Abstract

Shape memory polymers (SMPs) are an exciting class of stimuli-responsive smart materials that demonstrate reactive and reversible changes in mechanical property, usually by switching between different states due to external stimuli. We report on the development of a polyurethane-based SMP foam for effective pressure redistribution that demonstrates controllable changes in dynamic pressure redistribution capability at a low transition temperature (∼24 °C)—ideally suited to matching modulations in body contact pressure for dynamic pressure relief (e.g., for alleviation or pressure ulcer effects). The resultant SMP material has been extensively characterized by a series of tests including stress–strain testing, compression testing, dynamic mechanical analysis, optical microscopy, UV–visible absorbance spectroscopy, variable-temperature areal pressure distribution, Fourier transform infrared spectroscopy, Raman spectroscopy, X-ray diffraction, differential scanning calorimetry, dynamic thermogravimetric analysis, and 1H nuclear magnetic resonance spectroscopy. The foam system exhibits high responsivity when tested for plantar pressure modulation with significant potential in pressure ulcers treatment. Efficient pressure redistribution (∼80% reduction in interface pressure), high stress response (∼30% applied stress is stored in fixity and released on recovery), and excellent deformation recovery (∼100%) are demonstrated in addition to significant cycling ability without performance loss. By providing highly effective pressure redistribution and modulation when in contact with the body’s surface, this SMP foam offers novel mechanisms for alleviating the risk of pressure ulcers.

1. Introduction

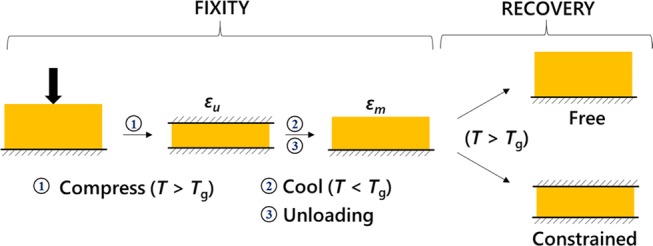

Shape memory polymers (SMPs) can temporarily and securely hold a deformed shape but recover to an original, “true” shape, in response to an external stimulus such as temperature, pH, etc.1−8 This unique “shape memory effect” comprises shape fixity and shape recovery (Figure 1). Shape fixity enables acquisition of a temporary, deformed shape via a suitable programming process, whereas shape recovery retrieves the original shape via controlled application of a stimulus.9−12 This shape controllability (i.e., fixity or recovery) is currently at the forefront of multiple research domains spanning biomedical,13−17 textiles,18−20 aerospace,21,22 etc. Primarily in biomedical, SMP are attractive in critical applications including sutures,23 stents,24 embolic biomedical devices,25 drug delivery devices,26,27 tissue scaffolds,28,29 and compression stockings.30−33 To further extend understanding of such materials, this study will systematically characterize the use of porous, open-cell SMP foams as smart contact surfaces for controlled, dynamic pressure (re)distribution on the human body.

Figure 1.

Diagram of the volume changes expected in shape fixity and recovery processes of shape memory polymers, below or above the polymer glass-transition temperature, Tg, upon application and/or removal of an external pressure constraint.

Pressure ulcers/injuries arise when uncontrolled, uneven, and prolonged pressure distribution between the body and support surface generates localized regions of high pressure.34 High pressure damages soft tissue, especially near bony prominences due to their low curvature, and significantly compresses vascular networks, decreasing the supply of oxygen and essential nutrients, resulting in tissue ischemia and, finally, tissue breakdown. The resultant chronic ulcers may cause significant pain, discomfort, decreased quality of life, and, when associated with superimposed infection, may even lead to death.35,36 Despite several available, yet oft-ineffective ulcer treatment measures, the first, most basic preventive and recommended action is to reduce the interfacial pressure between the skin and support surface.

Pressure distribution is the dispersion of localized peak pressure or shear forces over larger areas. Usually, it is carried out by either; (i) a reactive surface (e.g., foam or gel mattresses) where pressure reduction occurs through increased contact area, or (ii) an active surface that repositions body weight by periodically shifting the contact area via alternate inflation and deflation of a series of air-filled bladders. Both have questionable efficacy, and many challenges still exist in current medical practice:

-

(A)

Contemporary foam-based reactive surfaces primarily exhibit passive pressure reduction; they have fixed immersion (extent of allowing the body to sink into the surface) and envelopment (ability to conform to bodily contours, especially around anatomical landmarks, e.g., heel, sacrum, coccyx, etc.).37−41 Thus, it is virtually impossible for such modalities to achieve adjustable pressure distribution, if required.

-

(B)

Currently available dynamic air mattresses fail miserably in envelopment. They are also costly, complicated in design, and noisy in use.

-

(C)

No currently available surface can combine both active and reactive functions, for selective response to patient needs.

-

(D)

Although manual repositioning of patients aids pressure relief, it is tedious and labor-intensive, placing unduly heavy burdens on medical care providers.

SMP foams are the focus of this paper due to their low density, high compressibility, flexibility, softness, and wearer comfort, potentially ideal as a cushioning, contouring, responsive, and material that can be easily processed. Open-celled structures potentially offer greater comfort due to their higher air and moisture permeabilities compared to closed-cell structures (e.g., syntactic foams).42−46 The unique stimulus-responsive and dynamic shape-change properties of SMP could solve some of the pressure redistribution challenges.47−50 The nature of the foam material (i.e., the firmness or softness) tends to determine the pressure generated on the body’s surface.51,52 Current commercial cushioning materials (e.g., sleeping mattresses, shoe insoles, car seats, etc.) have a fixed stiffness, meaning they are completely unsuited for externally responsive pressure modulation. Conversely, SMP demonstrates a notable modulus change in response to a variable external stimulus, typically heat.53,54 Such changes are superior to conventional polymers in their mechanical and thermodynamical properties around the (glass) transition temperature (Tg here, ∼24 °C) tuned around the SMP normal working temperature (here, ∼20 °C). Thus, above Tg, the SMP behaves rubbery, elastic, and soft; below Tg, it becomes hard and displays glassy behavior. Such reversible firmness change properties are ideal for matching to body temperature fluctuations.54 Additionally, SMP shape fixity properties can be further exploited to reshape the selecting part of a foam substrate for maximal immersion and envelopment.

This paper will explore the use of SMP foams as reactive and smart surfaces for pressure distribution, using insoles and foot pressure redistribution as an illustrative application. Plantar pressure redistribution is important because localized and prolonged plantar pressure leads to chronic pressure sores, nonhealing wounds, and ultimately results in foot ulceration, with further potential limb loss in high-risk groups, e.g., diabetic patients, sufferers of muscular dystrophy, and the elderly.55−58 Lightweight and flexible orthotic foams can reduce fatigue, relieve pressure, and increase circulation by evenly redistributing normal and shear stresses arising from bodily weight along the length and breadth of the foot, for personalized comfort and support.59 Broadly, two possible methods exist for utilizing SMP foam shape fixation for pressure redistribution: (i) Shaped fixing, where a predetermined shape is achieved prior to foot application; the coverage area is increased to reduce pressure. There is no temperature fluctuation for pressure relief and foam Tg > 50 °C so there is little shape change if the foot temperature increases; (ii) Redistribution of pressure points, where the fixed shape is used but temperature fluctuation is done externally in the foot to selectively release the contact stress or pressure. This shifts pressure points naturally, preventing excessive stress during plantar loading, especially over sensitive areas (e.g., bony prominences),59 and the actuation range of the foam will be lower (∼30–50 °C). This paper will systematically characterize thermally actuated SMP foams as used for dynamic plantar pressure redistributive applications.

2. Results and Discussion

2.1. Shape Memory Polyurethane (SMPu) Polymer Foam Synthesis

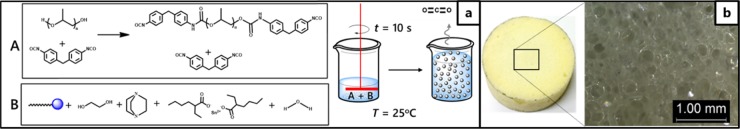

Shape memory polyurethane (SMPu) foam was synthesized using the gas foaming technique where a chemical blowing agent (i.e., water) reacts with isocyanate monomers to produce carbon dioxide (Figure 2a).60,61 The novelty of this synthetic work is that this poly(propylene glycol) (PPG)–poly(ethylene glycol) system for different methods for pressure control has not been explored previously. After foaming, the open-cell SMPu samples were cured for a further 24 h in air at 80 °C. Such samples were subsequently characterized and tested without further treatment, against a thermoplastic polyurethane (TPU) reference material. Figure 2b shows the SMPu foam structure where released CO2 gas promoted self-assembly of a porous architecture with good interconnectivity.9 The SMPu foam density was 64.7 kg m–3, with a porosity of 94% and pore size range of 0.1–0.5 mm.

