Abstract

Effect of different contents of ground ginger [0%, 1%, 3%, 5%, and 7% (w/w)] on flour quality, dough and biscuit characteristic and acrylamide content were investigated. Texture results showed that by adding 1% (w/w) ground ginger, hardness of dough, hardness and chewiness of biscuit decreased, which was beneficial for biscuit making. Moreover, the L* value of biscuit dropped while the a* and b* value rose with the increase of ginger contents, indicating darker, redder and yellower biscuits. Sensory score of biscuits became worse but acrylamide content reduced with the addition of ground ginger. The phenol hydroxyl group of gingerol played a more important role in the reaction of formation of acrylamide than the side chain. Finally, biscuit with 1% ground ginger content showed good texture, color and acceptable sensory evaluation, as well as lowering the acrylamide content by 6.2%.

Keywords: Ginger, Dough, Biscuit, Texture, Acrylamide

Introduction

Biscuit is a baking snack mainly made with wheat flour, sugar and butter. Due to its long shelf life, convenience of eating and human preference to sweet taste, it is an important part of the world’s food industry (Filipcev et al., 2014).

During the baking process of biscuit, Maillard reaction endows the pleasant and desirable color, flavor and taste to biscuit, but also generates undesirable chemicals such as acrylamide (Becalski et al., 2003). Acrylamide is considered as a reproductive toxin, damaging the nervous system in humans and other animals (Jr and Lehning, 1994). The acrylamide content in different kinds of food can be detected by LC–MS (Rosen and Hellenas, 2002) and GC–MS (Pittet et al., 2004). Acrylamide content in biscuits is varied from dozens to hundreds µg/kg, depending on ingredients, processing conditions, and detection methods (Rufianhenares et al., 2007).

In order to control the acrylamide content in food, substances like amino acids (Kim et al., 2010) and polyphenols (Totlani and Peterson, 2006) were employed. Polyphenols could inhibit acrylamide formation by trapping carbonyl compounds or preventing against lipid oxidation (Liu et al., 2015). Naringenin (Edoardo et al., 2010) was found to be able to trap Maillard reaction intermediates by C6 or C8 position of the A-ring. Green tea extract alone or combined with microwave pre-cooking was an effective mitigation strategy for acrylamide formation (Demirok and Kolsarici, 2014). In addition, bioactive ginger constituents alleviated protein glycation by trapping methyglyoxal (Zhu et al., 2015).

Ginger is a monocotyledonous herbaceous plant, widely used as a spice in food. So far, hundreds of chemical compounds have been isolated and identified from extracts of ginger rhizomes. Biological effects of ginger are attributed to pungent compounds, which mostly were gingerols, especially the 6-gingerol (Singh et al., 2008). So far, investigations have been focused on the anti-inflammatory and antioxidant properties of ginger (Mashhadi et al., 2013). Ginger biscuit is popular due to its advantages in masking the bad flavor in biscuit as a flavoring agent (Akinwande et al., 2008), prolonging the shelf life of biscuit (Oluwamodupe et al., 2012) and alleviating nausea or vomiting of pregnancy (Basirat et al., 2009). Recently, the evaluation of antioxidant, rheological and sensorial properties of wheat flour, dough and bread containing ground ginger has been conducted, which showed good effects with 3% addition (Balestra et al., 2011). However, little is understood about the application of ground ginger in flour characteristics, dough texture and biscuit making. Moreover, as a good anti-oxidant, ginger is supposed to affect the acrylamide content in biscuit making, which has not been investigated yet.

The objective of this work is to study the effect of ground ginger on flour quality and dough characteristic change and to evaluate the alteration of color, texture, sensory score and acrylamide content of biscuit products.

Methods and materials

Materials

Wheat flour was from Nanshun, Shenzhen, China. Butter was purchased from Extend, Shanghai, China. Cane sugar was from Taikoo, Guangzhou, China, and baking powder was provided by Shinuo, Shanghai, China. Table salt was purchased from local market, Guangzhou, China. 6-gingerol (> 99.9%), Methylated-6-gingerol (> 95%) and O-methoxyl-p-propyl phenol (> 95%) were brought from Aladin. Methanol was chromatographically pure, and other chemicals were of analytic purity.

Preparation of ground ginger

Ginger obtained from the local market in Guangzhou, China. It was cleaned and sliced into small pieces. Ginger slices were dried in a vacuum freeze drier (Alpha 2-4, Christ, Germany) and smashed in a pulverizer (FW135, Test Electron, China). The ginger powder was sifted through a 100-mesh sieve and kept dry.

