Abstract

Aim:

The aim of the study was to investigate the effect of disinfection and steam autoclaving on the elastic recovery of three different elastomeric impression materials.

Settings and Design:

In vivo - comparative study.

Materials and Methods:

Ninety dumbbell-shaped specimens of commercially available two addition-cured silicones (AFFINIS and AQUASIL) and one condensation-cured silicone (SPEEDEX) impression materials were prepared and treated with chemical disinfectant and steam autoclaving. Specimens were seal packed and sent to laboratory for testing elastic recovery. After the specimen had been pulled to failure, the broken parts were fitted back together, and the distance between the marks was measured using an electronic Vernier caliper.

Statistical Analysis Used:

one-way analysis of variance test and Tukey post hoc test for multiple comparisons.

Results:

The result showed significant difference in elastic recovery of AFFINIS when it was disinfected and steam autoclaved whereas elastic recovery showed no significant difference when SPEEDEX and AQUASIL were disinfected and steam autoclaved. Similarly, results were alike when AFFINIS, SPEEDEX, and AQUASIL were compared on disinfection. However, significant difference was noted on steam autoclaving, highest being the mean value of AFFINIS.

Conclusion:

Within the limitations of this in vitro study, conclusion was made that the elastic recovery of AFFINIS was the least which improved with disinfection and autoclaving. Elastic recovery of SPEEDEX and AQUASIL was similar. However, all the three materials used in the study can be safely sterilized after clinical use and before being sent to the laboratory without significantly affecting their elastic recovery.

Keywords: Disinfection, elastic recovery, polyvinyl siloxane, sterilization

INTRODUCTION

The fabrication of a good prosthesis begins with making of a good impression. Fabricating a precisely fitting prosthesis fully depends on an accurate impression making. From time to time, impression materials have evolved due to their better physical and handling properties and impression materials that have received a lot of attention are irreversible hydrocolloids, polyethers, polyvinyls, and polysulfides.[1]

In the clinical scenario, a set impression is a pool for pathogens after its removal from the patient's mouth. During the time of model fabrication, these microorganisms travel into the model from the impression, posing risk for clinicians as well as laboratory workers through secondary contact. Hence a standard infection control protocol must be followed in our daily routine to minimize the risk of spread of these microorganisms which leads to infectious diseases.[2]

Transmissible diseases like herpes, hepatitis, and HIV infections command that dental practitioners must follow this protocol in order to dodge the cross infection and the menace of disease spread. At present, several rules and regulations are put forward by various bodies such as American Dental Association, Center for Disease Control and British Dental Association Advisory Service and Occupational Safety and Health Administration for sterilization and infection control in dentistry.[3]

Impression disinfection can be performed by immersion or spray methods with a suitable disinfectant. The antibacterial efficiency and dimensional stability are two important parameters that are evaluated after disinfection of an impression. Impression sterilization is more effective than disinfection because disinfection only aims at killing the microorganisms that produce diseases but has no effect on bacterial spores.[4] The most effective way that is claimed so far for the control of cross-infection and contamination by microorganisms is steam autoclave sterilization.

Ideally, the maximum elasticity was observed in polyvinyl siloxanes (PVS) because of their good elastic recovery and resistance to deformation and high tear strength. PVS has a property to deform at much slower rates than other elastomeric impression materials and tear at points of less permanent deformation.[5]

The elastic recovery is an important parameter that includes the concept of time, as these parameters represent the ability of the impression to remain unaffected by storage. This parameter also represents that the impressions that are polymerized will show sufficient stiffness to resist deformation when poured with gypsum product, and the poured impressions can be retrieved from the cast without permanent deformation of the impression so that the same impression can be used more than once.[6]

PVS represents best elastic recovery than polyether and polysulfide.[1] PVS is the impression material which can withstand the sterilization procedure and yet can produce an accurate cast.[7] A survey was done by dentists and found that 50% of the dental professionals would favor an impression material which can be autoclaved.[8,9]

Nowadays, there are impression materials available in market which can withstand high temperature and can be sterilized; these materials are known as autoclavable impression materials. The latest elastomeric impression materials are quadrafunctionally modified siloxanes with quadrafunctional hydrophilic property. The quadrafunctional hydrophilic structure of the material is an excellent combination of a cross-linked polymer with an exclusive surface active element. Hence, quadrafunctional hydrophilic impression materials are a combination of properties of polyether impression materials and addition-cured silicone impression materials.

