Abstract

Lead halide perovskites have displayed the highest solar power conversion efficiencies of 23% but the toxicity issues of these materials need to be addressed. Lead‐free perovskites have emerged as viable candidates for potential use as light harvesters to ensure clean and green photovoltaic technology. The substitution of lead by Sn, Ge, Bi, Sb, Cu and other potential candidates have reported efficiencies of up to 9%, but there is still a dire need to enhance their efficiencies and stability within the air. A comprehensive review is given on potential substitutes for lead‐free perovskites and their characteristic features like energy bandgaps and optical absorption as well as photovoltaic parameters like open‐circuit voltage (V OC), fill factor, short‐circuit current density (J SC), and the device architecture for their efficient use. Lead‐free perovskites do possess a suitable bandgap but have low efficiency. The use of additives has a significant effect on their efficiency and stability. The incorporation of cations like diethylammonium, phenylethyl ammonium, phenylethyl ammonium iodide, etc., or mixed cations at different compositions at the A‐site is reported with engineered bandgaps having significant efficiency and stability. Recent work on the advancement of lead‐free perovskites is also reviewed.

Keywords: lead‐free perovskites, photovoltaic parameters, stability

1. Introduction

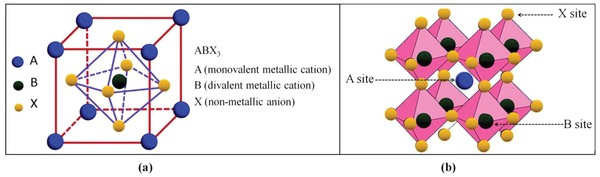

Perovskite originally referred to a mineral calcium titanium oxide, CaTiO3, discovered in 1839 in Ural Mountains of Russia by Gustav Rose, a German mineralogist and later named after a Russian mineralogist count Lev Aleksevich Perovski.1 Since then, the term perovskite has been used for any organic/inorganic compound (synthetic/natural) with the similar crystal structure and stoichiometry as of CaTiO3, that is, ABX3, where A is monovalent metallic cation, most usually from group I of the periodic table. B is divalent metallic cation, a transition metal and X is a nonmetallic anion (halide). However, for O2− anions, A and B are divalent and tetravalent cations, respectively. The size of cation A must be larger than that of cation B. Ideally, perovskite crystal structure is described as a body centered cubic structure with monovalent cation A dodecahedrally (12‐fold) coordinated by X anions as shown in Figure 1 .2 The volume occupied by A ions depends on the electronegativity and size of B and X ions, respectively. A superfluity of organic/inorganic compounds has been discovered that exists in perovskite crystal structure framework ABX3 like BaTiO3, SrTiO3, KNbO3, etc.

Figure 1.

a) Schematic view of cubic perovskite crystal structure for ABX3 compound, b) 3D crystal structure in which the A site is confined within a cage determined by the octahedral coordination of B site with X site. Reproduced with permission.1 Copyright 2019, Royal Society of Chemistry.

Generally, perovskite materials can be classified into two groups, namely, inorganic oxide perovskite and halide perovskite that further encompass alkali halide and organometal halide perovskite materials. There are some perovskite materials like MgCNi3 having neither oxygen nor halide component and hence do not belong to either of the groups.3 In alkali halide perovskites, A‐site is occupied by a monovalent organic cation such as CH3NH3 (methylammonium or MA), NH2(CH)NH2 (formamidinium or FA), or inorganic cations such as rubidium (Rb), caesium (Cs), etc., the B‐site by a divalent metal cation lead (Pb) or tin (Sn), and X‐site by a halide anion. In today's scientific world, it is the halide perovskites that have grabbed all the attention of silicon‐dominated photovoltaics industry and whole of the photovoltaics research is now focused in developing perovskite materials for solar energy conversion.

The suitability of a particular combination of cations to organize into a perovskite structure can be estimated based on two important parameters. The first one is the Goldschmidt tolerance factor (t), a dimensionless number, calculated from the ratio of ionic radii4

| (1) |

where r A and r B are the ionic radii of cations A and B, and r X is the ionic radius of anion. For a particular perovskite structure, the tolerance factor (t) can be calculated by substituting the ionic radii of cations and anions. If t = 1, it indicates the formation of an ideal cubic structure having size of cation A larger than that of B. The tolerance factor (t) must lie in the range of 0.8–1.0 for the formation of stable perovskite structures. If t < 0.8 or t > 1.0, the cation A is too small or too big to fit into BX6 octahedron, thereby resulting in the formation of alternative structures. The tolerance factor (t) leading to formation of different types of structures with examples is mentioned in Table 1 .

Table 1.

Goldschmidt tolerance factor (t) of various perovskite materials5

The second one is the octahedral factor (μ) which is the ratio between ionic radii of B and X

| (2) |

The octahedral factor (μ) must lie in the range of 0.44–0.72 for B and X in order to form a stable BX6 octahedron.2 The tolerance factor has an immense role to play in finding alternative lead halide perovskite materials as many different cations can be inserted in ABX3 structure framework leading to development of varied materials with specific engineered properties.8

The effective ionic radii of organic molecular cations and Shannon ionic radii of inorganic cations as well as the effective ionic radii of various anions are listed in Table 2 .9, 10, 11, 12, 13

Table 2.

(a) Effective ionic radii of organic molecular cations. (b) Shannon ionic radii of inorganic cations. (c) Effective ionic radii of various anions

| (a) | ||

| Cation A | Effective ionic radii (r eff) [pm] | Ref. |

| Ammonium [NH4]+ | 146 | 10 |

| Hydrazinium [NH3NH2]+ | 217 | 10 |

| Azetidinium [(CH)3NH2]+ | 250 | 10 |

| Formamidinium [CH(NH2)2]+ | 253 | 10 |

| Imidazolium [C3N2H5]+ | 258 | 10 |

| Dimethylammonium [(CH)2NH2]+ | 272 | 10 |

| Ethyl ammonium [(CH3CH2)NH3]+ | 274 | 10 |

| Guanidinium [(NH2)3C]+ | 278 | 10 |

| Tetramethylammonium [(CH3)4N]+ | 292 | 10 |

| Thiazolium [C3H4NS]+ | 320 | 11 |

| Tropylium [C7H7]+ | 333 | 11 |

| Hydroxylamine [NH3OH]+ | 216 | 10 |

| Methylammonium [CH3NH3]+ | 217 | 10 |

| Piperazinium [C4H12N2]2+ | 322 | 9 |

| Dabconium [C4H14N2]2+ | 339 | 9 |

| K+ | 164 | 12 |

| Rb+ | 172 | 12 |

| Cs+ | 188 | 12 |

| (b) | ||

| Cation B | Effective ionic radii (r eff) [pm] | Ref. |

| Be2+ | 16 | 12 |

| Mg2+ | 72 | 12 |

| Ca2+ | 100 | 12 |

| Sr2+ | 118 | 12 |

| Ba2+ | 135 | 12 |

| Mn2+ | 66 | 12 |

| Fe2+ | 78 | 12 |

| Co2+ | 58 | 12 |

| Ni2+ | 55 | 12 |

| Pd2+ | 86 | 12 |

| Pt2+ | 60 | 12 |

| Cu2+ | 73 | 12 |

| Zn2+ | 60 | 12 |

| Cd2+ | 78 | 12 |

| Hg2+ | 69 | 12 |

| Ge2+ | 73 | 12 |

| Sn2+ | 110 | 13 |

| Pb2+ | 119 | 12 |

| Eu2+ | 117 | 12 |

| Tm2+ | 103 | 12 |

| Yb2+ | 103 | 12 |

| Sn[4+] | 69 | 12 |

| Te+ | 150 | 12 |

| Au+ | 137 | 12 |

| Au3+ | 85 | 12 |

| Sb+ | 76 | 12 |

| Bi3+ | 103 | 12 |

| Te[4+] | 97 | 12 |

| La3+ | 103 | 12 |

| Ce3+ | 101 | 12 |

| Pr3+ | 99 | 12 |

| Nd3+ | 98 | 12 |

| Sm3+ | 96 | 12 |

| Eu3+ | 95 | 12 |

| Gd3+ | 94 | 12 |

| Dy3+ | 91 | 12 |

| Er3+ | 89 | 12 |

| Tm3+ | 88 | 12 |

| Lu3+ | 86 | 12 |

| Pu3+ | 100 | 12 |

| Am3+ | 98 | 12 |

| Bk3+ | 96 | 12 |

| (c) | ||

| Anion X | Effective ionic radii (r eff) [pm] | Ref. |

| Fluoride, F− | 129 | 9 |

| Chloride, Cl[−] | 181 | 9 |

| Bromide, Br[−] | 196 | 9 |

| Iodide, I[−] | 220 | 10 |

| Formate, HCOO[−] | 136 | 9 |

| BH4 [−] | 203 | 11 |

The Goldschmidt tolerance factor (t) has played a pivotal role in development of perovskites10 and is now being used to engineer/synthesize new organic–inorganic stable perovskites structures by formulating the composition of perovskite. The tolerance factor can be tuned to the stable perovskite range by mixing distinct A/B cations and X anions in a particular composition.14, 15, 16, 17

2. Perovskite Sensitized Solar Cell

Solar energy has always been sought to be converted into electrical energy through photovoltaic effect of light absorbing semiconductor in order to obtain clean and green energy. The traditional first generation crystalline silicon solar employed for this purpose enjoy a market share of more than 90% in PV market.18 The second generation solar cells consist of thin films such as cadmium telluride, copper indium gallium selenide, and amorphous silicon. The third generation has a number of thin film technologies such as dye‐sensitized solar cells (DSSCs) in development phase. The crystalline silicon solar cell has a theoretical limiting power efficiency of 33.16%19 noted as a Shockley Queisser limit in 1961. An efficiency of 25.6%20 for a silicon solar cell has been reported in 2014 that further grows to 46.1%21 in four‐junction GaInP/GaAs/GaInAsP/GaInAs solar cell reported by French‐German collaboration. The triple‐junction thin film solar cells achieved an efficiency of 13.6% in June 2015.22 The research teams at NREL, EPFL, and GSEM have reported Sun efficiencies of dual‐junction GaInP/GaAs solar cell devices up to 32.8%.23 Although, the monocrystalline silicon cells have photovoltaic conversion efficiency of more than 20%,24 they are characterized by high cost, difficult preparation conditions, and serious environmental pollution.25 Also, cadmium telluride and copper indium gallium selenium thin film solar cells' large‐scale use puts a pressure on environmental pollution. DSSCs showing an efficiency of more than 13% have low cost and easy fabrication but absorption layer in such cells is very thick26 and light dyes used in such cells suffer from phenomenon of light bleaching.