Figure 2.

(a) Schematic of the shape memory polymer foam preparation process involving step A: Formation of a “prepolymer” through mixing of 4,4′-methylene diphenyl diisocyanate (MDI) and poly(propylene glycol), followed by step B: Mixing of the prepolymer with ethylene glycol (EG), amine and tin catalysts as well as H2O, prior to carrying out the foaming and curing processes. (b) Pore structure and size distributions of the microcellular shape memory polyurethane polymer foam as observed by optical microscopy.

2.2. Shape Memory Polyurethane Polymer Foam Bonding Interactions and Materials Characterization

All expected thermoplastic polyurethane signals were observed in the attenuated total reflectance (ATR)-Fourier transform infrared (FTIR) spectra. Additional assignments (see Figure S3, Supporting Information (SI)) indicate clear differences between the TPU and SMPu foam concerning incidence and intensity of IR bands, due to the partial degradation of TPU as well as the organic reactants used to form the SMPu foam.62−64 The shift of certain bands (N–H, C=O, and C–O stretches of TPU are shifted to lower wavenumbers for SMPu foam) indicates increased hydrogen bonding effects in the hard segments.65,66 Such differences are caused by the changes made to the parent TPU structure upon mixing with MDI and other components, during the SMPu foam formation process. These structural changes cause modifications of, e.g., modulus, stiffness, etc., and thus facilitate the reversible shape memory properties. For example, there are a greater number of signals for −CH stretches and bends as well as shifted and changed band profiles at 1729 cm–1, representing hydrogen-bonded carbonyl stretching components (−C=O) of the urethane ester groups and corroborated by the C–O–C moiety at 869 cm–1, for the SMPu foams. Likewise, a smaller shoulder at 3450 cm–1, present in the bands for the SMPu foams but absent in the parent TPU, is consistent with non-hydrogen-bonded urea and urethane N–H groups, possibly from the amine catalysts.

There is broad Raman band position agreement between TPU and SMPu foam (see Figure S4, SI). Data were acquired both above and below the Tg; data below the Tg for the SMPu foam were acquired while the sample has a constrained, temporarily fixed shape, to ensure the sub-Tg condition. While structural disorder revealed by a shift in temperature around the Tg is expected, only moderate changes in detected bonding interactions were observed here.63,67−70 The SMPu foam shows increased relative intensity for the H-bonded urethane stretch (1706 cm–1), believed to be due to the disordered hard segments of poly(urethane urea) dispersed in the soft-segment phase.71 In addition to increased band intensities, there are several shifted or absent bands for the SMPu foams versus the TPU reference. Both 977 and 865 cm–1 (both C–O–C) bands are absent, while the 1439 cm–1 (C–H) and 1048 cm–1 (C–O) bands are shifted, for the foam. This indicates the additional formation of chemical interactions thought to be induced by the presence of oxygen functional groups and/or additional disorder-related defects. Finally, the SMPu foam shows further weak band(s) at <300 cm–1; in the 235–295 cm–1 region, which is completely absent for the TPU and likely corresponds to aliphatic chains, possibly arising from the use of linkers or blowing agents in the formation of the SMPu foams. Proton nuclear magnetic resonance (1H NMR) confirms that the broader SMPu foam chemical structure is heavily dependent on the precursor mixture components and ratios used (see Figure S5 and refer to Table 1). Signals at 7.074 and 7.248 ppm conform to the Ha and Hb of the MDI precursor aromatic ring; the presence of PPG precursor indicated by shifts at 4.992 ppm (CH group) and 1.571–1.119 ppm (signals of CH3 protons at slightly different chemical environment); and the signals at 3.5–3.2 ppm from the CH2 protons of the EG precursor.72,73

The differential scanning calorimetry (DSC) curves (second heating) of the SMPu foam, (see Figure S6, SI), probing the crystallinity show no significant inflection point, peak, or step change in the DSC curves of either the as-synthesized SMPu foam or TPU (reference standard), over −80 to 100 °C that would otherwise indicate a kinetic change at the Tg.74,75 This is a known problem for medical-grade urethanes and other highly cross-linked materials, where the Tg often becomes flat and diffuse such that it cannot be seen in DSC.76 Dynamic mechanical analysis (DMA) data are more sensitive than DSC (up to 100 times) to changes occurring at the Tg (see Figure 3), and this corresponds to what is observed here.76,77 This signifies that both the SMPu foam and TPU are extensively amorphous and display typically glassy behavior over the temperature range, perhaps explained by the high miscibility of hard and soft phases, smaller more imperfectly packed hard domains, and ready chain mobility.75,78−82 This amorphous character is further affirmed by the X-ray diffraction (XRD) data (see Figure S7, SI); the diffraction patterns comprise only a broad amorphous peak at 2θ = 20–22° over the entire acquisition range. This amorphous behavior is as expected for segmented Tg-type TPU-based materials.83

Figure 3.

(a) Results of dynamic mechanical analysis (DMA) testing on SMPu foams indicating the elastic modulus and tan δ responses respectively in response to a controlled variation in temperature. (b) Compressive stress–strain results for SMPu foams at different temperatures.

Dynamic thermogravimetric analysis (TGA) curves illustrate the thermal stabilities of TPU and SMPu foams under both inert (i.e., N2) and oxidizing (i.e., air) conditions while their first derivatives highlight degradation weight loss maxima over the 35–600 °C range (see Figure S8 and Table S1, SI). Broadly, SMPu foams exhibit simple thermal decomposition with the formation of gaseous byproducts, whereas TPU undergoes multistep decomposition. Initial weight losses (≤2%) are due to loss of adsorbed moisture and the thermolysis processes disrupting the weakest structural bonds, a well-known trait of TPU-based samples. The slightly higher SMPu foam weight loss is likely due to the greater adsorbed moisture on the foam’s larger surface area as well as evaporation of components such as CO2 and long-chain alkyl fragments from the foaming agents. The SMPu foam presents primarily a single degradation stage, whereas the pure TPU demonstrates a two-/three-stage decomposition process, in line with previous reports.84−86 For TPU, the first decomposition stage relates to scission of the principal urethane linkages, corresponding to degradation of TPU hard segments; the second decomposition stage likely relates to degradation of the soft phase.87−89 SMPu foams have a slightly earlier decomposition temperature onset in weight loss; the foams are less structurally thermostable due to decomposition of the present TPU parent material during foam formation as well as the decreased distinction between hard and soft segments.90 In air, a final degradation step is found for both the SMPu foam and TPU at ca. 540–575 °C, believed to correspond to C–C and C–O bonds on the main polyurethane chain and the char formed in the previous stages. No further hydrolysis steps were observed here at elevated temperatures.91 The final char residual weight was higher for TPU, due to part degradation of the SMPu foam during production of the initial foam.

2.3. Shape Memory Polyurethane Polymer Foam Polymer Properties Testing

The temperature-dependent mechanical properties of the SMPu polymer foam, including modulus and tan δ (efficiency of energy loss due to molecular disentanglement and rearrangements), are reported in Figure 3a. A sharp decline in elastic modulus occurs over −5 to 25 °C, in conjunction with a prominent peak in the tan δ spectrum, where the maximum indicates the glass-transition temperature; Tmax ≡ Tg ∼ 24 °C. The tan δ−Tg for SMPu composites is higher than that of its TPU counterpart (<0 °C); hence, unmodified TPU would be unsuitable for any kind of bodily responsive pressure redistributive scenario in reality, which is attributed to the increased free volume between polymeric chains and their greater mobility, in the foam structure.92−95 Above the Tg, the material exhibits properties reflective of the rubbery state, indicating the transition of soft segments in the SMP network. tan δ is linked to a material’s energy dissipating quality;96 the low values in the rubbery state and high strain recovery rates observed for SMPu indicate close to ideal spring behavior.97 These results were similar to thermomechanical compression tests conducted on the Instron tensile/compression tester, where a high compressive modulus is observed at low temperature (<10 °C), corresponding to a low force requirement, while a low modulus is found at a higher temperature (>20 °C)—0.01078 MPa (i.e., ≈10 kPa) (Figure 3b), which is still significant but orders of magnitude (102–103) lower than reported values for TPU standards (depending on elastomer composition) at room temperature in dry environments.93,98,99

