Abstract

This paper reports the results of an investigation of the stability of a selection of small industrial platinum resistance thermometers (IPRTs) upon heat treatment and handling. Ninety-four IPRTs, of several models, obtained from five manufacturers were studied. Most of the IPRTs exhibited calibration drifts and also effects due to the presence of moisture or strain. There was no apparent improvement in the stability if the resistance ratio, R(t)/R0= W(t), instead of resistance were used as the criterion. Comparisons are made of the relative stability of the products of the five companies.

Keywords: Industrial platinum resistance thermometers (IPRTs), platinum resistance thermometers (PRTs), temperature, thermometers, thermometry

Introduction

Industrial platinum resistance thermometers (IPRTs) are usually considered to have several advantages over other types of thermometers. The IPRTs have a fairly low resistance (about 25 Ω to 2000 Ω), are usable over a wide temperature range and to high temperatures, are available in a variety of sizes and shapes, are said to be fairly rugged, and have a nearly linear resistance-versus-temperature relationship. Some of their disadvantages are that they have a temperature sensitivity of only 0.4% change in resistance per kelvin and that they may have limited stability.

The use of IPRTs in industry, in monitoring the operation of electric generating plants, and by instrument manufacturers has been increasing over the past several years and is now widespread. Despite this, prior to 1982 there was very little information in the literature about their performance [1–5]1 and especially in the very important region from about 0 °C to 250 °C. In 1982, several papers on IPRTs were presented at the Sixth International Symposium on Temperature [6–11]. In a preliminary report [11] at that Symposium, we presented results of an investigation of the stability of 60 IPRTs upon thermal cycling and normal handling.

It should be clear that IPRTs are not intended to be replacements or substitutes for Standard Platinum Resistance Thermometers (SPRTs) [12]. The SPRT is intended to be used in the laboratory where accuracy and stability are of foremost importance, whereas the IPRTs are intended for industrial applications where generally a compromise must be made among several important features which include not only accuracy and stability, but also interchangeability, size, ruggedness, response time, and cost. Because of the method of fabrication, IPRTs have several features that are either nonexistent or negligible in SPRTs. The platinum wire of IPRTs is fully supported [9] in order to protect the thermometer from mechanical shock and this may lead to contamination, a problem not encountered with SPRTs. Also, there is a problem of strain in IPRTs caused by the difference in the thermal expansion of the platinum and the material on which it is mounted [9]. This problem is absent or causes errors that are negligible in SPRTs.

This article reports results of the investigation of 94 IPRTs, including those of the 60 IPRTs reported at the Sixth International Symposium on Temperature [11]. Products of five IPRT manufacturers were included in this study2. The stability of those IPRTs was evaluated over the range from 0 °C to 100 °C after being heat-treated for some time at a temperature near 250 °C.

Experimental Details

Selection of IPRTs

The thermometers that we investigated were obtained from the five manufacturers listed in table 1. The IPRTs obtained for the study were representative of the usual industrial productions of these companies. Although there are other manufacturers of IPRTs, it was thought that the products of these five companies are representative of all commercially available IPRTs. A total of 94 IPRTs comprising 35 models from these companies was investigated. Table 2 contains a list of the manufacturers (by their code letters), the number of different models or styles represented by the products from each manufacturer, the number of IPRTs of each model or style from each manufacturer, and the total number of IPRTs from each manufacturer. As indicated in table 2, our study did not include the same number of IPRTs from each of the companies. The nominal resistances of the IPRTs at 0 °C, i.e., their R0 values, ranged from 50 ohms to 2000 ohms and the distribution of the different R0 values is given in table 3. With the exception of 8 IPRTs, the maximum operating temperature as specified by the manufacturers was in the range 250 °C to 1000 °C.

Table 1.

Manufacturers whose products were investigated in this study.

| Burns Engineering, Inc. | |

| Engelhard Industries | |

| Minco Products, Inc. | |

| Rosemount, Inc. | |

| H. E. Sostman & Co. | (now Sostman Division of Yellow Springs Instruments, Inc.) |

Table 2.

Industrial platinum resistance thermometers investigated.

| Manufacturer | Number of models represented | Number of IPRTs of each model | Total number of IPRTs from each manufacturer |

|---|---|---|---|

| A | 19 | 1, 3, 3, 4, 3, 1, 3, 2, 3, 1, 1, 1, 2, 5, 1, 3, 2, 2, 2 | 43 |

| B | 6 | 6, 4, 4, 3, 1, 1 | 19 |

| C | 4 | 2, 1, 1, 3 | 7 |

| D | 6 | 2, 5, 2, 1, 2, 2 | 14 |

| E | 6 | 2, 3, 2, 1, 2, 1 | 11 |

Table 3.

