Abstract

Carbon fibre composites offer considerable potential for mass reduction in automotive applications. However, raw material cost is one of the major factors that constraints its extensive use in this mass market. Here we report a systematic study that presents the cost contributors by considering the entire process chain of the carbon fibre manufacturing. The sensitivity analysis revealed that the final cost of Polyacrylonitrile (PAN) precursor and carbon fibres were strongly influenced by tow size. It was observed that a prompt decrease in the precursor and carbon fibre cost per kg for tow sizes from 3k to 12k, later this decrement was gradual and almost became stable above 50k. Moreover, with an increase in tow size from 3k to 50k, the contribution of the precursor on the final carbon fibre cost decreased from 76.6% to 49.6%. On the other hand, the contribution of the other factors increased with increase in the tow size, for instance, labour (9.86%–17.78%), Energy (2.49%–6.48%) and Depreciation (6.11%–11.01%). Nevertheless, precursor holds the major share in determining the final price of the carbon fibres.

Keywords: Chemical engineering, Mechanical engineering, Chemical reaction engineering, Chemical synthesis, Energy economics, Carbon fibre, Cost model

Chemical engineering: Mechanical engineering; Chemical reaction engineering; Chemical synthesis; Energy economics; Carbon fribre; Cost model.

1. Introduction

Carbon fibres are well known as the material of the modern era due to their exceptional properties such as specific tensile strength and tensile modulus, excellent resistance to creep, high electrical and thermal conductivity, good chemical and thermal stability in the absence of oxidising agents [1, 2]. They find applications in the fields of aerospace, automobiles, renewable energy and sports equipment manufacturing [1, 3]. However, until recently, aerospace and wind energy applications are the major markets for carbon fibre composite materials. In recent times, the automotive industry has emerged as the market with significant potential to use carbon fibre composites [4]. Moreover, new emission norms also require automobile manufacturers to look for lightweight structural materials and it is recognized that carbon fibre composites are one of the alternatives to replace components which are usually made of traditional metals [5]. However, the high cost of carbon fibre composites today makes this transition from metals to composites very challenging. The carbon fibre cost is considered as the major contributor to the overall cost of the composite [5, 6, 7]. Based on a production plant of capacity 1500 tonnes per year, the cost of carbon fibres is approximately $10.0 per lb. It was estimated that with a reduction of around 50 % of the manufactured cost of carbon fibres, it is expected to increase the opportunities of using carbon composites in a wider range of applications [8]. Polyacrylonitrile (PAN) is currently considered to be the most suitable precursor for the manufacture of carbon fibres, at least 90% of the current carbon fibre production is based on PAN precursor fibres because of its ability to produce high quality carbon fibres [9, 10]. Hence, in this study we aimed to identify the cost contributors for the manufacture of carbon fibres using PAN precursor and provide solutions to reduce the overall carbon fibre cost.

Various carbon fibre cost models were available in the literature, however, the majority of the models concentrated on the carbon fibre manufacturing from commercially acquired PAN precursor fibres. For example, Gill et al. [11] presented the cost model of carbon fibre manufacturing by dividing the total cost into fixed and variable costs. Fixed costs include overhead costs, investment in the facility, and labour costs. Variable costs include material cost, chemical cost and cost of energy. They validated their cost model on three carbon fibre manufacturers across the globe [11]. Based on the predicted market price at a particular region and the actual selling price of carbon fibres, they noticed a high percentage of error. The reasons for this significant difference in the actual and predicted values are 1. Lack of information on the capital investments of the companies considered 2. Dissimilarities in the chosen process parameters, and 3. Insufficient specific information on the chemical consumables. It is very evident from this study that almost 42–62% error is possible between predicted and actual market prices, which shows the importance of having the knowledge of expenses during the real-time process [11]. From online sources we were able to identify a benchmark costing study conducted by Omnia LLC [12] for the establishment of a carbon fibre manufacturing plant in Iceland. They considered almost every aspect involved in manufacturing to understand the cost contribution at each stage of this process. For example, capital cost and installation, labour required and cost involved, energy required for running the plant and transportation involved in importing the precursor fibres [12]. They performed this analysis for a proposed plant with a total production capacity of 4,000 mt/annum, comprising two lines of 2,000 mt/annum capacity [12]. Similarly, in one of the conference proceedings James Fry [13] from Harper International, presented the estimated cost distribution of carbon fibre manufacturing, by considering a 12k fibre tow, production capacity of 1,500 tonnes per annum. It was mentioned that more than 50% of the cost is contributed from precursor, stabilization takes 30–40% of total energy consumption and the labour cost is more than the energy consumption. Moreover, Mr Fry showed some estimations to improve the capacity of the production by considering the number of filaments per mm and line width and highlighted the challenges to improve the production capacity related to requirements of space, technical requirements and consumption of energy [13]. However, like other studies, this analysis does not include precursor manufacturing. Recently Ellringmann et al. [14] highlighted the drawbacks in the existing models and developed a modular approach, which considered both precursor and carbon fibre manufacturing. Interestingly, they highlighted that the carbon fibre cost is highly sensitive to energy and oil prices. However, this work focussed only on 24k tow and lacks the dependency of carbon fibre cost with respect to tow size and production capacity [14]. Overall, attempts have been made in the past to develop practical cost models and identify the cost contributors for carbon fibres, however, the majority of studies were concentrated on the carbon fibre manufacturing.

Hence, this project aims to develop a cost model that assists automobile engineers to attain a reasonable understanding of the cost-sensitive elements of the entire process chain from precursor manufacturing and its conversion to carbon fibres. In this study, a systematic approach was followed to choose a reference process for precursor manufacturing by reviewing various research papers, online resources and available patents. Later on, we narrowed the available options for raw materials, processing methods and proposed a baseline for precursor manufacturing. Cost estimation of precursor manufacturing and critical factors for cost contribution were presented. Next, based on inputs from industry experts and available resources, a baseline for carbon fibre cost estimation was identified and finally, a cost model which completes the entire process chain of carbon fibre manufacturing was developed. Finally, key elements which govern the cost of carbon fibres are highlighted.