For cushioning and pressure distribution applications, foam density and compression firmness (i.e., resistance to deformation) are the most important parameters. Foam firmness directly influences internal pressure development, and even slight changes in firmness can cause varying interactions with contacting tissue and so generate different interfacial pressures. Furthermore, foam firmness or softness is important in product design, especially for optimum pressure performance for postural control and wearer satisfaction. For example, although soft cushions (low firmness) decrease excessive compressive forces on joints, reducing ulcer risk, the excessive softness also reduces mechanical support, causing poor postural stability. Conversely, a firmer foam, with high rigidity, generates sufficient reactive forces to maintain postural stability, especially for older adults. Conventional foams, including ordinary polyurethane, do not exhibit heat-stimulated firmness modulation across a normal working temperature range, making them completely unsuited to any intended dynamic response application. Commercial products can only be altered at the production stage by modifying the chemical formulations and processing technologies. Conversely, the SMPu foam presented here as proof of concept can respond quickly and reversibly to allow a significant change in firmness over a narrow temperature range (i.e., in response to ambient heat stimuli).100,101 The transition range of SMP can be readily tuned further to work across different temperature domains. In terms of relevance to orthotics, the SMPu reported here will be in the viscoelastic rubbery state for the projected duration and conditions of operation, exhibiting a springy, puttylike behavior that is ideal for pressure relief and support. The extended presence of the rubbery state thought to be aided by the use and presence of cross-linkers in the polymer system, extends the rubbery plateau and delays transition to viscous and fluid states.102

Figure 4a shows the influence of temperature on SMPu foam firmness, expressed in compression force deflection (CFD; the pressure (lb in.–2) needed to compress to 25% of the specimen height). A sharp increase (up to 200%) in CFD is noted when the temperature is varied within the SMPu transition range,30 lowering from 25 to 10 °C. Lower CFD values indicate a softer foam of smaller compression modulus, while higher CFD numbers stage firmer response with high modulus. A soft SMPu foam deforms easily, providing more interfacial contact area (i.e., higher immersion) to cover body contours for pressure reduction (i.e., higher envelopment).

Figure 4.

(a) Firmness response of the SMPu foam against temperature. (b) Tekscan F-scan pressure system for dynamic, variable temperature, areal pressure distribution measurement on SMPu foams in response to a static external downward force from the heel of an adult male. (c) Areal pressure distribution of the SMPu foams under different surface temperatures, upon exposure to a constant, static external downward force. (Photograph courtesy of Bipin Kumar. Copyright 2019.)

This firmness variability was further validated using a Tekscan F-scan foot pressure measuring system to examine the pressure distribution of the SMPu foam by altering the temperature (Figure 4b,c). At lower temperature (≤5 °C), the SMPu foam is rigid with a high elastic modulus, due to which more pressure peaks (in red) are obtained over a concentrated region. At higher temperature (≥25 °C), the SMPu foam softens with a low modulus; a near-6-fold difference in firmness over the 5–25 °C range. Thus, the pressure is effectively redistributed and lower-pressure peaks become apparent. As such, this temperature range of operation is ideally suited for when the SMPu foam is in direct contact with anatomical extremities, which are able to experience temperature fluctuations spanning this range.

Apart from a reversible firmness change, the SMPu foam also allows unique shape fixing and recovery properties. Through simple programming steps, the required shape can be temporarily fixed by deforming the sample at high temperature (T > Tg) to the target and then cooling it down to low temperature (T < Tg) under specific external constraints. Different shapes/concavities (A–D) were reversibly fixed from the original foam specimen under such temperature variation conditions (Figure 5a).

Figure 5.

(a) Various programmed temporary shapes (A–D) from an SMPu foam (original) upon application of an external constraint at T > Tg and then cooling the constrained shape down to T < Tg to “fix” the desired temporary shape. (b) Pressure distribution of the programmed shapes (P–R) with varying surface troughs indicating variations in interfacial contact area with the spherical indenter. (Photograph courtesy of Bipin Kumar. Copyright 2019.)

The pressure interaction depends on both immersion (ability to sink into the surface) and envelopment (ability to conform to the body contour) of the surface in contact. Some anatomical landmarks (e.g., heel, sacrum, coccyx, etc.) have a complex contour and are always at high risk of pressure peaks due to either poor immersion or envelopment at the contact surfaces. However, with the unique shape fixing ability of the SMPu foam, the anatomical shapes and selective contours can be readily generated directly at the site of interaction to provide greater contact area for pressure reduction and support. This pressure reduction ability was further validated to check the pressure interaction of different programmed shapes (P–R; Figure 5b). For the foam specimens fixed to different levels of spherical concavities, a higher trough from the surface (shape R) results in a larger contact with the spherical indenter and produces lower pressure compared to a shallower trough (shape P). Thus, there is an almost 80% reduction in interfacial pressure going from shape P to R.

Figure 6a shows the recovery of the original SMPu foam from a compressed state upon exposure to a heat stimulus. Once recovered, the foam can be reprogrammed to a new shape, without any residual memory effects. The whole cycle of shape fixing and recovery can be repeated multiple times, without adverse effects (Figure 6b,c).103 The shape fixity (the ratio of the remained deformation and the maximum deformation applied) is ∼88%, and full recovery (i.e., 100% from the fixed shape to its original shape) can be observed without any loss in performance. When measured under a given constraint, i.e., a given sustained strain, the amount of recovery stress generated in the sample is indicated in Figure 6d. Almost 30% of the applied stress is stored during shape fixing, which is then released in the recovery process.

Figure 6.

(a) Timed shape recovery process from a compressed SMPu foam (∼25% overall volume) to completely uncompressed (i.e., 100% volume) upon application of a heat stimulus (T > Tg; 24 °C). (b) Three-dimensional shape memory cycle plot of stress, strain, and temperature. (c) Stress response of SMPu polymer foam in the thermomechanical cycles of fixing and recovery upon application known strain rates. (d) Recovery stress of SMPu polymer foam for different programmed strain rates. Programming and recovery conditions; step 0: heating of specimen above Tg (30 °C); step 1: application of compressive load at high temperature to a strain value (5–50%); step 2: cooling the specimen to 50 °C; step 3: release of constraint to fix the deformed shape, and; step 4: heat the specimen to 30 °C without any constraint. (Photograph courtesy of Bipin Kumar. Copyright 2019.)

3. Conclusions

Highly responsive, shape memory polyurethane (SMPu) foams have been synthesized using a simple gas foaming technique. Biomechanical testing of the resilient, moderately deformable SMPu foams exhibits efficient pressure redistribution (∼80% reduction of interfacial pressure), stress response (∼30% applied stress stored in fixity), shape recovery properties (∼100% recovery), extended rubbery plateau, and high cycling stability to compression, of this well-investigated system, among the most impressive reported to date.104

While we have demonstrated highly responsive temperature actuation across the SMPu foam material on a macro scale, localized selectivity of temperature actuation across a surface must still be achieved for enhanced patient responsivity and improved outcomes. Furthermore, refinements and improved control over the gas foaming synthetic method are also needed to achieve and ensure a higher transition temperature, through variation of reaction mixture ratios and components. In addition, PU-based structures, including foams, are known to be flammable—to differing degrees depending on PU source and mixture composition (i.e., polymer chain composition, polymer density, etc). These properties can be mitigated through inclusion of flame retardants active in the condensed phase, e.g., halogenated flame retardants, inorganic fillers, carbon compounds, etc., to confer heat resistance, suppress smoke, and minimize flashover effects.105−108 Such improvements will be the focus of future research studies.

Using the illustrative example of plantar pressure redistribution, the SMPu foam showed effective capabilities in dissipating localized pressure buildup arising from weight-bearing stress forces acting on the feet, knees, hips, and back, with progressive deformation occurring in response to increasing load, especially over/beneath bony prominences, to adjacent tissue so as to provide support and relief from discomfort, ulcers, hot spots, etc.109 Thus, this nontoxic, low-temperature-responsive SMPu foam can facilitate preprogrammed modulation of the interface firmness and pressure to support related ergonomics, promote medical intervention, and aid wearer comfort. These findings, based on extensive characterization of the SMPu foam will be of direct relevance to diabetics, the elderly, treating bedsore ailments, sufferers of muscular dystrophy, and many other at-risk groups, while the broader principles will appeal to any involved in the smart materials and functional polymers field.

4. Materials and Methods

4.1. Chemicals and Shape Memory Polyurethane Polymer Foam Synthesis

Details of the synthesis process for shape memory polyurethane (SMPu) foam are given in Table 1, which lists the chemical components used in foam production. The SMPu foam was produced via a prepolymer process from 4,4′-methylene diphenyl diisocyanate (MDI; Sigma-Aldrich Chemical Company), poly(propylene glycol) (PPG, Mn: 725; Sigma-Aldrich Chemical Company), and ethylene glycol (EG; Sigma-Aldrich Chemical Company). The MDI and PPG were reacted in a specific molar ratio for 2 h at 80 °C to give the prepolymer. Then, the chain extender (EG) was added together with the suitable amount of amine catalyst (A-1 and A-33; Shijiazhuang Chuanghong Technology Co. Ltd., China), tin catalyst (T-9; Air Product), and surfactant (Dabco DC5179; Air Product). Diols (e.g., 1,4-butane diol or ethylene glycol) or diamines have frequently been used as cross-linkers in making shape memory polyurethane for decades.110,111 Hydroxyl functional cross-linkers such as EG usually also serve as chain extenders, although in cases where water is present simultaneously, there are competitive effects; regardless, the hydroxyl groups of both routes will favor urethane linkage formation.88,112,113 Deionized water (resistivity, 18 MΩ cm) was used as the chemical blowing agent for gas foaming. Mixing time was 10 s, and observed cream time was 40 s. After foaming, the sample was cured for 24 h at 80 °C.