Ice-point resistance distribution of IPRTS.

| R0 (Ω) | Number of IPRTs |

|---|---|

| 50 | 2 |

| 100 | 63 |

| 200 | 7 |

| 425 | 2 |

| 470 | 4 |

| 500 | 2 |

| 550 | 3 |

| 1000 | 3 |

| 1250 | 1 |

| 2000 | 7 |

Thirteen IPRTs were fairly large in that their sheaths were about 0.25 inches in diameter and varied in length from 2.5 to 14 inches.3 Four of these had tapered sheaths so that the diameter of the sheaths in the sensitive region of the IPRT was 1/8 inch. Another 14 IPRTs had sheaths with diameters of 1/8 inch and lengths of 5.5 inches. Four surface sensor types were quite large also; the dimensions of one of these were 0.75×0.50×0.10 inches and of the other three were 1.00×0.75×0.10 inches. The remaining 63 IPRTs were much smaller in size, usually of the order of 1/8 inch in diameter and perhaps 1/2 to 1 inch long for the probe-type sensors and perhaps 1/8×1/8×0.05 inches for the surface sensor type. Some of the IPRTs had two leads, some had three leads, and others had four leads. In all cases, four lead-wires from the measuring equipment were either welded to or soldered with Au-Sn eutectic solder to the leads of the IPRTs, as close to the thermometers as practicable if four sufficiently long lead-wires were not provided on the IPRTs by the manufacturer.

The temperature-sensitive elements of all the IPRTs were constructed of platinum wire. Although IPRTs comprised of platinum films are available commercially, the stability of that type of sensor was not investigated because of their greater tendency toward hysteresis. The methods of construction, the methods of supporting the platinum wire elements, the encapsulation of the platinum elements and their supports, and the physical dimensions of the IPRTs varied from manufacturer to manufacturer and from model to model of a given manufacturer. The surface temperature sensors had encapsulations of ceramic, stainless steel, or platinum. The probe-type IPRTs contained the platinum elements in glass, ceramic, stainless steel, gold-plated brass, or gold- plated Kovar.

Equipment

An ice bath provided the temperature for the calibration of the IPRTs at 0 °C. A well-stirred, temperature-controlled oil bath provided the other temperatures in the range from 0 °C to 100 °C at which the IPRTs were tested. The temperature controller used a thermistor as the temperature sensing element. In the range from 20 °C to 60 °C, the temperature of the oil bath was regulated to ⩽ ±1 mK, whereas in the range from about 80 °C to 100 °C, the nonuniformity and fluctations in the bath increased to ⩽ ±2 mK. The oil bath temperatures were measured with an SPRT. The triple point of water was the reference point for the SPRT. The resistances of the SPRT and the IPRTs were measured with an automatic ac bridge [13] operating at 384 Hz and having a resolution of 1 part in 107. The bridge provided a constant current for the SPRT and a constant power for the IPRT measurements. The IPRTs were connected via a scanner to a microcomputer that controlled their calibration measurements and also their switching by the scanner.

A three-zone furnace was used to heat-treat the IPRTs at 235 °C. The temperature of the furnace was controlled at the set point to within ±2 °C.

Measurement Procedure

Ten sets of 10 IPRTs each were comprised of the 94 IPRTs investigated. Set X contained five IPRTs that had been studied previously in set VI, and set IX contained one IPRT that had been studied previously in set III. Except for the six IPRTs of sets IX and X that had been studied during the investigation of sets III and VI, the IPRTs for each set were selected arbitrarily from the products of the five manufacturers. There was no statistical selection of the thermometers. Two sets of IPRTs were studied concurrently.

The measurement protocol used in investigating the stability of the IPRTs upon thermal treatment and handling was as follows. The tests began by calibrating the IPRTs of a given set at 0 °C, 20 °C, 40 °C, 60 °C, 80 °C, and 100 °C. Measurements were made with the IPRTs located directly in the oil of the temperature-controlled oil bath or in a tube of oil immersed in an ice bath. The power dissipated in the IPRTs during measurements was 20 μW and, as we will see later, the self-heating was negligible (i.e., equivalent to < 1 mK). Furthermore, the IPRTs were sufficiently immersed (12 to 15 cm) in the bath fluid that the effects of the external environment were negligible.

Following calibration at the six temperatures, the IPRTs were placed in a glass tube in a cold furnace. The system, which was constructed so that it could be purged, was flushed with argon for 15 minutes and then the furnace heated to 235 °C, while continuing to pass argon through the system. After 15 minutes, the furnace would be at the desired temperature of 235 °C. The IPRTs were left in the furnace at that temperature for an additional 24 hours, with argon continuing to flow slowly through the system. At the end of the 24-hour heat-treatment period, the furnace was turned off. Thirty minutes later, the flow of argon was stopped and the IPRTs removed. Then, usually over the next two days, the resistances of the sensors were measured again at the same six temperatures at which they were calibrated previously. With the exception of sets I and II, the heat treatment and measurement cycle as just described was repeated nine times, for a total of 10 heat treatment periods followed by calibration.