An efficient solar cell technology must ensure low raw material and finished material cost, high light absorption and solar power conversion efficiency, high abundance of raw material, low toxicity, and less environmental pollution. In order to achieve it, the organic/inorganic perovskite compounds can be used in light harvesting layer as these materials have all the requisite properties that make them suitable for use in PV27 applications. With the discovery of metal halide perovskite, especially MAPbI3, FAPbI3 as light absorbers, the use of perovskites in PV technology has been explored as they are cost effective and readily available for large‐scale use.28, 29, 30, 31, 32, 33, 34, 35, 36, 37, 38 The organic–inorganic perovskite materials have been pioneering in fabricating high solar power conversion efficiency hybrid solar cells from time to time.32, 39, 40, 41, 42, 43, 44, 45 Miyasaka and co‐workers reported the first perovskite sensitized solar cell (PSSC) in between 2006 and 2008 using CH3NH3PbI3 and CH3NH3PbBr3 absorbers and reported solar power conversion efficiency varying between 0.4 and 2% for solid‐state and liquid electrolyte cells, respectively.46, 47 A MAPbI3‐based solar cell with solar power conversion efficiency of 3.8% has been reported by Kojima et al. in 2009 and was the first peer reviewed publication on perovskite‐sensitized solar cell.28 Park and co‐workers using CH3NH3PbI3 liquid electrolyte solar cell reported an improved efficiency of 6.5%.48 In 2011, Snaith along with his co‐workers developed a solid‐state perovskite solar cell (PSC) using 2,2(7,7)‐tetrakis‐(N,N‐dimethoxyphenylamine)9,9(Spiro‐bifluorene) (Spiro‐OMeTAD) for hole transportation and produced solar power conversion efficiencies between 8 and 10%49 achieving a major breakthrough in performance efficiency of PSSC in comparison to DSSCs having only 7% efficiency.50 In 2012, Kim et al. replaced the liquid electrolyte with a solid‐state hole conducting material depositing the perovskite precursor over the mesoporous TiO2 layer achieving a solar power conversion efficiency (SPCE) of 9.7%.30 Later, increased efficiencies of 10.9% were reported by Lee et al.51 Gratzel and co‐workers reported a SPCE of 15% by using sequential deposition to produce pinhole‐free perovskite layer.52 Liu et al. Introduced Zn2SnO4 nanocrystalline thin film on PCBM buffer layer to make electron extraction process easy, thereby, increasing SPCE to 17.76.53 You et al. and Yang et al. first fabricated all metal oxide layer based perovskite solar cell reporting an efficiency of 16.1% and more stability of the material in 2016.54 Yang et al. and his team reported SPCE of 22.1%55 in defect engineered thin perovskite layers in PSSCs containing formamidinium with multiple cations and mixed halide anions in 2017. The SPCE of solid‐state PSSCs was around 10% in 2012 that later grew up to 22.1% in 2017. This has been achieved through engineering of perovskite composition and thin film deposition methods. The big issue of degradation of perovskite in polar liquid electrolyte has been solved by use of solid‐state PSSCs that have shown 500 h stability in ambient conditions without encapsulation but still the PSSCs have to prove its stability in air, on exposure to humidity,56, 57, 58 UV light,59 and high temperatures.60, 61 Research has also revealed that PSSCs also suffer from anomalous current–voltage hysteresis as reported by Snaith and co‐workers in 201462 that can have adverse effects on the stability of PSSCs.63, 64

3. Device Configuration and Working Principles of Perovskite Solar Cell

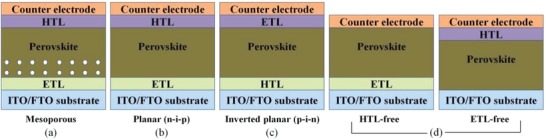

In the first perovskite solar cell fabricated in 2009, perovskite nanoparticles were used as a light absorber replacing dyes in dye‐sensitized solar cells. In the fabricated device, mesoporous TiO2 layer of several micrometer thickness acts as an anode and a platinum‐coated glass acted as a cathode in a liquid electrolyte based device.28, 29 However, the device suffered seriously from the stability issue as the perovskite light absorber layer dissolves or decomposes in the liquid electrolyte very rapidly. Hence, the liquid electrolyte was replaced by a solid‐state material to act as a hole transport material (HTM) resulting in a solid‐state mesoscopic perovskite solar cell with an improved stability. Organic Spiro‐OMeTAD was used as a hole transport material in such cells.49 The perovskite materials when used as a light absorber enhances the device stability and performance to its broad optical absorption range than the conventional dyes.65 In a mesoscopic perovskite solar cells, a compact metal oxide (TiO2) layer is deposited on a fluorine‐doped tin oxide (FTO) glass substrate by spin‐coating on which is further deposited a mesoporous TiO2 layer by spin‐coating. The perovskite light absorber layer is grown on the scaffold of mesoporous TiO2 layer which is further deposited by a HTM by spin‐coating and finally to a metal‐back electrode (Ag or Au). The device configuration of mesoporous perovskite solar cell is shown in Figure 2 a.66

Figure 2.

a) Device structure of mesoporous PSCs, b) planar heterojunction, c) inverted planar PCSs, and d) HTM‐free PSCs. Reproduced with permission.66 Copyright 2016, Springer Nature.

TiO2 is most commonly employed in mesoporous layer that facilitates in the formation of inner connected layer of perovskite crystals by allowing their deep penetration into the pores of mesoporous layer. Compact TiO2 layer transports electrons, blocks holes, and suppresses the recombination of electron–hole pairs. The mesoporous TiO2 layer needs a high‐temperature sintering that can consequently increase the device fabrication time. Since the perovskite materials have ambipolar nature, they have the potential of transporting electrons and holes on their own in between two electrodes so a planar structure is viable for them.67 Also, the perovskite solar cells using planar structure over time have revealed the best device performance as that of a mesoporous structure.32, 67 The device with planar configuration has reported almost 100% internal quantum efficiencies ascertaining them as an efficient device structure.43 Thus, typically there are two major device configurations for a perovskite solar cell, viz., a planar heterojunction/conventional structure (n‐i‐p) and an inverted planar structure (p‐i‐n). In a planar heterojunction structure (n‐i‐p) as shown in Figure 2b,66 a compact electron transport layer (ETL) of 30–50 nm of TiO2 (most commonly) is deposited on a transparent conducting oxide substrate that can be indium‐doped tin oxide (ITO) or FTO. The mesoporous TiO2 layer is removed and perovskite light absorber to sandwich between an ETL and a hole transport layer (HTL) by spin‐coating or by vapor deposition and vapor‐assisted solution process on a compact TiO2 32, 33 layer and finally connected to a metal electrode such as Au, Ag, or Pt. Spiro‐OMeTAD or poly‐triallylamine (PTAA) can be used in ETL. For an inverted planar structure (p‐i‐n) as shown in Figure 2c,66 a hole transport layer of poly(3,4‐ethylene dioxythiophene):poly(styrene sulfonate) (PEDOT:PSS) or NiOx is deposited on a conducting glass substrate that is most commonly ITO followed by a photoactive perovskite light absorber layer and is further covered by an electron transport layer of [6,6]‐phenyl‐C61‐butyric acid methyl ester (PC61BM) or zinc oxide (ZnO) and finally to a metal electrode of Au, Ag, or Al. The electron and holes are generated in the photoactive perovskite layer on absorption of photons of incident light and move to the opposite electrodes constituting current. HTL is used to receive the holes generated in the perovskite layer and transports them to the surface of the metal electrode whereas ETL transports electrons, block holes, and inhibits the electron–hole recombination in the FTO conductive substrate. The material used in ETL must be a n‐type semiconductor with high carrier mobilities, transparent to light, and with a suitable energy band structure matching with that of the perovskite material. ETL must have lowest unoccupied molecular orbital (LUMO) and highest occupied molecular orbital (HOMO) higher than the photoactive perovskite layer while HTL can facilitate hole motion only if the HOMO matches with the valence band of the perovskite material. The inverted planar structure has an operational edge over a conventional structure as it required a temperature of 300 °C for device fabrication in contrast to a planar heterojunction structure where a temperature up to 500 °C is required. Moreover, the hysteresis effect of perovskite solar cells is rarely observed in a planar inverted structure while this effect is most commonly observed in planar heterojunction devices.68 The highest device performance has been observed with the planar heterojunction structure using TiO2 as an electron transport layer.69 The most commonly reported structure is inverted planar device PEDOT:PSS/light absorber/PCBM as it is easily fabricated and more cost effective.68, 70 The poor SPCE of inverted planar structure may be due to a barrier at the contact interface between Fermi level of the metal electrode and lowest unoccupied molecular orbit of the ETL.126 In a planar heterojunction structure, the expensive HTL of Spiro‐OMeTAD may be removed leading to a new device framework known as planar HTM‐free architecture71, 72 as shown in Figure 2d.66

4. Why Lead‐Free?

The use of organic–inorganic lead halide perovskite such as MAPbI3 and FAPbI3 has caused an increase in solar power conversion efficiencies from 3.8% in 200928 to 22.1%34, 35, 73, 74, 75, 76 in last nine years as these materials do possess requisite optoelectronic features such as a direct bandgap, long charge carrier lifetime, diffusion length, high charge carrier mobility, and strong optical absorption coefficient.77, 78, 79, 80, 81, 82, 83, 84, 85, 86, 87, 88, 89, 90 Lead halide perovskite has high open‐circuit voltages due to photon recycling as a result of which they have long charge extraction lengths through multiple absorption–emission events within the perovskite active layer.91 The metal lead has invaluable intrinsic properties like high melting point, high density, malleability, ductility, corrosion resistance, etc. Despite having all characteristic features to be exploited in commercial PV solar market, it is the toxic nature of lead in lead halide perovskite solar cells that hinders its use in silicon‐dominated PV market. The stringent directives of European Union clearly prohibits the use of hazardous substance in electrical and electronic equipment and lead has been identified as one of the ten hazardous chemicals listed by ROHS in order to avoid its exposure to environment and people as well.92, 93 The toxicity of lead is due to its affinity for band formation with thiol and cellular phosphate groups of numerous enzymes, proteins, and cell membranes.94 Lead halide perovskite solar cells do contain a considerable portion of lead, that is, 33% by weight. Lead is carcinogenic in nature and has no safe threshold limit of exposure. It can cause serious toxicological implications on human beings leading to cardiovascular and development diseases by inflicting the functioning of liver, kidney, brain, and central nervous system. Exposure to lead can produce irreversible health damages in infants and pregnant ladies.95, 96, 97 Also, organic–inorganic lead halide perovskites are liable to degradation under moisture, rain, heat, and prolonged illumination in air.98, 99, 100 Therefore, instability is another prime issue linked with these materials that reduces their working life span which is the most important prerequisite for commercialization on large scale as PV panels are generally placed over roof tops or in open fields so their exposure to rain is inevitable.

Hailegnaw et al. have reported that in case of a catastrophic failure of a solar plant, the impact of rain of different pHs on MAPbI3 films is complete degradation of perovskite material leaving behind PbI2 in water in the order of 10−8 mol L−1 which is of course low but higher than that of CdTe, CdS, and PbS values varying from 10−27 to 10−34 so it becomes most probable that lead, being soluble in water, may leech into the underground water resources.101 Not only this, Hailegnaw et al. have analyzed the impact of leaching lead out of the damaged solar panels on the soil and reported that the leakage of lead due to broken encapsulation or sealing will induce the concentration of Pb in first cm of ground below the damaged solar panel by 70 ppm.101 Taking into consideration the repercussions of use of toxic lead halide perovskites, it becomes pertinent to investigate lead‐free perovskite materials providing better stabilities with solar power conversion efficiencies without compromising human health and environment.

5. Characteristic Features of Lead‐Free Perovskites

The perovskite based materials used in solar cells do possess such a structure that enables them to have most suitable optical bandgaps to act as a light absorber. These materials do possess a high dielectric constant, long diffusion length, and a broad optical absorption range covering the entire visible spectrum and into the infrared. Perovskite materials exhibit ambipolar properties that enable them to display both n‐type and p‐type behavior on exposure to photons of incident light. The rate of nonradiative recombination in such material is strongly suppressed that is essential for high solar power conversion efficiencies. The presence of hysteresis loss in these materials clearly indicates the presence of magnetic properties at room temperature or above. Another important characteristic of these materials is that they are deposited by low‐temperature solution methods that provide easy fabrication with low production cost. Besides they are typically flexible, light weight, and semitransparent making them more appealing for use in photovoltaic applications.

