Abstract

Two experiments were conducted to determine the effects of calcium to phosphorus (Ca:P) ratio in diets adequate in standardized total tract digestible (STTD) P on performance of 26- to 127-kg pigs fed diets with or without phytase. Pens of pigs (n = 1,134 in Exp. 1 and n = 1,215 in Exp. 2, initially 26.3 and 25.3 kg) were blocked by body weight (BW) and allotted to treatments in a randomized complete block design. There were 27 pigs per pen with 7 and 9 replicates per treatment in Exp. 1 and Exp. 2, respectively. Treatments were formulated to contain 0.75:1, 1.00:1, 1.25:1, 1.50:1, 1.75:1, and 2.00:1 analyzed Ca:P ratios in Exp. 1, and 0.75:1, 1.00:1, 1.25:1, 1.50:1, and 2.00:1 analyzed Ca:P ratios in Exp. 2. These correspond to a range of 0.96:1 to 2.67:1 and 0.95:1 to 2.07:1 STTD Ca:STTD P ratios in Exp. 1 and Exp. 2, respectively. Experiment 2 diets contained 1,000 phytase units of Ronozyme HiPhos 2500 (DSM Nutritional Products, Inc., Parsippany, NJ) with release values of 0.132% STTD P, 0.144% total Ca, and 0.096% STTD Ca. Diets contained 122% of NRC (2012) STTD P estimates for the weight range across 4 phases. In Exp. 1, increasing Ca:P ratio increased (quadratic, P < 0.05) average daily gain (ADG) and average daily feed intake (ADFI). Feed efficiency (G:F) worsened (quadratic, P < 0.05) at the highest ratio. Hot carcass weight (HCW) and bone ash increased (quadratic, P < 0.05) while carcass yield decreased (linear, P < 0.10) with increasing Ca:P ratio. The maximum responses in ADG, HCW, and bone ash were estimated at 1.38:1, 1.25:1, and 1.93:1 analyzed Ca:P and at 1.82:1, 1.64:1, and 2.57:1 STTD Ca:STTD P, respectively. In Exp. 2, increasing Ca:P ratio increased (quadratic, P < 0.05) ADG and bone ash, and improved G:F (linear, P < 0.05). There was a quadratic increase (P < 0.05) in HCW and decrease in carcass yield (P < 0.10). The maximum responses in ADG, HCW, and bone ash were estimated at 1.63:1, 1.11:1 to 1.60:1, and 1.25:1 analyzed Ca:P and at 1.75:1, 1.28:1 to 1.71:1, and 1.40:1 STTD Ca:STTD P, respectively. Expressing ADG on a STTD Ca:STTD P basis provided a more consistent estimate of the ideal Ca:P ratio among the 2 studies than analyzed Ca to analyzed P ratio. A STTD Ca:STTD P ratio between 1.75:1 to 1.82:1 can be used for 26- to 127-kg pigs that are fed diets adequate in STTD P with or without added phytase to maximize growth rate without reducing bone ash.

Keywords: bone mineralization, calcium, finishing pigs, growth, modeling, phosphorus

INTRODUCTION

Calcium (Ca) and phosphorus (P) are the most abundant minerals in the pig and are involved in the lean tissue deposition, synthesis and maintenance of the skeletal structure, and in many other nonskeletal functions (Crenshaw, 2001; Berndt and Kumar, 2009; Kiarie and Nyachoti, 2010). Historically, swine diets are formulated with low margins of safety for P. Several reasons include an increase in dietary costs as well as an increase in P excretion if P is in excess (Fan et al., 2001; Maguire et al., 2005). Conversely, an abundant supply of Ca associated with its low cost and lack of environmental concerns likely leads to an increased risk for excess Ca in swine diets (Hall et al., 1991).

An excess or deficiency of either Ca or P may affect the utilization of the other mineral (Veum, 2010). Therefore, swine diets should supply not only the individual requirements of both minerals but also consider and adequate ratio between Ca and P (Ca:P). It is well established in the literature that a wide Ca:P ratio is detrimental to pig growth performance and bone mineralization, which is particularly evident when pigs are fed diets deficient or marginal in P (González-Vega et al., 2016a, 2016b; Merriman et al., 2017; Wu et al., 2018). Moreover, an excess Ca or a wide Ca:P ratio can promote the formation of insoluble Ca-phytate-P complexes in the small intestine and reduce the efficacy of exogenous phytases (Lei et al., 1994; Liu et al., 1998; Dersjant-Li et al., 2015).

A recent study has determined the requirement of standardized total tract digestible (STTD) P of growing-finishing pigs (Vier et al., 2017). Therefore, the objective of this study was to determine the effects of feeding different Ca:P ratios in diets adequate in STTD P on growth performance, carcass characteristics, and bone mineralization of 26- to 127-kg pigs fed diets with or without phytase.

MATERIALS AND METHODS

The Kansas State University Institutional Animal Care and Use Committee (Manhattan, KS) approved all experimental procedures in this study.

Animals and Diets

Two studies were conducted at a commercial research-finishing site in southwestern Minnesota (New Horizon Farms, Pipestone, MN). The facilities were naturally ventilated and double-curtain-sided. Two barns were used containing 42 pens (3.05 × 5.49 m2) each, with completely slatted concrete flooring and a deep pit for manure storage. Each pen was equipped with a 4-hole stainless steel, dry self-feeder (Thorp Equipment, Thorp, WI) and 1 cup waterer. The facilities were equipped with a computerized feeding system (FeedPro; Feedlogic Corp., Willmar, MN) capable of measuring and recording daily feed additions to individual pens. Thirteen barrows and 14 gilts (PIC 359 × 1050, Genus PIC, Hendersonville, TN) were housed in each pen and were allowed ad libitum access to feed and water throughout the experiment.

A total of 1,134 pigs (initially 26.3 kg) in Exp. 1 and 1,215 pigs (initially 25.3 kg) in Exp. 2 were used in 110-d and 114-d growth trials, respectively. After placement in the finishing facility, pigs were fed a common diet containing 0.65% total Ca and 0.41% STTD P (0.54% total P) until the beginning of both trials. At day 0 of each trial, pens of pigs were sorted by average BW and randomly allotted to dietary treatments in a randomized complete block design with BW as the blocking factor. There were 27 pigs per pen with 7 replicate pens per treatment in Exp. 1 and 9 replicate pens per treatment in Exp. 2.

All treatment diets were manufactured at the New Horizon Farms Feed Mill in Pipestone, MN and fed in meal form. In Exp. 1, diets were formulated to 0:75:1, 1.00:1, 1.25:1, 1.50:1, 1.75:1, and 2.00:1 analyzed Ca:P ratios. In Exp. 2, diets were formulated to 0:75:1, 1.00:1, 1.25:1, 1.50:1, and 2.00:1 analyzed Ca:P ratios. Coefficients for STTD of P in feed ingredients were obtained from NRC (2012), and values for STTD of Ca were obtained from Stein et al. (2016). A weighted average of STTD Ca:STTD P ratios across dietary phases was calculated. In Exp. 1, these ratios were 0:96:1, 1.30:1, 1.65:1, 1.98:1, 2.32:1, and 2.67:1 STTD Ca:STTD P ratios across dietary treatments. In Exp. 2, these ratios were 0:95:1, 1.18:1, 1.40:1, 1.62:1, and 2.07:1 STTD Ca:STTD P ratios across dietary treatments. Prior to the experiments, 3 samples of the ingredients used in the diets that contained Ca and P were analyzed for Ca (method 985.01; AOAC International, 1990) and P (method 985.01; AOAC International, 1990) in duplicate (Ward Laboratories, Inc., Kearney, NE; Table 1). The average of the 6 lab results for each ingredient was used for diet formulation. The experimental diets were corn-soybean-meal–based and fed in 4 different phases (Tables 2 and 3). The diets were formulated to contain adequate STTD P across the dietary treatments in all phases based on the estimated requirement previously determined in this facility (Vier et al., 2017). Thus, formulated STTD P levels were 0.38%, 0.33%, 0.29%, and 0.25% for phases 1, 2, 3, and 4, respectively, which represented 122% of NRC (2012) estimates. In Exp. 1, phase 1 diets were fed from day 0 to 28 (26.3- to 50.2-kg); phase 2 diets were fed from day 29 to 56 (50.2- to 78.2-kg); phase 3 diets were fed from day 57 to 85 (78.2- to 107.8-kg); and phase 4 diets were fed from day 86 to 110 (107.8- to 127.6-kg). In Exp. 2, phase 1 diets were fed from day 0 to 25 (25.3- to 44.6-kg); phase 2 diets were fed from day 26 to 58 (44.6- to 74.4-kg); phase 3 diets were fed from day 59 to 87 (74.4- to 103.0-kg); and phase 4 diets were fed from day 88 to 114 (103.0- to 126.6-kg).

Table 1.

Analyzed Ca and P concentrations in feed ingredients (as-fed basis)1

| Item | Ca, % | P, % |

|---|---|---|

| Corn | 0.03 | 0.22 |

| Soybean meal, 46.5% crude protein | 0.51 | 0.65 |

| Monocalcium P (21% P) | 15.23 | 18.78 |

| Limestone | 34.64 | 0.07 |

| Vitamin and trace mineral premix | 6.21 | 0.02 |

1A total of 6 samples of each ingredient were submitted to Ward Laboratories, Inc. (Kearney, NE) and were analyzed in duplicate for Ca and P concentration. Average values were reported and were used in diet formulation.

Table 2.

