Abstract

In this article, we provide information about culture media, including minimal liquid media, rich liquid media, solid media, top agar, and stab agar. We also provide descriptions and useful information about tools used with growth media such as inoculating loops, sterile toothpicks and spreaders.

Introduction

Escherichia coli is a rod-shaped gram negative bacterium normally resident in human and other mammalian colons. It can grow rapidly on minimal medium that contains a carbon compound such as glucose (which serves both as a carbon source and an energy source) and salts that supply nitrogen, phosphorus, and trace metals. E. coli grows more rapidly, however, on a rich medium that provides the cells with amino acids, nucleotide precursors, vitamins, and other metabolites that the cell would otherwise have to synthesize. The purpose of these three articles (Units 1.1, 1.2, and 1.3) is to provide basic information necesary to culture and manipulate E. coli. A more detailed introduction to certain aspects of E. coli biology is found unit 1.4.

When E. coli is grown in liquid culture, a small number of cells are first inoculated into a volume of sterile medium. After a period of time, called the lag period, the bacteria begin to divide. In rich medium a culture of a typical strain will double in number every 20 or 30 min. This phase of exponential growth of the cells in the culture is called log phase (sometimes subdivided into early-log, middle-log, and late-log phases). Eventually the cell density increases to a point at which nutrients or oxygen become depleted from the medium, or at which waste products (such as acids) from the cells have built up to a concentration that inhibits rapid growth. At this point, which, under normal laboratory conditions occurs when the culture reaches a density of 1–2 × 109 cells/ml, the cells stop dividing rapidly. This phase is called saturation and a culture that has just reached this density is said to be freshly saturated.

With very few exceptions, the bacterial strains used in recombinant DNA work are derivatives of E. coli strain K–12. This strain was isolated at Stanford University from a human sample in the 1920s (Bachman, 1973). The generation of well-behaved mutants derivatives altered in biosynthesis by Tatum and coworkers (Gray and Tatum, 1944) allowed the discovery of genetic recombination in K-12 (Lederberg and Tatum, 1946) and the fact that K-12 was in use in the lab for studies of recombination led to the discovery that it harbored a lysogenic bacteriophage, phage λ, (Lederberg, 1951, Lederberg and Lederberg, 1953).

Despite the considerable development of the brewer’s yeast Saccharomyces cerevisiae as a working organism, E. coli K-12 remains the preferred host for most molecular biological manipulations. Many key advances in molecular biology came from studies of this organism and of the bacteriophages (many derived from λ) and plasmids that use it as a host. Much of the cloning technology in current use exploits facts about E. Coli K-12, its plasmids and phages, learned during the 1960s and 1970s.

Work during the 1990s characterized K-12’s genome (a 4,639,221 bp circular chromosome) (Blattner et al., 1997). Many molecular biological methods developed since then (e.g., Recombineering using RecF, which depends on functions encoded by a hitherto unidentified prophage, Thomason et al., 2014) depend on knowledge derived from its genome sequence, as do most subsequent studies illuminating aspects of its growth, for example the understanding of iron transport relevant for growth in minimal medium (Welz and Braun, 1998) make use of knowledge derived from the genome sequence.

Media Preparation and Bacteriological Tools

We provide recipes for minimal liquid media, rich liquid media, solid media, top agar, and stab agar. Tryptone, yeast extract, agar (Bacto-agar), nutrient broth, and Casamino Acids are from Difco. NZ Amine A is from Hunko Sheffield (Kraft).

Minimal Media

Ingredients should be added to water in a 2-liter flask and heated with stirring until dissolved. The medium should then be poured into separate bottles with loosened caps and autoclaved at 15 lb/in2 (1.05 kg/ cm2) on the liquid cycle for 15 min. Do not add nutritional supplements or antibiotics to any medium until it has cooled to <50°C. After the bottles cool to below 40°C, the caps can be tightened and the concentrated medium stored indefinitely at room temperature. All recipes give the amount of ingredients when mixed with distilled, deionized water to a total volume of 1 liter.

M9 medium, 5×

30 g Na2HPO4

15 g KH2PO4

5 g NH4Cl

2.5 g NaCl

15 mg CaCl2 (optional)

As noted below, M9 lacks iron (see below). It can be supplemented with 2.5 mg FeSO4∙7H2O per liter.