For sets I and II, on which the measurements were started first and with which the measurement design was developed for the remaining sets, the situation was somewhat different. The lead-wires of the IPRTs of those sets had been initially soldered to the lead-wires going to the scanner with Pb, anticipating no problems since the IPRTs were to be heated always in an argon atmosphere. Unfortunately, during the heat-treatment of the IPRTs, oxidation of the solder junctions occurred slowly, presumably due to air in the oil remaining in the Teflon tubing around the junctions. This became apparent during the measurements by the erratic behavior of the resistances of the IPRTs. After the 15th thermal cycle, the Pb-soldered junctions of set I were replaced with welded junctions and those of set II were replaced with soldered junctions using Au-Sn eutectic solder. In subsequent tests, no deterioration of these new junctions and no differences in the behavior of the welded and the Au-Sn eutectic soldered junctions were observed. Based on the performance of these new junctions, the remaining IPRTs were connected to the measurement system lead-wires by means of Au-Sn eutectic solder, which was a simpler operation than welding.

Experiments were performed during the early thermal cycles of sets I and II to determine the appropriate conditioning time for the IPRTs at 235 °C. Based on the results of heat-treatment times of 2 hours, 6 hours, 24 hours, and 30 hours, a heating time of 24 hours was selected. There were no apparent differences among the results for 6 hour, 24 hour, and 30 hour heat-treatment times, so a 24 hour heating time was selected as being a reasonable compromise.

Discussion of Errors

Errors in Resistance Measurements

Resistance measurements of the SPRT for temperature determinations and of the IPRTs at the various test temperatures were made with an automatic ac bridge [13], a simplified version of which has been described by Brown, et al. [14]. The uncertainty of any one measurement with this bridge was estimated to be ±4 parts in 107. An average of 10 resistance measurements, rather than an individual measurement, was taken as the resistance value of the SPRT or of an IPRT at a given temperature. By this technique, the uncertainty in the resistance measurements could be reduced to an estimated ±2 parts in 107.

Errors in Temperature Measurements

The SPRT used in temperature measurements had been previously calibrated by the Platinum Resistance Thermometer Calibration Laboratory of the National Bureau of Standards [12]. That calibration consisted of resistance measurements of the SPRT at the triple point of water and the freezing points of tin and zinc. The uncertainties in realizing those fixed points of the International Practical Temperature Scale of 1968 (amended addition of 1975) [15] (IPTS-68) are ±0.1 mK for the triple point of water and ±1 mK for the freezing points of tin and zinc. The combination of these yields an uncertainty in the calibration of ±0.4 mK. This is important in the accurate determination of temperatures but is immaterial in our investigation of the stability of IPRTs since the sensors were tested always at the same temperatures.

The estimated uncertainties in the ac bridge measurements correspond to an uncertainty in temperature of about ±0.1 mK.

The fluctuations in the bath fluid temperature were larger at 80 °C and 100 °C than at the lower temperatures because of the reduced sensitivity at the higher temperatures of the thermistor used as the control sensor of the temperature controller. The magnitude of the uncertainty at 80 °C and 100 °C was estimated to be ⩽±2 mK. At lower temperatures, the uncertainty in the measured temperature was estimated to be ⩽± 1 mK.

The uncertainty in the temperature of the conditioning furnace was estimated to be ±2 °C. It is thought that this uncertainty did not play a significant role in the behavior of the IPRTs.

Errors Due to Self-Heating

An experiment was performed to ascertain the amount of self-heating of the IPRTs when their resistances were being measured with 10 μW and 20 μW of power being dissipated. The results indicated that the maximum amount of self-heating at 20 μW was ⩽1 mK. The uncertainty in the resistance measurements due to changes in the self-heating was much less than the equivalent of 1 mK, however, and that is the relevant uncertainty since our primary interest was in changes of IPRT resistance. During stability measurements, the resistances were measured always with 20 μW of power being dissipated in the IPRTs.

Errors Due to Inadequate Immersion

For all resistance measurements in the temperature range 0 °C to 100 °C, the IPRTs were immersed 12 to 15 cm in either the well-stirred constant-temperature-bath oil or in the oil in the thermometer well of the ice bath. The adequacy of immersion was checked and it was found that the uncertainty in the measurements due to improper immersion was negligible. The uncertainty was within that of the resistance measurements.

Results and Analysis

Two of the 94 IPRTs investigated failed (open circuit) during the course of the heat treatments, one of them functioning normally through six heat treatments before failing. Essentially three types of behavior were exhibited by the IPRTs that maintained their integrity throughout the series of thermal treatments. Of the 92 IPRTs that did not fail during the tests, 39 underwent decreasing resistances by amounts equivalent to from 2 mK to 900 mK. This type of behavior is exemplified by the results of IPRT RA3/9 shown in figure 1. Four of these 39 IPRTs had changes in resistance in excess of the equivalent of 200 mK over the course of the study. Thirty-four of the 92 IPRTs exhibited resistance increases by amounts equivalent to from 1 mK to 120 mK over the time of the 10 heat treatments and calibrations. This type of behavior of the IPRTs is exemplified by the results of IPRT PB9/55 shown in figure 2. An additional IPRT having this type of behavior had a very large change, in excess of the equivalent of 1 K. The remaining 19 IPRTs showed the third type of behavior, that of scatter in the results but no discernible drift. The behavior of these IPRTs is exemplified by the results of IPRT RE6/66 shown in figure 3.

