Abstract

The use of lemongrass oil as food preservative present great potential, however it has high volatility and intense aroma, making them limited to be used as food additives. Microencapsulation processes become interesting alternatives to overcome these issues. This work investigated the influence of the partial replacement of gum arabic by modified starches on the microencapsulation of lemongrass oil as core material. Gum arabic and its combinations with modified starches: cassava and corn maltodextrins with different dextrose equivalent (DE) and octenyl succinic anhydride modified starch (OSA-starch) were studied. The emulsions were spray dried at controlled temperature of 170 °C. The evaluated parameters particles solubility, moisture content, and oil composition did not showed significant differences among the treatments. Replacement of gum arabic by maltodextrin DE20 and OSA-starch resulted in higher wetting times. Oil retention was increased (81.2%) when gum arabic was replaced by OSA-starch; the treatment without substitution, with only gum arabic had 67.5% of oil retention. Application of OSA-starch in association with gum arabic in microencapsulation by spray drying of lemongrass oil presented greater potential to be used due to its higher oil retention. Polymer blends should be assessed since they present advantages over individually applied polymers. Although maltodextrins show some differences compared to the treatment with only gum arabic, it may also be a viable alternative because of its lower cost.

Keywords: Microencapsulation, Maltodextrin, Gum arabic, Volatile components

Introduction

Oils are rich in bioactive compounds, have several functional effects and can be industrially used. Bioactive compounds are usually found mainly in vegetables, and promote health and well-being, making the body more balanced (Valdes et al. 2017), favoring homeostasis, which serves as a first-line barrier against the invasion of pathogens, not only by controlling infections, but also facilitating immune responses (Kugapreethan et al. 2017). In addition to promoting aroma, essential oils are used as food additives.

Lemongrass oil is usually obtained by steam distillation of the lemongrass plant, has a large consumption in the form of tea in Brazil (Gaonkar et al. 2016) and it contains important monoterpenes, basically citral that is a natural mixture of two isomers. It has antimicrobial function (Balakrishnan et al. 2014) and is mostly used in order to reduce proliferation of Listeria monocytogenes in food (Hadjilouka et al. 2017). The oil has sensory qualities, presents bioactive compounds and can be used for the control of microorganisms.

However, its direct application in food is restricted due to its intense flavor, low bioactivity and intense volatility (Gharib et al. 2017). In order to ensure bioavailability and decrease their volatility the oils can be encapsulated (Liolios et al. 2009). The aroma of microencapsulated oil does not have the same intensity as when it is in liquid form, therefore this form it is preferred for food formulations.

Encapsulation is a technique used to protect solids or liquids by coating compounds within the polymer matrix, improving their stability. This technique can be used in many food products to mask flavor and for antimicrobial and antioxidant use (Rutz et al. 2017). During the drying process, the evaporation of water is fast and the entrapment of organic volatile compounds occurs quasi-instantaneously in the polymeric matrix.

Active ingredients are encapsulated to ensure improved stability in final products and during processing, to decrease evaporation and degradation of volatile actives (He et al. 2016). There are several ways of encapsulating bioactive compounds, for example, by the spray drying and freeze drying techniques (Rezende et al. 2018). Gum arabic has been widely used as an encapsulating agent (Binsi et al. 2017), although, many studies suggested its replacement by modified starches and maltodextrins, due to its cost and changes in properties of the wall materials (Rajabi et al. 2015). Modified starch with octenyl succinic anhydride (OSA-starch) is used because it can lead to the formation of less porous materials (Fontes et al. 2013), and due to its amphiphilic nature and the consequent biosafety of this starch derivative, it can be an ideal wall material for spray drying (Domian et al. 2018). OSA-starch performed better emulsification properties because of the substitution of functional groups (ocetyl succinic groups) that has both hydrophilic and hydrophobic characteristic (Bajaj et al. 2019) and has been used for encapsulation of hydrophobic compounds, such as vitamin E (Hategekimana et al. 2015). Maltodextrin has been widely used as a wall material, it was shown to be effective in the microencapsulation of bioactive components of saffron by spray drying, where it was used to form blends with gum arabic and gelatin (Rajabi et al. 2015).

Although gum arabic is considered a suitable wall material, its cost is relatively high, which is a limitation to its use. Thus, the search for alternatives polymers for gum arabic has been encouraged. Therefore, the aim of this work was to assess the differences in microparticle characteristics with different modified starches in replacement by gum arabic.