In the light of these facts, a study was planned to evaluate the elastic recovery of various elastomeric impression materials on autoclaving and comparing it to the currently practiced method of chemical disinfection. The aim of the study was to investigate the effect of disinfection and steam autoclaving on the elastic recovery of three different elastomeric impression materials. The null hypothesis was that there will be no effect on the elastic recovery of the materials when they are chemically disinfected and steam autoclaved.

MATERIALS AND METHODS

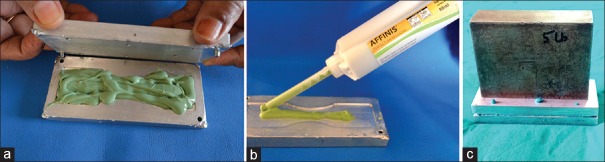

The study was approved by Institutional Review Board. Measurement of elastic recovery of AFFINIS (light body consistency addition cured PVS impression material AFFINIS, Coltene/Whaledent Pvt., Ltd., 9450 Alstalten, Switzerland, batch H80440), SPEEDEX (light body consistency condensation-cured silicone impression material, SPEEDEX, Coltene/Whaledent Pvt., Ltd., 9450 Alstalten, Switzerland, batch H44:41), AQUASIL (light body consistency addition-cured PVS impression material, AQUASIL, Dentsply Australia Pvt., Ltd., batch IN2139356) was done by treating these materials with disinfectant (SURFASEPT S.A, aldehyde free disinfectant solution, containing isopropyl alcohol - 70% w/w and chlorhexidine gluconate - 2.5% w/w, SURFASEPT S. A Septodent Healthcare India Pvt., Ltd., batch S019 L01150) and steam autoclaving (Gnatus Bioclave) [Figure 1].

Figure 1.

Impression materials used

The specimens prepared for elastic recovery were dumbbell shaped similar to the specimen used for rubber testing by ASTM test no D412. These typical dumbbell-shaped specimens were created to exert a uniform pressure across the gripping surfaces. As the tension increases, it prevents slippage to favor failure of the specimens in the straight reduced section.[10]

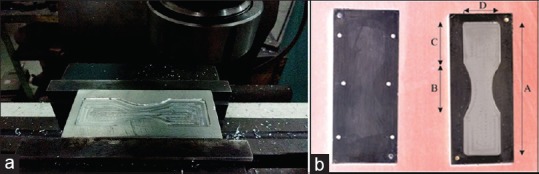

These specimens were prepared with the help of a metal die with a lower and upper member. The lower member had an aluminum mold of dimensions of 11.5 cm × 5 cm × 1 cm. It had an hour glass shape recess cut to a thickness of 1 mm. It also had two holes placed diagonally at two corners for seating the stops present in upper member. The upper member consisted of an aluminum lid covering the lower member. It had six escape holes for the excess material to flow so as to get a 1 mm consistent thickness of the specimen. The lid also had two stops placed diagonally on the two corners to get a stable stop while seating the upper member on the lower member [Figure 2a and b].

Figure 2.