The lead‐based halide perovskites have reported a highest solar power conversion efficiency of 22% up to now within 8 years of research.102 The efficiency limit of perovskite solar cell has been envisaged to be 31% based on detailed balance calculations much closer to the Shockley–Queisser limit of 33%.103 Although the lead‐based halide perovskites have all the structural, optical, and electrical features for use in perovskite solar cell as a light absorber but due to toxicity issues of lead, it is pertinent to replace it by another suitable elements such as tin, germanium, bismuth, etc. The lead‐free perovskites have attracted the attention of the researchers at present time due to significant properties of these materials that can be engineered to make them suitable for their use as light absorbers in perovskite solar cells. Lead‐free perovskite methylammonium tin iodide MASnI3 is a direct gap semiconductor with an optical bandgap of 1.3 eV104, 105, 106 which is close to 1.5 eV of MAPbI3. It exhibits a strong photoluminescence emission corresponding to the onset at 950 nm in 700–1000 nm range of the absorption edge at room temperature. MASnI3 has an electrical conductivity of 5 × 10−2 S cm−1 at room temperature that corresponds to a Seebeck coefficient of ≈–60 µV K−1. The material exhibits a carrier concentration of the order of ≈1 × 1014 cm−3 having excellent electron mobilities of the order of ≈2000 cm2 V−1 s−1 and hole mobility of 300 cm2 V−1 s−1 in comparison to lead halide perovskites that have an electron mobility of 66 cm2 V−1 s−1 and hole mobility of 105 cm2 V−1 s−1.84 Table 3 summarizes the electron and hole mobilities of all the lead‐free perovskite materials. The Hall measurements of as‐grown crystals of MASnI3 have revealed a hole concentration of about 9 × 1017cm−3 with a hole mobility of about 200 cm2 V−1 s−1 at 250 K.107

Table 3.

Charge carrier mobility of lead‐free perovskites

| Light absorber | Architecture | Measurement method | Component | Mobilities [cm−1 V−1 s−1] | Ref. |

|---|---|---|---|---|---|

| MASnI3 | Poly c | Hall | Electron | 2320 | 105 |

| MASnI3 | Poly c | Hall | Hole | 322 | 105 |

| MASnI3 | Single c | Hall | Hole | 200 | 107 |

| MASnI3 | Poly c | Hall | Hole | 50 | 121 |

| MASnI3 | Mesostructural | THzC | Total | 1.6 | 120 |

| FASnI3 | Poly c | Hall | Electron | 103 | 105 |

| FASnI3 | Film | THzC | Total | 22 | 122 |

| CsSnI3 | Poly c | Hall | Electron | 536 | 105 |

| CsSnI3 | Poly c | Hall | Hole | 585 | 123 |

| (C6H5C2H4NH3)2SnI4 | Film | FET | Hole | 0.6 | 124 |

| PEASnI4 | Film | FET | Hole | 15 | 125 |

| (MA)3Sb2IxBr9− x | Single c | SCLC | Electron | 12.3 | 116 |

| (MA)3Sb2IxBr9− x | Single c | SCLC | Hole | 4.8 | 116 |

| Ba2BiTaO6 | Film | Hall | Hole | 30 | 126 |

| MASnI3 | Mesostructural | – | Electron | 2000 | 106 |

| MBI | Single c | Hall | Total | 1–11 | 127 |

| (MA)3Sb2I9 | Single c | SCLC | Hole | 4.8 | 116 |

| (MA)3Sb2I9 | Single c | SCLC | Electron | 12.3 | 116 |

| (MA)3Sb2I9 | Film | SCLC | Hole | 1.2 × 10−4 | 116 |

| (MA)3Sb2I9 | Film | SCLC | Electron | 1.5 × 10−4 | 116 |

| Cs2SnI6 | Poly c | Hall | Hole | 310 | 115 |

| MA3Bi2I9 | Single c | SCLC | Hole | 29.7 | 128 |

| MA3Bi2I9 | Single c | Hall | Electron | 1 | 127 |

| (MA)2SnI6 | Poly c | Hall | Electron | 3 | 129 |

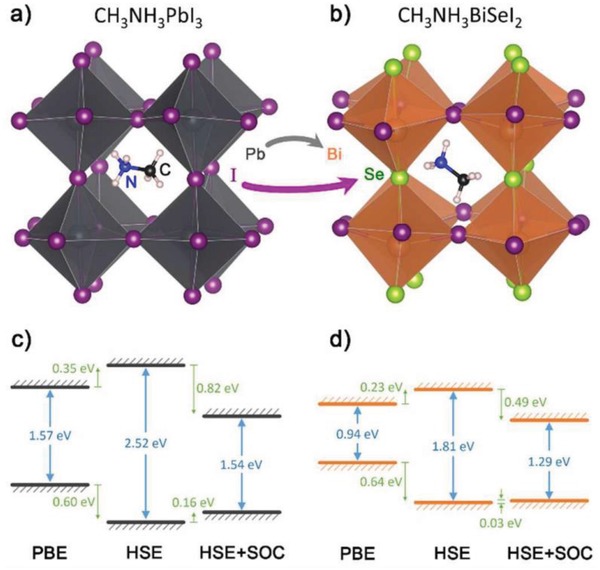

Although tin halide perovskite has higher charge carrier mobilities, Sn2+ has a strong tendency to get oxidized to Sn4+ causing a p‐type self‐doping.108 The artificial hole doping of the halide‐based perovskites increases their electrical conductivity and they exhibit a metal‐like conducting behavior.107 The formamidinium tin iodide (FASnI3) has an optical bandgap of 1.41 eV that is much closer to the bandgap 1.5 eV of MAPbI3 making it a potential candidate to display an optical absorption up to 950 nm.109 The cesium tin iodides (CsSnI3) display a bandgap of ≈1.3 eV at 300 K close to the optimum value of 1.5 eV for photovoltaic performance.110 Bismuth‐based halide perovskites display lower light absorption onset at 450 nm with absorption coefficient of ≈1 × 105 cm−1 that are lower as compared to MAPbI3 that has an absorption coefficient of around 2 × 105 cm−1 at 450 nm.111

Lead‐free perovskites have high exciton binding energies that provide them stable optical properties. The exciton binding energies of bismuth‐based halide perovskites MA3Bi2I9, Cs3Bi2I9, and MA3Bi2I9Clx are of 70, 270, and 300 meV that are much higher than that of lead‐based halide perovskites (25–50 meV).111 UV–vis absorption measurements for Cs3Bi2I9 have reported a strong exciton absorption peak at room temperature. Cs3Bi2I9 exhibits an exciton absorption peak at ≈485 nm (2.56 eV) with an indirect optical bandgap of ≈2.1 eV. The films exhibited an optical absorption coefficient of ≈1 × 104 cm−1 at 450 nm. In spite of indirect bandgaps, the material is still a potential candidate for use as a light absorber due to strong exciton binding energy.112 CsSnI3 perovskite exhibits a direct bandgap of 1.32 eV with an exciton binding energy of 18 meV at room temperature. The large binding energy is on the account of exciton motion in the 2D layer of SnI4 tetragons present in the material.123

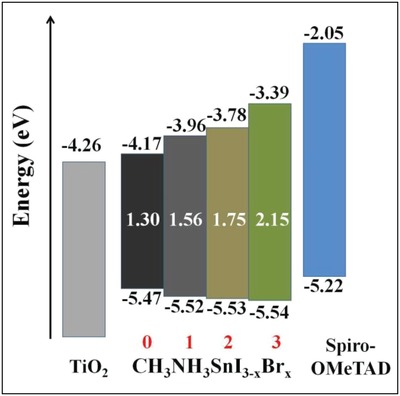

Tin‐based perovskites are prepared by using solution methods and crystallizes at room temperature whereas lead‐based halide perovskites crystallize by heating. The variation in composition of halide anion in lead‐free perovskites has a significant effect on the absorption coefficient of these materials thus paving the way for engineering the bandgaps and optical absorption spectrum of these materials. The tin‐based hybrid halide perovskites MASnI3− xBrx (x = 0, 1, 2, 3) synthesized in an inert atmosphere in the nitrogen glove box exhibit an optical absorption onset that can be blueshifted from 954 to 577 nm by varying the composition of halide anion, that is, for x = 0 and x = 3 whereas for x = 1 and 2, optical absorption onset at 795 and 708 nm has been reported. Also ultraviolet photoelectron spectroscopy (UPS) measurements of valence band energy E VB of MASnI3− xBrx under high vacuum have revealed that the bandgaps can be engineered from 1.30 eV for MASnI3 to 2.15 eV for MASnBr3.106 Not only this, the color of the tin‐based hybrid halide perovskite MASnI3− xBrx shows a variation with increased bromine content from black (x = 0) to dark brown (x = 1) and yellow (x = 3); thus, colorful solar devices can be designed by using bandgap engineering. Thus, the composition of tin‐based mixed halide perovskite can be tailored to emit between 954 and 574 nm in contrast to lead‐based counterparts that display photovoltaic emission in between 700 and 800 nm. The emitted wavelengths are in agreement with the values of bandgaps obtained through experiments clearly indicating the presence of direct optical bandgaps in MASnI3.106

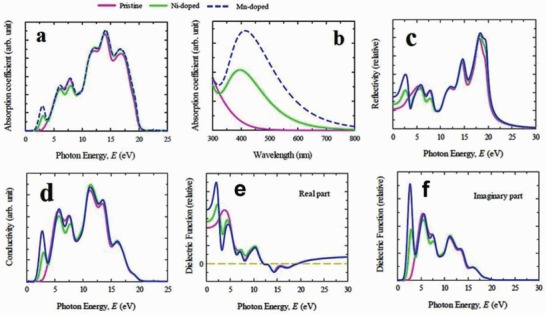

The investigation of Ge mixed halide perovskites MAGeI3− xClx [x = 0, 1, 1.5, 2, 3] by using first principle calculations has reported a bandgap of 1.8 eV for MAGeI3 (x = 0) whereas MAGeCl3 (x = 3) has a much wider bandgap of 3.8 eV clearly demonstrating the effect of doped chlorine in MAGeI3 perovskites. The absorption coefficients also display an increasing trend when the proportion of x decreases from 3 to 0 attributed to the redshift of the optical bandgap caused due to change in chemical composition of the material.113 In case of antimony‐based mixed halide perovskites MA3Sb2IxBr9− x, the optical bandgap onset for perovskite films shows a decreasing trend, that is, the optical absorption onset is blueshifted from 558 to 453 nm as x changes from 9 to 0. The hole and electron mobilities of MA3Sb2I9 single crystals have been calculated by using space charge limited current methods114, 115 and are shown in Table 3. The MA3Sb2I9 single crystals have high absorption coefficient greater than 105 cm−1 at absorption peak wavelengths. The absorption onset for [x = 0, 3, 6] in MA3Sb2IxBr9− x films are 453, 486, and 516 nm with a direct bandgap of 2.78, 2.66, and 2.49 eV, respectively.116 Lead‐free perovskites do possess suitable carrier diffusion lengths and minority charge carrier lifetimes exhibiting photovoltaic performance. The long carrier diffusion lengths of electrons and holes in MASnI3 are 279 ± 88 and 193 ± 46 nm, respectively, obtained by broadband transient absorption and time‐resolved fluorescence spectroscopy. Addition of SnF2 in MASnI3 films results in not only increase in diffusion lengths to more than 500 µm but also enhances the fluorescence lifetime up to ten times.117 The background concentration of doped holes has an effect on the diffusion lengths of MASnI3 perovskite. As the background doping level in MASnI3 decreases, there is a corresponding increase in diffusion length. For a doping concentration below 1015 cm−3, the diffusion length can be engineered to increase above 1 µm in length that is close to the value shown by lead‐based halides.120 Lead‐free CsSnI3 perovskite films synthesized by the solution method have carrier lifetime of ≈54 ps, minority carrier diffusion length of ≈1.6 nm, and a doping concentration of more than 9.2 × 1018 cm−3 obtained as a consequence of better quality of crystalline films whereas single crystals of CsSnI3 have a long minority carrier diffusion length of more than 930 nm which is comparable to that of the lead‐based perovskites110 having diffusion lengths exceeding 1 µm.74

