Abstract

Slips, trips, and falls (STFs) pose a significant financial burden to employers and account for over 33% of the total nonfatal workers’ compensation cost in the United States. Previous analyses documenting the burden of STF incidents in the mining industry have focused on occupational fatalities or STFs during equipment ingress, egress. There is limited information on the burden of nonfatal STF incidents in the mining industry and most of it is outdated. Hence, to increase awareness and highlight the importance of STFs in the mining industry, this analysis documents the burden associated with nonfatal STF incidents at surface stone, sand, and gravel (SSG) mines from 2008 through 2017. In this time frame, nonfatal STF incidents occurred at a rate of 62 per 10,000 full-time equivalent (FTE) employees per year. Pits had a higher prevalence of injuries, but plants had a higher incidence rate. In addition, nonfatal STF incidents at surface SSG mines led to approximately 23,800 total days lost per year with an estimated cost to the mining industry of $17.5 million per year. Assessed violations that are not related to reported injuries but are related to STF hazards identified during Mine Safety and Health Administration (MSHA) inspections cost the mining industry approximately $3 million per year from 2013 through 2017. Based on the data analyzed in this study, falls to the lower level pose a higher burden in terms of cost; however, falls to the same level have a higher number of incidents and incidence rate.

Keywords: Slip, Fall, Injury, Cost, Burden, Mining

1. Introduction

Based on 2015 injury data for nonfatal accidents for all U.S. businesses, falls to the same level, falls to the lower level, and slips or trips without falls accounted for $11.2, $5.9, and $2.3 billion, respectively, in total workers’ compensation costs or direct costs (Liberty Mutual Insurance, 2018). These costs combined accounted for 33.1% of the direct cost of workplace injuries, making slips, trips, and falls (STF) the single largest contributor to workplace injury costs, with overexertion as the second largest contributor at 23.4%. From 2012 through 2015, there was an increase in the direct cost of STF injuries for all U.S. businesses; in contrast, the cost of overexertion injuries decreased from 2012 through 2015 (Liberty Mutual Insurance, 2014, 2016, 2017, 2018). The increasing cost of STF injuries indicates that they continue to pose a significant financial burden to U.S. employers.

Over 20 years ago, Leamon and Murphy (1995) indicated that slips and falls are a significant cause of occupational injuries, and multiple studies have since investigated STFs. In addition, STFs are a recurring issue, are not isolated geographically, and account for between 20% and 40% of incidents across countries (U.S., U.K., and Sweden) (Courtney et al., 2001). STF-related incidents are not isolated to a specific industry, and they have been identified and investigated in industries as diverse as healthcare (Bell et al., 2008; Bell et al., 2010), food service (Chang et al., 2008; Courtney et al., 2013, 2010), mail delivery (Bentley, 1998; Bentley and Haslam, 2001), dairy farming (Bentley et al., 2005), helicopter manufacturing (Amandus et al., 2012), and among electricians (Lombardi et al., 2009).

One industry that is closely related to mining—the focus of this work—is construction. Mining and construction have similarities due to the nature of the work, which is often performed outdoors, using large mobile equipment, and in environments that will change as production or construction progresses. The burden associated with STF incidents in the construction industry has also received a significant amount of attention (Bentley et al., 2006; Chi et al., 2005; Helander, 1991; Lehtola et al., 2008; Lipscomb et al., 2006; Radomsky et al., 2001).

STF-related incidents in the mining industry were investigated as early as the 1980s, where incidence rates of 22.65 per 1,000 employees were identified for mining and quarrying in the U.K. and accounted for 17.5% of all accidents (Buck and Coleman, 1985). Radomsky et al. (2001) analyzed Mine Safety and Health Administration (MSHA) data for the U.S. from 1996 through 1999 and identified approximately 85 fall-related fatalities per year and a total of approximately 11,870 days lost due to nonfatal fall injuries per year. Their study identified that the largest proportion of fall fatalities occurred in stone (40%) and sand and gravel (21%) mines. In comparison, the largest proportion of nonfatal days lost injuries occurred in coal (43%) and stone (27%) mines. However, the type of mine (underground/surface) was not identified in the analysis, which could potentially have a significant impact on the results due to the types of fall hazards encountered. A more recent analysis of STF-related fatalities that took place from 2003 through 2012 indicated approximately 6.2 STF-related fatalities per year based on MSHA fatal reports (Nasarwanji, 2016). Others have used Bureau of Labor Statistics (BLS) data to investigate STF injuries, and the portions of the mining industry that fall under the Occupational Safety and Health Administration (OSHA) are often included as part of the analysis (Yeoh et al., 2012; Yoon and Lockhart, 2006).

When considering STF injuries in the mining industry, one area that has received special attention is access to machinery and equipment. Albin and Adams (1989) indicated that STFs accounted for 20% of accidents when considering maintenance work at surface mines, with much of their study focused on access to machinery via stairs and ladders (Albin, 1988; Albin and Adams, 1989). A more recent analysis by Santos et al. (2010) indicated that a large proportion of injuries from haul trucks were due to slips or falls. Other analyses have also found that STFs can play a major role in falls during ingress to and egress from equipment (Moore et al., 2009; Nasarwanji et al., 2018).

Although efforts have been made to identify and quantify the impact of STFs in the mining industry, most of the analysis has focused on general occupational fatalities or the use of equipment. The little information that is available for the mining industry on nonfatal incidents is either outdated or is not specific to commodity or location within the operation (operating location). This lack of information makes it difficult to determine the current impact of STFs on the mining industry. In addition, it is imperative to periodically evaluate the impact of STFs to identify if there have been changes and if additional research is warranted. Further, although the economic burden posed by STFs is known in general, the economic burden posed by STFs for the mining industry is largely unknown and warrants investigation.

The National Institute for Occupational Safety and Health (NIOSH) uses three key elements—burden, need, and impact—to identify and define research priorities (www.cdc.gov/niosh/programs/bni.html). Within this framework, “burden provides evidence of the health and safety and economic burden (or potential burden) of workplace risks and hazards.” The objective of the analysis in this paper is to document the burden associated with STFs from 2008 through 2017 in terms of injury incidence rates (IRs), number of injuries, reported days lost from work, and cost to the surface stone, sand, and gravel (SSG) mining sector. The overall goal of this paper is to raise awareness and emphasize the importance of slips, trips and, falls in the mining industry, encourage research to reduce and prevent STF in the mining industry, and to encourage the industry and suppliers to adopt solutions that enable mines to proactively remediate STF risk.

2. Methods

2.1. Injury characterization

2.1.1. Datasets

Mines in the U.S. are required to report employment data as well as any accidents, injuries, or illnesses that occur (other than those requiring minor first aid only) to MSHA under part 50 of the U.S. Code of Federal Regulations (CFR). The annual records of accidents, injuries, or illnesses and employment records are publicly available through MSHA. NIOSH adds several recoded and computed variables to the accident, injury, or illness records and publishes these along with the employment records as SPSS (IBM SPSS Inc., Chicago, IL) datasets, details of which can be accessed at www.cdc.gov/niosh/mining/data/default.html. Two separate datasets—the accident, injury, or illness dataset and the employment dataset—published by NIOSH were used for this analysis.