Figure 1–

Variation of the resistance of IPRT RA3/9 with heat treatment. Measurements were made at 0 °C, 20 °C, 40 °C, 60 °C, 80 °C, and 100 °C, as indicated on the graph. Resistance differences expressed as equivalent temperature differences in m °C are indicated. Time 0 refers to the original calibration prior to heat treatment.

Figure 2–

Variation of the resistance of IPRT PB9/55 with heat treatment. Measurements were made at 0 °C, 20 °C, 40 °C, 60 °C, 80 °C, and 100 °C, as indicated on the graph. Resistance differences expressed as equivalent temperature differences in m °C are indicated. Time 0 refers to the original calibration prior to heat treatment.

Figure 3–

(Left)Variation of the resistance of IPRT RE6/66 with heat treatment. Measurements were made at 0 °C, 20 °C, 40 °C, 60 °C, 80 °C, and 100 °C, as indicated on the graph. Resistance differences expressed as equivalent temperature differences in m °C are indicated. Time 0 refers to the original calibration prior to heat treatment.

One IPRT, PC2/40, that was tested as part of set III and five IPRTs, PA 10/25, PA2/22, PD2002/21, PA 1001/48, and RD4/11, that were tested as part of set VI were subsequently tested again as parts of sets IX and X, respectively. The results obtained for those sensors at 40 °C are shown in figure 4. Three of them developed discontinuities in their resistance temperature relationships by being kept at room temperature from the time the studies of sets III and VI were completed and those of sets IX and X were begun. The behavior of the other three was unaffected by time at room temperature.

Figure 4–

(Below) Variation of the resistances R of 6 IPRTs with heat treatment. Figure 4D gives the results for PC2/40 of sets III and IX; figures 4A, 4B, 4C, 4E, and 4F show the results for IPRTs PA 10/25, PA2/22, PD2002/21, PA1001/48, and RD4/11, respectively, of sets VI and X. Measurements on these 6 IPRTs were made at 0 °C, 20 °C, 40 °C, 60 °C, 80 °C, and 100 °C, but only those at 40 °C are shown here. Time 0 refers to the original calibrations of IPRTs of sets III and VI prior to heat treatment. The * represents data for the original calibrations and those obtained after heat treatment. The ■ represents data of a measurement sequence performed after a preceding sequence, but without an intervening heat treatment; the ▲ represents data of the intital measurement sequence performed on sets IX and X.

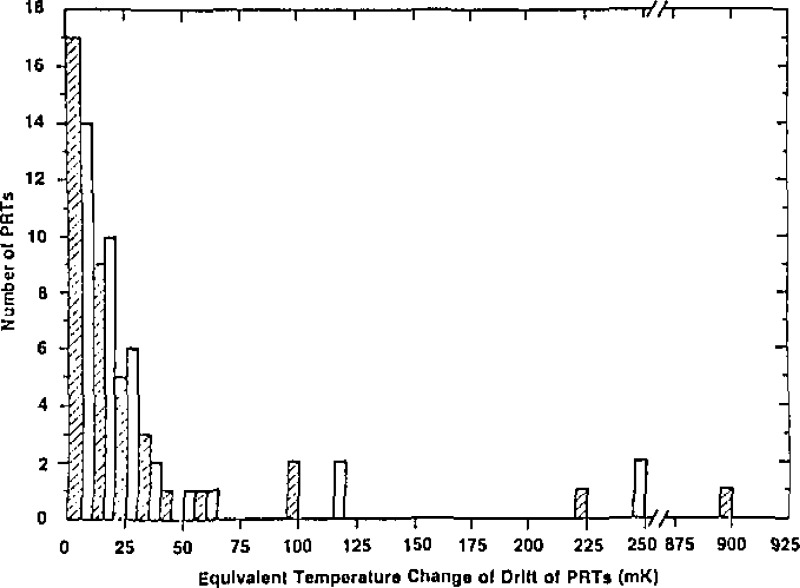

The magnitude of the change in calibration (drift) for each of the IPRTs investigated from the various companies is given in table 4. The mean values of the calibration drifts for the IPRTs of each company were calculated 1) by considering all of the IPRTs of sets I through X, 2) by considering all of the IPRTs of sets III through X, 3) by considering the IPRTs of sets III through X, but omitting the values of those IPRTs that are considered to be outliers in those sets, and 4) by considering the IPRTs of sets III through X, but omitting the values of those IPRTs that are repeats and those considered to be outliers in those sets. These data are depicted graphically by the histograms of figures 5, 6, and 7. Figure 5 shows the results of the 92 IPRTs that did not fail plus the results for those six IPRTs of sets IX and X that were studied previously in sets III and VI, i.e., there are 98 entries. Figure 6 shows the results for the IPRTs of sets III through X that did not fail and includes the six IPRTs of sets IX and X that were studied also in sets III and VI, i.e., there are 78 entries. Figure 7 displays the results for the IPRTs of sets III through X that did not fail but it does not contain the results for those IPRTs of sets IX and X that had been studied previously in sets III and VI, i.e., there are 72 entries.

