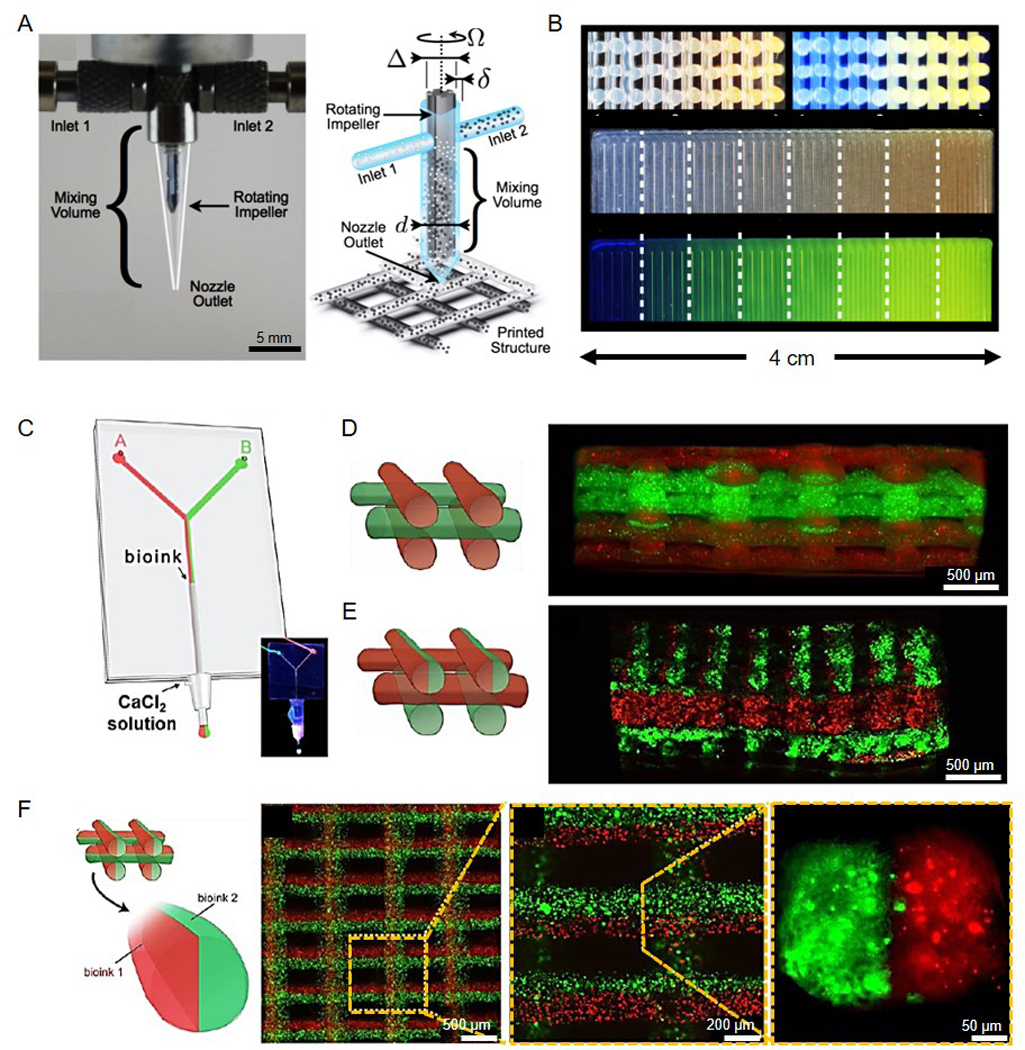

Cell-laden hydrogels have also been recently used to fabricate biological structures with DMD stereolithography bioprinters. Chen and co-workers proved this concept by bioprinting cell-laden GelMA constructs (Figure 7D).[151] They also presented the suitability of stereolithography as a platform to study cell interaction by creating complex micro-features in a short amount of time and eventually achieving high-throughput screening platforms. Yang and co-workers combined the process of stereolithography and extrusion-based bioprinting in a “hybprinter”, which was able to create scaffolds with rigid and soft components made from PCL and cell-laden PEGDA.[152] Viability studies with HUVECs displayed a high cell viability after bioprinting of a conduit structure (Figure 7E), exhibiting the capacity of this bioprinting system for tissue engineering applications.