Diet composition for phases 1 to 4 diets (Exp. 1; as-fed basis)1

| Item | Phase 1 | Phase 2 | Phase 3 | Phase 4 |

|---|---|---|---|---|

| Ingredient, % | ||||

| Corn | 67.09–63.12 | 75.42–71.94 | 80.49–77.33 | 80.91–78.02 |

| Soybean meal, 46.5% CP | 29.97–30.25 | 21.79–22.04 | 16.88–17.10 | 16.82–17.02 |

| Beef tallow | 0.50–1.95 | 0.50–1.75 | 0.50–1.65 | 0.50–1.55 |

| Monocalcium phosphate, 21% P | 1.25 | 1.08 | 0.90 | 0.68 |

| Limestone | 0.20–2.44 | 0.25–2.23 | 0.28–2.06 | 0.29–1.92 |

| Sodium chloride | 0.35 | 0.35 | 0.35 | 0.35 |

| L-lysine HCl | 0.30 | 0.30 | 0.30 | 0.23 |

| DL-methionine | 0.09 | 0.06 | 0.04 | 0.01 |

| L-threonine | 0.10 | 0.09 | 0.10 | 0.08 |

| L-tryptophan | 0.01 | 0.01 | 0.02 | 0.01 |

| Vitamin and trace mineral premix2 | 0.15 | 0.15 | 0.15 | 0.15 |

| Total | 100.00 | 100.00 | 100.00 | 100.00 |

| Calculated analysis | ||||

| Standardized ileal digestible amino acids, % | ||||

| Lysine | 1.15 | 0.95 | 0.83 | 0.77 |

| Isoleucine:lysine | 63 | 62 | 61 | 66 |

| Leucine:lysine | 132 | 139 | 146 | 157 |

| Methionine:lysine | 32 | 32 | 31 | 30 |

| Methionine and cysteine:lysine | 56 | 57 | 58 | 59 |

| Threonine:lysine | 62 | 63 | 65 | 67 |

| Tryptophan:lysine | 18.9 | 18.6 | 18.7 | 18.8 |

| Valine:lysine | 69 | 69 | 70 | 75 |

| Total lysine, % | 1.29 | 1.07 | 0.94 | 0.88 |

| Net energy, kcal/kg | 2,469 | 2,520 | 2,553 | 2,557 |

| Crude protein, % | 19.4 | 16.0 | 14.1 | 13.9 |

| Calcium, % | 0.48–1.27 | 0.43–1.12 | 0.38–1.01 | 0.35–0.93 |

| STTD Ca3, % | 0.36–0.97 | 0.32–0.85 | 0.28–0.76 | 0.25–0.70 |

| Phosphorus, % | 0.64 | 0.57 | 0.51 | 0.47 |

| STTD P4, % | 0.38 | 0.33 | 0.29 | 0.25 |

| Available phosphorus, % | 0.32 | 0.28 | 0.24 | 0.19 |

| Calcium:phosphorus | 0.75:1–2.00:1 | 0.75:1–2.00:1 | 0.75:1–2.00:1 | 0.75:1–2.00:1 |

| STTD Ca:STTD P | 0.95:1–2.56:1 | 0.95:1–2.60:1 | 0.96:1–2.68:1 | 0.99:1–2.80:1 |

1Treatments were formulated to 0.75:1, 1.00:1, 1.25:1, 1.50:1, 1.75:1, and 2.00:1 analyzed calcium to analyzed phosphorus ratios across dietary phases. These represent a weighted average of 0.96:1, 1.30:1, 1.65:1, 1.98:1, 2.32:1, and 2.67:1 STTD Ca:STTD P ratios. Treatments were achieved with the addition of limestone at the expense of corn. Beef tallow was added to balance net energy across treatments. Phase 1 diets were fed from day 0 to 28 (26.3- to 50.2-kg BW), phase 2 from day 28 to 56 (50.2- to 78.2-kg BW), phase 3 from day 56 to 85 (78.2- to 107.8-kg BW), and phase 4 from day 85 to 110 (107.8- to 127.6-kg BW).

2Provided per kg of premix: 8,818,490 IU vitamin A; 1,102,311 IU vitamin D; 35,273 IU vitamin E; 3,527.4 mg vitamin K; 30.9 mg vitamin B12; 39,683 mg niacin; 22,046 mg pantothenic acid; 6,614 mg riboflavin, 165 g Zn from Zn sulfate; 165 g Fe from iron sulfate; 40 g Mn from manganese oxide; 17 g Cu from copper sulfate; 0.3 g I from calcium iodate; 0.3 g Se from sodium selenite.

3STTD Ca = standardized total tract digestible calcium. The STTD Ca were determined based on the analyzed Ca in feed ingredients and the coefficients for STTD of Ca in feed ingredients from Stein et al. (2016).

4STTD P = standardized total tract digestible phosphorus. The STTD P were determined based on the analyzed P in feed ingredients and the coefficients for STTD of P from NRC (2012).

Table 3.

Diet composition for phases 1 to 4 diets (Exp. 2; as-fed basis)1

| Item | Phase 1 | Phase 2 | Phase 3 | Phase 4 |

|---|---|---|---|---|

| Ingredient, % | ||||

| Corn | 67.85–64.83 | 76.19–73.60 | 81.22–78.99 | 81.56–79.50 |

| Soybean meal, 46.5% CP | 29.91–30.13 | 21.74–21.92 | 16.83–16.99 | 16.77–16.92 |

| Beef tallow | 0.50–1.60 | 0.50–1.45 | 0.50–1.30 | 0.50–1.25 |

| Monocalcium phosphate, 21% P | 0.48 | 0.30 | 0.15 | – |

| Limestone | 0.23–1.94 | 0.28–1.73 | 0.31–1.58 | 0.32 – 1.48 |

| Sodium chloride | 0.35 | 0.35 | 0.35 | 0.35 |

| L-lysine HCl | 0.30 | 0.30 | 0.30 | 0.23 |

| DL-methionine | 0.09 | 0.06 | 0.04 | 0.01 |

| L-threonine | 0.10 | 0.09 | 0.10 | 0.08 |

| L-tryptophan | 0.01 | 0.01 | 0.02 | 0.01 |

| Phytase2 | 0.04 | 0.04 | 0.04 | 0.04 |

| Vitamin and trace mineral premix3 | 0.15 | 0.15 | 0.15 | 0.15 |

| Total | 100.00 | 100.00 | 100.00 | 100.00 |

| Calculated analysis | ||||

| Standardized ileal digestible amino acids, % | ||||

| Lysine | 1.15 | 0.95 | 0.83 | 0.77 |

| Isoleucine:lysine | 63 | 62 | 61 | 66 |

| Leucine:lysine | 132 | 140 | 146 | 158 |

| Methionine:lysine | 32 | 32 | 31 | 30 |

| Methionine and cysteine:lysine | 56 | 57 | 58 | 59 |

| Threonine:lysine | 62 | 63 | 65 | 67 |

| Tryptophan:lysine | 18.9 | 18.6 | 18.7 | 18.8 |

| Valine:lysine | 69 | 69 | 70 | 75 |

| Total lysine, % | 1.29 | 1.07 | 0.94 | 0.88 |

| Net energy, kcal/kg | 2,489 | 2,540 | 2,571 | 2,575 |

| Crude protein, % | 19.4 | 16.1 | 14.1 | 14.0 |

| Analyzed calcium, % | 0.37–0.97 | 0.31–0.82 | 0.27–0.72 | 0.25–0.66 |

| Total calcium with phytase, % | 0.51–1.11 | 0.45–0.96 | 0.42–0.86 | 0.39–0.80 |

| STTD Ca4 with phytase, % | 0.35–0.78 | 0.31–0.67 | 0.27–0.59 | 0.26–0.55 |

| Phosphorus, % | 0.49 | 0.41 | 0.36 | 0.33 |

| STTD P5 with phytase, % | 0.38 | 0.33 | 0.29 | 0.26 |

| Available phosphorus, % | 0.32 | 0.27 | 0.24 | 0.21 |

| Analyzed calcium:phosphorus | 0.75:1–2.00:1 | 0.75:1–2.00:1 | 0.75:1–2.00:1 | 0.75:1–2.00:1 |

| STTD Ca:STTD P | 0.93:1–2.07:1 | 0.94:1–2.06:1 | 0.95:1–2.06:1 | 0.98:1–2.09:1 |

1Treatments were formulated to 0.75:1, 1.00:1, 1.25:1, 1.50:1, and 2.00:1 analyzed calcium to analyzed phosphorus ratios across dietary phases. These represent a weighted average of 0.95:1, 1.18:1, 1.40:1, 162:1, and 2.07:1 STTD Ca:STTD P ratios. Treatments were achieved with the addition of limestone at the expense of corn. Beef tallow was added to balance net energy across treatments. Phase 1 diets were fed from day 0 to 25 (25.3- to 44.6-kg BW), phase 2 from day 26 to 58 (44.6- to 74.4-kg BW), phase 3 from day 59 to 87 (64.4- to 103.0-kg BW), and phase 4 from day 88 to 114 (103.0- to 126.6-kg BW).

2Phytase (Ronozyme HiPhos, DSM Nutritional Products, Parsippany, NJ) was included at 1,000 FYT/kg releasing an assumed 0.15% aP, 0.132% STTD P, 0.144% total Ca, and 0.096% STTD Ca.

3Provided per kg of premix: 8,818,490 IU vitamin A; 1,102,311 IU vitamin D; 35,273 IU vitamin E; 3,527.4 mg vitamin K; 30.9 mg vitamin B12; 39,683 mg niacin; 22,046 mg pantothenic acid; 6,614 mg riboflavin; 165 g Zn from Zn sulfate; 165 g Fe from iron sulfate; 40 g Mn from manganese oxide; 17 g Cu from copper sulfate; 0.3 g I from calcium iodate; 0.3 g Se from sodium selenite.

4STTD Ca = standardized total tract digestible calcium. The STTD Ca were determined based on the analyzed Ca in feed ingredients and the coefficients for STTD of Ca in feed ingredients from Stein et al. (2016). These values also include the 0.096% STTD Ca release by phytase.

5STTD P = standardized total tract digestible phosphorus. The STTD P were determined based on the analyzed P in feed ingredients and the coefficients for STTD of P from NRC (2012). These values also include the 0.132% STTD P release by phytase.

The analyzed Ca:P ratios in Exp. 1 were achieved by increasing the amount of limestone at the expense of corn while maintaining monocalcium phosphate constant across treatments. No phytase was added to these diets. In Exp. 2, the diets contained 1,000 phytase units (FYT) of Ronozyme HiPhos 2500 (DSM Nutritional Products, Inc., Parsippany, NJ) with assumed release values of 0.15% available P, 0.132% STTD P, 0.144% total Ca, and 0.096% STTD Ca. Therefore, the STTD P and STTD Ca concentrations included the expected phytase release of 0.132% STTD P and 0.096% STTD Ca. The analyzed Ca:P ratios to form the dietary treatments represent the analyzed Ca and P in feed ingredients, without including any Ca release from phytase. The treatments were achieved by increasing the amount of limestone at the expense of corn while maintaining monocalcium phosphate constant across treatments. In both experiments, beef tallow was included in diets to equalize net energy across dietary treatments without giving phytase any energy value in the second experiment.

Pens of pigs were weighed, and feed disappearance was recorded on day 0, 28, 56, 85, and 110 in Exp. 1 and on day 0, 25, 58, 87, and 114 in Exp. 2 to determine average daily gain (ADG), average daily feed intake (ADFI), and gain-to-feed ratio (G:F). Removals and mortality were recorded, and the weight gain and feed consumption were accounted for in the analysis of the data.

Carcass and Bone Data Collection

The 2 heaviest pigs in each pen were selected, weighed, and marketed on day 86 in Exp. 1 and day 99 in Exp. 2 according to standard farm protocol. These pigs were included in calculation of pen growth performance, but not carcass characteristics. On day 110 and 114 in Exp. 1 and Exp. 2, respectively, final pen weights were taken, and 1 barrow and 1 gilt were identified to represent the mean individual pig weight of the pen, tattooed with a pen identification and marked for bone data collection. These pigs were transported to a commercial abattoir in northwest Iowa (Natural Food Holdings, Sioux Center, IA) for processing and bone collection. Following processing, the left front feet were separated at the junction of carpals and radius and ulna and individually placed in a zip-lock plastic bag with a permanent identification tag within the bag. These feet were transferred on dry ice to the Kansas State University Swine Laboratory and stored at −20 °C until analysis of bone mineral content.