Materials and methods

Material

Lemongrass oil (Cymbopogon flexuosus) was purchased from Ferquima® (Vargem Grande, Brazil). Gum arabic (Colloides Naturels Brasil, Sao Paulo, Brazil), corn maltodextrin DE10 and DE20 (Maltogil, Cargil, Sao Paulo, Brazil), cassava maltodextrin DE10 (Neomalt 5010B, AgroComercial Mandioca S.A., Maripa, Brazil), and modified starch with octenyl succinic anhydride (OSA-starch) (Capsul®, National Starch Food Innovation, São Paulo, Brazil) were used as carrier materials.

Preparation of emulsions and microencapsulation process

The wall material (60 g) was previously hydrated with deionized water (125 g) to facilitate homogenization. After 24 h, the oil was added slowly in each solution of wall material by mechanical stirring at 20 Hz for 120 s using an Ultra-turrax (IKA, T18 basic, Wilmington, USA). The emulsion was then subjected to ultrasound at 160 W of nominal power for 120 s (Branson DigitalSonifier®, model S-450D, Branson Ultrassonics Corporation, Dun Bury, USA), reaching an energy of 96 J mL−1. The height contact between the ultrasonic probe and the emulsions was standardized to 30 mm. The prepared of emulsion was 200 g for each treatment, with 7.5% of essential oil and 30% of wall material (%w w−1). Five treatments were performed in triplicate, according to Table 1.

Table 1.

Composition of the feed emulsions

| Treatment | Feed emulsion (m/m) |

|---|---|

| GA | Gum arabic |

| Mcor10 | Gum arabic + corn maltodextrin DE10 (1:1) |

| Mcor20 | Gum arabic + corn maltodextrin DE20 (1:1) |

| Mcas10 | Gum arabic + cassava maltodextrin DE10 (1:1) |

| OSA-starch | Gum arabic + OSA-Starch (1:1) |

By using the laser diffraction particle size analyzer (Mastersizer 3000, Malvern Instruments Ltd, Malvern, UK), distribution size parameters were calculated: [D32] (Eq. 1) and [D43] (Eq. 2). Span was calculated to determine the width of the droplet size distribution (Eq. 3).

| 1 |

| 2 |

where [D32] is the surface diameter of particles (μm), [D43] is the volumetric diameter of particles (μm), d is the droplet diameter, n is the number of droplets between two consecutive diameters (μm).

| 3 |

where span is the polydispersity index (PDI) and the variables, d10, d50, and d90 are droplet diameters at 10%, 50% and 90% cumulative volume, respectively.

Microencapsulation was performed using a spray-dryer equipment (model MSD 1.0, Labmaq, Ribeirao Preto, Brazil) with a two-fluid atomizer. The drying operation was carried out with a programmed inlet temperature of 170 °C, feed rate at 0.9 L h−1 (2.5 × 10−7 m3 s−1) and compressed air of 35 L min−1 (5.8 × 10−4 m3 s−1 The selection of emulsion composition, emulsification and drying conditions were conducted based on previous studies (Fernandes et al. 2016). The outlet temperature was not controlled, however it was measured and recorded, ranging between 90 and 105 °C.

Microparticles characterization

Oil retention

This analysis was performed to assess the amount of essential oil present in the microparticles (g 100 g−1). To calculate the oil retention, 10 g of microparticles were weighed and 500 mL of deionized water was added. The distillation process was conducted in a Clevenger apparatus until the volume of the extracted oil was constant and then the corresponding mass was calculated by the density of the lemongrass oil previously measured. The determination of the oil retention (%) was based on the initial mass of oil in the emulsion and calculated on a dry basis (d.b.).