6. Hole Transport Material and Electron Transport Material in Lead‐Free Perovskite Solar Cells

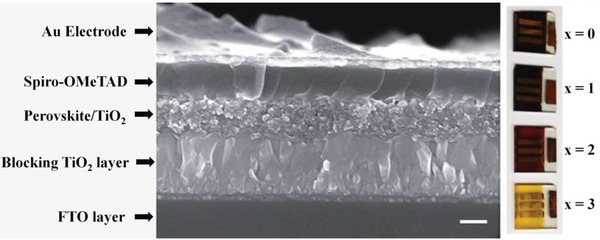

Lead‐free perovskites have been prepared by using mesoporous perovskite solar cells in planar heterojunction and inverted planar structures. Spiro‐OMeTAD is most commonly used hole transport material in lead‐free perovskites as it has the ability to penetrate deep into the pores of the perovskite layer but it has a low hole mobility and complicated device processing. Also it deteriorates the stability of the fabricated device.130, 131 Therefore, dopants are added into it in order to enhance its conductivity. The first lead‐free perovskite device was prepared by solvent engineering method by employing MASnI3 as a light absorber. Spiro‐OMeTAD has been used as a HTM on the top of the perovskite layer in a device architecture of FTO/compact TiO2/mesoporous TiO2 layer/MASnI3 light absorber/Spiro‐OMeTAD/Au.120 An additive doping of hydrogen bis(trifluoromethane sulfonyl)imide (H‐TFSI) and tert‐butyl pyridine is done into Spiro‐OMeTAD to enhance the rate of hole extraction and transport.132 The additive doping of lithium bis(trifluoro methyl sulfonyl)imide salt (Li‐TFSI) and 4‐tert‐butyl pyridine (TBP) deteriorates the stability of MASnI3 perovskite device than H‐TFSI.120 In another approach, also Spiro‐OMeTAD used as a HTM is doped with lithium bis(trifluoro methyl sulfonyl)imide and 2,6‐lutidine in order to enhance its hole mobility.49 The solar cell capacitance simulator and analytical calculations (SCAPS) have reported an efficiency of above 15% in lead‐free tin‐based MASnI3 perovskites employing Spiro‐OMeTAD as a hole transport material.133 Chlorobenzene (CB), Li‐TFSI, and TBP have been used as an additive in Spiro‐OMeTAD in lead‐free Ma3Bi2I9 perovskites.111 Oxygen‐doped Spiro‐OMeTAD employed as a HTM in Cs3Bi2I9 perovskite solar device has yielded the maximum of the reported solar power conversion efficiencies.134 The Spiro‐OMeTAD as a HTM has been used in lead‐free tin, germanium, antimony, bismuth, and copper‐based perovskite devices. Figure 3 shows the scanning electron microscopy (SEM) image of a MASnI3 perovskite device with Spiro‐OMeTAD as a HTM.106

Figure 3.

SEM image of a photovoltaic device using CH3NH3SnI3 perovskite material. Reproduced with permission.106 Copyright 2014, Springer Nature.

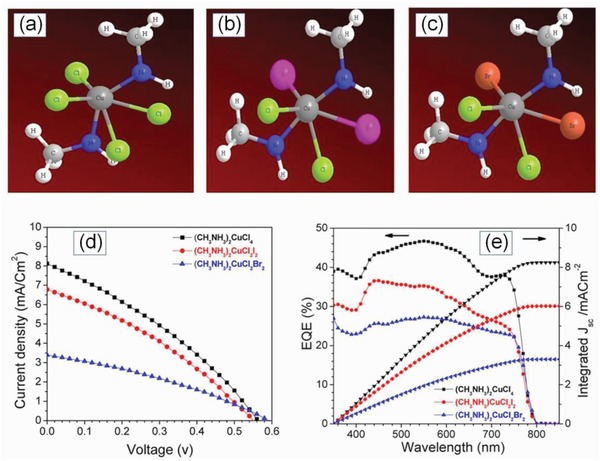

Cu‐based lead‐free perovskites reported so far have a planar heterojunction (n‐i‐p) structure employing Spiro‐OMeTAD as a HTM with a highest reported efficiency of 2.41%. The low efficiency is attributed to the mismatch in the energy levels between the (MA)2CuClxBr4− x and Spiro‐OMeTAD as a HTM leading to a poor hole extraction in the device.135, 136, 137 Another polymeric organic HTM PTAA has been employed in planar heterojunction n‐i‐p perovskite devices.138, 139 Owing to its large hole mobility the use of PTAA as a HTM in Cs3Sb2I9 perovskite solar cells has reported a V OC of 250–300 meV and an extremely low solar power conversion efficiency.140 The doping of bismuth‐based perovskite Cs3Bi2I9 films with N,N‐dimethyl formamide/hydroiodide (HI) solution featured a pure crystalline film with an excellent thermal stability.141 PTAA employed as a HTM in ethylene diammonium and methylammonium tin iodide en[MASnI3] has reported a SPCE of 6.63% with a very high current density of 24.3 mA cm−2 in a device architecture of FTO/C‐TiO2/mp‐TiO2/en[MASnI3]/PTAA/Au.142 Many research groups have synthesized lead‐free MASnI3, FASnI3, and CsSnI3 perovskite solar devices by using PTAA as a HTM. The presence of another polymeric organic poly(3‐hexyl thiophene) (P3HT) as a HTM in lead‐free perovskites can enhance the SPCE as well as stability of the fabricated device due to its potential to decrease the resistance from the hole transfer impedance. P3HT has been employed as a HTM instead of Spiro‐OMeTAD for Cs3Bi2I9 perovskite solar devices.111 In another research, P3HT is used as a HTM in thin films of CsBi3I10 perovskite deposited by solution processing in device architecture of glass/FTO/compact TiO2/mesoporous TiO2/CsBi3I10 light absorber/P3HT/Ag. The addition of dopant 4‐tert‐butyl pyridine in Spiro‐OMeTAD employed as a HTM in CsBi3I10 perovskite dissolves the light absorbing perovskite layer143 and suffers from stability and degradation issues. Unlike Spiro‐OMeTAD, P3HT enhances the SPCE of the fabricated perovskite device as in CsSnBr3 films, an efficiency of 0.11% was enhanced to 3.2% by replacing Spiro‐OMeTAD HTM by P3HT.144 Also, P3HT employed as a HTM in MA3Bi2I9 films enhance the overall performance of the fabricated device.127 P3HT has been employed as a HTM in MASnBr3, FASnI3, CsSnI3, en[MASnI3], Cs2SnI6, MA3Bi2I9, Cs3Bi2I9, CsBi3I10, AgBi2I7, and AgBiI5 perovskite solar devices.

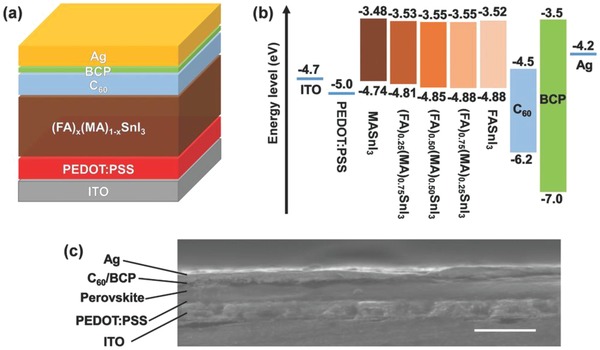

In an inverted planar (p‐i‐n) perovskite device, the hole transport layer is kept under the perovskite light absorber layer that alleviates the stringent requirement of efficient conductivity of hole transport material. Polymeric organic HTM PEDOT:PSS is used in such devices. PEDOT:PSS is used as a HTM in FASnI3 perovskite solar cells in an inverted planar (p‐i‐n) architecture and at present has reported a maximum SPCE of 8.12% in FA0.75MA0.25SnI3 in lead‐free tin‐based perovskite with a V OC of 0.61 V.145 The PEDOT:PSS with intercalated polyethylene glycol (PEG) used as a HTM in FASnI3 perovskite solar cell alleviates the energy level mismatch between the perovskite light absorber and PEDOT:PSS as HTM. As a consequence, the SPCE increased from 2.01 to 5.12% in the forward scan.146 The inverted planar (p‐i‐n) device structure employed for antimony‐based MA3Sb2I9 perovskite films has reported a SPCE of 0.5% with a V OC of 0.89 V.147 Additives are added into PEDOT:PSS in order to enhance the conductivity and morphology of PEDOT:PSS films. Polyorganic solvents such as dimethyl sulfoxide (DMSO), dimethylformamide (DMF), and ethylene glycol have been used as additives in lead‐free perovskite device fabrication.148 The addition of additive in PEDOT:PSS films leads to enhancement in efficient hole extraction and collection rate attributed to the strong dipole–dipole or dipole–charge interactions between the polar additive and PEDOT:PSS used as a HTM in fabricated perovskite device.149 PEDOT:PSS as a HTM has been employed in lead‐free MASnI3, FASnI3, FASnI3Br, FA1− xMAxSnI3, MA3Bi2I9, MA3Sb2I9, and Cs3Sb2I9 reported perovskite solar devices. Figure 4 shows the device structure and energy band diagram of (FA)x(MA)1− xSnI3 perovskite solar cell.150 The use of Spiro‐OMeTAD as a HTM damages the perovskite film. In order to overcome this issue, inverted planar (p‐i‐n) perovskite solar cells of MASnI3 have been prepared by using PEDOT:PSS doped with poly‐TPD as a HTM as shown in Figure 4.150 Figure 4 shows the (a) schematic device structure of (FA)x(MA)1− xSnI3 perovskite solar cell, (b) band alignment diagram, and (c) cross‐sectional SEM image of a completed device (scale bar: 500 nm).[150] Addition of poly‐TPD layer into PEDOT:PSS resulted into suppressed charge recombination and better efficiencies.151

Figure 4.

a) Schematic device structure of (FA)x(MA)1− xSnI3 perovskite solar cell. b) Band alignment diagram. c) Cross‐sectional scanning electron microscope (SEM) image of a completed device (scale bar: 500 nm). Reproduced with permission.150 Copyright 2017, Wiley‐VCH.

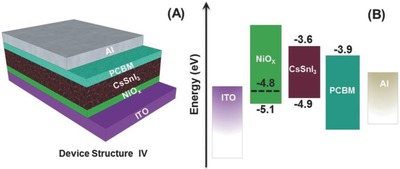

Besides organic HTMs, inorganic NiO (nickel oxide) and CuI (copper iodide) have also been used as a HTM in inverted planar (p‐i‐n) structures. NiO has a large work function of 15.2 eV in comparison to 5.2 eV for PEDOT:PSS that makes it viable for use as a HTM in perovskite solar cells reporting a higher V OC.152, 153, 154, 155 The thickness and morphology of NiO as a HTM has a direct impact on charge collection and recombination in perovskite solar devices. The use of NiO as a HTM leads to more air stability in FASnI3 perovskite inverted planar (p‐i‐n) solar cell using (PEA)2FA8Sn9I28 as a light absorber reporting a SPCE of 5.94%.156 NiOx has been employed as a HTM instead of Spiro‐OMeTAD in inverted planar structured B‐ϒ‐CsSnI3 PSCs in order to overcome the low conductivity of the undoped Spiro‐OMeTAD. The perovskite device exhibited an enhanced SPCE of 2.61% higher than that of Spiro‐OMeTAD used as a HTM.157 Figure 5 shows the device structure and corresponding energy diagram employing NiOx as a HTM in B‐ϒ‐CsSnI3 perovskite solar cells.157

Figure 5.

A) Scheme of the “inverted” structure planar B‐γ‐CsSnI3 PSC device employing NiOx as HTL and PCBM as ETL, and B) corresponding energy level diagram (the dashed line indicates NiOx work function). Reproduced with permission.157 Copyright 2016, Wiley‐VCH.

CuI has a hole conductivity greater than that of Spiro‐OMeTAD that enables CuI to improve the fill factor (FF) of the perovskite device employing it as a HTM.158 CuI has been used as a HTM in fabrication of CsSnI3 perovskite solar cells reporting a V OC of 0.55 V and enhanced air stability.159 Figure 6 shows the device architecture of CsSnI3 using CuI as a HTM and SEM image of CsSnI3 films.159

Figure 6.

a) Schematic of the device architecture used in this work; b) SEM image of a CsSnI3 film prepared with a 10 mol% excess SnI2 and spin cast at 4000 rpm from 8 wt% solution onto an ITO glass substrate coated with a 100 nm layer of CuI. Reproduced with permission.159 Copyright 2015, Royal Society of Chemistry.

