Abstract

We investigate selected chemical, technical, and economic aspects of the production of fish oil rich in polyunsaturated omega-3 fatty acids from anchovy filleting leftovers using d-limonene as the extraction solvent at ambient temperature and pressure. Entirely derived from the orange peel prior to orange squeezing for juice production, the bio-based solvent is easily recovered, affording a circular economy process with significant potential for practical applications.

1. Introduction

Omega-3 polyunsaturated fatty acids (PUFAs) provide numerous health benefits.1 In brief, the ability of tissue’s self-defense against oxidative stress depends upon its ω-6:ω-3 lipid composition.2 In 1971 Bang, Dyerberg, and Nielsen reported surprisingly low plasma cholesterol, triglycerides, and β-lipoprotein concentration in blood samples from 61 male and 69 female Inuit living in Greenland.3 Even though in agreement with the fact that heart disease accounted for only 5.3 per cent of deaths amongst Greenland males, aged 45 to 64 (a much lower figure compared to counterpart males eating then typical and vastly different diet), the results were most surprising because the dietary habits of the Inuit population studied, mostly eating fish, seal, and whale meat and their oil, were “very like those of the carnivorous animals”.3 In 1975, the same team reported the discovery in the same Inuit plasma lipids of two fatty acids, eicosapentaenoic acid (EPA, C20:5n-3) and docosahexaenoic acid (DHA, C22:6n-3).4 Fish, whale, seal, and cod liver oils, indeed, are all rich in both EPA and DHA PUFAs.

Today omega-3 nutrients, mostly of marine origin, are widely consumed across the World as dietary supplements (52.9% of global value share in 2017)5 and as valued ingredients for infant formula (20.2% of the value share) and pharmaceuticals (15.4%).

As recently noted by Winkler,6 less than 20% of world’s population eats as much as 250 mg/day of seafood omega-3, and because the lowest target for EPA and DHA intake is 250 mg/day, it follows that “more than 80% of the World is failing to meet even the lowest recommended intake.”6 Accordingly, the omega-3 index reflecting the omega-3 status in the body, namely the total concentration of EPA and DHA in red blood cells expressed as a percentage of total fatty acid content (a biomarker for fatty acid composition, correlating with tissue fatty acid composition, measured in erythrocytes of low biologic variability),7 “in many parts of the world, including in Asia Pacific, remains much lower than optimal”.8

The use of fishery byproducts, (discards in the marine fisheries and leftovers in fish processing companies available worldwide in several million tonnes per year amount),9 as raw materials for the production of fish oil omega-3 extracts is highly desirable.10 Anchovies, for example, are amid world’s largest fish catches which has led several governments to establish quotas to limit overfishing. Out of 1.2 million of tonnes of fish caught in the Mediterranean and in the Black Sea, small pelagics sardines and anchovies account for one-third of all catches.11

Mostly used to produce animal feed and fish oil, anchovies are also processed to produce valued and expensive fillets. One method recently introduced to obtain valued anchovy oil from anchovy filleting leftovers relies on d-limonene as the green biosolvent.12 Limonene indeed is a renewable solvent present as the main component of orange oil obtained from waste orange peel.13 In the following, we investigate selected chemical, technical, and economic aspects of the production of fish oil rich in polyunsaturated omega-3 fatty acids from anchovy filleting waste using (+)-limonene at ambient temperature and pressure as the unique extraction solvent.

2. Results and Discussion

2.1. Limonene Versus Hexane for Anchovy Oil Extraction

Orange-derived d-limonene has been used and applied successfully for decades in the food, cosmetic, and personal care product industries for its flavor and fragrance qualities added to its physical and chemical properties.14 Its more recent use as an extraction solvent of lipids offers several technical, environmental, and health advantages over the use of n-hexane.14,15 Besides excellent yields, for example, in extraction of rice bran oil compared to extraction with conventional n-hexane,16 the amount of the oxidation products in the recovered limonene is <1 wt % of the original biosolvent.