M63 medium, 5×

10 g (NH4)2SO4

68 g KH2PO4

2.5 mg FeSO4∙7H2O

Adjust to pH 7 with KOH

A medium, 5×

5 g (NH4)2SO4

22.5 g KH2PO4

52.5 g K2HPO4

2.5 g sodium citrate∙2H2O

Before they are used, concentrated media should be diluted to 1× with sterile water and supplemented with the following sterile solutions, per liter.

1 ml 1 M MgSO4∙7H2O

10 ml 20% carbon source (sugar or glycerol)

and, if required:

0.1 ml 0.5% vitamin B1 (thiamine)

5 ml 20% Casamino Acids or

l amino acids to 40 μg/ml ordl amino acids to 80 μg/ml

Antibiotic (see Table 1)

Table 1.

Antibiotics, Their Modes of Action, and Modes of Bacterial Resistancea

| Antibioticb | Stock conc.(mg/ ml) |

Final conc.(μg/ ml) |

Mode of action |

Mode of resistance |

|---|---|---|---|---|

| Ampicillinc | 4 | 50 | Bacteriocidal; only kills growing E. coli; inhibits cell wall synthesis by inhibiting formation of the peptidoglycan cross-link | β-lactamase hydrolyzes ampicillin before it enters the cell |

| Chloramphenicol in methanol | 10 | 20 | Bacteriostatic; inhibits protein synthesis by interacting with the 50S ribosomal subunit and inhibiting the peptidyltransferase reaction | Chloramphenicol acetyltransferase inactivates chloramphenicol |

| d-Cycloserine, d in 0.1 M sodium phosphate buffer, pH 8 | 10 | 200 | Bacteriocidal; only kills growing E. coli; inhibits cell wall synthesis by preventing formation of d-alanine from l-alanine and formation of peptide bonds involving d-alanine | Mutations destroy the d-alanine transport system |

| Gentamycin | 10 | 15 | Bacteriocidal; inhibits protein synthesis by binding to the L6 protein of the 50S ribosomal subunit | Aminoglycoside acetyltransferase and aminoglycosidenucleotidyltransferase inactivate gentamycin; mutations in rplF(encodes the L6 protein) prevent the gentamycin from binding |

| Kanamycin | 10 | 30 | Bacteriocidal; inhibits protein synthesis; inhibits translocation and elicits miscoding | Aminoglycoside phosphotransferase, also known as neomycin phosphotransferase, aminoglycoside acetyltransferase, and aminoglycoside nucleotidyltransferase inactivates kanamycin |

| Kasugamycin | 10 | 1000 | Bacteriocidal; inhibits protein synthesis by altering the methylation of the 16S RNA and thus an altered 30S ribosomal subunit | Mutations prevent kasugamycin from binding to the ribosome; mutations decrease uptake of kasugamycin |

| Nalidixic acid, pH to 11 with NaOH | 5 | 15 | Bacteriostatic; inhibits DNA synthesis by inhibiting DNA gyrase | Mutations in the host DNA gyrase prevent nalidixic acid from binding |

| Rifampicin, e in methanol | 34 | 150 | Bacteriostatic; inhibits RNA synthesis by binding to and inhibiting the β subunit of RNA polymerase rifampicin sensitivity is dominant. | Mutation in the β subunit of RNA polymerase prevents rifampicin from complexing; rifampicin resistance is recessive |

| Spectinomycin | 10 | 100 | Bacteriostatic; inhibits translocation of peptidyl tRNA from the A site to the P site | Mutations in rpsE (encodes the S5 protein) prevent spectinomycin from binding; spectinomycin sensitivity is dominant and resistance is recessive |

| Streptomycin | 50 | 30 | Bacteriocidal; inhibits protein synthesis by binding to the S12 protein of the 30S ribosomal subunit and inhibiting proper translation streptomycin sensitivity is dominant | Aminoglycoside phosphotransferase inactivates streptomycin; mutations in rpsL (encodes the S12 protein) prevent streptomycin from binding streptomycin resistance is recessive |

| Tetracycline, e in 70% ethanol | 12 | 12 | Bacteriostatic; inhibits protein synthesis by preventing binding of aminoacyl tRNA to the ribosome A site | Active efflux of drug from cell |

• Data assembled from Foster (1983), Gottlieb and Shaw (1967), and Moazed and Noller (1987).

• All antibiotics should be stored at 4°C, except tetracycline, which should be stored at −20°C. All antibiotics should be dissolved in sterile distilled H2O unless otherwise indicated. Antibiotics dissolved in methanol often can be dissolved in the less hazardous ethanol.

• Carbenicillin, at the same concentration, can be used in place of ampicillin. Carbenicillin can be stored in 50% ethanol/50% water at −20°C.