(a and b) Metal die fabrication where A - 10 cm, B - 4 cm, C - 3 cm, D - 3 cm

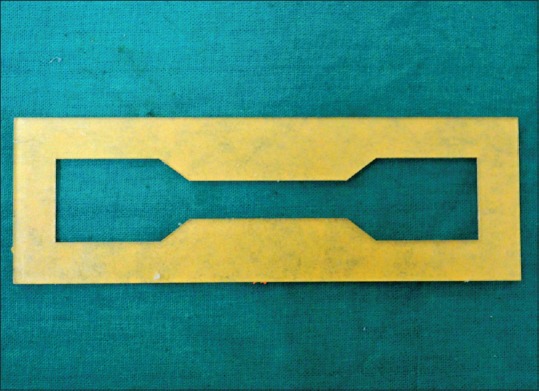

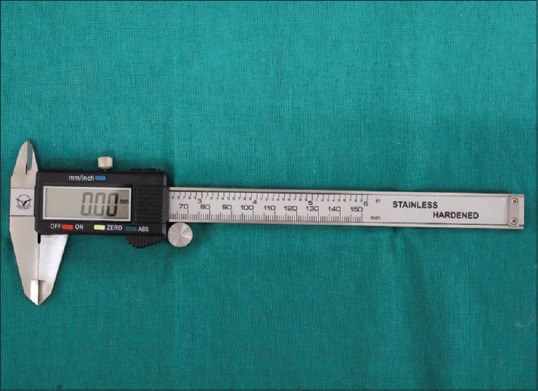

For measuring the elastic recovery, 30 specimens for each of the three test materials were prepared by placing the material in the lower member and cover it with the upper member, and over that a 5 lb weight was placed while the excess material flows out of the escape holes to get a consistent 1 mm thickness of the specimen. The samples were trimmed to the dimensions of an acrylic stencil (A - 3.8 cm, B - 0.9 cm, C - 0.6 cm, D - 0.4 cm) with the help of Bard Parker blade. The thickness was measured with a digital Vernier caliper to rule out any discrepancy [Figures 3–5a–c and 6].

Figure 3.

Acrylic Stencil was prepared with the following dimensions: A - 3.8 cm, B - 0.9 cm, C - 0.6 cm, D - 0.4 cm

Figure 5.

(a-c) Loading of impression material in the die

Figure 6.

Retrieved specimen from metal die

Figure 4.

Electronic Vernier caliper

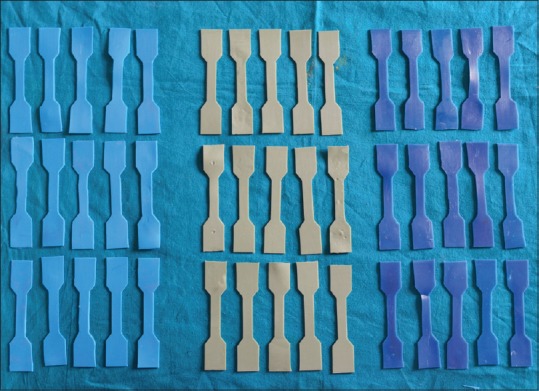

Hence, 10 specimens of each impression material, i.e., a total of 90 samples were prepared. The samples were divided into 3 groups which included the group to be autoclaved, disinfected, and untreated group. These groups were further subdivided into 3 subgroups of AFFINIS, SPEEDEX, and AQUASIL test materials [Figure 7].

Figure 7.

Specimens for elastic recovery testing

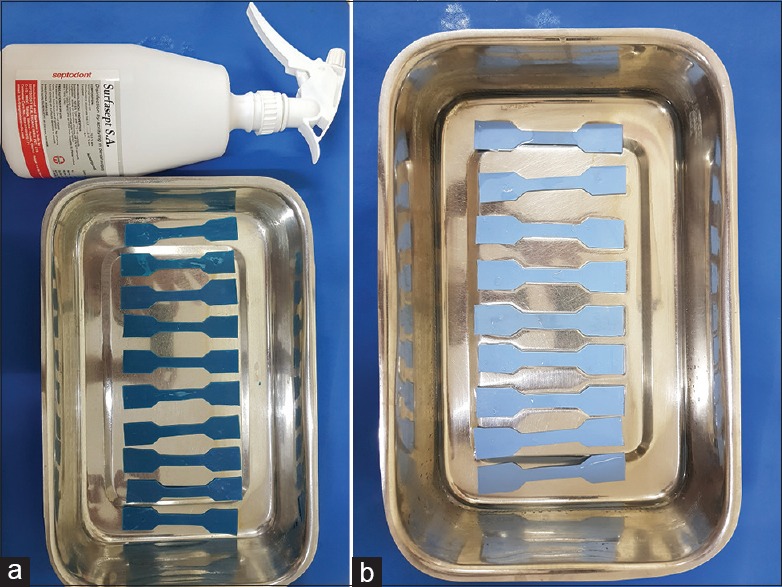

The silicone impression specimens which were allocated to the autoclave treatment group were placed on sterilization trays and underwent a standard autoclave cycle at 134°C for 30 minutes [Figure 8a and b]. For disinfection procedure, specimens were placed in chemical disinfectant SURFASEPT S.A, an aldehyde-free disinfectant solution, containing isopropyl alcohol - 70% w/w and chlorhexidine gluconate - 2.5% w/w for 10 min, as recommended by the manufacturer, and then rinsed under the tap for 30 s [Figure 9]. After the sterilization of all specimens, they were bagged and sealed for subsequent analysis within 24 hours. A 24 hour time period was used to simulate transportation from the dental department to the dental laboratory.

Figure 8.