The remaining pigs were individually tattooed with the specific pen identity on the shoulder to allow for carcass measurements to be recorded on a pen basis. These pigs were transported to a commercial packing plant in southwestern Minnesota (JBS Swift and Company, Worthington, MN) for processing and carcass data collection. Carcass measurements included hot carcass weight (HCW), loin depth, backfat depth, and percentage lean. Fat depth and loin depth were measured with an optical probe inserted between the third and fourth last rib (counting from the ham end of the carcass) at a distance approximately 7 cm from the dorsal midline. Percentage carcass yield was calculated by dividing the average pen HCW collected at the plant by the average final live weight at the farm before transport.

Bone Ash Analysis

After thawing overnight, the feet were autoclaved for 1 h at 121 °C. The third and fourth metacarpals of each foot were removed. These bones were cleaned of extraneous soft tissue, and refrozen. The third metacarpal was dried at ambient temperature for 24 h and cut in half and weighed. They were wrapped in cheesecloth to keep their tag identification number and defatted by petroleum ether using a Soxhlet apparatus for 7 d. Defated metacarpals were placed in a drying oven at 105 °C for 24 h to determine dry fat-free weight. Bones were then ashed in a muffle furnace at 600 °C for another 24 h to determine percentage ash. Ash is expressed as a percentage of dried fat-free bone weight.

Chemical Analysis

Representative diet samples were obtained from 6 feeders of each treatment approximately 3 d after the beginning and 3 d before the end of the phase and delivered to the Kansas State University Swine Laboratory, Manhattan, KS, and stored at −20 °C until analysis. Samples of the diets were combined within dietary treatment, and a composite sample from each treatment was analyzed in duplicate (Ward Laboratories, Inc., Kearney, NE; Tables 5 and 6). Samples were analyzed for Ca and P (method 985.01; AOAC International, 1990).

Table 5.

Chemical analysis of experimental diets (Exp. 2; as-fed basis)1,2

| Analyzed Ca:P ratio: | 0.75:1 | 1.00:1 | 1.25:1 | 1.50:1 | 2.00:1 | |

|---|---|---|---|---|---|---|

| Item | STTD Ca:STTD P ratio2: | 0.95:1 | 1.18:1 | 1.40:1 | 1.62:1 | 2.07:1 |

| Calcium (Ca), % | ||||||

| Phase 1 | 0.47 | 0.53 | 0.70 | 0.84 | 0.97 | |

| Phase 2 | 0.33 | 0.38 | 0.56 | 0.69 | 0.87 | |

| Phase 3 | 0.30 | 0.41 | 0.54 | 0.62 | 0.87 | |

| Phase 4 | 0.27 | 0.36 | 0.50 | 0.48 | 0.81 | |

| Phosphorus (P), % | ||||||

| Phase 1 | 0.54 | 0.53 | 0.53 | 0.54 | 0.52 | |

| Phase 2 | 0.45 | 0.45 | 0.46 | 0.47 | 0.46 | |

| Phase 3 | 0.39 | 0.41 | 0.39 | 0.41 | 0.40 | |

| Phase 4 | 0.36 | 0.35 | 0.38 | 0.35 | 0.36 | |

| Ca:P ratio | ||||||

| Phase 1 | 0.87:1 | 1.00:1 | 1.32:1 | 1.56:1 | 1.87:1 | |

| Phase 2 | 0.73:1 | 0.84:1 | 1.22:1 | 1.47:1 | 1.89:1 | |

| Phase 3 | 0.77:1 | 1.00:1 | 1.38:1 | 1.51:1 | 2.18:1 | |

| Phase 4 | 0.75:1 | 1.03:1 | 1.32:1 | 1.37:1 | 2.25:1 |

1Representative samples of treatment diets were taken from 6 feeders per dietary treatment 3 d after the beginning and 3 d before the end of the phase and stored at −20 °C. After blending, subsamples were submitted to Ward Laboratories, Inc. (Kearney, NE) and Midwest Laboratories (Omaha, NE) for analyses in duplicate. Values represent the average across laboratories.

2Coefficients for standardized total tract digestibility (STTD) of P were obtained from NRC (2012), while values for STTD Ca in feed ingredients were obtained from Stein et al. (2016). These represent a weighted average of the ratio between STTD Ca:STTD P across treatments for the 4 dietary phases.

Table 6.

Least square means for growth performance, carcass characteristics, and bone mineralization of growing-finishing pigs fed increasing analyzed calcium to analyzed phosphorus (Ca:P) ratio from 26- to 127-kg body weight (BW) in Exp. 11

| Analyzed Ca:P ratio2: | 0.75:1 | 1.00:1 | 1.25:1 | 1.50:1 | 1.75:1 | 2.00:1 | SEM | P-value | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Item3 | STTD Ca:STTD P4: | 0.96:1 | 1.30:1 | 1.65:1 | 1.98:1 | 2.32:1 | 2.67:1 | Linear | Quadratic | |

| Grower period (day 0 to 56) | ||||||||||

| ADG, g | 902 | 930 | 927 | 910 | 943 | 923 | 11.1 | 0.129 | 0.279 | |

| ADFI, g | 1,913 | 1,911 | 1,934 | 1,906 | 1,949 | 1,961 | 31.9 | 0.073 | 0.439 | |

| G:F, g/kg | 472 | 487 | 480 | 478 | 485 | 471 | 5.0 | 0.791 | 0.037 | |

| Finisher period (day 56 to 110) | ||||||||||

| ADG, g | 942 | 977 | 994 | 985 | 951 | 932 | 18.6 | 0.390 | 0.009 | |

| ADFI, g | 2,811 | 2,979 | 2,970 | 2,941 | 2,860 | 2,866 | 37.1 | 0.708 | 0.002 | |

| G:F, g/kg | 335 | 328 | 335 | 3,335 | 333 | 325 | 5.4 | 0.388 | 0.400 | |

| Overall period (day 0 to 110) | ||||||||||

| ADG, g | 923 | 955 | 961 | 949 | 950 | 929 | 10.4 | 0.953 | 0.005 | |

| ADFI, g | 2,338 | 2,408 | 2,419 | 2,396 | 2,382 | 2,383 | 28.8 | 0.483 | 0.028 | |

| G:F, g/kg | 395 | 397 | 398 | 396 | 399 | 390 | 3.9 | 0.479 | 0.116 | |

| BW, kg | ||||||||||

| Day 0 | 26.3 | 26.3 | 26.3 | 26.3 | 26.3 | 26.3 | 0.71 | 0.967 | 0.860 | |

| Day 56 | 77.1 | 78.6 | 78.6 | 77.6 | 79.2 | 78.1 | 1.14 | 0.262 | 0.203 | |

| Day 110 | 124.9 | 129.0 | 130.0 | 128.2 | 127.9 | 125.6 | 1.72 | 0.906 | 0.006 | |

| Carcass characteristics5 | ||||||||||

| HCW, kg | 93.0 | 95.9 | 96.2 | 94.6 | 94.4 | 92.7 | 1.18 | 0.298 | 0.003 | |

| Yield, % | 74.5 | 74.4 | 74.0 | 73.8 | 73.8 | 73.8 | 0.33 | 0.066 | 0.471 | |

| Backfat, mm6 | 16.8 | 16.3 | 16.8 | 16.9 | 16.3 | 16.5 | – 7 | 0.584 | 0.823 | |

| Fat-free lean, %6 | 56.8 | 56.7 | 56.9 | 57.1 | 57.3 | 57.0 | – 7 | 0.236 | 0.832 | |

| Loin depth, mm6 | 68.4 | 69.0 | 68.8 | 70.9 | 69.7 | 68.3 | – 7 | 0.597 | 0.067 | |

| Bone characteristics8 | ||||||||||

| Ash, %6,9 | 61.2 | 61.5 | 62.4 | 62.3 | 62.4 | 62.5 | 0.19 | <0.001 | 0.017 | |

1A total of 1,134 pigs (PIC 359 × 1050, initially 26.3 kg) were used in a 110-d growth trial with 27 pigs per pen and 7 pens per treatment.

2Treatments were formulated to be adequate in standardized total tract digestible phosphorus (STTD P) within phases, which corresponded to 0.38, 0.32, 0.29, and 0.26% STTD P for phases 1, 2, 3, and 4, respectively.

3ADG = average daily gain; ADFI = average daily feed intake; G:F = gain-to-feed ratio; HCW = hot carcass weight.

4Coefficients for standardized total tract digestibility (STTD) of P were obtained from NRC (2012), while values for STTD Ca in feed ingredients were obtained from Stein et al. (2016). These represent a weighted average of the ratio between STTD Ca:STTD P across treatments for the 4 dietary phases.

5Nine hundred and seven pigs were transported to a commercial packing plant for processing and data collection (Swift and Company, Worthington, MN).

6Adjusted for HCW.

7SEM for backfat were 0.31, 0.30, 0.29, 0.29, and 0.29; SEM for fat free lean were 0.30, 0.29, 0.28, 0.28, 0.28, and 0.28; SEM for loin depth were 0.84, 0.82, 0.81, 0.81, 0.80, and 0.81 for 0.75:1, 1.00:1, 1.25:1, 1.50:1, 1.75:1, and 2.00:1 analyzed total Ca:P, respectively.

8Eighty-four pigs (2 pigs per pen, 1 barrow/1 gilt) visually assumed to represent the mean live weight of the pen were subsampled and shipped to a separate processing facility for bone collection (Natural Foods Holdings, Inc., Sioux Center, IA). A total of 84 third metacarpals were autoclaved for 1 h. After cleaning, bones were placed in Soxhlets containing petroleum ether for 7 d as a means of removing water and fat. They were then dried at 105 °C for 7 d, and then ashed at 600 °C for 24 h.

9The 2-way interaction and the effect of gender were tested and no evidence for significant effects was observed.

Statistical Analysis

Experimental growth data were analyzed as a randomized complete block design with block as a random effect and pen as the experimental unit. The study was structured as a split-plot design in a randomized complete block design for the bone data for both trials. The whole-plot treatments included the different Ca:P ratios. Within each of the dietary treatments, there was a 1-way treatment structure with gender as the factor level. A random effect of block by treatment was used to identify the pair of pigs (1 barrow and 1 gilt) within each pen as the experimental unit for gender. The 2-way interaction between dietary treatments and sex was tested. Response variables were analyzed using generalized linear and nonlinear mixed models. Polynomial contrasts were implemented to evaluate the functional form of the dose response to increasing dietary Ca:P ratios on ADG, ADFI, G:F, BW, percentage bone ash, HCW, carcass yield, carcass backfat, carcass fat-free lean, and carcass loin depth. Backfat depth, loin depth, and percentage lean were adjusted to a common HCW. The Kenward–Roger method was used to adjust the denominator degrees of freedom and correct the standard errors for bias (Littell et al., 2006). The coefficients for the unequally spaced linear and quadratic contrasts in Exp. 2 were derived using the IML procedure in SAS (Version 9.3, SAS Institute Inc., Cary, NC). Statistical models were fit using GLIMMIX procedure of SAS. Results were considered significant at P ≤ 0.05 and marginally significant at 0.05 < P ≤ 0.10.

