Abstract

In this research, hydroxyapatite (HAp) was synthesized from chicken eggshell waste by hydrothermal method for the development of bio-composite material suitable for biomedical implant. However, since environmental influences on natural materials are unique for different geographical locations in the world, the use of agro wastes from these locations need to be investigated. This work provides the detail results of the potentials of eggshell as HAp source. High-density polyethylene (HDPE)/HAp composites were developed by random dispersion of Hap (10, 20, 30 and 40 wt.%) in HDPE matrix, and were designated as HAC10, HAC20, HAC30, and HAC40. The HAp-filled HDPE composites were developed by a hot compression moulding process. The samples were subjected to tensile, flexural, impact, fracture toughness and wear tests according to ASTM standards in order to establish their structural performance as an implant material. Furthermore, the samples were also tested for hydrophilicity using tap water and simulated body fluid (SBF). X-ray diffraction analysis showed strong peaks of hydroxyapatite phase which established that the influence of the selected processing conditions on the poultry eggshell as a natural source for the biomedical application was suitable for the synthesis of high-quality hydroxyapatite. The mechanical properties of the developed composites were enhanced to the level of the required properties expected of an implant material compared to the control sample except for impact strength. Water absorption characteristics of the developed composite samples also displayed expected behaviour in SBF solution than in tap water thereby promoting the material as a good implant material. From the results, the sample with 40 wt.% HAp possess the highest values in the mechanical properties examined while sample from 20 wt.% had the best fracture toughness. The results revealed that these waste eggshells could be successfully converted into useful biocompatible HAp particles needed for the enhancement of the mechanical properties of polymer composites to meet the structural challenges of bio-composites.

Keywords: Biomedical engineering, Materials science, Materials application, Biomedical materials, Hydroxyapatite, High-density polyethylene, Bio-composites, Poultry eggshell, Structural performance

1. Introduction

Bio-composites are composite materials containing one or more biologically derived phases. Hydroxyapatite (HAp) represents the largest inorganic portion of teeth and bone tissues. It plays significant roles in diverse synthetic biomaterials due to its excellent biocompatibility [1, 2]. Bio-composites, which can exist as films, membranes, coatings, and particles, are becoming important and prevalent materials as a result of growing environmental concerns. Apart from improving the physical and mechanical properties of these materials, some researches have investigated their use in applications including sensors, scaffolds, implants, and tissue engineering [3].

The use of particles from cow and goat bones as reinforcements in polymers has been confirmed to be suitable structurally for biomedical application [4, 5]. The synthesis of HAp from chicken eggshell is eco-friendly and it is promising for treating bone related problems such as bone cancer, tumour, and fracture, at a reduced cost [1]. The major constituent of chicken eggshell is CaCO3. It constitutes about 94 % of the shell chemical composition. Some other components of eggshells are magnesium carbonate (1%), insoluble proteins, calcium phosphate (1%), and organic matters (4%) [1]. During calcination of the shell, CaCO3 is decomposed to form calcium oxide (CaO) which is further processed to form HAp. It is worthy of mentioning that the quality of HAp depends greatly on the calcination temperature. For instance, any disease transmitting pathogens present in the HAp that may be transferred to patients are destroyed at high temperature [1]. Furthermore, HAp characteristics such as pore size, phase and efficiency are also affected [6]. HAp can serve as reinforcing filler in polymer, metal or ceramic matrices. Other than this, HAp is biocompatible and has the ability to bond directly to hard tissues.

Although metallic implants exhibit higher strength, they suffer from low biocompatibility, and high density. Furthermore, their high stiffness results in stress shielding when used as implant materials. For example, 316 stainless steel possesses a Young's modulus of 190–193 GPa and ultimate tensile strength of 515–619 MPa [7], which are higher than those of human cortical bone (ultimate compressive strength of 70–230 MPa and modulus of 3–30 GPa) [8]. In contrast, HAp reinforced polymer composites (HAp/polymers) are better-off and can overcome some of the challenges associated with metallic and ceramic-based implants. More also, implants made from HAp/polymers can be used to treat problems like bone resorption, orbital floor fractures, middle ear, post-enucleation socket syndrome, etc. [9].

The number of people facing the challenges of bone tissue related problems, such as trauma, bone cancer, bone fracture and ageing are increasing over the years globally [10, 11]. Hence, there is high demand for biomaterials to adequately meet the needs across the globe. Researchers have continued to engage in research to develop suitable biomaterials for tissue replacement. Synthetic biomaterials have been used to substitute or modify body tissue in order to improve the quality of life of the patient [12]. HAp-based composites are proven to meet these requirements. However, limited availability of HAp and high cost of synthetic Hap are among the factors that have discouraged the wide usage of HAp-derived composites as implants for bone tissue repair globally. Therefore, there are concerted research efforts geared towards developing alternative sources, especially from renewable or agricultural wastes, for biomaterials [13].

Research and development on the use of animal wastes are on-going globally and this work revealed the potentials that are imbedded in the eggshell from Nigeria which are readily available as waste. This became necessary since their constituents depend on feeding, age, breed and many other factors that have to do with the geographical location of the chicken that lay the egg. Therefore, the present study considers the suitability of this waste for biomedical applications since researches have established that their thermal stability is affected by stoichiometry ratio from the mineralised composition [14, 15]. However, as the specific medical application determine the design and selection parameters for biomaterials which includes; excellent biocompatibility, osseo-integration, adequate mechanical properties, high wear and corrosion resistance as well as good physical and chemical properties [16], this work focused on the development of HAp-reinforced high-density polyethylene composites for use as potential biomedical implants. The hydroxyapatite was synthesized from waste eggshells using hydrothermal method. The results obtained indicated that high quality hydroxyapatite could be synthesised from these eggshells to reduce the menace posed by the disposal of such waste materials. Furthermore, the developed composites exhibited improved structural properties that made them suitable candidate for biomedical application.

