Abstract

In this research, the unrefined non-centrifugal sugar (UNCS) quality obtained from two sugarcane varieties (RD 7511 and CC 8475) and using two types of technologies (traditional and Ward-Cimpa production facilities) were evaluated. The parameters monitored through the process were impurities, total soluble solids, acidity, pH, and temperature profile. Microbiological analyses were carried out on beating, molding, packing, and storage operations; and finally, an organoleptic analysis was carried out on the final UNCS product. Results showed that the UNCS obtained from variety CC 8475 had higher consumer acceptance; meanwhile, the technologies assessed did not show significant differences in final product quality. However, these technologies showed significant differences in the highest temperature, syrup, and juice properties. Microbiological analyses highlighted beating and molding as the critical points in UNCS production safety. Finally, it was evident that the implementation of new technologies or the improvement of the furnace, as in the Ward-Cimpa production facility, is not enough to achieve food safety requirements, as many other conditions affect the microbiological quality of the product. Although the temperatures reached on the Ward-Cimpa furnace are higher than those reached with the traditional furnace and thus, enough to kill all the harmful microorganisms, contamination in downstream operations still occurs.

Keywords: Industrial engineering, Food technology, Food safety, Manufacturing engineering, Heat transfer, Food quality, Microbial ecology of foods, Food acceptance, Jaggery, Kokuto, Beverage quality, Consumer acceptation, Ward-Cimpa chamber, Sugar cane juice, Microbiology quality

Industrial engineering; Food technology; Food safety; Manufacturing engineering; Heat transfer; Food quality; Microbial ecology of foods; Food acceptance; Jaggery; Kokuto; Beverage quality; Consumer acceptation; Ward-Cimpa chamber; Sugar cane juice; Microbiology quality

1. Introduction

In recent years, an increase in the number of research studies focused on modernizing production facilities for the production of unrefined non-centrifugal sugar (UNCS) has been carried out. This upgrading has been motivated by the current food consumption trends towards high-quality products that are also healthier. This is the case of UNCS that provides not only sucrose but also contains minerals in quantities similar to those recommended for daily intake.

UNCS is manufactured in several countries and is known as kokuto sugar (Japan), jaggery (the Philippines), gur (India), panela (Colombia and Peru), chancaca (Honduras), rapadura (Brazil), and piloncillo (Costa Rica). The UNCS agroindustry is working on different strategies to respond to food consumption trends and to improve the competitiveness of this productive chain (Jaffé, 2014; Gutiérrez et al., 2018). One of the research lines is focused on identifying varieties that combine high production per hectare with high UNCS quality, maintaining good flavor, color, texture, and solubility (López, 2013; Ramírez et al., 2014; Ordoñez et al., 2013). However, the UNCS production process has been the line that has achieved the most significant advances (Asikin et al., 2016; Prada-Forero et al., 2014, 2015; Torregrosa et al., 2016). Rodriguez et al. (2018) describe in detail different technologies currently available for UNCS production. These illustrate the progress achieved in combustion and heat transfer, which have increased the efficiency of the process and have managed to reduce the environmental impact. Conditions for extraction, cleaning, and clarification operations have also been improved, leading to better color and appearance of the final UNCS (López, 2013; Prada-Forero et al., 2015; Asikin et al., 2016). In addition, good manufacturing practices (GMP) in the UNCS industry and new product presentations, such as granulated or powder UNCS, have been proposed (Ordoñez-Díaz and Rueda-Quiñónez, 2017; Bustamante and Intriago, 2015) as new market strategies to improve its competitiveness (Contreras et al., 2016) and reach higher-value markets (Castellano, 2014). In this sense, UNCS is not only considered as a mere sweetener by consumers, as it contains some functional compounds (Mascietti, 2014; Jaffé, 2015; Shrivastav et al., 2016; García et al., 2017).

The UNCS production is a process in which sugar cane stalks are crushed through roller mills to extract the juice. The process is shown in Fig. 1. The fresh sugar cane juice undergoes a pre-cleaning operation in which all solids present in the juice, such as particles of bagasse or any other suspended material, are removed by passing the juice through one or two filters connected in series. Then, solids-free juice is taken into a clarification step in which, by increasing pH and temperature, and by adding natural clarifying agents or flocculants, undesirable compounds like gums, proteins, fats, and waxes are removed by sedimentation. This operation is carried out in one or two pans in which juice is heated up to its bubble temperature. The juice is then evaporated in a series of open pans, where its viscosity and its sugar concentration is increased. When the juice reaches 60° Brix, it receives the name of sugar cane honey. This honey undergoes further concentration in small open pans until attaining the highest temperature (116–124 °C) and also the maximum sugar concentration (88–94° Brix); subsequently, the time (set-point) in which the viscous cane syrup must be removed from the pan and directed towards the molding operations is established, and a series of wood molds are used to give UNCS its final shape. Then, the UNCS is cooled and packed into carton packages or plastic bags. In other cases, the highly viscous and heated product is placed into a stainless steel bowl or pan where it is whipped vigorously to produce granulated UNCS. This product is also packed in plastic bags.

