Abstract

β-Carotene is one of the most abundant natural pigments in foods; however, usage of β-carotene is limited because of its instability. Microencapsulation techniques are usually applied to protect microencapsulated β-carotene from oxidization. In this study, β-carotene was microencapsulated using different drying processes: spray-drying, spray freeze-drying, coating, and spray granulation. The properties of morphology, particle size, water content, thermal characteristic, and chemical stability have been explored and compared. Scanning electron microscopy measurements showed that the coated powder had a dense surface surrounded by starch and suggested that the coating process gave a microencapsulated powder with the smallest bulk density and the best compressibility among the prepared powders. The chemical stabilities of microcapsules were evaluated during six months of storage at different temperatures. The coated powder had the highest mass fraction of β-carotene, which indicated that the coating process was superior to the three other drying processes.

Keywords: β-Carotene, Microencapsulation, Spray-drying, Spray freeze-drying, Coating, Spray granulation

1. Introduction

There are three main sources of β-carotene: chemical synthesis, phytoextraction, and microbial fermentation. The production of β-carotene via microbial fermentation is sustainable and eco-friendly, and it is also very safe and economic compared with phytoextraction and chemical synthesis (Sandmann, 1994).

β-Carotene is a coloring agent and vitamin A precursor (Ballesteros et al., 2017). It is also an excellent antioxidant (Ozhogina and Kasaikina, 1995) that scavenges free radicals in the human body and can help to prevent cancer, tumor metastasis, and cardiovascular diseases, and improve reproducibility (Tomita et al., 1987; Feng et al., 2009). However, β-carotene is sensitive to oxidization and degradation on exposure to heat, light, and oxygen because of its active chemical properties and unsaturated structure that includes nine conjugated double bonds (Gardner et al., 2010). Furthermore, β-carotene is soluble in oil but not in water (Chen et al., 2017). These characteristics limit the use of β-carotene in beverages and other applications. To overcome these issues, microencapsulation is a common and useful method to protect β-carotene from deterioration and improve its water solubility. Many studies have shown that microencapsulation can stabilize β-carotene. For instance, Jiang et al. (2017) proved that the storage stability of β-carotene microcapsules coated in whey protein isolate and galactose was better than that of β-carotene crystals. Coronel-Aguilera and San Martín-González (2015) reported that spray-drying and coating of β-carotene emulsions prepared using maltodextrin and sodium caseinate as wall materials gave good protection and vivid color during storage.

To date, spray-drying, spray granulation, coating, spray freeze-drying, and combinations of these techniques have been used in preparation of microencapsulated powders. Traditional spray-drying is one of the most common drying technologies in food and pharmaceutical fields because it is a flexible, inexpensive, and efficient process (Chegini and Ghobadian, 2005; Aghbashlo et al., 2012). Spray-drying is a suitable method for encapsulating fish oil within wall materials sourced from milk, and prevents significant deterioration of oil quality (Loksuwan, 2007; Encina et al., 2016). Tonon et al. (2011) reported on microencapsulation of flaxseed oil by spray-drying with different inlet temperatures. Shamaei et al. (2017) investigated the effects of the wall material composition and spray-drying conditions on the physicochemical properties of walnut oil microcapsules. Loksuwan (2007) used modified starch as a wall material to produce microencapsulated β-carotene by spray-drying. For spray freeze-drying, the emulsions are sprayed into extremely cold air or liquid nitrogen by a spray nozzle and then form as frozen droplets, which are placed in a vacuum freeze dryer to sublimate the ice and form the dried powders (Tong et al., 2011; Wanning et al., 2015). Spray freeze-drying is especially suitable for materials that are prone to oxidation and degradation (Ixtaina et al., 2015), because it has the advantages but none of the drawbacks of spray-drying and freeze-drying. The energy consumption and drying time are reduced in spray freeze-drying compared with freeze-drying. Furthermore, the granulation and fluidity of powder manufactured by spray freeze-drying are excellent. Compared with spray-drying, spray freeze-drying retains the nutrients and does not change the biological activity of the target material, which is better for shelf life. In the study of Parthasarathi and Anandharamakrishnan (2016), vitamin E microcapsules were effectively prepared by spray freeze-drying with whey protein isolate as the encapsulating agent, and the product showed excellent solubility and encapsulation efficiency. For coating, powder particles such as starch are suspended in an air stream maintained at a specific temperature and will be adhered on the surface of sprayed particles from a nozzle (Anwar et al., 2010; Coronel-Aguilera and San Martín-González, 2015). Thus, an additional wall will be formed to protect the core material. This method provides further protection of microencapsulated powders above that of the primary microencapsulation method, and could be used for β-carotene powders. For spray granulation, the emulsions are sprayed into the chamber, which contains backing particles such as maltodextrin at a certain temperature. The hot air removes the moisture and the emulsions will be agglomerated with the maltodextrin at the same time. The drying temperature of spray granulation is relatively low, and this method can be used to make granules from materials like maltodextrin (Guignon et al., 2002; Anwar et al., 2010). This helps improve the powder solubility, which is important for application.