2. Materials and method

2.1. Materials

Chicken eggshells were collected from a household poultry farm in Akure, Ondo State, Nigeria. High density polyethylene (HDPE) was supplied by MARLEX Company (Lagos, Nigeria). Distilled water and orthophosphoric acid (H3PO4, ≥99.0% purity) were obtained Pascal Scientific Laboratory, Akure, Ondo State, Nigeria.

2.2. Preparation of eggshells

The eggshells were gotten from about 20-week old black chickens (Gallus domesticus) of frizzled feather and naked neck structure with an average body weight of 0.70.24 kg. The collected eggshells were cleaned, washed and boiled in distilled water for about 10 min to remove its membranes. Then, the cleaned shells were dried for 24 h in an oven (model KX350A; KENXIN International Co. Ltd., China) at 80 °C before being placed in an electric furnace (model TT-EF; Techmel & Techmel USA) maintained at 1000 °C for 1 h.

2.3. Calcination of eggshells

In the first stage of the calcination process, a heating rate of 7 °C/min was used to heat the eggshells from room temperature to 550 °C and held for 2 h. In the second stage, a heating rate of 5 °C/min was used to heat-treat to 700 °C with a holding time of 2 h. Finally, using a heating rate of 4 °C/min, the shells were heated to 1000 °C and held for 1 hat that temperature. At this stage, the shells transformed into calcium oxide (CaO) by evolving carbon (iv) oxide (CO2) as shown in Eq. (1).

| (1) |

2.4. Synthesis of hydroxyapatite powder (HAp)

The CaO produced from the calcined eggshell was converted into HAp in orthophosphoric acid (H3PO4) following the procedures reported by Hui et al., [16]. A stoichiometric amount of the calcined sample was dispersed in a beaker containing 100 ml of distilled water and placed on a hot plate maintained at 90 °C for 2 h. 20 ml of analytical grade of orthophosphoric acid was added to the beaker and stirred at 120 rpm. Initially, a suspension was observed following which the solution became clear after about 30 mins of mixing. The pH value of the solution was kept below 2 by adding drops of sodium hydroxide solution as required. The solution was aged for 7 days, filtered, and the residue was dried at 105 °C for 1 h in an oven. Thereafter, the dried residue was heated to 1000 °C in a furnace at 15 °C/min for 1 h. Finally, the lumped hydroxyapatite solids formed were manually ground into powders and sieved to obtain 18.52 ± 8.55 μm particle sizes. The expected reaction of Hap synthesis is given in Eq. (2).

| (2) |

It should be noted that when CaO was dispersed in water, calcium hydroxide might be produced. So, the actual reaction is as shown in Eq. (3).

| (3) |

2.5. Fabrication of composites

Hydroxyapatite reinforced high density polyethylene (HAp/HDPE) composite samples were fabricated by compression moulding technique. The composites were produced by randomly dispersing 10, 20, 30 and 40 wt.% of HAp particles in HDPE matrix which was achieved by first compounding the blend/mixture with hot compression machine followed by grinding before the final compression in the test specimen moulds. The compounding was done by first pressing the mixture in hot compression machine (for each weight fractions) followed by grinding with grinding machine. The granulated samples were re-compacted after pouring known weight inside the test moulds for the different tests to be carried out and placed in the heating and compression machine. The developed composites have the HAp uniformly dispersed in the HDPE matrix.

They were designated as HAC10, HAC20, HAC30, and HAC40, respectively. Unreinforced HDPE sample (designated as control) was also produced for the basis of comparison. Silicone oil was applied on the edges of the mould to ensure easy removal of the composites from the mould. Teflon sheets were also placed at the top and bottom layers of the mould. Thereafter, the mould containing the pre-blend was placed in a compression moulding machine maintained at 150 °C and 10 tons for 10–15 mins. Samples were carefully demoulded to avoid damage. To produce tensile, flexural, impact and wear samples, the moulds were designed according to the sample dimensions required for ASTM standard.

2.6. Characterisation techniques

2.6.1. Scanning electron microscopy (SEM)

JEOL JSM-6490 scanning electron microscopy (SEM; USA) was conducted on the synthesized dried HAp powder sample. Accelerating voltage was 20 kV at a working distance of 14 mm. Polished surfaces of the composite samples were examined by the SEM.

2.6.2. X-ray diffraction (XRD)

XRD technique was applied to study the phase composition of the synthesised Hap powder sample. X-ray diffractograms were obtained from an X-ray machine (9 kW Rigaku Smart Lab, Japan) using Cu K-β filter at a scanning speed of 14°/min. Scan range was 2θ = 10–80°.

2.6.3. Fracture toughness measurement

Single edge notches (SEN) were cut on the samples for the fracture toughness measurements using a thin razor blade. 10% (a/D) was used to determine the pre-crack length. Samples were subjected to tension at a strain rate of 50 mm/s. The fracture toughness of the samples was determined according to Eq. (4)

| (4) |

Where, = fracture toughness, = applied stress, = pre-crack length and = width of the test samples.