Computational comparison of the solvation power of d-limonene and n-hexane for salmon fish oil using both the conductor-like screening model for real solvents (COSMO-RS) and the Hansen solubility parameter (HSP) models to evaluate the solubility of selected components of salmon oil in n-hexane and d-limonene shows that d-limonene is a better solvent than hexane for all triacylglycerols, diacylglycerols, free fatty acids, and ergosterol studied.17

The former model relies on quantum calculation software combining quantum chemical (COSMO) and statistical thermodynamics (RS). The HSP computational model, in its turn, is based on the relative energy difference number (RED) to determine whether the alternative solvent and the solute are miscible (eq 1)

| 1 |

where Rb is the radius of a Hansen solubility sphere and Ra is the distance of a solvent molecule located inside the Hansen solubility sphere.17 A potentially good solvent has a RED number <1 (while an unsuitable solvent has RED >1) because, reflecting to the “like dissolves the like” empirical rule, the smaller Ra, the higher is the affinity between the solute and the solvent. Calculations were performed using the HSPiP 4.0 software (Hansen-solubility, Denmark).

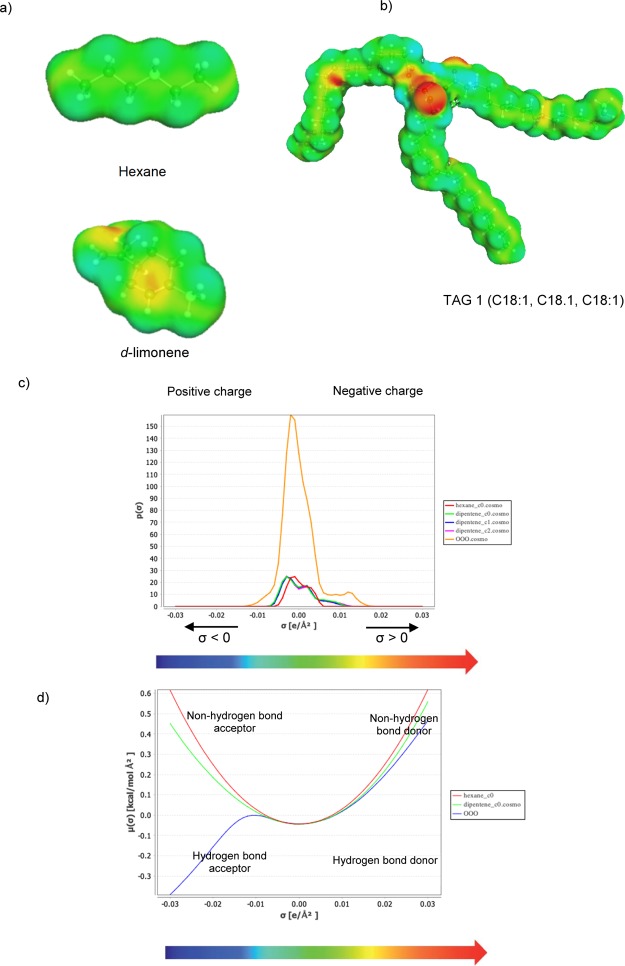

Similarly, the COSMO calculations were performed for each molecule of interest. In said calculations, the molecules are considered in a virtual conductor environment. A solute molecule induces a polarization charge density at the interface between the molecule and the conductor on the molecular surface. The 3D polarization density distribution on the surface of each molecule is converted into the σ-profile, namely, a distribution function displaying the relative amount of surface with polarity σ on the surface of the molecule. In said σ-profile, blue represents strongly positive polar regions and red represents highly negative polar surfaces, whereas green and yellow are used to identify regions of lower polarity.16

In general, even though the overall number of fatty acids in fish oil can approach 100 (leading, e.g., to 250 different triacylglycerols in menhaden oil),18 the lipid profile of fish oils is primarily described by reference to two polyunsaturated (20:5(n-3), 22:6(n-3)), four monounsaturated (16:1, 18:1, 20:1, 22:1), and two saturated (14:0, 16:0) fatty acids.19 Anchovy oil makes no exception, with palmitic acid (16:0) being the major SFA; oleic acid (18:1) being the most abundant monounsaturated fatty acids (MUFA); and DHA, EPA, and α-linolenic acid being the most abundant PUFAs.20