There have been many reports on preparation of microcapsules by different methods, such as spray-drying, spray granulation, coating, and spray freeze-drying (Desobry et al., 2010). However, few studies have systematically compared the effects of these methods on the properties of β-carotene powder. Therefore, the purpose of this work was to establish the most suitable process to produce β-carotene microcapsules by comparing the powder morphologies, particle sizes, thermal properties, and stability of powders prepared using these methods. Our aim was to develop a method that could be used for protecting materials that are prone to oxidation and degradation.

2. Materials and methods

2.1. Materials

The crystalloid β-carotene (98%, mass fraction) was obtained from Cabio (Wuhan, China). Starch (average molecular weight is about 50 000 Da) and modified starch (starch sodium octenyl succinate) were purchased from Ingredion (Westchester, IL, USA). Maltodextrin (dextrose equivalent (DE) value is 19% in dry basis) and sunflower oil were supplied by Cargill (Jilin, China). All other chemicals were of analytical grade.

2.2. Preparation of β-carotene emulsions

First, the wall materials, i.e. modified starch (38%, mass fraction) and maltodextrin (46%, mass fraction), were dissolved in distilled water under shearing. Simultaneously, crystalloid β-carotene (1%, mass fraction) was mixed with sunflower oil (15%, mass fraction) via shearing, followed by instant melting at 170 °C. Then, coarse emulsions were produced by mixing the β-carotene suspension with the wall material solution. Finally, the coarse emulsions were homogenized by homogenizer (ATS Engineering Inc., AH-Basic II, Canada) at 800 MPa for three times. The droplet size distribution of the final emulsions was determined using Malvern Mastersizer 2000 (Malvern Instruments Ltd., Malvern, UK). The prepared emulsions were stored in the dark.

2.3. Preparation of β-carotene microcapsules

2.3.1 Spray-drying

Prepared β-carotene emulsion was spray-dried by a trial-scale spray drier (QZR-5 from Linzhou Drying Equipment Co., Ltd., Wuxi, China). The inlet temperature was operated at 170 °C, air pressure was 2.5 MPa, and flow rate was adjusted from 30 to 50 r/min to maintain the outlet temperature at around 60 °C.

2.3.2 Spray freeze-drying

The equipment was assembled by us, the chamber was filled with nitrogen, and then the emulsions were sprayed into the chamber by a spray nozzle at a pressure of 1.5 MPa. The frozen droplets were placed in a vacuum freeze dryer (2KBTES freeze dryer, SP Industries, USA) at −35 °C and degree of vacuum of −0.099 MPa.

2.3.3 Coating

Coating was performed in a 5-kg encapsulation system (East Dry Equipment Co., Ltd., Changzhou, China). The β-carotene emulsion was sprayed with a rotary atomizer and coated with starch particles in a fluidized bed. The inlet air temperature and the fluidized bed temperature were 65 and 45 °C, respectively.

2.3.4 Spray granulation

Spray granulation was performed in a fluidized bed (DPL1/3 from Jinggong Pharmaceutical Machinery Co., Ltd., Chongqing, China). Maltodextrin was preheated at the bottom of the fluidized bed as the seed material, and the inlet air temperature and the fluidized bed temperature were 65 and 45 °C, respectively. The airflow rate and feeding rate were 150 and 50 g/min, respectively.

2.4. Determination of β-carotene content and retention ratios in the powders

A sample of the β-carotene powder (50–60 mg) was accurately weighed into a 50-mL centrifuge tube, and then 100 mg of trypsin and 10 mL of deionized water were added. After shaking slightly, the tube was placed in a water bath at 40–45 °C until all granules had dissolved. After enzymatic hydrolysis, 3 g of NaCl and 30 mL of mixed solvent (acetone:petroleum ether=1:1, v/v) were added sequentially to the tube, which was then shaken for 1 min and left to stand for 2–3 min. This was followed by transfer of the supernatant to a 100-mL volumetric flask. Then, 30 mL of the mixture was added to a centrifuge tube and the above process was repeated four times. The supernatants were combined and further mixed solvent was added to make up the volume to 100 mL (Loksuwan, 2007). The absorbance (X) was measured at 455 nm using an ultraviolet spectrophotometer (TU-1901 from Persee Co., Ltd., Beijing, China), and the concentration of the extract (C) was calculated using the standard curve (C=592.735X−133.293) and the following equation:

C1=C2/M×A×100%, (1)

where C1 is β-carotene content (%), C2 is the concentration of the tested sample (g/mL), M is the mass of the sample (g), and A is the multiple of sample dilution (mL).