2.6.4. Abrasion test

The abrasion test or wear resistances of the control and HAp/HDPE composite samples were examined by using a Taber abrasion tester (TABER Rotary Platform Abrasion Tester - Model 5135, USA) in accordance with ASTM D4060-10 standard. The standard calculates abrasion resistance as loss in weight at a specified number of abrasion cycles. A set of two rotating abrasive wheel of thickness (12.6 mm) and diameter (50 mm) was run against the test samples and were subjected to a contact load of 1000 g. The rotational speed of operation was set at 60 rpm for about 10,000 cycles. The wear indices of the test samples were calculated based on the samples weight loss as shown in Eq. (5).

| (5) |

Where ,, and C are the initial weight of sample, final weight of sample and number of test cycles, respectively.

2.6.5. Tensile test

Tensile properties of the control and HAp/HDPE composite samples were conducted on a universal testing machine (UTM, FS 300–1023, USA) at a crosshead speed of 5 mm/min. The test was carried out at room temperature and in accordance with ASTM D-638-14 standard. Specimen dimension is based on Type IV specification with an overall length of 115 mm with a thickness of 3 mm.

2.6.6. Flexural test

Flexural properties of the control and HAp/HDPE composite samples were examined by a universal testing machine (UTM FS 300–1023, USA) according to ASTM D-790-03 standard. At least five samples from each lot were tested in accordance with the standard. Test specimen had a dimension of 150 × 50 × 3 mm that was hooked on the grip of the machine. The test speed was 5 mm/min over a span of 65 mm and the obtained results were analysed afterward.

2.6.7. Impact test

The impact energy (notched) of the composites was measured on an impact tester (Housefield Balance, USA) in accordance with ASTM D-256. Test specimens with dimensions 60 × 15 × 3 mm were notched and point of impact was on the un-notched side.

2.6.8. Water absorption test

Water absorption test was carried out by immersing the control HDPE and HAp/HDPE composite samples in tap water and simulated body fluid (SBF). The SBF was supplied by Aventra Innovation Company, Nigeria, having a composition of glucose (5.0 g), sodium chloride (0.9 g), water (70 ml), electrolytes (Na+ 150 Cl− 150) and a calculated osmolarity of 570 m Osm/litre. The initial and final weight of the test samples were recorded at intervals of 24 h for a total of 96 h. Finally, the percentage water absorption was calculated according to Eq. (6).

| (6) |

Where; W is the percentage water absorption, and are initial and final weight of samples before after immersion.

3. Results and discussion

3.1. Microstructural characterisation and X-ray diffraction pattern of synthesised HAp powder

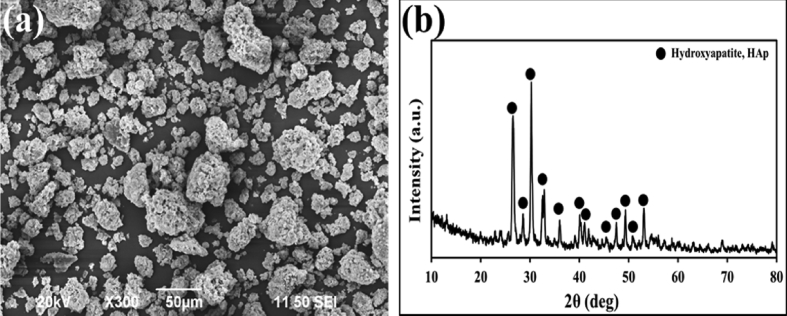

The SEM image of the synthesized HAp sample is presented in Fig. 1(a). From the image, it was observed that the particles of the as-synthesized HAp were highly agglomerated with no regular shape. Analysed average diameter of particles was average of about 18.71 ± 10.74 μm. Particle agglomeration could be ascribed to the hydrothermal method utilised in synthesising the powder. Mechanical milling of the powder may be used to obtain smaller sizes as reported in an earlier study [17]. However, the as-synthesised powder was utilised in composite development without further treatment.

Fig. 1.

(a) SEM image of synthesised HAp powder (b) XRD pattern of synthesised HAp.

The X-ray diffraction pattern of the as-synthesized HAp powder is shown in Fig. 1(b). All peaks were indexed as HAp (DB card no 01-072-1243). Compared to some previous works [17, 18], minor peaks of calcite (CaCO3) and calcium oxide (Ca(OH)2) were found in the XRD patterns. This was attributed to the incomplete reaction and inadequate utilisation of calcium or phosphorous precursors. However, in this study no such minor peaks were detected, which suggested that the hydrothermal process adopted in this research was successful for synthesising HAp from eggshell.