Dough preparation and biscuit making

Biscuit dough was prepared according to the following formula: 160 g of wheat flour, 40 g of sugar, 40 g of egg, 40 g of butter, 10 g of water, 1 g of baking powder and 1 g of salt. Five groups of ground ginger were at the 0%, 1%, 3%, 5% and 7% (w/w) level based on the total weight (see Table 1). All ingredients were blended using the kneading function of a bread maker (PEG600, Petrus, China) and sealed at room temperature (25 °C ± 1 °C) for 20 min. Dough was cut into same sizes (5 mm × 4 cm × 4 cm) and baked in an oven (MG25NF-ARF, Media, China) at 150 °C for 20 min. Biscuits were then allowed to cool and kept at the room temperature.

Table 1.

Formula of biscuit making

| Ground ginger content (%) | Wheat flour (g) | Sugar (g) | Egg (g) | Butter (g) | Water (g) | Baking powder (g) | Salt (g) | Ground ginger (g) |

|---|---|---|---|---|---|---|---|---|

| 0 | 160 | 40 | 40 | 40 | 10 | 1 | 1 | 0 |

| 1 | 160 | 40 | 40 | 40 | 10 | 1 | 1 | 2.92 |

| 3 | 160 | 40 | 40 | 40 | 10 | 1 | 1 | 8.76 |

| 5 | 160 | 40 | 40 | 40 | 10 | 1 | 1 | 14.60 |

| 7 | 160 | 40 | 40 | 40 | 10 | 1 | 1 | 20.44 |

Effect of ground ginger on flour quality

Five groups of wheat flour added with ground ginger at the 0%, 1%, 3%, 5% and 7% (w/w) level were mixed well. Samples of 4 g were taken from each group and determined by a Micro-dough Lab machine (Perten, Sweden). The apparatus setting was kept at 30 °C, pre-mix time of 1 min and stirring rate of 60 r/min. Peak resistance (FU), development time (min), stability time (min), softening degree (FU) and mixing tolerance index (FU) were determined and analyzed.

Texture characteristics of dough and biscuit

Dough texture analysis

Texture profile analysis of dough was performed using a texture analyzer (TA-XT Plus, Stable Micro System, Britain) with a P/36 probe (Meullenet et al., 1998). Each dough sample was cut into a cuboid (5 mm × 4 cm × 4 cm). The TA setting was kept at a pre-test speed of 2 mm/s, a test speed of 1 mm/s, a post-test speed of 10 mm/s and a compression degree of 50%. Finally, values of hardness and adhesiveness were collected and analyzed.

Biscuit texture analysis

Hardness test of biscuit was measured using a texture analyzer (TA-XT Plus, Stable Micro System, Britain) with the P/2 probe. The TA setting was kept at a pre-test speed of 2 mm/s, a test speed of 2 mm/s, a post-test speed of 10 mm/s and trigger force of 30 g (Tyagi et al., 2007). Ultimately, values of hardness and chewiness were collected and analyzed.

Color measurements

Color differences of dough and biscuit were measured by a spectrophotocolorimeter (CM-5, Konica Minolta, Japan) (Laguna et al., 2012). In this system, the L* value is a measure of lightness, ranging from 0 (black) to 100 (white), the a* value ranges from − 100 (greenness) to + 100 (redness), and the b* value ranges from − 100 (blueness) to + 100 (yellowness).

LC–MS detection of acrylamide

Pretreatment of biscuit samples was based on QuEChERS method with a slight modification (Bustamante-Rangel et al., 2013; Xu et al., 2014). In short, n-hexane was used to degrease, water and acetonitrile was used to extract (1:1, v/v) and PSA was used to purify. Acrylamide content of the biscuit samples was analyzed by a HPLC system (1525, Waters, USA) equipped with a quadrupole mass spectrometer (ZQ2000, Waters, USA). The HPLC separation was conducted with a C18 column (4.6 mm × 250 mm, 5 μm, 100A, Sigma). The mobile phase consisted of methanol and water (1:9, v/v), and the elution flow rate was set at 0.8 mL/min. The injection volume was 20 μL. Mass spectrometer was in the positive ionization mode, using an electrospray interface (ESI) as ionization source. The operating conditions were set as follows: capillary voltage at 3 kV, cone voltage at 20 kV, source temperature at 100 °C, desolvation temperature at 300 °C, desolvation gas flow at 350 L/h and cone gas flow at 50 L/h.