Table 1. Specific Weight Compositions of Components Required for the Formation of a Dynamically Responsive Shape Memory Polymer Polyurethane (SMPu) Foam.

| raw materials | chemicals specification | wt % |

|---|---|---|

| polyol | poly(propylene glycol) (PPG; Mn: 725; Sigma-Aldrich Chemical Company) | 57.04 |

| diisocyanate | 4,4′-methylene diphenyl diisocyanate (MDI; Sigma-Aldrich Chemical Company) | 38.74 |

| cross-linker and chain extender | ethylene glycol (EG; Sigma-Aldrich Chemical Company) | 2.50 |

| blowing agent and chain extender | deionized H2O | 0.64 |

| amine catalyst | A-1 (Shijiazhuang Chuanghong Technology Co. Ltd.) comprises 70% bis(2-dimethylaminoethyl)ether, i.e., BDMAEE: 30% dipropylene glycol | 0.09 |

| amine catalyst | A-33 (Shijiazhuang Chuanghong Technology Co. Ltd.) comprises 99% triethylenediamine | 0.12 |

| tin catalyst | Dabco T-9 (Air Product) comprises 97% stannous octoate: 3% 2-ethylhexanoic acid | 0.07 |

| surfactant | Dabco DC5179 (Air Product) | 0.81 |

4.1.1. Shape Memory Polyurethane Polymer Foam Material Characterization

For thermomechanical characterization, the compression tests were conducted on an Instron tester attached to a heating chamber. The compression stress, strain, and modulus were examined at a different temperature range (5–50 °C). The foam firmness was also obtained in compression force deflection (CFD), defined as the pressure (lb in.–2) needed to compress a foam specimen by a specified percentage of its original thickness. Herein, the CFD at 25% compression was recorded at different temperatures.

Foam density was determined using standard protocols (ASTM D 1622) by cutting foam with specific dimensions and measuring its weight. Pore dimensions and distribution were examined by Leica optical microscopy (model: M165C; ASTM D 3576). The polymer thermal transition, cycling, and degradation were mapped using thermogravimetric analysis (TGA) in triplicate and differential scanning calorimetry (DSC) cycling tests. TGA measurements were carried out on a Mettler-Toledo Star e TGA Thermogravimetric Analyzer, under both air (50 mL min–1) and N2 (50 mL min–1) conditions in dynamic mode, at a 10 °C min–1 ramp rate, over the 35–600 °C range. DSC was done on a PerkinElmer DSC 8000 under N2 (50 mL min–1) flow, over the −80 to 100 °C range, at a ramp rate of 10 °C min–1 and kept under hold conditions for 1 min at −50 °C. This scanning process was repeated up to three cycles, and the result of the second scan was used to obtain a transition endothermic peak. The first scan was performed to remove the residual solvent unconverted monomer. The dynamic mechanical analysis (DMA) was conducted on a PerkinElmer DMA tester to ascertain the variation in the modulus (glassy/rubbery) with temperature. Furthermore, wide-angle X-ray diffraction (WAXD) was also employed to check the crystallinity in the synthesized SMPu foam along with an ordinary thermoplastic polyurethane (TPU) as a reference. The WAXD profile was collected using a Rigaku SmartLab X-ray diffractometer with Cu Kα radiation (λ = 1.542 Å), operating at 60 kV and 60 mA, over the 2θ range of 10–40°.

Raman spectroscopy was carried out on a BaySpec Nomadic Raman Microscope, using a 785 nm laser excitation source, over the 200–3200 cm–1 range. All solid samples were analyzed at both ambient temperature and low temperature (T < Tg), by placement on a surface filled with a NH4Cl–ice water mixture. To confirm conversion below the Tg for the low-temperature reading and to ensure its state for the entirety of the acquisition period, the foam was fixed in a folded, constrained shape. Thermal equilibrium was ensured in all of the cases by maintaining the specimen under constant corresponding temperature for 5 min. Outputs are given relative to a 10 s integration time and 100% laser intensity. The band position and band intensity of the characteristic absorption peaks of the specimen were calculated by a Lorentzian curve-fitting procedure.114 At least five positions on each sample were scanned at each temperature, with near-identical profiles. Attenuated total reflectance FTIR (ATR-FTIR) spectroscopy was carried out on a PerkinElmer Spectrum 100. Measurements were done over the 4000–650 cm–1 range, at a resolution of 4 cm–1, with 20 scans per sample reading. Both TPU and SMPu solid samples were analyzed under ambient conditions. Results were ATR-corrected and baseline-subtracted using the onboard PerkinElmer Spectrum 100 software.

Chemical compositions of the final SMPu foam product were determined by liquid proton nuclear magnetic resonance (1H NMR) spectroscopy. Samples were analyzed on a Jeol ECZ 500 MHz NMR spectrometer operating at 495.13 MHz equipped with a double-resonance 5 mm Royal probe at 298 K. A total of 16–128 free induction decays (FIDs) were collected into 16 K data points with a spectral width of 9615.38 Hz (16 ppm). A 2 s relaxation delay is used between pulses. Spectra were analyzed in Delta (Jeol Ltd.). FIDs were zero-filled to 32 K, and an exponential line-broadening function of 0.2 Hz was applied to the FID prior to Fourier transformation. All of the sample spectra were phased and manually baseline-corrected, and spectra were referenced to trimethylsilane internal standard.

4.1.2. Shape Memory Property Testing

The fixity of the SMPu foam to different shapes and the shape recovery process were performed under both load-free and constrained (loaded) conditions. To fix a new shape, e.g., a shorter size, a cylindrical foam specimen was compressed at a “high” temperature (T > Tg; ∼40 °C) to a corresponding strain (εu) on the Instron Compression tester. Then, the compressed foam was cooled down to well below the transition temperature (T < Tg; ∼0 °C), and the foam was isothermally unloaded to zero stress level, to check the fixed strain level (εm). For the original shape recovery, the fixed foam was heated at high temperature (T > Tg), and both time and strain were recorded to examine the recovery process under a load-free state. This cycle of thermomechanical fixity and recovery was repeated five consecutive times to confirm repeatability. In addition to load-free shape recovery, constrained recovery testing was also conducted to obtain the amount of the recovery stress stored in the foam after fixity. The recovery stresses at different fixed strains (εm) were also measured. In addition to the use of Instron compression plates for deformation, other objects with spherical or sharp shapes were also used for memory testing to yield complex concavities of different shapes at selective foam sites.

4.1.3. Pressure (Re)Distribution Measurement

Two simple laboratory methods were employed for measurement of pressure distribution at the interfacial contact between the foam and the indenter. The first method used a spherical object indenting the foam under isothermal conditions (Figure 7), and the amount of contact area and the depth of penetration (from the top surface) marked between them were obtained.37 Using the immersion data, the pressure was calculated from the ratio of the object mass and the interfacial area of contact. The SMPu foam can be easily programmed (fixed) to different shapes, as explained in Section 2.3; varying concavity levels were fixed on the foam surface, and the interfacial pressure with the spherical object was analyzed.

Figure 7.

(a) Schematic of the response of the shape memory polymer foam upon application of an object mass of known shape and weight reflecting the contact area, used in the pressure test. (b) Image of Tekscan F-scan pressure measurement system setup used for pressure distribution measurement.

The second method of studying the interfacial contact includes an active measurement of the interfacial pressure distributions at different temperatures. The Tekscan F-scan foot pressure measurement system was used, consisting of several pressure points arranged on a flat film surface (Figure S1). First, the F-scan foot system was calibrated by an individual male volunteer after performing several initial trails under “walking calibration”. After calibration, the SMPu foam was placed over the pressure sensor and the individual stood still and stationary on the foam surface. The pressure data were transmitted in real time to a computer via a WiFi channel. The pressure distributions on the foam surface heated to different temperatures were recorded. Due to limited foam size available for the experiment, only the area of the plantar fasciitis (i.e., underneath the heel) was used in the analysis.

Acknowledgments

The authors thank Dr. Patrick Pang, Lab Manager of the HK PolyU ITC Materials Processing Department, for his invaluable help and assistance with ATR-FTIR, Raman, DSC, TGA, and general lab processes, as well as acknowledge the support from the HK PolyU University Research Facility on Chemical and Environmental Analysis (URFCE). They thank Dr. Nurulamin Noor, NIHR Academic Clinical Fellow in Medicine at the Cambridge Immunology Network, University of Cambridge, and Dr. Ameersing Luximon of the Hong Kong Ergonomics Society, for invaluable discussions and comments. They acknowledge the financial support received from the Department of Science and Technology, India (#RP03454) and The Hong Kong Polytechnic University (1-ZVK4 and 1-ZVLR).