• d-cycloserine solutions are unstable. They should be made immediately before use.

• Light-sensitive; store stock solutions and plates in the dark.

A note on metals and other trace nutrients. Like many bacteria, growth of E. coli is limited if iron is limited. E. coli has an active transport system that includes the receptor encoded by the fecA gene. This receptor imports Ferric Citrate into the cell. For many protocols that call for cells to be grown in M9, cells will grow more rapidly in M63 or A medium, possibly because the medium provides more accessible ferric iron.

During the late 20th and early 21st century, in many labs, distilled water piped through metal clean pipes was replaced with systems that produced distilled “deionized” water, which had been cleaned of metal ions and was delivered via plastic pipes. The consequence of this improvement in water quality has been that one hears reports that well characterized E. coli strains that previously grew well in mimimal medium did not grow as well. On establishing a lab in a new location, it is worth testing the growth of E. coli strains to be used in the M9 and A media above, comparing growth in media made from the available distilled water, and from water that contains 100 ml/ liter sterile tap water made by autoclaving water from the cold water tap. If the cells grow better in medium made with 1/10 tap water, one should supplement the M9 and A medium with FeSO4, or continue using medium made with diluted cold tap water.

RICH MEDIA

Unless otherwise specified, rich media should be autoclaved for 25 min on the liquid cycle at 15 lb/in2 (1.05 kg/ cm2). Antibiotics and nutritional supplements should be added only after the solution has cooled to 50°C or below. A flask containing liquid at 50°C feels hot but can be held continuously in one’s bare hands. All give the quantity of ingredients per liter of medium.

H medium

10 g tryptone

8 g NaCl

Lambda broth

10 g tryptone

2.5 g NaCl

TNT medium

10 g tryptone

5 g NaCl

0.1 mg Thiamine (vitamin B1)

Adjust pH to 7.3 by adding 5N NaOH dropwise

LB medium

10 g tryptone

5 g yeast extract

5 g NaCl

1 ml 1 N NaOH

The original recipe for LB medium (variously called Luria Broth, Lenox Broth, and Luria-Bertani medium), does not contain NaOH. There are many different recipes for LB that differ only in the amount of NaOH added. We use this formula in our own work. Even though the pH is adjusted to near 7 with NaOH, this medium is not very highly buffered, and the pH of a culture growing in it drops as it nears saturation.

NZC broth

10 g NZ Amine A

5 g NaCl

2 g MgCl2∙6H2O

Autoclave 30 min

5 ml 20% Casamino Acids

Superbroth

32 g tryptone

20 g yeast extract

5 g NaCl

5 ml 1 N NaOH

TB (terrific broth)

12 g Bacto tryptone

24 g Bacto yeast extract

4 ml glycerol

Add H2O to 900 ml and autoclave for 15 min at 15 lb/in2 (1.05 kg/ cm2) on the liquid cycle, then add to above sterile solution 100 ml of a sterile solution of 0.17 M KH2PO4 and 0.72 M K2HPO4.

Tryptone broth

10 g tryptone

5 g NaCl

2× TY medium

16 g tryptone

10 g yeast extract

5 g NaCl

TYGPN medium

20 g tryptone

10 g yeast extract

10 ml 80% glycerol

5 g Na2HPO4

10 g KNO3

The dry ingredients should initially be suspended in a small volume of water, the 10 ml 80% glycerol added, and the volume then brought to 1L with water.

SOLID MEDIA

Liquid media can be solidified with agar. For minimal plates, dissolve the agar in water and autoclave separately from the minimal medium; autoclaving the two together will give rise to an insoluble precipitate. For rich plates, autoclave the agar together with the other ingredients of the medium. Cool the agar to about 50°C and add other ingredients if necessary. At this temperature, the medium will stay liquid indefinitely, but it will rapidly solidify if its temperature falls much below 45°C. Finally, pour the medium into sterile disposable petri dishes (plates) and allow to solidify.

Freshly poured plates are wet and unable to absorb liquid spread onto them. Moreover, plates that are even slightly wet tend to exude moisture underneath bacteria streaked on them, which can cause the freshly streaked bacteria to float away. So for most applications, dry the plates by leaving them out at room temperature for 2 or 3 days, or by leaving them with the lids off for 30 min in a 37°C incubator or in a laminar flow hood. Store dry plates at 4°C, wrapped in the original bags used to package the empty plates. Dry plates should be inverted when incubated or stored to prevent droplets of condensation on the lid from falling back onto the agar surface.