Effect of gingerol and its derivatives on acrylamide

0.01 M 6-gingerol (solution A), methylated-6-gingerol (solution B), O-methoxyl-p-propyl phenol (solution C) and acrylamide standard solution were firstly prepared using methanol. A was mixture of 1.0059 g of glucose/asparagine at the molar ratio of 1.5/1.0 was added into the vessel. 200 μL of 0.01 M solution B and C were then added, while the same volume of methanol was added into the control group. With agitating, 550 μL of water was added and incubated at 190 °C for 16 min. Meanwhile, 2 mL of 0.01 M acrylamide standard solution and 0.01 M solution A/B/C were added, while the same volume of methanol was added into the control group. The whole system was incubation at 160 °C for 16 min, and ended by ice bath.

Sensory evaluation and fuzzy reasoning

Sensory characteristics of biscuits were evaluated by a group of panelists consisted of ten postgraduates from School of Food Science and Engineering, South China University of Technology. Sensory attributes included appearance, color, taste, texture and impurity. Four different expressions (excellent, good, fair and poor) were chosen for each of five sensory attributes. Fuzzy reasoning method was used to evaluate the overall acceptability to remove a halo effect.

In this study, fuzzy set PA was for sensory attributes, including elements of appearance, color, taste, texture and impurity. And the membership degree was 0.1, 0.2, 0.4, 0.2 and 0.1, respectively. Another fuzzy set PB was established to represent the preference degree, consisting of elements of excellent, good, fair and poor (Lee and Kwon, 2007).

Statistical analysis

All experiments and analytical measurements were run in triplicate. The results presented were the means and standard deviations of the experiments. Means of each parameter were analyzed by analysis of variance (ANOVA). Statistical analyses were performed using SPSS software (version 22.0). Differences between treatments at 5% level (p < 0.05) were considered as significant.

Results and discussion

Effect of ground ginger on flour quality

The changes of different content of ground ginger on flour quality are shown in Table 2. No significant differences (p < 0.05) were observed on peak resistance and development time with the increase of ground ginger content. However, stability time increased significantly at the 5% level (p < 0.05), compared with other groups. Moreover, softening degree and mixing tolerance index reduced with the increase of ground ginger content, which was similar to the previous study (Ozdal et al., 2013).

Table 2.

Effect of different content of ground ginger on flour, dough and biscuit properties

| Ground ginger content (%) | 0 | 1 | 3 | 5 | 7 |

|---|---|---|---|---|---|

| Flour quality | |||||

| Peak resistance (FU) | 494.8 ± 5.27a | 494.8 ± 4.08a | 493.1 ± 8.50a | 494.8 ± 4.08a | 498.1 ± 6.23a |

| Development time (min) | 0.90 ± 0.03a | 0.90 ± 0.01a | 0.83 ± 0.05a | 0.83 ± 0.05a | 0.80 ± 0.01a |

| Stability time (min) | 1.10 ± 0.05a | 1.30 ± 0.14a | 1.83 ± 0.68a | 3.47 ± 0.05b | 2.57 ± 0.97a |

| Softening degree (FU) | 226 ± 3.1a | 213 ± 6.2b | 207 ± 2.4 cd | 197 ± 2.4c | 193 ± 2.4 cd |

| Mixing tolerance index (FU) | 149 ± 1.2a | 142 ± 6.2a | 118 ± 2.4b | 100 ± 0.3c | 90 ± 4.1c |

| Dough texture | |||||

| Hardness (g) | 3568.48 ± 71.88a | 3285.51 ± 79.73b | 5421.69 ± 88.10c | 7580.87 ± 33.50d | 10,660.58 ± 81.38e |

| Adhesiveness (g) | − 614.74 ± 81.75a | − 595.89 ± 30.45a | − 923.95 ± 66.64b | − 646.49 ± 65.63c | − 622.16 ± 89.76c |

| Biscuit texture | |||||

| Hardness (g) | 955.00 ± 21.21a | 785.00 ± 51.96b | 1530.00 ± 70.71c | 1396.67 ± 15.28c | 1590.00 ± 49.50c |

| Chewiness (g) | 2012.50 ± 37.48a | 1616.75 ± 28.19b | 2844.00 ± 57.98c | 2555.33 ± 42.36d | 2899.00 ± 79.90c |

Data are expressed as mean ± standard deviation

Values within a column followed by different superscript letters are significantly different (p < 0.05)