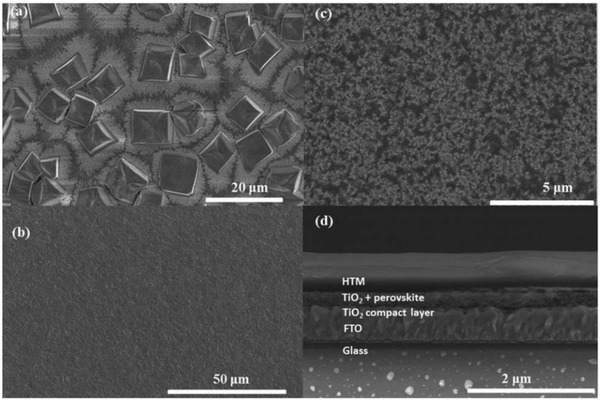

Perovskite solar cells without a HTM layer have the advantage of having simple structures, easy fabrication process, and higher stability if the work function of the metal electrode used in perovskite solar cells is close to the maximum valence band of perovskite light absorber, then absence of hole transport layer has no impact on the built‐in electric field.160 The perovskite material in HTL‐free devices works as a light absorber and a hole transport layer in such cells.161 A HTL‐free solar cell of MASnI3 has reported an efficiency of 3.15%, J SC of 21.4 mA cm−2 that has been prepared through a solvent engineering method having a device architecture of the form FTO/c‐TiO2/mp‐TiO2/MASnI3 light absorber/Au.162 HTL‐free CsSnI3 PSC has stability ten times greater than the devices using same device architecture using MAPbI3 as a light absorber.163 Inorganic metal oxides like TiO2, ZnO, SnO2 and organic fullerene derivatives like phenyl‐C60‐butynic and methyl ester (PC60BM) or PC70BM have been employed as an ETM for perovskite solar cells. The efficient ETM should have the capability to engineer the optical bandgap for maximum absorption of incident light by the perovskite light absorber layer and must have a better electron extraction and hole blocking property in order to suppress the electron–hole recombination at the interface of the device. TiO2 as an ETM has been employed in device fabrication of most of the reported lead‐free perovskite solar cells. On the top of a mesoporous TiO2 layer, the perovskite film of MASnI3 is crystallized upon spin‐coating and it penetrates into the pores of ETM. The MASnI3 films fabricated on the top of 400 nm thick mp‐TiO2 layer are better than that of prepared on an 80 nm thick mp‐TiO2 layer. The mesoporous MAPbI3− xClx perovskite films have a better film morphology than that of MASnI3 films fabricated in a similar way and architecture as shown in Figure 7 .120 Figure 8 shows the schematic energy‐level diagram of CH3NH3SnI3− xBrx compounds.106

Figure 7.

SEM images. a) Top view of a film of CH3NH3SnI3 spin‐coated onto mesoporous TiO2 (80 nm thickness). b) Top view of a spin‐coated film of CH3NH3PbI3− xClx on mesoporous TiO2 (400 nm thickness). c) Top view of a spin‐coated film of CH3NH3SnI3 on mesoporous TiO2 (400 nm thickness). d) Cross‐sectional view of a complete device active layer composed of FTO glass/compact TiO2 (50 nm)/mesoporous TiO2 infiltrated with CH3NH3SnI3 (400 nm)/Spiro‐OMeTAD (600 nm). Reproduced with permission.120 Copyright 2014, Royal Society of Chemistry.

Figure 8.

Schematic energy‐level diagram of CH3NH3SnI3− xBrx compounds. Reproduced with permission.106 Copyright 2014, Springer Nature.

By controlled crystallization, it is possible to enhance the quality of film formation.120 In another approach, solvent engineering method was employed to prepare thin films of MASnI3. A 30 nm thick TiO2 compact layer as an ETM is deposited on the substrate by atomic layer deposition system. The perovskite light absorber crystals infiltrate into the pores of mp‐TiO2 layer and remaining pores of mesoporous TiO2 layer are filled up by the HTM forming a 200 nm thick capping layer on the top of the composite structure.106

In a planar heterojunction (n‐i‐p) structure, a compact TiO2 layer is deposited on a glass that is further covered by a mesoporous TiO2 layer in order to enhance the electron collection and to avoid hysteresis loss during V–I measurements.164 By employing mp‐TiO2 as an ETM, the homogenous MASnI3 films prepared by vapor‐assisted solution process165, 166 have reported a J SC of 17.4 mA cm−2 when used as a light absorber in perovskite solar cells. The SPCE of pristine FASnI3 films was 0.003% by using mesoporous TiO2 layer as an ETM. The low value of SPCE is attributed to high background carrier density of 1019 cm−3 that leads to a metal like conductivity and device short circuiting.156 However, the addition of Br2 into FASnI3 films lowers the background carrier density of the perovskite. As a consequence of reduction in tin vacancies, the leakage current of the device is reduced that further increases the recombination lifetime and finally V OC and FF of the fabricated device and SPCE up to 5.5%.167 TiO2 as an ETM has an intrinsic low mobility and this has been a generation of deep traps by UV light that results in charge accumulation, recombination classes, and severe V–I hysteresis.41, 59, 62, 168, 169 The evaporation‐assisted method combining thermal evaporation with solution method has been employed to obtain uniform, full coverage, dense, and pinhole‐free CsSnI3 films eliminating the direct contact between HTM and ETM and reduces the consequent recombination. Evaporation‐assisted solution method makes it feasible for convenient tuning of SnF2 addition as a solvent. The conventional mesoporous n‐i‐p structure PSCs with an architecture FTO/bl‐TiO2/mp‐TiO2/CsSnI3/OMeTAD/Au has reported an efficiency of 2.2% in the device based on a 66 nm thickness of CsI.170 In CsSnBr3, the best reported SPCE so far is 2.1% that is due to the significant role of SnF2 addition as a solvent that alleviates the serious mismatch of band energy levels between the perovskite light absorber and TiO2 layer as an ETM.102

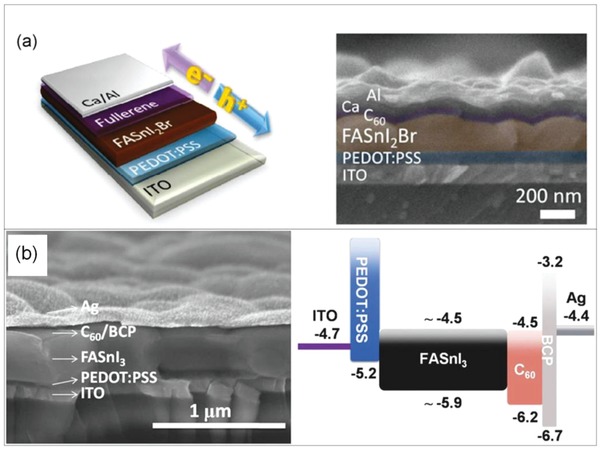

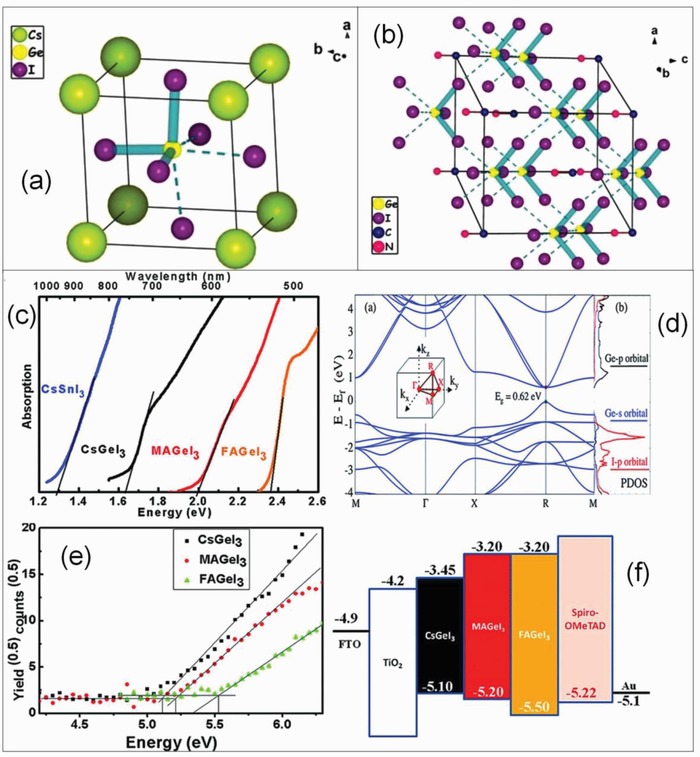

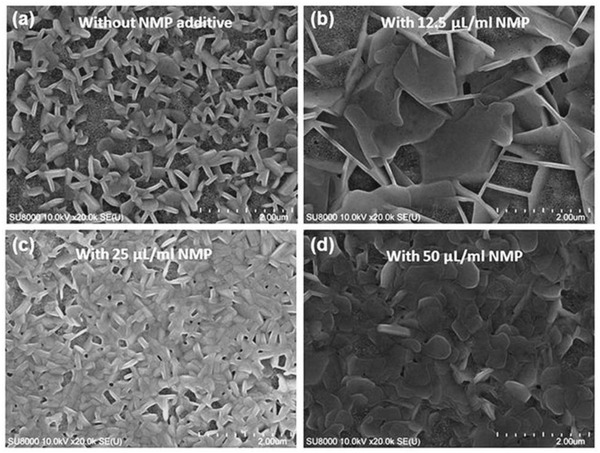

Germanium‐based perovskites have been fabricated by employing compact and mesoporous TiO2 layer as ETM and Spiro‐OMeTAD as a HTM. The fabrication films of CsGeI3 and MAGeI3 displayed a smooth morphology with a SPCE of 0.11 and 0.20% whereas that of FAGeI3 exhibited a poor morphology leading to no photovoltaic behavior. The poor performance of the device is attributed to oxidation of Ge2+ into Ge4+ during fabrication process.144 However, TiO2 requires a high‐temperature sintering and exhibits degradation in SPCE on exposure to UV light. TiO2 requires high‐temperature annealing but the substrate cannot withstand such a high temperature. The mesoporous TiO2 (n‐i‐p) devices have exhibited better efficiencies whereas inverted planar (p‐i‐n) devices suffer from hysteresis losses. Tin‐based lead‐free perovskites are considered unsuitable for planar heterojunction solar cells due to their short diffusion lengths, a SPCE of 1.72% is shown by FASnI2Br films as a light absorber with C60 as ETM suggesting the significance of perovskite film morphology on the device performance. FASnI2Br films with an architecture ITO/PEDOT:PSS/FASnI2Br/ C60/Ca/Al reported a J SC of 6.82 mA cm−2 and V OC of 0.46 mV.171 Figure 9 shows the structure of (a) FASnI2Br (SEM image)171 and (b) FASnI3 (SEM image) and energy band diagram.172

Figure 9.

a) Configuration of the FASnI2Br‐based p‐i‐n heterojunction solar cells and its cross‐sectional SEM image of a typical device. Reproduced with permission.171 Copyright 2016, Springer Nature. b) Cross‐sectional SEM image of the entire device with 10 mol% SnF2 additives, in which each layer is labeled, and schematic of energy level diagram of our FASnI3 perovskite solar cells. Reproduced with permission.172 Copyright 2016, Wiley‐VCH.