Supporting Information Available

The Supporting Information is available free of charge on the ACS Publications website at DOI: 10.1021/acsomega.9b01167.

Mechanistic overview; ATR-FTIR spectra; variable-temperature Raman spectra; 1H NMR spectra; DSC curves; XRD patterns; and TGA thermograms and data tables (PDF)

The authors declare no competing financial interest.

Supplementary Material

References

- Lendlein A.; Gould O. E. C. Reprogrammable Recovery and Actuation Behaviour of Shape-Memory Polymers. Nat. Rev. Mater. 2019, 4, 116–133. 10.1038/s41578-018-0078-8. [DOI] [Google Scholar]

- Hager M. D.; Bode S.; Weber C.; Schubert U. S. Shape Memory Polymers: Past, Present and Future Developments. Prog. Polym. Sci. 2015, 49–50, 3–33. 10.1016/j.progpolymsci.2015.04.002. [DOI] [Google Scholar]

- Sun L.; Huang W. M.; Ding Z.; Zhao Y.; Wang C. C.; Purnawali H.; Tang C. Stimulus-Responsive Shape Memory Materials: A Review. Mater. Des. 2012, 33, 577–640. 10.1016/j.matdes.2011.04.065. [DOI] [Google Scholar]

- Hu J.; Zhu S.; Young R. J.; Cai Z.; Li L.; Han J.; Pan N. Stress Memory Materials and Their Fundamental Platform. J. Mater. Chem. A 2017, 5, 503–511. 10.1039/C6TA08005G. [DOI] [Google Scholar]

- Behl M.; Razzaq M. Y.; Lendlein A. Multifunctional Shape-Memory Polymers. Adv. Mater. 2010, 22, 3388–3410. 10.1002/adma.200904447. [DOI] [PubMed] [Google Scholar]

- Behl M.; Lendlein A. Shape-Memory Polymers. Mater. Today 2007, 10, 20–28. 10.1016/S1369-7021(07)70047-0. [DOI] [Google Scholar]

- Yao Y.; Luo Y.; Xu Y.; Wang B.; Li J.; Deng H.; Lu H. Fabrication and Characterization of Auxetic Shape Memory Composite Foams. Composites, Part B 2018, 152, 1–7. 10.1016/j.compositesb.2018.06.027. [DOI] [Google Scholar]

- Kim H. M.; Huang Z. M.; Kim J. S.; Youn J. R.; Song Y. S. Fabrication and Analysis of Dual-Scaled Shape Memory Foam. Eur. Polym. J. 2018, 106, 188–195. 10.1016/j.eurpolymj.2018.07.012. [DOI] [Google Scholar]

- Hasan S. M.; Nash L. D.; Maitland D. J. Porous Shape Memory Polymers: Design & Applications. J. Polym. Sci., Part B: Polym. Phys. 2016, 54, 1300–1318. 10.1002/polb.23982. [DOI] [Google Scholar]

- Leng J.; Lan X.; Liu Y.; Du S. Shape-Memory Polymers & Their Composites: Stimulus Methods & Applications. Prog. Mater. Sci. 2011, 56, 1077–1135. 10.1016/j.pmatsci.2011.03.001. [DOI] [Google Scholar]

- Yu K.; Ge Q.; Qi H. J. Reduced Time as a Unified Parameter Determining Fixity and Free Recovery of Shape Memory Polymers. Nat. Commun. 2014, 5, 3066 10.1038/ncomms4066. [DOI] [PubMed] [Google Scholar]

- Lendlein A.; Kelch S. Shape-Memory Polymers. Angew. Chem., Int. Ed. 2002, 41, 2034.. [DOI] [PubMed] [Google Scholar]

- Hardy J. G.; Palma M.; Wind S. J.; Biggs M. J. Responsive Biomaterials: Advances in Materials Based on Shape-Memory Polymers. Adv. Mater. 2016, 5717–5724. 10.1002/adma.201505417. [DOI] [PubMed] [Google Scholar]

- Chan B. Q. Y.; Low Z. W. K.; Heng S. J. W.; Chan S. Y.; Owh C.; Loh X. J. Recent Advances in Shape Memory Soft Materials for Biomedical Applications. ACS Appl. Mater. Interfaces 2016, 8, 10070–10087. 10.1021/acsami.6b01295. [DOI] [PubMed] [Google Scholar]

- Sehmi S. K.; Noimark S.; Weiner J.; Allan E.; MacRobert A. J.; Parkin I. P. Potent Antibacterial Activity of Copper Embedded into Silicone & Polyurethane. ACS Appl. Mater. Interfaces 2015, 7, 22807–22813. 10.1021/acsami.5b08665. [DOI] [PubMed] [Google Scholar]

- Gong T.; Zhao K.; Liu X.; Lu L.; Liu D.; Zhou S. A Dynamically Tunable, Bioinspired Micropatterned Surface Regulates Vascular Endothelial and Smooth Muscle Cells Growth at Vascularization. Small 2016, 12, 5769–5778. 10.1002/smll.201601503. [DOI] [PubMed] [Google Scholar]

- Han Y.; Hu J.; Jiang L. Collagen Skin, a Water-Sensitive Shape Memory Material. J. Mater. Chem. B 2018, 6, 5144–5152. 10.1039/C8TB01346B. [DOI] [PubMed] [Google Scholar]

- Gök M. O.; Bilir M. Z.; Gürcüm B. H. Shape-Memory Applications in Textile Design. Procedia – Soc. Behav. Sci. 2015, 195, 2160–2169. 10.1016/j.sbspro.2015.06.283. [DOI] [Google Scholar]

- Lv T.; Cheng Z.; Zhang E.; Kang H.; Liu Y.; Jiang L. Self-Restoration of Superhydrophobicity on Shape Memory Polymer Arrays with Both Crushed Microstructure and Damaged Surface Chemistry. Small 2017, 13, 1503402 10.1002/smll.201503402. [DOI] [PubMed] [Google Scholar]

- Venkatesan H.; Hu J.; Chen J. Bioinspired Fabrication of Polyurethane/Regenerated Silk Fibroin Composite Fibres with Tubuliform Silk-Like Flat Stress–Strain Behaviour. Polymers 2018, 10, 333 10.3390/polym10030333. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Liu Y.; Du H.; Liu L.; Leng J. Shape Memory Polymers and Their Composites in Aerospace Applications: A Review. Smart Mater. Struct. 2014, 23, 023001 10.1088/0964-1726/23/2/023001. [DOI] [Google Scholar]

- Zarek M.; Layani M.; Cooperstein I.; Sachyani E.; Cohn D.; Magdassi S. 3D Printing of Shape Memory Polymers for Flexible Electronic Devices. Adv. Mater. 2016, 28, 4449–4454. 10.1002/adma.201503132. [DOI] [PubMed] [Google Scholar]

- Lendlein A. Biodegradable, Elastic Shape-Memory Polymers for Potential Biomedical Applications. Science 2002, 296, 1673–1676. 10.1126/science.1066102. [DOI] [PubMed] [Google Scholar]

- Wache H. M.; Tartakowska D. J.; Hentrich A.; Wagner M. H. Development of a Polymer Stent with Shape Memory Effect as a Drug Delivery System. J. Mater. Sci.: Mater. Med. 2003, 14, 109–112. 10.1023/A:1022007510352. [DOI] [PubMed] [Google Scholar]

- Singhal P.; Small W.; Cosgriff-Hernandez E.; Maitland D. J.; Wilson T. S. Low Density Biodegradable Shape Memory Polyurethane Foams for Embolic Biomedical Applications. Acta Biomater. 2014, 10, 67–76. 10.1016/j.actbio.2013.09.027. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Serrano M. C.; Carbajal L.; Ameer G. A. Novel Biodegradable Shape-Memory Elastomers with Drug-Releasing Capabilities. Adv. Mater. 2011, 23, 2211–2215. 10.1002/adma.201004566. [DOI] [PubMed] [Google Scholar]

- Ng S.-W.; Noor N.; Zheng Z. Graphene-Based Two-Dimensional Janus Materials. NPG Asia Mater. 2018, 10, 217–237. 10.1038/s41427-018-0023-8. [DOI] [Google Scholar]

- Neuss S.; Blomenkamp I.; Stainforth R.; Boltersdorf D.; Jansen M.; Butz N.; Perez-Bouza A.; Knüchel R. The Use of a Shape-Memory Poly(E{lunate}-Caprolactone)Dimethacrylate Network as a Tissue Engineering Scaffold. Biomaterials 2009, 30, 1697–1705. 10.1016/j.biomaterials.2008.12.027. [DOI] [PubMed] [Google Scholar]