Stability time was an important indicator of wheat flour properties, representing the gluten strength and resistance to stirring. The longer of stability time, the stronger of gluten strength. The phenolic group was an excellent hydrogen donor that formed hydrogen bonds with the carboxyl groups of protein (Ozdal et al., 2013), improving the crosslinking of gluten proteins and tightened the network structure, and thus increasing the stability time (Zhang et al., 2016). The formation of some new covalent bonds between amino groups and hydroxyl groups also played an important role in improving flour quality. On the other hand, the antioxidant property of gingerols would inhibit the oxidation of free thiol groups on glutenin and thus the formation of disulphide bonds, weakening the gluten network (Lagrain et al., 2007). The combination (strengthening or weakening) effects of gingerols on flour was dependent on the concentration of gingerols. As shown in Table 2, the strengthening effect of gingerols became dominant at 5% ground ginger addition. Although there was more gingerols in flour with 7% ground ginger, contents of fibers or other chemicals accordingly increased, which might affect the disulfide bond of glutenin and decrease the gluten strength. Therefore, the stability time at 7% ground ginger addition was lower than at 5% (p < 0.05). These were similar with the previous studies, showing the chemical effect of the diet fiber leading to fewer disulphide bonds, less protein cross-linkage, and weaker gluten network (Carlos et al., 2010).

As Table 2 shown, there is no significant change of stability time at the low content of ground ginger especially at 1% level, which might be suitable for biscuit making.

Effect of ground ginger on dough and biscuit texture

The effect of different contents of ground ginger on dough and biscuit texture are presented in Table 2. Compared with that of the dough without ground ginger, hardness of the dough decreased at 1% ground ginger (p < 0.05). Phenols, fibers or other chemicals in ground ginger might affect the disulfide bond of glutenin and decreased the gluten strength, and thus leading to weaker gluten network and softer dough (Carlos et al., 2010). However, when the content of ground ginger was above 1%, more fiber was able to absorb water and filled in the gluten network and led to the increase of dough hardness, which was similar to the previous study. In addition, dough with 7% (w/w) ground ginger was difficult to take shape and became very dark with pungent flavor. Hardness and chewiness of the biscuit decreased at 1% ginger level, compared with the control. At higher content of ground ginger (over 3%), hardness and chewiness of the biscuit were significantly higher than the control (p < 0.05). Similar results were also reported in the evaluation of banana powder on biscuit texture. Lower in hardness and chewiness of biscuit indicated less work to be consumed when chewing. In the future, the three-point-bending test (Tyagi et al., 2007) should be conducted to better study the crisp of biscuit.

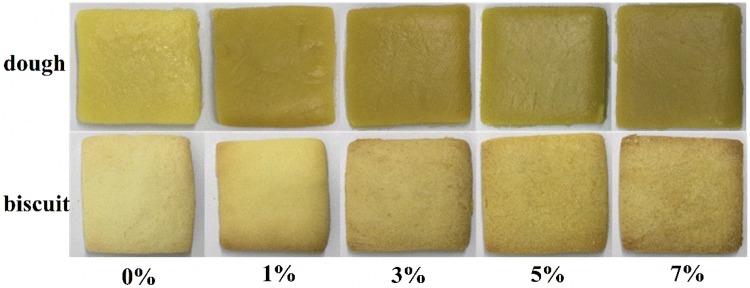

Color measurements

Expectedly, L* values of both the dough samples and the biscuit samples were decreased noticeably with the increase of ground ginger contents (Table 3). Similar trend was observed by adding de-oiled peanut meal flour to biscuits (Yadav et al., 2012). The a* value of the dough with ground ginger was significantly higher than the control (p < 0.05), while the b* value of the dough with 1% ground ginger was not significantly different from that of the control (p > 0.05). Both a* and b* value of the biscuit with ground ginger were significantly higher than those of the control. Ground ginger was yellow in nature, and it turned the biscuit to be yellower and redder after baking.

Table 3.

Color change of dough and biscuit with different content of ground ginger

| Ground ginger content (%) | 0 | 1 | 3 | 5 | 7 |

|---|---|---|---|---|---|

| Dough color measurements | |||||

| L* | 73.23 ± 0.11a | 65.76 ± 0.09b | 62.87 ± 0.15c | 61.24 ± 0.20d | 59.19 ± 0.27e |

| a* | 6.69 ± 0.16a | 8.67 ± 0.07b | 8.73 ± 0.05b | 7.40 ± 0.08c | 8.66 ± 0.17b |

| b* | 39.20 ± 0.33a | 38.80 ± 0.02a | 37.30 ± 0.21b | 38.99 ± 0.02a | 37.02 ± 0.33b |

| Biscuit color measurements | |||||

| L* | 83.50 ± 0.72a | 78.23 ± 0.41b | 73.93 ± 0.41c | 72.21 ± 0.45d | 71.72 ± 0.40d |

| a* | 5.44 ± 0.43a | 7.08 ± 0.37b | 8.60 ± 0.19c | 8.32 ± 0.21c | 8.24 ± 0.35c |

| b* | 27.91 ± 0.23a | 34.17 ± 0.43b | 32.41 ± 0.36c | 36.13 ± 0.16d | 34.33 ± 0.84b |