Minimal Plates

Autoclave 15 g agar in 800 ml water for 15 min. Add sterile concentrated minimal medium and carbon source. After medium has cooled to about 50°C, add supplements and antibiotics. Pouring 32 to 40 ml medium into each plate, expect about 25 to 30 plates per liter.

Rich Plates

To ingredients listed below, add water to 1 liter and autoclave 25 min. Pour LB and H plates with 32 to 40 ml medium, in order to get 25 to 30 plates per liter. Pour lambda plates with about 45 ml medium for about 20 plates per liter.

H plates

10 g tryptone

8 g NaCl

15 g agar

Lambda plates

10 g tryptone

2.5 g NaCl

10 g agar

LB plates

10 g tryptone

5 g yeast extract

5 g NaCl

1 ml 1 N NaOH

15 g agar or agarose

Additives

Antibiotics (if required):

Ampicillin to 50 μg/ml

Tetracycline to 12 μg/ml

Other antibiotics, see Table 1

Galactosides (if required):

Xgal to 20 μg/ml

IPTG to 0.1 mM

Other galactosides, see Table 2

Table 2.

Lactose Analogs Used in DNA Cloning Technology

| Galactoside | Stock concentrationa |

Use | Characteristics | Reference |

|---|---|---|---|---|

| Isopropyl-1-thio-β-d-galactoside (IPTG) | 100 mM | Very effective inducer | Nonmetabolizable inducer | Barkley and Bourgeois, 1978 (pp. 177-220) |

| 5-Bromo-4-chloro-3-indolyl-β-d - galactoside (Xgal) | 20 mg/ml (dissolved in N,N dimethyl formamide) | Identification of lacZ+ bacteria, especially useful for detecting β-galactosidase made by recombinant vectors | Noninducing chromogenic substrate of β-galactosidase (cleavage of Xgal results in blue color); production of blue color independent of lacY gene product | Miller, 1972 |

| Orthonitrophenyl- β-d -galactoside (ONPG) | 10 mM | β-galactosidase assays | Chromogenic substrate of β-galactosidase (cleavage of ONPG results in yellow color) | Miller, 1972 (pp. 352-355) |

| 6-O-β-d-Galacto-pyranosyl d -glucose (allolactose) | Inducer of the lactose operon in vivo; lactose is converted into allolactose by β-galactosidase | Zabin and Fowler, 1978 (pp. 89-121) | ||

| Phenyl-β-d-galacto-side (Pgal) | 2 mg/ml | Selection for lac constitutive mutants | Noninducing substrate of β-galactosidase; uptake partly dependent on lacY gene product | Miller, 1978 (pp. 31-88) |

| Orthonitrophenyl- β-d -thiogalacto- side (TONPG) | 10 mM | Selection for lac− mutants | Transported into cells by lac permease (the lacY gene product); inhibits cell growth at high concentration | Miller, 1978 (pp. 31-88) |

Stock solutions should be dissolved in sterile water unless otherwise noted.

TOP AGAR

Top agar is used to distribute phage or cells evenly in a thin layer over the surface of a plate. In a typical application, molten top agar is mixed with bacteria and the mixture poured onto a plate to make a thin layer that is allowed to solidify. This layer of cells then grows denser, forming the opaque lawn of cells. Top agar contains less agar than plates, and so stays molten for days when it is kept at 45° to 50°C. Top agarose is sometimes used when DNA is to be prepared directly from phage, and is also used when libraries are plated out to be screened by plaque lifting.

Prepare top agar in 1-liter batches, autoclave for 15 min to melt, cool to 50°C, swirl to mix, pour into separate 100-ml bottles, reautoclave, cool, and store at room temperature. Before use, melt the agar by heating in a water bath or microwave oven (see unit 1.11) then cool to and hold at 45° to 50°C. If melting in a microwave, be sure to loosen the caps to allow steam to escape from the bottles and avoid shattering.

H top agar

10 g tryptone

8 g NaCl

7 g agar

LB top agar

10 g tryptone

5 g yeast extract

5 g NaCl

7 g agar

Lambda top agar

10 g tryptone

2.5 g NaCl

7 g agar

Top agarose

10 g tryptone

8 g NaCl

6 g agarose

STAB AGAR

Stab agar is used for storing or transporting bacterial strains (see unit 1.3). The recipe below is for 1 liter.

Stab agar

10 g nutrient broth

5 g NaCl

6 g agar

10 mg cysteine∙Cl

10 mg thymine

Thymine is included so that thy- bacteria can grow. Cysteine is thought to increase the amount of time bacteria can survive in stabs.