2.1.2. Case selection and analyses

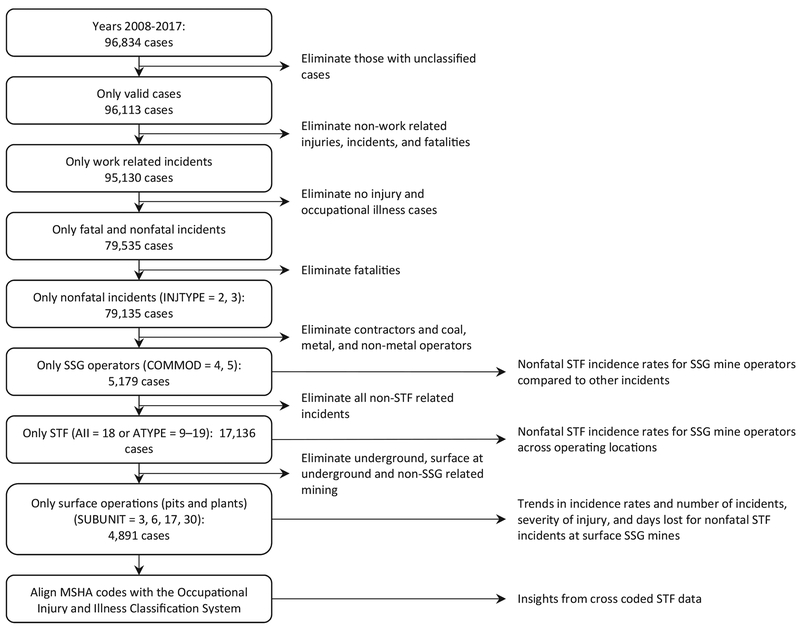

The dataset was preliminary cleaned to exclude unclassified cases, non-work related injuries and fatalities, cases with no injuries, occupational illnesses, and fatalities. STF incidents were identified based on two pre-coded variables in the accident, injury, or illness dataset: the accident type or event (ATYPE) and the accident/injury/illness classification (AII). ATYPE is the actual event that led to the reported injury (e.g. struck by, fall, caught in, or overexertion). In contrast, AII identifies the circumstances that contributed most directly to the accident or incident (e.g. hoisting, handling materials, or slip or fall of a person). For this analysis, STF incidents were defined as a slip or fall of a person (AII1 = 18) or when ATYPE started with the phrases “fall from,” “fall to,” “fall down,” or “fall on” (ATYPE = 9–19). The stone commodity was combined with sand and gravel to form the SSG category—the focus of this analysis. Contractors were eliminated due to a lack of employment information. Surface operations were selected based on the reported mine location (operating location) and were coded as pits (including surface operations, strip and open-pit mines and associated shops and yards, and dredge mining) (SUBUNIT = 3, 6) and plants (including mills, preparation plants, breaker operations, and independent shops and yards) (SUBUNIT = 17, 30). It is noteworthy that, although sand and gravel mines process materials in plants, MSHA only codes the mines as surface operations, strip, and open-pit mines and associated shops and yards, or dredge mining. Hence, in the current analysis for SSG mines, plants only include stone mines. Where reported, underground operating locations include underground operations and surface operations at underground mines including shops, yards, and tipples (SUBUNIT = 1, 2). In addition, where reported, coal mines have auger and culm banks (SUBUNIT = 4, 5) included under pits, and metal and nonmetal mines have other surface operations like brine pumping (SUBUNIT = 12) included under pits. From a total of 96,834 cases identified from 2008 through 2017, selecting only non-fatal STF incidents for surface SSG mine operators yielded 4,891 cases. The case selection flowchart and an overview of the analysis methods is shown in Fig. 1.

Fig. 1.

Flowchart showing case selection and an overview of analysis methods.

Analyses of SSG mine operators were carried out in five stages as described: (1) evaluation of nonfatal STF IRs compared to other incidents, (2) evaluation of nonfatal STF IRs across operating locations, (3) evaluation of trends in nonfatal STF IRs and number of incidents for surface SSG mine operators (hereafter referred to as surface SSG mines), (4) evaluation of severity of injury and days lost for nonfatal STF incidents at surface SSG mines, and (5) evaluation of nonfatal STF incidents at surface SSG mines aligned with the commonly used Occupational Injury and Illness Classification System (OIICS) (Bureau of Labor Statistics, 2014).

2.1.2.1. Nonfatal STF incidence rates for SSG mine operators compared to other incidents.

To evaluate nonfatal STF incidence rates (IRs) compared to other incidents, the accident, injury, or illness dataset and the employment dataset were further processed in four steps. First, ATYPE from the accident, injury, or illness dataset was recoded from 44 detailed categories to 10 overarching categories: (1) struck (against or by) (ATYPE = 1–8), (2) fall (from, down, to, on/onto) (ATYPE = 9–19), (3) caught in-under-between (ATYPE = 20–24), (4) overexertion (ATYPE = 27–30), (5) contact with physical hazards (electricity, heat/hot object, cold/cold object) (ATYPE = 31–35), (6) exposure to noxious substances (ATYPE = 36–38), (7) flash burns (ATYPE = 39, 40), (8) rubbed or abraded (ATYPE = 25), (9) bodily reactions not elsewhere classified (ATYPE = 26), and (10) unclassified or not elsewhere classified (ATYPE = 41–43). Second, the total number of incidents were calculated per year from the accident, injury, or illness dataset. Third, the total employment hours per year were calculated from the employment dataset. Fourth, IR was computed per 10,000 full-time equivalent (FTE) employees per year using Eq. (1) The total employee hours at a mine were only counted once, even if the mine had more than one reportable incident in that year.

| (1) |

2.1.2.2. Nonfatal STF incidence rates for SSG mine operators across operating locations.

To evaluate nonfatal STF incidence rates across operating locations, the accident, injury, or illness dataset was further reduced to include only STF incidents (as defined earlier), and the commodity was restricted to SSG. The employment dataset was also reduced to restrict the commodity to SSG. The total number of incidents per year was calculated for each operating location from the accident, injury, or illness dataset, and the total employment hours per year for each operating location were calculated from the employment dataset. The IR was computed per 10,000 FTE employees per year using Eq. (1).

2.1.2.3. Trends in incidence rates and number of incidents, severity of injury, and days lost for nonfatal STF incidents at surface SSG mines.

For all further analyses, cases were selected to represent nonfatal STF incidents for surface SSG mine operators (surface SSG mines). To calculate IRs, the total number of incidents per year and total employment hours per year were calculated for the two operating locations (pits and plants) from the accident, injury, or illness dataset and employment dataset, respectively. The IR was computed per 10,000 FTE employees per year using Eq. (1). The decreases in IRs and number of STF incidents were estimated with 95% confidence intervals (95% CI) using a linear regression model. The predictor in the model was the year and the criterion were the IRs or the number of STF incidents.

To evaluate seasonal trends, the four seasons were coded as spring (from March through May), summer (from June through August), autumn (from September through November), and winter (from December through February). To evaluate temporal trends during the working shifts, “hours worked” refers to the interval between the scheduled start time for the shift and the time when the injury occurred. A negative value indicates that the actual start time was earlier than the scheduled start time and that the injury occurred before the scheduled start time. Injury trends were also evaluated based on time and are shown on the military time scale.

The severity of injury, in terms of days away from work and/or days of restricted activity, is reported using descriptive statistics, including the number of incidents and percentage for the two operating locations (pits and plants). For days lost, the days per year and days per incident are reported for the days of restricted activity, actual days lost/away from work, and the total lost work days as averages and standard deviations (SD). Days of restricted activity and actual days lost/away from work are based on Form 7000–1 used by mines to report accidents, injuries, and illnesses to MSHA. Total lost work days is a variable computed by NIOSH, which represents the higher of the following two values: (1) the statutory days away from work (assigned based on the level of disability), or (2) the sum of days of restricted activity and the actual days lost from work.