Data are expressed as mean ± standard deviation

Values within a column followed by different superscript letters are significantly different (p < 0.05)

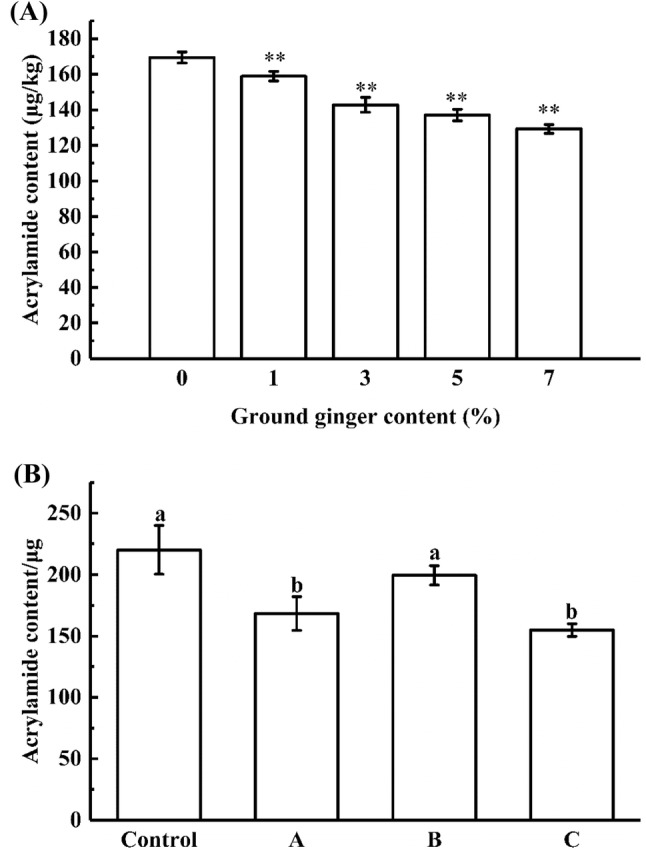

Effect of ground ginger on acrylamide content in the biscuit and mechanism

Significant reduction of acrylamide content in biscuit was observed when adding ground ginger (Fig. 1A). The acrylamide inhibition rate was 6.2% at the 1% ground ginger level, and was 15.6%, 19.1% and 23.7% at the 3, 5, 7% level. The acrylamide inhibition ability of ground ginger for the biscuit was dose-dependent. Antioxidants could inhibit acrylamide formation by hindering oil oxidation or trapping intermediates (Jin et al., 2013). In addition, bioactive ginger constituents alleviate protein glycation by trapping glucose thermal decomposition product called methyglyoxal (Zhu et al., 2015), which might affect the inhibition of acrylamide.

Fig. 1.

(A) Change of acrylamide content in biscuit with different ground ginger contents, ** indicates significant different to control (p < 0.05); (B) Effect of 6-gingerol and its derivatives on acrylamide contents in model systems. A: 6-gingerol, B: methylated-6-gingerol, C: O-methoxyl-p-propyl phenol, and superscript letters above the column indicate significant difference (p < 0.05)

In this study, gingerol and its derivatives were firstly added to react with acrylamide but failed (data not shown), indicating they could not decline acrylamide by reacting with acrylamide. Moreover, they were added to the Maillard Reaction system to detect the change of acrylamide content. Results showed that 6-gingerol and O-methoxyl-p-propyl phenol significantly lowered the content of acrylamide (Fig. 1B), while methylated-6-gingerol group showed no significant change. These proved that gingerol declined acrylamide through inhibition rather than elimination. Moreover, the phenol hydroxy of gingerol played a more important role in the reaction of formation of acrylamide than the side chain. Studies showed that the side chain structures of gingerol related compounds were related to the antioxidant activity (Lu et al., 2014), and antioxidants could inhibit acrylamide formation (Jin et al., 2013). Moreover, phenol hydroxy group might play an important role in the conversion from precursor to acrylamide (Liu et al., 2015).