3.2. Microstructural characterization of pure HDPE and HAp/HDPE composites

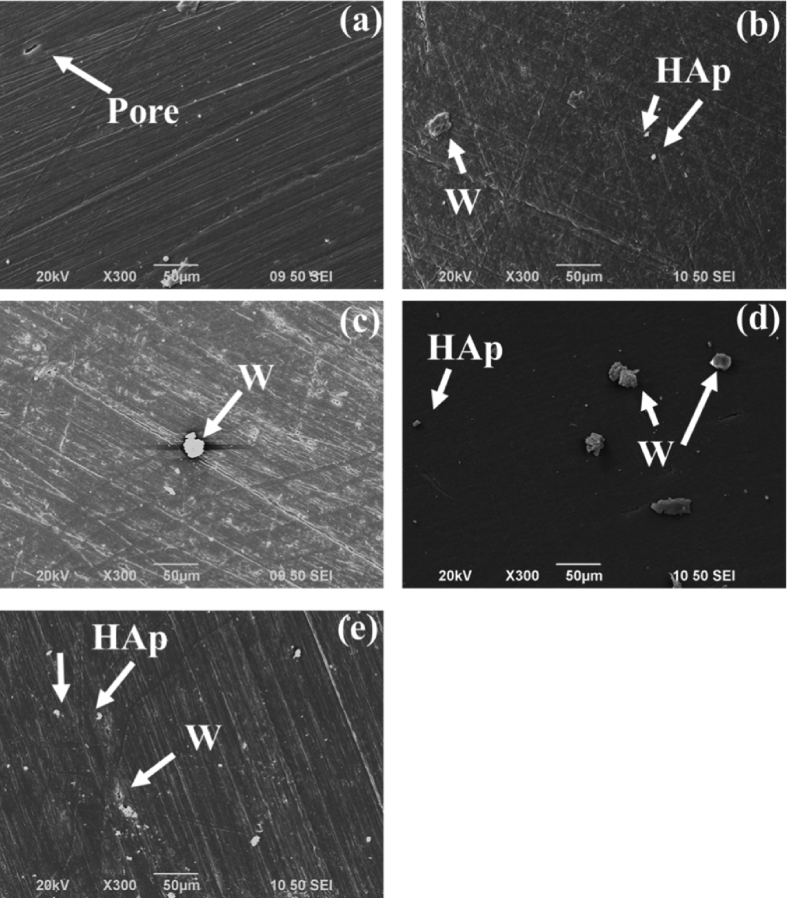

Fig. 2 shows the SEM images of the polished surfaces of the samples. SEM image of the control HDPE sample is shown in Fig. 2(a). From the SEM image, a clear microstructure could be observed with very minimal occurrences of voids. This indicated that the parameters utilised for the compression moulding process were appropriate. Fig. 2(b)–(c) show the SEM microstructural images of the composite samples. HAp fillers and polymer flashes appeared greyish against a black HDPE background. Compared to the image of the HAp reported in Fig. 1(a), the sizes of the particles in the composite samples reduced significantly. This could be attributed to the compression force utilised during composite synthesis. This reduction in particle size could be beneficial for improving some of the mechanical properties of the composites. In Fig. 2(b) for HAC10 composite, HAp fillers were mostly homogeneously distributed in the HDPE matrix, although some agglomerated HAp particles (labelled as “W”) could be seen. More so, no particle debonding was observed, an indication that a strong interface existed between the matrix and HAp. Similarly, HAC20 (Fig. 2(c)), HAC30 (Fig. 2(d)), and HAC40 (Fig. 2(e)) show evidence of uniform distribution of HAp particles. However, few agglomerates (labelled as “W”) were noticed which did not adversely affect the mechanical properties of the composites as shall be presented in the next few paragraphs.

Fig. 2.

Microstructural images of samples (a) HDPE control (b) HAC10 (c) HAC20 (d) HAC30 (e) HAC40.

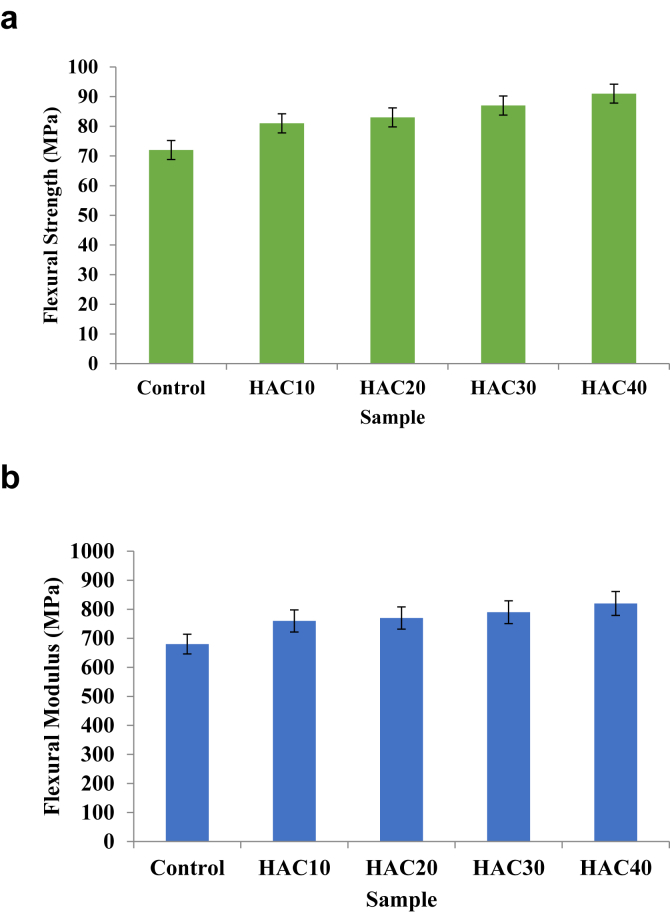

3.3. Flexural properties

The flexural strength of all the samples as a function of HAp content is shown in Fig. 3(a). The whiskers on the graph represent standard deviation of the data set. It was observed that the flexural strength increased as the HAp content increased up to a maximum value of 91 MPa at 40 wt.% HAp content. The results indicated that the presence of HAp filler in the composites resulted in an enhancement efficiency of about 26% compared to the control HDPE. Similar observation was obtained in the work of Jaggi et al. [9], where the flexural strength of the composite was enhanced by HAp addition. These improvements could also be linked to the good adhesion between the filler and the matrix [19, 20].