The retention rate (%) was calculated as (total β-carotene content of microcapsules)/(total initiative β-carotene content of the microcapsules)×100%.

2.5. Powder particle size distribution

The powder particle size distribution of β-carotene microencapsulated powders was measured using Mastersizer 2000. The following equation was used to determine the span index:

Span=(d90−d10)/d50, (2)

where d10, d50, and d90 are the particle sizes (µm) at the 10th, 50th, and 90th percentiles of the cumulative density distribution, respectively.

2.6. Water content and bulk density

The water content was measured using a moisture analyzer (HB43-S Halogen, Mettler Toledo, Zurish, Switzerland). A sample of the powder (2–3 g) was placed in an aluminum pan and heated at 105 °C. The water content (%) was recorded after the data stabilized. Measurements were carried out after powder production.

The sample was poured fully into a 100-mL cylinder, and the mass (g) was recorded to measure the bulk density of powders.

2.7. Differential scanning calorimetry

Differential scanning calorimetry (DSC) thermos grams of the samples were obtained using DSC6220 (SEIKO, Tokyo, Japan) with a heating rate of 10 °C/min from 25 to 300 °C. Nitrogen was used as a protective gas with a flow rate of 20 mL/min. The sample size was approximately 5 mg.

2.8. Morphology analysis by scanning electron microscopy

Scanning electron microscopy (SEM) was applied for investigation of the morphologies of the samples. Each sample was attached to an SEM specimen stub by double-sided adhesive tape, and then coated with gold under vacuum before examination by SEM (JSM-5510LV, JEOL, Japan) with an acceleration voltage of 20 kV.

2.9. Stability of the microcapsules

β-Carotene microcapsules made by the four methods were placed in amber glasses and sealed with lids. The samples were separately stored in the dark at 4, 25, or 37 °C for six months. The β-carotene content and retention rate were measured every month.

2.10. Statistical analysis

All measurements were performed in triplicate and the data were analyzed by SPSS 16.0 software (SPSS Inc., Chicago, IL, USA). The independent-sample t-test was applied and the significance level was <0.05. All graphs were created using Origin 8.0 (Origin Lab Corporation, Northampton, MA, USA).

3. Results

3.1. β-Carotene content and retention rate

The target β-carotene content from the formulation was 1.00%; however, the contents of all the samples were lower than this (Table 1). The β-carotene content for the spray dried sample was only 0.88% after drying. This could be attributed to the high temperature causing wall material degradation and decomposition of β-carotene. In the coated product, the β-carotene content was almost the same as in the original formulation, which could be because it was tightly embedded in the coating.

Table 1.

Properties of powders prepared by different methods

| Method | β-Carotene content (%) | D[4, 3] (μm) | Span | Moisture (g/100 g) | Bulk density (g/L) | SEM | DSC (°C) | Stability |

| Spray-drying | 0.88±0.01a | 171.90±6.10a | 15.90±0.65a | 1.51±0.06a | 521.20±1.42a | Cracks and holes | Tg: 110 Tm: multiple | Worse |

| Spray freeze-drying | 0.95±0.02b | 442.50±25.26b | 1.63±0.05b | 1.79±0.09b | 531.80±7.46b | Smooth with a few small holes | Tg: 95 Tm: 200 | Good |

| Coating | 0.98±0.02c | 284.30±10.83c | 0.88±0.04c | 1.95±0.06bc | 650.30±2.95c | Densely wrapped by starch | Tg: 95 Tm: 230 | Best |

| Spray granulation | 0.94±0.03b | 217.70±15.62d | 2.21±0.03d | 1.88±0.09bc | 529.60±2.36bd | Adhered by maltodextrins | Tg: 100 Tm: 200 | Very good |

D[4, 3] represents volume mean diameter. SEM: scanning electron microscopy; DSC: differential scanning calorimetry; Tg: glass translation temperature; Tm: melting temperature. Different superscript letters indicate significant difference (P<0.05)

3.2. Powder particle size

The average particle sizes of the powders from the four methods varied from 171.9 to 442.5 µm (Table 1). The highest span was observed in the spray dried sample, and the particles obtained by spray-drying were irregular and scattered over a wide range. The lowest span was found in the coated sample.