Sensory evaluation

In order to correctly conduct the sensory evaluation of food products, fuzzy reasoning is widely applied in food such as sausages (Lee and Kwon, 2007) and so on. In fuzzy theory, a subject can be described by fuzzy sets with some elements and their membership degrees. Then the fuzzy sets could be re-estimated to the real numbers by defuzzification.

Significant color differences were observed between the group ginger added biscuits and the control (Fig. 2), which was similar with the color determination results. The color of the ginger-free-biscuit was plain, and that with 1% ground ginger was more golden yellow. In addition, the appearance of biscuits with higher ginger contents (above 3%) were more textured and rougher possibly because of the fibers in ground ginger.

Fig. 2.

Dough and biscuit with different contents of ground ginger

The fuzzy matrix (Ri) for biscuits with different contents of ground ginger were as follows:

where R1 to R5 represented biscuits with ground ginger at the 0%, 1%, 3%, 5% and 7% level. Sensory attributes were on the vertical and preference degrees were on the horizontal.

Hence, the evaluation results of group A:

In the defuzzification process, the elements values for preference levels were assumed as scores of 4, 3, 2 and 1, respectively, based on the fact that higher the preference levels, the higher the elements scores. Thus, the total score of five groups were: S1 = 3.38, S2 = 3.22, S3 = 3.22, S4 = 2.89, S5 = 2.32. Finally, it could be easily concluded that the result of sensory evaluation was: group A > group B = group C > group D > group E.

Correlation analysis among different measurements

Table 4 shows the Pearson Correlation Coefficient among different measurements. Ground ginger content showed great correlation with the L* properties of dough and biscuit, in accordance with the results of color and texture experiments. In addition, the index between dough hardness and ginger content was 0.978, but the index between biscuit hardness and ginger content was only 0.763, showing that ginger had different effects on dough and biscuit texture, probably because of the heating and water migration during baking procedure.

Table 4.

Pearson correlation coefficient among different attributes

| Variables | Ground ginger content | Dough L* | Biscuit L* | Dough hardness | Biscuit hardness | Biscuit chewiness | Sensory evaluation |

|---|---|---|---|---|---|---|---|

| Ground ginger content | 1 | − 0.902 | − 0.905 | − 0.978 | − 0.763 | 0.822 | − 0.791 |

| Dough L* | − 0.902 | 1 | 0.983 | − 0.798 | − 0.691 | − 0.695 | − 0.667 |

| Biscuit L* | − 0.905 | 0.983 | 1 | − 0.801 | − 0.764 | − 0.763 | 0.637 |

| Dough hardness | 0.978 | − 0.798 | − 0.801 | 1 | 0.735 | 0.820 | − 0.808 |

| Biscuit hardness | 0.763 | − 0.691 | − 0.764 | 0.735 | 1 | 0.968 | − 0.544 |

| Biscuit chewiness | 0.822 | − 0.696 | − 0.763 | 0.820 | 0.968 | 1 | − 0.613 |

| Sensory evaluation | − 0.791 | 0.667 | 0.637 | − 0.808 | − 0.544 | − 0.613 | 1 |

All values are significant at 0.05 level

In conclusion, the present work investigated the effects of ground ginger on quality of flour, characteristic of dough and biscuit. Results showed that by adding 1% (w/w) ground ginger, hardness and chewiness of dough and biscuit slightly reduced, which was beneficial for biscuit making. Moreover, the 1% ground ginger made biscuits yellower and darker, and lowered the acrylamide by 6.2%, while the sensory evaluation remained acceptable. The biscuits with ground ginger addition produced less acrylamide, and it was proved that the phenol hydroxyl group of gingerol played a more important role in the reaction of formation of acrylamide than the side chain.

In this work, ground ginger was found to inhibit the formation of acrylamide, but more studies should be carried out on the mechanism. Additionally, further researches ought to be conducted on the rheological properties of dough and the crisp of biscuit. In summary, this work might help to enlarge the application of ginger in bakery products.

Acknowledgements

This work is supported by the National Key R&D Program of China (No. 2017YFC1600401), YangFan Innovative and Enterpreneurial Research Team Project (Nos. 2014YT02S029), and the National 973 Project (2012CB720801).

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Contributor Information

Huaijie Yang, Email: hsdyhj@foxmail.com.

Lin Li, Email: felinli@scut.edu.cn.

Yongpo Yin, Email: 747333821@qq.com.

Bing Li, Phone: +86 20 87113252, Email: lcbingli@scut.edu.cn.

Xia Zhang, Email: cexzhang@scut.edu.cn.