Fig. 3.

Effect of hydroxyapatite particles on (a) flexural strength and (b) flexural modulus of the samples.

Fig. 3(b) shows the flexural modulus of the samples. It was observed that the flexural modulus (680 MPa) of the control HDPE was lower than that of the composite samples. The flexural modulus tends to increase as the HAp content increases from 10 – 40 wt.% HAp addition similar to the results obtained in Fig. 3(a). Composite with 40 wt.% HAp content denoted as HAC40 exhibited the highest flexural modulus of 820 MPa which culminated to about 21% enhancement compared to the control sample. This further justifies the optimistic influence of the HAp filler on the HDPE matrix in enhancing the flexural performance.

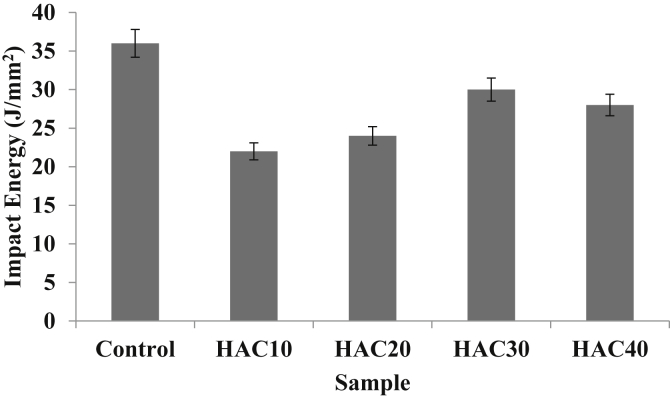

3.4. Impact energy

The effect of HAp content on the impact energies of the sample was as shown in Fig. 4. The whiskers on the graph represent standard deviation of the data set. The test was carried out to determine the energy lost per unit cross-sectional area at the notch (J/mm2). It was observed that the impact energies of the composites were lower than that of the control HDPE (36 J/mm2). However, among the composites, it was 30 wt.% HAp content that had the highest impact energy with a value of 30 J/mm2. The presence of hard fillers stiffened and hardened the matrix, which resulted in the reduced toughness of the matrix. This submission agreed with the results presented in an earlier study on recycled low-density PE/bean pod ash composites [21].

Fig. 4.

Effect of hydroxyapatite particles on the impact energy of the composite samples.

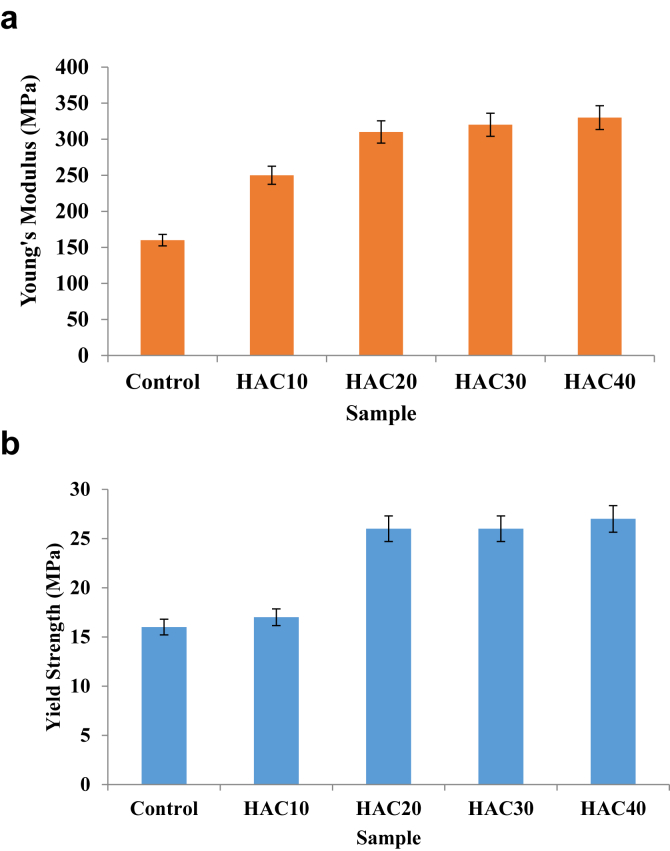

3.5. Tensile properties

The whiskers on the graph represent standard deviation of the data set. Generally, the Young's moduli of the composites were found to increase as HAp content increased, as shown in Fig. 5(a). However, there was a sudden increase in the moduli as from 20 wt.% HAp addition up to 40 wt.%. This was an indication that the addition of HAp that is less than 20 wt.% may not produce high enhancement of the modulus of HDPE. It was observed that control HDPE exhibited the lowest Young's modulus of 160 MPa while HAC40 composite had the highest value of 330 MPa. Accordingly, the incorporation of HAp fillers in the HDPE matrix resulted in modulus enhancement by about 106% for HAC40 and 94% for HAC20 whereas it was 56% for HAC10.

Fig. 5.

Effect of hydroxyapatite particles on (a) Young's modulus and (b) Yield strength of the samples.