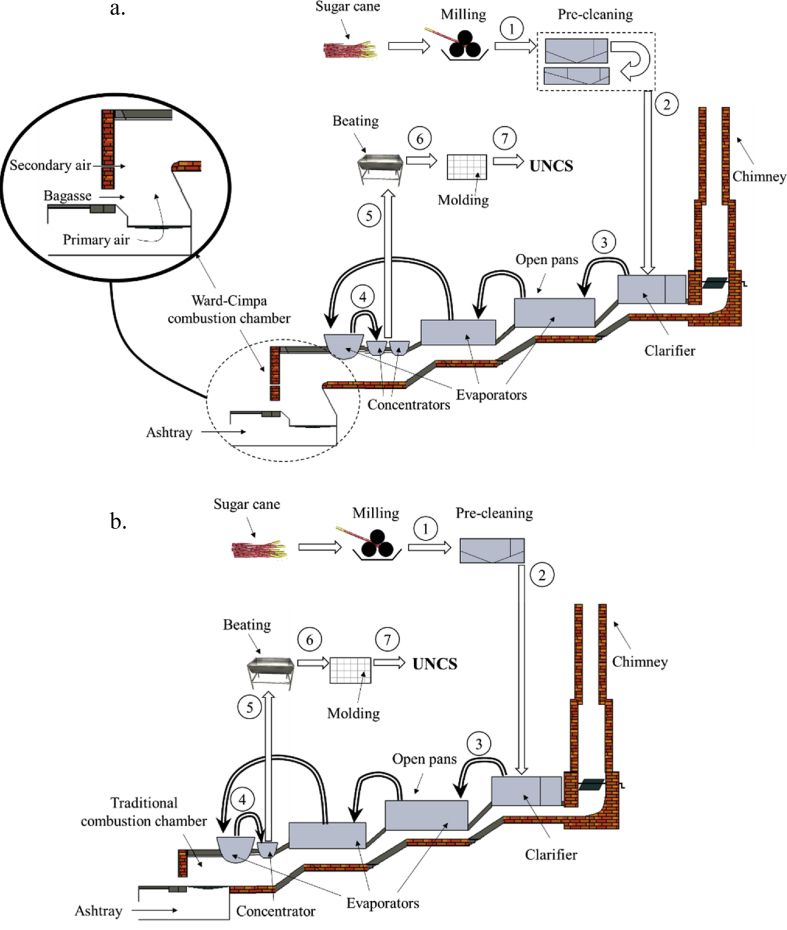

Fig. 1.

Furnace for UNCS production: a) Furnace designed with a zoom of the Ward-Cimpa combustion chamber, and b) Traditional furnace. All the sampling points for analysis can be observed: 1) milling, 2) pre-cleaning, 3) clarification, 4) evaporation, 5) concentration, 6) beating, and 7) molding.

The different chambers, pan designs, and UNCS production facilities used in this process are widely described by Rodriguez et al. (2018). However, a brief explanation of the differences between the two technologies under evaluation in the present study is provided as follows. The UNCS manufacturing process is carried out in a furnace, as can be seen in Fig. 1.

The most important progress achieved in the UNCS production process corresponds to the redesign of the combustion chamber. The new design, known as Ward-Cimpa (Fig. 1a) allows higher combustion gas temperatures (1,100 °C) compared to the traditional (Fig. 1b) combustion chamber that only reaches 650–850 °C; furthermore, the new combustion chamber also reaches higher global thermal efficiency, i.e., 44% in the Ward-Cimpa vs. 32% in the traditional furnace, respectively (Rodriguez et al., 2018).

The higher global thermal efficiency reached by the Ward-Cimpa combustion (WCC) chamber requires integration with the other operation processes, to make better use of the advantages previously mentioned. The production facilities with the WCC chamber are more efficient because they reach higher gas combustion temperature; this, in turn, increases the evaporation and juice concentration rate. Thus, as the WCC facilities demand a higher amount of clean juice, the pre-cleaner system becomes a bottleneck for UNCS production if this section is not improved as well. Therefore, to solve this issue, a double pre-cleaner is installed in the facilities that incorporate a WCC chamber, as can be observed in Fig. 1a.

Furthermore, concerning the sugarcane varieties that will be used to produce UNCS, these should meet certain basic parameters, such as high cane tonnages per unit area without decreasing production time, high by-product yield derived from harvest and UNCS processing for animal feeding purposes. Preferably, these should be resistant to diseases of economic importance in its production system, have a wide adaptive range to different environmental conditions, juice with high sucrose content, and high juice extraction in the mill. Moreover, also resistance to overturning, uniform plant development, and low or no flowering stage to avoid affecting the production. Finally, the sugarcane varieties should be resistant to drought and also to high aluminum concentration in the soil, and resistant to sucrose inversion after cutting (Ramírez et al., 2014). Among the most popular sugar cane varieties cultivated in Colombia, CCSP 89-43, CC 91-1555, CC 92-2154, CC 93-7510, CC 99-1405, CC 01-678, CC 01-1305, RD 75-11, CC 88-439, CC 92-2198, CC 92-2965, CC 93-714, CC 93-3458, CC 93-7711, and CC 00-2639 are highlighted (García et al., 2007). Among these, RD7511 and CC8475 show a conversion ratio from sugars to NCS higher than 11%, and their sugarcane productivity is higher than 120 t ha−1 with a minimum UNCS production of 20 t ha−1 (Ramírez et al., 2014). Nonetheless, RD7511 has a thicker cane and is preferred by producers given its higher cane yield. On the other hand, and despite having CC8475 a thinner cane on average, and also a lower cane yield compared to RD7511, it exhibits higher sugar yield per hectare and also better performance in hillside areas.

Studies such as the one carried out by García et al. (2017) have shown that sugar cane varieties exhibit very different yields and juice composition features that are affected additionally, by the production conditions and the maturity of the cane when harvested. Sugar cane yield in Colombia ranges from 60 to 130 t ha−1, while the conversion rate from sugar to UNCS varies between 0.041 and 0.155 kg kg−1 of sugar cane, i.e., 2 to 20 t ha−1 of UNCS (García et al., 2007). This same study pointed out that operational conditions, such as pH, temperature, and pressure, exert a more profound effect on final product quality compared to intrinsic varietal features.

According to Prada-Forero (2006), the UNCS quality factors affected by the technology used are the presence of insoluble solids (impurities) and hardness. The first is influenced by the heating velocity and the cleaning efficacy (number of pre-cleaning steps or design); while the latter is affected mostly by the heating speed, i.e., the faster the heating, the lower the presence of reducing sugars, and subsequently, the UNCS becomes harder.

Despite the complete review carried out by Rodriguez et al. (2018) on the different types of UNCS production facilities, as well as other studies published by García et al. (2017), Prada-Forero et al. (2015), Chaves et al. (2015), and Prada-Forero et al. (2014) concerning the effect of some operational conditions on the UNCS quality, there is not enough information on the incidence of technological advances (new designs) and varieties on UNCS safety and its sensorial quality, i.e., consumer acceptance features. Accordingly, the aim of this study was to evaluate if the production technology and the sugarcane variety exert any effect on UNCS quality.

2. Materials and methods

2.1. Sugar cane varieties

The sugarcane varieties selected for this work were RD7511 and CC8475, as they meet the minimum feature requirements for sugarcane and UNCS production. Both sugarcane varieties were harvested from a commercial farm (55°55′57″ of latitude N and at 73°37′16″ of longitude W) located in San José de Pare, department of Santander, Colombia.

