Abstract

Abstract

The sensory characteristics of goat yogurt could be greatly improved by integrating to a culture typical of yogurt starters, Streptococcus thermophilus, Lactobacillus delbrueckii spp. bulgaricus, with cultures of Leuconostoc lactis. The addition of L. lactis requires the use of the definition of “fermented milk” to the product, although it is prepared according to the same technology. The experimental plan has designed the use of inoculation with a bacterial concentration of at least 109, for each microbial species considered, with the aim of increasing the probiotic effect of yogurt and fermented milk. Descriptive analysis of the samples was conducted using the profile sheet obtained applying the consensus profiling method (UNI EN ISO 13299:2010) by a trained panel. The acceptability of our products was evaluated by 62 consumers through 7‐points hedonic scale. The results of this study indicated that the addition of L. lactis to the traditional yogurt starter produced a noticeable improvement to the sensory characteristics of fermented goat milk.

Practical Application

To improve the sensory characteristics of goat's yogurt to make it more acceptable to the consumer and increase market demand we tested the integration of Leuconostoc lactis to typical starter cultures. The experimentation carried out tested different combinations of fermenting microorganisms with the aim of developing a better flavor as compared to that of traditional yogurt, which is often unpleasant to consumers. The addition of L. lactis to the starter culture of the goat's milk results in less aggressive aromatic notes and greater appreciation as confirmed by consumers who tested the product.

Keywords: goat milk, fermented milk, quality, sensory profile, yogurt

Introduction

Yogurt is an important dairy product consumed worldwide and appreciated for its sensory characteristics, obtained by the protosymbiotic fermentation of milk using a live and active cultures of Lactobacillus delbrueckii spp. bulgaricus and Streptococcus thermophilus (Aryana & Olson, 2017; Esmerino et al., 2017a,b). In recent years, the production of fermented milk (FM) and yogurt has increased significantly, reaching 35.5 million tons in 2015, with a growth of 20% over the previous 5 years (World Yogurt Market Report, 2016).

Yogurt is traditionally made with cow's milk. However, over the years, milk from other sources has been used to make yogurt. Goat's milk, is particularly suitable for the production of yogurt, due to its composition, as well as providing numerous health benefits (Verruk, Dantas, & Prudencio, 2019).

Indeed, many studies on the chemical composition of goat's milk have amply demonstrated its nutritional value higher than cow's milk (Costa et al., 2014, 2015). The increase in interest for dairy goat's milk products is due to the constant worldwide production of goat's milk, which reached almost 18 million tons in 2017, earning the third place as milk produced in the world, behind cow's milk and buffalo (FAO STAT, 2018; Pulina et al., 2018).

Therefore, fermented goat's milk products could represent a good opportunity to increase the supply of dairy products with greater nutritional value (Atamian, Olabi, Baghdadi, & Toufeili, 2014; Eissa, Mohamed Ahmed, Yagoub, & Babiker, 2010; Eissa, Babiker, & Yagoub, 2011; Ribeiro & Ribeiro, 2010).

Furthermore, the goat milk is also an excellent substrate for the growth of probiotic cultures (Mituniewicz‐Malek, Zielińska, & Ziarno, 2019), defined as “live microorganisms which, when administered in adequate quantities, confer a benefit to the health on the host” (Hill et al., 2014) and offers the advantage of a great digestibility and tolerance (Champagne, Cruz, & Daga, 2018; Verruck, Dantas, & Prudencio, 2019).

However, consumer acceptance of goat yogurt is low due to its “goaty” flavor (Uysal‐Pala, Karagul‐Yuceer, Pala, & Savas, 2006) resulting from high levels of caproic, caprylic, and capric fatty acids compared to other ruminant species (Costa, Beltrão Filho, De Sousa, Cruz, & Queiroga, 2016; Gamage et al., 2016; Kesenkaş, Karagözlü, Yerlikaya, Özer, Akpinar, & Akbulut, 2017).

Considering the importance of sensory perception and prospects for inclusion in the market, our work was developed with the goal of improving the characteristics of fermented goat's milk, by testing the addition of Leuconostoc lactis to traditional culture starter.

The Leuconostoc strains, in fact, can influence the characteristics of dairy products, for the many actions carried out, as shown by several researchers in their studies.

Nieto‐Arribas, Seseña, Poveda, Palop, and Cabezas (2010), in agreement with other authors (Buffa, Morais, Jimẽnez‐Belenguer, Hemãndez‐Gimẽnez, & Guamis, 2005; Perez, Cardarell, & Zarate, 2002), verified that no lipolytic activity was present on the 23 Leuconostoc strains, isolated from Manchego cheese.

This feature is an undeniable advantage in the aromatic development of dairy products, and goat product in particular, as it reduces the free fatty acids that can favor the appearance of an unpleasant rancid flavor.

In addition, some studies (Hemme & Foucaud‐Scheunemann, 2004; Vedamuthu, 1994) have shown that Leuconostoc isolated from goat's milk, was able to produce dextrans that increase the viscosity and improve the consistency of soft cream products.

The advantageous result of the presence of dextrans and other exopolysaccharides, in the production of FM, has long been recognized (de Vuyst & Degeest, 1999; Duboc & Mollet, 2001), since they stabilize the casein network favoring the bond with water and reducing syneresis.

Furthermore, as evidenced by several researchers (Franciosi, Settanni, Cavazza, & Poznanski, 2009; Garibal, Rodriguez‐Alonso, & Centeno, 2008; Nieto‐Arribas et al., 2010), the genus Leuconostoc is able to positively influence the aroma of FM, producing pleasant aromas of butter and yogurt, only in mixed cultures.

In fact, the pure cultures of Leuconostoc spp. do not produce diacetyl from the metabolism of citrate, but pyruvate is converted into lactate and acetyl phosphate (via acetylCoa). Instead, in mixed cultures, Leuconostoc is able to produce diacetyl and acetoin, since the optimum pH for this reaction is reached (Cogan, 1985; Cogan & Hill, 1993; Fox, Lucey, & Cogan, 1990; Hugenholts, 1993; Mcsweeney & Sousa, 2000).

Based on these findings, we tested the suitability of adding L. lactis, to conventional microbial cultures of goat yogurt (Bifidobacterium animalis supp. lactis BB‐12 and Lactobacillus acidophilus LA‐5), to improve the flavor of goat milk yogurt, in order to make it more attractive to consumers.

It is supposed that our goal can be achieved because, the “goaty” character, could be attenuated by at least three related Leuconostoc actions, such as the reduction of free fatty acids (lower lipolysis), the formation of pleasant aromatic notes of butter (diacetyl production) and an improved palatability due to the creamy consistency (dextrans synthesis).

Chemical composition, microbiological, and sensory properties of fermented goat milk and yogurt produced in this study were analyzed.