In addition, the effects of the analyzed Ca:P ratios and STTD Ca:STTD P ratios on overall ADG, ADFI, G:F, HCW, and percentage bone ash were fit using procedures outlined by Gonçalves et al. (2016). Briefly, models were expanded to account for heterogeneous residual variances when needed. Competing statistical models included a linear (LM), quadratic polynomial (QP), broken-line linear (BLL), and broken-line quadratic (BLQ). Dose response models were compared based on the Bayesian information criterion (BIC), where the smaller the value, the better (Milliken and Johnson, 2009). A decrease in BIC greater than 2 was considered a significant improvement in model fit. The 95% confidence interval (CI) of the estimated requirement to reach maximum performance or to reach plateau performance was computed. Results reported correspond to inferences based on the best fitting models.

RESULTS

Chemical Analysis

In both Exp. 1 and Exp. 2, the analyzed Ca and P contents of experimental diets were consistent with formulated values (Tables 4 and 5). In Exp. 1, the average Ca:P ratio across the 4 phases were consistent with formulated values at 0.77:1, 1.02:1, 1.25:1, 1.55:1, 1.77:1, and 2.07:1 for the 0.75:1, 1.00:1, 1.25:1, 1.50:1, 1.75:1, and 2.00:1 treatments, respectively. In Exp. 2, the average Ca:P ratio across the 4 phases were also similar to formulated values at 0.78:1, 0.97:1, 1.32:1, 1.47:1, and 2.06:1 for the 0.75:1, 1.00:1, 1.25, 1.50, and 2.00:1 treatments, respectively.

Table 4.

Chemical analysis of experimental diets (Exp. 1; as-fed basis)1

| Analyzed Ca:P ratio: | 0.75:1 | 1.00:1 | 1.25:1 | 1.50:1 | 1.75:1 | 2.00:1 | |

|---|---|---|---|---|---|---|---|

| Item | STTD Ca:STTD P ratio2: | 0.96:1 | 1.30:1 | 1.65:1 | 1.98:1 | 2.32:1 | 2.67:1 |

| Calcium (Ca), % | |||||||

| Phase 1 | 0.49 | 0.74 | 1.08 | 1.24 | 1.37 | 1.74 | |

| Phase 2 | 0.62 | 0.97 | 0.85 | 1.12 | 1.31 | 1.33 | |

| Phase 3 | 0.47 | 0.68 | 0.74 | 0.95 | 1.03 | 1.33 | |

| Phase 4 | 0.41 | 0.48 | 0.73 | 0.88 | 1.12 | 1.13 | |

| Phosphorus (P), % | |||||||

| Phase 1 | 0.70 | 0.80 | 0.83 | 0.76 | 0.80 | 0.78 | |

| Phase 2 | 0.70 | 0.73 | 0.71 | 0.70 | 0.72 | 0.67 | |

| Phase 3 | 0.64 | 0.69 | 0.67 | 0.68 | 0.68 | 0.64 | |

| Phase 4 | 0.55 | 0.58 | 0.52 | 0.56 | 0.55 | 0.57 | |

| Ca:P ratio | |||||||

| Phase 1 | 0.70:1 | 0.93:1 | 1.30:1 | 1.63:1 | 1.71:1 | 2.23:1 | |

| Phase 2 | 0.89:1 | 1.33:1 | 1.20:1 | 1.60:1 | 1.82:1 | 1.99:1 | |

| Phase 3 | 0.73:1 | 0.99:1 | 1.10:1 | 1.40:1 | 1.51:1 | 2.08:1 | |

| Phase 4 | 0.75:1 | 0.83:1 | 1.40:1 | 1.57:1 | 2.04:1 | 1.98:1 |

1Representative samples of treatment diets were taken from 6 feeders per dietary treatment 3 d after the beginning and 3 d before the end of the phase and stored at −20 °C. After blending, subsamples were submitted to Ward Laboratories, Inc. (Kearney, NE) and Midwest Laboratories (Omaha, NE) for analyses in duplicate. Values represent the average across laboratories.

2Coefficients for standardized total tract digestibility (STTD) of P were obtained from NRC (2012), while values for STTD Ca in feed ingredients were obtained from Stein et al. (2016). These represent a weighted average of the ratio between STTD Ca:STTD P across treatments for the 4 dietary phases.

Experiment 1

During the grower period, which corresponds to phases 1 and 2 (day 0 to 56), there was no evidence of differences (P > 0.05) in ADG as the ratio between Ca and P increased (Table 6). In contrast, increasing Ca:P ratio resulted in a marginal increase (linear, P < 0.10) in ADFI, and in an improvement (quadratic, P < 0.05) in G:F. The greatest improvement in G:F occurred as the analyzed Ca:P ratio increased from 0.75:1 to 1.00:1, which is equivalent to increasing STTD Ca:STTD P from 0.96:1 to 1.30:1, and then it worsened at the highest ratio of 2.00:1 analyzed Ca:P (2.67:1 STTD Ca:STTD P). During the finisher period, which corresponds to phases 3 and 4 (day 56 to 110), increasing the Ca:P ratio resulted in an increase (quadratic, P < 0.05) in ADG driven by an increase (quadratic, P < 0.05) in ADFI. The greatest improvement occurred as the analyzed Ca:P ratio increased from 0.75:1 to 1.25:1 for ADG, which represents an increase in STTD Ca:STTD P ratio from 0.96:1 to 1.65:1, and from 0.75:1 to 1.00:1 analyzed Ca:P or 0.96:1 to 1.30:1 STTD Ca:STTD P for ADFI, and then started to decrease at the higher ratios. Overall, increasing Ca:P ratio increased (quadratic, P < 0.05) ADG, ADFI, and final BW. The greatest increase was observed as the ratio increased from 0.75:1 to 1.25:1 analyzed Ca:P (0.96:1 to 1.65:1 STTD Ca:STTD P), decreasing at the higher ratios. Feed efficiency was relatively similar from an analyzed Ca:P ratio of 0.75:1 to 1.75:1 (0.96:1 to 2.32:1 STTD Ca:STTD P), and started to worsen (quadratic, P < 0.05) at the highest ratios.

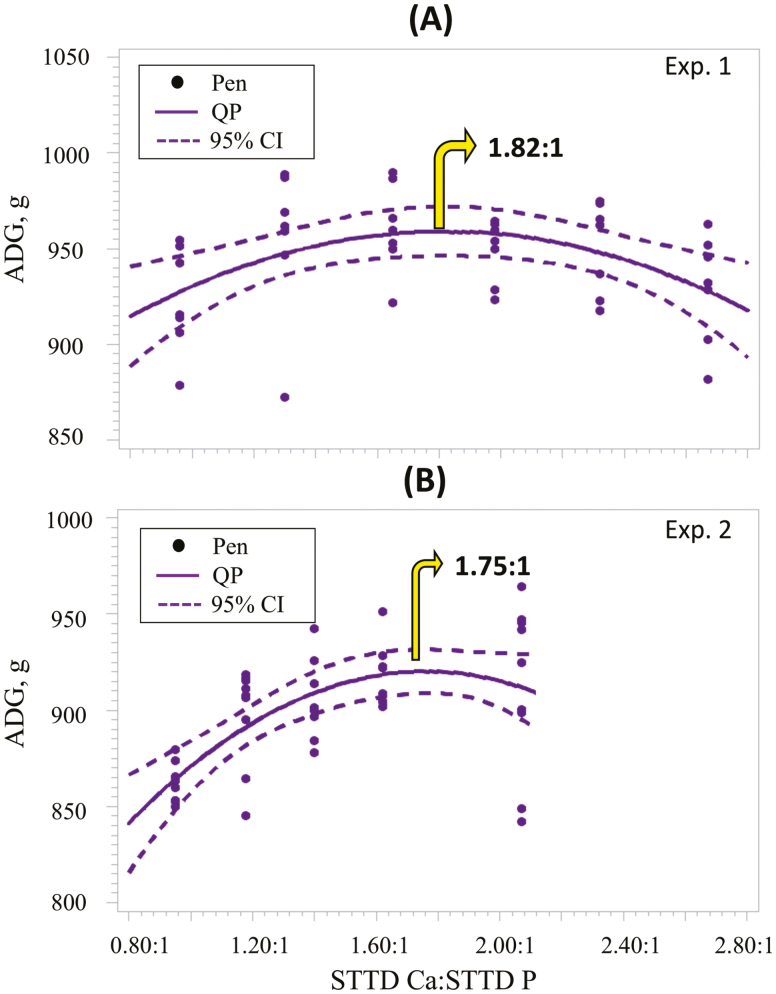

Homogeneous variance was used for ADG and heterogeneous variance was used for ADFI and G:F models (Tables 8 and 9). The QP model estimated the analyzed Ca:P ratio for maximum ADG at 1.38:1 (95% CI: 1.00:1, 1.75:1). Similarly, the QP model had the best fit for ADG as a function of STTD Ca:STTD P (Fig. 1A), estimating the maximum mean ADG at 1.82:1 (95% CI: 1.30:1, 2.31:1). The QP model estimated the maximum mean ADFI at 1.49:1 analyzed Ca:P ratio (95% CI: 0.90:1, >2.00:1). Both the QP and BLL had similar fit to the ADFI data as a function of increasing STTD Ca:STTD P, estimating the maximum mean ADFI at 1.97:1 (95% CI: 1.30:1, >2.67:1) and 1.30:1 (95% CI: 0.93:1, 1.67:1), respectively. The analyzed Ca:P ratio for maximum mean G:F was estimated at 1.29:1 (95% CI: <0.75:1, >2.00:1) based on the QP model. Also based on the QP model, the STTD Ca:STTD P ratio for maximum mean G:F was estimated at 1.69:1 (95% CI: <0.96:1, >2.67:1).

Table 8.