2.1.2.4. Nonfatal STF incidents at surface SSG mines aligned with the Occupational Injury and Illness Classification System.

MSHA’s unique coding of injuries into two variables, ATYPE and AII, makes it difficult to compare results to other commonly used illness and injury classification schemes, such as the Occupational Injury and Illness Classification System 2.01 (OIICS) (Bureau of Labor Statistics, 2014). Therefore, the MSHA dataset was recoded to aid in a comparison with other published work, to help with estimation of economic burden, and to align the MSHA STF incidents with the OIICS. Two variables (AII and ATYPE) from the MSHA accident, injury, or illness dataset were combined and recoded into a single categorical variable with three categories: falls to the lower level (to match OIICS code: 43), falls to the same level (to match OIICS code: 42), and slips or trips without falls (to match OIICS code: 40/41) (Bureau of Labor Statistics, 2014). Falls to the lower level were coded when ATYPE was a fall down a raise, a shaft, or a manway underground; a fall from scaffolding, elevated walkway, platform, headframe, derrick, tower, machine, vehicle, equipment, spilled material, ladder, down stairs; or a fall to the lower level not otherwise classified (ATYPE = 9–16). Falls to the same level were coded when ATYPE was a fall to a walkway or working surface, a fall onto or against objects, or a fall on the same level not otherwise classified (ATYPE = 17–19). Slips or trips without falls was coded when AII was a slip or fall of a person (AII = 18) with ATYPE, other than those included in falls to the lower level and falls to the same level (ATYPE = 1–8 & 20–44). Severity of injury and days lost were calculated as described in Section 2.1.2.3.

2.2. Economic burden

2.2.1. Safety Pays in mining estimates

Accessing the economic and financial burden associated with STF incidents in the mining industry can be a challenge due to a lack of data. Mines are not required to report to MSHA on the cost of injuries, and insurance claim data is not readily available for the mining industry specifically. To estimate the financial burden associated with STF injuries in the mining industry, an online cost estimator called “Safety Pays in Mining,” recently released by NIOSH, was utilized to estimate the direct and indirect cost of STF injuries. The tool is based on data provided by the Ohio Bureau of Workers’ Compensation and represents the costs of lost-time workers’ compensation insurance claims adjusted to the U.S. dollar value in 2015 (Heberger, 2018). Details and limitations of the Safety Pays in Mining cost estimator can be found at https://www.cdc.gov/niosh/mining/content/economics/safetypays.html.

The Safety Pays in Mining cost estimator provides the percentile distribution of direct cost, the mean direct cost, and the associated indirect cost for “slips or trips without falls,” “falls on same level,” and “falls to the lower level” at surface SSG mines. The total number of incidents per year from the accident, injury, or illness dataset aligned with the OIICS was used to calculate the cost of the nonfatal STF incidents. Estimates for the direct, indirect, and total cost of nonfatal STF incidents are reported based on the median (50th percentile), mean, and the cost distribution from the Safety Pays in Mining cost estimator. When calculating the cost based on the percentile distribution, the number of STF incidents were proportioned to match the percentile distribution of costs from the Safety Pays in Mining cost estimator; i.e. the first 25% of incidents were assigned an arbitrary minimum value of $1.00, the next 25% were attributed to the 25th percentile cost, the next 25% were attributed to the 50th percentile cost, the next 15% were attributed to the 75th percentile cost, the next 5% were attributed to the 90th percentile cost, and the last 5% were attributed to the 95th percentile cost. As the cost distribution in the Safety Pays in Mining cost estimator is significantly skewed towards the higher end, the cost distribution calculated would be most representative of the cost of non-fatal STF incidents at surface SSG mines, with the mean overestimating the cost and the median underestimating the cost.

2.2.2. Cost of assessed violations related to STF

MSHA is responsible for conducting regular safety inspections at mines. Based on these inspections, MSHA may identify violations of Title 30 of the U.S. Code of Federal Regulations (30 CFR) on Mineral Resources. These violations can lead to an assessed monetary penalty to the mine. Assessed monetary penalties for violations related to STF hazards pose a financial cost to mining companies, and these penalties have been used as a second source to evaluate financial burden in this research study. It should be noted that violations are not directly related to reported injuries, but represent hazards identified during inspections by MSHA.

A public record of violations and the assessed monetary penalties to the mines by MSHA were evaluated for violations that took place for the five-year period from 2013 to 2017. Violations initially cited can be contested, and after resolution a final assessed monetary value is attributed to the violation, which the mine is responsible for paying. The assessed violations dataset was cross-referenced with the MSHA employment dataset to select surface SSG operators. Most violations at surface SSG mines (84.8%) were associated with 30 CFR Part 56, Safety and Health Standards. After a review of 30 CFR Part 56 (www.msha.gov/regs/30cfr/), four specific categories of violations were investigated further that represent STF hazards in the environment: (1) 30 CFR Part 56 Subpart J (§56.11001–§56.11027) on travelways, (2) 30 CFR §56.20003 on housekeeping, (3) 30 CFR Part 56 Subpart P (§56.17001) on illumination of surface working areas, and (4) 30 CFR §56.15005 on safety belts and lines. The number of violations, average and median cost per violation, and total cost of the violations are reported in the results.