2.2. Production technology

The two technologies evaluated were i) a furnace with a traditional combustion chamber, and ii) a furnace with the improved Ward-Cimpa combustion chamber. The first UNCS production facility, in addition to having a traditional chamber, also includes a pre-cleaner, two clarifying pans, three semi-spherical evaporators, and an open pan concentrator. It is located in the municipality of San José de Pare at 5°55′57″ of latitude N and at 73°37′16″ of longitude W. The second UNCS production facility includes a WCC chamber with two pre-cleaners instead of only one, two clarifying pans, three evaporator pans, and two pan concentrators. It is located in the municipality of Santana, in the region of la Hoya del Río Suarez, at 6°04′55.6″ of latitude N and 73°28′2.9″ of longitude W.

2.2.1. Sample collection

Samples were taken at the exit end of each operation unit (i.e., milling, pre-cleaning, clarification, evaporation, concentration, beating, and molding, as can be observed in Fig. 1). Sampling was carried out from three subsequent UNCS production batches to have three replicates for the analysis. Each sample was subjected to physicochemical characterization, including microbiological and sensory evaluations to the UNCS, as this is the final product for consumers.

2.3. Physical characteristics

The response variables included moisture content, density, dissolution capacity, impurities content, texture, and color. Moisture content was evaluated employing protocol AOAC 925.45, and density that was assessed according to the NTC 5863-1 (Colombian Technical Standard NTC, for its abbreviation in Spanish).

Dissolution capacity was established by preparing a solution with 20 g of crushed UNCS in 250 mL of water, stirring at 150 rpm at a temperature of 24 °C for 2 min. Then, the solution was filtered through a previously weighted Whatman No. 4 filter paper, and the residue was dried at 60 °C for 30 min. Afterward, the weight of the insoluble residue was obtained, calculating the dissolution capacity in Eq. (1), according to Palacios (2012):

| (1) |

The initial UNCS weight was 20 g (Palacios, 2012).

Impurities content was measured using a sample of 50 g of crushed UNCS dissolved in 100 mL of distilled water at room temperature. Then, the solution was filtered with a vacuum pump in a Büchner funnel equipped with a No. 4 Whatman filter paper. The solids retained were dried in an oven at 60 °C for 30 min and subsequently weighed. The impurities were calculated according to Eq. (2) as follows:

| (2) |

Texture is a critical characteristic that was measured using a texturometer equipped with the Nexagen® software, including a puncture to establishing fracturability (kgf) in UNCS samples of 9 cm2 and 0.3 cm of thickness, respectively (Alvis et al., 2011).

Color was established using a Konica Minolta CR 400 colorimeter. The CIELAB space was used to establish the values of coordinates L*, a*, and b* that correspond to the variation between luminosity, reddish-greenish, and yellowish-blue, respectively, as well as the tone (Chroma) and color angle (°HUE) calculated from these same parameters (García et al., 2017).

2.4. Chemical characteristics

The following chemical characteristics were evaluated according to their respective AOAC method: pH (AOAC 981.12), titratable acidity (AOAC 942.15), and total soluble solids (AOAC 970.59).

2.5. Sensory evaluation

This analysis was solely carried out for UNCS using subjective tests, i.e., a consumer acceptance test carried out through a survey. The target group, which was previously selected, included 76 frequent UNCS consumers. This target group conducted an online survey that allowed identifying color, taste, and smell attributes as the most relevant UNCS traits for consumers. Based on this information, an acceptance test with a verbal hedonic scale of five categories was designed and applied to 76 panelists. As UNCS is mostly consumed as a beverage, the samples used for the test were prepared by diluting 100 g of UNCS in 1 L of drinking water (40 °C), achieving a concentration of 10%. Samples were presented to subjects in 30 mL disposable cups in random order. Subjects were asked to drink the content of each cup and hold the liquid in their mouths as long as they needed to make hedonic and perceptual judgments. Next, they were asked to expel or spit out the beverage completely, then eat a piece of unsalted soda cracker and thoroughly rinse their mouth with drinking water. Each sample was rated along a 5-points category scale that ranged from “I like it very much” to “I dislike it very much.”

The endorsement of an ethical committee was not necessary for the development of this project, as the UNCS is a natural sweetener that has some minerals and vitamins, and is consumed daily by the population in many different countries. The NTC 4206 (ICONTEC, 2016), that is the national standard guide recommended by carried out this kind of sensory test; and also the ISO 6658:2017 were taken as guide for this sensory taste. According to Declaration of Helsinki (WMA, 1954) and amended by the WMA General Assembly, Seoul, Korea, October 2008, the Ethical committee is addressed only in case of Medical Research Involving Human Subjects; and this is not the case. Only an acceptance taste session was carried out with the UNCS as a beverage, as is traditionally consumed by Colombians, not any kind of medical study.

2.6. Microbiological analysis

Critical control points were established throughout the sample analysis taken from utensils, surfaces, employees that handle the UNCS, as well as from the environment at the production sites, to compare the two processing technologies assessed according to their microbiological conditions. The microbiological analysis was carried out in downstream operations after the highest temperature was reached (116°C–124 °C). Before this point, no microbial analysis was carried out considering that at this temperature, no food pathogen can survive. The analysis included counting mesophilic aerobes, fecal and total coliforms, fungi (molds) and yeasts, to verify GMP during the UNCS production process, following the Colombian Technical Standard NTC-5230.

2.7. Statistical analysis

This research was carried out employing a 2 × 2 factorial design, with the sugarcane variety and the processing technology as the factors evaluated. All analyses were executed in triplicate, and the results were presented as means ± SD. The analysis of variance was carried out using ANOVA procedures (ANOVA, Statgraphic Plus, 5.1, Manugistic Inc., Rockville, MD, USA). Significant differences for physicochemical characteristics were evaluated according to Tukey's multiple range test. Further, differences at p < 0.05 were considered statistically significant. For the sensory evaluations, a non-parametric Mann-Whitney test was performed.

3. Results and discussion

3.1. Physical characteristics

3.1.1. Moisture content

Both technologies meet the requirements established in resolution 779 of 2006 of Ministerio de Protección Social [Ministry of Social Protection] of Colombia, indicating that the maximum moisture content should be 9% for UNCS as a solid block, and 5% for granulated or powder UNCS. Results for UNCS employing the Ward-Cimpa technology achieved a humidity of 6.1%, while UNCS elaborated with the traditional technology, reported a value of 7.2% without showing significant differences between the varieties assessed. This low moisture content is adequate for this UNCS product as it leads to a better appearance, texture, and lower contamination risk.

3.1.2. Dissolution capacity

Significant differences were found associated with the sugarcane variety with p < 0.05. The UNCS obtained from variety CC 8475 reported an average solubility of 79.77 ± 4.83% compared to variety RD 7511 that reached an average solubility of 65.96 ± 4.64%. This trait is vital for consumer acceptance, as higher dissolution capacity shortens the preparation time of UNCS beverages.