TOOLS

Inoculating Loops and Needles

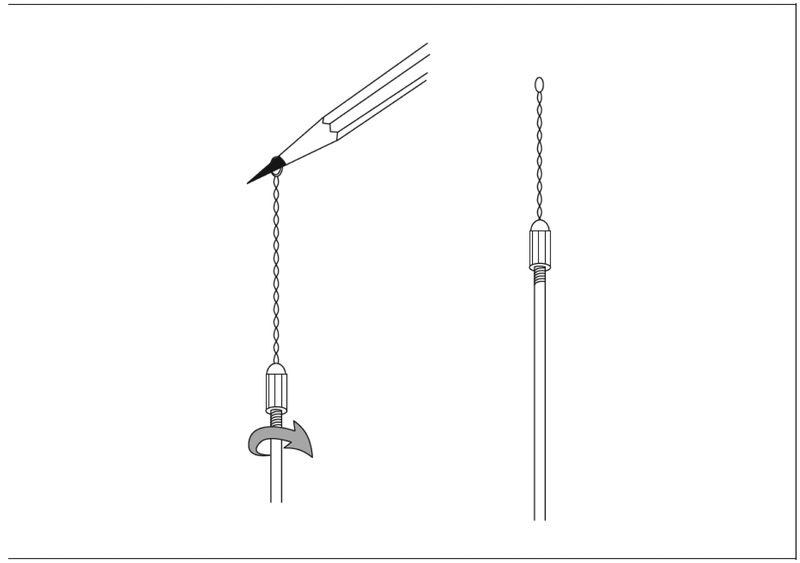

Inoculating loops are used to move small numbers of bacteria or phage to a plate or to a new container of liquid medium. Inoculating loops may be purchased from any general scientific supply company. However, most researchers prefer to use loops made in the laboratory. These are made by inserting both ends of a 10-in. piece of 28-G platinum wire into an inoculating loop holder (also widely available) and twirling the holder while tugging on the middle of the wire with the point of a pencil (see Fig. 1.1.1).

Figure 1.

Making an inoculating loop

Sterilize the loop by holding it in a bunsen burner flame until it is red hot. Cool the loop by touching it to a sterile portion of the surface of an agar plate until it stops sizzling.

Inoculation needles may also be utilized and are particularly helpful when transferring closely spaced bacterial colonies. Reusable inoculating needles may be made from platinum or nichrome wire affixed to a metallic handle as above. These are sterilized as described above for inoculating loops.

Alternatively, disposable, single use sterile inoculating needles are also commercially available.

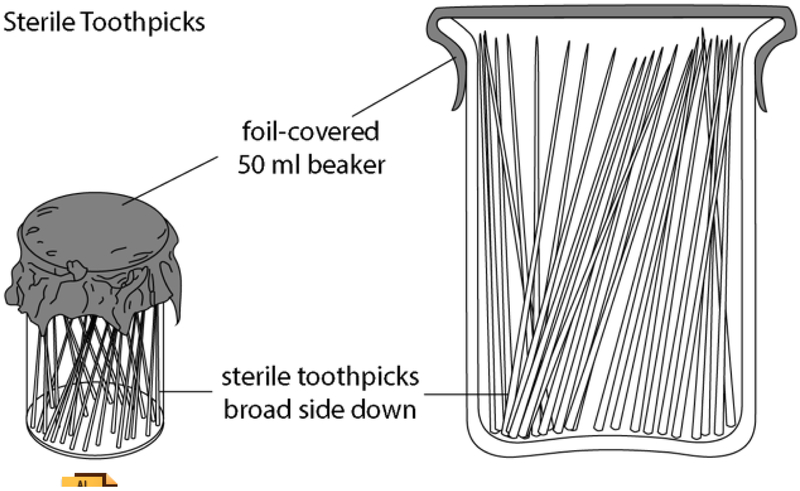

Sterile Toothpicks

The broad side of flat wooden toothpicks may also be used for streaking out bacteria. Round wooden toothpicks, or the pointed end of flat toothpicks, are sometimes used to pick individual colonies or phage plaques. To sterilize, place toothpicks in a small beaker, cover the beaker with foil, and autoclave at 121°C at one atmosphere (1.05 kg/ cm2) on the dry cycle. Alternatively, simply autoclave the whole box of toothpicks and hold them in the middle when picking them up out of the opened box. It is convenient to put used toothpicks into another smaller beaker which, when full, is covered with foil and autoclaved. Used toothpicks can be saved, reautoclaved, and used again (see Fig. 2).