Materials and Methods

Starter cultures

All the microorganisms used for experimentation came from the collection of the National Reference Center for Ovine and Caprine Milk and Dairy Products Quality (CRELDOC), Rome, Italy. S. thermophilus (LAB 42 strain) and L. delbrueckii spp. Bulgaricus (LAB 43 strain) were isolated from goat's milk yogurt and L. lactis from raw buffalo milk. Starter cultures were prepared from cryopreserved strains through the revitalization of broth culture, MRS broth (de Mann, Rogasa and Shape‐Oxoid) for L. delbrueckii and BHI broth (Brain Heart Infusion Broth‐Oxoid) for S. thermophilus and L. lactis. All bacteria has been incubated under aerobic conditions except L. delbrueckii, which was incubated in anaerobic jars (Anaero Gen TM, Oxoid) at 37 °C for 48 hr. Revitalized strains were isolated on MRS agar for L. delbrueckii and M17 agar (Oxoid) for S. thermophilus and L. lactis MRS agar have been incubated at 37 °C for 72 hours and M17 at 37 °C for 48 hr.

Yogurt (Y) and FM preparation

To standardize the production of yogurt and fermented milk, using a raw material with homogeneous composition and sensory characteristics, it decided to work with UHT caprine milk from the same production lot. For each microbial species considered, a solution with a bacterial concentration of about 109cfu/mL was prepared.

S. thermophilus and L. delbrueckii spp. bulgaricus in a 1:1 ratio used for yogurt while for FM was added also L. lactis in a 1:1 ratio.

Flasks containing 100 mL of milk heated to 40 °C were inoculated with the cultures at a concentration of 20 mL/L and 30 mL/L for yogurt and FM respectively defined according to previous testing to ensure a final count minimum of about 6 log CFU/mL, and finally were incubated at 41.5 ± 1 °C in a controlled temperature thermostat.

The coagulation of milk was monitored for pH during the incubation period until a pH of 4.50 ± 0.05 (pH end). When the pH end was achieved, the yogurt and the FM were immediately cooled at 4 ± 1 °C and stored at the same temperature for 28 days.

Physicochemical, microbiological, and sensory analyses were conducted on milk and on milk products after 24 hr from production and after 7, 14, 21, and 28 days of conservation. Analyses physicochemical and microbiological were performed in triplicate.

Physicochemical analysis

Yogurt and FM were evaluated for fat, protein, total solids, and humidity by: FoodScan (Foss‐Electric PD, Italy), according to ISO 21543/IDF 201:2006 (Milk products–Guidelines for the application of near infrared spectrometry), while the lactose content was determined by MilkoScan (FT 6000 Foss‐Electric PD, Italy).

The pH was determined using a pH meter (Mettler Delta 345) with a standardized glass electrode in the range 7.0 to 4.0. Four consecutive measurements were made on dairy products at a temperature of 21 ± 1 °C.

Microbiological analysis

The enumeration of S. thermophiles, L. lactis, and L. delbrueckii were determined by the same conditions as described above. Yeast and mold enumeration was carried out on YEDCA agar plates, incubated at 25 °C for 5 days while contaminating microorganisms were determined by spread plate techniques on Blood Agar and incubated at 37 °C for 24 hr.

Sensory analysis

The purpose of sensory analysis was to define the sensory profile of the yogurt and the FM using a descriptive test.

Sensory profile: The analyses were carried out in the sensory laboratory at Tuscia University, equipped according to the specifications reported in UNI ISO 8589: 2007. The panel comprised of 10 expert sensory assessors (UNI EN ISO 8586‐2: 2008) (eight women and two men, aged 25–57 years), by staff and students of the Tuscia University, with particular experience in sensory profile development. They were asked to evaluate eight goat yogurt products commercially available to identify sensory attributes related to appearance, taste, flavor, and texture.

Development of the descriptor set: four open roundtable tasting sessions were conducted to specifically develop a list of detailed terms to evaluate the sensory characteristics of goat yogurt and FM (UNI EN ISO 13299: 2010), 36 descriptors were identified by the panel. A first skimming eliminated the repetitive and redundant terms and led to the selection of 28 attributes (Table 1). In order to reduce the number of descriptors and determine the most significant of these, judges were asked to assess the intensity of perception for each identified descriptor, measured on a scale from 0 to 7, (0 = absence of perception; 7 = very strong perception). The weight percentage of each descriptor was measured using the geometric mean (M) which is the square root of the product of the frequency (F) of the citations and the relative intensity (I) for each attribute (ISO 11035: 1994). Of the descriptors identified, only those with a weight percentage above 35% were selected.

Table 1.

Weight percentage of the attributes selected by panel

| Attributes | Weight% | |

|---|---|---|

| 1 | Creamy | 38.54 |

| 2 | Filante | 23.40 |

| 3 | Gluey | 28.11 |

| 4 | Sour | 59.87 |

| 5 | Salty | 45.44 |

| 6 | Sweet | 35.92 |

| 7 | Bitter | 3.30 |

| 8 | Umami | 12.65 |

| 9 | Mineral | 27.04 |

| 10 | Lemon | 36.99 |

| 11 | Lactic | 38.64 |

| 12 | Cooked milk | 35.25 |

| 13 | Stable | 8.28 |

| 14 | Goaty | 36.48 |

| 15 | Wool | 5.54 |

| 16 | Animal | 6.64 |

| 17 | Buttery | 35.08 |

| 18 | Cookies | 19.57 |

| 19 | Floury | 16.63 |

| 20 | Vinegar | 9.53 |

| 21 | Rancid butter | 35.62 |

| 22 | Yeast | 9.85 |

| 24 | Astringency | 45.16 |

| 25 | Density | 27.21 |

| 26 | Fat | 35.37 |

| 27 | Viscosity | 39.57 |

| 28 | Cohesion | 28.50 |

In this way, the results of the definitive list consisted of 13 sensory attributes, as highlighted in bold in Table 1.

Panel training

In order to confirm the sensory attributes identified by the judges, the most appropriate reference standards were selected for each of them (Table 2). The search for reference standards required two 1‐hour sessions. For a reliable evaluation, at least two points of the scale were anchored to the reference material during the panel training. Each descriptor was measured using a discrete reference scale from 0 (no perception) to 7 (high perception). The panel training with the described standards on the same yogurt used to develop the descriptor set took three 1‐hour sessions.

Table 2.