Volatile profile of the essential oil main components

Samples of the essential oil obtained from the Clevenger distillation were diluted in hexane (HPLC purity) to a concentration of 250 ppm and analyzed by gas chromatography. Analyzes were performed in a gas chromatograph coupled to a mass spectrometer (CGMS-QP2010 Plus, Shimadzu). An Rtx-5MS column was used with the following temperature schedule for one min: heat rate of 4 °C min−1 until 180 °C; after, a heating rate of 30 °C min−1 was used until 250 °C, with residence time of 2 min. Split injection mode (1:20) and injector temperature of 220 °C were used. Helium was used as the drag gas (1.23 mL min−1), and the injection volume was of 1 µL. The main components of the essential oil, processed in the spray dryer and raw oil, were evaluated based on the comparison of the relative area of the peaks. The area ratios of all peaks in encapsulated and raw essential oil chromatograms were used for fingerprints. The differences between the encapsulated and bulk lemongrass oil compositions were evaluated using the vector angle method (Yang et al. 2009), according to Eq. 4:

| 4 |

where s(x, y) is the statistical similarity, xi is the fraction of component “i” in the crude oil and yi is the fraction of component “i” in the encapsulated oil.

Moisture content

The moisture of the powders was measured by a methodology described by the Association of Official Analytical Chemists (AOAC 2007). The product was subjected to a temperature of 105 °C in a laboratory kiln until constant weight.

Wettability and solubility

Wettability is the time that water takes to spread through the product, being a property of great importance in the reconstitution of the powder. To measure the wettability of the powders, 0.1 g of the sample was used over 400 mL of deionized water at 25 °C described by Fuchs et al. (2006) with adaptations.

Solubility of the powder was determined using procedures described with by Campelo et al. (2018) with adaptations. To determine the solubility 2.5 g of microparticles sample was weighed and added in a calibrated beaker containing 20 mL of deionized water and subjected to manual stirring. After this procedure, the solution was mechanically stirred for 2 min. The material was then transferred to a tube and centrifuged for 15 min at 1950g. The supernatant (5 mL) was transferred to a petri dish and dried at 105 °C until constant weight. The solubility was calculated by the following equation:

| 5 |

where S (%) is the solubility, mss is the solid supernatant mass (g) and msample is the sample mass (g).

Water adsorption kinetic and hygroscopicity

A sample of 1 g of previously dried powder was placed in a desiccator hermetically sealed at 25 °C with saturated NaCl salt solution, which corresponds to 75% moisture in the vapor pressure of the air. The weight gains were assessed at times 1, 2, 4, 6, 8, 10, 12, 24, 36, 48 and 72 h. For the hygroscopicity calculation, after 14 days the sample was weighed one more time and the amount of water mass absorbed by the sample was expressed in g of water per 100 g of the dried product (Cai and Corke 2000).

Moisture sorption isotherm

To determine the moisture sorption isotherms, saturated solutions of salts were disposed in a closed environment at 25 °C. Each saturated salt solution represented an established water activity, ranging from 0.121 to 0.970, the samples were then kept in desiccators with saturated salt solution of known relative humidity (Muzaffar and Kumar 2016). Collected data were converted into relative mass gains, correlating with the respective water activity using the Guggenheim, Anderson and de Boer (GAB) mathematical model (Eq. 6).

| 6 |

where Xeq: equilibrium moisture content (g/100 g dry powder); Xm: monolayer moisture content (g/100 g dry powder); C, K: model constants related to the monolayer and monolayer properties; aw: water activity.

Particle size and morphology

The particle morphology was analyzed using a Scanning Electron Microscopy (SEM) with working distance of 7 mm. The particulates were immobilized in stubs using double-sided adhesive tape. The samples were covered with gold through a vacuum chamber and assessed using a LEO EVO 40 XVP scanning electron microscope (Carl Zeiss, Oberkochen, Germany), operating at 20 kV with magnifications ranging from 500 to 1000. The determination of the mean particle size (D32) was performed with the assistance of AxionVision software®, in which the scaling information allows to calculate the size of a partial image.

Thermogravimetric analysis

The thermogravimetric (mass loss) and thermogravimetric derivative (dTG) were obtained using TGA50H (Corporation Shimadzu, Kyoto, Japan) by placing approximately 5 mg of the sample in each pan. The analyzes were conducted following the operating conditions: alumina pan; nitrogen dynamic atmosphere with flow rate of 50 mL min−1, temperature variation of 10 °C min−1, and a temperature range from 25 to 500 °C.

Statistical analysis

The experiment was performed in completed randomized design (CRD) and analysis of variance using SISVAR software to assess the effects of the five encapsulation formulations on the characteristics of microencapsulated lemongrass oil in triplicate. The differences between the mean values obtained were analyzed using the Scott–Knott’s test (p < 0.05).