Figure 2.

Sterile toothpicks.

Disposable pipet tips

Most tips for pipeting devices, such as 200ul “green” tips, come prepackaged in racks. These come from the manufacturers clean, but not sterile. One sterilizes the rack of tips by autoclaving for 15 min or longer at 121° on the dry cycle. One can then carefully remove a tube from the rack with one’s fingers and use it as one would use a toothpick.

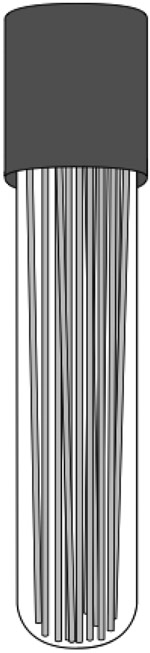

Applicator sticks

Sterile wooden applicator sticks can also be used to streak out bacteria and to inoculate liquid cultures (Walter, 1968). 14 cm round sticks can be purchased from most scientific supply houses. To sterilize them, place the sticks in 15cm x 2cm culture tubes (see Figure 3), place those tubes in a rack, and autoclave for 15 min at 121on the dry cycle.

Figure 3.

Sterile applicator sticks.

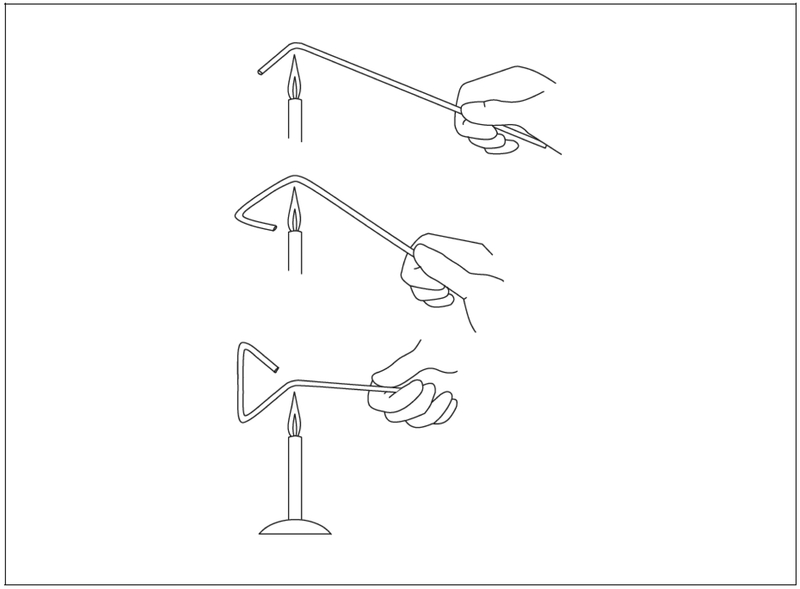

Spreaders

Spreaders are used to distribute liquid containing bacterial cells evenly over a plate. They are made by heating and bending a 4-mm glass rod (see Fig. 4). Less durable spreaders can be made from glass tubing and even from glass Pasteur pipets. Before each use, sterilize the spreader by dipping the triangular part into a container of ethanol, passing the spreader through a gas flame to ignite the ethanol, and letting the flame burn out. Be careful not to ignite the ethanol in the container. Cool the spreader by touching it to the surface of an agar plate that has not yet been spread with cells. Autoclavable, reusable stainless steel spreaders can also be used as above. Finally, disposable, single use plastic spreaders are also commercially available.

Figure 4.

Making a spreader from a glass rod

Glass Beads

Although spreaders are useful for many applications, when processing large numbers of plates it can become a time-consuming process. A popular alternative practice is to use 4-mm glass beads that have been sterilized. To make them, fill a 100ml or other glass bottle leaving room at the top (see Figure 5), and autoclave for 15 min on the dry cycle, and dry for at least another 30 min. A half dozen or more beads distribute the liquid culture on surface of the agar when the plate is shaken horizontally in all directions. The beads are then discarded and the plate inverted and placed in the incubator. Stacks of plates can be handled together when plating many culture samples.

Figure 5.

Bottle with sterile glass beads.