Sensory attributes definition and reference standards used for goat yogurt and fermented milk adapted by ISO 22935‐1 (2009)

| Attribute | Definition | Reference |

|---|---|---|

| Creamy | Thick and smooth, like cream | Whipping cream |

| Sour | Gustatory complex sensation, generally due to the presence of organic acids. Fermented milk | 0.35 g and 0.83 g lactic acid/L |

| Salty | Fundamental taste sensation of which NaCl is typical | 0.25 and 0.60 g NaCl/100 g |

| Sweet | Fundamental taste sensation of which sucrose is typical | 0.5% and 2% sucrose in water |

| Citrusy (lemon type) | The sour, sweet, floral aromatics associated with lemon | Real lemon juice |

| Lactic | Cow milk flavor | Full fat milk |

| Cooked milk | Boiled milk flavor | Milk eat to 85 °C for 45 min |

| Goaty | Goat fresh cheese flavor | Goat fresh cheese |

| Buttery/Fat | Butter flavor/Greasy film in the mouth after swallowing | Butter |

| Rancid butter | Rancid butter flavor | Oxided butter |

| Astringency | Rough sensation on the tongue's surface | 0.1% Tannic acid powder in water |

| Viscosity | Rated at which sample flows on the tongue | Creamy yogurt |

Descriptive analysis

The samples for each sensory test were taken simultaneously from separate production lines to have a direct comparison between the two production lines and five retention times (0, 7, 14, 21, and 28 days).

An aliquot (30 mL) of each sample was put into odorless disposable shorts (50 mL) of polystyrene, coded with a random three‐digit number and immediately covered with a plastic cover. The samples were given to the judges immediately, in the sensory lab booths, with tasteless and odorless bottled spring water to rinse the mouth between samples, and the profile card (Table 3). The tests were conducted in duplicate on the samples presented in a complete random block design.

Table 3.

Sensory profile card used to define the sensory profile of the yogurt and the fermented milk

| Sample | Name | Data |

|---|---|---|

| Descriptors of appearance | Score from 0 to 7 | |

| Creamy | Dense egg cream (7) | |

| Descriptors of flavor | ||

| Sour | ||

| Salty | ||

| Sweet | ||

| Fermented milk | ||

| Citrusy (lemon type) | ||

| Lactic (pasteurized milk) | ||

| Goaty | ||

| Buttery | ||

| Rancid butter | ||

| Descriptors of body and texture | ||

| Astringency | Rough sensation on the tongue's surface | |

| Fat | Greasy film in the mouth after swallowing | |

| Viscosity | Sliding resistance during the suction |

Judges received the 10 samples in pairs of two (yogurt and FM) for five different storage times, and evaluating the intensity of each attribute recognized in the samples.

The panelist was asked to take a 15‐min break after completing five pairs of samples, and the next five pairs were presented after the break. The panelist took approximately 10 mL of each sample at a time and assessed the intensity of sensory attributes using a 7‐point scale. First, the overall appearance was evaluated. Second, taste and smell descriptors were evaluated. Finally, tactile sensation descriptors in the mouth were evaluated. The whole test was replicated after 2 days.

Consumer test

Sensory acceptance tests were developed utilizing the hedonic scale, with 62 volunteer untrained adult tasters of both genders, aged between 20 and 60 years, possessing educational levels from undergraduate to graduate, and being accustomed to the frequent consumption of yogurt based on cow's milk, recruited from students, administration staff and professors of the Tuscia University, Viterbo, Italy. Before the experiments began, participants were provided with information on hygiene and safety of goat yogurt and FM samples offered to them and then were given oral instructions on how to conduct the experiment.

The tests were conducted in individual booths, where consumers received an evaluation sheet to evaluate the products, using a balanced 7‐point hedonistic verbal scale ranging from 1 (dislike extremely) to 7 (liked extremely), suitable to consumers involved in the preference test on our products (Cardello, 2017; Karagül‐Yüceer & Drake, 2013; Lim, 2011; Masamba & Ali, 2013; Suriasih, Hartawan, Sucipta, Lindawati, & Okarini, 2014).

Note that 30 mL of each sample encoded with a three‐digit number were randomly distributed to the judges in a 50 mL disposable cup. Consumers have evaluated the samples in pairs (yogurt and FM at each time of storage) presented simultaneously.

It was also given bottled water odorless and tasteless to cleanse the palate between samples.

Statistical analysis

The results of the analysis performed triplicate on all samples were averaged and the standard deviation calculated.

One‐way analysis of variance (ANOVA) was carried out on sensory data in order to find significant difference among samples. When differences were observed at a significance level of P < 0.05, a multiple comparison of means was performed using the Fisher's least significant difference (LSD).

To highlight the relationships between all the attributes and the samples of our study, a principal components analysis (PCA) was conducted using the matrix with 10 lines, linked to samples and 8 columns associated with statistically significant attributes (P < 0.05).

The PCA was performed using Unscrambler® v.9.7 (Camo Software AS Oslo, Norway).

Results and Discussion

Physical‐chemical analyses

The starting milk used for testing displayed the following contents: fat 3.74%, protein 3.47%, lactose 3.92%, pH 6.91. Results concerning the physicochemical characteristics after fermentation and during refrigerated storage of yogurt and FM are summarized in Table 4. Overall, the mean values of lactose, proteins, and pH were statistically different (P < 0.05) in two products, while no difference was observed for fat, total solid and humidity. Compared to the initial content, the lactose reduced (P < 0.05) during the fermentation process by approximately 35% in yogurt and 26% in the FM; In addition, there was a further reduction of 1.52% and 0.25% during storage for the yogurt and fermented milk, respectively. The FM showed greater lactose content than the yogurt, as a function of time (Table 4) showing significant differences between the two products (P < 0.05) to 14 and 28 days of storage. These differences may be attributable to the fermenting bacteria used, as previously reported (Kneifel, Jaros, & Erhard, 1993).

Table 4.

Mean value (± SE) of composition (%) and pH during storage of yogurt (Y) and fermented milk (FM) at 4 °C

| Total solid | Humidity | Fat | ||||

|---|---|---|---|---|---|---|

| Storage time, d | Y | FM | Y | FM | Y | FM |

| 0 (24 hours) | 11.29 ± 0.06A, a | 11.27 ± 0.11A, a | 88.71 ± 0.06A, a | 88.73 ± 0.11A, a | 3.59 ± 0.06A, a | 3.62 ± 0.01A, a |

| 7 | 11.37 ± 0.13A, a | 11.39 ± 0.13A, a | 88.63 ± 0.13A, a | 88.61 ± 0.13A, a | 3.78 ± 0.16A, a | 3.70 ± 0.15A, a |

| 14 | 11.46 ± 0.03A, a | 11.26 ± 0.10A, a | 88.54 ± 0.03A, a | 88.74 ± 0.10A, a | 3.70 ± 0.14A, a | 3.65 ± 0.14A, a |

| 21 | 11.58 ± 0.09A, a | 11.26 ± 0.07A, b | 88.42 ± 0.09A, a | 88.74 ± 0.07A, b | 3.59 ± 0.18A, a | 3.62 ± 0.15A, a |