- Wu X.; Mahalingam S.; VanOosten S. K.; Wisdom C.; Tamerler C.; Edirisinghe M. New Generation of Tunable Bioactive Shape Memory Mats Integrated with Genetically Engineered Proteins. Macromol. Biosci. 2017, 17, 1600270 10.1002/mabi.201600270. [DOI] [PubMed] [Google Scholar]

- Kumar B.; Hu J.; Pan N. Smart Medical Stocking Using Memory Polymer for Chronic Venous Disorders. Biomaterials 2016, 75, 174–181. 10.1016/j.biomaterials.2015.10.032. [DOI] [PubMed] [Google Scholar]

- Narayana H.; Hu J.; Kumar B.; Shang S.; Han J.; Liu P.; Lin T.; Ji F.; Zhu Y. Stress-Memory Polymeric Filaments for Advanced Compression Therapy. J. Mater. Chem. B 2017, 5, 1905–1916. 10.1039/C6TB03354G. [DOI] [PubMed] [Google Scholar]

- Kumar B.; Pan N.; Hu J. L. Shape Memory Compression System for Management of Chronic Venous Disorders. Smart Text. Appl. 2016, 145–159. 10.1016/b978-0-08-100574-3.00008-4. [DOI] [Google Scholar]

- Hu J.; Kumar B.; Narayana H. Stress Memory Polymers. J. Polym. Sci., Part B: Polym. Phys. 2015, 53, 893–898. 10.1002/polb.23726. [DOI] [Google Scholar]

- Edsberg L. E.; Black J. M.; Goldberg M.; McNichol L.; Moore L.; Sieggreen M. Revised National Pressure Ulcer Advisory Panel Pressure Injury Staging System: Revised Pressure Injury Staging System. J Wound Ostomy Cont. Nurs. 2016, 43, 585–597. 10.1097/WON.0000000000000281. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Chou R.; Dana T.; Bougatsos C.; Blazina I.; Starmer A. J.; Reitel K.; Buckley D. I. Pressure Ulcer Risk Assessment & Prevention: A Systematic Comparative Effectiveness Review. Ann. Intern. Med. 2013, 159, 28–38. 10.7326/0003-4819-159-1-201307020-00006. [DOI] [PubMed] [Google Scholar]

- Ahmad M.; Luo J.; Miraftab M. Feasibility Study of Polyurethane Shape-Memory Polymer Actuators for Pressure Bandage Application. Sci. Technol. Adv. Mater. 2012, 13, 015006 10.1088/1468-6996/13/1/015006. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bader D. Laboratory Measurement of the Interface Pressures Applied by Active Therapy Support Surfaces: A Consensus Document. J. Tissue Viability 2010, 19, 2–6. 10.1016/j.jtv.2009.11.010. [DOI] [PubMed] [Google Scholar]

- Tobushi H.; Okumura K.; Endo M.; Hayashi S. Thermomechanical Properties of Polyurethane-Shape Memory Polymer Foam. J. Intell. Mater. Syst. Struct. 2001, 12, 283–287. 10.1106/FNSX-AP9V-QP1R-NMWV. [DOI] [Google Scholar]

- Tobushi H.; Shimada D.; Hayashi S.; Endo M. Shape Fixity and Shape Recovery of Polyurethane Shape-Memory Polymer Foams. Proc. Inst. Mech. Eng., Part L 2003, 217, 135–143. 10.1177/146442070321700205. [DOI] [Google Scholar]

- Santo L. Shape Memory Polymer Foams. Prog. Aerosp. Sci. 2016, 81, 60–65. 10.1016/j.paerosci.2015.12.003. [DOI] [Google Scholar]

- Kang S. M.; Lee S. J.; Kim B. K. Shape Memory Polyurethane Foams. Express Polym. Lett. 2012, 6, 63–69. 10.3144/expresspolymlett.2012.7. [DOI] [Google Scholar]

- Jiang L.; Hu H. Finite Element Modeling of Multilayer Orthogonal Auxetic Composites under Low-Velocity Impact. Materials 2017, 10, 908 10.3390/ma10080908. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Li G.Self-Healing Composites: Shape Memory Polymer-Based Structures; John Wiley & Sons, 2014. [Google Scholar]

- Ahmed M. F.; Li Y.; Yao Z.; Cao K.; Zeng C. TPU/PLA Blend Foams: Enhanced Foamability, Structural Stability, and Implications for Shape Memory Foams. J. Appl. Polym. Sci. 2019, 136, 47416 10.1002/app.47416. [DOI] [Google Scholar]

- Menon A. V.; Madras G.; Bose S. Shape Memory Polyurethane Nanocomposites with Porous Architectures for Enhanced Microwave Shielding. Chem. Eng. J. 2018, 352, 590–600. 10.1016/j.cej.2018.07.048. [DOI] [Google Scholar]

- Weems A. C.; Li W.; Maitland D. J.; Calle L. M. Polyurethane Microparticles for Stimuli Response and Reduced Oxidative Degradation in Highly Porous Shape Memory Polymers. ACS Appl. Mater. Interfaces 2018, 10, 32998–33009. 10.1021/acsami.8b11082. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Zhang Y.; Li Y.; Liu W. Dipole-Dipole & h-Bonding Interactions Significantly Enhance the Multifaceted Mechanical Properties of Thermoresponsive Shape Memory Hydrogels. Adv. Funct. Mater. 2015, 25, 471–480. 10.1002/adfm.201401989. [DOI] [Google Scholar]

- Pei Z.; Yang Y.; Chen Q.; Wei Y.; Ji Y. Regional Shape Control of Strategically Assembled Multishape Memory Vitrimers. Adv. Mater. 2016, 28, 156–160. 10.1002/adma.201503789. [DOI] [PubMed] [Google Scholar]

- Guo M.; Pitet L. M.; Wyss H. M.; Vos M.; Dankers P. Y. W. W.; Meijer E. W. Tough Stimuli-Responsive Supramolecular Hydrogels with Hydrogen-Bonding Network Junctions. J. Am. Chem. Soc. 2014, 136, 6969–6977. 10.1021/ja500205v. [DOI] [PubMed] [Google Scholar]

- Fang C.; Leng J.; Sun H.; Gu J. A Multi-Branch Thermoviscoelastic Model Based on Fractional Derivatives for Free Recovery Behaviors of Shape Memory Polymers. Mech. Mater. 2018, 120, 34–42. 10.1016/j.mechmat.2018.03.002. [DOI] [Google Scholar]

- Mak A. F. T.; Zhang M.; Tam E. W. C. Biomechanics of Pressure Ulcer in Body Tissues Interacting with External Forces during Locomotion. Annu. Rev. Biomed. Eng. 2010, 12, 29–53. 10.1146/annurev-bioeng-070909-105223. [DOI] [PubMed] [Google Scholar]

- Amano Y.; Hidema R.; Gong J.; Furukawa H. Creation of Shape-Memory Gels with Inter-Crosslinking Network Structure. Chem. Lett. 2012, 41, 1029–1031. 10.1246/cl.2012.1029. [DOI] [Google Scholar]

- Miaudet P.; Derre A.; Maugey M.; Zakri C.; Piccione P. M.; Inoubli R.; Poulin P. Shape and Temperature Memory of Nanocomposites with Broadened Glass Transition. Science 2007, 318, 1294–1296. 10.1126/science.1145593. [DOI] [PubMed] [Google Scholar]

- Meng Y.; Jiang J.; Anthamatten M. Body Temperature Triggered Shape-Memory Polymers with High Elastic Energy Storage Capacity. J. Polym. Sci., Part B: Polym. Phys. 2016, 54, 1397–1404. 10.1002/polb.23990. [DOI] [Google Scholar]

- Duscher D.; Neofytou E.; Wong V. W.; Maan Z. N.; Rennert R. C.; Inayathullah M.; Januszyk M.; Rodrigues M.; Malkovskiy A. V.; Whitmore A. J.; Walmsley G. G.; Galvez M. G.; Whittam A. J.; Brownlee M.; Rajadas J.; Gurtner G. C. Transdermal Deferoxamine Prevents Pressure-Induced Diabetic Ulcers. Proc. Natl. Acad. Sci. U.S.A. 2015, 112, 94–99. 10.1073/pnas.1413445112. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Amin N.; Doupis J. Diabetic Foot Disease: From the Evaluation of the “Foot at Risk” to the Novel Diabetic Ulcer Treatment Modalities. World J. Diabetes 2016, 7, 153. 10.4239/wjd.v7.i7.153. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Urbancic-Rovan V. Causes of Diabetic Foot Lesions. Lancet 2005, 366, 1675–1676. 10.1016/S0140-6736(05)67673-8. [DOI] [PubMed] [Google Scholar]

- World Health Organization. Global Report on Diabetes; WHO, 2016; Vol. 978.