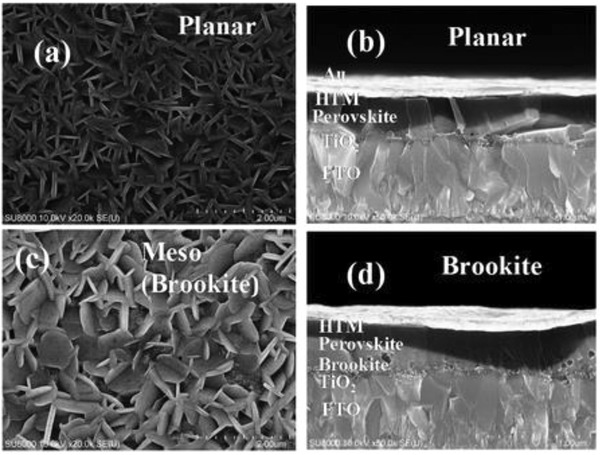

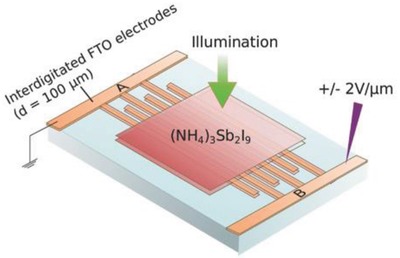

Anatase, rutile, and brookite are three stable phases in TiO2 when used as an ETM. For anatase TiO2‐based perovskite solar cells, the electron diffusion constant was ten times higher but the time constant for recombination was ten times lower than for rutile TiO2‐based one. Fast charge recombination in anatase TiO2‐based device is the result of poor charge separation in TiO2/perovskite interface.173 Figure 10 shows the MBI perovskite layer deposited on a compact, mesoporous, and brookite TiO2.174 Fullerene C60 and its derivatives such as PC60BM or PC70BM have been employed as an interfacial material at the interface between TiO2 and perovskite layer because of its high electron mobility. A self‐assembled C60 monolayer was introduced on TiO2 surface that enhances the charge separation, reduces the capacitance of TiO2 and V–I hysteresis.175 Organic ETM of PC60BM or PC70BM is more efficient to collect electrons in comparison to mp‐TiO2 in inverted planar p‐i‐n devices as they can passivate the charge traps of metal oxide176, 177, 178 and hence can reduce the nonradiative recombination channels at the surface leading to an improved SPCE with a very low hysteresis.179, 180 The perovskite layer of Cs3Sb2I9 was prepared through a single‐step spin‐coating process for an inverted planar p‐i‐n structure using architecture glass/ITO/PEDOT:PSS/Cs3Sb2I9/PC71BM/C60/bathocuproine (BCP)/Al. PC71BM/C60 is a double fullerene layer employed as an ETM to minimize the trap densities.181 Also, the perovskite solar cells with a p‐i‐n structure of ITO/PEDOT:PSS/(NH4)3Sb2I9/PC61BM/Al were synthesized to study the photovoltaic performance of (NH4)3Sb2I9 reporting a SPCE of 0.51%.147

Figure 10.

Top and cross‐sectional SEM view of MBI perovskite layer deposited on a,b) TiO2 compact layer and c,d) brookite mesoporous layer. Reproduced with permission.174 Copyright 2016, American Chemical Society.

The selection of charge extraction layers by modulating a desirable energy band alignment between the conduction band edge of CsSnI3 and LUMO of ETL is another feasible strategy. A V OC of 0.55 V was reported for CsSnI3 perovskite solar device using p‐i‐n structure ITO/CuI/CsSnI3/indane‐C60‐bisadduct ICBA/BCP/Al architecture. Here, ICBA acted as an ETM.159 BCP is used as an interfacial material in between C60 derivatives and the metal electrodes. The FF was significantly improved by using electrode interfacial layer. In an inverted planar (p‐i‐n) FASnI3 perovskite device, C60 has been employed as an ETM for efficient electron extraction.172 A solution gel derived ZnO used as an ETL bilayer fabricated at <110 °C facilitates the improved energy level alignment and enhanced charge carrier extraction and a PCBM layer is used to reduce the hysteresis and enhance the perovskite thermal stability.

ZnO can be a potential candidate to replace TiO2 as an ETM layer without causing a marked effect on the performance of PSCs.182, 183 The doping of pure ZnO nanorods with Au/Al results in high electron mobility and high electron density.184 From SCAPS‐1D, the use of ZnO nanorods as an ETM and Cu2O as a HTM for MASnI3 perovskite devices has displayed the best performance among all the PSCs. Cu2O is a suitable HTM layer in PSCs due to its high hole mobility and low electron affinity. The device displayed a maximum SPCE for ZnO nanorods/MASnI3/Cu2O structure exhibiting a J SC of 32.26 mA cm−2, V OC of 0.85 V, FF of 0.74, and SPCE of 20.23%.185 The ETM used in a perovskite solar cell has a significant impact on the SPCE of the device when bl‐TiO2 layer in Ag2Bi3I11 is replaced by bl‐SnO2, there is a significant increase in current density from 1.33 mA cm−2 (TiO2) to 2.31 mA cm−2 (SnO2) attributed to better electron extraction by SnO2 ETM.186

7. Lead‐Free Perovskites

7.1. Tin‐Based Perovskites

Tin is the most suitable candidate for substitution of lead for lead‐free perovskite solar cell because of its similar valence electronic configuration as that of lead and approximate same ionic radius of Sn2+ (115 pm) as that of Pb2+ (119 pm). It has lower value of electronegativity Sn2+ (1.96) than that of Pb2+ (2.33).237 Tin‐based perovskites have optical bandgap of 1.2–1.6 eV most suitable for their use as light absorbers, large carrier mobilities, and low exciton binding energies of 18 meV.105, 119, 187 Tin‐based perovskites are represented by the general formula ASnX3 where A can be MA+, Fa+ or Cs+ cation, and X is a halogen anion.

Methylammonium tin halides MASnX3 have a direct bandgap of 1.20–1.35 eV, electron mobility of 2320 cm2 V−1 s−1, hole carrier mobility of 322 cm2 V−1 s−1,105, 188 and long charge carrier diffusion length of more than 500 nm.117 The first completely lead‐free Sn‐based perovskite MASnI3 was processed on a mesoporous TiO2 scaffold that achieved SPCE of 8.4% under 1 sun illumination in a highly inert atmosphere in a glove box with V OC of 0.88 V, J SC of 16.8 mA cm−2, and FF of 0.42 obtained from material having optical bandgap of 1.23 eV.120 A Sn‐based perovskite model with the novel architecture of glass/ZnO:Al/TiO2/Ch3NH3Sncl3/CuI/Au, devised by Mandadapu et al.,189 has been analyzed by using the solar cell capacitance simulator (SCAPS‐ID), with the predicted parameters such as thickness 0–6 µm, defect density of 1014 cm−3 of light absorber layer, and bandgap 1.3 eV. The model achieved a SPCE of 24.82%, V OC of 1.04 V, J SC of 3.50 mA cm−2, and FF of 0.78. The excellent results of this model clearly signify the enormous potential of Sn‐based perovskites for their efficient use in solar cells. Since then an extensive work has been carried out on preparation and characterization of Sn‐based perovskites material to examine their structural, optical, and charge transport abilities for efficient use as light absorber in perovskite solar cells.188 The perovskite solar cells with CH3NH3SnBr3 as light absorber reported a SPCE of 0.35% for coevaporation and 0.12% for sequential deposition method.190 The composition of a halide anion in mixed halide tin‐based perovskites has an influence on the photovoltaic performance exhibited by them. The mixed halide tin‐based perovskite MASnI3− xBrx was investigated by altering the Br−/I− ratio, it was reported that MASnBr3 as a light absorber displays more V OC (0.88 V) and less J SC (8.26 mA cm−2) in comparison to MASnIBr2 having V OC (0.82 V) and J SC (12.33 mA cm−2). Among all MASnI3− xBrx perovskites, MASnIBr2 has the highest reported SPCE of 5.73% under stimulated full sunlight.98 Also, the position of band edge of mixed halides perovskites, MASnI3− xBrx can be tuned from 954 nm (MASnI3) to 577 nm (MASnBr3) thus displaying a remarkable tunability of color. Also the mixed halides tin‐based perovskites MASnIBr2− xClx has been fabricated for carbon‐based mesoscopic cells devoid of ETM and HTM layers by varying the composition of SnCl2/SnBr2. The solar device with MASnIBr1.8Cl0.2 achieved the best photovoltaic performance of 3.11% with a long‐term stability in air. The device exhibited excellent charge recombination and dielectric relaxation properties.191 However, tin‐based perovskites have low values of SPCE due to fast oxidation of divalent Sn2+ into a more stable state Sn4+ and easy formation of Sn vacancies due to small value of formation energy. As a consequence of it, there is a large charge carrier recombination and high levels of self p‐doping in Sn‐based perovskites films. Thus, a lot of research has been carried out to suppress oxidation of divalent Sn2+. SnF2 has been added to such films to inhibit the oxidation process so as to reduce the background carrier hole density by filling Sn vacancies. The entire fabrication process is carried out in an inert atmosphere in the glove box encapsulated by hot melt polymer film, a glass cover slide with sealed edges so as to avoid the oxidation of perovskite film on exposition to ambient air that could cause its fast degradation. Addition of 5‐ammonium valeric acid iodide to MASnI3 suppressed oxidation of Sn2+ for better stability of the perovskite device.192 Hypophosphorous acid was also used for reducing the oxidation of divalent Sn2+ thereby reducing the number of Sn vacancies and charge carrier density. As a consequence of it, there is enhancement in charge recombination lifetime by fourfold than that of the control device.193

A SPCE of 2.14% was reported for a perovskite solar cell having MASnI3 with SnF2 additive as a light absorber. The fabricated device achieved V OC of 0.45 V, J SC of 11.48 mA cm−2, and FF of 0.48 and has long lifetimes of 200 h under 1 sun degradation conditions.194 However, an excess of SnF2 deteriorates the perovskite film morphology and device performance indicating that SnF2 concentration must be kept very low; as a result, the background charge carrier density remains too large to achieve high efficiency, thus it becomes mandatory to explore new and more efficient ways to alleviate the background charge carrier density for better performance of the perovskite solar cell. It was also proposed that the fabrication of perovskite film must be carried out under a reducing vapor atmosphere to reduce the hole density in MASnI3 films by inhibiting the oxidation of Sn2+ during the fabrication process. The excess use of SnF2 induces the phase separation in perovskite films. As a result of exposure to excess SnF2, plate like aggregates are formed in the film, thus it was resolved to use nonsolvent dripping process along with SnF2 via the formation of SnF2–pyrazine complex. Pyrazine has a strong binding affinity to SnF2 thereby suppressing the phase separation induced by the excess use of SnF2.195 Table 4 shows some photovoltaic parameters of methylammonium tin halides.

Table 4.

Photovoltaic parameters of methylammonium tin halides (MASnX3)

| Light absorber | E g | V OC | J SC | FF | SPCE | Architecture | Ref. |

|---|---|---|---|---|---|---|---|

| MASnI3 | 1.23 | 0.88 | 16.8 | 0.42 | 6.4 | FTO/c‐TiO2/mp‐TiO2/absorber/Spiro‐OMeTAD/Au | 120 |

| MASnI3 | 1.3 | 0.716 | 15.18 | 0.50 | 5.44 | FTO/c‐TiO2/absorber/Spiro‐OMeTAD/Au | 196 |

| MASnI3+SnF2 | 1.3 | 0.32 | 21.4 | 0.46 | 3.15 | FTO/c‐TiO2/mp‐TiO2/absorber/Au | 162 |

| MASnI3 | 1.3 | 0.38 | 12.1 | 0.36 | 1.7 | ITO/PEDOT:PSS/poly‐TPD/absorber/C60/BCP/Ag | 151 |

| MASnI3 | 1.26 | 0.27 | 17.4 | 0.39 | 1.86 | FTO/c‐TiO2/mp‐TiO2/absorber/PTAA/Au | 197 |

| MASnIBr2 | 1.75 | 0.82 | 12.33 | 0.57 | 5.73 | FTO/c‐TiO2/mp‐TiO2/absorber/Spiro‐OMeTAD/Au | 106 |

| MASnBr3 | 2.15 | 0.88 | 8.26 | 0.59 | 4.27 | FTO/c‐TiO2/mp‐TiO2/absorber/Spiro‐OMeTAD/Au | 106 |

| MASnBr3 | 2.2 | 0.50 | 4.27 | 0.49 | 1.12 | FTO/c‐TiO2/mp‐TiO2/absorber/P3HT/Au | 190 |

| MASnBr3 | 1.41 | 0.20 | 4.5 | 0.36 | 0.3 | ITO/PEDOT:PSS/absorber/PCBM/Bis‐C60/Ag | 198 |