(a and b) Autoclaving elastic recovery specimens

Figure 9.

(a and b) Disinfection of elastic recovery specimens

The prepared specimens were mounted on Instron universal testing machine [Figure 10] by clamping the ends in the serrated jaws of the testing apparatus. Tensile load of 10 mm/min was applied. The elongation at break (stretchability) was measured in millimeters. After the specimen had been pulled to failure, the broken parts were fitted back together and the distance between the marks was measured using an electronic caliper with a resolution of 0.01 mm after 2 h [Figure 11]. The change in length (Δ L) was measured, and percentage deformation was calculated which ultimately provided the elastic recovery.

Figure 10.

Universal testing machine

Figure 11.

Broken elastic recovery specimen

Data were entered in Microsoft Office Excel. Appropriate statistical tests were used to find significant association with the help of Mini Tab Version 18 software (Headquartered in State College, Pa., Minitab, LLC. operates offices in Phoenix, Arizona, Chicago). P < 0.05 was considered as statistically significant. One-way analysis of variance (ANOVA) was used to test for statistically significant differences within the groups and also across the groups. Tukey pairwise comparisons grouping information using the Tukey method at 95% confidence was used.

RESULTS

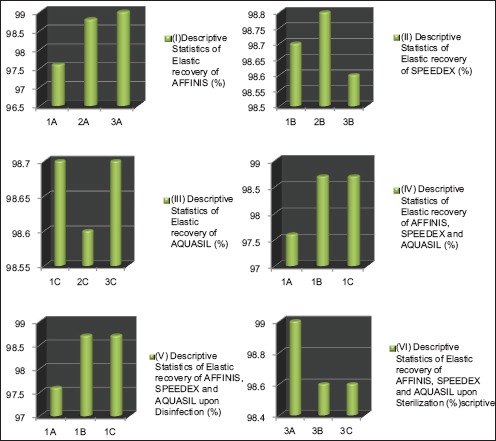

Elastic recovery of each material

A comparison of the mean values for each of the three impression material specimen was done. It was evaluated using one-way ANOVA. A significant difference was found in the mean values of AFFINIS in Table 1 and Graph I. The specimens were further compared using Tukey test in Table 2, and a significant difference was found in the groups, lowest being the control group followed by disinfection and sterilization group. On the other hand, one way ANOVA and Tukey test evaluated no significant difference in the mean values of elastic recovery of AQUASIL and SPEEDEX when they were disinfected, sterilized, and left untreated in Tables 3, 4 and Graph II and III.

Table 1.

Descriptive statistics of elastic recovery of AFFINIS (%)

| Group | n | Mean | SD | P |

|---|---|---|---|---|

| Group 1A | 10 | 97.6 | 0.339 | 0.000 |

| Group 2A | 10 | 98.8 | 0.318 | |

| Group 3A | 10 | 99.0 | 0.2976 |

SD: Standard deviation

Graph (I, II, III, IV, V, VI).

Descriptive statistics of elastic recovery of AFFINIS, SPEEDEX, and AQUASIL

Table 2.

Tukey pairwise comparisons grouping information using the Tukey method and 95% confidence of elastic recovery of AFFINIS (%)

| Factor | n | Mean | Grouping | Factor |

|---|---|---|---|---|

| 1A | 10 | 97.6 | * | 1A |

| 2A | 10 | 98.8 | 2A | |

| 3A | 10 | 99.0 | 3A |

Means that do not share a mark (*) are significantly different

Table 3.

Descriptive statistics of elastic recovery of SPEEDEX (%)

| Group | n | Mean | SD | P |

|---|---|---|---|---|

| 1B | 10 | 98.7 | 0.790 | >0.05 |

| 2B | 10 | 98.8 | 0.3128 | |

| 3B | 10 | 98.6 | 0.2161 |

SD: Standard deviation

Table 4.

Descriptive statistics of elastic recovery of AQUASIL (%)

| Group | n | Mean | SD | P |

|---|---|---|---|---|

| Group 1C | 10 | 98.7 | 0.455 | >0.05 |

| Group 2C | 10 | 98.6 | 0.1823 | |

| Group 3C | 10 | 98.7 | 0.2808 |

SD: Standard deviation

Effect on control groups of each material

In Table 5 and Graph IV, when the three impression materials were compared among each other using one-way ANOVA test and Tukey test, no significant difference was observed; all the three impression materials showed same values when left untreated.