2. Methodology

2.1. Precursor manufacturing and reference process

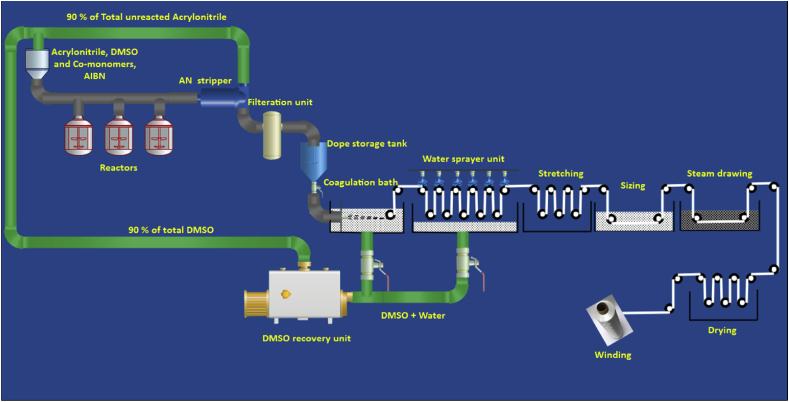

The manufacture of PAN precursor fibres includes various stages such as polymerisation, dope preparation, spinning, coagulation, washing, stretching, surface finish, winding and packing. The overview of the stages of precursor fibre manufacturing is shown in Fig. 1. Based on industry sources, we were able to obtain the information on the methods followed by commercial manufacturers and adopted in the present manufacturing units. Industrial lines are equipped with stripping columns which collect any unreacted monomer for feeding back into the reactor. Also, the solvent used (in one example, DMSO) is recovered from the coagulation baths and rinsing units for future re-use. The recovered solvent can be used for polymerisation, dope preparation and coagulation bath preparation. Since the volume of solvents used is relatively large, it will not be reasonable if solvent recovery is disregarded in developing a cost model.

Fig. 1.

Simplified process flow of an industrial precursor fibre manufacturing unit using DMSO solvent.

In each stage of the process, there are various options (chemicals or process methods) available as shown in Table 1. In order to develop a baseline, at first we have identified relatively common manufacturing methods and chemicals used for the production of commercial precursor fibres as listed in Table 2.

Table 1.

Examples of various alternatives available at each stage of precursor manufacturing.

| Polymerisation Type | Reaction Initiators | Solvents | Co-monomers | Spinning Method |

|---|---|---|---|---|

| Solution | AIBN | DMSO | Itaconic Acid (ITA) | Wet spinning |

| Suspension | Ammonium per Sulphate | DMF | Methyl methacrylate | Air gap or dry-jet-wet spinning |

| Batch | Potassium per sulphate | DMAc | Methacrylic acid | Melt spinning |

| Sodium metabisulphite | Sodium Thiocynate | Methyl acrylate | ||

| Vinyl acetate | ||||

| Acrylamide | ||||

| Acrylic acid |

Table 2.

Manufacturers and the reported methods used for precursor fibre manufacturing.

| Manufacturer | Polymerisation | Solvent | Initiator | Co-monomer | Spinning |

|---|---|---|---|---|---|

| Jilin [15, 16, 17] | Suspension (Tentative) | ITA, Methyl acrylate, Methyl methacrylate | Wet | ||

| Toray [18, 19, 20] | Solution | DMSO | AIBN | ITA | Dry-Wet or Air gap |

| Blue star [15, 21] | Suspension (Tentative) | Sodium thiocyanate | ITA, Methyl acrylate | Wet | |

| Dralon-N [22, 23] | DMF (Dry)/DMAc (Wet) | Dry or Wet | |||

| Dolan [24] | Methyl acrylate | ||||

| Dow Aksa [25] | Vinyl Acetate (Tentative) | ||||

| Kolon [26] | Solution | DMSO | Methacrylic acid, ITA | Wet (Tentative) | |

| Mitsubishi [15, 16, 17, 27, 28, 29, 30] | Suspension | Dimethylacetamide | Ammonium-persulfate, sodium hydrogen sulphite | Vinlyacetate, Acrylamide/Methacrylic acid | Wet |

| Cytec [31, 32] | Solution | DMSO | AIBN | ITA or Methacrylic acid | Dry-Wet |

| Hexcel [33, 34, 35] | Suspension (Tentative) | Water, Sodium thiocyante | Methacrylic acid | Dry-Wet | |

| Toho Tenax [36, 37] | Solution | Zinc chloride (Preferred)/DMF(Tentative) | ITA, Methylacrylate | Wet | |

| Asahi [38] | Wet |

It was very challenging to obtain the data related to PAN precursor manufacturing because of the confidential nature of the work and lack of knowledge of the technology acquisition history of the companies. However, we were able to obtain some of the information by going through the patents as listed in Table 2. From Table 1 and Table 2, it is evident that numerous options are available to be considered to develop a baseline reference process. Based on the acquired information, Toray and Cytec industries followed a similar approach for the manufacture of precursor fibres.

Considering the confidential nature of this process, we tried to adopt a cost-based approach by extracting the information on the market prices of various chemicals used and by comparing pros and cons of various manufacturing methods employed to establish a reference process for precursor fibre manufacturing. Interestingly, all comonomers have a similar price range in the market. Although commoners help to improve the thermal stabilisation capability of PAN fibres by controlling the exothermic nature of acrylonitrile fibres, it is suggested to have a low comonomer content in PAN fibres as it does not contribute to the formation of graphitic structure in the final carbon fibres. Further, it is reported to affect the properties of resultant carbon fibres by evolving as a defect in the structure during high temperature carbonisation [18]. Considering the above arguments, it is suggested to use only Itaconic acid as the comonomer in the precursor. Moreover, irrespective of the cost, DMSO has been chosen as the solvent because of the toxic nature of DMF. Kohler et al. [39] mentioned that the European Union has already listed DMF as one of the hazardous chemical substances in the SVHC (Substances of very high concern) list in 2012. There are higher chances to prohibit this solvent for industrial use in the near future. Similarly, China is following the footsteps of European Union in this perspective and in the process of implementing similar regulation program.