Fig. 5(b) shows the yield strengths of the samples as a function of HAp contents. It was observed that the yield strength of the samples increased as the filler content increases similar to what was obtained in 5 (a). The yield strength of the control HDPE was 16 MPa, whereas at 20 and 40 wt. % of HAp (HAC20 and HAC40), it increased to about 26 and 27 MPa, respectively. Therefore, the combined enhancement obtained for both yield strength and Young's modulus may be attributed to better dispersive mixing of HAp filler in the HDPE matrix emanating from the processing parameters. This observation was in consonance with the results presented in some earlier studies [19, 22, 23].

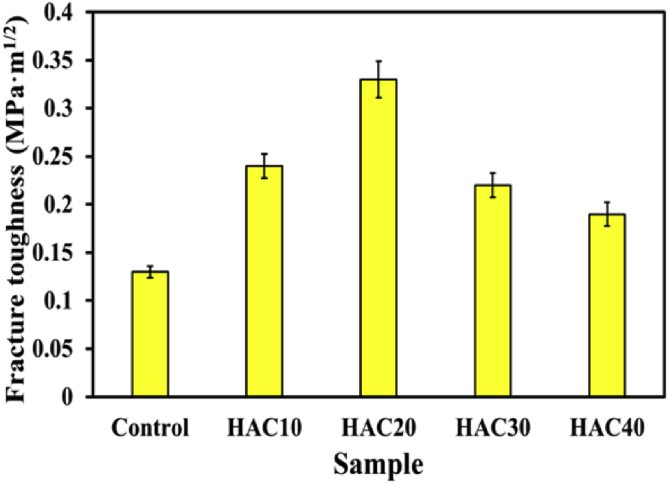

3.6. Fracture toughness

The fracture toughness of HDPE and its composites were determined from the expression given in Eq. (4). The whiskers on the graph in Fig. 6 represent standard deviation of the data set. The results presented in Fig. 6 showed that HAp/HDPE composites possessed higher fracture toughness (K1) values than the control HDPE. The fracture toughness of the developed composites was higher than that of the HDPE within the filer content considered. This revealed that, the inclusion of HAp particles in the HDPE matrix led to the enhancement of its fracture toughness. However, it was observed that the K1 values increased steadily as the HAp content increased up to a maximum value of 0.33 MPa m1/2 for HAC20 composite and then decreased drastically. The reason behind the sudden reduction in the fracture toughness of the composites may be attributed to high HAp content above the optimum value that can actually brought about enhancement. It is believed that above the optimum amount, reinforcement tends to form clusters which may act as crack initiators or stress raisers in the composite.

Fig.6.

Effect of hydroxyapatite particles on the fracture toughness of the samples.

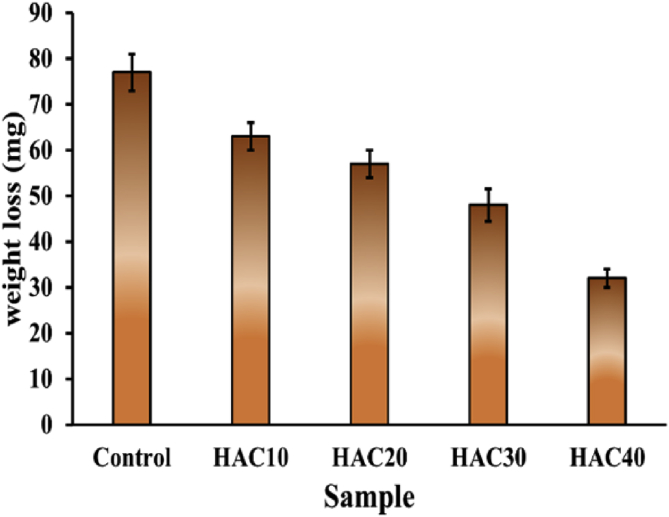

3.7. Abrasion

The wear resistance of the samples was calculated based on their weight loss as shown in Fig. 7. It is related to their mechanical properties in terms of their surface characteristics. It could be seen that the control HDPE experienced the greatest weight loss compared to the composite samples. Also, the weight loss of the samples decreased steadily as the HAp content increased. The result showed that the inclusion of HAp filler in the composites significantly enhanced their wear resistance properties. The wear rate of HAC40 composite was about 125% lower than that of the control HDPE, which indicated that the ploughing resistance on the composite surface was significantly improved due to HAp filler addition and the reduction in shear stress between the HAp/HDPE composite and the rotating wheel also contributed to its lower wear rate. Similar trend was obtained earlier by some researchers [24, 25].

Fig.7.

Effect of hydroxyapatite particles on the weight loss of the composite samples.