3. Results

3.1. Nonfatal STF incidence rates compared to other incidents and across operating locations

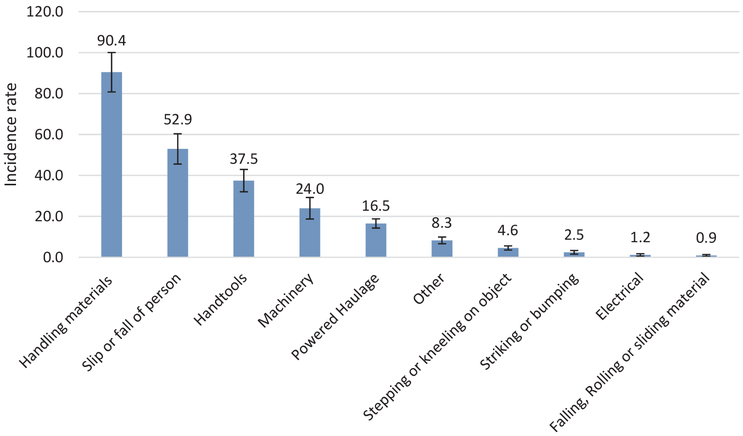

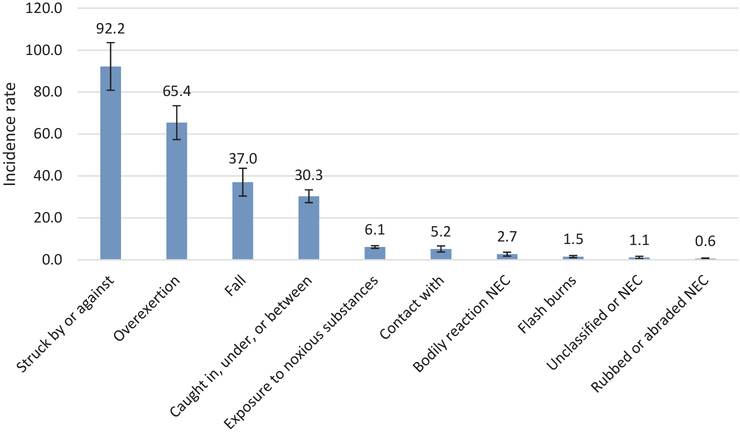

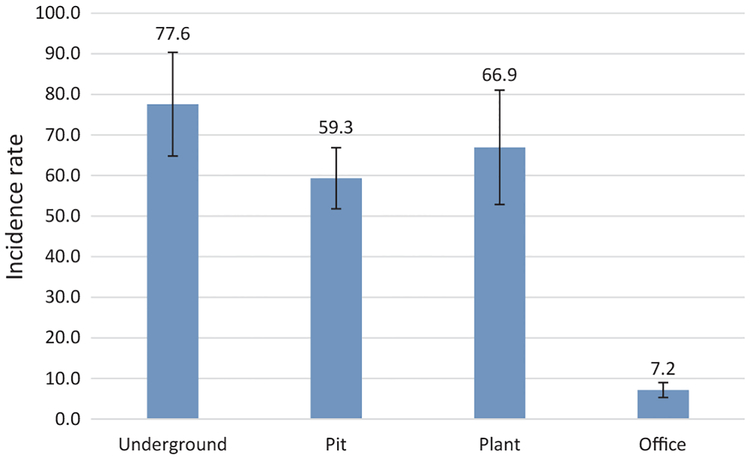

Nonfatal STFs occurred at a rate of 54.2 (SD = 7.8) per 10,000 FTE employees per year at SSG mines across all operating locations and at a rate of 62.1 (SD = 9.6) per 10,000 FTE employees per year at surface SSG mines. Figs. 2 and 3 show the IRs at SSG mines based on AII and ATYPE, respectively. Based on AII, slips or falls occurred at a rate of 52.9 per 10,000 FTE employees per year at SSG mines and were the second highest IR, second only to handling materials. Based on ATYPE, falls occurred at a rate of 37.0 per 10,000 FTE employees per year and were the third highest IR, with struck-by and overexertion being the top two. Fig. 4 shows the STF nonfatal IRs for the four primary operating locations at SSG mines. There were significant differences in the IRs between locations (F (3,36) = 92.86, p < 0.00); underground and plant were not significantly different, and pit and plant were not significantly different. IRs were the highest for underground locations (77.6 per 10,000 FTE employees per year), followed by the plants and then the pits (66.9 and 59.3 per 10,000 FTE employees per year, respectively). IRs at the office were the lowest among the four operating locations (7.2 per 10,000 FTE employees per year). Supplemental Data A provides a detailed table of IRs for SSG, metal, nonmetal, and coal mines based on AII, ATYPE, and operating location.

Fig. 2.

Nonfatal incidence rates from 2008 through 2017 (per 10,000 FTE employees per year) at stone, sand, and gravel mines for the top ten accident/injury/illness (AII) classifications. Error bars show the standard deviation.

Fig. 3.

Nonfatal incidence rates from 2008 through 2017 (per 10,000 FTE employees per year) at stone, sand, and gravel mines based on accident type or event (ATYPE). Error bars show the standard deviation. NEC = not elsewhere classified.

Fig. 4.

Slip, trip, and fall nonfatal incidence rates from 2008 through 2017 (per 10,000 FTE employees per year) at stone, sand, and gravel mines across operating locations. Error bars show the standard deviation.

3.2. Trends in nonfatal STFs at surface SSG mines

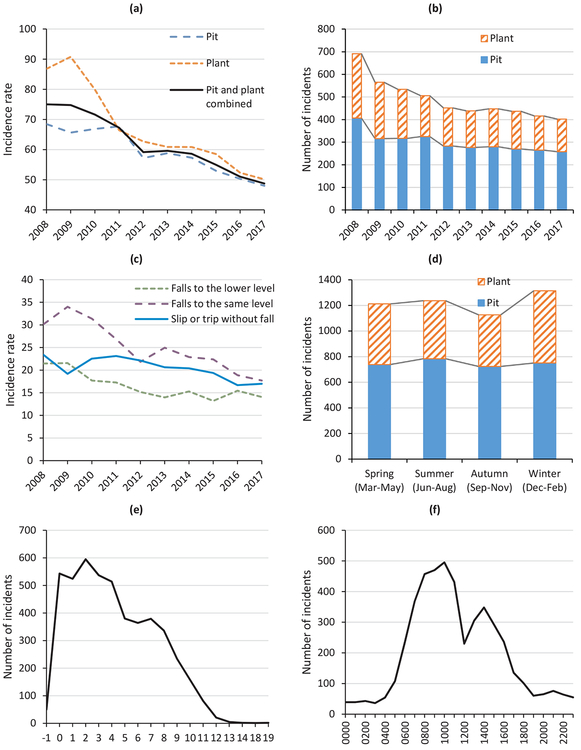

There was a significant decrease in the overall number of STF injuries at pits and plants at SSG mines, from 692 per year in 2008 to 402 per year in 2017, which accounts for a reduction rate of about 26 cases per year (95% CI: −36.7 to −15.7) (Fig. 5(b)). After being adjusted for fluctuations in employment, IR reduced steadily from 75.0 per 10,000 FTE employees per year in 2008 to 48.7 per 10,000 FTE employees per year in 2017, with an average reduction of 3.1 per 10,000 FTE employees per year (95% CI −3.6 to −2.3) (Fig. 5(a)). When separated into pits and plants at surface SSG mines, the number of STF incidents is higher at pits as compared to plants; however, the IR is higher at plants (Fig. 5(a) and (b)). The global trend in the reduction of STF incidents is mirrored in the IR for STFs when the STF codes are aligned with the OIICS (Fig. 5(c)). However, the decrease in IR for slips or trips without a fall (0.61 per year, 95% CI: −1.0 to −0.12) and falls to the lower level (0.84 per year, 95% CI: −1.3 to −0.43) have not shown a dramatic decrease as seen in falls to the same level (1.65 per year, 95% CI: −2.21 to −1.08). In addition, falls to the same level consistently have a higher IR as compared to falls to the lower level or slips or trips without falls.

Fig. 5.

Trends in nonfatal STF incidents at surface SSG mines (n = 4,891): (a) incidence rates (IR) (per 10,000 FTE employees per year) by operating location, (b) total number of incidents by operating location, (c) incidence rates (IR) (per 10,000 FTE employees per year) aligned with OIICS categories, (d) number of incidents by season and operating location, (e) number of incidents by hours worked (n = 4,726 due to missing data), and (f) number of incidents by time of day (n = 4,741 due to missing data).

Annual seasonal trends for STF incidents were identified. Autumn (September-November) had the lowest number of STF incidents, followed by spring (March-May), with the highest in summer (June-August) and winter (December-February) (Fig. 5(d)). The seasonal trend was more pronounced at pits as compared to plants. The number of STF-related incidents was the highest in the first four hours of the shift (based on the number of hours worked before the injury occurred) with a steady decline as the hours worked increases (Fig. 5(e)). Daily trends in the number of incidents were also identified with peaks at around 10 AM, and 2 PM with a slight dip around noon, potentially due to a break for lunch (Fig. 5(f)).