Various polymerisation methods are available in the literature such as 1. Solution polymerisation 2. Suspension polymerisation 3. Bulk polymerisation, and 4. Emulsion polymerisation. However, PAN precursor manufacturers widely use solution or suspension polymerisation methods [40]. In order to choose the best polymerisation method, the advantages and disadvantages of the two methods are listed in Table 3. From Table 3 solution polymerisation method has been selected because it supports the continuous process of precursor manufacturing.

Table 3.

Advantages and disadvantages of polymerisation methods.

| Solution | Suspension | Ref. |

|---|---|---|

Advantages:

|

Advantages:

|

[40, 41, 42] |

Disadvantages:

|

Disadvantages:

|

Different spinning methods are available for precursor fibre manufacturing. However, mainly wet and air gap spinning are employed by commercial manufacturers. The advantages and disadvantages of these two methods are compared in Table 4 in order to choose the spinning method for baseline process.

Table 4.

Comparison of Wet and Air gap spinning.

| Wet Spinning | Dry-Wet or Air gap Spinning | Ref. |

|---|---|---|

Advantages:

|

Advantages:

|

[40, 41, 42, 43] |

Disadvantages:

|

Disadvantages:

|

Considering the pros and cons of these two methods wet spinning has been chosen as it supports the production of larger tow size which is beneficial for automotive applications. Overall, the outcome for the identification of a baseline process for precursor manufacturing is provided in Table 5.

Table 5.

The baseline of various methods and chemicals used for precursor manufacturing.

| Process step/Chemicals | Raw material/method |

|---|---|

| Polymerisation type | Solution |

| Co monomers | ITA |

| Solvents | DMSO |

| Spinning | Wet |

| Initiator | AIBN |

In one of their chapters, Wheatley et al. [44] mentioned the details of their baseline for PAN manufacturing. They also considered only one comonomer (Methyl acrylate), solution polymerisation for precursor manufacturing. This further supports our assumptions.

3. Model

3.1. PAN precursor cost model

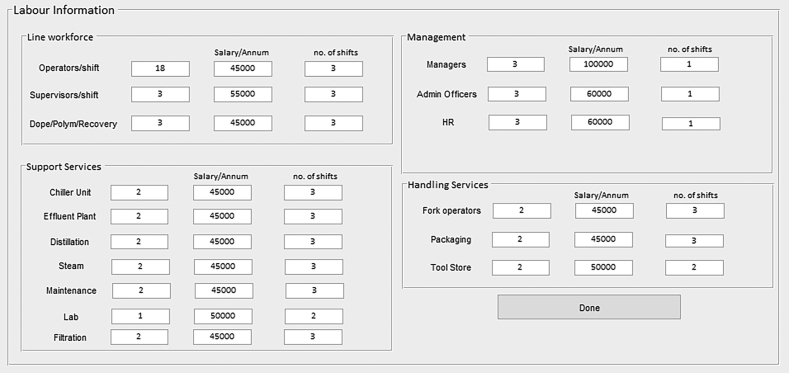

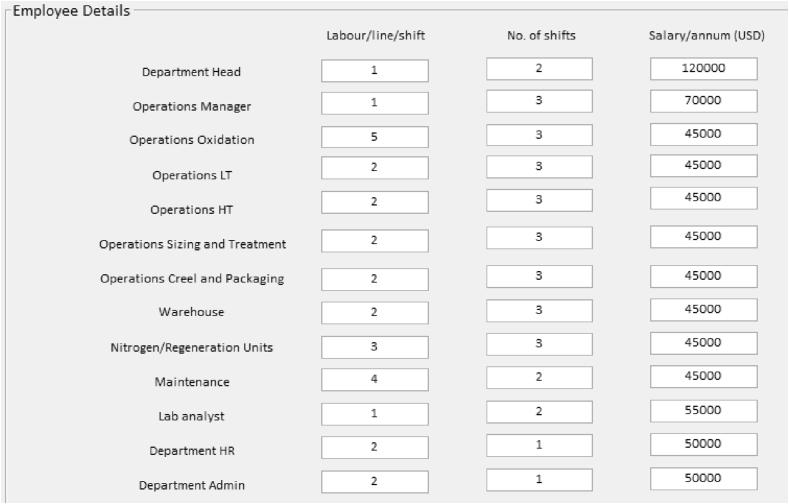

In order to develop a decent understanding of the influence of contributing factors to the manufacturing cost per kg of PAN precursor, it is recommended to perform the estimations by considering a precursor fibre production facility of at least 10,000 tonnes per annum capacity. In order to achieve this, seven individual precursor lines were considered with each having a capacity of approximately 1430 tonnes per annum. The size of the spinneret and number of spinnerets per line were considered as 24k and 26, respectively. To run the production lines, labour and the other staff details were considered as shown in Fig. 2.

Fig. 2.

Workforce details used for the cost model.