- Hall M.; Shurr D. G.; Zimmerman M. B.; Saltzman C. L. Plantar Foot Surface Temperatures with Use of Insoles. Iowa Orthop. J. 2004, 24, 72–75. [PMC free article] [PubMed] [Google Scholar]

- Andrieux S.; Quell A.; Stubenrauch C.; Drenckhan W. Liquid Foam Templating – A Route to Tailor-Made Polymer Foams. Adv. Colloid Interface Sci. 2018, 256, 276–290. 10.1016/j.cis.2018.03.010. [DOI] [PubMed] [Google Scholar]

- Barmouz M.; Behravesh A. H. The Role of Foaming Process on Shape Memory Behavior of Polylactic Acid-Thermoplastic Polyurethane-Nano Cellulose Bio-Nanocomposites. J. Mech. Behav. Biomed. Mater. 2019, 91, 266–277. 10.1016/j.jmbbm.2018.12.021. [DOI] [PubMed] [Google Scholar]

- Floros M.; Hojabri L.; Abraham E.; Jose J.; Thomas S.; Pothan L.; Leao A. L.; Narine S. Enhancement of Thermal Stability, Strength and Extensibility of Lipid-Based Polyurethanes with Cellulose-Based Nanofibers. Polym. Degrad. Stab. 2012, 97, 1970–1978. 10.1016/j.polymdegradstab.2012.02.016. [DOI] [Google Scholar]

- Zhu Y.; Hu J.; Luo H.; Young R. J.; Deng L.; Zhang S.; Fan Y.; Ye G. Rapidly Switchable Water-Sensitive Shape-Memory Cellulose/Elastomer Nano-Composites. Soft Matter 2012, 8, 2509. 10.1039/c2sm07035a. [DOI] [Google Scholar]

- Braun B.; Dorgan J. R.; Dec S. F. Infrared Spectroscopic Determination of Lactide Concentration in Polylactide: An Improved Methodology. Macromolecules 2006, 39, 9302–9310. 10.1021/ma061922a. [DOI] [Google Scholar]

- Liu X.; Wang T.; Li J.; Cheng J.; Zhang J. Synthesis and Properties of Segmented Polyurethanes with Hydroquinone Ether Derivatives as Chain Extender. J. Polym. Res. 2015, 22, 149 10.1007/s10965-015-0792-5. [DOI] [Google Scholar]

- Leitsch E. K.; Beniah G.; Liu K.; Lan T.; Heath W. H.; Scheidt K. A.; Torkelson J. M. Nonisocyanate Thermoplastic Polyhydroxyurethane Elastomers via Cyclic Carbonate Aminolysis: Critical Role of Hydroxyl Groups in Controlling Nanophase Separation. ACS Macro Lett. 2016, 5, 424–429. 10.1021/acsmacrolett.6b00102. [DOI] [PubMed] [Google Scholar]

- Parnell S.; Min K.; Cakmak M. Kinetic Studies of Polyurethane Polymerization with Raman Spectroscopy. Polymer 2003, 44, 5137–5144. 10.1016/S0032-3861(03)00468-3. [DOI] [Google Scholar]

- Aust J. F.; Higgins M. K.; Groner P.; Morgan S. L.; Myrick M. L. Fourier Transform Raman Spectroscopic Studies of a Polyimide Curing Reaction. Anal. Chim. Acta 1994, 293, 119–128. 10.1016/0003-2670(94)00100-6. [DOI] [Google Scholar]

- Cregut M.; Bedas M.; Assaf A.; Durand-Thouand M. J.; Thouand G. Applying Raman Spectroscopy to the Assessment of the Biodegradation of Industrial Polyurethanes Wastes. Environ. Sci. Pollut. Res. 2014, 21, 9538–9544. 10.1007/s11356-013-1772-0. [DOI] [PubMed] [Google Scholar]

- Janik H.; Pałys B.; Petrovic Z. S. Multiphase-Separated Polyurethanes Studied by Micro-Raman Spectroscopy. Macromol. Rapid Commun. 2003, 24, 265–268. 10.1002/marc.200390039. [DOI] [Google Scholar]

- Teo L.-S.; Chen C.-Y.; Kuo J.-F. Fourier Transform Infrared Spectroscopy Study on Effects of Temperature on Hydrogen Bonding in Amine-Containing Polyurethanes & Poly(Urethane–urea)S. Macromolecules 1997, 30, 1793–1799. 10.1021/ma961035f. [DOI] [Google Scholar]

- Pegoraro M.; Galbiati A.; Ricca G. 1H Nuclear Magnetic Resonance Study of Polyurethane Prepolymers from Toluene Diisocyanate and Polypropylene Glycol. J. Appl. Polym. Sci. 2003, 87, 347–357. 10.1002/app.10958. [DOI] [Google Scholar]

- Brame E. G.; Ferguson R. C.; Thomas G. J. Identification of Polyurethanes by High Resolution Nuclear Magnetic Resonance Spectrometry. Anal. Chem. 1967, 39, 517–521. 10.1021/ac60248a004. [DOI] [Google Scholar]

- Van Heumen J. D.; Stevens J. R. The Role of Lithium Salts in the Conductivity & Phase Morphology of a Thermoplastic Polyurethane. Macromolecules 1995, 28, 4268–4277. 10.1021/ma00116a030. [DOI] [Google Scholar]

- Datta J.; Kasprzyk P. Thermoplastic Polyurethanes Derived from Petrochemical or Renewable Resources: A Comprehensive Review. Polym. Eng. Sci. 2018, 58, E14–E35. 10.1002/pen.24633. [DOI] [Google Scholar]

- Menard K. P.; Menard N. R.. Dynamic Mechanical Analysis in the Analysis of Polymers and Rubbers. Encyclopedia of Polymer Science and Technology; John Wiley & Sons, Inc.: Hoboken, NJ, 2015; pp 1–33. [Google Scholar]

- Foreman J.; Sauerbrunn S. R.; Marcozzi C. L.. Exploring the Sensitivity of Thermal Analysis Techniques to the Glass Transition Document Reference: TA082; TA Instruments, Inc., 2006. [Google Scholar]

- Xu Y.; Petrovic Z.; Das S.; Wilkes G. L. Morphology and Properties of Thermoplastic Polyurethanes with Dangling Chains in Ricinoleate-Based Soft Segments. Polymer 2008, 49, 4248–4258. 10.1016/j.polymer.2008.07.027. [DOI] [Google Scholar]

- Liu J.-C.; Martin D. J.; Moon R. J.; Youngblood J. P. Enhanced Thermal Stability of Biomedical Thermoplastic Polyurethane with the Addition of Cellulose Nanocrystals. J. Appl. Polym. Sci. 2015, 132, 41970 10.1002/app.41970. [DOI] [Google Scholar]

- Van Ekeren P. J.; Carton E. P. Polyurethanes for Potential Use in Transparent Armour Investigated Using DSC and DMA. J. Therm. Anal. Calorim. 2011, 105, 591–598. 10.1007/s10973-011-1665-8. [DOI] [Google Scholar]

- Chen S.; Hu J.; Liu Y.; Liem H.; Zhu Y.; Meng Q. Effect of Molecular Weight on Shape Memory Behavior in Polyurethane Films. Polym. Int. 2007, 56, 1128–1134. 10.1002/pi.2248. [DOI] [Google Scholar]

- Li S.; Zhao J.; Zhang Z.; Zhang J.; Yang W. Aliphatic Thermoplastic Polyurethane-Ureas and Polyureas Synthesized through a Non-Isocyanate Route. RSC Adv. 2015, 5, 6843–6852. 10.1039/C4RA12195C. [DOI] [Google Scholar]

- Anandhan S.; Lee H. S. Influence of Organically Modified Clay Mineral on Domain Structure and Properties of Segmented Thermoplastic Polyurethane Elastomer. J. Elastomers Plast. 2014, 46, 217–232. 10.1177/0095244312465300. [DOI] [Google Scholar]

- Memarian F.; Fereidoon A.; Ghorbanzadeh Ahangari M. The Shape Memory, & the Mechanical and Thermal Properties of TPU/ABS/CNT: A Ternary Polymer Composite. RSC Adv. 2016, 6, 101038 10.1039/C6RA23087C. [DOI] [Google Scholar]

- Bera M.; Maji P. K. Effect of Structural Disparity of Graphene-Based Materials on Thermo-Mechanical and Surface Properties of Thermoplastic Polyurethane Nanocomposites. Polymer 2017, 119, 118–133. 10.1016/j.polymer.2017.05.019. [DOI] [Google Scholar]