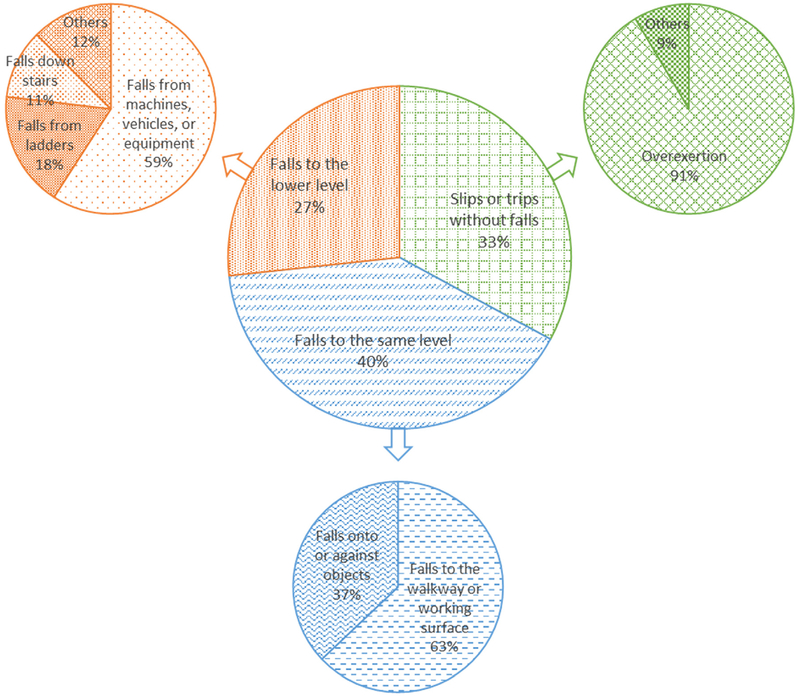

To help shed some light on the type of falls to the same level, falls to the lower level, and slips or trips without falls, detailed accident type (ATYPE) information is presented for the three categories of STF incidents aligned with the OIICS in Fig. 6. Falls to the same level were the most common, followed by slips or trips without falls and falls to the lower level (Fig. 6), similar to the trend seen in Fig. 5(c). Falls to the lower level were most often from machines, vehicles, and equipment (59%) and from ladders and stairs (29%). Falls to the same level were primarily due to falls to the walkway or working surface (63%). Slips or trips without falls were most often attributed to overexertion (91%).

Fig. 6.

Proportion of STF incidents based on the Occupational Injury and Illness Classification System and details of the accident type (ATYPE) associated with each of the three categories (n = 4,891).

3.3. Severity of injury and days lost for nonfatal STF incidents at surface SSG mines

About 83% of the STF incidents resulted in days of restricted activity, days away from work, or both, and about 17% resulted in injuries without days off or restricted activity. There was a significant association between severity of injury and operating location (χ2(4) = 117.0, p < 0.00), with a higher proportion of injuries resulting in days away from work (37.0%) at pits as compared to a higher proportion of injuries resulting in days of restricted activity (39.5%) at plants (Table 1). A total of 23,789 (SD = 2,016) days were lost per year due to nonfatal STF incidents at surface SSG mines, which represents 49.6 (SD = 7.4) total days lost per incident (Table 1). There were significantly more (χ2(1) = 14.57, p < 0.00) days of restricted activity per incident at plants (19.7 days per incident) as compared to pits (14.3 days per incident) due to STF incidents. In contrast, actual days lost per incident were higher at pits (34.5 days per incident) as compared to plants(28.8 days per incident) for STF incidents.

Table 1.

Severity of injury (number of cases) and days lost for nonfatal STF incidents at surface SSG mines by operating location from 2008 through 2017.

| Pit | Plant | Total | ||||

|---|---|---|---|---|---|---|

| n | Percent | n | Percent | n | Percent | |

| Severity of injury (number of cases) | ||||||

| Injury without days away or restricted activity | 609 | 20.3 | 333 | 17.6 | 942 | 19.3 |

| Injury with days of restricted activity only | 764 | 25.5 | 747 | 39.5 | 1,511 | 30.9 |

| Injury with days away only | 1,108 | 37.0 | 503 | 26.6 | 1,611 | 32.9 |

| Injury with days away and restricted activity | 513 | 17.1 | 309 | 16.3 | 822 | 16.8 |

| Injury with permanent disability, partial or total | 4 | 0.1 | 1 | 0.1 | 5 | 0.1 |

| Total | 2,998 | 100 | 1,893 | 100 | 4,891 | 100 |

| Mean | SD | Mean | SD | Mean | SD | |

| Days lost (per year) | ||||||

| Days of restricted activity | 4,263.6 | 482.0 | 3,662.3 | 846.9 | 7,925.9 | 1,138.7 |

| Actual days lost/away from work | 10,130.4 | 1,236.9 | 5,312.6 | 1,049.0 | 15,443.0 | 1,939.5 |

| Total lost work days | 14,809.5 | 1,324.2 | 8,979.9 | 1,409.0 | 23,789.4 | 2,016.0 |

| Days lost (per incident) | ||||||

| Days of restricted activity | 14.3 | 1.5 | 19.7 | 4.1 | 16.4 | 1.8 |

| Actual days lost/away from work | 34.5 | 6.9 | 28.8 | 6.1 | 32.3 | 6.3 |

| Total lost work days | 50.3 | 8.5 | 48.5 | 6.9 | 49.6 | 7.4 |

When the STF incidences were coded to align with the OIICS, falls to the lower level most often resulted in days away from work (39.9%) (Table 2). Slips or trips without falls most often led to days of restricted activity (36.8%); however, the number of days per incident was higher for actual days lost from work (9.2 days per incident) as compared to days of restricted activity (5.8 days per incident). Falls to the same level had a higher proportion of injuries without days lost or restricted activity (25.6%) as compared to the other two categories. Falls to the same level led to the highest total days lost per year (8,377 days per year) and represented 17.29 total days lost per incident, with falls to the lower level being a close second (8,308 days per year or 17.28 total days lost per incident). Slips or trips without falls had the lowest total days lost per year (7,103 days per year), accounting for 15.1 total days lost per incident.

Table 2.

Severity of injury (number of cases) and days lost for nonfatal STF incidents aligned with the OIICS at surface SSG mines from 2008 through 2017.

| Slips or trips without falls | Fall to the same level | Fall to the lower level | ||||

|---|---|---|---|---|---|---|

| n | Percent | n | Percent | n | Percent | |

| Severity of injury (number of cases) | ||||||

| Injury without days away or restricted activity | 235 | 14.6 | 506 | 25.6 | 201 | 15.4 |

| Injury with days of restricted activity only | 593 | 36.8 | 588 | 29.8 | 330 | 25.3 |

| Injury with days away only | 495 | 30.7 | 595 | 30.1 | 521 | 39.9 |

| Injury with days away and restricted activity | 284 | 17.6 | 286 | 14.5 | 252 | 19.3 |

| Injury with permanent disability, partial or total | 3 | 0.2 | 0 | 0.0 | 2 | 0.2 |

| Total | 1,610 | 100 | 1,975 | 100 | 1,306 | 100 |

| Mean | SD | Mean | SD | Mean | SD | |

| Days lost (per year) | ||||||

| Days of restricted activity | 2,777.0 | 590.3 | 2,947.5 | 500.2 | 2,201.4 | 622.1 |

| Actual days lost/away from work | 4,320.8 | 809.4 | 5,430.2 | 1,087.9 | 5,692.0 | 1,453.0 |

| Total lost work days | 7,103.3 | 978.9 | 8,377.7 | 1,514.2 | 8,308.4 | 1,436.3 |

| Days lost (per incident) | ||||||

| Days of restricted activity | 5.8 | 1.5 | 6.1 | 0.9 | 4.5 | 0.7 |

| Actual days lost/away from work | 9.2 | 2.8 | 11.2 | 2.0 | 11.9 | 3.5 |

| Total lost work days | 15.1 | 3.8 | 17.3 | 2.6 | 17.3 | 3.4 |

3.4. Economic burden

3.4.1. Safety Pays in mining estimates

Based on the Safety Pays in Mining cost estimator, the total cost (based on distribution) of nonfatal STF injuries at SSG mines is $17.49 million per year, which is divided as $5.60 million in direct costs and $11.89 million in indirect costs (Table 3). Although the overall number of incidents and IRs was lower for falls to the lower level (Fig. 5(c)), they had the highest cost (based on distribution) per incident (Table 3) due to the high direct cost (and associated indirect cost) per incident. Falls to the same level had the lowest cost (based on distribution) per incident but the highest number of incidents and IRs (Fig. 5(c) and Table 3). The total mean costs were higher at $59.19 million per year as compared to the total median costs at $2.95 million per year.