Derived from the combination of three free fatty acids (C18:1, C18:2, and C16:0) beyond EPA and DHA, the chemical structures simulated include four triacylglycerols [TAG 1 (C18:1, C18:1, C18:1), TAG 2 (C18:1, C18:1, C18:2), TAG 3 (C16:0, C18:1, C18:1), and TAG 4 (C16:0, C18:1, C18:2)] and four diacylglycerols [DAG 1 (C18:1, C18:1), DAG 2 (C18:1, C18:2), DAG 3 (C18:2, C18:2), and DAG 4 (C18:1, C16:0)]. The solubility and structures of three free fatty acids (FFA1, C18:1), (FFA2, C18:2), and (FFA3, C16:0) and ergosterol were simulated, too.

The TAGs selected, in the equivalent carbon number (ECN) 46–48 range, are amongst the most representative in anchovy oil.21 We briefly remind that hydrophobicity of TAG lipids is determined by the ECN (=total carbon atom number – 2 × number of double bonds). Phospholipids that represent about the 30% of total lipids in the fresh anchovies are not included in the simulation because their proportion in total lipid quickly decreases during storage of anchovy because of their rapid hydrolysis at temperatures above −29 °C.22

The chemical structure of TAG 1 (OOO, with oleic acid bound to all residues of the glycerol molecule) simulated in Figure 1, and the results of computation show that according both to HSP and COSMO-RS models, d-limonene is a better solvent for extraction of all the compounds studied.

Figure 1.

Step calculation with COSMO-RS: (a) d-limonene and n-hexane σ-surface; (b) oleic acid triglyceride (TAG 1) σ-surface; (c) energies of local surface interactions between σ-profiles of TAG 1 and solvents; (d) σ-potentials of TAG 1 and solvents.

2.2. Further Advantages

The use of limonene at room temperature as an anchovy leftover extraction solvent offers numerous additional advantages. Conventional extraction of salmon oil from lyophilized samples of salmon under reflux during 8 h in a Soxhlet apparatus takes place at the high boiling point around 180 °C of the terpene, followed by addition of 50% (v/v) water to the biosolvent and evaporation under reduced pressure.17 Regardless of the excellent solvation power predicted by computation, in practice, extraction under reflux of the aforementioned fish oil results in oil containing low TAG and high DAG amounts17 because of rapid oxidation of PUFAs at temperatures above 100 °C.23

Mild extraction of anchovy fillet leftovers with d-limonene at ambient temperature and pressure, on the other hand, reproducibly affords an orange oil rich in PUFAs. In detail, the anchovy oil from the leftovers of European anchovies caught in Sicily in early July contains EPA (5.4%), DHA (12.38%), and α-linolenic acid (0.96%), the most abundant omega-3 PUFAs, with palmitic acid (33.55%) being the major SFA and oleic acid (23.97%) being the most abundant MUFA.12

The presence of limonene traces in the residual anchovy fillet discards upon lipid extraction, likely to find use as an animal feed, is beneficial. In 2015, indeed, scholars in Algeria discovered that orange, lemon, and bergamot essential oils are highly effective in combating the growth of pathogenic bacteria causing most common fish food poisoning and recommended their use “as potent natural preservatives to contribute to the reduction of lipid oxidation in sardines”.24 Limonene, furthermore, is both bactericidal and bacteriostatic for several Gram-negative and Gram-positive fish pathogenic bacteria, which led another scholar based in Algeria to recommend its use as an alternative to antibiotics to prevent fish bacterial infections in aquaculture.25

One more problem solved by limonene-based extraction of anchovy leftovers is the significant odor of the dead anchovy fish residues. Such unpleasant odor is also due to the oxidation products formed by rapid oxidation at ambient conditions of free PUFAs, which are formed upon rapid hydrolysis of phospholipids contained in the cell membranes and which in fresh anchovy account for about 30% of total lipid.26 Stirring the milled leftovers in d-limonene at an extraction unit located within the anchovy processing plant would remove the triglycerides and the free PUFAs from the adipose tissues, inhibiting their oxidation, thanks to the antioxidant power of the terpene.