Background

Collectively, the tools and methods now used to grow and manipulate Escherichia coli constitute a powerful technology. During the late 19th and early 20th centuries, this newly developed technology permitted a great wave of discovery, and resulted in isolation of the microorganisms responsible for many diseases. Although the technology is powerful, its methods and the concepts that underly them are simple enough so that in affluent countries it is routinely taught to advanced secondary school students. Like all technologies, the invididual elements depend on ideas and contributions by individual people. The history of some of the contributions, including the invention of wire inoculating loops and needles, is obscure (at least to the authors) but many of the others are well recorded.

The key period in the development of the methods now used to grow and manipulate E. coli come from a burst of technical creativity mainly in the 1870s and 1880s, and largely due to competing groups in Paris (Pasteur) and Berlin (Koch).

One key element was development of liquid growth medium. Pasteur (1860) described a synthetic growth medium made of ash, sugar, ammonium salts, and yeast in 1860. In 1876 Koch described rich media, “Brühen” or “Fleischbrühen” (bouillons or broths), made from cow serum and beef extract, that allowed many bacterial species to grow well (Koch, 1876). Rich liquid medium allowed isolation of pure cultures of individual bacteria by serial dilution (described in the companion paper, Unit 1.3) into tubes of fresh medium.

A second key element was development of solid growth medium. 1881 Koch demonstrated use of solid medium made by adding gelatin to broth, which was poured onto open plates, that were then covered with a glass bell jar, and allowed to solidify (Collard, P. J., 1976). The resulting solid medium allowed investigators to isolate pure strains by streaking from a liquid or other sample, incubating the plates and bell jar together, and identifying single colonies (Unit 1.3) each formed by serial division of a single founder bacterium. Gelatin was not optimal: at the concentrations used, gelatin became very soft at temperatures near 40°, and any bacterial colony that secreted proteases tended to liquify the gelatin, and in 1882 Fannie Hesse (born Fannie Eilshemius and then working with her husband, Dr. Walther Hesse, in the Koch lab) suggested using agar as the gelling agent (Hesse, 1992). Koch described this use of agar in a clinical report (Koch, 1882). Use of agar based solid medium spread rapidly after Richard Julius Petri demonstrated that one could replace the open dishes and bell jars with “Petri dishes”, circular glass dishes with loose fitting tops (1887).

Finally, another development built on the knowledge that high-pressure steam provided a reliable means to kill live bacteria and bacterial spores and so sterilize media and glassware. As pressure increases, the temperature at which water forms steam increases, which means that for a chamber that contains water at the bottom and steam over it, with constant heat input, maintaining a constant steam pressure maintains the steam and the liquid at a constant temperature. Construction of such a device was probably first done by Charles Chamberland at the Institutute Pasteur in 1879. Development of this device, the autoclave, gave labs an easy way to sterilize glassware, and to heat media to dissolve ingredients and sterilize it at the same time. At sea level saturated steam at 1 atmosphere overpressure (1.05 kg/ cm2, 105kp, or 14.5 pounds per square inch) is at 121°C, and all recipes for modern media use exposure to saturated steam at this temperature and pressure as the standard means of sterilization.

In addition to being a powerful technology, the means used to manipulate E. coli also constitute a mature technology, in the sense that a 19th century researcher would be able to carry out the same operations in the same way in a 21st century lab. However, even mature technologies can be subject to slow improvements. Here are some we can mention. During the 1960s, as injection molding methods became cheap, pre-sterilized, disposable injection molded plastic polystyrene Petri dishes became widespread. Sterile devices allowing liquid medium to be sterilzed without heat by filtration became widespread in the 1970s after Millipore developed means to make through filters made of nitrocellulose with 0.45um holes (and later, 0.22um), small enough that most bacteria could not pass through them. Although we do not know when beakers of sterile toothpicks covered with aluminum foil became widely used in labs, we can speculate that that did not occur until the end of war production for WWII made cheap aluminum foil available for commercial use. The autoclaving of boxes of toothpicks was a trick that spread during the 1980s and the use of wooden applicator sticks (published by William Walter (1968) after eight years of testing on classes of university students) seems to have become firmly established in labs sometime during the 1990s.

Acknowledgement

This work was supported by NIH grant R21 CA223901 to RB.

Contributor Information

Karen Elbing, Clark & Elbing LLP, Boston, Massachusetts.

Roger Brent, Division of Basic Sciences, Fred Hutchinson Cancer Research Center, Seattle, Washington.