Table 5.

Descriptive statistics of elastic recovery of AFFINIS, SPEEDEX and AQUASIL (%)

| Group | n | Mean | SD | P |

|---|---|---|---|---|

| Group 1A | 10 | 97.6 | 0.318 | >0.05 |

| Group 1B | 10 | 98.7 | 0.3128 | |

| Group 1C | 10 | 98.7 | 0.1823 |

SD: Standard deviation

Effect of disinfection

Effect of disinfection was compared in between materials, i.e., AFFINIS, SPEEDEX, and AQUASIL. Table 6 and Graph V shows no difference in mean elastic recovery of all the three impressions.

Table 6.

Descriptive statistics of elastic recovery of AFFINIS, SPEEDEX, and AQUASIL on disinfection (%)

| Group | n | Mean | SD | P |

|---|---|---|---|---|

| Group 1A | 10 | 97.6 | 0.318 | >0.05 |

| Group 1B | 10 | 98.7 | 0.3128 | |

| Group 1C | 10 | 98.7 | 0.1823 |

SD: Standard deviation

Effect of sterilization

The comparison was done among three test specimens for elastic recovery on sterilization using one-way ANOVA test and Tukey test. According to Tables 7 and 8 and Graph VI, a significant difference was found in the mean values of elastic recovery of AFFINIS when compared to SPEEDEX and AQUASIL. AFFINIS being the highest while AQUASIL and SPEEDEX were almost alike.

Table 7.

Descriptive statistics of elastic recovery of AFFINIS, SPEEDEX, and AQUASIL on sterilization (%)

| Group | n | Mean | SD | P |

|---|---|---|---|---|

| Group 3A | 10 | 99.0 | 0.2976 | <0.05 |

| Group 3B | 10 | 98.6 | 0.2161 | |

| Group 3C | 10 | 98.6 | 0.2808 |

SD: Standard deviation

Table 8.

Tukey pairwise comparisons grouping information using the Tukey method and 95% confidence of AFFINIS, SPEEDEX, and AQUASIL on sterilization (%)

| Factor | n | Mean | Grouping | Factor |

|---|---|---|---|---|

| 3A | 10 | 99.0 | * | 3A |

| 3B | 10 | 98.6 | 3B | |

| 3C | 10 | 98.6 | 3C |

Means that do not share a mark (*) are significantly different

DISCUSSION

The increasing risk of cross-infection from patient to clinicians which is carried forward to the dental technicians through the dental impressions is a topic of interest these days. To protect the dental clinicians, a standard protocol for disinfection and sterilization of dental impressions is recommended.[11] A survey documented in U.S. dental laboratory directors in 2000 revealed that the majority of impressions were made of PVS (57%) or polyether (27%) materials. Only 44% of the respondents said that they knew if the received impressions were disinfected or not. Whereas, 23% had no idea about the methods used for disinfection and 47% did not know about the length of time involved in disinfection. About 45% of the respondents stated that they received inadequate information regarding the disinfection procedure. Thus, it shows that there was definite lack of communication between team members, and also, the problem was not only associated with the material being used for making impressions but the disinfection technique which was being used.[12]

Holtan et al. in 1991 conducted a study in which PVS impression material (President) was sterilized using steam autoclave and an ethylene oxide gas autoclave. He established that models made from ethylene oxide sterilized impressions were acceptable to use in fabricating fixed or removable prosthesis, while the models made from impressions sterilized in a steam autoclave can be used for the fabrication of diagnostic casts and some transitional prostheses, but not for routine construction of crowns or fixed partial dentures.[7]

The impression materials should have acceptable mechanical properties so as to ensure that it can withstand all the stresses produced during removal from mouth as well as retrieval from a plaster model without undergoing any change in dimensional stability and integrity, even after disinfection or steam autoclaving.[13] A good impression material must excel in many factors besides the dimensional accuracy. A dental impression material must have sufficient strength to allow retrieval of cast or model without tearing; so, it must also have an adequate elastic recovery even after disinfection and sterilization.[14]

PVS are frequently reported to be the most ideal elastic impression materials because they exhibit better elastic recovery and less permanent deformation than the other elastomers. Condensation silicones show 98.2%–99.6% elastic recovery while PVS shows 99.9% elastic recovery, with the least permanent deformation of. 03%–.5%.[9] Ideally, the material should show 0% permanent deformation for complete elastic recovery, but this is not clinically significant.[14] All of the materials tested in the study should meet the requirement of ISO 4823, which requires >96.5% elastic recovery, i.e., a range of 1%–3% permanent deformation of a material. The relative amount of permanent deformation following strain in compression increases in the following order: addition silicone, condensation silicone, polyether, and polysulfide.[13]