Finally, with its exquisite smell, d-limonene used to treat the anchovy leftovers would eliminate bad odor throughout the fishery plant and the associated health and worker well-being issues.

2.3. Economic Aspects

Extraction of fish oil with d-limonene from anchovy leftovers transforms a voice of cost into a revenue voice. Currently, for instance, anchovy fillet processing company in Sicily (Italy) pays waste-processing companies around $282(€250)/t to dispose of discards as biowaste which can no longer be landfilled.27

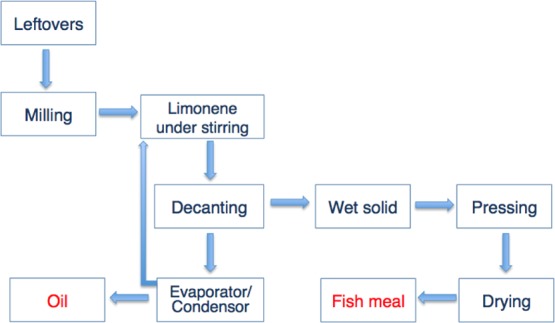

Displayed in Scheme 1, the process lately developed on the laboratory scale involves milling and homogenizing frozen anchovy (204 g) with the aid of an electric blender and a first aliquot of d-limonene at 4 °C, followed by overnight mild stirring in the presence of the biosolvent (157.4 g).12 Following decanting, the solvent is recovered by evaporation under reduced pressure (40 mbar) at 90 °C.

Scheme 1. Extraction of Oil and Fish Meal from Anchovy Discards Using d-Limonene as the Recyclable Extraction Solvent.

Assuming to upscale the laboratory process as such, processing 1 t of anchovy leftovers would afford approximately 14.7 kg of fish oil. The latter oil containing traces of edible limonene (a flavor with multiple health benefits)13 might be used directly to manufacture omega-3 dietary supplements, without the need of extensive refining to eventually convert the DHA and EPA triglycerides present in crude anchovy oil (Peruvian fish oil sold in early 2018 at $2600–2800/t)28 in their diethyl esters as it happens with current omega-3 purified extract manufacturing processes.10

Today’s best omega-3 dietary supplements, indeed, contain EPA and DHA in the triglyceride form (rather than as ethyl esters present in most commercial omega-3 dietary supplements) as this leads to a 70% higher increase in the omega-3 index when the ingredients are consumed as triglycerides.29

Upon extraction with limonene, the oil-free semi-solid anchovy residue comprised of milled leftovers rich in proteins, and bone minerals would first undergo a pressing step common to most fish meal-manufacturing processes, followed by a mild drying process to reduce the amount of water below 12 wt % so as the ensure the formation of safely stored fish meal. Such drying would be preferably carried out using a low cost solar air dryer similar to those widely used across the world to dry fish more rapidly and more effectively than in open air.30

Besides the initial purchase of citrus limonene (eventually recycled in consecutive extraction cycles), the two major costs that would be faced by a company willing to extract fish oil from anchovy-(or any other fish) processing waste would be (i) labor and (ii) electricity needed to recover the bio-based solvent by evaporation under reduced pressure. The price of citrus limonene has been increasing since 2007 and steeply again since 2013.31 Assuming a $9/kg rate, purchase of 1296 kg of d-limonene to process 1 t of anchovy leftovers would require a $11 664 investment. The cost of electricity of the extraction company, in its turn, would be dramatically reduced by self-producing power through a photovoltaic (PV) plant whose cost, following the recent dramatic uptake of the technology on a truly global scale,32 has reached historic low levels (complete PV systems of nominal power >30 kW currently routinely installed in Italy at <€1/W).