Best fitting models and calcium (Ca) to phosphorus (P) ratio for maximum response for different variables in Exp. 1 and Exp. 21

| Analyzed Ca:P | STTD Ca:STTD P2 | ||||

|---|---|---|---|---|---|

| Item3 | Best fitting model4 | Maximum response | 95% CI5 | Maximum response | 95% CI5 |

| Experiment 16 | |||||

| ADG | QP | 1.38:1 | 1.00:1, 1.75:1 | 1.82:1 | 1.30:1, 2.31:1 |

| ADFI | QP | 1.49:1 | 0.90:1, >2.00:1 | 1.97:1 | 1.30:1, >2.67:1 |

| ADFI | BLL | – | – | 1.30:1 | 0.93:1, 1.67:1 |

| G:F | QP | 1.29:1 | <0.75:1, >2.00:1 | 1.69:1 | <0.96:1, >2.67:1 |

| HCW | QP | 1.25:1 | 0.86:1, 1.72:1 | 1.64:1 | 1.07:1, 2.31:1 |

| Bone ash | QP | 1.93:1 | 1.40:1, >2.00:1 | 2.57:1 | 1.85:1, >2.67:1 |

| Experiment 27 | |||||

| ADG | QP | 1.63:1 | 1.25:1, >2.00:1 | 1.75:1 | 1.40:1, >2.07:1 |

| ADFI | LM | 2.00:1 | – | ≥2.07:1 | – |

| G:F | BLL | 1.05:1 | 0.81:1, 1.30:1 | – | – |

| G:F | LM | – | – | ≥2.07:1 | – |

| HCW | QP | 1.60:1 | 1.14:1, >2.00:1 | 1.71:1 | 1.28:1, >2.07:1 |

| HCW | BLL | 1.11:1 | 0.87:1, 1.36:1 | 1.28:1 | 1.06:1, 1.50:1 |

| Bone ash | BLL | 1.25:1 | 1.20:1, 1.40:1 | 1.40:1 | 1.26:1, 1.54:1 |

1A total of 1,134 and 1,214 pigs (PIC 359 × 1050, initially 26.3 and 25.3 kg) were used in a 110-d and 114-d growth trials with 27 pigs per pen and 7 and 9 pens per treatment in Exp. 1 and in Exp. 2, respectively.

2Coefficients for standardized total tract digestibility (STTD) of P were obtained from NRC (2012), while values for STTD Ca in feed ingredients were obtained from Stein et al. (2016). These represent a weighted average of the ratio between STTD Ca:STTD P across treatments for the 4 dietary phases.

3ADG = average daily gain; ADFI = average daily feed intake; G:F = gain-to-feed ratio; HWC = hot carcass weight.

4Results represent inferences yield based on the best fitting models. The best fitting models were selected based on the Bayesian Information Criteria (Miliken and Johnson, 2009). The competing models included a linear (LM), quadratic polynomial (QP), broken-line linear (BLL), and broken-line quadratic (BLQ).

5CI = confidence interval.

6Treatments were formulated to 0.75:1, 1.00:1, 1.25:1, 1.50:1, 1.75:1, and 2.00:1 analyzed calcium to analyzed phosphorus ratios across dietary phases. These represent a weighted average of 0.96:1, 1.30:1, 1.65:1, 1.98:1, 2.32:1, and 2.67:1 STTD Ca:STTD P ratios. Treatments were achieved with the addition of limestone at the expense of corn.

7Treatments were formulated to 0.75:1, 1.00:1, 1.25:1, 1.50:1, and 2.00:1 analyzed calcium to analyzed phosphorus ratios across dietary phases. These represent a weighted average of 0.95:1, 1.18:1, 1.40:1, 162:1, and 2.07:1 STTD Ca:STTD P ratios. Treatments were achieved with the addition of limestone at the expense of corn. Phytase (Ronozyme HiPhos, DSM Nutritional Products, Parsippany, NJ) was included at 1,000 FYT/kg releasing an assumed 0.15% aP, 0.132% STTD P, 0.144% total Ca, and 0.096% STTD Ca.

Table 9.

Equations based on the best fitting models for different response criteria in Exp. 1 and Exp. 21,2,3

| Item4 | Equations |

|---|---|

| Experiment 1 Analyzed Ca:P | |

| ADG, g | = 806.20 + 222.10 × (analyzed Ca:P) − 80.5513 × (analyzed Ca:P)2 |

| ADFI, g | = 2,219.21 + 245.73 × (analyzed Ca:P) − 82.6743 × (analyzed Ca:P)2 |

| G:F, g/kg | = 376.77 + 33.5039 × (analyzed Ca:P) − 13.0113 × (analyzed Ca:P)2 |

| HCW, kg | = 87.87 + 11.359 × (analyzed Ca:P) − 4.542 × (analyzed Ca:P)2 |

| Bone ash, % | = 58.91 + 3.67229 × (analyzed Ca:P) − 0.95170 × (analyzed Ca:P)2 |

| Experiment 1 STTD Ca:STTD P5 | |

| ADG, g | = 817.31 + 155.98 × (STTD Ca:STTD P) − 42.8764 × (STTD Ca:STTD P)2 |

| ADFI, g | = 2,231.27 + 173.21 × (STTD Ca:STTD P) − 44.0058 × (STTD Ca:STTD P)2 |

| ADFI, g | = 2,392.79 − 161.07 × (1.2988 − STTD Ca:STTD P) if STTD Ca:STTD P ratio < 1.30:1 |

| = 2,392.79 if STTD Ca:STTD P ratio ≥ 1.30:1 | |

| G:F, g/kg | = 378.33 + 23.6212 × (STTD Ca:STTD P) − 6.9747 × (STTD Ca:STTD P)2 |

| HCW, kg | = 194.96 + 17.5016 × (STTD Ca:STTD P) − 5.3251 × (STTD Ca:STTD P)2 |

| Bone ash, % | = 59.068 + 2.63163 × (STTD Ca:STTD P) − 0.51217 × (STTD Ca:STTD P)2 |

| Experiment 2 Analyzed Ca:P | |

| ADG, g | = 729.12 + 233.25 × (analyzed Ca:P) − 71.3315 × (analyzed Ca:P)2 |

| ADFI, g | = 2,109.55 + 98.8323 × (analyzed Ca:P) |

| G:F, g/kg | = 406.43 − 31.4661 × (1.0543 − analyzed Ca:P) if analyzed Ca:P ratio < 1.05:1 |

| = 406.43 if analyzed Ca:P ratio ≥ 1.05:1 | |

| HCW, kg | = 80.862 + 17.112 × (analyzed Ca:P) − 5.351 × (analyzed Ca:P)2 |

| HCW, kg | = 94.03 − 9.622 × (1.11 − analyzed Ca:P) if analyzed Ca:P ratio < 1.11:1 |

| = 94.03 if analyzed Ca:P ratio ≥ 1.11:1 | |

| Bone ash, % | = 61.83 − 2.65158 × (1.25 − analyzed Ca:P) if analyzed Ca:P ratio < 1.25:1 |

| = 61.83 if analyzed Ca:P ratio ≥ 1.25:1 | |

| Experiment 2 STTD Ca:STTD P | |

| ADG, g | = 650.05 + 309.12 × (STTD Ca:STTD P) − 88.5666 × (STTD Ca:STTD P)2 |

| ADFI, g | = 2,068.89 + 114.64 × (STTD Ca:STTD P) |

| G:F, g/kg | = 393.25 + 7.5673 × (STTD Ca:STTD P) |

| HCW, kg | = 75.051 + 22.761 × (STTD Ca:STTD P) − 6.646 × (STTD Ca:STTD P)2 |

| HCW, kg | = 94.03 − 10.574 × (1.2787 − STTD Ca:STTD P) if STTD Ca:STTD P ratio < 1.28:1 |

| = 94.03 if STTD Ca:STTD P ratio ≥ 1.28:1 | |

| Bone ash, % | = 61.827 − 2.94931 × (1.40 − STTD Ca:STTD P) if STTD Ca:STTD P ratio < 1.40:1 |

| = 61.827 if STTD Ca:STTD P ratio ≥ 1.40:1 |

1A total of 1,134 and 1,214 pigs (PIC 359 × 1050, initially 26.3 and 25.3 kg) were used in a 110-d and 114-d growth trials with 27 pigs per pen and 7 and 9 pens per treatment in Exp. 1 and in Exp. 2, respectively.

2Treatments were formulated to 0.75:1, 1.00:1, 1.25:1, 1.50:1, 1.75:1, and 2.00:1 analyzed calcium to analyzed phosphorus ratios across dietary phases. These represent a weighted average of 0.96:1, 1.30:1, 1.65:1, 1.98:1, 2.32:1, and 2.67:1 STTD Ca:STTD P ratios. Treatments were achieved with the addition of limestone at the expense of corn.

3Treatments were formulated to 0.75:1, 1.00:1, 1.25:1, 1.50:1, and 2.00:1 analyzed calcium to analyzed phosphorus ratios across dietary phases. These represent a weighted average of 0.95:1, 1.18:1, 1.40:1, 162:1, and 2.07:1 STTD Ca:STTD P ratios. Treatments were achieved with the addition of limestone at the expense of corn. Phytase (Ronozyme HiPhos, DSM Nutritional Products, Parsippany, NJ) was included at 1,000 FYT/kg releasing an assumed 0.15% aP, 0.132% STTD P, 0.144% total Ca, and 0.096% STTD Ca.

4Ca = calcium; P = phosphorus; ADG = average daily gain; ADFI = average daily feed intake; G:F = gain-to-feed ratio; HWC = hot carcass weight.

5Coefficients for standardized total tract digestibility (STTD) of P were obtained from NRC (2012), while values for STTD Ca in feed ingredients were obtained from Stein et al. (2016). These represent a weighted average of the ratio between STTD Ca:STTD P across treatments for the 4 dietary phases.

Figure 1.

Fitted quadratic polynomial (QP) regression model on average daily gain (ADG) as a function of increasing standardized total tract digestible (STTD) Ca:STTD P ratio in growing-finishing pigs. (A) In Exp. 1, the QP model estimated the maximum mean ADG at 1.82:1 STTD Ca:STTD P ratio (95% CI: 1.30:1, 2.31:1). The estimated regression equation was ADG, g = 817.31 + 155.98 × (STTD Ca:STTD P) − 42.8764 × (STTD Ca:STTD P)2. (B) In Exp. 2, the QP model estimated the maximum mean ADG at 1.75:1 STTD Ca:STTD P ratio (95% CI: 1.40:1, >2.07:1). Based on the best fitting model, the estimated regression equation was ADG, g = 650.05 + 309.12 × (STTD Ca:STTD P) − 88.5666 × (STTD Ca:STTD P)2.

For carcass characteristics, HCW increased (quadratic, P < 0.05) as the analyzed Ca:P ratio increased up to 1:25:1 and the STTD Ca:STTD P ratio increased up to 1.65:1, and started to decrease thereafter (Table 6). Percentage carcass yield decreased (linear, P < 0.10), with the greatest decrease as analyzed Ca:P ratio increased to 1.50:1 (1.98:1 STTD Ca:STTD P), with no further changes at the higher ratios. There was also a marginally significant response (quadratic, P < 0.10) in loin depth, with the greatest improvement occurring up to 1:50:1 analyzed Ca:P ratio, which represents 1.98:1 STTD Ca:STTD P ratio. No statistically significant differences (P > 0.10) were observed for carcass backfat and fat-free lean measurements. Heterogeneous variance was used to model HCW, with the QP model best fitting the HCW data (Tables 8 and 9). The QP model estimated the maximum mean HCW at 1.25:1 analyzed Ca:P ratio (95% CI: 0.86:1, 1.72:1) and at 1.64:1 STTD Ca:STTD P ratio (95% CI: 1.07:1, 2.31:1).