A total of 315 days of operation was taken in to account for these calculations. For polymerisation, two reactors of capacity 5,000 tonnes were considered. In order to establish the plant of this capacity (10,000 tonnes/annum) and daily power requirements, capital expenditure of approximately 74.1 million USD and approximately 116.6 MWh (which includes steam generation) per day were assumed. A straight line depreciation for 20 years has been considered to calculate the depreciation cost. The contribution from the factors such as Insurance, tax and filtration was assumed to be 1–2% of the total cost incurred by the other contributors. All these values were obtained through discussions with experts from commercial precursor manufacturing companies. In addition, the composition of the precursor was assumed as 96 wt% Acrylonitrile, 3 wt% methyl acrylate and 1 wt% Itaconic acid and the composition of the coagulation bath was considered as 65 wt% DMSO and 35 wt% water. The price of the reusable paper cores was considered approximately 7.5 USD per core. Based on Table 6, it is evident that the material cost from polymerisation to coagulation played a critical role in the final cost of PAN precursor. While assessing the expenses from polymerisation to coagulation, it has been observed that the cost of the precursor is influenced by the quantity of DMSO and acrylonitrile monomer recovered from the polymerisation and coagulation baths. Hence, the recovery of DMSO and acrylonitrile is considered to be very critical in defining the cost of the precursor. For instance, in the current work, the calculations are based on the assumption that 99.98% of the DMSO is recovered using the recovery process. Moreover, labour cost showed the second highest significant contribution towards the cost per kg of PAN precursor which was followed by depreciation and energy. However, data shown in Table 6 is merely associated with tow size of 24k. Based on the cost model developed, for the described configuration of the line, it was realised that for the tow sizes less than 12k, the labour cost was the most significant factor which contributed more than 37% of the final cost of precursor and material cost was significant only if the tow sizes greater than 12k because the plant capacity varies with tow size this will be discussed in the future sections.

Table 6.

An example of cost contribution from various factors per kg of PAN production based on the estimates.

| Item | Cost (USD) per Kg of PAN |

|---|---|

| Polymerisation to Coagulation | 2.02 |

| Energy | 0.147 |

| Labour | 0.644 |

| Water | 0.0378 |

| Sizing | 0.0139 |

| Depreciation | 0.370 |

| Final Packaging | 0.0278 |

| Insurance | 0.0326 |

| Tax | 0.016 |

| Filtration | 0.0326 |

| Waste Disposal | 0.005 |

| Total | 3.348 |

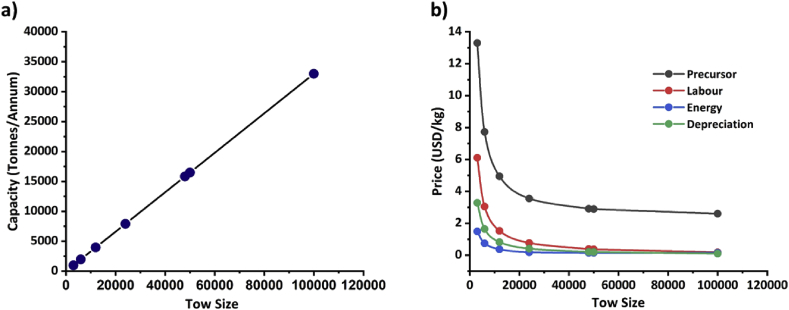

The relationships between factors such as capacity of the plant, cost per kg of PAN precursor, depreciation, labour, energy contributions with respect to tow size is presented in Fig. 3. The following assumptions are made to build these relationships:

-

1.

Capital is considered as constant i.e., 65 million USD.

-

2.

Six production (spinning) lines.

-

3.

The no. of spinnerets per line constant i.e., 24.

-

4.

Days of operation are 315 days per year (this includes spinneret changeover time).

Fig. 3.

Relationship between tow size and a) Capacity b) Various factors (Labour, Energy, and Depreciation) to the estimated manufacturing cost of PAN precursor.

From Fig. 3a, for a constant number of spinnerets and days of operation, the capacity of the production plant linearly increases with the tow size. However, an asymptotic relationship is observed between the final cost per kg of the precursor fibres and the tow size as shown in Fig. 3b. Initially, a dramatic decrease in the precursor price has been observed with an increase in the tow size until 24k and this decrement has become gradual between 24k and 50k and reached almost a stable condition after 50k. The trend in the manufacturing cost of the precursor can be attributed to the sensitivity of the significant contributors such as labour, depreciation and energy with respect to tow size/production capacity as shown in Fig. 3 b. Overall, with a further increase in the capacity of the plant by several thousand tonnes beyond 16.5 thousand tonnes per annum there is no substantial impact on the reduction of manufacturing cost per kg of PAN.

3.2. Carbon fibre manufacturing and cost estimation

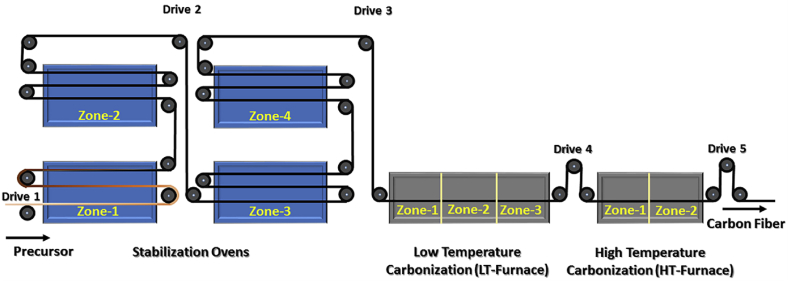

The process for the manufacture of carbon fibres from PAN precursor fibres used by industry today involves various stages of thermal treatment. A simplified schematic of this thermal treatment process is shown in Fig. 4. Initially, PAN fibres are thermally stabilized in air heated to between 225 and 260 °C under certain tensions and dwell times. This step is essential to prepare the fibres to withstand the high temperatures in subsequent steps. This is followed by low temperature (LT) carbonization and high temperature (HT) carbonization in an inert atmosphere at temperatures ranging from 500 to 1500 °C [45, 46]. The carbon fibres exiting from the HT furnace contain more than 90 wt% carbon. These fibres will be further processed through electrolytic surface treatment and coated with sizing before drying, winding and packaging.

Fig. 4.

A Schematic of carbon fibre manufacturing [45].