| MASnI3+hydrazine vapor | 1.3 | 0.38 | 19.9 | 0.51 | 3.80 | FTO/c‐TiO2/mp‐TiO2/absorber/PTAA/Au | 199 |

| MASnI3+SnF2 | – | 0.45 | 11.8 | 0.40 | 2.14 | FTO/PEDOT:PSS/absorber/C60/BCP/Ag | 194 |

| en[MASnI3]+SnF2 | 1.4 | 0.43 | 24.3 | 0.63 | 6.63 | FTO/c‐TiO2/mp‐TiO2/absorber/PTAA/Au | 142 |

| MASnI3+SnF2 | 0.46 | 21.4 | 0.42 | 4.29 | ITO/PEDOT:PSS/absorber/C60/BCP/Ag | 150 | |

| (FA)0.75(MA)0.25SnI3 | 1.33 | 0.61 | 21.2 | 0.62 | 8.12 | ITO/PEDOT:PSS/absorber/C60/BCP/Ag | 150 |

| (FA)0.75(MA)0.5SnI3 | 1.33 | 0.53 | 21.3 | 0.52 | 5.92 | ITO/PEDOT:PSS/absorber/C60/BCP/Ag | 150 |

| FASnI3 | 1.36 | 0.48 | 21.3 | 0.64 | 6.60 | ITO/PEDOT:PSS/absorber/C60/BCP/Ag | 150 |

| MASnIBr2− xClx +0%SnCl2+100% SnBr2 | 1.81 | 0.31 | 13.37 | 0.52 | 2.18 | Glass/FTO/TiO2/absorber/carbon | 191 |

| 10% SnCl2+90% SnBr2 | 1.87 | 0.38 | 13.99 | 0.57 | 3.11 | Glass/FTO/TiO2/absorber/carbon | 191 |

| 25% SnCl2+75% SnBr2 | 1.97 | 0.35 | 11.06 | 0.47 | 1.87 | Glass/FTO/TiO2/absorber/carbon | 191 |

| 50% SnCl2+50% SnBr2 | 1.49 | 0.24 | 9.33 | 0.47 | 1.07 | Glass/FTO/TiO2/absorber/carbon | 191 |

| 75% SnCl2+25% SnBr2 | 1.36 | 0.19 | 13.34 | 0.32 | 0.81 | Glass/FTO/TiO2/absorber/carbon | 191 |

| 100% SnCl2+0% SnBr2 | 1.25 | 0.12 | 19.12 | 0.30 | 0.74 | Glass/FTO/TiO2/absorber/carbon | 191 |

Formamidinium tin iodide FASnI3 has a direct bandgap of 1.41 eV closer to the requisite bandgap value for use in perovskite solar cells and do possess a single stable phase over a broad temperature range up to 200 °C. Sn‐based perovskite FASnI3 is more stable than MASnI3 due to suppression of oxidation of Sn2+ by FA+.188, 200 FASnI3 is first used as light absorber in perovskite solar cell by Koh et al.109 The fabricated films displayed a SPCE of 2.1%, J SC of 24.5 mA cm−2, V OC of 0.2 V, and FF of 0.36. Additive SnF2 is incorporated into FASnI3 to suppress the oxidation of Sn2+ for better film morphology. A SPCE of 4.8% has been achieved by incorporating SnF2 in FASnI3 to form a complex with SnF2 thereby improving the morphology of the perovskite film and slowing down the rate of crystallization of perovskite thin film. Antisolvent process can play a very significant role in preparing the uniform and pinhole‐free compact thin film with the use of diethyl ether as an antisolvent. A significant SPCE of 6.22% has been achieved in FASnI3 by using antisolvent process under forward scan with a small photocurrent hysteresis and a highly reproducibility.172

SnF2–pyrazine complex has been used to further enhance the morphology of FASnI3 perovskite that achieved a SPCE of 4.8%, V OC of 0.32 V, J SC of 23.7 mA cm−2, and improved stability. The encapsulated FASnI3 films displayed a stable performance for over 100 d maintaining 98% of their initial efficiency.195Chlorobenzene is also used as an antisolvent for FASnI3 films. The A‐site cation in Sn‐based perovskite has a significant effect on photovoltaic performance. The use of diethylammonium (en) and FA+ at A‐site of tin‐based perovskite results in a wider bandgap and an improved stability of photovoltaic performance. The complex en [FASnI3] displayed a SPCE of 7.1% and retained 96% of its initial efficiency over 1000 h without encapsulation. Also, the addition of en at A‐site cation along with (FA/MA/Cs) SnI3 cannot reduce dimensionality of the perovskite to 2D.192

The first mixed design composition in tin‐based perovskite was reported on FA1− xMAxSnBr3 with a cubic structure. The bandgap of the perovskite film was varied from 2.4 eV (x = 0) to 1.92 eV (x = 0.82) but the device displayed no photovoltaic performance.201

Another mixed A‐site cation perovskite (FA)x(MA)1− xSnI3 has been investigated for its use as a light absorber in a perovskite solar cell with an invested structure. By tuning the ratio of FA and MA yields the different values of SPCE. A SPCE of 8.12% is achieved for (FA)0.75(MA)0.25SnI3 with V OC of 0.61 V and bandgap of 1.33 eV. The high SPCE is attributed to the improved perovskite film morphology and reduced recombination process.150

Phenylethylammonium (PEA) is substituted at A‐site in tin‐based perovskite and pure 3D, 2D‐3D mixture and pure 2D perovskite are fabricated by tuning the ratio of PEA from 0 to 100% such that inside every two metal halide octahedral layers, there is bilayer of PEA. The resulting mixed cation perovskite is (PEA)2(FA)n −1SnnI3 n +1 where n is the number of tin iodide layers in the structure unit (n ≥ 1). For n = 3, 4, optical bandgaps of 1.5 and 1.42 eV are achieved. The 2D tin perovskite displayed better moisture stability than their 3D counterparts. Incorporation of 20% PEA into FA leads to low‐dimensional mixed perovskite (PEA)2FA8Sn9I28. The as‐fabricated solar cells achieved a SPCE of 5.9% with V OC of 0.55 V and J SC of 14.4 mA cm−2.156

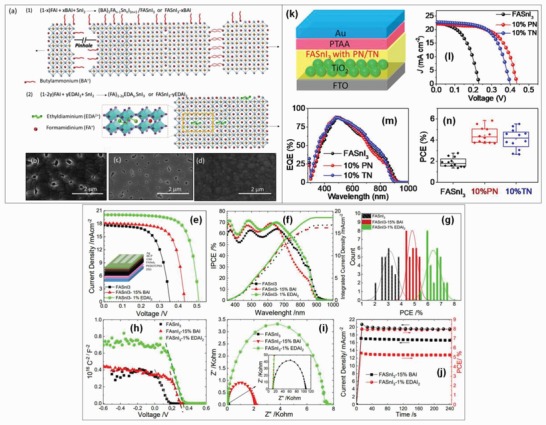

The incorporation of phenylethylammonium iodide (PEAI) obtained by evaporating it at the bilateral interface of a FASnI3 film enhances the V OC and FF of the mixed perovskite solar cell due to improvement in service coverage and formation of 2D‐3D bulk heterojunction structure whereas the presence of LiF at A‐site in tin‐based perovskite by evaporating it at the bilateral interface of FASnI3 film reduces the work function of PEDOT:PSS and aids in hole extracting at the ITO/PEDOT:PSS interfacial layer. A SPCE of 6.98% is achieved for LiF thickness of 5 nm in perovskite films with a V OC of 0.47 V and FF of 0.74, respectively.202 The incorporation of BAI as an additive to the tin‐based perovskite film as a light absorber changes the orientation of the crystal growth thereby enhancing the connectivity of the crystal grains. The fabricated FASnI3 devices doped with 15% BAI exhibited a SPCE of 5.5% in contrast to the pristine FASnI3 films having 4% efficiency.203 Similarly, the doping of EDAI2 into FASnI3 films results in the removal of pinholes in the perovskite films, inhibition of oxidation of Sn2+ into Sn4+, and passivation of surface defect states. The 1% EDAI2‐doped FASnI3 perovskite films displayed an efficiency of 8.9% with a stability of over 1400 h with only slight degradation for more than 200 h in contrast to pristine FASnI3 films with a SPCE of 7.4% only. The high efficiency is attributed to improved perovskite film morphology and passivation of surface defects that enable better separation of charge carriers and suppression of oxidation of Sn2+ to Sn4+.203 Figure 11 a shows the schematic representations of perovskite crystals in the presence of BAI and EDAI2 additives; top‐view SEM images of (b) pristine FASnI3, (c) FASnI3‐BAI 15%, and (d) FASnI3‐EDAI2 1%; (e) current–voltage curves, (f) corresponding IPCE spectra with integrated current densities, (g) histograms of 30 fresh cells fabricated under the same experimental conditions, (h) Mott–Schottky plots, (i) Nyquist plots obtained from electrochemical impedance spectra (EIS), and (j) stabilized power‐conversion efficiencies and photocurrent densities of the FASnI3‐BAI 15% and FASnI3‐EDAI2 1% devices for 240 s.203

Figure 11.

a) Schematic representations of perovskite crystals in the presence of BAI and EDAI2 additives; top‐view SEM images of b) pristine FASnI3, c) FASnI3‐BAI 15%, and d) FASnI3‐EDAI2 1%; e) current–voltage curves, f) corresponding IPCE spectra with integrated current densities, g) histograms of 30 fresh cells fabricated under the same experimental conditions, h) Mott–Schottky plots, i) Nyquist plots obtained from electrochemical impedance spectra (EIS), and j) stabilized power‐conversion efficiencies and photocurrent densities of the FASnI3‐BAI 15%and FASnI3‐EDAI2 1% devices for 240 s; Reproduced with permission.203 Copyright 2018, Royal Society of Chemistry. k) Device structure, l) J–V curves, m) EQE curves, and n) PCE statistics of the FASnI3 solar cells with and without 10% PN and 10% TN; Reproduced with permission.206 Copyright 2018, American Chemical Society.

Crystalline FASnI3 with the orthorhombic a‐axis out‐of‐plane direction was fabricated by mixing (0.08 m) 2D tin perovskite with (0.92 m) 3D tin perovskite in a planar p‐i‐n structure and achieved a SPCE of 9% with a V OC of 0.25 V with more efficient collection of charge and stability in ambient air.145 The introduction of a low‐dimensional interlayer to the interface in a FASnI3 perovskite solar cell can improve the morphology of the film reducing the number of trap sites. As a result, the charge accumulation and recombination in the device is suppressed leading to a high SPCE of 7.05%.204

The bifunctional ammonium cations, 2‐hydroxyethyl ammonium OH(CH2)NH3 +(HEA+), are incorporated into FASnI3 resulting in a mixed tin‐based perovskite HEAxFA1− xSnI3 where x = 0–1 and can act as a light absorber in carbon‐based mesoscopic solar cells. As a consequence of incorporation of HEA+, the crystal lattice changed from orthorhombic to rhombohedra (x = 0.2–0.4). For x ≥ 0.6, a 3D vacant perovskite (HEA)xFA1− xSn0.67I2.33 with a tetragonal structure is formed. The light absorbers in this series are synthesized by employing mesoporous solar cells using one‐step drop‐cast (DC), two‐step solvent–solvent extraction (SE), and a solvent extraction by using ethylenediammonium diiodide (EDAI2) as an additive. The fabricated solar device HEA0.4FA0.6SnI3 displayed the photovoltaic parameters with V OC of 0.371 V, J SC of 18.52 mA cm−2, FF of 0.562, and a stable SPCE of 3.9% for a period of 340 h.205 The FASnI3 perovskite light absorbers incorporated with a diammonium cation such as propylenediammonium (PW) and trimethylenediammonium (TN) display better efficiency than the pristine FASnI3 solar cell. The FASnI3 light absorbers mixed with 10% TN and 10% PN displayed a SPCE of 5.53 and 5.58% with a better film morphology along with retaining their 3D perovskite structure.206 Figure 11 shows the (k) device structure, (l) J–V curves, (m) EQE curves, and (n) PCE statistics of the FASnI3 solar cells with and without 10% PN and 10% TN.206 The addition of bromide into FASnI3 crystal lattice reduces the p‐doping in the perovskite film by reducing the Sn vacancies thereby lowering the current density of the light absorbers. As a result, there is an enhancement in charge recombination lifetime that increases V OC and FF of the devices having M‐TiO2 as electron transport layer. The fabricated devices achieved SPCE of 5.5% with high stability of encapsulated devices over 1000 h under continuous illumination including UV region.167 Table 5 shows some photovoltaic parameters of formamidinium tin halides.