3.1.3. Density

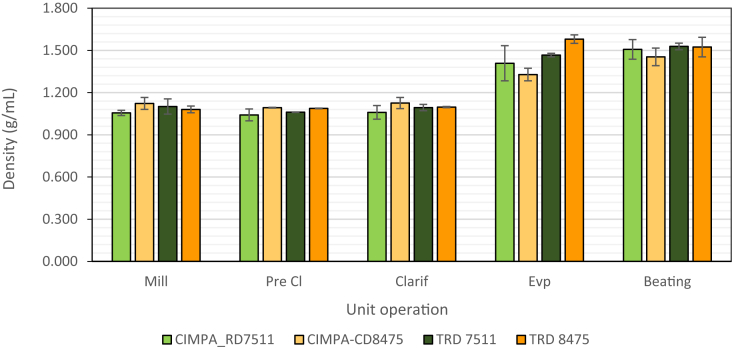

This feature showed an increase throughout the process corresponding to an increase in the concentration of total soluble solids (TSS). Alarcón et al. (2016) reported values of 1.23–1.34 g mL−1 for honey with TSS content between 50 and 70° Brix, similar to those obtained in this study. Density values achieved ranges between 1.4 and 1.5 g mL−1 (Fig. 2.), corresponding to TSS concentrations of 53 and 74° Brix, respectively. However, there were no significant differences due to the technology or the variety used. Density is essential to establish a set point to take the UNCS out from the furnace and direct it towards the beating step to cool it down and form its typical block presentation structure.

Fig. 2.

Density evolution throughout the production process of unrefined non-centrifugal sugar from two varieties (RD7511 and CC8475) and using two technologies (TRD: traditional; CIMPA: Cimpa-Ward) per unit operation: Mill: milling; Pre Cl: pre-cleaning, Clarif: clarification; Evp: evaporation; Beating.

Peña (2017) raised the relation between the density and the concentration of TSS, which allows having more objective and standardized criteria to determine the UNCS set point. Currently, producers carry out this step in a subjective manner, checking the viscosity and ebullition rate of the cane honey. This leads to UNCS with different particle size or texture, dissolution capacity, and sugar concentration.

3.1.4. Texture and color

These are a decisive factor for consumer acceptance, and therefore, these are usually assessed through sensory evaluations. However, more objective criteria that allow standardizing the UNCS quality, considering these two critical parameters, were measured using the following analytical methods.

3.1.4.1. Texture

This characteristic includes different traits, such as thickness, cohesiveness, smoothness, and adhesiveness, among others. Nonetheless, this study focused on UNCS hardness because of its importance for consumer acceptance. The results concerning this analysis showed no significant differences related to the variety or the technology, as shown in Table 1, although variety CC8475 showed higher resistance to fracturing tendency. Currently, there are no standards or quantitative recommendations for UNCS hardness, but it must be hard enough to allow handling, storing, and stacking without significant disintegration, and without hindering its preparation as a beverage. According to the results found in this study, a hardness value of 3 kgf is adequate for UNCS that will be commercialized as blocks. It is essential to point out that this feature allows discerning the reducing sugars content of UNCS (Thangavelu, 2009), i.e., when there is a lower reducing sugar content, the UNCS is harder. Thus, hardness can be used as an indirect measure of reducing sugar content in UNCS.

Table 1.

Texture analysis for unrefined non-centrifugal sugar in terms of fracturability (kgf) obtained with the sugarcane varieties RD 7511 and CC 8475.

| Technology | Fracturability (kgf) |

|

|---|---|---|

| Variety RD 7511 | Variety CC 8475 | |

| Traditional | 3.26 ± 0.37 | 3.66 ± 0.35 |

| Ward-Cimpa | 2.754 ± 0.57 | 7.68 ± 3.08 |

3.1.4.2. Color

This is one of the most critical consumer acceptance aspects of UNCS, but it is also one of the most complex variables to control and standardize. Many factors affect color, including the sugarcane variety and its chemical composition (sugars, flavonoids and organic acids), the agro-ecological conditions, the presence of diseases, the type and concentration of the clarifying extracts, the temperature profile, the residence times, and the efficiency of the clarification processes (Demera et al., 2015; Prada-Forero et al., 2015; Asikin et al., 2016; Lara and Clavijo, 2016; Gutiérrez et al., 2018; Rozo, 2017). Nevertheless, this study showed that the manufacturing technology did not affect this feature; on the contrary, the sugarcane variety showed marked significant differences in color parameters evaluated in UNCS samples from varieties CC 8475 and RD 7511 (Table 2).

Table 2.

Global average and standard deviation for color parameters in the CIELAB space: L*, tone and °HUE of sugarcane varieties (RD 7511 and CC 8475).

| Technology | L* |

Tone (Cr*) |

°HUE |

|||

|---|---|---|---|---|---|---|

| RD 7511 | CC 8475 | RD 7511 | CC 8475 | RD 7511 | CC 8475 | |

| Traditional | 27.89 ± 1.41 | 38.57 ± 3.48 | 6.0 ± 2.43 | 14.6 ± 1.54 | 52.9 ± 9.25 | 65.4 ± 5.88 |

| Ward-Cimpa | 30.78 ± 0.12 | 35.97 ± 1.45 | 5.8 ± 1.10 | 15.8 ± 0.85 | 43.3 ± 8.32 | 65.6 ± 1.48 |

Although the color is one of the most important parameters for consumer acceptance, there are no standards or color references that allows identifying and establishing the best color for UNCS products. Only orange-brown tones are recommended, avoiding too light or strong orange tones as these are associated with the addition of prohibited color modifier additives.

Although no significant differences were found for °HUE, L and Chroma related to the technology used, results showed °HUE values ranging from 43 to 65. HUE values close to 43° correspond to a reddish color while tones close to 60 °HUE are near the red-orange and brown balance. The latter describes the UCNS color preferred by consumers. Further, L* parameter showed values of 28 and 38 for UNCS elaborated from variety RD7511 and CC8475, respectively. This means that UNCS elaborated from sugarcane variety CC8475 leads to clearer and brighter colored products (Table 2). Finally, Chroma indicated colors of low average intensity for all UNCS elaborated using the two technologies and the two varieties assessed. Differences found in color parameters in UNCS samples from these two varieties could be because sugar cane variety RD7511 was affected by the presence of the sugarcane borer Diatraea saccharalis, which can, in turn, affect the color of the final product. Although this disease does not pose any risk for human health, it could produce unwanted color for the final UNCS product, considering that diseased cane stalks show different symptoms as a dark color that can be transferred to the juice. Furthermore, Diatraea saccharalis generates residues than can increase the content of impurities that may affect the final product color, if these are not completely removed. On the other hand, the effect of the technology used could be masked by an entire series of factors mentioned above that influence the final UNCS color, and that were not controlled in the process.