| 28 | 11.41 ± 0.15A, a | 11.40 ± 0.08A, a | 88.59 ± 0.15A, a | 88.60 ± 0.08A, a | 3.60 ± 0.10A, a | 3.61 ± 0.11A, a |

| Mean value | 11.42 ± 0.05a | 11.34 ± 0.03a | 88.58 ± 0.05a | 88.68 ± 0.03a | 3.65 ± 0.04a | 3.64 ± 0.02a |

| Proteins | Lactose | pH | ||||

|---|---|---|---|---|---|---|

| Storage time, days | Y | Y | Y | FM | Y | F M |

| 0 (24 hours) | 3.80 ± 0.11A, a | 2.56 ± 0.11A, a | 2.56 ± 0.11A, a | 7.65 ± 0.12A, a | 4.35 ± 0.11A, a | 4.52 ± 0.06A, b |

| 7 | 3.76 ± 0.06A, a | 2.53 ± 0.24A, a | 2.53 ± 0.24A, a | 7.69 ± 0.05A, a | 4.31 ± 0.07A, a | 4.46 ± 0.07A, a |

| 14 | 3.72 ± 0.08A, a | 2.49 ± 0.18A, a | 2.49 ± 0.18A, a | 7.61 ± 0.03A, a | 4.33 ± 0.08A, a | 4.43 ± 0.04A, a |

| 21 | 3.74 ± 0.10A, a | 2.51 ± 0.23A, a | 2.51 ± 0.23A, a | 7.64 ± 0.22A, b | 4.34 ± 0.06A, a | 4.47 ± 0.04A, a |

| 28 | 3.65 ± 0.06A, a | 2.50 ± 0.24A, a | 2.50 ± 0.24A, a | 7.79 ± 0.07A, a | 4.33 ± 0.10A, a | 4.49 ± 0.08A, a |

| Mean value | 3.73 ± 0.02a | 2.51 ± 0.01a | 2.51 ± 0.01a | 7.67 ± 0.03a | 4.33 ± 0.01a | 4.47 ± 0.01b |

AMeans in column with the same letters are not significantly different from each other at P < 0.05.

a,bMeans in row with the same letters are not significantly different from each other at P < 0.05.

Protein content increased more yogurt than the FM (3.73% compared with 3.63%). This finding may be due to the higher amount of inoculum in FM causing a higher dilution in preparation, therefore reducing the total protein amount.

The pH values in FM was on average higher than yogurt, showing a significant difference (P < 0.05) at time 0. This could be explained by the fact that the acid pH stimulates the metabolism of the citrate in L. lactis with the production of acetaldehyde, diacetyl, and acetoin (Starrenburg & Hugenholtz, 1991), leading to medium deacidification that partly counteracts the increase in acid production (Hache et al., 1999) in the FM.

Microbiological analyses

In the yogurt and FM prepared in this study, no yeast, mold, or contaminating bacteria were detected in any of the samples.

The results of the viable counts of the starter bacteria inoculated in yogurt (S. thermophilus and L. delbrueckii spp. bulgaricus) and in FM (S. thermophilus, L. delbrueckii spp. Bulgaricus, and L. lactis) during refrigerated storage are presented in Table 5. As shown, the maximum viable counts of the bacterial cultures were observed at 24 hours, except for the counts in M17 for FM at 28 days where the higher value was found. The addition of L. lactis did not have a negative effect on the counts of S. thermophilus and L. delbrueckii ssp. bulgaricus in FM, suggesting that the activities of L. lactis did not interfere with those of the lactic starters. Even though during storage there were no significant changes in the counts in all the samples, in FM the viable counts were subject to less variability than yogurt. This could be due to the best resistance of L. lactis to an acid pH (Cogan, 1985; Moon et al., 2015). In addition, some authors (Moon et al., 2015) found in L. lactis promising probiotic attributes, like resistance against acid bile salts, absence of transferable genes for antibiotic resistance, broad utilization of prebiotics.

Table 5.

Mean value ( ± SE) of lactic bacteria viable count (log10 CFU/g) grown in M17 Agar (S. termophylus, L. lactis) and MRS agar (L. delbrueckii spp. bulgaricus), during storage of yogurt (Y) and fermented milk (FM) at 4 °C

| M17 | MRS | M17 + MRS | ||||

|---|---|---|---|---|---|---|

| Storage time, days | Y | FM | Y | FM | Y | FM |

| 0 | 6.84 ± 0.56A, a | 8.43 ± 0.43A, b | 8.22 ± 0.31A, a | 8.29 ± 0.31A, a | 8.35 ± 0.22A, a | 8.68 ± 0.37A, a |

| 7 | 6.49 ± 0.61A, a | 8.44 ± 0.30A, b | 8.05 ± 0.46A, a | 7.80 ± 0.48A, a | 8.27 ± 0.25A, a | 8.54 ± 0.33A, a |

| 14 | 6.58 ± 0.57A, a | 8.29 ± 0.57A, b | 7.61 ± 0.48A, a | 7.53 ± 0.78A, a | 7.92 ± 0.28A, a | 8.38 ± 0.60A, b |

| 21 | 6.38 ± 0.62A, a | 8.22 ± 0.55A, b | 7.90 ± 0.62A, a | 7.44 ± 0.64A, a | 8.24 ± 0.28A, a | 8.32 ± 0.56A, a |

| 28 | 6.23 ± 0.71A, a | 8.58 ± 0.49A, b | 7.37 ± 0.84A, a | 7.53 ± 0.62A, a | 7.95 ± 0.37A, a | 8.63 ± 0.50A, b |

AMeans in column with the same letters are not significantly different from each other at P < 0.05.

a,b Means in row with the same letters are not significantly different from each other at P < 0.05.

Descriptive analysis

The geometric means, in accordance with ISO 11035: 1994, allowed the selection of the descriptors that represent the sensory profile of the two products. Table 1 illustrates the list of descriptors with an M value that exceed the defined threshold, used for the profile sheet.

In a recent article (Megalemou et al., 2017) that compared yogurt derived from different types of milk, the sample of goat yogurt was significantly higher for the attribute of “sour” for taste, the attributes of “persistent,” “intense,” and “goaty” for the aftertaste and the attributes of “velvety,” “smooth,” and “fluid” for the texture.

This confirms what detected through the descriptive analysis carried out in our study, for which, the strong “caprine” feature of goat yogurt (Y), is well characterized and different from the FM, by the selected descriptors (Table 6) of the sensory profile.

Table 6.