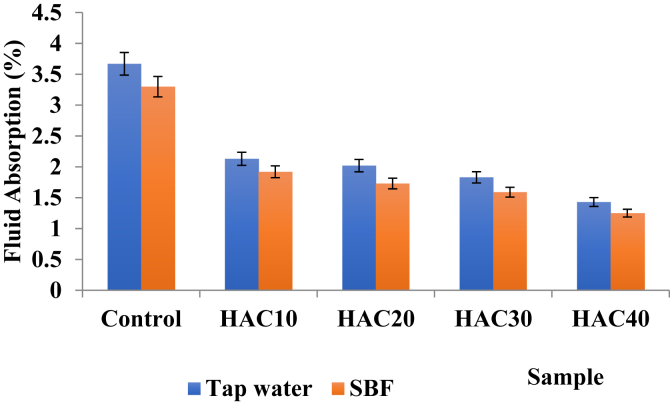

3.8. Water absorption

Fig. 8 shows the fluid absorption (%) of samples immersed in tap water and SBF. The fluid absorption property, otherwise known as hydrophilicity is crucial to composites used in tissue engineering, as high hydrophilic composites would accommodate cell attachment and enhanced its cell viability and proliferation [26]. As shown in Fig. 8, it was observed that all the composite samples absorbed less fluid during hours of immersion compared to the control. This may be due to the presence of more pores in the control sample than the composites. Less porosities or voids are likely to be present in the composites because the HAp particles might probably occupy these spaces in the developed composites. Hence, there is a gradual reduction in the amount of fluid absorbed as the filler content increases from 10 – 40 wt.%. The same trend was observed in both media with the control HDPE sample having the highest water absorption susceptibility of 3.67 and 3.30 % while sample HAC40 had the least with values 1.43 and 1.25% in tap water and SBF, respectively. However, after 96 hrs, all the samples immersed in tap water absorbed more fluid than those immersed in the SBF solution. The high resistance to fluid absorption from SBF may be due to the compositions of the fluid. This showed that the composite samples might perform better when applied in the body as their hydrophilicity was moderate in SBF solution compared to tap water. Relatively, the SBF was not aggressive to cause degradation due to high moisture absorption.

Fig.8.

Percentage fluid absorption after immersion for 96 hrs in tap water and SBF solution.

4. Conclusions

HAp particles were successfully synthesized from eggshell by hydrothermal method and were used to develop HDPE/HAp composites. The developed composites demonstrate enhanced mechanical properties expected of an implant material compared to the HDPE. Further findings were as follows.

-

❖

XRD result showed strong peaks of hydroxyapatite phase for the particulate sample which established that the processing conditions were suitable for the synthesis of high-quality hydroxyapatite from eggshell found in this geographical location with the stated conditions.

-

❖

All the developed composite samples showed enhanced mechanical properties compared to the HDPE matrix except for impact energy. Composite sample, HAC40 had the highest flexural strength and modulus (91 and 820 MPa, respectively), yield strength and Young's modulus (27 and 330 MPa, respectively) and wear resistance properties while HAC20 had the highest fracture toughness value (0.33 MPa m1/2).

-

❖

Fluid absorption properties of the developed composite samples were low in SBF solution than in tap water with HAC40 having the least value. This confirmed the suitability of this composite material as a good implant material with moderate absorption.

-

❖

The results authenticated the acceptance of the eggshell from this geographical location as a naturally originated resource for biomedical application. And, that 20–40 wt.% of the HAp content will give the desirable optimum properties.

Declarations

Author contribution statement

Isiaka Oluwole Oladele: Conceived and designed the experiments; Analyzed and interpreted the data; Wrote the paper.

Okikiola Ganiu Agbabiaka: Performed the experiments; Analyzed and interpreted the data; Wrote the paper.

Adeolu Adesoji Adediran & Akeem Damilola Akinwekomi: Analyzed and interpreted the data; Wrote the paper.

Augustine Olamilekan Balogun: Contributed reagents, materials, analysis tools or data; Wrote the paper.

Funding statement

Authors acknowledged Landmark University Centre for Research Innovation and Development (LUCRID) for their support towards this work.

Competing interest statement

The authors declare no conflict of interest.

Additional information

No additional information is available for this paper.

References

- 1.Abdulrahman I., Tijani H.I., Mohammed B.A., Saidu H., Yusuf H., Ndejiko J.M., Mohammed S. From garbage to biomaterials an overview on egg shell based hydroxyapatite. J. Mater. 2014;2014:1–6. [Google Scholar]

- 2.Franklin D.S., Guhanathan S. Performance of silane-coupling agent-treated hydroxyapatite diethylene glycol-based pH-sensitive biocomposite hydrogels, Iran. Polym. J. 2014;23:809–817. [Google Scholar]

- 3.Haraguchi K. Biocomposites. In: Kobayashi S., Mullen K., editors. Encycl. Polym. Nanomater. Springer Berlin; Heidelberg: 2014. p. 2014. [Google Scholar]

- 4.Oladele I.O., Adewole T.A. Influence of cow bone particle size distribution on the mechanical properties of cow bone-reinforced polyester composites. Biotechnol. Res. Int. 2013;2013:1–5. doi: 10.1155/2013/725396. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 5.Oladele I.O., Isola B.A. Development of bone particulate reinforced epoxy composite for biomedical application. J. Appl. Biotechnol. Bioeng. 2016;1:35–40. [Google Scholar]

- 6.Lin K., Liu X., Chang J., Zhu Y. Facile synthesis of hydroxyapatite nanoparticles, nanowires and hollow nano-structured microspheres using similar structured hard-precursors. Nanoscale. 2011;3:3052–3055. doi: 10.1039/c1nr10334b. [DOI] [PubMed] [Google Scholar]

- 7.Aherwar A., Singh A.K., Patnaik A. Current and future biocompatibility aspects of biomaterials for hip prosthesis. AIMS Bioeng. 2016;3:23–43. [Google Scholar]

- 8.Choy M.T., Tang C.Y., Chen L., Wong C.T., Tsui C.P. In vitro and in vivo performance of bioactive Ti6Al4V/TiC/HA implants fabricated by a rapid microwave sintering technique. Mater. Sci. Eng. C. 2014;42:746–756. doi: 10.1016/j.msec.2014.06.015. [DOI] [PubMed] [Google Scholar]