Based on information obtained from various sources, a cost estimation model for the production of carbon fibres was developed. The details of the information gathered and assumptions are given below:

-

•

Yield is considered to be 50% i.e., 2.0 kg of PAN is required to produce 1.0 kg of CF which is considered from OMNIA LLC [12] and linear density calculations.

-

•

The nominal width of the carbon fibre line is considered to be 2.5m [13,47].

-

•

2,500 filaments per mm are considered to allocate tow spacing [13].

-

•

OMNIA LLC [12] report suggested $28m investment required for one 2,000 TPA capacity carbon fibre production line, however, in order to accommodate the building and associated equipment $5m was added and the capital expenditure (CAPEX) was considered as $33m USD. Here the following estimations are obtained based on one production line with a capacity of approximately, 2000 TPA.

-

•

The number of production days varies with tow size, because the set up time is slightly different for different tow sizes.

-

•

The nominal speed of the carbon fibre processing line is 720 m/h. (Harper's reports suggested 10–20 m/min (i.e., 600–1200 m/h)) [13, 47, 48].

-

•

Residence time in oxidation ovens is 55min.

-

•

No of ovens are considered as 6 (typically 6 to 8 ovens will be used in the industry [47]), heated length of each oxidation oven is 10 m (typically industrial oven heated length is less than 15 m length [47]) and the number of passes are calculated as 11 based on chosen residence time).

-

•

Residence time in each furnace was considered as 1.5min [47].

-

•

Heated length of each furnace was taken as 18 m and only one pass in the furnace. (Typically this value is in between 15 to 20 m [47]).

-

•

Tow size was assumed as 50k filaments.

-

•

The input precursor cost has been taken from the PAN cost model for each respective tow size.

-

•

Electricity price from the utility was assumed as 0.04 USD per kWh.

The cost estimation per kg of carbon fibre produced by considering a production line with a capacity of approximately 2,140 tonnes per annum is presented in this section. In order to achieve this tonnage only one individual carbon fibre line was chosen. To successfully operate the production line and conduct administrative work per day, a factory workforce with various designations from different departments were considered and detailed in Fig. 5. A total of 277 days of operation was taken in to account for these calculations. This includes white warmup time for each reset of spools, maintenance and time for setting each spool. In order to establish the plant, capital expenditure of approximately 33 million USD was considered which includes both equipment and site cost. The power supply to run the plant of this capacity was considered as approximately 155.5 MWh (which includes nitrogen generation) per day. Natural gas is needed for the operation of an incinerator to treat exhaust gases. Natural gas consumption for these calculations was proportionately estimated by considering the line capacity and natural gas consumption of the Pilot Line at Carbon Nexus. The other costs were assumed as 0.5% of all the expenses and packaging cost was assumed as 50% of the sum of the tube and cardboard box costs incurred per kg of carbon fibre. Based on this analysis a total of 10.87 USD is required to produce 1 kg of carbon fibre.

Fig. 5.

Workforce assumptions for one carbon fibre production line.

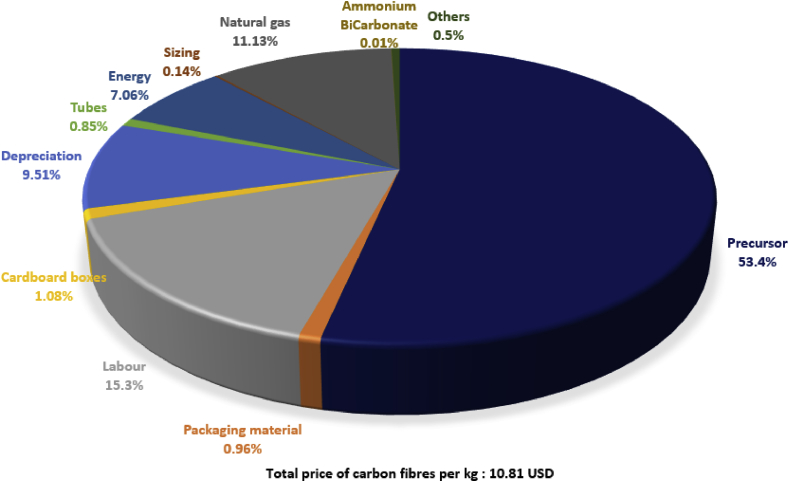

The percentage contribution of various factors on the cost of carbon fibres per kg is shown in Fig. 6. The precursor contributes to 53.4% of the total cost of carbon fibre which is in good agreement with the other research [14], this is followed by labour (15.3%), natural gas (11.13%), depreciation (9.51%) and energy (7.06%). Interestingly, natural gas has been identified as one of the major contributors to the carbon fibre cost which is not mentioned elsewhere

Fig. 6.

Cost contribution of various elements in carbon fibre production.

Further sensitivity analysis was conducted by developing correlations between tow size, capacity and various costs, parameters involved in the production of carbon fibres by considering the following assumptions:

-

•

Precursor packaged on spools (rather than in boxes) was considered for the analysis.

-

•

The weight of each precursor spool was assumed as constant (300 kg) irrespective of tow size.

-

•

For precursor cost, similar assumptions were considered as mentioned earlier. For instance, 6 production lines, 24 spinnerets per line, capital expenditure is constant etc.,

-

•

Only one carbon fibre production line was considered.

-

•

No. of filaments per mm was considered as 2,500 f/mm.

-

•

Width of the line was considered as 2.5m.

-

•

Tow width was assumed between 3 mm to 41 mm for the tow sizes ranging between 3k to 100k filaments.