Changes in sensorial attributes of goat yogurt and fermented milk during storage

| Storage period, days | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 7 | 14 | 21 | 28 | ||||||

| Parameter | Y0 | FM0 | Y7 | FM7 | Y14 | FM14 | Y21 | FM21 | Y28 | FM28 |

| Creamy | 1.80 ± 0.25a | 2.00 ± 0.19a | 1.00 ± 0.30a | 1.83 ± 0.18b | 0.80 ± 0.28a | 1.40 ± 0.30b | 0.20 ± 0.02a | 1.20 ± 0.27b | 0.20 ± 0.03a | 1.20 ± 0.28b |

| Sour | 3.33 ± 0.38a | 2.33 ± 0.28b | 4.20 ± 0.32a | 2.20 ± 0.41b | 3.80 ± 0.11a | 2.20 ± 0.09b | 3.80 ± 0.34a | 2.20 ± 0.18b | 4.00 ± 0.42a | 1.60 ± 0.30b |

| Salty | 3.17 ± 0.20a | 1.67 ± 0.22b | 2.60 ± 0.31a | 0.80 ± 0.51b | 2.60 ± 0.24a | 1.20 ± 0.32b | 2.40 ± 0.18a | 0.80 ± 0.09b | 2.60 ± 0.33a | 0.80 ± 0.25b |

| Sweet | 0.83 ± 0.09a | 1.70 ± 0.30b | 1.20 ± 0.15a | 1.80 ± 0.22b | 0.67 ± 0.11a | 1.50 ± 0.28b | 1.00 ± 0.11a | 1.80 ± 0.22b | 1.00 ± 0.09a | 1.80 ± 0.10b |

| Goaty | 3.40 ± 0.18a | 1.60 ± 0.28b | 3.00 ± 0.30a | 1.17 ± 0.38b | 1.80 ± 0.41a | 1.00 ± 0.35b | 1.40 ± 0.22a | 0.40 ± 0.29b | 1.40 ± 0.50a | 0.00 ± 0.00b |

| Butter | 0.33 ± 0.09a | 1.50 ± 0.18b | 0.60 ± 0.08a | 1.80 ± 0.18b | 0.80 ± 0.09a | 1.60 ± 0.15b | 0.60 ± 0.04a | 1.40 ± 0.31b | 0.80 ± 0.09a | 1.60 ± 0.30b |

| Rancid butter | 0.83 ± 0.18a | 0.50 ± 0.08a | 1.60 ± 0.08a | 0.20 ± 0.08b | 1.60 ± 0.30a | 0.20 ± 0.05b | 1.20 ± 0.30a | 0.20 ± 0.08b | 1.20 ± 0.20a | 0.20 ± 0.02b |

| Viscosity | 0.83 ± 0.15a | 1.00 ± 0.30a | 1.00 ± 0.15a | 1.60 ± 0.16b | 1.00 ± 0.27a | 1.60 ± 0.33a | 1.10 ± 0.16a | 1.50 ± 0.12b | 1.20 ± 0.09a | 1.60 ± 0.12b |

Value are means of three independent determinations. Mean values having different superscript letters in a row are significantly different in pairs (Y/FM) (P ≤ 0.05).

The selected attributes, significantly discriminating for the samples, were one for appearance (creamy), three for taste (sour, salty, and sweet), three for flavor (goaty, butter, and rancid butter) and one for texture (viscosity). Furthermore, the data show that the sample of goat yogurt (Y) is characterized by higher acidity, salinity and goaty aroma, while the FM sample is more creamy, sweeter, more buttery and has a lower intensity for all aggressive features linked to goat's milk (sour, salty, goaty).

The opposite result was observed by Pimentel, Cruz, and Prudencio (2013), for whom the addition of probiotics (Lactobacillus paracasei ssp. Paracasei) did not change the sensory profile of low‐fat yoghurt from cow's milk. This result suggests the possibility of attributing sensory changes, perceived in FM compared to Y, to the specific probiotic strain used or to goat milk. Both hypotheses could be further examined.

Recently, many researchers have focused their attention on the possibility of incorporating fruit juices and pulp or other natural sweeteners such as honey with goat yogurt to improve taste (Machado et al., 2017; Ranadheera, Evans, Adams, & Baines, 2012; Silva et al., 2017). In fact, the sweet taste mitigates the goat flavor that makes these products not always particularly pleasing to the customer. The addition of components extraneous to the product, made these formulations susceptible to interfere with the fermentative activity.

Our proposal, to add the L. lactis to the goat yogurt starter culture, enhance the product's acceptability, without the use of other ingredients and does not interfere with the fermentation process.

Consumer test

The results of the preference tests clearly showed that FM always obtained the highest score compared to conventional yogurt (Y), as shown in Table 7.

Table 7.

Mean acceptability values preference test of goat's yogurt (Y) and fermented milk (FM) samples

| Y | FM | |

|---|---|---|

| 0 | 3.85 ± 0.80a | 5.62 ± 0.65b |

| 7 | 3.84 ± 0.62a | 5.52 ± 0.48b |

| 14 | 4.02 ± 0.58a | 5.74 ± 0.66b |

| 21 | 4.73 ± 0.45a | 5.72 ± 0.51b |

| 28 | 4.71 ± 0.72a | 6.00 ± 0.53b |

| Mean | 4.23a | 5.72b |

Values are means of 62 determinations. Means values having different superscript letters in a row are significantly different (P ≤ 0.005).

If to consider an acceptable product, the average value of the preference, must be at least 70% of the maximum value of the hedonistic scale used in the tests (Gularte, 2002), then, for our products, the threshold had to be about 5.

The Table 7 shows that the FM sample scored an average value equal to 5.72 ± 0.19, higher than the threshold of acceptability.

The preference scores at all storage times for goat yogurt are significantly lower (P < 0.005) than those of fermented goat milk studied in our work.

These results suggest that the addition of the L. lactis to traditional initial culture had a positive impact on the acceptability of the FM compared to traditional goat yogurt (Y) and confirms that the differences found by the group of experts are indeed perceived by consumers.

Our proposal, validated by this result, could probably represent a possible solution to increase the consumption of goat's milk products.

Principal component analysis

The PCA is the most widely used technique to display concealed relevant information in a data matrix, and this approach allows you to evaluate the clustering of samples in the class who seem to have the greatest similarity (Granato et al., 2018a).