Table 4.

IPRT calibration drift in mK. Underlined numbers in sets IX and X are the numbers for the IPRTs which had been previously measured in sets III and VI

| Company | Set I | Set II | Set III | Set IV | Set V | Set VI | Set VII | Set VIII | Set IX | Set X |

|---|---|---|---|---|---|---|---|---|---|---|

| A | 0 | 5 | 5 | 225 | 27 | 23 | 0 | 28 | 2 | |

| 7 | 2 | 8 | 25 | 18 | 17 | 0 | 20 | 0 | ||

| 6 | 0 | 100 | 10 | 0 | 7 | |||||

| 0 | 20 | 8 | 8 | 35 | 7 | |||||

| 0 | 25 | 13 | 100 | 0 | ||||||

| 8 | 0 | 0 | 26 | |||||||

| 5 | 15 | 20 | 4 | |||||||

| 5 | 4 | |||||||||

| 11 | ||||||||||

| Mean for Sets I–X = 18 (for 46 entries); 19 (for 43 entries, ignoring the 3 outliers). | ||||||||||

| Mean for Sets III–X = 22 (for 36 entries); 24 (for 33 entries, ignoring the 3 outliers). | ||||||||||

| Mean for Sets III–X = 12 (for 33 entries, ignoring 3 repeats); 12 (for 30 entries, ignoring 3 repeats and 3 outliers). | ||||||||||

| A | 55 | 20 | 58 | 33 | ||||||

| 25 | 16 | 38 | ||||||||

| 10 | 35 | |||||||||

| 2 | 0 | |||||||||

| 8 | 10 | |||||||||

| 40 | 120 | |||||||||

| 25 | 28 | |||||||||

| 15 | ||||||||||

| 117 | ||||||||||

| Mean for Sets III —X = 34; 25 (ignoring 2 outliers). | ||||||||||

| C | 20 | 10 | 15 | 0 | 8 | |||||

| 12 | 14 | |||||||||

| 900 | ||||||||||

| Mean for Sets III–X = 122 (for 8 entries); 11 (for 7 entries, not counting outlier). | ||||||||||

| Mean for Sets III–X = 12 (for 6 entries, ignoring repeat and outlier). | ||||||||||

| D | 0 | 250 | Open | 30 | Bad | 18 | ||||

| 3 | 45 | 250 | 65 | 15 | 10 | |||||

| 0 | 8 | 15 | ||||||||

| 5 | ||||||||||

| Mean for Sets I–X = 51 (for 14 entries); 57 (for 12 entries, ignoring open circuit, bad IPRT, and 2 repeats). | ||||||||||

| Mean for Sets III–X = 71 (for 10 entries); 85 (for 8 entries, ignoring open circuit, bad IPRT, and 2 repeats). | ||||||||||

| Mean for Sets III–X = 26 (for 8 entries, ignoring open circuit, bad IPRT, and 2 outliers); 30 (for 6 entries, ignoring open circuit, bad IPRT, 2 outliers, and 2 repeats). | ||||||||||

| E | 0 | 1 | 0 | 20 | 8 | 26 | ||||

| 0 | 5 | 0 | ||||||||

| 7 | ||||||||||

| 0 | ||||||||||

| Mean for Sets I–X = 6. | ||||||||||

| Mean for Sets III–X = 11. | ||||||||||

Figure 5–

Histogram of the drifts of all 98 IPRTs of sets I through X that did not fail during the investigation of their stability.

Figure 6–

Histogram of the drifts of all 78 IPRTs of sets III through X that did not fail during the investigation of their stability.

Figure 7–

Histogram of the drifts of the 72 IPRTs of sets III through X that did not fail during the investigation of their stability and that excludes the 6 IPRTs of sets IX and X that had been examined previously in sets III and VI.

The calibration drifts of the IPRTs of sets I and II given in table 4 may be unusually small as a result of having had 15 prior heat treatments for a total time at 235 °C of about 186 hours. As can be seen from figures 1, 2, 3, and 4, such heat treatments could cause the IPRTs to become more stable, although some of the IPRTs of the other sets also had small drifts without the benefit of the additional time spent at 235 °C.

When the resistance data measured at 0 °C, 20 °C, 40 °C, 60 °C, 80 °C and 100 °C for each IPRT were plotted as a function of the time that the IPRT was kept at 235 °C, the scatter of the points about a smooth line through them was as follows: One IPRT had a scatter in resistance equivalent to ± 15 mK, one of ± 12 mK, two of ± 10 mK, three of ±6 mK, and all others of the 90 of the 94 IPRTs that did not fail or have enormous changes in resistance had a scatter of ⩽±5 mK, with the majority of the latter having a scatter of from ±3 mK to ±5 mK.