3. Conclusions

Extraction of anchovy fish oil rich in omega-3 lipids from anchovy discards using orange oil-derived d-limonene is advantageous and economically and technically feasible. The capital investment in the low-energy extraction setup, including the bio-based solvent13 and the solar air dryer,30 is relatively modest, and the operational costs are mostly due to labor and electricity to separate the oil from the agro solvent.

Overall, the process cuts the cost of the conventional energy-intensive extraction process, and the associated significant infrastructure required first to manufacture refined fish oil typically containing about 30% omega-3 fatty acids (18% in EPA and 12% in DHA) via several consecutive steps including neutralization with alkalis, bleaching, deodorization, and degumming.10 As the solar and bioeconomy unfolds across the world,33 shifting omega-3 lipids extraction from blue fish to blue fish waste is now possible, thanks to a natural solvent of exceptional properties.

A leading practitioner of Australia’s health food and supplements industry lately suggested how the multi-billion-dollar success story of omega-3 supplements in Australia was based on a foundation of quality and innovation, within a regulatory framework encouraging consumer trust.34 The same analyst forecasts that “higher quality concentrated omega-3s will grow, particularly in the natural and medical practitioner channels”.34 Extraction of fish oil rich in omega-3 from anchovy leftovers using biobased limonene affords oil chiefly suited for nutraceutical applications. Anchovy oil indeed is particularly rich in cholecalciferol (vitamin D3),35 which, as shown by calculations reported herein, is highly soluble in d-limonene.

Besides being a source of essential omega-3 lipids, fish and fish products are commonly regarded as the most important natural food sources of vitamin D, a regulator of inflammation playing an important role in the immune system, currently an underconsumed nutrient of public health concern in several countries,36 for which dietary guidelines recommend increased intake either from the few foods that contain it (oily fish, milk products, and mushrooms) or through dietary supplements.

Acknowledgments

This study is dedicated to the memory of Professor Ines Donato for her long-term support and dedication to University of Palermo’s chemistry students.

The authors declare no competing financial interest.

References

- Shahidi F.; Ambigaipalan P. Omega-3 Polyunsaturated Fatty Acids and Their Health Benefits. Annu. Rev. Food Sci. Technol. 2018, 9, 345–381. 10.1146/annurev-food-111317-095850. [DOI] [PubMed] [Google Scholar]

- Lands W. E. M.Fish, Omega-3 and Human Health, 2nd ed.; AOCS Publishing: Urbana, IL, 2005. [Google Scholar]

- Bang H. O.; Dyerberg J.; Nielsen A. B. Plasma lipid and lipoprotein pattern in Greenlandic West-coast Eskimos. Lancet 1971, 297, 1143–1146. 10.1016/s0140-6736(71)91658-8. [DOI] [PubMed] [Google Scholar]

- Dyerberg J.; Bang H. O.; Hjørne N. Fatty acid composition of the plasma lipids in Greenland Eskimos. Am. J. Clin. Nutr. 1975, 28, 958–966. 10.1093/ajcn/28.9.958. [DOI] [PubMed] [Google Scholar]

- The United States leads the global market in terms of value (approximately 30% of the value share in 2017), followed by China (19.9%) and Europe (19.2%). See: Schutt, E. cit. In: T. Koe, NutraIngredients Omega-3 Summit: China surpasses Europe for the first time for share of market value, nutraingredients-asia.com, Feb 21, 2019.

- Winkler J. T. The Most Hidden of All the Hidden Hungers: The Global Deficiency in DHA and EPA and What to do About It. World Rev. Nutr. Diet. 2018, 118, 123–130. 10.1159/000484645. [DOI] [PubMed] [Google Scholar]

- Harris W. S.; von Schacky C. The Omega-3 Index: a new risk factor for death from coronary heart disease?. Prev. Med. 2004, 39, 212–220. 10.1016/j.ypmed.2004.02.030. [DOI] [PubMed] [Google Scholar]

- von Schacky C.One dose doesn’t fit all—things we learned from the Omega-3 Index. NutraIngredients Omega-3 Summit; Preventive Cardiology University of Munich and Omegametrix: Singapore, Feb 20–22, 2019.