- 9.Jaggi H.S., Kumar S., Das D., Satapathy B.K.R., Ray A.R. Morphological correlations to mechanical performance of hydroxyapatite-filled HDPE/UHMWPE composites. J. Appl. Polym. Sci. 2015;132:1–10. [Google Scholar]

- 10.Lindfors N., Geurts J., Drago L., Arts J.J., Juutilainen V., Hyvönen P., Suda A.J., Domenico A., Artiaco S., Alizadeh C., Brychcy A., Bialecki J., Romano C. Antibacterial bioactive glass, S53P4, for chronic bone infections–A multinational study. In: Drago L., editor. A Mod. Approach to Biofilm-Related Orthop. Implant Infect. Adv. Exp. Med. Biol. Springer; Cham: 2016. pp. 81–92. [DOI] [PubMed] [Google Scholar]

- 11.Zakaria S.M., Sharif-Zein S.H., Othman M.R., Yang F., Jansen J.A. Nanophase hydroxyapatite as a biomaterial in advanced hard tissue engineering: a review. Tissue Eng. B Rev. 2013;19:431–441. doi: 10.1089/ten.TEB.2012.0624. [DOI] [PubMed] [Google Scholar]

- 12.Oladele I.O., Agbabiaka O.G., Olasunkanmi O.G., Balogun A.O., Popoola M.O. Non-synthetic sources for the development of hydroxyapatite. J. Appl. Biotechnol. Bioeng. 2018;5 1–0. [Google Scholar]

- 13.Hernandez S. ASM International; 2003. Overview of Biomaterials and Their Use in Medical Devices. [Google Scholar]

- 14.Champion E. Sintering of calcium phosphate bioceramics. Acta Biomater. 2013;9:5855–5875. doi: 10.1016/j.actbio.2012.11.029. [DOI] [PubMed] [Google Scholar]

- 15.Veljović D., Jokić B., Petrović R., Palcevskis E., Dindune A., Mihailescu I.N., Janaćković D. Processing of dense nanostructured HAP ceramics by sintering and hot pressing. Ceram. Int. 2009;35:1407–1413. [Google Scholar]

- 16.Hui P., Meena S.L., Singh G., Agarawal R.D., Prakash S., Hui P., Meena S.L., Singh G., Agarawal R.D., Prakash S. Synthesis of hydroxyapatite bio-ceramic powder by hydrothermal method. J. Miner. Mater. Charact. Eng. 2010;09:683–692. [Google Scholar]

- 17.Gergely G., Wéber F., Lukács I., Tóth A.L., Horváth Z.E., Mihály J., Balázsi C. Preparation and characterization of hydroxyapatite from eggshell. Ceram. Int. 2010;36:803–806. [Google Scholar]

- 18.Ling A., Hanafi P., Bakar A.A. Eco-friendly coupling agent-treated kenaf/linear low-density polyethylene/poly (vinyl alcohol) composites, Iran. Polym. J. 2018;27:87–96. [Google Scholar]

- 19.Suttivutnarubet C., Jaturapiree A., Chaichana E. Synthesis of polyethylene/coir dust hybrid filler via in situ polymerization with zirconocene/MAO catalyst for use in natural rubber biocomposites, Iran. Polym. J. 2016;25:841–848. [Google Scholar]

- 20.Atuanya C.U., Edokpia R.O., Aigbodion V.S. The physio-mechanical properties of recycled low density polyethylene (RLDPE)/bean pod ash particulate composites. Results Phys. 2014;4:88–95. [Google Scholar]

- 21.Ahmad S., Azman A., Mat H., Wahit U. Effects of ENR and OMMT on barrier and tensile properties of LDPE nanocomposite film, Iran. Polym. J. 2015;24:367–378. [Google Scholar]

- 22.Padmanabhan S.K., Salvatore L., Gervaso F., Catalano M., Taurino A., Sannino A., Licciulli A., Virginia W. Synthesis and characterization of collagen scaffolds reinforced by eggshell derived hydroxyapatite for tissue engineering. J. Nanosci. Nanotechnol. 2015;15:504–509. doi: 10.1166/jnn.2015.9489. [DOI] [PubMed] [Google Scholar]

- 23.Matějka V., Fu Z., Kukutschová J., Qi S., Jiang S., Zhang X., Yun R., Vaculík M., Heliová M., Lu Y. Jute fibers and powderized hazelnut shells as natural fillers in non-asbestos organic non-metallic friction composites. Mater. Des. 2013;51:847–853. [Google Scholar]

- 24.Jia Z., Hao C., Yan Y., Yang Y. Effects of nanoscale expanded graphite on the wear and frictional behaviors of polyimide-based composites. Wear. 2015;338–339:282–287. [Google Scholar]

- 25.Maheshwari S.U., Samuel V.K., Nagiah N. Fabrication and evaluation of (PVA/HAp/PCL) bilayer composites as potential scaffolds for bone tissue regeneration application. Ceram. Int. 2014;40:8469–8477. [Google Scholar]

- 26.Azzaoui K., Lamhamdi A., Mejdoubi E.M., Berrabah M., Hammouti B., Elidrissi A., Al-Deyab S.S. Synthesis and characterization of composite based on cellulose acetate and hydroxyapatite application to the absorption of harmful substances. Carbohydr. Polym. 2014;111:41–46. doi: 10.1016/j.carbpol.2014.04.058. [DOI] [PubMed] [Google Scholar]