Results and discussion

Emulsion droplets size analysis, oil retention and components profile

The different formulations used in preparation of the emulsions presented significant influence on the droplet size after the emulsification process (Table 2). Replacement of gum arabic by maltodextrin caused a decrease on the droplet diameter; emulsion with cassava maltodextrin (Mcas10) has higher polydispersity, according to span value. On the other hand, a substitution by OSA-starch presented the lowest span value, showing a higher size distribution homogeneity than the others.

Table 2.

Droplet size of the emulsions

| Treatment | [D43] (µm) | [D32] (µm) | Span |

|---|---|---|---|

| GA | 35.70 ± 6.03a | 0.70 ± 0.08b | 5.27 ± 2.96b |

| Mcas10 | 7.61 ± 1.56c | 0.30 ± 0.01c | 23.24 ± 3.55a |

| Mcor10 | 5.81 ± 0.36c | 0.20 ± 0.01d | 5.55 ± 0.27b |

| Mcor20 | 1.30 ± 0.01d | 0.18 ± 0.01d | 2.84 ± 0.01c |

| OSA-starch | 19.90 ± 0.04b | 17.30 ± 0.01a | 1.03 ± 0.02d |

Mean value ± standard deviation. Mean followed by the same lowercase letter in the column do not differ by Scott–Knott test (p > 0.05)

Oil retention was calculated based on the initial amount of oil in the emulsion and its relation to the oil content found in the microparticles. Thus, the values found for the treatments were in ascending order: Mcor20 (55.0%), Mcor10 (65.0%), GA (67.5%), Mcas10 (68.2%), OSA-starch (81.2%). There was no significant difference between Mcor10, GA and Mcas10 treatments. The treatment with the best yield was OSA-starch as wall material and the lowest yield was that when maltodextrin DE20 was used. The higher oil retention of OSA-starch may be related to the emulsifying capacity of this starch in comparison to the other modified starches used in this experiment, being a good replacer for gum arabic due to their low cost and tasteless (Bajaj et al. 2019). This starch, when modified with succinic anhydride, gains a lipophilic element and results in amphipathic molecular structures. Emulsification of the oil during the preparation of the spray feed emulsion has a great influence on the core material retention. The substitution by maltodextrin DE20, a polymer with smaller chains, provided a considerable reduction in oil retention.

Analyzes must focus not only on the amount of oil carried by the microparticles, but also on the components profile, since the aim of microencapsulation is to protect the bioactive compounds. Concerning this observation, chromatography was performed in order to compare the main bioactive components present in the bulk lemon grass essential oil to the respective spray dried microparticles. According with Gaonkar et al. (2016), citral was the major component found in this essential oil. The constitution of the bulk oil observed in this study, in descending order, was as following: citral (85.8%), nerol (3.8%), geraniol (2.9%), canfeno (1.4%), and other minor components (6.0%). Essential oils are basically composed of terpenes, a class of substances which ensure desired properties.

In Fig. 1 it is possible to observe that none of the chemical compounds of the essential oil processed by spray drying was totally lost after the drying process when compared to the original oil, only some minor changes were observed. Thus, the main components did not disappear of any treatment, showing their preservation even with the drying process at high temperatures. This fact is important for the maintenance of the essential oil bioactivity, which can modify the profile.

Fig. 1.

Profile of the lemongrass oil main components and similarity obtained from the microparticles and from the bulk essential oil

Chromatographic fingerprint technique has been widely used to control and to evaluate the quality of products, aiming to show similarity to a standard (Yang et al. 2009). Figure 1 shows the similarity of the oil constitution of the bulk oil in relation to microencapsulated oils. The treatment with DE10 corn maltodextrin showed the greatest similarity, however, cassava maltodextrin with the same dextrose equivalent was the treatment that presented the lowest similarity. Therefore, different sources of starch can provide different levels of protection to the encapsulated oil. Thus, it is reinforced the needs for evaluation of different polymer blends since the partial replacement of gum arabic by maltodextrin, in this case, the Mcor10 treatment favored a greater maintenance of the same components of the oil after the spray drying process, when compared even with gum arabic itself.