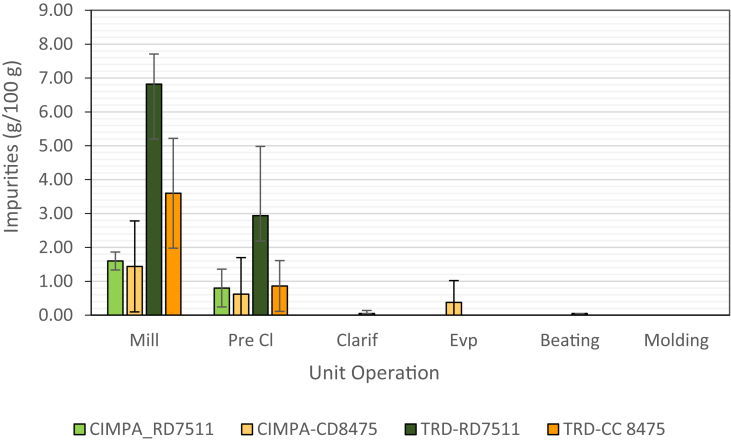

3.1.5. Impurities content

WCC technology showed lower contents of impurities throughout the entire process compared to those found with the traditional production facility (Fig. 3). However, during the clarification step, these differences disappeared, and the juices from the two technologies showed minimal impurities, without significant differences among them. This indicates that the operating conditions during juice clarification in the traditional production facility are more demanding when for example, clarifying mucilaginous extracts (e.g., Guazuma ulmifolia Lamark, Ochroma lagopus SW, or Triumfetta lapull). Further, this is also the case when adding lime (CaO); although lime is usually added to increase the pH until values around 5.7 ± 0.1 to reduce the formation of reducing sugars (Prada-Forero et al., 2015), this increase contributes to destabilize, agglomerate and remove colloid and pigmented materials that reduce the final UNCS quality. Hence, it seems that a higher amount of lime was added to the juice from the RD7511 variety, as it showed the highest amount of impurities when it came out from the mill (Fig. 3). This was corroborated by the pH values reached by the juice from this same variety coming out of the clarification step.

Fig. 3.

Impurity dynamics throughout the production process of unrefined non-centrifugal sugar from two varieties (RD7511 and CC8475) and using two technologies (TRD: traditional; CIMPA: Cimpa-Ward) per unit operation: Mill: milling; Pre Cl: pre-cleaning; Clarif: clarification; Evp: evaporation; Beating; and Molding.

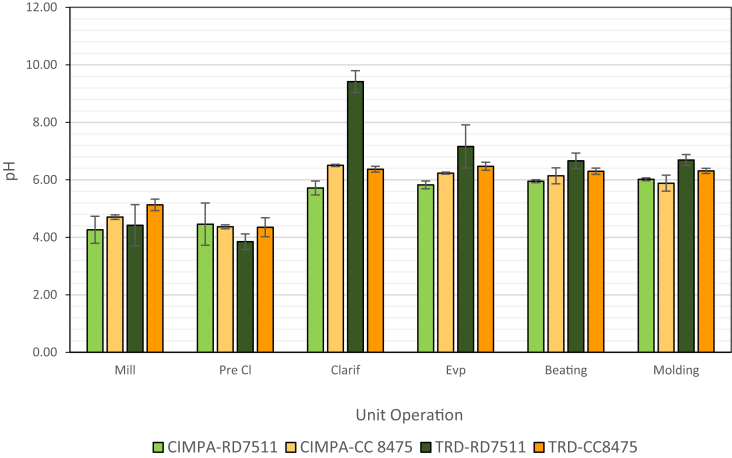

3.2. Chemical characterization

Total soluble solids content in the two sugarcane varieties was low (17° Brix), probably because the test was performed during the rainy season. The sugar content in UNCS is discussed in the sensory evaluation section, as the sweetness is more important for consumers than the sugar content. Concerning pH, Fig. 4 shows the dynamics of pH throughout the UNCS manufacturing process. The pH of the UNCS samples elaborated in a traditional furnace showed higher values compared to those recommended for UNCS, which should be among 5.8 and 6.0. On the other hand, the pH of UNCS samples elaborated in a WCC facility is within the range recommended to reduce sucrose inversion and contribute to obtaining products of higher microbiological stability and shelf life. These differences observed between the two technologies assessed could be due to the more efficient pre-cleaner system installed in the WCC facility that significantly reduces the impurities present in the juice. Thus, when the juice arrives into the clarification system, the amount of lime added to remove the residual impurities is lower than what is required for juice in the traditional system with a less efficient pre-cleaning system. If the latter occurs without control, a higher amount of lime will have to be added to the juice in the clarification system, as it will have a higher presence of impurities; besides, higher pH values will also be obtained.

Fig. 4.

Evolution of the pH throughout the production process of unrefined non-centrifugal sugar from two varieties (RD7511 and CC8475) and using two technologies (TRD: traditional; CIMPA: Cimpa-Ward) per unit operation: Mill: milling; Pre Cl: pre-cleaning; Clarif: clarification; Evp: evaporation; Beating; and Molding.

Finally, it is essential to point out that the WCC facility requires shorter residence times, a condition that contributes to the safety of the UNCS, as high temperature for extended periods leads to the formation of unwanted compounds such as acrylamides that undermine the safety of the final product (Vargas et al., 2014).