3.3. Water content and density

The β-carotene powder prepared by spray-drying had the lowest water content because this method used the highest inlet air temperature. The largest bulk density of β-carotene powder was obtained with the coating process because of the good fluidity and large particle sizes. The bulk density of powder from spray-drying was the lowest at 521.2 g/L. No significant differences were found between the bulk density of spray-drying, spray freeze-drying, and spray granulation. Tonon et al. (2011) and Goula et al. (2004) obtained similar results that higher temperatures could result in lower bulk density, which probably occurred because the faster rate of particle drying formed a larger volume. Meanwhile, Cai and Corke (2000) concluded that the lower the bulk density, the more occluded air was present in the powders, which increased the possibility for oxidative degradation and reduced the storage stability.

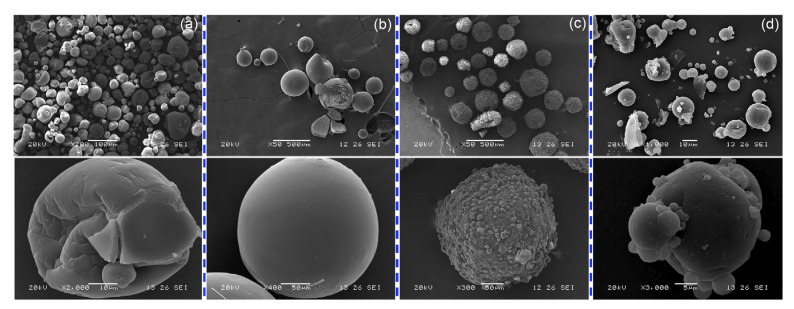

3.4. Morphology analysis by SEM

There were obvious cracks and holes on the surface of the powder prepared by spray-drying (Fig. 1a). These would be caused by the high air inlet temperature used for drying. The surface collapsed because the water evaporated rapidly (Gharsallaoui et al., 2007; Ballesteros et al., 2017; Jiang et al., 2017). The surface of the powder produced by spray freeze-drying was smooth with a few small holes (Fig. 1b). The surface of the coated powder had numerous starch particles and showed densely wrapped particles (Fig. 1c), which would have a positive effect on the powder stability. The images show obvious adhesion between the powders on the surfaces of the granulated powder (Fig. 1d). Our results show that the morphologies are characteristic of the drying process and could be used to predict differences in the properties of the powders.

Fig. 1.

SEM photographs of β-carotene microencapsulated powders prepared by four methods

(a) Spray-drying; (b) Spray freeze-drying; (c) Coating; (d) Spray granulation. SEM: scanning electron microscopy

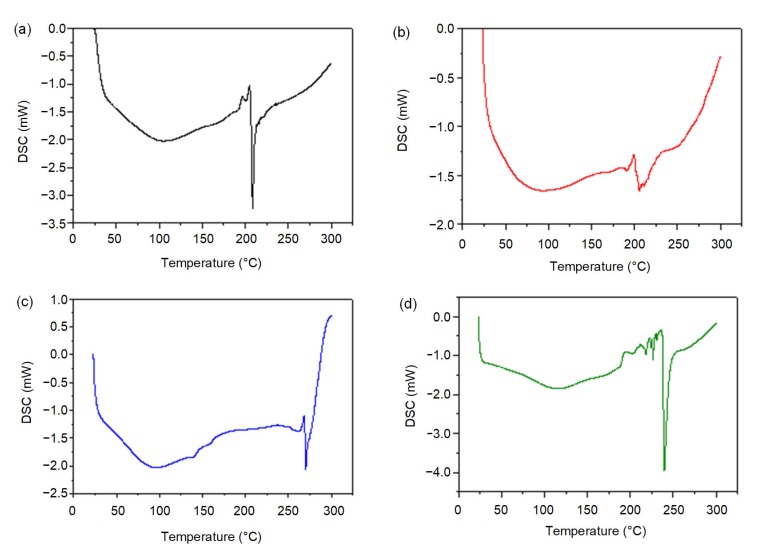

3.5. DSC

Aghbashlo et al. (2012) have analyzed the energy changing of spray-drying process of fish oil microencapsulation as drying temperature changed and DSC is a reliable equipment to study energy changing. DSC results for the β-carotene powders prepared by spray-drying, spray freeze-drying, coating, and spray granulation showed remarkable changes in the glass translation temperature (Tg) and melting temperature (Tm) after drying (Fig. 2). The DSC results of the β-carotene microcapsules showed one smooth peak at around 100 °C and one sharp peak at around 200 °C, which can be assigned as Tg and Tm, respectively. Coronel-Aguilera and San Martín-González (2015) observed that the Tg and Tm values of uncoated β-carotene were 48.7 and 153.4 °C, respectively, and that these values increased with increases in the air inlet temperature. Desobry et al. (2010) observed Tg values of 46, 47, and 48 °C for β-carotene encapsulated with maltodextrin by spray-drying, freeze-drying, and drum-drying, respectively.