For bone mineralization, the 2-way interaction between dietary treatment and gender was tested and no evidence (P > 0.10) for a significant interaction was observed (Table 6). There was also no evidence (P > 0.10) for a significant gender effect on percentage bone ash (62.1% and 62.0% for barrows and gilts, respectively). Bone mineralization increased (quadratic, P < 0.05) with increasing Ca and P ratio. The greatest improvement in percentage bone ash was observed as analyzed Ca:P ratio increased from 0.75:1 to 1.25:1 or from 0.96:1 to 1.65:1 STTD Ca:STTD P, with diminishing returns thereafter. Heterogeneous variance was used to model percentage bone ash, with the QP model representing the best fit (Tables 8 and 9). The maximum mean percentage bone ash as a function of analyzed Ca:P ratio was estimated at 1.93:1 (95% CI: 1.40:1, >2.00:1), with 99.8% of maximum bone ash achieved at 1.63:1 analyzed Ca:P. The maximum mean percentage bone ash as a function of STTD Ca:STTD P was estimated at 2.57:1 (95% CI: 1.85:1, >2.67:1), with 99.5% of maximum bone ash achieved at 1.82:1 STTD Ca:STTD P.

Experiment 2

During the grower period, which corresponds to phases 1 and 2 (day 0 to 58), there was a marginal increase (quadratic, P < 0.10) in ADG with the greatest gain observed at 1.50:1 analyzed Ca:P ratio, which is equivalent to 1.62:1 STTD Ca:STTD P, with no improvements thereafter (Table 7). However, there was no evidence (P > 0.10) of differences in ADFI and G:F due to increasing Ca:P ratio. During the finisher period, which corresponds to phases 3 and 4 (day 59 to 114), increasing Ca:P ratio resulted in an increase (quadratic, P < 0.05) in ADG driven by an increase (quadratic, P < 0.05) in ADFI. The greatest improvements in ADG and ADFI were observed as the ratio increased to 1.25:1 analyzed Ca:P, which is equivalent to 1.40:1 STTD P, with no further benefits at higher ratios. Feed efficiency improved (linear, P < 0.05) as the ratio increased up to the highest ratio of 2.00:1 analyzed Ca:P (2.07:1 STTD Ca:STTD P).

Table 7.

Least square means for growth performance, carcass characteristics, and bone mineralization of growing-finishing pigs fed increasing analyzed calcium to analyzed phosphorus (Ca:P) ratio from 26- to 127-kg body weight (BW) in Exp. 21

| Item4 | Analyzed Ca:P ratio2,3: | 0.75:1 | 1.00:1 | 1.25:1 | 1.50:1 | 2.00:1 | SEM | P-value | |

|---|---|---|---|---|---|---|---|---|---|

| STTD Ca:STTD P5: | 0.95:1 | 1.18:1 | 1.40:1 | 1.62:1 | 2.07:1 | Linear | Quadratic | ||

| Grower period (day 0 to 58) | |||||||||

| ADG, g | 820 | 838 | 830 | 852 | 830 | 12.3 | 0.390 | 0.061 | |

| ADFI, g | 1,695 | 1,701 | 1,694 | 1,742 | 1,706 | 37.7 | 0.349 | 0.289 | |

| G:F, g/kg | 485 | 494 | 491 | 489 | 487 | 5.7 | 0.908 | 0.179 | |

| Finisher period (day 59 to 114) | |||||||||

| ADG, g | 895 | 952 | 980 | 982 | 994 | 11.7 | <0.001 | 0.001 | |

| ADFI, g | 2,685 | 2,769 | 2,814 | 2,825 | 2,816 | 41.8 | 0.011 | 0.044 | |

| G:F, g/kg | 334 | 344 | 345 | 348 | 354 | 5.7 | 0.002 | 0.229 | |

| Overall (day 0 to 114) | |||||||||

| ADG, g | 861 | 898 | 905 | 918 | 913 | 8.6 | <0.001 | 0.001 | |

| ADFI, g | 2,173 | 2,220 | 2,228 | 2,269 | 2,245 | 37.1 | 0.025 | 0.090 | |

| G:F, g/kg | 397 | 405 | 407 | 405 | 407 | 4.7 | 0.018 | 0.116 | |

| BW, kg | |||||||||

| Day 0 | 25.3 | 25.3 | 25.4 | 25.3 | 25.3 | 0.93 | 0.924 | 0.766 | |

| Day 58 | 73.6 | 74.5 | 74.3 | 75.4 | 74.2 | 1.55 | 0.427 | 0.096 | |

| Day 114 | 121.8 | 127.3 | 127.8 | 128.7 | 127.3 | 1.80 | 0.001 | <0.001 | |

| Carcass characteristics6 | |||||||||

| HCW, kg | 90.4 | 92.9 | 93.6 | 94.6 | 94.0 | 1.33 | 0.002 | 0.014 | |

| Yield, % | 74.4 | 73.1 | 73.2 | 73.5 | 73.6 | 0.42 | 0.550 | 0.090 | |

| Backfat, mm7 | 16.1 | 16.0 | 16.5 | 16.2 | 16.2 | – 8 | 0.855 | 0.604 | |

| Fat-free lean, %7 | 57.4 | 57.5 | 57.2 | 57.2 | 57.3 | – 8 | 0.650 | 0.615 | |

| Loin depth, mm7 | 69.5 | 70.2 | 69.8 | 68.7 | 69.2 | – 8 | 0.406 | 0.984 | |

| Bone characteristics9 | |||||||||

| Ash, %7,10 | 60.5 | 61.1 | 61.9 | 61.8 | 61.8 | 0.19 | <0.001 | 0.001 |

1A total of 1,214 pigs (PIC 337 × 1050, initial pen average BW of 25.3 kg) were used in a 114-d growth trial with 27 pigs per pen and 9 pens per treatment.

2Treatments were formulated to be adequate in STTD P within phases, which corresponded to 0.38, 0.32, 0.29, and 0.26% STTD P for phases 1, 2, 3, and 4, respectively.

3Phytase (Ronozyme HiPhos, DSM Nutritional Products, Parsippany, NJ) was added to the diets at 1,000 FYT/kg feed with assumed release values of 0.15% avP, 0.132% STTD P, 0.144% total Ca, and 0.096% STTD Ca.

4ADG = average daily gain; ADFI = average daily feed intake; G:F = gain-to-feed ratio; HWC = hot carcass weight.

5Coefficients for standardized total tract digestibility (STTD) of P were obtained from NRC (2012), while values for STTD Ca in feed ingredients were obtained from Stein et al. (2016). These represent a weighted average of the ratio between STTD Ca:STTD P across treatments for the 4 dietary phases.

6Nine hundred and seven pigs were transported to a commercial packing plant for processing and data collection (Swift and Company, Worthington, MN).

7Adjusted for HCW.

8SEM for backfat were 0.38, 036, 0.37, and 0.38; SEM for fat-free lean were 0.25, 0.24, 0.25, 0.25, and 0.25; SEM for loin depth were 0.71, 0.68, 0.68, 0.68, and 0.70 for the 0.75:1, 1.00:1, 1.25:1, 1.50:1, and 2.00:1 analyzed Ca:P ratio treatments, respectively.

9Ninety pigs (2 pigs per pen, 1 barrow/1 gilt) visually assumed to represent the mean live weight of the pen were subsampled and shipped to a separate processing facility for bone collection (Natural Foods Holdings, Inc., Sioux Center, IA). A total of 90 third metacarpals were autoclaved for 1 h. After cleaning, bones were placed in Soxhlets containing petroleum ether for 7 d as a means of removing water and fat. They were then dried at 105 °C for 7 d, and then ashed at 600 °C for 24 h.

10The 2-way interaction was tested and no evidence for significant interaction was observed. There was a marginal significant gender effect (P < 0.10) on percentage bone ash, with barrows having greater bone mineralization than gilts (61.6% and 61.3% for barrows and gilts, respectively).

For overall growth performance (day 0 to 114), increasing Ca:P ratio increased (quadratic, P < 0.05) ADG and final BW. The greatest increase in both criteria was observed as the ratio increased from 0.75:1 to 1.50:1 analyzed Ca:P (0.95:1 to 1.62:1 STTD Ca:STTD P), with no improvements thereafter. Similarly, there was a marginal increase (quadratic, P < 0.10) in ADFI, with the greatest intake observed at an analyzed Ca:P ratio of 1.50:1 or at an STTD Ca:STTD P ratio of 1.62:1. Feed efficiency improved (linear, P < 0.05) with increasing the Ca:P ratio, with the greatest improvement, however, as the analyzed Ca:P ratio increased from 0.75:1 to approximately 1.00:1 and 1.25:1 or from 0.95:1 to approximately 1.18:1 and 1.40:1 STTD Ca:STTD P.

Homogeneous variance was used for G:F models and heterogeneous variance was used for ADG and ADFI models (Tables 8 and 9). The best fitting model for ADG was the QP model. The analyzed Ca:P ratio for maximum ADG was estimated at 1.63:1 (95% CI: 1.25:1, >2.00:1). The STTD Ca:STTD P ratio for maximum ADG (Fig. 1B) was estimated at 1.75:1 (95% CI: 1.40:1, >2.07:1). The best fitting model for ADFI was the LM, which estimated the maximum mean ADFI at greater than 2.00:1 analyzed Ca:P ratio and greater than 2.07:1 STTD Ca:STTD P ratio. Broken-line linear model provided the best fit for G:F, with the breakpoint observed at 1.05:1 analyzed Ca:P ratio (95% CI: 0.81:1, 1.30:1). As a function of STTD Ca:STTD P, G:F increased linearly as the ratio increased based on the LM model.

For carcass characteristics, HCW increased (quadratic, P < 0.05) as the analyzed Ca:P ratio increased up to 1:50:1 and up to 1.61:1 STTD Ca:STTD P ratio, with no further benefits thereafter (Table 7). Percentage carcass yield decreased (quadratic, P < 0.10) from 0.75:1 analyzed Ca:P ratio to 1.25:1 and from 0.95:1 STTD Ca:STTD P ratio to 1.40:1, slightly increasing at higher ratios. No evidence of differences (P > 0.10) was observed for backfat depth, fat-free lean, and loin depth measurements. Heterogeneous variance was used for HCW, with the QP and BLL models having similar fit (Tables 8 and 9). The QP model estimated the maximum mean HCW at 1.60:1 analyzed Ca:P ratio (95% CI: 1.14:1, >2.00:1), while the BLL plateau was estimated at 1.11:1 analyzed Ca:P ratio (95% CI: 0.87:1, 1.36:1). The QP model estimated the maximum mean HCW at 1.71:1 STTD Ca:STTD P ratio (95% CI: 1.28:1, >2.07:1), while the BLL plateau was estimated at 1.28:1 STTD Ca:STTD P ratio (95% CI: 1.06:1, 1.50:1).