Table 5.

Photovoltaic parameters of formamidinium tin halides (FASnX3)

| Light absorber | E g | V OC | J SC | FF | SPCE | Architecture | Ref. |

|---|---|---|---|---|---|---|---|

| FASnI3+SnF2 | 1.41 | 0.24 | 24.5 | 0.36 | 2.1 | FTO/c‐TiO2/mp‐TiO2/absorber/Spiro‐OMeTAD/Au | 195 |

| FASnI3+SnF2 pyrazine | 1.4 | 0.32 | 23.7 | 0.63 | 4.8 | FTO/c‐TiO2/mp‐TiO2/absorber/Spiro‐OMeTAD/Au | 109 |

| FASnI3+diethyl ether | 1.36 | 0.47 | 22.1 | 0.60 | 6.22 | ITO/PEDOT:PSS/absorber/C60/BCP/Ag | 172 |

| FASnI3+SnF2 | 1.4 | 0.48 | 21.3 | 0.64 | 6.6 | ITO/PEDOT:PSS/absorber/C60/BCP/Ag | 150 |

| FASnI3+SnF2 | 1.4 | 0.38 | 23.1 | 0.60 | 5.27 | FTO/c‐TiO2/mpTiO2/ZnS/absorber/PTAA/Au | 207 |

| en[FASnI3] | 1.5 | 0.48 | 22.5 | 0.66 | 7.14 | FTO/c‐TiO2/mp‐TiO2/absorber/PTAA/Au | 208 |

| FA0.25MA0.75SnI3+SnF2 | 1.28 | 0.48 | 20.7 | 0.45 | 4.49 | ITO/PEDOT:PSS/absorber/C60/BCP/Ag | 150 |

| FA0.50MA0.50SnI3+SnF2 | 1.33 | 0.53 | 21.3 | 0.52 | 5.92 | ITO/PEDOT:PSS/absorber/C60/BCP/Ag | 150 |

| FA0.75MA0.25SnI3+SnF2 | 1.33 | 0.61 | 21.2 | 0.62 | 8.12 | ITO/PEDOT:PSS/absorber/C60/BCP/Ag | 150 |

| FA0.8Cs0.2SnI3 | 1.41 | 0.24 | 16.05 | 0.35 | 1.4 | ITO/PEDOT:PSS/absorber/PCBM/Bis‐C60/Ag | 198 |

| FASnI3 | 1.37 | 0.31 | 18.36 | 0.67 | 3.85 | ITO/PEDOT:PSS/absorber/C60/BCP/Ag | 202 |

| FASnI3+50% PEAI | 1.38 | 0.38 | 19.96 | 0.69 | 5.28 | ITO/PEDOT:PSS/absorber/C60/BCP/Ag | 202 |

| (PEA)2(FA)2Sn2I28+SnF2 | 1.789 | 0.59 | 14.4 | 0.69 | 5.94 | ITO/NiOx/absorber/PCBM/Al | 156 |

| (BA)2(MA)3Sn4I13+SnF2 | 1.42 | 0.229 | 24.1 | 0.45 | 2.53 | FTO/c‐TiO2/mp‐TiO2/absorber/PTAA/Au | 209 |

| FASnI3+LiF (0 nm) | – | 0.38 | 19.65 | 0.71 | 5.04 | ITO/PEDOT:PSS/absorber/C60/BCP/Ag | 202 |

| FASnI3+LiF (3 nm) | – | 0.42 | 19.83 | 0.73 | 5.96 | ITO/PEDOT:PSS/absorber/C60/BCP/Ag | 202 |

| FASnI3+LiF (5 nm) | – | 0.47 | 20.00 | 0.73 | 6.77 | ITO/PEDOT:PSS/absorber/C60/BCP/Ag | 202 |

| FASnI3+LiF (8 nm) | – | 0.45 | 16.66 | 0.65 | 4.71 | ITO/PEDOT:PSS/absorber/C60/BCP/Ag | 202 |

| FASnI3 | – | 0.36 | 17.6 | 0.62 | 4.0 | ITO/PEDOT:PSS/absorber/C60/BCP/Ag | 203 |

| FASnI3+15% (BAI) | 1.40 | 0.44 | 18.0 | 0.69 | 5.5 | ITO/PEDOT:PSS/absorber/C60/BCP/Ag | 203 |

| FASnI3+1% EDAI2 | 1.43 | 0.51 | 20.0 | 0.71 | 7.4 | ITO/PEDOT:PSS/absorber/C60/BCP/Ag | 203 |

| FASnI3+2% EDAI2 | 1.44 | 0.58 | 21.3 | 0.71 | 9.6 | ITO/PEDOT:PSS/absorber/C60/BCP/Ag | 203 |

| FASnI3 | – | 0.525 | 24.1 | 0.71 | 9.0 | ITO/PEDOT:PSS/absorber/C60/BCP/Al | 145 |

| HEA0.4FA0.6SnI3 +3%EDAI2 | – | 0.371 | 18.52 | 0.562 | 3.9 | – | 205 |

| FASnI3+10%TN | – | 0.398 | 22.72 | 0.610 | 5.53 | FTO/mp‐TiO2/absorber/PTAA/Au | 206 |

| FASnI3+10%PN | – | 0.435 | 22.15 | 0.606 | 5.85 | FTO/mp‐TiO2/absorber/PTAA/Au | 206 |

Cesium tin iodide perovskite CsSnI3 possess a direct bandgap of 1.30 eV, a melting point of 435 °C indicating its better thermal stability and a 3D orthorhombic structure110, 210, 211 whereas cesium tin bromide perovskite CsSnBr3 has a bandgap of 1.7 eV.102 Cesium‐based tin perovskite has a high hole mobility of 585 cm−1 V−1 s−1, low exciton binding energy (180 meV) than MAPbI3.119, 187 The melt‐synthesized CsSnI3 ingots containing high‐quality large single crystal grains have been reported to have bulk carrier lifetime more than 6.6 ns, doping concentration of about 4.5 × 1017 cm−3, and minority carrier diffusion lengths approaching to 1 µm.118 A SPCE of 23% was predicted for optimized single crystal solar cells CsSnI3 highlighting their great potential for use in perovskite solar cell. The CsSnI3 was first used in a Schottky‐type perovskite solar cell consisting of simple layer architecture of ITO/CsSnI3/Au/Ti on a glass substrate that achieved an efficiency of 0.9%. A HTM‐free CsSnI3 perovskite solar cell with SnI2 as an additive displayed an efficiency of up to 2.76% with a V OC of 0.43 V and FF of 0.39.212 The use of excess SnI2 as an additive in CsSnI3 not only suppress Sn2+ vacancies but also reduces p‐type conductivity thereby producing a SPCE of 4.8% in CsSnI3 perovskite solar cells.213 The thin films of CsSnIBr3 were fabricated with the addition of hypophosphorous acid (HPA) with thermal stability up to 473 K achieving a SPCE of 3% that last for over 77 d.193 The results of a computational study on mixed cesium perovskite RbyCs1− ySn (BrxI3− x)3 as a light absorber have revealed that the substitution of Rb+ for Cs+ enhanced the quality of perovskite film and its practical applicability in perovskite solar cells.214 Another study on CsSnI3 and CsSnI3− xBrx as light absorbers in n‐i‐p devices structure reported an efficiency of 2%. CsSnI3 has a small bandgap of 1.27 eV to a near‐infrared absorption onset to 950 nm and exhibited a high charge carrier density up to27.67 mA cm−2.215

An excess of SnCl2 and SnI2 to CsSnI3 perovskite films can have masked influence on both stability and SPCE of the corresponding cells reported to be of 3%. An extensive monitoring of oxidation of CsSnI3 in the air by using additives SnCl2, SnBr2, and SnI2 has been carried out to measure electronic, optical absorption spectrum with time and reported that it exhibits the highest stability by inhibiting the crystallization/decomposition.163, 192 The addition of SnF2 lowers the background charge carrier density by neutralizing traps.214, 216 The mesostructured CsSnI3 displayed a SPCE of 2.02% with the addition of 20% SnF2 as an additive. Also a spectral response of 950 nm is demonstrated with SnF2 addition. As a result, the concentration of the defect is reduced that further suppressed the background charge carrier density.215 The anionic substitution of Br− in CsSnI3− xBrx (0 ≤x ≤ 3) results in change in crystal structure from orthorhombic to cubic framework for CsSnBr3 enhancing the V OC and J SC as a result of decrease in tin vacancies and low charge carrier densities of 1015 cm−3.217 The carrier lifetime gets enhanced and the PL line width has reduced when the temperature decreases below 110 K due to the phase transition from orthorhombic to tetragonal phase in CsSnX3 that improved the solar cell performance.218

The evaporation method comprising of thermal evaporation with solution method has been used to produce smooth uniform dense pinhole‐free CsSnI3 films that achieved a SPCE of 1.86% with V OC of 0.265 V, J SC of 15.25 mA cm−2, and FF of 0.46, by using the architecture (FTO/bl‐TiO2/mp‐TiO2/absorber/Spiro‐OMeTAD).102The undesirable p‐doping of CsSnI3 perovskite films can be reduced by the addition of piperazine that can improve the morphology of the film as well as can alleviate the crystallization of excess SnI2 at the same time. With the use of piperazine as an additive, CsSnI3 perovskite devices displayed a SPCE of 3.83%.219 Table 6 shows some photovoltaic parameters of cesium‐based perovskites. Figure 12 shows schematic diagram along with the performance of CsSnI3‐based perovskite solar cell.170

Table 6.

Photovoltaic parameters of cesium‐based perovskites

| Light absorber | E g | V OC | J SC | FF | SPCE | Architecture | Ref. |

|---|---|---|---|---|---|---|---|

| CsSnI3+SnI2 | 1.3 | 0.38 | 25.71 | 0.49 | 4.81 | FTO/c‐TiO2/mp‐TiO2/absorber/PTAA/Au | 213 |

| CsSnI3+SnI2 | 1.3 | 0.43 | 12.3 | 0.39 | 2.76 | ITO/CuI/absorber/ICBA/BCP/Al | 159 |

| CsSnI3 | 1.3 | 0.52 | 10.2 | 0.62 | 3.31 | ITO/NiOx/absorber/PCBM/Al | 157 |

| CsSnI3+SnCl2 | 1.3 | 0.50 | 9.89 | 0.68 | 3.56 | ITO/absorber/PC61 BM/BCP/Al | 163 |

| CsSnI3+SnF2 | 1.27 | 0.20 | 22.7 | 0.29 | 1.66 | FTO/TiO2/mp‐TiO2/absorber/Spiro‐OMeTAD/Au | 217 |

| CsSnI3+SnF2 | 1.25 | 0.17 | 30.8 | 0.34 | 1.83 | FTO/c‐TiO2/mp‐TiO2/absorber/PTAA/Au | 199 |

| CsSnI3+SnF2 | 1.3 | 0.24 | 27.7 | 0.37 | 2.0 | FTO/c‐TiO2/mp‐TiO2/absorber/m‐MTDATA/Au | 215 |

| CsSnI3 | 1.3 | 0.42 | 4.8 | 0.22 | 0.88 | ITO/absorber/Au/Ti | 212 |

| CsSnBr3+SnF2 | 1.8 | 0.45 | 2.4 | 0.55 | 0.55 | ITO/MoO3/absorber/C60/BCP/Ag | 220 |