Fig. 2.

DSC results for β-carotene powders prepared by four methods

(a) Spray-drying; (b) Spray freeze-drying; (c) Coating; (d) Spray granulation. DSC: differential scanning calorimetry

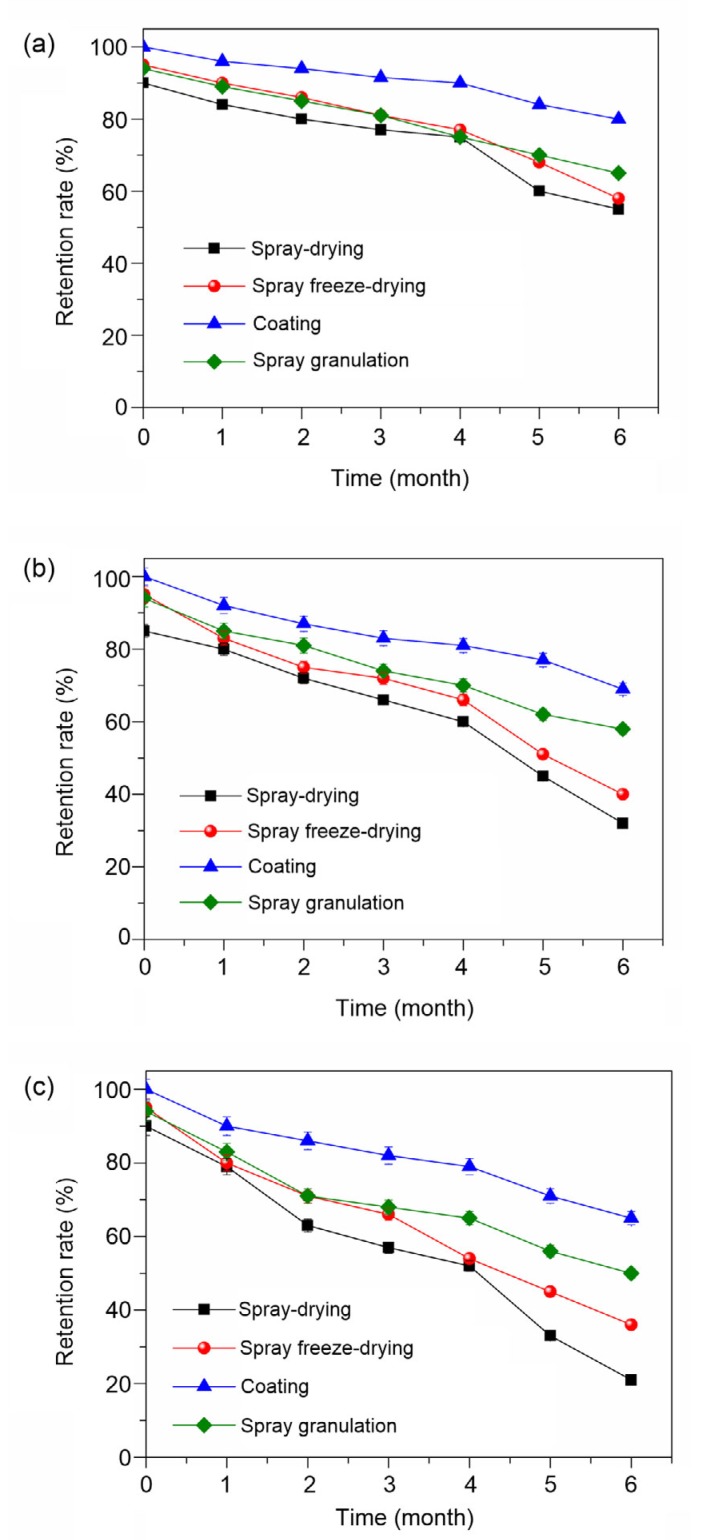

3.6. Microcapsule stability

We measured the effects of storage temperature and drying method on the stability of β-carotene microcapsules (Fig. 3). Microencapsulated β-carotene powders prepared by the coating method had higher retention rates than the other three powders after storage at 4, 25, and 37 °C. These results were consistent with those from SEM. The retention rate of β-carotene microencapsulated powder prepared by spray-drying showed a sharp drop from 90.13% to 21.47% after six months of storage at 37 °C.

Fig. 3.