Table 3.

Estimated cost of injuries per year for STF incidents at surface SSG mines from 2008 through 2017 based on the Safety Pays in Mining cost estimator.

| Slips or trips without falls | Falls to the same level | Falls to the lower level | Total | |

|---|---|---|---|---|

| Average number of incidents per year | 161 | 198 | 131 | 490 |

| Cost based on distribution | ||||

| Direct cost | $1,688,930 | $1,746,905 | $2,171,358 | $5,607,193 |

| Indirect cost | $3,580,503 | $3,703,392 | $4,603,242 | $11,887,137 |

| Total cost | $5,269,433 | $5,450,297 | $6,774,600 | $17,494,329 |

| Median cost per year | ||||

| Direct cost | $322,000 | $257,400 | $366,800 | $946,200 |

| Indirect cost | $682,640 | $545,688 | $777,616 | $2,005,944 |

| Total cost | $1,004,640 | $803,088 | $1,144,416 | $2,952,144 |

| Mean cost per year | ||||

| Direct cost | $5,393,500 | $6,989,400 | $6,589,300 | $18,972,200 |

| Indirect cost | $11,434,220 | $14,817,528 | $13,969,316 | $40,221,064 |

| Total cost | $16,827,720 | $21,806,928 | $20,558,616 | $59,193,264 |

3.4.2. Cost of assessed violations related to STF

The cost of assessed violations was considered for the five-year period from 2013 to 2017. Overall, the four specific violations of interest accounted for 13.7% (n = 23,688) of all health and safety violations at surface SSG mines with a total assessed monetary value of $14.9 million, which represented about 23.6% of the overall assessed cost of health and safety violations to SSG mines from 2013 through 2017 (Table 4). Travelways (Subpart J) was the third most cited health and safety violation (n = 13,387) overall and had the fourth highest total sum of assessed monetary value ($6.2 million), with the top two being related to machinery and equipment and electricity. Each assessed violation related to travelways had an average monetary value of $461 (SD = $2,187) and a median value of $116 per violation. Over 76% of the violations on travelways were attributed to safe access, handrails and toe boards, and construction and maintenance of ladders, and these violations accounted for about 83.6% of the total monetary assessed value.

Table 4.

Cost of assessed violations between 2013 and 2017 for slip, trip, and fall related hazards.

| Citation category | Number of Citation | Assessed value of citation | |||

|---|---|---|---|---|---|

| Sum | Average | SD | Median | ||

| Travelways | 13,387 | $6,170,224 | $461 | $2,187 | $116 |

| Housekeeping | 8,692 | $6,719,937 | $773 | $2,270 | $138 |

| Safety belts and lines | 1,108 | $1,863,735 | $1,682 | $4,369 | $473 |

| Illumination | 501 | $130,916 | $261 | $555 | $116 |

| Total | 23,688 | $14,884,812 | |||

Housekeeping was the most frequently cited violation in its Subpart related to miscellaneous items, and accounted for 8,692 violations with the total sum of assessed violations of $6.7 million (average value of $773 [SD = $2,270] and median value of $138 per violation). Illumination accounted for 501 violations with the total sum of assessed violations of $0.13 million (average value of $261 (SD = $555) and the median value of $116 per violation). Safety belts and lines was also the most frequently cited violation in its Subpart related to personal protective equipment and accounted for 1,108 violations with the total sum of assessed violations of $1.9 million (average value of $1,682 [SD = $4,369] and median value of $473 per violation).

4. Discussion

Due to the limited and outdated literature on the burden associated with STF incidents in the mining industry, this analysis documents the burden of nonfatal STF incidents for surface SSG mines from 2008 through 2017—including IRs, number of injuries, days lost, injury cost, and cost of noncompliance with regulations. STF incidents are consistently among the top three causes of nonfatal incidents in mining (the top two based on AII and top three based on ATYPE). Nonfatal STF incidents occur at rates of approximately 62 per 10,000 FTE employees per year at surface SSG mines or approximately 490 incidents per year. In comparison, Bureau of Labor Statistics (BLS) data for the five-year period from 2012 to 2016 indicates that STF related nonfatal occupational injuries and illnesses across industries have an IR of approximately 28 per 10,000 FTE employees per year (Bureau of Labor Statistics, 2017).

Our findings indicate that the number of nonfatal STF incidents at surface SSG mines are higher at pits, but plants have a higher IR. In the current analysis, due to the way MSHA codes mines, pits include both stone mines and sand and gravel mines, which could be the cause of the higher prevalence of STF incidents at pits. In comparison, MSHA only provides codes that relate to plants at stone mines. Hence, the reported number of incidents and the associated IRs at plants only represent stone mines, due to limitations of the dataset. STF incidents at the pit also have a higher number of days away from work per incident compared to plants. Interventions to help reduce nonfatal STF incidents at pits would benefit all surface SSG mines.

Seasonal effects could be due to increased employment and outdoor production activities over the summer months, when most mines are fully operational, and due to environmental hazards, such as ice and snow, experienced in the winter months. For this study, employment, production, or hazard-related information was not available by season—hence, the seasonal effects warrant further investigation to aid STF prevention efforts.

The trend to have a larger number of incidents at the beginning of the shift could be attributed to work environments or walkways that are either unfamiliar or have changed prior to the shift start with STF hazards present or could stem from environmental hazards that were not adequately identified and/or remediated prior to or during work. MSHA has acknowledged the importance of workplace examinations and recently (January 2017, revised in April 2018) published a new rule as part of 30 CFR Part 56 Subpart Q on Safety Programs related to “Examinations of Working Places in Metal and Nonmetal Mines”(§56.18002 & §56.18002T). This rule includes pre-shift exams. There is a minor increase in the number of incidents at around hour 7, which may be close to the end of an 8-hour shift and could potentially be attributed to fatigue, hurrying to get work completed before the end of the shift, and putting away maintenance equipment such as hoses, ladders at the end of the shift (Bhatt et al., 2005; Espy et al., 2010; Helbostad et al., 2010; Lew and Qu, 2014; Parijat and Lockhart, 2008). Finally, daily trend findings should be viewed with caution as there are potentially more miners working during the day and there may be overlap between shifts, especially around early morning and late afternoon. The current employment dataset does not provide adequate information—such as employment by shift—to further interpret the observed daily trends.

One challenge associated with using the MSHA accident, injury, or illness dataset is that STF incidents are coded under two variables: AII and ATYPE. However, segregating STF incidents into three categories aligned with the OIICS led to some interesting insights into nonfatal STF incidents at SSG mines. Previous work has shown that falls from height accounted for nearly 60% of STF-related fatalities in the mining industry (Nasarwanji, 2016). In comparison, our analysis indicates that falls to the lower level was the least prevalent cause of nonfatal STF incidents. Nonfatal falls to the same level has also shown a greater decline over the reporting period as compared to falls to the lower level, or slips or trips without falls. Potentially, this finding indicates a need to focus on the reduction of falls to the lower level and slips or trips without falls. However, considering the financial burden, falls to the lower level had the highest cost associated with the injuries. In addition, the days lost and days lost per incident for falls to the lower level were similar to those for falls to the same level. Falls to the lower level that are most commonly associated with falls from machines and equipment have been investigated previously (Albin, 1988; Albin and Adams, 1989; Moore et al., 2009; Nasarwanji et al., 2018; Santos et al., 2010) and continue to warrant further research. In addition, falls down stairs and ladders should be investigated further.