Three IPRTs, one from each of three different models, from manufacturer A exhibited more change in resistance upon heat treatments than those of other models obtained from that company. Other IPRTs of those same three models, however, did not show such large changes. For the products of manufacturer B, the IPRTs of one model definitely had greater changes in resistance with heat treatments than did those of the other models. For manufacturer C, one model, for which there was only one IPRT, was considerably less stable than the other models upon heat treatments. One should not be hasty in drawing conclusions from this since that IPRT may not be representative of its model. For manufacturer D, the IPRTs of one model definitely appeared to be more unstable to changes in resistance with heat treatments than those of the other models of this company. Also, one IPRT of another model became open circuit and another IPRT of yet a different model had a very large change in resistance. Not all IPRTs of the latter model exhibited such large changes, however. All models of manufacturer E appeared to be quite good, although one model, for which there was only one IPRT involved in the investigation, may have been marginally less stable than the other models.

Since the ice-point resistance value of an IPRT is determined essentially by the diameter of the platinum wire of which the sensor is made, one might expect the stability of the thermometers to be a function of their R0 values. From our results, however, there does not appear to be any correlation between resistance value and stability upon heat treatment and handling. Of course, the IPRTs were heated to only about 235 °C, a relatively low temperature, so a dependence of the stability of the thermometers on resistance might develop if the sensors were heated to elevated temperatures.

About 90% of the IPRTs investigated exhibited hysteresis over the temperature range in which they were tested, i.e., over the range from 0 °C to 100 °C. We attribute this hysteresis to the presence of either strains in the platinum wire which forms the sensing elements or of moisture inside the encapsulation of the IPRTs.

Normally the IPRTs were heat-treated following the completion of a set of resistance measurements over the range from 0 °C to 100 °C. The heat treatment would be followed then by another set of resistance measurements at the same temperatures at which the IPRTs were tested before heat treatment. When, however, a measurement sequence was followed by another measurement sequence without the intervening heat treatment, 65 IPRTs (about 69%) had resistances at each temperature of measurement that were smaller than those measured in the previous sequence of measurements. Furthermore, when, following conditioning of the IPRTs at 235 °C, the resistances of the thermometers were measured at 0 °C, 20 °C, 40 °C, 60 °C, 80 °C, and 100 °C, and then the IPRTs measured in the reverse sequence, the measured resistance values at any given temperature of the reverse sequence were less than those obtained in the previous sequence at the same temperature. At any given temperature, the resistances continued to decrease with repeated sequential measurements, especially if the IPRTs were exposed to 0 °C between the sequences. This behavior was interpreted as being the result of increased shunting of the platinum sensing element by the presence of moisture. In order to test this hypothesis, thermal cycle 21 of set II proceeded in the normal manner, i.e., heat treatment of the IPRTs at 235 °C for 24 hours and then measurement of their resistances at the test temperatures of 0 °C, 20 °C, 40 °C, 60 °C, 80 °C, and 100 °C. Then, in what is called cycle 21B, the resistances of the IPRTs were measured at 40 °C, and then at 0 °C. Measurements similar to those of cycle 21B were made in cycles 21C and 21D. The measurements were discontinued after measurements at 40 °C of cycle 21E. Some typical results of those tests are shown in figure 8. Some of the IPRTs exhibited total changes equivalent to 35 mK in these tests.

Figure 8–

Results of the test for the presence of moisture in IPRT RD6/72. Sensor cycled between 40 °C and 0 °C. See text for elaboration.

It is believed that these tests showed that the resistance decreases were due to shunting as a result of “wetness.” Note the large differences in the resistance at 40 °C of cycle 21B from those of thermal cycles 21 and 21C. This indicates that an appreciable amount of moisture was driven off the platinum element and its lead- wires during the calibration process of cycle 21 (measurements at 0 °C, 20 °C, 40 °C, 60 °C, 80 °C, and 100 °C) but that it recondensed during further measurements at 0 °C of cycle 21B. The elimination or the reduction of shunting (by the moisture) as a result of heating during the calibration process was possibly demonstrated also by some IPRTs which showed progressively less change in resistance at increasingly higher test temperatures as a function of time at 235 °C (see fig. 2). That is to say, the change in resistance with time at 235 °C was considerably less at the higher test temperatures than it was at the lower temperatures.

When a measurement sequence was followed by another measurement sequence without an intervening heat treatment, 18 IPRTs exhibited evidence of strain of the platinum elements. This was manifested by increased resistances at the test temperatures.

Eighty-three IPRTs showed effects of either moisture or strain. The magnitudes of these effects and the distribution among the manufacturers of the IPRTs showing these effects are given in table 5. Only nine of the 92 IPRTs that did not fail during our investigation were free of moisture or strain effects. The magnitudes of the effects, expressed as equivalent temperature changes, are those maximum values obtained by comparing the results of a calibration at the six test temperatures with those of the preceding calibration without an intervening heat treatment.

Table 5.