Blomberg et al. reported that PVS have sufficient elastic recovery to allow an impression to be poured only 6 min after removal from the mouth.[9] Marcinak and Draughn evaluated the dimensional change in addition silicones by delaying the pouring of impressions from 2 h to 1 week. They concluded that these materials remained remarkably accurate even after 1 week, with the greatest change at any time being 0.3%.[15] Lacy et al. measured the time-dependent accuracy of elastomeric impression materials and concluded that PVS were the most stable of all elastomers.[16]

According to elastomer theory, shear modulus of an impression material is directly related to the removal of an impression from the mouth as well as poured gypsum model. On these grounds, it was concluded that removal of an impression from mouth and cast is easiest in light bodied silicones followed by light-bodied polysulfides, heavy body silicones, heavy body polysulfides, and polyethers. According to fracture mechanics theory, failure of an impression is due to the stresses at a critical or weak point. Therefore, modulus of elasticity and tear strength are related.[17,18]

Quadrafunctional hydrophilic property of the material is a combination of a cross-linked polymer with an exclusive surface active element. The excellent tear strength is achieved by polymer chain of the material and the surface active agent responsible for their wettability comparable to polyether impression materials. This unique modification of PVS helps to record excellent surface details even in humid atmosphere. The quadrafunctional property of modified PVS offers very high tear strength shown by no other impression material.[19]

Hence, quadrafunctional hydrophilic impression materials are a complete package and combination of properties of polyether and addition-cured impression materials. They have wettability as good as polyether and also show good dimensional accuracy and high resistance to deformation with excellent surface details, and most importantly, materials can be disinfected as well as sterilized without any change in above-mentioned properties.[19]

The autoclavable impression material available in market is AFFINIS. This newly introduced PVS impression material is accurate and dimensionally stable for clinical use when steam autoclaved at 134°C for 18 min.[20]

This study shows that the three elastomeric impression materials tested can withstand higher temperature of sterilization by steam autoclaving without significant effect on their elastic recovery. AFFINIS, the autoclavable impression material, showed increase in elastic recovery properties on treatment with chemical disinfection and autoclave sterilization. Dental professionals may now autoclave these materials in their day-to-day practice without any concern of alteration in physical properties of the materials studied.

CONCLUSION

Within the limitations of this in vitro study, the following conclusions were drawn:

Untreated specimens of AFFINIS showed the least elastic recovery compared to SPEEDEX and AQUASIL, which were similar to each other

On chemical disinfection, elastic recovery of all the three impression materials was found to be similar with AFFINIS showing the best results

On steam autoclaving, AFFINIS showed a remarkable improvement in its elastic recovery, whereas there was no significant change in elastic recovery of SPEEDEX and AQUASIL

Considering the importance of need for sterilization of impressions, the three impression materials tested can be safely autoclaved without significantly affecting the elastic recovery from a clinical point of view.

Financial support and sponsorship

Nil.

Conflicts of interest

There are no conflicts of interest.

REFERENCES

- 1.Rubel BS. Impression materials: A comparative review of impression materials most commonly used in restorative dentistry. Dent Clin North Am. 2007;51:629–42, vi. doi: 10.1016/j.cden.2007.03.006. [DOI] [PubMed] [Google Scholar]

- 2.Craig RG, Powers JM. 11th ed. St. Louis, MO: Mosby; 2002. Restorative Dental Materials; p. 331, 332, 335, 339, 340, 363, 366. [Google Scholar]

- 3.Al-Jabrah O, Al-Shumailan Y, Al-Rashdan M. Antimicrobial effect of 4 disinfectants on alginate, polyether, and polyvinyl siloxane impression materials. Int J Prosthodont. 2007;20:299–307. [PubMed] [Google Scholar]

- 4.Abdelaziz KM, Hassan AM, Hodges JS. Reproducibility of sterilized rubber impressions. Braz Dent J. 2004;15:209–13. doi: 10.1590/s0103-64402004000300009. [DOI] [PubMed] [Google Scholar]