Slips or trips without a fall accounted for nearly one-third of all incidents, and the IR had the least decline as compared to the other categories over the reporting period. Slips or trips without a fall were also most often categorized as overexertion (91.3%), which would usually be considered a musculoskeletal disorder (MSD). A recent analysis by Weston et al. (2016) also found that slips and falls contribute to MSDs and suggest that recovery from a slip or trip to prevent a fall may lead to MSDs. Exploring the overlap between slips and falls and musculoskeletal disorders may help reduce the top two causes of nonfatal injuries in mining (Weston et al., 2016).

Finally, falls to the same level were the most prevalent STF incidents with the highest IR. Although the current analysis indicates that falls to the walkway and falls onto and against objects are a concern, they are relatively generic categories and additional investigation on the root cause of each incident—i.e., investigating how falls to the same level are initiated and how they can be prevented—would help reduce the burden of STF incidents at SSG mines.

4.1. Limitations

One of the limitations of this analysis was the use of only publicly available MSHA datasets. Although MSHA provides the most comprehensive accident, injury, or illness dataset for the mining industry and SSG sector, the BLS also publishes data on mine operations, which was not considered in this analysis. Another limitation of the dataset is the use of only reportable STF incidents. If an STF event does not lead to a reportable incident, such as an individual needing first aid due to the event, it would not be captured by this analysis. Previous work that considered reported STF events across three countries and multiple data sources (not including MSHA’s accident, injury, or illness dataset) found that there is a lack of good reporting of incidents, especially for STF events (Courtney et al., 2001). Hence, this analysis provides a conservative estimate of the burden associated with STF incidents in the SSG mining industry; the actual number of STF events may be higher. In addition, this analysis relied on the pre-coded accident, injury, or illness dataset and did not focus on any narrative text available for the incident, which can be considered for a more detailed future analysis for specific types of STF incidents.

Analysis of economic burden was based on the Safety Pays in Mining cost estimator; thus, our analysis has the same limitations as those of the application (Heberger, 2018). The main limitation of the Safety Pays in Mining cost estimator is that the data is solely based on lost-time workers’ compensations claims from the Ohio Bureau of Workers’ Compensation. The assessed cost of violations was restricted to categories within 30 CFR; however, an assessed violation does not necessarily imply the hazard would lead to a reportable nonfatal injury or an STF incident specifically. In addition, we selected categories from 30 CFR Part 56, Safety and Health Standards, that were most related to STF hazards; however, there may be other categories that relate to STF hazards that were not captured.

5. Conclusions

The objective of this work was to document the burden associated with nonfatal STF incidents at surface SSG mines based on data from the years 2008–2017. Nonfatal STF incidents at surface SSG mines occurred at the rate of approximately 62 per 10,000 FTE employees per year, or approximately 490 incidents per year. These incidents led to approximately 23,800 total days lost per year and had a cost of $17.5 million per year. In addition to recorded injuries, assessed violations that are not related to reported injuries but related to STF hazards identified during MSHA inspections cost the mining industry approximately $3 million per year from 2013 through 2017, which represents approximately 14% of all health and safety violations and about 24% of the overall assessed cost of health and safety violations to SSG mines. Defining research priorities for nonfatal STF incidents at surface SSG mines can be challenging as falls to the lower level pose a higher burden in terms of cost, but falls to the same level have a higher number of incidents and incidence rate. Addressing both types of injuries, along with the overlap between STFs and MSDs, will be beneficial for reducing the burden of STFs at surface SSG mines.

Supplementary Material

Footnotes

Disclaimer

The findings and conclusions in this report are those of the authors and do not necessarily represent the official position of the National Institute for Occupational Safety and Health, Centers for Disease Control and Prevention.

Appendix A. Supplementary material

Supplementary data to this article can be found online at https://doi.org/10.1016/j.ssci.2019.08.007.

Codes used in the MSHA accident, injury, or illness dataset available through NIOSH have been presented to aid replication of the analysis and to help health and safety professionals and organizations to categorize STF incidents at their own sites. The data coding scheme can be found at https://www.cdc.gov/niosh/mining/UserFiles/data/guide_2016.pdf and https://www.cdc.gov/niosh/mining/UserFiles/data/codes.pdf.

References

- Albin TJ, 1988. Relative contribution of behavior to slip and fall acidents in mining maintenance. In: Paper Presented at the Proceeding of the Human Factros Society 32nd Annual Meeting. [Google Scholar]

- Albin TJ, Adams WP, 1989. Slip and fall accidents during eqipment maintenance in the surface mining industry In: Mital A (Ed.), Advances in Industrial Ergonomics and Safety I. Taylor and Francis. [Google Scholar]

- Amandus H, Bell J, Tiesman H, Biddle E, 2012. The epidemiology of slips, trips, and falls in a helicopter manufacturing plant. Hum. Factors: J. Hum. Factors Ergonomics Soc. 54 (3), 387–395. 10.1177/0018720811403140. [DOI] [PubMed] [Google Scholar]

- Bell JL, Collins JW, Wolf L, Grönqvist R, Chiou S, Chang W-R, Evanoff B, 2008. Evaluation of a comprehensive slip, trip and fall prevention programme for hospital employees**. Ergonomics 51 (12), 1906–1925. 10.1080/00140130802248092. [DOI] [PubMed] [Google Scholar]

- Bell JL, Collins JWD, Dalsey E, Virginia S, 2010. Slip, Trip, and Fall Prevention for Healthcare Workers (2011–123). Retrieved from https://www.cdc.gov/niosh/docs/2011-123/pdfs/2011-123.pdf. [Google Scholar]

- Bentley T, 1998. Slip, trip and fall accidents occurring during the delivery of mail. Ergonomics 41 (12), 1859–1872. 10.1080/001401398186027. [DOI] [PubMed] [Google Scholar]

- Bentley T, Haslam RA, 2001. Identification of risk factors and countermeasures for slip, trip and fall accidents during the delivery of mail. Appl. Ergon 32 (2), 127–134. 10.1016/S0003-6870(00)00048-X. [DOI] [PubMed] [Google Scholar]

- Bentley T, Hide S, Tappin D, Moore D, Legg S, Ashby L, Parker R, 2006. Investigating risk factors for slips, trips and falls in New Zealand residential construction using incident-centred and incident-independent methods. Ergonomics 49 (1), 62–77. 10.1080/00140130612331392236. [DOI] [PubMed] [Google Scholar]

- Bentley T, Tappin D, Moore D, Legg S, Ashby L, Parker R, 2005. Investigating slips, trips and falls in the New Zealand dairy farming sector. Ergonomics 48 (8), 1008–1019. 10.1080/00140130500182072. [DOI] [PubMed] [Google Scholar]

- Bhatt T, Wening JD, Pai YC, 2005. Influence of gait speed on stability: recovery from anterior slips and compensatory stepping. Gait & Posture 21 (2), 146–156. 10.1016/j.gaitpost.2004.01.008. [DOI] [PubMed] [Google Scholar]

- Buck PC, Coleman VP, 1985. Slipping, tripping and falling accidents at work: a national picture. Ergonomics 28 (7), 949–958. 10.1080/00140138508963217. [DOI] [PubMed] [Google Scholar]

- Bureau of Labor Statistics, 2014. Occupational Injury and Illness Classification Manual. Retrieved from https://www.bls.gov/iif/oshoiics.htm.