For bone mineralization, the 2-way interaction between dietary treatment and gender was tested and no evidence (P > 0.10) for significant interaction was observed. There was a marginal significant gender effect (P < 0.10) on percentage bone ash, with barrows having greater bone mineralization than gilts (61.6% and 61.3% for barrows and gilts, respectively). Percentage bone ash increased (quadratic, P < 0.05) with increasing Ca:P ratio (Table 7). The greatest improvement in percentage bone ash was observed as analyzed Ca:P ratio increased from 0.75:1 to 1.25:1 and as the STTD Ca:STTD P ratio increased from 0.95:1 to 1.40:1, with no further increase thereafter. Heterogeneous variance was used for percentage bone ash, with the BLL being the best fitting model (Tables 8 and 9). The plateau for maximum mean percentage bone ash was estimated at 1.25:1 analyzed Ca:P ratio (95% CI: 1.10:1, 1.40:1) and at 1.40:1 STTD Ca:STTD P ratio (95% CI: 1.26:1, 1.54:1).

DISCUSSION

An abundance or deficiency of either Ca or P may influence the absorption and utilization of the other mineral, as both minerals are interdependent (Crenshaw, 2001). As an example, it has been extensively demonstrated that an excess of Ca is detrimental to pig growth performance, and this effect is exacerbated when diets are marginal or low in P (Reinhart and Mahan, 1986; González-Vega et al., 2016b; Wu et al., 2018). This effect may occur through a P digestibility reduction (Stein et al., 2011) when diets contain a high Ca concentration. This leads to the formation of Ca-P insoluble complexes in the gastrointestinal tract which leads to decreased P digestion and absorption (Brink et al., 1992; Heaney and Nordin, 2002; González-Vega and Stein, 2014). The detrimental effects of high Ca diets on pig growth performance were alleviated by increasing the dietary concentration of STTD P. These observations emphasize the importance of considering an appropriate ratio between Ca and P when formulating diets for pigs to ensure optimum absorption of both minerals and optimum performance of pigs.

In Exp. 1, we observed that at high concentrations of Ca, corresponding to an analyzed Ca:P ratio greater than 1.38:1 or an STTD Ca:STTD P ratio greater than 1.82:1, ADG is reduced mainly due to a reduction in feed intake. Similar observations were described by Sørensen et al. (2018). Results from this experiment are in agreement with a study with added phytase in 9- to 23-kg nursery pigs where narrowing the ratio of total Ca:total P from 2.00:1 to 1.20:1 resulted in improvements in growth performance, independent of the dietary P concentration (Qian et al., 1996). Wu et al. (2018) also observed that excess Ca impairs ADG, ADFI, and G:F of nursery pigs fed diets deficient in P, and that these negative effects are ameliorated by providing more P in the diet. These detrimental effects of high Ca or wide Ca:P ratios were also reported by González-Vega et al. (2016a) with 11- to 25-kg pigs, González-Vega et al. (2016b) with 25- to 50-kg pigs, and Merriman et al. (2017) with 100- to 130-kg pigs that were fed diets with no added phytase. Interestingly, the negative effects of increased dietary Ca concentration in the present study were observed in diets containing 122% of NRC (2012) STTD P requirement estimates across phases. Therefore, the current study demonstrated that the ratio between Ca and P is important even when dietary P concentration is provided in excess of those suggested by the NRC (2012).

In Exp. 2, we observed that growth rate, feed intake, and feed efficiency are improved with increasing Ca:P ratio. Differently than the results from Exp. 1, growth performance was not reduced at the highest Ca level or the highest analyzed Ca:P and STTD Ca:STTD P ratios. Due to the addition of phytase in these diets, the analyzed Ca levels were approximately 30% below the analyzed Ca concentration in Exp. 1. This explains why pigs were able to tolerate a wider analyzed Ca:P ratio when phytase was added to the diets. Moreover, lower growth rate and feed intake were observed in both experiments with low Ca diets, which corresponded to narrow analyzed Ca:P ratios. The study conducted by Lagos et al. (2019) suggested that binding of Ca due to an abundance of P can also occur as demonstrated by a reduced ADG in diets with excess P and low Ca compared to higher Ca concentration in their study. This observation from the current study is in contrast to results from González-Vega et al. (2016b) and Merriman et al. (2017), where it was not possible to decrease pig growth performance through a reduction in dietary Ca concentration. As opposed to our study that evaluated varying analyzed Ca:P ratios throughout the entire grower and finisher periods, the aforementioned studies were short-term experiments. Thus, pigs may have had enough bone mineral reserves to supply Ca and P and alleviate their deficiencies during the aforementioned experiments.

Recent research has demonstrated that the addition of phytase can improve the STTD of Ca in feed ingredients and, therefore, should be considered when formulating diets for pigs (González-Vega et al., 2015; Stein et al., 2016). Observations from our study demonstrated that, as opposed to analyzed Ca:P, the ratio of STTD Ca:STTD P is more accurate when comparing results between the 2 studies with or without added phytase. As an example, growth rate was maximized at 1.38:1 in Exp. 1 and at 1.63:1 in Exp. 2 on an analyzed Ca to analyzed P basis. However, growth rate was maximized at 1.82:1 in Exp. 1 and at 1.75:1 in Exp. 2 on an STTD Ca to STTD P basis. This further illustrates the value of comparing Ca and P nutrient values on a STTD basis. Moreover, these results are in agreement with data from Lagos et al. (2019) that suggested a STTD Ca:STTD P ratio greater than 1.50:1 is needed to maximize growth in 50- to 85-kg pigs if the STTD P exceeds NRC (2012) estimates, which was the case of the current study.

Negative effects of high Ca levels and wide total Ca:P ratios on efficacy of phytase have also been reported (Qian et al., 1996). According to the authors, a reduction in the dietary total Ca:P from 2.0:1 to 1.2:1 resulted in an improvement of approximately 16% in the releasing ability of phytase to increase growth and bone performance. This detrimental effect on phytase efficacy is consistent to other observations in weanling pigs (Lei et al., 1994) and broilers (Shirley and Edwards, 2002). The binding capacity of phytate to Ca resulting in insoluble complexes resistant to phytase hydrolysis is among the potential mechanisms of the detrimental effects of high Ca on phytase efficacy (Selle et al., 2009; Dersjant-Li et al., 2015). Other mechanisms include a competitive inhibition of the active sites of the enzyme, and the high acid-binding capacity of limestone and monocalcium phosphate (Selle et al., 2009; Dersjant-Li et al., 2015). However, in this study the analyzed Ca concentration in diets containing added phytase was possibly not high enough to elicit such detrimental effects on phytase activity. Moreover, Qian et al. (1996) observed that the high Ca or wide Ca:P ratio effects on efficacy of phytase were more detrimental at low P concentrations.

The greatest carcass weight occurred at a ratio of 1.25:1 analyzed Ca:P and 1.65:1 STTD Ca:STTD P in Exp. 1 and at a ratio of 1.50:1 analyzed Ca:P and 1.62:1 STTD Ca:STTD P in Exp. 2. Similarly, results from Hanni et al. (2005) have shown that increasing the ratio between Ca and P improved HCW, with detrimental effects at a ratio greater than 1.50:1 total Ca:P. Our results are in accordance with findings from Liu et al. (1998) and Hanni et al. (2005) in which backfat depth, fat-free lean, and loin depth were not affected by the ratio between Ca and P. There was, however, a marginal curvilinear response in loin depth up to 1.50:1 analyzed Ca:P ratio or 1.62:1 STTD Ca:STTD P ratio in Exp. 2. Percentage carcass yield decreased as the Ca:P ratio increased. There is not a clear explanation for the reduction in yield, but this observation was consistent among Exp. 1 and Exp. 2. In contrast, other studies have indicated no evidence for influence of Ca and P ratios on carcass yield (Liu et al., 1998; Hanni et al., 2005).

Bone mineral deposition is dependent on the presence of both Ca and P, and they accumulate in a constant Ca:P ratio of 2.2:1 in the form of hydroxyapatite (Crenshaw, 2001). Findings from several studies suggest that pigs are able to deposit significantly more Ca and P in bones than the amount needed to optimize pig growth performance (González-Vega et al., 2016a, 2016b; Merriman et al., 2017; Lagos et al., 2019). In our study, however, increasing Ca and P to maximize growth rate resulted in 99.5% to 99.8% and 100% of maximum bone mineralization in Exp. 1 and Exp. 2, respectively. This observation contradicts the expectation that concentrations of Ca and P to maximize synthesis of skeletal tissue is greater than the amount required to maximize muscle growth. Therefore, results from our study suggest that if P exceeds the NRC (2012) requirements, Ca concentration is not so important to optimize bone mineralization. Different from Exp. 1, we observed a marginally greater percentage bone ash for barrows compared to gilts in Exp. 2. A greater bone mineralization in barrows compared to gilts have been reported in a study evaluating increasing levels of STTD P (Vier et al., 2017), whereas other studies have reported no evidence for differences (Crenshaw et al., 1981; Hanni et al., 2005).

Taken together, results from this study highlighted the importance of considering an appropriate ratio between Ca and P when formulating diets for pigs, even when dietary P concentration is provided in excess of that suggested by the NRC (2012). Our data suggest that the analyzed Ca:P ratio to optimize growth performance, HCW, and bone mineralization ranged from 1.25:1 to 1.93:1 and 1.05:1 to 1.63:1 in diets without or with phytase, respectively. A more consistent ratio among experiments was observed for ADG on a STTD Ca:STTD P basis, with estimated requirements at 1.75:1 and 1.82:1 in diets without and with phytase, respectively. Bone mineralization was maximized at 2.57:1 and 1.40:1 STTD Ca:STTD P ratio. However, approximately 99.5% to 100% of maximum bone ash was captured at the ratios needed to maximize growth rate. In conclusion, a ratio between 1.75:1 and 1.82:1 STTD Ca:STTD P can be used in diet formulation of 26- to 127-kg pigs that are fed diets adequate in STTD P with or without added phytase to optimize growth rate without reducing bone mineralization. These data demonstrate the value of comparing Ca and P nutrient values on a STTD basis.

Footnotes

Agricultural Experiment Station, Manhattan, KS 66506-0210.

Appreciation is expressed to PIC North America (Hendersonville, TN) and DSM Nutritional Products Inc. (Parsippany, NJ) for partial funding and technical expertise. Special appreciation is also expressed to New Horizon Farms (Pipestone, MN) for use of the feed mill and animal facilities, and to Marty Heintz, Heath Houselog, and Whitney Adler for technical assistance.