Effects of moisture and strain on IPRTs. Underlined numbers are the numbers of sets IX and X which had been previously measured in sets III and VI

| Manufacturer | Dry and no strain, Sets I-X | Total number of IPRTs from each manufacturer | Number of IPRTs showing effects of moisture | Number of IPRTs showing effects of strain | Magnitude of effect (equivalent temperature changes) | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Moisture (mK) | Strain (mK) | |||||||||

| A | 6 | 43 | 23 | 14 | 15, 17, 10, 10, 10, 10, 17, 16, 6, 10, 3, 15, 8, 5, 5, 5, 8, 8, 10, 10, 7, 4, 2 | 15, 5, 5, 5, 3, 8, 4, 3, 4, 3, 2, 1, 3, 2 | ||||

| B | 0 | 19 | 17 | 10, 5, 10, 10, 7, 10, 15, 3, 6, 5, 2, 18, 12, 8, 9, 4, 4 | 2, 1 | |||||

| C | 2 | 7 | 3 | 2 | 12, 0, 2 | 3, 2 | ||||

| D | 1 | 14 (1 bad and 1 open) | 11 | 0 | 20, 13, 25, 1, 8, 12, 10, 3, 10, 0, 10 | |||||

| E | 0 | 11 | 11 | 0 | 10, 5, 3, 13, 13, 10, 3, 1, 10, 10, 14 | |||||

| Total | 9 | 94 | 65 | 18 | ||||||

| Percent | 9.6% | (1 bad and 1 open) 2.1% | 69.15% | 19.15% | ||||||

Figure 9 shows the results of a dry and unstrained IPRT, RD7/73. The behavior depicted in this figure is to be compared with that of the IPRTs that exhibit the effects of moisture, such as that shown in figure 8 for IPRT RD6/72.

Figure 9–

Results of the test for the presence of moisture in IPRT RD7/73. Sensor cycled between 40 °C and 0 ‘C. See text for elaboration.

The ice-point resistances, R0, of most of the IPRTs varied with the time spent at 235 °C, as did the resistances at the other test temperatures. The magnitude of the changes in the R0 values of the IPRTs varied by the equivalent of from 5 mK or less to more than 3 K. The maximum changes in R0, expressed as the equivalent temperature changes, are given in the histogram shown in figure 10. The results shown in this figure are comprised of those of the IPRTs of sets I through X that did not fail and the histogram includes results of the six IPRTs of sets IX and X that had been tested previously in sets III and VI. Figure 11 is the histogram of the results of the IPRTs of sets I through X that did not fail but it does not include the results of the six IPRTs of sets IX and X that had been tested previously in sets III and VI. With reference to figure 11, one can see that 39 IPRTs (42%) had changes in of the equivalent of 15 mK or less; 48 IPRTs (52%) had changes in R0 of the equivalent of 25 mK or less; 65 IPRTs (71%) had changes of the equivalent of 50 mK or less; and 12 IPRTs (13%) had changes of the equivalent of greater than 100 mK.

Figure 10–

Histogram of the maximum change in R0 incurred by the 98 IPRTs of sets I through X that did not fail during tests of their stability upon heat treatment and handling. The change in R0 is expressed as the equivalent change in temperature.

Figure 11–

Histogram of the maximum change in R0 incurred by the 92 IPRTs of sets I through X, excluding the 2 IPRTs that failed and the 6 IPRTs of sets IX and X that had been tested previously in sets III and VI, during tests of their stability upon heat treatment and handling. The change in R0 is expressed as the equivalent change in temperature.

With the exception of some of the IPRTs noted earlier in the discussion of the effects of moisture, the changes in R0 with time spent at 235 °C have the same apparent general behavior as the changes in the resistances at the other test temperatures (see figs. 1–4). Consequently, one might expect that the ratio of the resistance at temperature t to the resistance at 0 °C, i.e., R(t)/R0=W(t), would exhibit less change than just the resistance itself upon heat treatment and handling. That, however, was not found to be the case. There was no apparent improvement in the stability of the IPRTs when considering the W(t) instead of the resistance.

Conclusions

The results from the 94 thermometers investigated in the study of the stability of IPRTs upon heat treatment and handling showed that there were no major differences among the products of the different manufacturers, although manufacturer D had an exceptionally high percentage of IPRTs that either failed or exhibited very large changes in resistance. This, however, may have been fortuitous. Manufacturers B and D each had one model of IPRTs that definitely appeared to be less stable than the products of their other models. Only 12 IPRTs (13%) were stable to 5 mK or less upon heat treatment; thus, most of the IPRTs exhibited calibration drift and effects due to the presence of moisture or strain. Wetness definitely is a problem with IPRTs and the magnitude of the effect can be ascertained only by experiments designed to test for its presence. There does not appear to be any advantage in obtaining the resistance ratio, W(t), as a way of increasing measurement precision.

Before an IPRT is put into use at almost any level of precision and accuracy, it should be tested for calibration drift and it should be tested at a temperature other than the ice point, unless it is to be used at 0 °C or below. Also, if an inaccuracy of ⩽±30 mK is needed, the IPRT should be tested for the presence of moisture. Notwithstanding the calibration drift and the possibility of the presence of moisture or strain, IPRTs should be excellent for use in temperature control at a fixed temperature which is greater than about 5 °C.