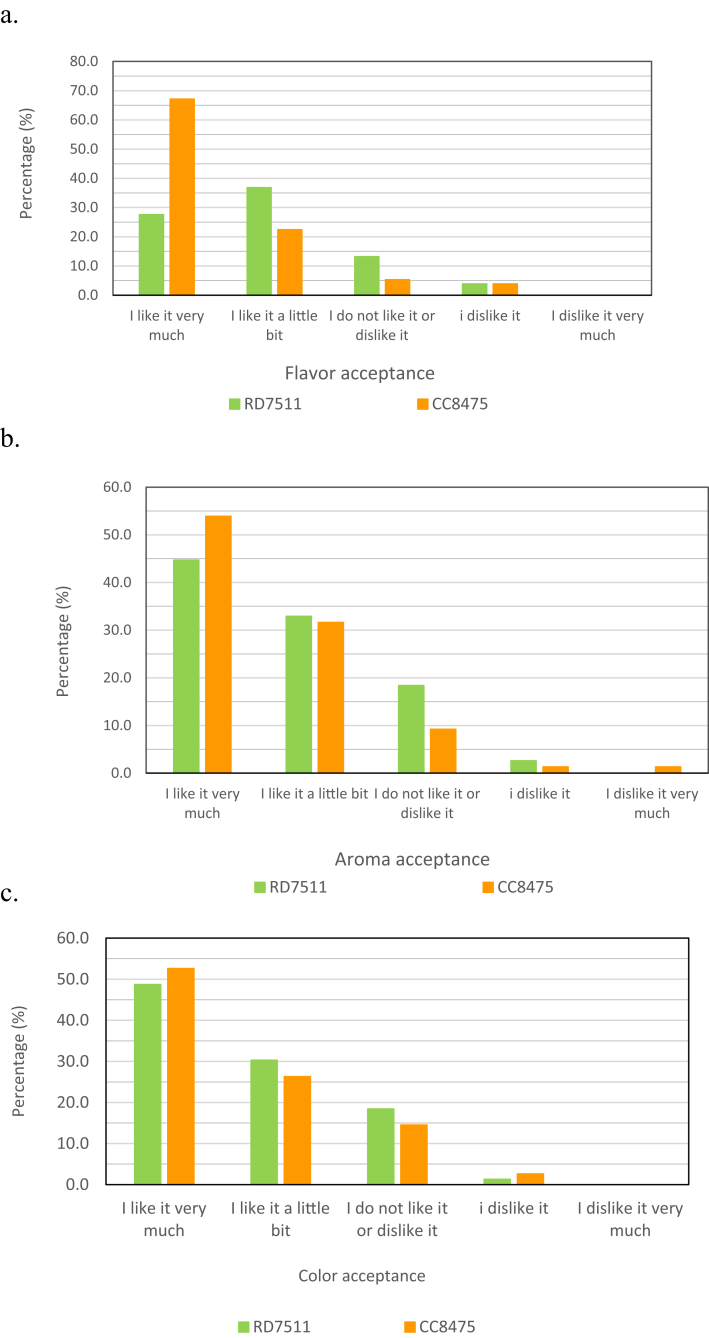

3.3. Sensory analysis

A sensory analysis together with a microbiological assessment are necessary to evaluate UNCS quality compared to only carrying out a physicochemical analysis, as the final goal is to respond to consumer expectations. In this sense, food security and organoleptic traits are the best criteria used by consumers to define UNCS quality. A global analysis on how consumers perceive sweetness or acidity, smell, flavor, and color in UNCS, was carried out. Despite being UNCS consumed as a beverage, it is commercialized in solid form, mostly in blocks. Consumers typically seek a product with a slightly sweet taste, light brown color, and its typical aroma. The results of the survey are presented in Fig. 5, where a good acceptance of the UNCS beverage elaborated with both varieties is observed. The analysis of results using the Mann Whitney test and the Minitab® software did not report significant differences between the two varieties for any of the sensory attributes evaluated by the consumers surveyed. Nevertheless, Fig. 5 shows consumers taste ratings for UNCS beverage, showing that the one elaborated with variety CC8475 had a better taste compared to variety RD7511.

Fig. 5.

Sensory acceptance test for unrefined non-centrifugal sugar elaborated from two sugarcane varieties (RD7511 and CC8475) in the Ward-Cimpa production facility. The following variables were assessed: a) flavor (taste), b) aroma, and c) color.

The sensorial quality of UNCS is difficult to control and standardize as many of the parameters, such as color, taste, texture, and aroma, depend on different factors like soil quality, sugarcane variety, environmental relationships, resistance to diseases, cane stalk features, and operational conditions along the furnace operations, among others. This makes the elaboration process and the quality and homogeneity of the UNCS produced challenging to standardize. Therefore, any technological development (design) must be accompanied by a thorough knowledge of the entire production system, from the cultivation of the sugar cane, until the final UNCS product is obtained. This should include all the effects that the new designs may generate, to offer an integrated technology solution that responds to the expectations of producers, but also to the quality and safety requirements that the consumers are demanding. Therefore, when UNCS producers attain process standardization and guarantee high-quality UNCS, this product will be able to reach higher-value markets (Quezada and Gallardo, 2014; Quezada et al., 2017).

3.4. Microbiological analysis

Table 3 shows the results of the microbiological analysis carried out to ensure product quality and safety, contributing to increasing the competitiveness of this productive chain. The microbiological analysis identified the beating operation as the one with the highest contamination risk, both due to the lack of basic and necessary practices such as hand washing, as well as limitations in facilities, tools, and cleaning and disinfection practices.

Table 3.

Identification of critical microbiological control points.

| Technology | Process point | Sample | Dilution | Total coliforms (cfu/100 cm2) | Fecal coliforms (cfu/100 cm2) | Mesophilic aerobes (cfu/100 cm2) | Molds and yeasts |

|---|---|---|---|---|---|---|---|

| Ward-Cimpa | Beating | Hands | 2 | - | - | 1 | - |

| Pans | 2 | - | - | - | - | ||

| Tools | 2 | 19 | 4 | 18 | Presence | ||

| Molding | Tables | 2 | 2 | - | 4 | - | |

| Drawers | 2 | - | - | 7 | Presence | ||

| Storage | Containers | 2 | - | - | 3 | - | |

| General | Environment | N.A. | - | - | 58 | Presence | |

| Traditional | Beating | Hands | 2 | 16 | - | 27 | - |

| Pans | 2 | - | - | - | - | ||

| Tools | 2 | 3 | 1 | 17 | Presence | ||

| Molding | Tables | 2 | - | - | - | - | |

| Drawers | 2 | - | - | - | Presence | ||

| Storage | Containers | 2 | - | - | - | - | |

| General | Environment | N.A. | - | - | 102 | Presence |

N.A. Not available.