LITERATURE CITED

- AOAC International 1990. Official methods of analysis of AOAC International. 15th ed. Assoc. Off. Anal. Chem. Int., Gaithersburg, MD. [Google Scholar]

- Berndt T., and Kumar R.. . 2009. Novel mechanisms in the regulation of phosphorus homeostasis. Physiology 24:17–25. doi: 10.1152/physiol.00034.2008 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Brink E. J., Beynen A. C., Dekker P. R., van Beresteijn E. C. H., and van der Meer R.. . 1992. Interaction of calcium and phosphate decreases ileal magnesium solubility and apparent magnesium absorption in rats. J. Nutr. 122:580–586. doi: 10.1093/jn/122.3.580 [DOI] [PubMed] [Google Scholar]

- Crenshaw T. D. 2001. Calcium, phosphorus, vitamin D, and vitamin K in swine nutrition. In: Lewis A. and Southern L. L., editors, Swine nutrition. 2nd ed. CRC Press, Boca Raton, FL: p. 196–221. [Google Scholar]

- Crenshaw T. D., Peo E. R., Lewis A. J., Moser B. D., and Olson D.. . 1981. Influence of age, sex and calcium and phosphorus levels on the mechanical properties of various bones in swine. J. Anim. Sci. 52:1319–1329. doi: 10.2527/jas1981.5261319x [DOI] [PubMed] [Google Scholar]

- Dersjant-Li Y., Awati A., Schulze H., and Partridge G.. . 2015. Phytase in non-ruminant animal nutrition: a critical review on phytase activities in the gastrointestinal tract and influencing factors. J. Sci. Food Agric. 95:878–896. doi: 10.1002/jsfa.6998 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Fan M. Z., Archbold T., Sauer W. C., Lackeyram D., Rideout T., Gao Y., de Lange C. F., and Hacker R. R.. . 2001. Novel methodology allows simultaneous measurement of true phosphorus digestibility and the gastrointestinal endogenous phosphorus outputs in studies with pigs. J. Nutr. 131:2388–2396. doi: 10.1093/jn/131.9.2388 [DOI] [PubMed] [Google Scholar]

- Gonçalves M. A., Bello N. M., Dritz S. S., Tokach M. D., DeRouchey J. M., Woodworth J. C., and Goodband R. D.. . 2016. An update on modeling dose-response relationships: accounting for correlated data structure and heterogeneous error variance in linear and nonlinear mixed models. J. Anim. Sci. 94:1940–1950. doi: 10.2527/jas.2015-0106 [DOI] [PubMed] [Google Scholar]

- González-Vega J. C., Liu Y., McCann J. C., Walk C. L., Loor J. J., and Stein H. H.. . 2016a. Requirement for digestible calcium by eleven- to twenty-five–kilogram pigs as determined by growth performance, bone ash concentration, calcium and phosphorus balances, and expression of genes involved in transport of calcium in intestinal and kidney cells. J. Anim. Sci. 94:3321. doi: 10.2527/jas.2016-0444 [DOI] [PubMed] [Google Scholar]

- González-Vega J. C., and Stein H. H.. . 2014. Invited review - calcium digestibility and metabolism in pigs. Asian Austral. J. Anim. Sci. 27:1–9. doi: 10.5713/ajas.2014.r.01 [DOI] [PMC free article] [PubMed] [Google Scholar]

- González-Vega J. C., Walk C. L., Murphy M. R., and Stein H. H.. . 2016b. Requirement for digestible calcium by 25 to 50 kg pigs at different dietary concentrations of phosphorus as indicated by growth performance, bone ash concentration, and calcium and phosphorus balances. J. Anim. Sci. 94:5272–5285. doi: 10.2527/jas.2016-0751 [DOI] [PubMed] [Google Scholar]

- González-Vega J. C., Walk C. L., and Stein H. H.. . 2015. Effects of microbial phytase on apparent and standardized total tract digestibility of calcium in calcium supplements fed to growing pigs. J. Anim. Sci. 93:2255–2264. doi: 10.2527/jas.2014-8215 [DOI] [PubMed] [Google Scholar]

- Hall D. D., Cromwell G. L., and Stahly T. S.. . 1991. Effects of dietary calcium, phosphorus, calcium: phosphorus ratio and vitamin K on performance, bone strength and blood clotting status of pigs. J. Anim. Sci. 69:646–655. doi: 10.2527/1991.692646x [DOI] [PubMed] [Google Scholar]

- Hanni S. M., Tokach M. D., Goodband R. D., Derouchey J. M., Nelssen J. L., and Dritz S. S.. . 2005. Effects of increasing calcium-to-phosphorus ratio in diets containing phytase on finishing pig growth performance. Prof. Anim. Sci. 21:59–65. doi: 10.15232/S1080-7446(15)31167-0 [DOI] [Google Scholar]

- Heaney R. P., and Nordin B. E.. . 2002. Calcium effects on phosphorus absorption: implications for the prevention and co-therapy of osteoporosis. J. Am. Coll. Nutr. 21:239–244. doi: 10.1080/07315724.2002.10719216 [DOI] [PubMed] [Google Scholar]

- Kiarie E., and Nyachoti C. M.. . 2010. Bioavailability of calcium and phosphorus in feedstuffs for farm animals. In: Vitti D. M. S. S. and Kebreab E., editors, Phosphorus and calcium utilization and requirements in farm animals. CABI, Wallingford, UK: p. 76–93. [Google Scholar]

- Lagos L. V., Walk C. L., Murphy M. R., and Stein H. H.. . 2019. Effects of dietary digestible calcium on growth performance and bone ash concentration in 50- to 85-kg growing pigs fed diets with different concentrations of digestible phosphorus. Anim. Feed Sci. Technol. 247:262–272. doi: 10.1016/j.anifeedsci.2018.11.019 [DOI] [Google Scholar]

- Lei X. G., Ku P. K., Miller E. R., Yokoyama M. T., and Ullrey D. E.. . 1994. Calcium level affects the efficacy of supplemental microbial phytase in corn-soybean meal diets of weanling pigs. J. Anim. Sci. 72:139–143. doi: 10.2527/1994.721139x [DOI] [PubMed] [Google Scholar]

- Littell R. C., Milliken G. A., Stroup W. W., Wolfinger R. D., and Schabenberger O.. . 2006. SAS® for mixed models. 2nd ed. SAS Inst. Inc., Cary, NC. [Google Scholar]

- Liu J., Bollinger D. W., Ledoux D. R., and Veum T. L.. . 1998. Lowering the dietary calcium to total phosphorus ratio increases phosphorus utilization in low-phosphorus corn-soybean meal diets supplemented with microbial phytase for growing-finishing pigs. J. Anim. Sci. 76:808–813. doi: 10.2527/1998.763808x [DOI] [PubMed] [Google Scholar]

- Maguire R. O., Dou Z., Sims J. T., Brake J., and Joern B. C.. . 2005. Dietary strategies for reduced phosphorus excretion and improved water quality. J. Environ. Qual. 34:2093–2103. doi: 10.2134/jeq2004.0410 [DOI] [PubMed] [Google Scholar]

- Merriman L. A., Walk C. L., Murphy M. R., Parsons C. M., and Stein H. H.. . 2017. Inclusion of excess dietary calcium in diets for 100- to 130-kg growing pigs reduces feed intake and daily gain if dietary phosphorus is at or below the requirement. J. Anim. Sci. 95:5439–5446. doi: 10.2527/jas2017.1995 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Milliken G. A., and Johnson D. E.. . 2009. Analysis of messy data, volume 1: designed experiments. 2nd ed. CRC Press, Boca Raton, FL. [Google Scholar]

- NRC 2012. Nutrient requirements of swine. 11th rev. ed. Natl. Acad. Press, Washington, DC. [Google Scholar]

- Qian H., Kornegay E. T., and Conner D. E.. . 1996. Adverse effects of wide calcium:phosphorus ratios on supplemental phytase efficacy for weanling pigs fed two dietary phosphorus levels. J. Anim. Sci. 74:1288–1297. doi: 10.2527/1996.7461288x [DOI] [PubMed] [Google Scholar]

- Reinhart G. A., and Mahan D. C.. . 1986. Effect of various calcium:phosphorus ratios at low and high dietary phosphorus for starter, grower and finishing swine. J. Anim. Sci. 63:457–466. doi: 10.2527/jas1986.632457x [DOI] [Google Scholar]

- Selle P. H., Cowieson A. J., and Ravindran V.. . 2009. Consequences of calcium interactions with phytate and phytase for poultry and pigs. Livest. Sci. 124:126–141. doi: 10.1016/j.livsci.2009.01.006 [DOI] [Google Scholar]

- Shirley R. B., and Edwards H. M.. . 2002. Dietary calcium affects phytase activity when phytase is supplemented in excess of industry standards. Poult. Sci. 81(Suppl. 1):11. (Abstr.). doi:10.1093/ps/82.4.671 [Google Scholar]

- Sørensen K. U., Tauson A. H., and Poulsen H. D.. . 2018. Long term differentiated phosphorus supply from below to above requirement affects nutrient balance and retention, body weight gain and bone growth in growing-finishing pigs. Livest. Sci. 211:14–20. doi: 10.1016/j.livsci.2018.03.002 [DOI] [Google Scholar]

- Stein H. H., Adeola O., Cromwell G. L., Kim S. W., Mahan D. C., and Miller P. S.; North Central Coordinating Committee on Swine Nutrition (NCCC-42) 2011. Concentration of dietary calcium supplied by calcium carbonate does not affect the apparent total tract digestibility of calcium, but decreases digestibility of phosphorus by growing pigs. J. Anim. Sci. 89:2139–2144. doi: 10.2527/jas.2010-3522 [DOI] [PubMed] [Google Scholar]

- Stein H. H., Merriman L. A., and González-Vega J. C.. . 2016. Establishing a digestible calcium requirement for pigs. In: Walk C. L., Kühn I., Stein H. H., Kidd M. T., and Rodehutscord M., editors, Phytate destruction - consequences for precision animal nutrition. Wageningen Academic Publishers, Wageningen, The Netherlands: p. 207–216. https://www.wageningenacademic.com/doi/10.3920/978-90-8686-836-0_13 (Accessed 10 April 2019). [Google Scholar]

- Veum T. L. 2010. Phosphorus and calcium nutrition and metabolism. In: Vitti D. M. S. S. and Kebreab E., editors, Phosphorus and calcium utilization and requirements in farm animals. CABI, Wallingford, UK: p. 94–111. [Google Scholar]

- Vier C. M., Wu F., Menegat M. B., Cemin H., Dritz S. S., Tokach M. D., Goncalves M. A. D., Orlando U. A. D., Woodworth J. C., Goodband R. D., . et al. 2017. Effects of standardised total tract digestible phosphorus on performance, carcass characteristics, and economics of 24 to 130 kg pigs. Anim. Prod. Sci. 57:2424. doi: 10.1071/ANv57n12Ab071 [DOI] [Google Scholar]

- Wu F., Tokach M. D., Dritz S. S., Woodworth J. C., DeRouchey J. M., Goodband R. D., Gonçalves M. A. D., and Bergstrom J. R.. . 2018. Effects of dietary calcium to phosphorus ratio and addition of phytase on growth performance of nursery pigs. J. Anim. Sci. 96:1825–1837. doi: 10.1093/jas/sky101 [DOI] [PMC free article] [PubMed] [Google Scholar]