- Zeller D.; Cashion T.; Palomares M.; Pauly D. Global marine fisheries discards: A synthesis of reconstructed data. Fish Fish. 2018, 19, 30–39. 10.1111/faf.12233. [DOI] [Google Scholar]

- Ciriminna R.; Meneguzzo F.; Delisi R.; Pagliaro M. Enhancing and improving the extraction of omega-3 from fish oil. Sustainable Chem. Pharm. 2017, 5, 54–59. 10.1016/j.scp.2017.03.001. [DOI] [Google Scholar]

- Food and Agriculture Organization of the United Nations . New Report Raises Hopes for Mediterranean and Black Sea Fisheries, fao.org, Dec 11, 2018.

- Ciriminna R.; Scurria A.; Avellone G.; Pagliaro M. A Circular Economy Approach to Fish Oil Extraction. ChemistrySelect 2019, 4, 5106–5109. 10.1002/slct.201900851. [DOI] [Google Scholar]

- Ciriminna R.; Lomeli-Rodriguez M.; Demma Carà P.; Lopez-Sanchez J. A.; Pagliaro M. Limonene: A Versatile Chemical of the Bioeconomy. Chem. Commun. 2014, 50, 15288–15296. 10.1039/c4cc06147k. [DOI] [PubMed] [Google Scholar]

- Virot M.; Tomao V.; Ginies C.; Chemat F. Total Lipid Extraction of Food Using d-Limonene as an Alternative to n-Hexane. Chromatographia 2008, 68, 311–313. 10.1365/s10337-008-0696-1. [DOI] [Google Scholar]

- Aissou M.; Chemat-Djenni Z.; Yara-Varón E.; Fabiano-Tixier A.-S.; Chemat F. Limonene as an agro-chemical building block for the synthesis and extraction of bioactive compounds. C. R. Chim. 2017, 20, 346–358. 10.1016/j.crci.2016.05.018. [DOI] [Google Scholar]

- Liu S. X.; Mamidipally P. K. Quality Comparison of Rice Bran Oil Extracted with d-Limonene and Hexane. Cereal Chem. 2005, 82, 209–215. 10.1094/cc-82-0209. [DOI] [Google Scholar]

- Cascant M. M.; Breil C.; Garrigues S.; de la Guardia M.; Fabiano-Tixier A. S.; Chemat F. A green analytical chemistry approach for lipid extraction: computation methods in the selection of green solvents as alternative to hexane. Anal. Bioanal. Chem. 2017, 409, 3527–3539. 10.1007/s00216-017-0323-9. [DOI] [PubMed] [Google Scholar]

- Dugo P.; Beccaria M.; Fawzy N.; Donato P.; Cacciola F.; Mondello L. Mass spectrometric elucidation of triacylglycerol content of Brevoortia tyrannus (menhaden) oil using non-aqueous reversed-phase liquid chromatography under ultra high pressure conditions. J. Chromatogr. A 2012, 1259, 227–236. 10.1016/j.chroma.2012.03.067. [DOI] [PubMed] [Google Scholar]

- Gunstone F.; Harwood J. L.; Padley F. B.. The Lipid Handbook; Chapman and Hall: London, 1986; p 130. [Google Scholar]

- Kaya Y.; Turan H. Fatty acid composition of anchovy (Engraulis engrasicolis L. 1758) oil produced in Sinop-Turkey. J. FisheriesSciences.com 2008, 2, 693–697. 10.3153/jfscom.2008036. [DOI] [Google Scholar]

- Zhang H.; Shen Y.; Zhang Y.; Li L.; Wang X. Regiospecific Analysis of Fatty Acids and Calculation of Triglyceride Molecular Species in Marine Fish Oils. BioMed Res. Int. 2018, 2018, 9016840. 10.1155/2018/9016840. [DOI] [PMC free article] [PubMed] [Google Scholar]

- De Koning A. J. The free fatty acid content of fish oil, Part IV: Rates of free fatty acid formation from phospholipids and neutral lipids in anchovy (Engraulis capensis) stored at various temperatures. Fat Sci. Technol. 1995, 97, 341–346. 10.1002/lipi.19950970908. [DOI] [Google Scholar]