Acknowledgments

My thanks go to G. A. Evans, Jr., who made most of the measurements reported here, and to Dr. D. D. Thornton and Mrs. S. D. Wood, who assisted in some of the initial aspects of this study. I am grateful also to the companies for providing the IPRTs requested and investigated in this study.

Biography

About the Author: B. W. Mangum is a physicist in NBS’ Temperature and Pressure Division.

Footnotes

Figures in brackets indicate literature references at the end of this paper.

Certain commercial equipment, instruments, or materials are identified in this paper in order to adequately specify the experimental procedure. Such identification does not imply recommendation or endorsement by the National Bureau of Standards, nor does it imply that the materials or equipment identified are necessarily the best available for the purpose.

Since the dimensions help identify the size of the units, and are in common usage, we have not used the SI unit (i.e., cm).

References

- [1].Carr K. R. An Evaluation of Industrial Platinum Resistance Thermometers, in Temperature. Its Measurement and Control in Science and Industry, (Instrument Society of America, Pittsburgh, 1972), Vol. 4, Part 2, pp. 971–982. [Google Scholar]

- [2].Quinn T. J. Report on the Examination of Industrial Platinum Resistance Thermometers, Proces Verbaux du CCT, Document No. CCT/73–65, 1973.

- [3].Sinclair D. H.; Terbeek H. G. and Malone J. H., Calibration of Platinum Resistance Thermometers, in Temperature, Its Measurement and Control in Science and Industry, (Instrument Society of America, Pittsburgh, 1972), Vol. 4, Part 2, pp. 983–988. [Google Scholar]

- [4].Chattle M. V. Resistance Ratio/Temperature Relationships for Industrial Platinum Resistance Thermometers, NPL Report QU (U.K. Natl. Phys. Lab., Div. of Quantum Metrol.), QU 30, 1975, 18 pp. [Google Scholar]

- [5].Chattle M. V. Resistance Ratio/Temperature Relationships for Industrial Platinum Resistance Thermometers of Thick Film Construction, NPL Report QU (U.K. Natl. Phys. Lab., Div. of Quantum Metrol.), QU 42, 1977, 11 pp. [Google Scholar]

- [6].Actis A. and Crovini L., Interpolating Equations for Industrial Platinum Resistance Thermometers in the Temperature Range from −200 to +420 °C, in Temperature, Its Measurement and Control in Science and Industry, (American Institute of Physics, New York, 1982), Vol. 5, Part 2, pp. 819–827. [Google Scholar]

- [7].Bass N. M. Construction of a Laboratory Working Thermometer Using Industrial Platinum Resistance Sensors, in Temperature, Its Measurement and Control in Science and Industry, (American Institute of Physics, New York, 1982), Vol. 5, Part 2, pp. 813–814. [Google Scholar]

- [8].Connolly J. J. The Calibration Characteristics of Industrial Platinum Resistance Thermometers, in Temperature, Its Measurement and Control in Science and Industry, (American Institute of Physics, New York, 1982), Vol. 5, Part 2, pp. 815–817. [Google Scholar]

- [9].Curtis D. J. Thermal Hysteresis and Stress Effects in Platinum Resistance Thermometers, in Temperature, Its Measurement and Control in Science and Industry, (American Institute of Physics, New York, 1982), Vol. 5, Part 2, pp. 803–812. [Google Scholar]

- [10].McAllan J. V. Practical High Temperature Resistance Thermometry, in Temperature, Its Measurement and Control in Science and Industry, (American Institute of Physics, New York, 1982), Vol 5, Part 2, pp. 789–793. [Google Scholar]

- [11].Mangum B. W. and Evans G. A. Jr., Investigation of the Stability of Small Platinum Resistance Thermometers, in Temperature, Its Measurement and Control in Science and Industry, (American Institute of Physics, New York, 1982), Vol. 5, Part 2, pp. 795–801. [Google Scholar]

- [12].Riddle J. L.; Furukawa G. T. and Plumb H. H., Platinum Resistance Thermometry, National Bureau of Standards (U.S.) Monograph 126, 1973. (Superintendent of Documents, U.S. Government Printing Office, Washington, DC 20402: ). [Google Scholar]

- [13].A simplified version of this bridge is described in detail in the paper of ref. 14.

- [14].Brown N. L.; Fougere A. J., McLeod J. W, and Robbins R. J., An Automatic Resistance Thermometer Bridge, in Temperature, Its Measurement and Control in Science and Industry, (American Institute of Physics, New York, 1982), Vol. 5, Part 2, pp. 719–727. [Google Scholar]

- [15].Comptes rendus des séances de la Quinzième Conférence Générale des Poids et Mesures, Resolution 7, p. 105, Annexe 2, p. Al(1975); Also, Metrologia 12, 7 (1976). [Google Scholar]