Literature Cited

- Bachmann B (1972) Pedigrees of some mutant strains of Escherichia coli K-12. Bacteriological Reviews 36, 525–557 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Barkley MD and Bourgeois S 1978. Repressor recognition of operator and effectors In The Operon (Miller J, ed.) pp. 177–220. Cold Spring Harbor Laboratory, Cold Spring Harbor, N.Y [Google Scholar]

- Blattner FR, Plunkett G III, Bloch CA, Perna NT, Burand V Riley M, Collado-Vides J, et al. (1997) The complete genome sequence of Escherichia coli K-12 Science 277, 1453–1462 [DOI] [PubMed] [Google Scholar]

- Collard PJ The development of microbiology. Cambridge: Cambridge University Press, 1976, pp. 28. cited in Sandle, T. Pharmaceutical Microbiology: Essentials for Quality Assurance and Quality Control, (2015), Woodhead Publishing, Cambridge, UK, Chapter 5. [Google Scholar]

- Foster TJ 1983. Plasmid-determined resistance to antimicrobial drugs and toxic metal ions in bacteria. Microbiol. Rev 47:361–409. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Gray CH and Tatum EL (1944) X-ray induced growth factor deficiencies in bacteria. Proc. Natl. Acad. Sci. USA 30, 404–410 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Gottlieb D and Shaw PD 1967. Antibiotics. I Mechanism of Action. Springer-Verlag, New York [Google Scholar]

- Hesse W (1992) Walther and Angelina Hesse-- Early Contributors to Bacteriology ASM News 58, 425–428 [Google Scholar]

- Koch R (1876) Die Äetiologie der Milzbrand-Krankheit, begründet auf die Entwicklungsgeschichte des Bacillus Anthracis. Beitr z Biol D Pflanzen 2:277–310. Publication server of the Robert Koch Institute, downloaded 2 October 2018 [Google Scholar]

- Koch R (1882) Die Äetiologie der Tuberculose, Berliner Klinische Wochenschrift (Berlin Clinical Weekly), 19, 221–230. [Google Scholar]

- Lederberg J and Tatum EL (1946) Gene recombination in Escherichia coli. Nature 158, 558. [DOI] [PubMed] [Google Scholar]

- Lederberg J, and Tatum EL (1946) Novel genotypes in mixed cultures of biochemical mutants of bacteria. Cold Spring Harb. Symposium Quant. Biol 11: 113–114 [Google Scholar]

- Lederberg EM (1951) Lysogenicity in E. coli K-12. Genetics 36, 560 [Google Scholar]

- Lederberg EM and Lederberg J (1953) Genetic studies of lysogenicity in E. coli. Genetics 38, 51–64 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Miller J 1972. Experiments in Molecular Genetics. Cold Spring Harbor Laboratory, Cold Spring Harbor, N.Y [Google Scholar]

- Miller JH 1978. The lacI gene: Its role in lac operon control and its uses as a genetic system In The Operon (Miller J, ed.) pp. 31–88. Cold Spring Harbor Laboratory, Cold Spring Harbor, N.Y [Google Scholar]

- Moazed D and Noller HF 1987. Interaction of antibiotics with functional sites in 16S ribosomal RNA. Nature 327:389–394. [DOI] [PubMed] [Google Scholar]

- Petri RJ (1887) Eine kleine Modification des Koch’schen Plattenverfahrens (A small modification of Koch’s plate method), Centralblatt für Bakteriologie und Parasitenkunde, 1 : 279–280. [Google Scholar]

- Pressler U, Staudenmaier H, Zimmermann L, and Braun V (1988) Genetics of the iron dicitrate transport system of Escherichia coli. J Bacteriol. 1988; 170:2716–2724. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Sandle T Pharmaceutical Microbiology: Essentials for Quality Assurance and Quality Control, (2015), Woodhead Publishing, Cambridge, UK, Chapter 5. [Google Scholar]

- Thomason LC, Sawitzke JA, Li X, Costantino N, and Court DL (2014) Recombineering: genetic engineering in bacteria using homologous recombination. Curr Protoc Mol Biol 106:1.16.1–39. [DOI] [PubMed] [Google Scholar]

- Walter WG (1968) The use of wooden applicator sticks. The American Biology Teacher 30, 473–475 [Google Scholar]

- Welz D and Braun V (1998) Ferric Citrate Transport of Escherichia coli: Functional Regions of the FecR Transmembrane Regulatory Protein. J Bacteriol. 1998 May; 180(9): 2387–2394. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Zabin I and Fowler AV 1978. β-galactosidase, the lactose permease protein, and thiogalactoside transacetylase In The Operon (Miller J, ed.) pp. 89–122. Cold Spring Harbor Laboratory, Cold Spring Harbor, N.Y [Google Scholar]