Wenjuan Jiao, Email: 839962149@qq.com.

Yi Liang, Email: 157979141@qq.com.

References

- Akinwande BA, Ade Omowaye BIO, Olaniyan SA, et al. Quality evaluation of ginger-flavoured soy-cassava biscuit[J] Nutrition Food Sci. 2008;38(5):473–481. doi: 10.1108/00346650810906994. [DOI] [Google Scholar]

- Balestra F, Cocci E, Pinnavaia G, et al. Evaluation of antioxidant, rheological and sensorial properties of wheat flour dough and bread containing ginger powder[J] LWT Food Sci. Technol. 2011;44(3):700–705. doi: 10.1016/j.lwt.2010.10.017. [DOI] [Google Scholar]

- Basirat Z, Moghadamnia AA, Kashifard M, et al. The effect of ginger biscuit on nausea and vomiting in early pregnancy.[J] Acta Medica Iranica. 2009;4(1):106–112. [Google Scholar]

- Becalski A, Lau BP, Lewis D, Seaman SW. Acrylamide in foods: occurrence, sources, and modeling. J. Agric. Food Chem. 2003;51:802–808. doi: 10.1021/jf020889y. [DOI] [PubMed] [Google Scholar]

- Bustamante-Rangel M, Delgado-Zamarreño MM, Pérez-Martín L, Carabias-Martínez R. QuEChERS method for the extraction of isoflavones from soy-based foods before determination by capillary electrophoresis-electrospray ionization-mass spectrometry. Microchem. J. 2013;108:203–209. doi: 10.1016/j.microc.2012.10.023. [DOI] [Google Scholar]

- Carlos C, Rogério M, Paulo VP, et al. Effect of dietary fibre and MTGase on the quality of mackerel surimi gels[J] J. Sci. Food Agric. 2010;89(10):1648–1658. [Google Scholar]

- Demirok E, Kolsarici N. Effect of green tea extract and microwave pre-cooking on the formation of acrylamide in fried chicken drumsticks and chicken wings. Food Res. Int. 2014;63:290–298. doi: 10.1016/j.foodres.2014.04.003. [DOI] [Google Scholar]

- Edoardo C, Teresa O, Özgeç A, Vural G, Vincenzo F. Lipid oxidation promotes acrylamide formation in fat-rich model systems. Food Res. Int. 2010;43:1021–1026. doi: 10.1016/j.foodres.2010.01.013. [DOI] [Google Scholar]

- Filipcev B, Simurina O, Bodroza-Solarov M. Quality of gingernut type biscuits as affected by varying fat content and partial replacement of honey with molasses. J. Food Sci. Technol. 2014;51:3163–3171. doi: 10.1007/s13197-012-0805-x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Jin C, Wu X, Zhang Y. Relationship between antioxidants and acrylamide formation: a review. Food Res. Int. 2013;51:611–620. doi: 10.1016/j.foodres.2012.12.047. [DOI] [Google Scholar]

- Jr LPR, Lehning EJ. Acrylamide-induced distal axon degeneration: a proposed mechanism of action[J] Neurotoxicology. 1994;15(2):247–259. [PubMed] [Google Scholar]

- Kim CT, Hwang ES, Lee HJ. Reducing acrylamide in fried snack products by adding amino acids. J. Food Sci. 2010;70:354–358. doi: 10.1111/j.1365-2621.2005.tb09966.x. [DOI] [Google Scholar]

- Lagrain B, Thewissen BG, Brijs K, Delcour JA. Impact of redox agents on the extractability of gluten proteins during bread making. J. Agric. Food Chem. 2007;55:5320–5325. doi: 10.1021/jf070639n. [DOI] [PubMed] [Google Scholar]

- Laguna L, Varela P, Salvador A, Sanz T, Fiszman SM. Balancing texture and other sensory features in reduced fat short-dough biscuits. J. Texture Stud. 2012;43:235–245. doi: 10.1111/j.1745-4603.2011.00333.x. [DOI] [Google Scholar]

- Lee SJ, Kwon YA. Study on fuzzy reasoning application for sensory evaluation of sausages. Food Control. 2007;18:811–816. doi: 10.1016/j.foodcont.2006.04.004. [DOI] [Google Scholar]

- Liu Y, Wang P, Chen F, Yuan Y, Zhu Y, Yan H, Hu X. Role of plant polyphenols in acrylamide formation and elimination. Food Chem. 2015;186:46–53. doi: 10.1016/j.foodchem.2015.03.122. [DOI] [PubMed] [Google Scholar]