Some of the deficiencies identified were the absence of illumination and ventilation in the beating and molding room, and the use of utensils made of wood and other porous materials with a tendency to crack and pierce, becoming a focus of contamination (Montenegro, 2015; Mendieta et al., 2017). Furthermore, analyses of the utensils used found total and fecal coliforms. This requires the immediate implementation of good management practices to guarantee the quality and harmlessness of the UNCS, eliminating contamination risks by controlling the critical points that were identified. Moreover, high humidity conditions were found in the molding and storage rooms, favoring the growth of fungi and yeasts. This is why room ventilation must be improved without delay. Additionally, there are minimal care conditions when drying and packing the UNCS products, agreeing with the results obtained by Corrales et al. (2012). These authors found that the environmental conditions in the packaging stage of the UNCS favor fungi growth (Aspergillus sp., Penicillium sp., Fusarium sp. and Mucor sp.) as well as osmophilic yeasts that can deteriorate and re-contaminate the final product diminishing its useful life. This translates into lower income for producers, lower possibilities of expanding the market, and higher risks of market loss or closure.

Likewise, infrastructure conditions in the two furnaces evaluated were not adequate to meet the provisions of resolution 779 of 2006, chapter 4, article 9 of Ministerio de Protección Social [Social Protection Ministry], mostly because the materials used in the walls, tables, tools, and utensils, are not appropriate for food processing and handling as they are difficult to clean and disinfect, and they are porous, absorbent and have cracks.

4. Conclusions

Despite the important progress achieved in combustion and heat transfer processes implemented in a production facility designed with a Ward-Cimpa combustion chamber compared to a traditional facility, there are still gaps regarding the quality and safety of the unrefined non-centrifugal sugar (UNCS) produced that have not been considered when the technology was improved. These gaps include the lack of more adequate conditions and materials for beating and molding, especially if they are in direct contact with the UNCS.

The sugarcane varieties assessed showed differences in dissolution capacity. For example, UNCS elaborated with the juice from variety CC8475 showed a higher solubility capacity compared to RD7511, a feature that is very important when used to prepare beverages.

In terms of the sensory analysis, a high acceptance degree of the color and aroma of the UNCS elaborated with the two sugarcane varieties was found; thus, it seems that organoleptic characteristics are not affected by the production technologies evaluated.

Tools, personnel and facilities for beating, molding, packaging and storing UNCS showed deficiencies in both technologies evaluated, for which a prompt effort is required to implement good management practices in the elaboration of UNCS to reduce microbiological risks, but also to train all workers that manipulate the UNCS in contamination risk and food safety.

Declarations

Author contribution statement

Tatiana Vera: Performed the experiments; Analyzed and interpreted the data; Wrote the paper.

Oscar Andrés Mendieta Menjura: Conceived and designed the experiments; Contributed reagents, materials, analysis tools or data.

Angela Maria Otálvaro A.: Contributed reagents, materials, analysis tools or data; Wrote the paper.

Cristina García: Conceived and designed the experiments; Analyzed and interpreted the data; Wrote the paper.

Funding statement

This work was supported by the Ministerio de Agricultura y Desarrollo Rural (MADR) of Colombia for financing the Project “Generation of agronomic recommendations and new technologies in the production of UNCS in Colombia,” from which this research was carried out and implemented by Corporación Colombiana de Investigación Agropecuaria (AGROSAVIA).

Competing interest statement

The authors declare no conflict of interest.

Additional information

Data associated with this study has been deposited at Mendeley under the accession number I: 10.17632/hn6hh2h7wd.1

Acknowledgements

The authors wish to express our deep gratitude to Liliana Gaona García, the Editor in chief of Agrosavia because of their constant support structuring the document; and also to Karen Amaya Vecht, for her help with the translation.

References

- Alarcón A.L., Narváez P.C., Orjuela A., Osorio C. Caracterización fisicoquímica y perfil de azúcares de mieles de caña en la producción de panela. Agron. Colomb. 2016;34(1Supl):S1280–S1283. [Google Scholar]

- Alvis A., Pérez L., Arrazola G. Determinación de las Propiedades de Textura de Tabletas de Chocolate Mediante Técnicas Instrumentales. Inf. Tecnol. 2011;22(3):11–18. [Google Scholar]

- Asikin Y., Hirose N., Tamaki H., Ito S., Oku H., Wada K. Effects of different drying - solidification processes on physical properties, volatile fraction, and antioxidant activity of non centrifugal cane brown sugar. LWT - Food Sci. Technol. (Lebensmittel-Wissenschaft -Technol.) 2016;66:340–347. [Google Scholar]

- Bustamante K., Intriago C. Unidad académica de ciencias administrativas y Comerciales; 2015. Estudio de Factibilidad para la implementación de una planta procesadora de caña de azúcar y producción de mascarilla de panela como producto natural hidratante para la piel en la Ciudad de Milagro; p. 179. [Google Scholar]

- Castellano A.G. Administración de Empresas; Bogotá: 2014. Plan de exportación de pulverizada saborizada con destino a Estados Unidos. Corporación Universitaria Uniminuto. Ciencias empresariales; p. 119. [Google Scholar]

- Contreras P.C., Ramírez J., Fonseca S. 2016. Plan Estratégico de Ciencia, Tecnología e Innovación del Sector Agropecuario Colombiano. Cadena Agroindustrial de la panela. 2016. Corpoica, MADR, Colciencias; p. 33. [Google Scholar]

- Corrales L., Muñoz M., González L. Estudio descriptivo de las prácticas de manufactura en la industria panelera de los trapiches San Francisco y La Esmeralda en Boyacá y Caldas. Nova-Publicación Científica en Ciencias Biomédicas. 2012;10(18):135–250. [Google Scholar]

- Chaves G.A., García B.H., Prada F.L. Efectos de la presión de evaporación y la variedad de caña en la calidad de la miel y la panela. Corpoica Ciencia y Tecnololgía Agropecuaria, Mosquera (Colombia) 2015;16(2):153–165. 0122-8706. [Google Scholar]

- Demera F.M., Almeida A.M., Moreira J.C., Zambrano L., Loor R.K., Cedeño D.C. Clarificación del jugo de caña de azúcar (Saccharum officinarum L.) mediante el empleo de mucílagos naturales. Revista Alimentos hoy. 2015;23(36):51–61. [Google Scholar]

- García B.H., Albarracin C.L., Toscano L.A., Santana M.N., Insuasty B. 2007. Guía tecnológica para el manejo integral del sistema productivo de caña panelera. Corporación Colombiana de Investigación Agropecuaria. Produmedios; p. 154. [Google Scholar]