Moisture content, solubility, wettability, water adsorption kinetic and hygroscopicity

Moisture, solubility, wettability and hygroscopicity results are presented in Table 3. The moisture content of essential oil microparticles generally range from 1 to 2% (Fernandes et al. 2016). Treatments averages ranged from 0.90 to 1.66%, although it was observed no significant differences. The inlet air temperature influences the moisture content of the final product, and the temperature used for all treatments was 170 °C. The high temperature applied was sufficient to maintain similar moisture content in all treatments, due to the high heat transferring and, consequently, greater evaporation of water during the process. The values of moisture were low enough to be considered microbiological and chemical safe, as well as, to not alter the product due to its moisture. To avoid microbial growth on food products, the moisture content must be kept below approximately 10% (Zambrano et al. 2019).

Table 3.

Physical and chemical parameters of the spray-dried microparticles

| Treatment | Moisture content (%) | Solubility (%) | Wettability (s) | Hygroscopicity (g 100 g−1) |

|---|---|---|---|---|

| GA | 1.66 ± 0.22a | 77.3 ± 1.3a | 128 ± 6a | 15.5 ± 0.4a |

| Mcor10 | 0.96 ± 0.31a | 75.6 ± 0.9a | 129 ± 2a | 13.3 ± 0.6b |

| Mcor20 | 1.43 ± 0.23a | 75.5 ± 0.8a | 240 ± 16b | 12.9 ± 0.3b |

| Mcas10 | 1.25 ± 0.58a | 77.1 ± 1.7a | 147 ± 2a | 13.0 ± 0.8b |

| OSA-starch | 0.90 ± 0.10a | 77.2 ± 1.0a | 254 ± 8b | 12.2 ± 0.2b |

Means followed by the same letters in the same column did not differ by the Scott–Knott test (p > 0.05)

The incorporation of vegetable oils into food is a limiting factor because oil presents low solubility in water (Shamaei et al. 2017). The solubility values found in all treatments presented no statistically difference, possibly influenced by the presence of gum arabic in all treatments, which have hydrophobic amino acid radicals in their structure (Farooq et al. 2017). The treatments showed solubility ranging from 75.5 to 77.3%. The treatments OSA-starch and Mcor20 presented higher wetting time, being a detrimental characteristic for the reconstitution of the powder, admitting that the lower the time for the powder to be incorporated into the liquid, the faster the homogenization of the product.

Currently, there is an increasing demand for food products that are practical and of fast process. In this context, the powdered foods have deserved prominence. It is considered that surface wetting by the liquid is a limiting step of the powder reconstituting process. The ability of the particles to mix with water is one of the most important reconstitution properties (Bae and Lee 2008). There is a tendency for smaller particles to agglomerate at the instant of water addition and to hinder the process of water spreading on the surface of the microparticles.

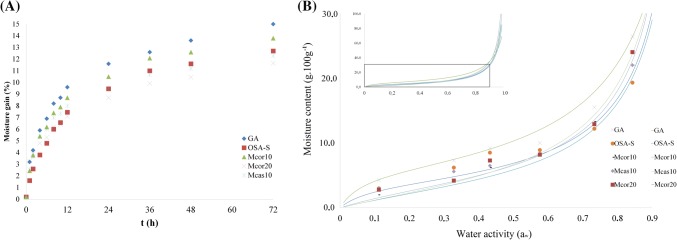

Moisture adsorption kinetics curves were constructed in order to understand the behavior of the powdered material for each treatment until 72 h, at 25 °C and 75% Relative Humidity (RH) (Fig. 2a). It was observed that the OSA-starch treatment presented less absorbed water in the first 6 h, however, after 36 h its adsorption was higher than the Mcor20 and Mcas10 treatments. The powder from GA treatment was the one that most adsorbed water throughout the time. After 72 h, the treatment using corn maltodextrin DE20 presented adsorption 20% lower than the treatment using only gum arabic. The rate at which water adsorption occurs is directly related to the hygroscopicity of the material. Increasing the moisture content of the powder is an unwanted circumstance once it changes its physical characteristics and makes it sticky, mainly by lowering the glass transition temperature.

Fig. 2.