Retention rates of β-carotene microencapsulated powders after storage at 4 (a), 25 (b), and 37 °C (c)

Data are expressed as mean±standard deviation (SD), n=3

4. Discussion

To investigate how the different drying treatments impacted the powder characteristics, we measured retention rate, particle size, water content, and bulk density.

For the coating method, the morphology is characteristic and indicative of various properties. The coated powder particles had relatively regular shapes and their surfaces were covered by starch particles, which could protect the β-carotene. This meant that the β-carotene content remained almost the same as that in the original formulation. The span is commonly used for laser diffraction to describe the distribution width (Eggerstedt et al., 2012). Regular particles have low spans, which may be helpful for applications like dry blending. The water content and bulk density of the coated sample were the highest among the prepared powders because of the low drying temperature. It has been mentioned previously that the inlet temperature is an important factor that influences the morphologies of micro particles, and those obtained at low inlet temperatures are prone to agglomeration because of high water content (Wang et al., 2011). However, the surface of the coated powder was covered by starch particles, which prevented agglomeration. This meant that most of the particles were still single particles.

For spray-drying, the inlet and outlet temperatures were 170 and 60 °C, and the sample remained in the chamber during the whole process. The high temperature caused wall material degradation and led to decomposition of β-carotene. Consequently, this sample had the lowest retention rate of β-carotene. The spray-dried sample also had the lowest water content and bulk density among the samples because of the high drying temperature.

The process of spray freeze-drying consists of spraying, immediate freezing, and sublimation under vacuum. Compared with coating, spray-drying, and spray granulation, this process gives the largest particles, as seen in the SEM image of the spray freeze-dried sample. The unique structure with holes on the surface influenced the stability of the samples prepared at a lower temperature (Rahman et al., 2002).

The spray granulation process has been described in detail previously (Anwar and Kunz, 2011), and involves spraying of emulsions and coating by an external seed material that is preheated in the chamber. In our study, the particles grew in size from less than 5 µm to more than 100 µm, and the surfaces of the particles obtained by spray granulation were raspberry-like because of the successive layers. In the stability tests, these samples were more stable than the spray-dried and spray freeze-dried samples.

DSC was used to analyze how the heat capacities of the materials changed with temperature. The values of Tg and Tm that we measured were obviously higher than those from previous studies (Coronel-Aguilera and San Martín-González, 2015). These may be affected by the matrix of modified starch and maltodextrin. However, the β-carotene micro particles contained many ingredients, and this needs further investigation.

Stability is an important index for evaluating β-carotene shelf life, which can be influenced by temperature, time, oxygen exposure, and light. In this study, to explore influences of temperature and time on stability, the samples were placed in amber glasses and sealed with lids to reduce exposure to light. The stability is related to the structure of the microcapsules (Kong et al., 2018). For instance, β-carotene crystals are dispersed and embedded in matrices in the form of an emulsion and sprayed drops are covered by starch particles, which can protect the material at the core. Therefore, the coated granules had superior stability than the other granules (Grünewald et al., 2010). The drying process could influence the microstructure and status of products, and the relationship between structure and properties was not investigated in this study.

5. Conclusions

β-Carotene microcapsules were produced using modified starch and maltodextrin as wall materials and dried by spray freeze-drying, traditional spray-drying, coating, and spray granulation. The β-carotene microcapsules prepared by coating showed outstanding stability and uniform particle structures compared with the others. In addition, DSC results proved that microencapsulation could improve the Tg and Tm values of β-carotene microcapsules. This may help to improve the thermal stability of β-carotene. The heat capacity of wall materials during thermal changes should be investigated in further research.

Acknowledgments

We thank Gabrielle DAVID, PhD, from Liwen Bianji, Edanz Group China (http://www.liwenbianji.cn/ac), for editing the English text of this manuscript.

Footnotes

Project supported by the Hubei Province Technology Innovation Project (No. 2017ACA083), China

Contributors: Xiang-yu LI and Min XIAO performed the experimental research and data analysis, wrote and edited the manuscript. Mian-bin WU and Zhi-ming WANG performed the data analysis and wrote the paper. Shu-huan LU collected and analyzed the data. Jian-ming YAO and Li-rong YANG contributed to the study design, data analysis, writing and editing of the manuscript. All authors have read and approved the final manuscript and, therefore, had full access to all the data in the study and take responsibility for the integrity and security of the data.

Compliance with ethics guidelines: Xiang-yu LI, Mian-bin WU, Min XIAO, Shu-huan LU, Zhi-ming WANG, Jian-ming YAO, and Li-rong YANG declare that they have no conflict of interest.

No studies using human or animal subjects were performed by any of the authors.