- Lu DL, Li XZ, Dai F, Kang YF, Li Y, Ma MM, Ren XR, Du GW, Jin XL, Zhou B. Influence of side chain structure changes on antioxidant potency of the [6]-gingerol related compounds. Food Chem. 2014;165:191–197. doi: 10.1016/j.foodchem.2014.05.077. [DOI] [PubMed] [Google Scholar]

- Mashhadi NS, Ghiasvand R, Askari G, et al. Anti-oxidative and anti-inflammatory effects of ginger in health and physical activity: review of current evidence[J] Int. J. Prev. Med. 2013;4(1):36–42. [PMC free article] [PubMed] [Google Scholar]

- Meullenet J, Lyon BG, Carpenter JA, Lyon CE. Relationship between sensory and instrumental texture profile attributes. J. Sens. Stud. 1998;13:77–93. doi: 10.1111/j.1745-459X.1998.tb00076.x. [DOI] [Google Scholar]

- Oluwamodupe G, Francisca O, Omolara OA, et al. Effect of ginger spices (Zingiber officinale) on the shelflife of cookies (biscuit) produced from blends of melonflour ‘egusi’ (Critrullus coloynthis l) and wheat flour (Triticum spp)[J] Prime J. Microbiol. Res. 2012;5(2):131–136. [Google Scholar]

- Ozdal T, Capanoglu E, Altay F. A review on protein–phenolic interactions and associated changes. Food Res. Int. 2013;51:954–970. doi: 10.1016/j.foodres.2013.02.009. [DOI] [Google Scholar]

- Pittet A, Périsset A, Oberson JM. Trace level determination of acrylamide in cereal-based foods by gas chromatography–mass spectrometry. J. Chromatogr. A. 2004;1035:123–130. doi: 10.1016/j.chroma.2004.02.037. [DOI] [PubMed] [Google Scholar]

- Rosen J, Hellenas KE. Analysis of acrylamide in cooked foods by liquid chromatography tandem mass spectrometry. Analyst. 2002;127:880–882. doi: 10.1039/b204938d. [DOI] [PubMed] [Google Scholar]

- Rufianhenares JA, Arribas-Lorenzo G, Morales FJ. Acrylamide content of selected Spanish foods: Survey of biscuits and bread derivatives. Food Addit. Contam. 2007;24:343–350. doi: 10.1080/02652030601101169. [DOI] [PubMed] [Google Scholar]

- Singh G, Kapoor IPS, Singh P, Heluani CSD, Lampasona MPD, Catalan CAN. Chemistry, antioxidant and antimicrobial investigations on essential oil and oleoresins of Zingiber officinale. Food Chem. Toxicol. 2008;46:3295–3302. doi: 10.1016/j.fct.2008.07.017. [DOI] [PubMed] [Google Scholar]

- Totlani VM, Peterson DG. Epicatechin carbonyl-trapping reactions in aqueous maillard systems: identification and structural elucidation. J. Agric. Food Chem. 2006;54:7311–7318. doi: 10.1021/jf061244r. [DOI] [PubMed] [Google Scholar]

- Tyagi SK, Manikantan MR, Oberoi HS, Kaur G. Effect of mustard flour incorporation on nutritional, textural and organoleptic characteristics of biscuits. J. Food Eng. 2007;80:1043–1050. doi: 10.1016/j.jfoodeng.2006.08.016. [DOI] [Google Scholar]

- Xu D, Deng X, Fang E, Zheng X, Zhou Y, Lin L, Chen L, Wu M, Huang Z. Determination of 23 phthalic acid esters in food by liquid chromatography tandem mass spectrometry. J. Chromatogr. 2014;1324:49–56. doi: 10.1016/j.chroma.2013.11.017. [DOI] [PubMed] [Google Scholar]

- Yadav DN, Thakur N, Sunooj KV. Effect of partially de-oiled peanut meal flour (DPMF) on the nutritional, textural, organoleptic and physico chemical properties of biscuits. Food Nutr. Sci. 2012;3:471–476. [Google Scholar]

- Zhang H, Zhu Y, Zhang S, et al. Effect of tea polyphenols on rheological properties of high-gluten wheat dough[J] Food Sci. 2016;37(13):42–46. [Google Scholar]

- Zhu Y, Zhao Y, Wang P, Ahmedna M, Sang S. Bioactive ginger constituents alleviate protein glycation by trapping methylglyoxal. Chem. Res. Toxicol. 2015;28:1842–1849. doi: 10.1021/acs.chemrestox.5b00293. [DOI] [PubMed] [Google Scholar]