- 5.Chee WW, Donovan TE. Polyvinyl siloxane impression materials: A review of properties and techniques. J Prosthet Dent. 1992;68:728–32. doi: 10.1016/0022-3913(92)90192-d. [DOI] [PubMed] [Google Scholar]

- 6.Shen C. Impression materials. In: Anusavice KJ, editor. Philips' Science of Dental Materials. 11th ed. St. Louis: Elsevier; 2003. pp. 224–3. [Google Scholar]

- 7.Holtan JR, Olin PS, Rudney JD. Dimensional stability of a polyvinylsiloxane impression material following ethylene oxide and steam autoclave sterilization. J Prosthet Dent. 1991;65:519–25. doi: 10.1016/0022-3913(91)90292-5. [DOI] [PubMed] [Google Scholar]

- 8.Giammanco GM, Melilli D, Rallo A, Pecorella S, Mammina C, Pizzo G. Resistance to disinfection of a polymicrobial association contaminating the surface of elastomeric dental impressions. New Microbiol. 2009;32:167–72. [PubMed] [Google Scholar]

- 9.Blomberg PA, Mahmood S, Smales RJ, Makinson OF. Comparative elasticity tests for elastomeric (non putty) impression materials. Aust Dent J. 1992;37:346–52. doi: 10.1111/j.1834-7819.1992.tb00759.x. [DOI] [PubMed] [Google Scholar]

- 10.ASTM International. ASTM D412-06ae2, Standard Test Methods for Vulcanized Rubber and Thermoplastic Elastomers – Tension. West Conshohocken, PA: ASTM International; 2006. [Google Scholar]

- 11.Infection control recommendations for the dental office and the dental laboratory. Council on dental materials, instruments, and equipment. Council on dental practice. Council on dental therapeutics. J Am Dent Assoc. 1988;116:241–8. doi: 10.14219/jada.archive.1988.0341. [DOI] [PubMed] [Google Scholar]

- 12.Kugel G, Perry RD, Ferrari M, Lalicata P. Disinfection and communication practices: A survey of U.S. Dental laboratories. J Am Dent Assoc. 2000;131:786–92. doi: 10.14219/jada.archive.2000.0278. [DOI] [PubMed] [Google Scholar]

- 13.Lu H, Nguyen B, Powers JM. Mechanical properties of 3 hydrophilic addition silicone and polyether elastomeric impression materials. J Prosthet Dent. 2004;92:151–4. doi: 10.1016/j.prosdent.2004.05.016. [DOI] [PubMed] [Google Scholar]

- 14.Klooster J, Logan GI, Tjan AH. Effects of strain rate on the behavior of elastomeric impression. J Prosthet Dent. 1991;66:292–8. doi: 10.1016/0022-3913(91)90252-r. [DOI] [PubMed] [Google Scholar]

- 15.Marcinak CF, Draughn RA. Linear dimensional changes in addition curing silicone impression materials. J Prosthet Dent. 1982;47:411–3. doi: 10.1016/s0022-3913(82)80092-9. [DOI] [PubMed] [Google Scholar]

- 16.Lacy AM, Fukui H, Bellman T, Jendresen MD. Time-dependent accuracy of elastomer impression materials. Part II: Polyether, polysulfides, and polyvinylsiloxane. J Prosthet Dent. 1981;45:329–33. doi: 10.1016/0022-3913(81)90400-5. [DOI] [PubMed] [Google Scholar]

- 17.Callister WD., Jr . 1st ed. New York: John Willey & Sons, Inc; 1985. Materials science and Engineering; pp. 362–7. [Google Scholar]

- 18.Herfort TW, Gerberich WW, Macosko CW, Goodkind RJ. Tear strength of elastomeric impression materials. J Prosthet Dent. 1978;39:59–62. doi: 10.1016/s0022-3913(78)80048-1. [DOI] [PubMed] [Google Scholar]

- 19.Millar BJ, Sanjukta D. Effect of autoclave sterilisation on the dimensional stability and tear strength of three silicone impression materials. Open J Stomatol. 2014;4:518–26. [Google Scholar]

- 20.Reddy SM, Vijitha D, Karthikeyan S, Balasubramanian R, Satish A. Evaluation of dimensional stability and accuracy of autoclavable polyvinyl siloxane impression material. J Indian Prosthodont Soc. 2013;13:546–50. doi: 10.1007/s13191-012-0168-z. [DOI] [PMC free article] [PubMed] [Google Scholar]