References

- 1.Aghbashlo M, Mobli H, Rafiee S, et al. Energy and exergy analyses of the spray drying process of fish oil microencapsulation. Biosyst Eng. 2012;111(2):229–241. doi: 10.1016/j.biosystemseng.2011.12.001. [DOI] [Google Scholar]

- 2.Anwar SH, Kunz B. The influence of drying methods on the stabilization of fish oil microcapsules: comparison of spray granulation, spray drying, and freeze drying. J Food Eng. 2011;105(2):367–378. doi: 10.1016/j.jfoodeng.2011.02.047. [DOI] [Google Scholar]

- 3.Anwar SH, Weissbrodt J, Kunz B. Microencapsulation of fish oil by spray granulation and fluid bed film coating. J Food Sci. 2010;75(6):E359–E371. doi: 10.1111/j.1750-3841.2010.01665.x. [DOI] [PubMed] [Google Scholar]

- 4.Ballesteros LF, Ramirez MJ, Orrego CE, et al. Encapsulation of antioxidant phenolic compounds extracted from spent coffee grounds by freeze-drying and spray-drying using different coating materials. Food Chem. 2017;237:623–631. doi: 10.1016/j.foodchem.2017.05.142. [DOI] [PubMed] [Google Scholar]

- 5.Cai YZ, Corke H. Production and properties of spray-dried Amaranthus betacyanin pigments. J Food Sci. 2000;65(7):1248–1252. doi: 10.1111/j.1365-2621.2000.tb10273.x. [DOI] [Google Scholar]

- 6.Chegini GR, Ghobadian B. Effect of spray-drying conditions on physical properties of orange juice powder. Dry Technol. 2005;23(3):657–668. doi: 10.1081/DRT-200054161. [DOI] [Google Scholar]

- 7.Chen JJ, Li F, Li ZZ, et al. Encapsulation of carotenoids in emulsion-based delivery systems: enhancement of β-carotene water-dispersibility and chemical stability. Food Hydrocoll. 2017;69:49–55. doi: 10.1016/j.foodhyd.2017.01.024. [DOI] [Google Scholar]

- 8.Coronel-Aguilera CP, San Martín-González MF. Encapsulation of spray dried β-carotene emulsion by fluidized bed coating technology. LWT-Food Sci Technol. 2015;62(1):187–193. doi: 10.1016/j.lwt.2014.12.036. [DOI] [Google Scholar]

- 9.Desobry SA, Netto FM, Labuza TP. Comparison of spray-drying, drum-drying and freeze-drying for β-carotene encapsulation and preservation. J Food Sci. 2010;62(6):1158–1162. doi: 10.1111/j.1365-2621.1997.tb12235.x. [DOI] [Google Scholar]

- 10.Eggerstedt SN, Dietzel M, Sommerfeld M, et al. Protein spheres prepared by drop jet freeze drying. Int J Pharmaceut. 2012;438(1-2):160–166. doi: 10.1016/j.ijpharm.2012.08.035. [DOI] [PubMed] [Google Scholar]

- 11.Encina C, Vergara C, Giménez B, et al. Conventional spray-drying and future trends for the microencapsulation of fish oil. Trends Food Sci Technol. 2016;56:46–60. doi: 10.1016/j.tifs.2016.07.014. [DOI] [Google Scholar]

- 12.Feng J, Deng FY, Yu YL, et al. Effects of β-carotene microcapsules on reproducibility, immunity and antioxidant capability in late-pregnancy sows. J Zhejiang Univ (Agric Life Sci) 2009;35(6):665–669. doi: 10.3785/j.issn.1008-9209.2009.06.012. (in Chinese) [DOI] [Google Scholar]

- 13.Gardner CM, Burke NAD, Stöver HDH. Cross-linked microcapsules formed from self-deactivating reactive polyelectrolytes. Langmuir. 2010;26(7):4916–4924. doi: 10.1021/la903540c. [DOI] [PubMed] [Google Scholar]

- 14.Gharsallaoui A, Roudaut G, Chambin O, et al. Applications of spray-drying in microencapsulation of food ingredients: an overview. Food Res Int. 2007;40(9):1107–1121. doi: 10.1016/j.foodres.2007.07.004. [DOI] [Google Scholar]

- 15.Goula AM, Adamopoulos KG, Kazakis NA. Influence of spray drying conditions on tomato powder properties. Dry Technol. 2004;22(5):1129–1151. doi: 10.1081/DRT-120038584. [DOI] [Google Scholar]