- Wang J.; Yuan B.; Mu X.; Wang W.; Hu W.; Hu Y. Novel Incorporation of Mesoporous NiCo2O4 into Thermoplastic Polyurethane for Enhancing Its Fire Safety. RSC Adv. 2016, 6, 109620–109632. 10.1039/C6RA24264B. [DOI] [Google Scholar]

- Hou Y.; Duan L.; Gui Z.; Hu Y. An Infiltration Method to Synthesize Thermoplastic Polyurethane Composites Based on Size-Controlled Graphene Foams. Composites, Part A 2017, 97, 67–75. 10.1016/j.compositesa.2017.02.023. [DOI] [Google Scholar]

- Polat Y.; Pampal E. S.; Stojanovska E.; Simsek R.; Hassanin A.; Kilic A.; Demir A.; Yilmaz S. Solution Blowing of Thermoplastic Polyurethane Nanofibers: A Facile Method to Produce Flexible Porous Materials. J. Appl. Polym. Sci. 2016, 133, 43025 10.1002/app.43025. [DOI] [Google Scholar]

- Gundogdu N. A. S.; Akgul Y.; Kilic A. Optimization of Centrifugally Spun Thermoplastic Polyurethane Nanofibers for Air Filtration Applications. Aerosol Sci. Technol. 2018, 52, 515–523. 10.1080/02786826.2018.1433813. [DOI] [Google Scholar]

- Vitkauskien I.; Makuška R.; Stirna U.; Cabulis U. Thermal Properties of Polyurethane-Polyisocyanurate Foams Based on Poly(Ethylene Terephthalate) Waste. Mater. Sci. 2011, 17, 249–253. 10.5755/j01.ms.17.3.588. [DOI] [Google Scholar]

- Lai S.-M.; Wang C.-K.; Shen H.-F. Properties & Preparation of Thermoplastic Polyurethane/Silica Hybrid Using Sol-Gel Process. J. Appl. Polym. Sci. 2005, 97, 1316–1325. 10.1002/app.21833. [DOI] [Google Scholar]

- Ahmad Z.; Ansell M.; Smedley D.; Tahir P. M. Creep Behavior of Epoxy-Based Adhesive Reinforced with Nanoparticles for Bonded-In Timber Connection. J. Mater. Civ. Eng. 2012, 24, 825–831. 10.1061/(ASCE)MT.1943-5533.0000453. [DOI] [Google Scholar]

- Dutta J.; Naskar K. Investigation of Morphology, Mechanical, Dynamic Mechanical and Thermal Behaviour of Blends Based on Ethylene Vinyl Acetate (EVA) and Thermoplastic Polyurethane (TPU). RSC Adv. 2014, 4, 60831–60841. 10.1039/C4RA07823C. [DOI] [Google Scholar]

- Mi H.-Y.; Salick M. R.; Jing X.; Jacques B. R.; Crone W. C.; Peng X.-F.; Turng L.-S. Characterization of Thermoplastic Polyurethane/Polylactic Acid (TPU/PLA) Tissue Engineering Scaffolds Fabricated by Microcellular Injection Molding. Mater. Sci. Eng., C 2013, 33, 4767–4776. 10.1016/j.msec.2013.07.037. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Behera P. K.; Usha K. M.; Guchhait P. K.; Jehnichen D.; Das A.; Voit B.; Singha N. K. A Novel Ionomeric Polyurethane Elastomer Based on Ionic Liquid as Crosslinker. RSC Adv. 2016, 6, 99404–99413. 10.1039/C6RA21650A. [DOI] [Google Scholar]

- Saber-Sheikh K.; Clarke R. L.; Braden M. Viscoelastic Properties of Some Soft Lining Materials. I-Effect of Temperature. Biomaterials 1999, 20, 817–822. 10.1016/S0142-9612(98)00236-1. [DOI] [PubMed] [Google Scholar]

- Singhal P.; Rodriguez J. N.; Small W.; Eagleston S.; Van de Water J.; Maitland D. J.; Wilson T. S. Ultra Low Density and Highly Crosslinked Biocompatible Shape Memory Polyurethane Foams. J. Polym. Sci., Part B: Polym. Phys. 2012, 50, 724–737. 10.1002/polb.23056. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Patton S.; Chen C.; Hu J.; Grazulis L.; Schrand A.; Roy A. Characterization of Thermoplastic Polyurethane (TPU) and Ag-Carbon Black TPU Nanocomposite for Potential Application in Additive Manufacturing. Polymers 2017, 9, 6 10.3390/polym9010006. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kanyanta V.; Ivankovic A. Mechanical Characterisation of Polyurethane Elastomer for Biomedical Applications. J. Mech. Behav. Biomed. Mater. 2010, 3, 51–62. 10.1016/j.jmbbm.2009.03.005. [DOI] [PubMed] [Google Scholar]

- Qu X. Impacts of Different Types of Insoles on Postural Stability in Older Adults. Appl. Ergon. 2015, 46, 38–43. 10.1016/j.apergo.2014.06.005. [DOI] [PubMed] [Google Scholar]

- Scarfato P.; Di Maio L.; Incarnato L. Structure and Physical-Mechanical Properties Related to Comfort of Flexible Polyurethane Foams for Mattress & Effects of Artificial Weathering. Composites, Part B 2017, 109, 45–52. 10.1016/j.compositesb.2016.10.041. [DOI] [Google Scholar]

- Obi B. E. In Polymeric Foams Structure–Property–Performance: A Design Guide; Obi B. E., Ed.; William Andrew, 2017. [Google Scholar]

- Zheng N.; Fang Z.; Zou W.; Zhao Q.; Xie T. Inside Cover: Thermoset Shape-Memory Polyurethane with Intrinsic Plasticity Enabled by Transcarbamoylation (Angew. Chem. Int. Ed. 38/2016). Angew. Chem., Int. Ed. 2016, 55, 11304. 10.1002/anie.201606585. [DOI] [PubMed] [Google Scholar]

- Brodsky J. W.; Kourosh S.; Stills M.; Mooney V. Objective Evaluation of Insert Material for Diabetic and Athletic Footwear. Foot Ankle 1988, 9, 111–116. 10.1177/107110078800900303. [DOI] [PubMed] [Google Scholar]

- Mittal V.; Kim J.-K.; Pal K.. Recent Advances in Elastomeric Nanocomposites; Springer, 2011. [Google Scholar]

- Liu C.; Zong R.; Chen H.; Wang J.; Wu C. Comparative Study of Toxicity for Thermoplastic Polyurethane and Its Flame-Retardant Composites. J. Thermoplast. Compos. Mater. 2019, 1393–1407. 10.1177/0892705718798409. [DOI] [Google Scholar]

- Liu X.; Hao J.; Gaan S. Recent Studies on the Decomposition and Strategies of Smoke and Toxicity Suppression for Polyurethane Based Materials. RSC Adv. 2016, 6, 74742–74756. 10.1039/C6RA14345H. [DOI] [Google Scholar]

- McKenna S. T.; Hull T. R. The Fire Toxicity of Polyurethane Foams. Fire Sci. Rev. 2016, 5, 3 10.1186/s40038-016-0012-3. [DOI] [Google Scholar]

- Wise D. L., Trantolo D. J., Altobelli D. E., Yaszemski M. J., Gresser J. D., Eds. Human Biomaterials Applications, 2nd ed.; Humana Press, 2013. [Google Scholar]

- Gogoi S.; Barua S.; Karak N. Cross-Linking Kinetics of Hyperbranched Epoxy Cured Hyperbranched Polyurethane and Optimization of Reaction Conversion by Central Composite Design. Chem. Eng. Sci. 2015, 127, 230–238. 10.1016/j.ces.2015.01.053. [DOI] [Google Scholar]

- Chattopadhyay D. K.; Sreedhar B.; Raju K. V. S. N. Effect of Chain Extender on Phase Mixing and Coating Properties of Polyurethane Ureas. Ind. Eng. Chem. Res. 2005, 44, 1772–1779. 10.1021/ie0492348. [DOI] [Google Scholar]

- Delpech M. C.; Coutinho F. M. B. Waterborne Anionic Polyurethanes and Poly(Urethane-Urea)s: Influence of the Chain Extender on Mechanical and Adhesive Properties. Polym. Test. 2000, 19, 939–952. 10.1016/S0142-9418(99)00066-5. [DOI] [Google Scholar]

- Choi J.; Moon D. S.; Jang J. U.; Yin W. B.; Lee B.; Lee K. J. Synthesis of Highly Functionalized Thermoplastic Polyurethanes and Their Potential Applications. Polymer 2017, 116, 287–294. 10.1016/j.polymer.2017.03.083. [DOI] [Google Scholar]

- Wojdyr M. Fityk: A General-Purpose Peak Fitting Program. J. Appl. Crystallogr. 2010, 43, 1126–1128. 10.1107/S0021889810030499. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.