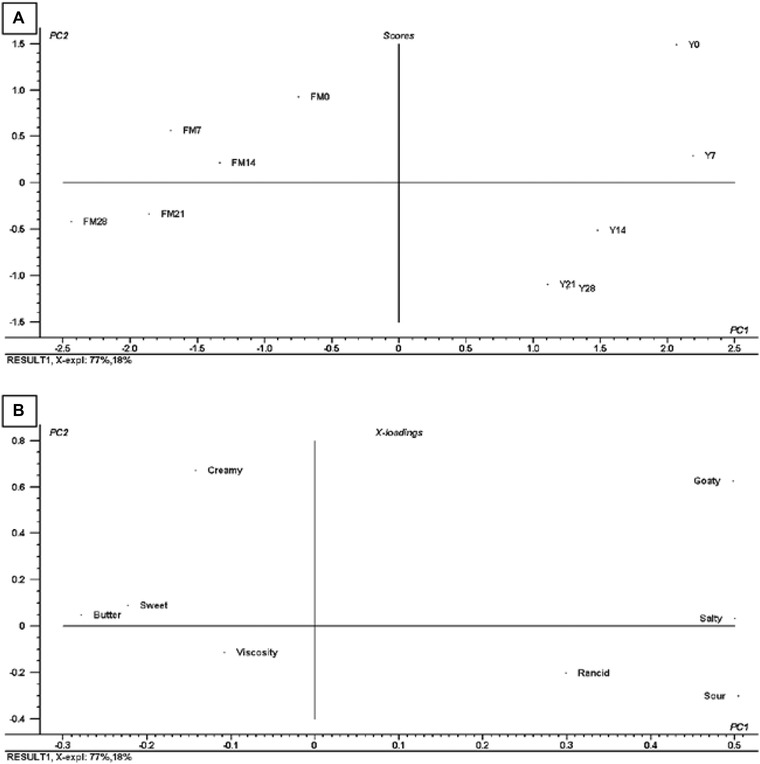

According to the Kaiser criterion (Kaiser, 1960) reported by Granato, Santos, Escher, Ferreira, and Maggio (2018b), the optimal number of PCs is defined by the sum of the eigenvalues higher than 1, therefore we considered the first two PCs, which explained about 95% of the total variance, assuring a good discrimination of the samples.

Table 8 shows that the two PCs accounted for 77% and 18% of the variance, respectively.

Table 8.

Factor loadings for each principal components and communalities

| PC 1 (77%) | PC 2 (18%) | Communalities | |

|---|---|---|---|

| Creamy | −0.143 | 0.672 | 0.472 |

| Sour | 0.504 | −0.302 | 0.345 |

| Salty | 0.500 | 0.034 | 0.251 |

| Sweet | −0.223 | 0.089 | 0.058 |

| Goaty | 0.498 | 0.627 | 0.641 |

| Butter | −0.279 | 0.049 | 0.080 |

| Rancid | 0.299 | −0.202 | 0.130 |

| Viscosity | −0.108 | −0.113 | 0.024 |

| Eigenvalue | 2.31957 | 0.53205 |

The score plot (Figure 1A) showed good separation between samples, depending on the different type of inoculum (FM and Y) and the storage time.

Figure 1.

Score (A) and loading (B) plots of the PC analysis.

In addition, the loading plot (Figure 1B) indicated the main sensory attributes responsible in the discrimination between the FM and Y samples.

As shown in Table 8, the PC1 explained 77% of the variance and differentiated the samples according to the values of sour, salty, and goaty, resulting mainly linked to the fermentation process (Y and FM).

Instead, the PC2 clarified a further 18% of the variation of the data and distributed the samples according to the values of creaminess and goaty, relative to the storage time, which clearly mitigated these aspects in the samples.

It is interesting to note that based on the distribution of samples, according to the PCA, the attributes that justify the good acceptability of the FM samples by the consumer, in the hedonic test, are presumably four: creamy, salty, goaty, and sour, according to the Communalities (CM) values reported in the Table 8.

Conclusions

In order to encourage the consumption of dairy products from goat's milk, various proposals have been made to improve the sensory qualities (flavor and texture feel) characterized by a strong unpleasant goaty flavor. The most promising results seem to be related to the addition of probiotic strains to the traditional starter yogurt culture. As highlighted by Mituniewicz‐Malek et al. (2019), the selection of the strain is fundamental for the improvement of the sensory features of the final product.

Furthermore various authors (Benyoucef et al., 2017; Ranadheera, Naumovski, & Ajlouni, 2018), have revealed that the composition of goat's milk is particularly suitable for the development and long‐term survival of the probiotic flora. This property has allowed the addition of L. lactis to traditional microbial yogurt starter culture, greatly improving the sensory characteristics of the product. The objective achieved with the addition of Leuconostoc is linked to the metabolism of this microorganism which, as previously explained, can modify the sensory profile of dairy products. The low lipolytic activity, the production of dextran and diacetyl, under specific operating conditions, allow Leuconostoc to significantly mitigate the unpleasant characteristics of goaty in goat's milk yogurt.

The use of natural culture microorganisms enhances the aromatic characteristics of the goat's FM, without adding sweeteners or other ingredients, which might create interference with fermentation activity.

The diminution of the less pleasant sensory attributes, such as sour, salty and the feeling of goat, combined with an increase in positive attributes such as sweetness and creaminess enhanced the sensory profile of fermented goat's milk, increasing its acceptability.

This improvement can help to stimulate the consumption of products made from goat milk with a consequent positive effect on health.

Author Contributions

D. De Santis conceived the presented idea, developed the sensory analysis, supervised the findings of this work, and the writing of the manuscript. G. Giacinti and G. Chemello performed the microbiological analysis. M.T. Frangipane contributed to the implementation of the research and to the analysis of the results. All authors discussed the results and contributed to the final manuscript.

References

- Aryana, K. J. , & Olson, D. W. (2017). A 100‐year review: Yogurt and other cultured dairy products. Journal of Dairy Science, 100, 9987–10013. [DOI] [PubMed] [Google Scholar]

- Atamian, S. , Olabi, A. , Baghdadi, O. K. , & Toufeili, I. (2014). The characterization of the physicochemical and sensory properties of full‐fat, reduced‐fat and low‐fat bovine, caprine, and ovine Greek yogurt (Labneh). Food Science & Nutrition, 2, 164–173. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Benyoucef, A. , Hansal, N. , Said, L. , Lhadj Said, M. A. , Bentabet, H. , Kihal, M. , & Benmechernene, Z. (2017). Evaluation of technological properties of Leuconostoc mesonteroides (V1) strain isolated from Algerian goat's milk. Advances in Enviromental Biology, 11, 26–38. [Google Scholar]

- Buffa, M. , Morais, J. , Jimẽnez‐Belenguer, A. , Hemãndez‐Gimẽnez, E. , & Guamis, B. (2005). Technological characterization of lactis acid bacteria isolated from raw ewes’ milk for cheese making. Milchwissenschaft, 61, 404–407. [Google Scholar]

- Cardello, A. (2017). Hedonic scaling: Assumptions, contexts and frames of reference. Current Opinion in Food Science, 15, 14–21. [Google Scholar]

- Champagne, C. P. , Cruz, A. G. , & Daga, M. (2018). Strategies to improve the functionality of probiotics in supplements and foods. Current Opinion in Food Science, 22, 160–166. [Google Scholar]

- Cogan, T. M. (1985). The Leuconostocs: Milk products In Gilliland S. E. (Ed.), Bacterial starter cultures for foods (pp. 25–40). Boca Raton, FL: CRC Press. [Google Scholar]