- García J.M., Narváez P.C., Heredia F.J., Orjuela A., Osorio C. Physicochemical and sensory (aroma and colour) characterization of a non-centrifugal cane sugar (‘‘panela”) beverage. Food Chem. 2017;228(2017):7–13. doi: 10.1016/j.foodchem.2017.01.134. [DOI] [PubMed] [Google Scholar]

- Gutiérrez M.L., Arias G.S., Ceballos P.A. Advances in traditional production of panela in Colombia: analysis of technological improvements and alternatives. Ingeniería y Competitividad. 2018;20(1):107–123. [Google Scholar]

- ICONTEC, (Instituto Colombiano de Normas Técnicas) 2016. NTC 4206. Análisis Sensorial. Metodología. Estimación de la magnitud de Atributos Sensoriales; p. 23. [Google Scholar]

- ISO, (International Standard Organization) 2017. Sensory Analysis. Methodology. General Guidance; p. 26. [Google Scholar]

- Jaffé W. Nutritional and functional components of non-centrifugal cane sugar: a compilation of the data from the analytical literature. J. Food Compos. Anal. 2015;43:194–202. [Google Scholar]

- Jaffé W. Panelamonitor.org. Consulted July 6 of 2018. 2014. Non centrifugal cane sugar (UNCS) (panela, jaggery, gur, muscovado) process technology and the need of its innovation. [Google Scholar]

- Lara N., Clavijo A. Sugarcane juice properties as control parameters during the procurement process of granulated panela, process in open system. Agron. Colomb. 2016;34(1Supl):S1363–S1366. [Google Scholar]

- López L.J. 2013. Manejo agronómico del cultivo de la caña de azúcar para panela en Antioquia. Bogotá (Colombia): Corpoica, 2015; p. 100. [Google Scholar]

- Mascietti M. 2014. Panela propiedades, información y aceptación. Facultad de ciencias médicas, Departamento de metodología de la investigación. Licenciatura en Nutrición. Universidad FASTA, Mar de Plata. Argentina; p. 61. [Google Scholar]

- Mendieta O.A., García M.C., Peña A.C., Rodríguez J. 2017. Las buenas prácticas de manufactura en la producción de panela. Corpoica; p. 84. [Google Scholar]

- Montenegro D.Y. 2015. Manual de buenas prácticas de manufactura en la producción de panela de caña, en la vereda Yumbito, municipio el Tambo Cauca. Ingeniería Industrial. Universidad de San Buenaventura. Cali; p. 117. [Google Scholar]

- Ordoñez L.R., Martínez S.F., García B.H. Proceso agroindustrial de la producción de panela. Tecnura. 2013;17(35):47–54. [Google Scholar]

- Ordoñez-Díaz M., Rueda-Quiñónez L. Evaluación de los impactos socio-ambientales asociados a la producción de panela en Santander (Colombia) Reporte de caso. Corpoica Ciencia Tecnología Agropecuaria, Mosquera (Colombia) 2017;18(2):379–396. [Google Scholar]

- Palacios L.M. 2012. Factibilidad técnica para la obtención de panela porcionada de alta velocidad de disolución a nivel de trapiche. Departamento de Ingeniería Civil y Agrícola Programa Curricular de Maestría en Ingeniería Agrícola. Bogotá, Colombia; p. 259. [Google Scholar]

- Peña H.A.C. 2017. Evaluación del proceso de obtención de jarabes a partir de mieles de caña panelera. Tesis de maestría, Universidad Nacional de Colombia - Sede Bogotá. [Google Scholar]

- Prada-Forero L.E., Chaves-Guerrero A., García-Bernal H.R. Efectos de la presión de evaporación y la variedad de caña en la calidad de la miel y la panela. Corpoica. Ciencia y Tecnología Agropecuaria. 2015;16(2):153–165. [Google Scholar]

- Prada-Forero L.E., García-Bernal H.R., Chaves-Guerrero A. Efectos de la presión de evaporación y la concentración de antiespumante y del uso de floculante y coadyuvante en la calidad de la miel y la panela. Corpoica. Ciencia y Tecnología Agropecuaria. 2014;15(2):153–172. [Google Scholar]

- Prada-Forero L.E. La limpieza de los jugos. Un requisito indispensable para la calidad de la panela y de las mieles. Revista innovación y Cambio Tecnológico. 2006;4(1):12–19. [Google Scholar]

- Quezada W., Gallardo I. Clarificación del jugo de caña mediante el empleo de plantas mucilaginosas. ICIDCA. Sobre los Derivados de la Caña de Azúcar. 2014;48(3):41–48. [Google Scholar]

- Quezada W.F., Quezada W.D., Molina F.A. 2017. Agroindustria panelera: alternativa para su intensificación. 6th Engineering, Science and Technology Conference – Panama; pp. 19–27. [Google Scholar]

- Ramírez D.J., Insuasty B., Murcia P.M. 2014. Variedades de caña de azúcar empleadas para la agroindustria panelera de Colombia Barbosa, Colombia: Corpoica; p. 116. [Google Scholar]

- Rodriguez J., Velásquez F., Espitia J., Escobar S., Mendieta O. Thermal performance evaluation of production technologies for non-centrifuged sugar for improvement in energy utilization. Energy. 2018;152:858e865. [Google Scholar]

- Rozo T.C. 2017. Manual técnico de buenas prácticas de manufactura (BMP) para el proceso tecnológico de producción de panela. Facultad de ingeniería Agroindustrial. Corporación universitaria del Huila. [Google Scholar]

- Shrivastav P., Verma A., Walia R., Parveen R., Singh A. Jaggery: a revolution in the field of natural sweeteners. Eur. J. Pharma. Med. Res. 2016;3(3):198–202. [Google Scholar]

- Thangavelu S. Juice sucrose and jaggery [gur] research - a review. Cooperative Sugar. 2009;40(10):47–62. [Google Scholar]

- Torregrosa A., Gómez C.L., Vergara A., Meneses L. Evaluación de variables asociadas al proceso de fabricación de miel de caña de azúcar y evaluación sensorial del producto. Agron. Colomb. 2016;34(1Supl):S662–S664. [Google Scholar]

- Vargas J.J., Talero Y.V., Trujillo F.A., Camelo L.R. Determinación de acrilamida en el procesamiento de la panela por cromatografía líquida. Rev. Cienc. Desarro. 2014;5(2) [Google Scholar]

- WMA, (The World Medical Association, Inc) 1954. DECLARATION of HELSINKI Ethical Principles for Medical Research Involving Human Subjects, Amended by General Assembly, Seoul, Korea, October 2008. [Google Scholar]