- 16.Grünewald G, Westhoff B, Kind M. Fluidized bed spray granulation: nucleation studies with steady-state experiments. Dry Technol. 2010;28(3):349–360. doi: 10.1080/07373931003641495. [DOI] [Google Scholar]

- 17.Guignon B, Duquenoy A, Dumoulin ED. Fluid bed encapsulation of particles: principles and practice. Dry Technol. 2002;20(2):419–447. doi: 10.1081/DRT-120002550. [DOI] [Google Scholar]

- 18.Ixtaina VY, Julio LM, Wagner JR, et al. Physicochemical characterization and stability of chia oil microencapsulated with sodium caseinate and lactose by spray-drying. Powder Technol. 2015;271:26–34. doi: 10.1016/j.powtec.2014.11.006. [DOI] [Google Scholar]

- 19.Jiang ZM, Bai LN, Yang N, et al. Stability of β-carotene microcapsules with Maillard reaction products derived from whey protein isolate and galactose as coating materials. J Zhejiang Univ-Sci B (Biomed & Biotechnol) 2017;18(10):867–877. doi: 10.1631/jzus.B1700082. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 20.Kong LY, Bhosale R, Ziegler GR. Encapsulation and stabilization of β-carotene by amylose inclusion complexes. Food Res Int. 2018;105:446–452. doi: 10.1016/j.foodres.2017.11.058. [DOI] [PubMed] [Google Scholar]

- 21.Loksuwan J. Characteristics of microencapsulated β-carotene formed by spray drying with modified tapioca starch, native tapioca starch and maltodextrin. Food Hydrocoll. 2007;21(5-6):928–935. doi: 10.1016/j.foodhyd.2006.10.011. [DOI] [Google Scholar]

- 22.Ozhogina OA, Kasaikina OT. β-carotene as an interceptor of free radicals. Free Radical Biol Med. 1995;19(5):575–581. doi: 10.1016/0891-5849(95)00064-5. [DOI] [PubMed] [Google Scholar]

- 23.Parthasarathi S, Anandharamakrishnan C. Enhancement of oral bioavailability of vitamin E by spray-freeze drying of whey protein microcapsules. Food Bioprod Process. 2016;100:469–476. doi: 10.1016/j.fbp.2016.09.004. [DOI] [Google Scholar]

- 24.Rahman MS, Al-Amri OS, Al-Bulushi IM. Pores and physico-chemical characteristics of dried tuna produced by different methods of drying. J Food Eng. 2002;53(4):301–313. doi: 10.1016/S0260-8774(01)00169-8. [DOI] [Google Scholar]

- 25.Sandmann G. Carotenoid biosynthesis in microorganisms and plants. In: Christen P Hofmann E., editor. EJB Reviews 1994. Springer, Berlin, Heidelberg; 1994. pp. 129–146. [DOI] [PubMed] [Google Scholar]

- 26.Shamaei S, Seiiedlou SS, Aghbashlo M, et al. Microencapsulation of walnut oil by spray drying: effects of wall material and drying conditions on physicochemical properties of microcapsules. Innov Food Sci Emerg Technol. 2017;39:101–112. doi: 10.1016/j.ifset.2016.11.011. [DOI] [Google Scholar]

- 27.Tomita Y, Himeno K, Nomoto K, et al. Augmentation of tumor immunity against syngeneic tumors in mice by β-carotene. J Natl Cancer Inst. 1987;78(4):679–681. doi: 10.1093/jnci/78.4.679. [DOI] [PubMed] [Google Scholar]

- 28.Tong HHY, Du Z, Wang GN, et al. Spray freeze drying with polyvinylpyrrolidone and sodium caprate for improved dissolution and oral bioavailability of oleanolic acid, a BCS Class IV compound. Int J Pharmaceut. 2011;404(1-2):148–158. doi: 10.1016/j.ijpharm.2010.11.027. [DOI] [PubMed] [Google Scholar]

- 29.Tonon RV, Grosso CRF, Hubinger MD. Influence of emulsion composition and inlet air temperature on the microencapsulation of flaxseed oil by spray drying. Food Res Int. 2011;44(1):282–289. doi: 10.1016/j.foodres.2010.10.018. [DOI] [Google Scholar]

- 30.Wang RX, Tian ZQ, Chen LY. A novel process for microencapsulation of fish oil with barley protein. Food Res Int. 2011;44(9):2735–2741. doi: 10.1016/j.foodres.2011.06.013. [DOI] [Google Scholar]

- 31.Wanning S, Süverkrüp R, Lamprecht A. Pharmaceutical spray freeze drying. Int J Pharm. 2015;488(1-2):136–153. doi: 10.1016/j.ijpharm.2015.04.053. [DOI] [PubMed] [Google Scholar]