- Cogan, T. M. , & Hill, C. (1993). Cheese starter cultures In Fox P. F. (Ed.), Cheese: Chemistry, phisic and microbiology (2nd ed., pp. 193–225). London: Chapman & Hall. [Google Scholar]

- Costa, M. P. , Balthazar, C. F. , Franco, R. M. , Mársico, E. T. , Cruz, A. G. , & Conte Junior, C. A. (2014). Changes on expected taste perception of probiotic and conventional yogurts made from goat milk after rapidly repeated exposure. Journal of Dairy Science, 97, 2610–2618. [DOI] [PubMed] [Google Scholar]

- Costa, M. P. , Balthazar, C. F. , Rodrigues, B. L. , Lazaro, C. A. , Silva, A. C. , Cruz, A. G. , & Conte Junior, C. A. (2015). Determination of biogenic amines by high‐performance liquid chromatography (HPLC‐DAD) in probiotic cow's and goat's fermented milks and acceptance. Food Science and Nutrition, 3, 172–178. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Costa, R. G. , Beltrão Filho, E. M. , De Sousa, S. , Cruz, G. R. B. , & Queiroga, R. C. R. E. (2016). Physicochemical and sensory characteristics of yogurts made from goat and cow milk. Animal Science Journal, 87, 703–709. [DOI] [PubMed] [Google Scholar]

- De Vuyst, L. , & Degeest, B. (1999). Heteropolysaccharides from lactic acid bacteria. FEMS Microbiology Reviews, 23, 153–177. [DOI] [PubMed] [Google Scholar]

- Duboc, P. , & Mollet, B. (2001). Applications of exopolysaccharides in the dairy industry. International Dairy Journal, 11, 759–768. [Google Scholar]

- Eissa, E. A. , Mohamed Ahmed, I. A. , Yagoub, A. E. A. , & Babiker, E. E. (2010). Physicochemical, microbiological and sensory characteristics of yogurt produced from goat milk. Livestock Research for Rural Development, 22(8), 247–253. [Google Scholar]

- Eissa, E. A. , Babiker, E. E. , & Yagoub, A. E. A. (2011). Physicochemical, microbiological and sensory properties of Sudanese yogurt (zabadi) made from goat's milk. Animal Production Science, 51, 53–59. [Google Scholar]

- Esmerino, E. A. , Ferraz, J. P. , Tavares Filho, E. R. , Pinto, L. P. F. , Freitas, M. Q. , Cruz, A. G. , & Bolini, H. M. A. (2017a). Consumers’ perceptions toward 3 different fermented dairy products: Insights from focus groups, word association, and projective mapping. Journal of Dairy Science, 11, 8849–8860. [DOI] [PubMed] [Google Scholar]

- Esmerino, E. A. , Castura, J. C. , Ferraz, J. P. , Tavares Filho, E. R. , Silva, R. , Cruz, A. G. , … Bolini, H. M. A. (2017b). Dynamic profiling of different ready‐to‐drink fermented dairy products: A comparative study using Temporal Check‐All.That‐Apply (TCATA), Temporal Dominance of Sensations (TDS) and Progressive Profile (PP). Food Research International, 101, 249–258. [DOI] [PubMed] [Google Scholar]

- FAOSTAT, Food and Agriculture Organization of the United Nations Statistics Division . (2018). <Retrieved from http://faostat3.fao.org/home/E>.

- Fox, P. F. , Lucey, J. A. , & Cogan, T. M. (1990). Glycolysis and related reactions during cheese manufacture and ripening. Critical Review of Food Science Nutrition, 29, 237–253. [DOI] [PubMed] [Google Scholar]

- Franciosi, E. , Settanni, L. , Cavazza, A. , & Poznanski, E. (2009). Biodiversity and technological potential of wild lactic acid bacteria from raw cows’ milk. International Dairy Journal, 19, 3–11. [Google Scholar]

- Gamage, G. , Adikari, A. , Nayananjalie, W. , Prasanna, P. , Jayawardena, N. , & Wathsala, R. (2016). Physicochemical, microbiological and sensory properties of probiotic drinking yoghurt developed with goat milk. International Journal of Scientific and Research Publications, 6, 203–208. [Google Scholar]

- Garibal, J. I. , Rodriguez‐Alonso, P. , & Centeno, J. A. (2008). Characterization of lactic acid bacteria isolated from raw cows’ milk cheeses currently produced in Glicia (NW Spain). LWT Food Science and Technology, 41, 1452–1458. [Google Scholar]

- Granato, D. , Putnik, P. , Kovačević, D. B. , Santos, J. S. , Calado, V. , Rocha, R. S. , … Pomerantsev, A. (2018a). Trends in chemiometrics: Food authentication, microbiology, and effects of processing. Comprehensive Reviews in Food Science and Food Safety, 17, 663–677. [DOI] [PubMed] [Google Scholar]

- Granato, D. , Santos, J. S. , Escher, G. B. , Ferreira, B. L. , & Maggio, R. M. (2018b). Use of principal component analysis (PCA) and hierarchical cluster analysis (HCA) for multivariate association between bioactive compounds and functional properties in foods: A critical perspective. Trends in Food Science and Technology, 72, 83–90. [Google Scholar]

- Gularte, M. A. (2002). Manual de análise sensorial de alimentos . p.59. Universidad Federal de Pelotas, Pelotas.

- Hache, C. , Cachon, R. , Wache, Y. , Belguendouz, T. , Riondet, C. , & Deraedt, A. (1999). Influence of lactose‐citrateco‐metabolism on the differences of growth and energetic in Leuconostoclactis, Leuconostocmesenteroides ssp. mesenteroides and Leuconostocmesenteroides ssp. cremoris. Sysematic Applied Microbiology, 22, 507–513. Retrieved from 10.1016/S0723-2020(99)80002-2 [DOI] [PubMed] [Google Scholar]

- Hemme, D. , & Foucaud‐Scheunemann, C. (2004). Leuconostoc,characteristics, use in dairy technology and prospects in functional foods. International Dairy Journal, 14, 467–494. [Google Scholar]

- Hill, C. , Guarner, F. , Reid, G. , Gibson, G. R. , Merenstein, D. J. , Pot, B. , … Sanders, M. E. (2014). The International Scientific Association for Probiotics and Prebiotics consensus statement on the scope and appropriate use of the term probiotic. Consensus Statement, 11, 506–514. [DOI] [PubMed] [Google Scholar]

- Hugenholts, J. (1993). Citrate metabolism in lactic acid bacteria. FEMS Microbiology Reviews, 12, 165–168. [Google Scholar]

- Kaiser, H. F. (1960). The application of electronic computers to factor analysis. Educational and Psychological Measurement, 20, 141–151. [Google Scholar]