- Bureau of Labor Statistics, 2017. Case and Demographic Characteristics for Work-related Injuries and Illnesses Involving Days Away From Work. Retrieved from http://www.bls.gov/iif/oshcdnew.htm.

- Chang W-R, Huang Y-H, Way Li K, Filiaggi A, Courtney TK, 2008. Assessing slipperiness in fast-food restaurants in the USA using friction variation, friction level and perception rating. Appl. Ergon 39 (3), 359–367. 10.1016/j.apergo.2007.08.004. [DOI] [PubMed] [Google Scholar]

- Chi C-F, Chang T-C, Ting H-I, 2005. Accident patterns and prevention measures for fatal occupational falls in the construction industry. Appl. Ergon 36 (4), 391–400. 10.1016/j.apergo.2004.09.011. [DOI] [PubMed] [Google Scholar]

- Courtney TK, Sorock GS, Manning DP, Collins JW, Holbein-Jenny MA, 2001. Occupational slip, trip, and fall-related injuries - can the contribution of slipperiness be isolated? Ergonomics 44 (13), 1118–1137. 10.1080/00140130110085538. [DOI] [PubMed] [Google Scholar]

- Courtney TK, Verma SK, Chang W-R, Huang Y-H, Lombardi DA, Brennan MJ, Perry MJ, 2013. Perception of slipperiness and prospective risk of slipping at work. Occup. Environ. Med 70 (1), 35–40. 10.1136/oemed-2012-100831. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Courtney TK, Verma SK, Huang Y-H, Chang W-R, Li KW, Filiaggi AJ, 2010. Factors associated with worker slipping in limited-service restaurants. Injury Prevention 16 (1), 36–41. 10.1136/ip.2009.022749. [DOI] [PubMed] [Google Scholar]

- Espy DD, Yang F, Bhatt T, Pai YC, 2010. Independent influence of gait speed and step length on stability and fall risk. Gait & Posture 32 (3), 378–382. 10.1016/j.gaitpost.2010.06.013. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Heberger JR, 2018, February, 25–28, 2018 Demonstrating the financial impact of mining injuries with the safety pays in mining web application In: Paper Presented at the 2018 SME Annual Conferece and Expo., Minneapolis, MN. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Helander MG, 1991. Safety hazards and motivation for safe work in the construction industry. Int. J. Ind. Ergon 8 (3), 205–223. 10.1016/0169-8141(91)90033-I. [DOI] [Google Scholar]

- Helbostad JL, Sturnieks DL, Menant J, Delbaere K, Lord SR, Pijnappels M, 2010. Consequences of lower extremity and trunk muscle fatigue on balance and functional tasks in older people: A systematic literature review. BMC Geriatrics 10 (1), 56 10.1186/1471-2318-10-56. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Leamon TB, Murphy PL, 1995. Occupational slips and falls: more than a trivial problem. Ergonomics 38 (3), 487–498. 10.1080/00140139508925120. [DOI] [PubMed] [Google Scholar]

- Lehtola MM, van der Molen HF, Lappalainen J, Hoonakker PLT, Hsiao H, Haslam RA, Verbeek JH, 2008. The effectiveness of interventions for preventing injuries in the construction industry: a systematic review. Am. J. Prev. Med 35 (1), 77–85. 10.1016/j.amepre.2008.03.030. [DOI] [PubMed] [Google Scholar]

- Lew FL, Qu X, 2014. Effects of mental fatigue on biomechanics of slips. Ergonomics 57 (12), 1927–1932. 10.1080/00140139.2014.937771. [DOI] [PubMed] [Google Scholar]

- Liberty Mutual Insurance, 2014. 2014 Liberty mutual workplace safety index. Retrieved from https://helmsmantpa.com/Documents/WSI%202014.pdf.

- Liberty Mutual Insurance, 2016. 2016 Liberty mutual workplace safety index. Retrieved from http://cdn2.hubspot.net/hubfs/330425/2016_Liberty_Mutaul_Workplace_Safety_Index.pdf?t=1491583224866.

- Liberty Mutual Insurance, 2017. 2017 Liberty mutual workplace safety index. Retrieved from https://www.carpentersafety.org/sites/www.carpentersafety.org/files/assets/2017%20WSI.pdf.

- Liberty Mutual Insurance, 2018. 2018 Liberty mutual workplace safety index. Retrieved from https://business.libertymutualgroup.com/business-insurance/Documents/Services/Workplace%20Safety%20Index.pdf.

- Lipscomb HJ, Glazner JE, Bondy J, Guarini K, Lezotte D, 2006. Injuries from slips and trips in construction. Appl. Ergon 37 (3), 267–274. 10.1016/j.apergo.2005.07.008. [DOI] [PubMed] [Google Scholar]

- Lombardi DA, Matz S, Brennan MJ, Smith GS, Courtney TK, 2009. Etiology of work-related electrical injuries: a narrative analysis of workers’ compensation claims. J. Occup. Environ. Hyg 6 (10), 612–623. 10.1080/15459620903133683. [DOI] [PubMed] [Google Scholar]

- Moore SM, Porter WL, Dempsey PG, 2009. Fall from equipment injuries in U.S. mining: Identification of specific research areas for future investigation. J. Saf. Res 40 (6), 455–460. 10.1016/j.jsr.2009.10.002. [DOI] [PubMed] [Google Scholar]

- Nasarwanji MF, 2016. Contributing factors to slip, trip, and fall fatalities at surface coal and metal/nonmetal mines. In: Paper presented at the Proceedings of the Human Factors and Ergonomics Society Annual Meeting. [Google Scholar]

- Nasarwanji MF, Pollard J, Porter W, 2018. An analysis of injuries to front-end loader operators during ingress and egress. Int. J. Ind. Ergon 62, 84–92. 10.1016/j.ergon.2017.07.006. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Parijat P, Lockhart TE, 2008. Effects of lower extremity muscle fatigue on the outcomes of slip-induced falls. Ergonomics 51 (12), 1873–1884. 10.1080/00140130802567087. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Radomsky MC, Ramani RV, Flick JP, 2001. Slips, trips & falls in construction & mining: causes & controls. Professional Saf. 46 (9), 30–37. [Google Scholar]

- Santos BR, Porter WL, Mayton AG, 2010. An analysis of injuries to haul truck operators in the U.S. mining industry. In: Proceedings of the Human Factors and Ergonomics Society Annual Meeting, 54(21), pp. 1870–1874. doi: 10.1177/154193121005402109. [DOI] [Google Scholar]

- Weston E, Nasarwanji MF, Pollard JP, 2016. Identification of work-related musculoskeletal disorders in mining. J. Saf. Health Environ. Res 12 (1), 274–283. [PMC free article] [PubMed] [Google Scholar]

- Yeoh HT, Lockhart TE, Wu X, 2012. Non-fatal occupational falls on the same level. Ergonomics 56 (2), 153–165. 10.1080/00140139.2012.746739. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Yoon H-Y, Lockhart TE, 2006. Nonfatal occupational injuries associated with slips and falls in the United States. Int. J. Ind. Ergon 36 (1), 83–92. [DOI] [PMC free article] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.