- Vaskova H.; Buckova M. Thermal degradation of vegetable oils: spectroscopic measurement and analysis. Procedia Eng. 2015, 100, 630–635. 10.1016/j.proeng.2015.01.414. [DOI] [Google Scholar]

- Pathirana H. N. K. S.; Wimalasena S. H. M. P.; De Silva B. C. J.; Hossain S.; Heo G.-J. Antibacterial activity of lime (Citrus aurantifolia) essential oil and limonene against fish pathogenic bacteria isolated from cultured olive flounder (Paralichthys olivaceus). Fish. Aquat. Life 2018, 26, 131–139. 10.2478/aopf-2018-0014. [DOI] [Google Scholar]

- Djenane D. Chemical Profile, Antibacterial and Antioxidant Activity of Algerian Citrus Essential Oils and Their Application in Sardina pilchardus. Foods 2015, 4, 208–228. 10.3390/foods4020208. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Rubin D.Process for preparation of oil-free fish meal and recovery of polyunsaturated fatty acids. U.S. Patent 4961936 A, 1987.

- Distretto Produttivo della Pesca—COSVAP . Progetto “Nuove Rotte: Blue Economy”. Piano Sviluppo di Filiera. PO FESR Sicilia 2007/2013—Obiettivo Operativo 5.1.1. Linea d’intervento 5.1.1.1–5.1.1.2, Laboratorio 10—Eco-Innovazione dei processi produttivi, Fase B Analisi Ambientale, Mazara del Vallo, Italy, 2015. [Google Scholar]

- Mereghetti M.Fish Oil Prices Jump Up, Following Difficult Anchovy Season in Peru, undercurrentnews.com, March 7, 2018.

- Neubronner J.; Schuchardt J. P.; Kressel G.; Merkel M.; von Schacky C.; Hahn A. Enhanced increase of omega-3 index in response to long-term n-3 fatty acid supplementation from triacylglycerides versus ethyl esters. Eur. J. Clin. Nutr. 2011, 65, 247–254. 10.1038/ejcn.2010.239. [DOI] [PubMed] [Google Scholar]

- Sengar S.; Khandetod Y.; Mohod A. Low cost solar dryer for fish. Afr. J. Environ. Sci. Technol. 2009, 3, 265–271. [Google Scholar]

- Parrino F.; Fidalgo A.; Palmisano L.; Ilharco L. M.; Pagliaro M.; Ciriminna R. Polymers of Limonene Oxide and Carbon Dioxide: Polycarbonates of the Solar Economy. ACS Omega 2018, 3, 4884–4890. 10.1021/acsomega.8b00644. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Meneguzzo F.; Ciriminna R.; Albanese L.; Pagliaro M. The Great Solar Boom: A Global Perspective into the Far Reaching Impact of an Unexpected Energy Revolution. Energy Sci. Eng. 2015, 3, 499–509. 10.1002/ese3.98. [DOI] [Google Scholar]

- Pagliaro M.; Meneguzzo F. Que faire ? A Bioeconomy and Solar Energy Institute at Italy’s Research Council in the Context of the Global Transition to the Solar Economy. Chem.—Eur. J. 2017, 23, 15276–15282. 10.1002/chem.201703146. [DOI] [PubMed] [Google Scholar]

- Barraket P.Australia’s Omega-3 Success Story and What It Has To Teach the Rest of the World. NutraIngredients Omega-3 Summit, Singapore, Feb 20–22, 2019.

- Coppes Petricorena Z.Chemical Composition of Fish and Fishery Products. In Handbook of Food Chemistry; Cheung P. C. K., Mehta B. M., Eds.; Springer: Berlin, 2015; pp 403–435. [Google Scholar]

- In the U.S., for example, the 2015 Dietary Guidelines for Americans review of the research identified four nutrients of public health concern: calcium, vitamin D, potassium, and dietary fiber. See at the URL: https://health.gov/dietaryguidelines/2015/guidelines/ (last accessed April 16, 2019).