- Karagül‐Yüceer, Y. , & Drake, M. A. (2013). Sensory analysis of yogurt. Manufacturing Yogurt and Fermented Milks, 16, 353–356. [Google Scholar]

- Kneifel, W. , Jaros, D. , & Erhard, F. (1993). Microflora and acidification properties of yogurt and yogurt‐related products fermented with commercially available starter cultures. International Journal of Food Microbiology, 18, 179–189. [DOI] [PubMed] [Google Scholar]

- Kesenkaş, H. , Karagözlü, Yerlikaya, O. , Özer, E. , Akpinar, A. , & Akbulut, N. (2017). Physicochemical and sensory characteristics of winter yogurt produced from mixtures of cow's and goat's milk. Journal of Agricultural Sciences, 23, 53–62. [Google Scholar]

- Lim, J. (2011). Hedonic scaling: A review of methods and theory. Food Quality and Preference, 22, 733–747. [Google Scholar]

- Machado, T. A. D. G. , Oliveira, M. E. G. , Campos, M. I. F. , Assis, P. O. A. , Souza, E. L. , Madruga, M. S. , … Queiroga, R. C. R. E. (2017). Impact of honey on quality characteristics of goat yogurt containing probiotic Lactobacillus acidophilus . Food Science and Technology, 80, 221–229. [Google Scholar]

- Masamba, K. G. , & Ali, L. (2013). Sensory quality evaluation and acceptability determination of yogurt made from cow, goat and soy milk. African Journal of Food Science and Technology, 4, 44–47. [Google Scholar]

- Mcsweeney, P. , & Sousa, M. (2000). Biochemical pathways for the production of flavor compounds in cheeses during ripening: A review. Le Lait, INRA Editions, 80, 293–324. [Google Scholar]

- Megalemou, K. , Sioriki, E. , Lordan, R. , Dermiki, M. , Nasopoulou, C. , & Zabetakis, I. (2017). Evaluation of sensory and in vitro anti‐thrombotic properties of traditional Greek yogurts derived from different types of milk. Heliyon, 3, e00227. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Mituniewicz‐Malek, A. , Zielińska, D. , & Ziarno, M. (2019). Probiotic monocultures in fermented goat milk beverages‐sensory quality of final product. International Journal of Dairy Technology, 72, 1–8. [Google Scholar]

- Moon, J. S. , Choi, H. S. , Shin, S. Y. , Noh, S. J. , Jeon, C. O. , & Han, N. S. (2015). Genome sequence analysis of potential probiotic strain Leuconostoc lactis EFEL005 isolated from kimchi. Journal of Microbiology, 53(5), 337–342. [DOI] [PubMed] [Google Scholar]

- Nieto‐Arribas, P. , Seseña, S. , Poveda, M. J. , Palop, L. , & Cabezas, L. (2010). Genotypic and technological characterization of Leuconostoc isolate sto be used as adjunct starters in Manchego cheese manufacture. Food Microbiology, 27, 85–93. [DOI] [PubMed] [Google Scholar]

- Pẽrez, G. , Cardarell, E. , & Zarate, V. (2002). Random amplified polymorphic DNA analysis for differentiation of Leuconostoc mesentereides subspecies isolated from Tenerife cheese. Letters in Applied Microbiology, 34, 82–85. [DOI] [PubMed] [Google Scholar]

- Pimentel, T. C. , Cruz, A. G. , & Prudencio, S. H. (2013). Short communication: Influence of long‐chain inulin and Lactobacillus paracasei subspecies paracasei on the sensory profile and acceptance of traditional yogurt. Journal of Dairy Science, 96, 6233–6241. [DOI] [PubMed] [Google Scholar]

- Pulina, G. , Milàn, M. J. , Lavìn, M. P. , Theodoridis, A. , Morin, E. , Capote, J. , … Caja, G. (2018). Invited review: Current production trends, farm structures, and economics of the dairy sheep and goat sectors. Journal of Dairy Science, 101, 6715–6729. [DOI] [PubMed] [Google Scholar]

- Ranadheera, C. S. , Evans, C. A. , Adams, M. C. , & Baines, S. K. (2012). Probiotic viability and physico‐chemical and sensory properties of plain and stirred fruit yogurts made from goat's milk. Food Chemistry, 135(3), 1411–1418. [DOI] [PubMed] [Google Scholar]

- Ranadheera, C. S. , Naumovski, N. , & Ajlouni, S. (2018). Non‐bovine milk products as emerging probiotic carriers: Recent developments and innovations. Current Opinion in Food Science, 22, 109–114. [Google Scholar]

- Ribeiro, A. C. , & Ribeiro, S. D. A. (2010). Specialty products made from goat milk. Small Ruminant Research, 89, 225–233. [Google Scholar]

- Silva, F. A. , Gomes de Oliveira, M. E. , Feitosa de Figueirêdo, R. M. , Sampaio, K. B. , Leite de Souza, E. , Vasconcelos de Oliveira, C. E. , … De Cassia Ramos do Egypto Queiroga, R. (2017). The effect of Isabel grape addition on the physicochemical, microbiological and sensory characteristics of probiotic goat milk yogurt. Food & Function, 8, 2121–2132. [DOI] [PubMed] [Google Scholar]

- Starrenburg, M. , & Hugenholtz, J. (1991). Citrate fermentation by Lactococcus and Leuconostoc spp. Applied Environmental Microbiology, 57, 3535–3540. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Suriasih, K. , Hartawan, M. , Sucipta, N. , Lindawati, S. A. , & Okarini, I. A. (2014). Microbiological, chemical and sensory characteristics of yogurt prepared from blended cow and goat milk. Food Science and Quality Management, 34, 93–102. [Google Scholar]

- UNI ISO 11035 . (1994). International Organization for Standardization.

- UNI ISO 8589 . (2007). International Organization for Standardization.

- UNI EN ISO 8586‐2 . (2008). International Organization for Standardization.

- UNI EN ISO 13299 . (2010). International Organization for Standardization.

- Uysal‐Pala, C. , Karagul‐Yuceer, Y. , Pala, A. , & Savas, T. (2006). Sensory properties of drinkable yogurt made from milk of different goat breeds. Journal of Sensory Studies, 21, 520–533. [Google Scholar]

- Vedamuthu, E. R. (1994). The dairy Leuconostoc: Use in dairy products. Journal of Dairy Science, 77, 2725–2737. [Google Scholar]

- Verruk, S. , Dantas, A. , & Prudencio, E. S. (2019). Functionally of the components from goat's milk, recent advances for functional dairy products development and its implications on human health. Journal of Functional Foods, 52, 243–257. [Google Scholar]

- World Yogurt Market Report 2000–2025 . (2016). PM Food & Dairy Consulting.