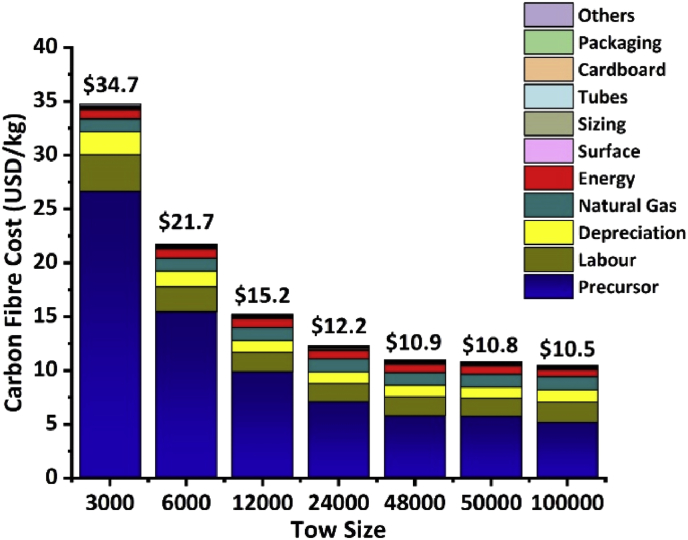

The variation in cost incurred to produce a kg of carbon fibres with respect to tow size is shown in Fig. 7. From Fig. 7, it is evident that with an increase in tow size there is a dramatic decrease in carbon fibre cost for tow sizes less than 12k, then it becomes gradual between 12k and 50k. For higher tow sizes the difference in cost is almost negligible. Moreover, with an increase in tow size from 3k to 100k the contribution of the precursor is decreased from 76.6% to 49.6% while the other contributors such as labour cost, depreciation cost and energy cost increased from 9.86% to 17.78%, 6.11%–11.01% and 2.49%–6.48%, respectively. Overall, the precursor cost is the governing cost contributor for the final cost of carbon fibres. These reasons appear to be driving the current research trends inclined towards the utilisation of larger tow sizes and even textile-grade precursor tows for the production of carbon fibres to meet the requirements of low to medium strength composite applications.

Fig. 7.

Carbon fibre cost in relation to tow size.

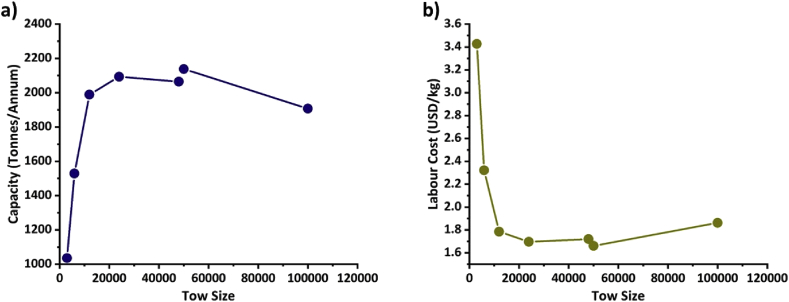

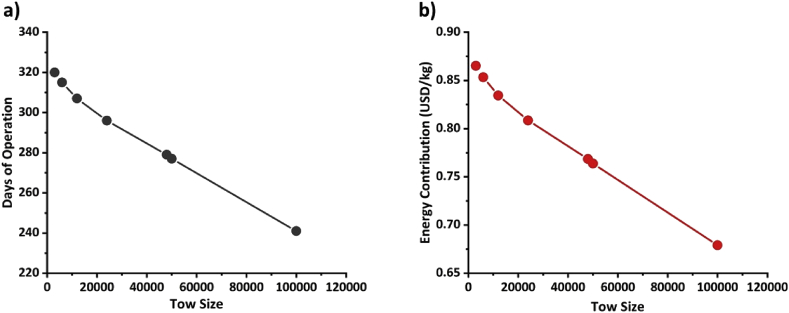

Interestingly, Fig. 8a shows a non-linear relationship between the capacity of the plant and the tow size because of the sensitivity to the number of processible tows towards the tow size for the considered roller width and the days of operation i.e., the higher the tow size the higher the tow width and the lesser the no. of processible tows. Moreover, for a constant precursor spool weight, the length of precursor will be lower for higher tow sizes which further increases the downtime because of more frequent changeovers for resetting and white warm-up and decreases the total days of operation as shown in Fig. 9a.

Fig. 8.

Variation of a) production capacity and b) labour cost contribution with respect to tow size.

Fig. 9.

Variation of a) energy contribution and b) days of operation with respect to tow size for fixed precursor package size.

Also, from Fig. 8b, it is clearly evident that the relationship between the labour cost contribution and the tow size is inversely proportional to the relationship between the capacity and the tow size. Also, Fig. 9b shows that there is a decrease in energy costs with increase in tow size which is associated with the decrease in the no. of days of operation as shown in Fig. 9a. These relationships further highlight the significance of tow size in trading-off the various costs involved in the final carbon fibre cost. Moreover, the productivity improvement and further reduction of carbon fibre cost can be achieved with the box type precursor set up. However, the development of these estimations will be considered for future work.

4. Conclusion

A cost model was developed by considering the entire process chain and assessing the costs involved at each stage of PAN precursor manufacturing and its subsequent conversion into carbon fibres. Based on this model, various factors such as material, labour, depreciation, energy, tow size, capacity and natural gas were considered for their contribution to the final manufactured cost of carbon fibres. Material cost was the major cost contributor to the PAN precursor, given a tow size greater than or equal to 12k. On the other hand, labour cost holds a major contribution to the final cost of PAN precursor for tow sizes less than 12k. In addition, with an increase in tow size an asymptotic trend was observed in the cost of precursor and carbon fibres indicating no significant influence on the final cost of carbon fibres if the tow sizes higher than 50k. Overall, our findings indicated that the precursor cost was the major contributor on the final cost of carbon fibres and the production of large tows, say of size 50k, can be beneficial in reducing the carbon fibre production cost and enabling carbon fibre to meet the requirements of mass-production markets such as the automotive sector.

Declarations

Author contribution statement

Srinivas Nunna: Conceived and designed the experiments; Performed the experiments; Analyzed and interpreted the data; Wrote the paper.

Patrick Blanchard: Conceived and designed the experiments; Analyzed and interpreted the data; Contributed reagents, materials, analysis tools or data.

Derek Buckmaster: Conceived and designed the experiments; Analyzed and interpreted the data.

Sam Davis: Contributed reagents, materials, analysis tools or data.

Minoo Naebe: Conceived and designed the experiments; Analyzed and interpreted the data; Contributed reagents, materials, analysis tools or data; Wrote the paper.

Funding statement

This work was supported by Ford Motor company under the University Research Program (URP) scheme. This work was also supported by the Australian Research Council World Class Future Fibre Industry Transformation Research Hub (IH140100018) and Australian Research Council Training Centre for Light Weight Automotive Structures (ATLAS).

Competing interest statement

The authors declare no conflict of interest.

Additional information

No additional information is available for this paper.

Acknowledgements

We also thank CSIRO, waurn ponds precursor manufacturing line operational team for providing us with the platform to reach out the industrial experts.

References

- 1.Nunna S., Naebe M., Hameed N., Fox B.L., Creighton C. Evolution of radial heterogeneity in polyacrylonitrile fibres during thermal stabilization: an overview. Polym. Degrad. Stab. 2017;136:20–30. [Google Scholar]

- 2.Huang X. Fabrication and properties of carbon fibers. Materials. 2009;2(4):2369–2403. [Google Scholar]

- 3.Khayyam H., Jazar R.N., Nunna S., Golkarnarenji G., Badii K., Mousa Fakhrhoseini S., Kumar S., Naebe M. PAN precursor fabrication, applications and thermal stabilization process in carbon fiber production: experimental and mathematical modelling. Progress Mater. Sci. 2019 [Google Scholar]

- 4.Jacob A. Carbon fibre and cars – 2013 in review. Reinforc Plast. 2014;58(1):18–19. [Google Scholar]

- 5.Mainka H., Täger O., Körner E., Hilfert L., Busse S., Edelmann F.T., Herrmann A.S. Lignin – an alternative precursor for sustainable and cost-effective automotive carbon fiber. J. Mater. Res. Technol. 2015;4(3):283–296. [Google Scholar]

- 6.Mainka H., Täger O., Stoll O., Körner E., Herrmann A.S. SPE & Automotive Composites Conference and Exhibition 13th Annual. 2013. Alternative precursors for sustainable and cost-effective carbon fibers usable within the automotive industry. [Google Scholar]

- 7.Frank E., Hermanutz F., Buchmeiser M.R. Carbon fibers: precursors, manufacturing, and properties. Macromol. Mater. Eng. 2012;297(6):493–501. [Google Scholar]

- 8.Yoo S.H., Park S., Park Y., Lee D., Joh H.-I., Shin I., Lee S. Facile method to fabricate carbon fibers from textile-grade polyacrylonitrile fibers based on electron-beam irradiation and its effect on the subsequent thermal stabilization process. Carbon. 2017;118(Suppl. C):106–113. [Google Scholar]

- 9.Kaur J., Millington K., Smith S. Producing high-quality precursor polymer and fibers to achieve theoretical strength in carbon fibers: a review. J. Appl. Polym. Sci. 2016;133(38) [Google Scholar]

- 10.Rahaman M.S.A., Ismail A.F., Mustafa A. A review of heat treatment on polyacrylonitrile fiber. Polym. Degrad. Stab. 2007;92(8):1421–1432. [Google Scholar]

- 11.Singh Gill A., Visotsky D., Mears L., Summers J.D. Cost estimation model for polyacrylonitrile-based carbon fiber manufacturing process. J. Manuf. Sci. Eng. 2016;139(4) 041011-041011-8. [Google Scholar]

- 12.LLC O. 2012. Assessment of Carbon Fiber Manufacturing Cost.http://www.invest.is/files/skjol/pdff/omnia_carbon_fiber_extract.pdf [Google Scholar]

- 13.Fry J. JEC world; Paris: 2016. The Future of High Capacity Carbon Fiber Production. [Google Scholar]

- 14.Ellringmann T., Wilms C., Warnecke M., Seide G., Gries T. Carbon fiber production costing: a modular approach. Text. Res. J. 2016;86(2):178–190. [Google Scholar]

- 15.Arbab S., Zeinolebadi A. A procedure for precise determination of thermal stabilization reactions in carbon fiber precursors. Polym. Degrad. Stab. 2013;98(12):2537–2545. [Google Scholar]

- 16.Zhao W., Lu Y., Zhou L., Jiang J., Wang J., Chen Q., Tian F. Effects on the oriented structure and mechanical properties of carbon fibers by pre-irradiating polyacrylonitrile fibers with γ ray. J. Mater. Sci. 2016;51(15):7073–7084. [Google Scholar]

- 17.Fu Z., Gui Y., Cao C., Liu B., Zhou C., Zhang H. Structure evolution and mechanism of polyacrylonitrile and related copolymers during the stabilization. J. Mater. Sci. 2014;49(7):2864–2874. [Google Scholar]

- 18.Ichikawa T., Ochi T., Kishiro A., Kato Y., Shibata T., Ise M. Google Patents; 2014. Polyacrylonitrile Fiber Manufacturing Method and Carbon Fiber Manufacturing Method. [Google Scholar]

- 19.Ichikawa T., Ochi T., Kishiro A., Kato Y., Shibata T., Ise M. Google Patents; 2013. Polyacrylonitrile Fiber Manufacturing Method and Carbon Fiber Manufacturing Method. [Google Scholar]

- 20.Tanaka F., Endo M., Okishima Y. Google Patents; 2010. Polyacrylonitrile Polymer, Method of Producing the Same, Method of Producing Precursor Fiber Used for Producing Carbon Fiber, Carbon Fiber and Method of Producing the Same. [Google Scholar]

- 21.Chen J.C., Harrison I.R. Modification of polyacrylonitrile (PAN) carbon fiber precursor via post-spinning plasticization and stretching in dimethyl formamide (DMF) Carbon. 2002;40(1):25–45. [Google Scholar]

- 22.Simitzis J., Soulis S. Correlation of chemical shrinkage of polyacrylonitrile fibres with kinetics of cyclization. Polym. Int. 2008;57(1):99–105. [Google Scholar]

- 23.http://www.dralon.com/en/fiber-types/production-processes/

- 24.Fitzer E., Müller D.J. The influence of oxygen on the chemical reactions during stabilization of pan as carbon fiber precursor. Carbon. 1975;13(1):63–69. [Google Scholar]

- 25.Karacan I., Erdoğan G. The role of thermal stabilization on the structure and mechanical properties of polyacrylonitrile precursor fibers. Fibers Polym. 2012;13(7):855–863. [Google Scholar]

- 26.Yoon J.Y., Cho E.J. Google Patents; 2015. Method for Preparing Carbon Fiber and Precursor Fiber for Carbon Fiber. [Google Scholar]

- 27.Qin X., Lu Y., Xiao H., Song Y. Improving stabilization degree of stabilized fibers by pretreating polyacrylonitrile precursor fibers in nitrogen. Mater. Lett. 2012;76(0):162–164. [Google Scholar]

- 28.Amakawa T.M.R.C.L., Hamada M.M.R.C.L., Kageyama Y.M.R.C.L., Okuya T.M.R.C.L. Google Patents; 2001. Acrylonitril-based Precursor Fiber for Carbon Fiber and Method for Production Thereof. [Google Scholar]

- 29.Kasabo Y., Ikeda K., Fujii Y., Mishina Y., Ochi R. Google Patents; 2004. Acrylic Fiber and a Manufacturing Process Therefor. [Google Scholar]

- 30.Ikeda K., Kawamura A. Google Patents; 2014. Process of Making a Carbon Fiber Precursor Fiber Bundle. [Google Scholar]

- 31.Taylor T.B. Google Patents; 2016. Densification of Polyacrylonitrile Fiber. [Google Scholar]

- 32.Cook J.D., Taylor T., Deshpande G.V., Tang L., Meece B.D.W., Crawford S., Chiu S.C., Harmon B.D., Thomas A. Google Patents; 2016. Manufacture of Intermediate Modulus Carbon Fiber. [Google Scholar]

- 33.Paul J.T. Google Patents; 1991. Method of Manufacturing Carbon Fiber Using Preliminary Stretch. [Google Scholar]

- 34.León C.A.L. Google Patents; 2016. Carbon Fibers Having Improved Strength and Modulus and an Associated Method and Apparatus for Preparing Same. [Google Scholar]

- 35.León C.A.L. Google Patents; 2014. Carbon Fibers Having Improved Strength and Modulus and an Associated Method and Apparatus for Preparing Same. [Google Scholar]

- 36.Yoshikawa H., Oyama T., Kimura H. Google Patents; 2010. Carbon Fiber Strand and Process for Producing the Same. [Google Scholar]

- 37.Yoshikawa H., Oyama T., Suzuki T., Enomoto H. Google Patents; 2009. Carbon Fiber. [Google Scholar]

- 38.Wangxi ZHANG M.L. DSC study on the polyacrylonitrile precursors for carbon fibers. J. Mater. Sci. Technol. 2005;21(04):581–584. [Google Scholar]

- 39.Köhler T., Peterek S., Gries T. Wet spinning PAN-fibres from aqueous solutions of ZnCl2 and NaSCN. IOP Conf. Ser. Mater. Sci. Eng. 2017;254:1–4. [Google Scholar]

- 40.Frank E., Ingildeev D., Buchmeiser M.R. Woodhead Publishing; Oxford: 2017. 2 - High-Performance PAN-Based Carbon Fibers and Their Performance Requirements Structure and Properties of High-Performance Fibers; pp. 7–30. [Google Scholar]

- 41.Frank E., Steudle L.M., Ingildeev D., Spörl J.M., Buchmeiser M.R. Carbon fibers: precursor systems, processing, structure, and properties. Angew. Chem. Int. Ed. 2014;53(21):5262–5298. doi: 10.1002/anie.201306129. [DOI] [PubMed] [Google Scholar]

- 42.Morgan P. Taylor & Francis Group, LLC; 2005. Carbon Fibres and Their Composites. [Google Scholar]

- 43.Morris E.A., Weisenberger M.C. American Chemical Society; 2014. Solution spinning of PAN-based polymers for carbon fiber precursors; pp. 189–213. Polymer Precursor-Derived Carbon. [Google Scholar]

- 44.Wheatley A., Warren D., Das S. John Wiley & Sons Ltd; 2013. Low-Cost Carbon Fibre: Applications, Performance and Cost Models, Advanced Composite Materials for Automotive Applications; pp. 405–434. [Google Scholar]

- 45.Nunna S., Maghe M., Fakhrhoseini S.M., Polisetti B., Naebe M. A pathway to reduce energy consumption in the thermal stabilization process of carbon fiber production. Energ. 2018;11(1-10):1145. [Google Scholar]

- 46.Nunna S., Maghe M., Rana R., Varley R.J., Knorr D.B., Jr., Sands J.M., Creighton C., Henderson L.C., Naebe M. Time dependent structure and property evolution in fibres during continuous carbon fibre manufacturing. Materials. 2019;12(7) doi: 10.3390/ma12071069. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 47.Harper International . JEC Europe; Paris: 2013. Processing Advancements within Reach for Achieving Significant Reductions in Carbon Fiber Cost of Manufacturing.https://newharperintl.wpengine.com/wp-content/uploads/2011/09/processing-advancements-within-reach.pdf [Google Scholar]

- 48.Witting P. Carbon Fiber; 2016. How Will Carbon Fiber Manufacturing Quadruple to Meet Market Demands.https://newharperintl.wpengine.com/wp-content/uploads/2011/09/how-will-carbon-fiber-manufacturing-quadruple-to-meet-market-demands.pdf [Google Scholar]