Kinetic curves of water content gain over 72 h for the microparticles (25 °C and 75% RH) (a); and moisture sorption isotherms of the microparticles produced, adjusted by the GAB model, at 25 °C (b)

Carbohydrate molecules tend to rapidly adsorb water (Fan et al. 2017). On the other hand, the increase in the mass ratio of oil to wall material may lead to the formation of particles with higher surface oil, decreasing the particle hygroscopicity. Water adsorption is a critical factor in shelf life, as it accelerates degradation reactions and the oxidation process, and modifies the product characteristics (Martysiak-Żurowska et al. 2017). For the relative humidity of the environment used in the experiment no agglomeration and no significant visual differences were observed in any of the five treatments, the crystalline behavior is influenced by the hygroscopic capacity (Bisinella et al. 2017). Maltodextrins usually do not present high hygroscopicity, increasing the amount of this carbohydrate in powder formulations make them less hygroscopic. The results obtained showed that the treatment with pure gum arabic presented hygroscopicity of 15.5 g 100 g−1, being the one that presented the greatest hygroscopicity. In the case of the other treatments, there were no significant differences between them, ranging from 12.2 to 13.3 g 100 g−1.

Moisture sorption isotherm

The conservation of product quality depends on the state of the water. The adsorption or desorption of water in food depends on the water activity of the food and on the pressure exerted by the relative humidity of the environment (Basu et al. 2006). The equilibrium moisture is a mechanism understood by the adaptation of experimental models, kinetic models and thermodynamic parameters (Tharaneedhar et al. 2017). Guggenheim–Anderson–de Boer (GAB) model was used to describe the moisture adsorption isotherm behavior. Regarding the powder physical characteristics, there was a visual decrease in flowability above 0.75 water activity and liquefaction at 0.97 water activity at 25 °C for all treatments (Fig. 2b).

In the GAB model, the value of Xm refers to the water monolayer, meaning the amount of water saturating the first active site layer, considered an important parameter in food storage and in its deterioration (Basu et al. 2006). The treatment GA showed higher Xm (5.14 g 100 g−1) and Mcor20 the lowest values (3.84 g 100 g−1). All treatments with partial gum replacement showed a type 3 isotherm, known as the Flory-Higgins isotherm, although the treatment with only gum arabic had a more similar type 2 profile, known as sigmoid for soluble products, exhibiting an asymptotic tendency as the water activity varies.

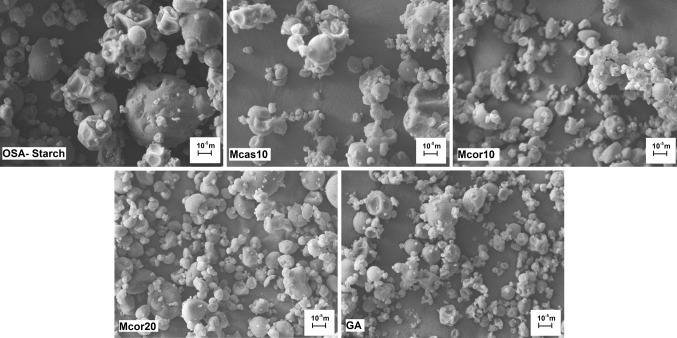

Particle size and morphology

Through SEM observations, it was possible to verify that there were no cracks and breaks in the capsules produced with all formulations of wall materials studied, a relevant and advantageous fact that guarantees low gas permeability and, consequently, is considered ideal for oil protection. Surface characteristics in the morphology for each treatment showed some differences, one of them is that the treatment with modified OSA-starch presented more roughness and the treatments with maltodextrin showed more smoothness. Although some superficial differences were observed, the format of all treatments was very similar to spheres (Fig. 3). The particles formed by spray drying usually have a spherical shape (Zhang et al. 2017), where morphology and particle size can be modified based on the carrier material used and the process parameters (Shenoy et al. 2015). In the present study, it was evidenced that smaller particles have more roughness and folds. The presence of maltodextrin, independent on the botanical source or the equivalent dextrose contributed to the decrease the particles roughness (Fig. 3). Differently when OSA-starch was used, the microparticles showed a rough surface for this treatment. Surface roughness of the microparticles are formed due to the contraction of the particles during drying and cooling steps. Microparticles formed using maltodextrin possible dried faster in spray drying than OSA-starch and consequently showed structures with a smoother surface.

Fig. 3.

Morphology of the microparticles obtained by scanning electron microscopy (SEM) using the different wall materials

Mean surface diameter D3,2 was used as parameter to compare the average particle size between the treatments: OSA-starch (12,64 µm), Mcas10 (6,78 µm), Mcor10 (5,97 µm), Mcor20 (5,20 µm) and GA (4,62 µm). Spray dried particles size influences the flowability and dispersion of the powders produced, being samples essentially spherical and having sizes around 5–10 μm (Qu and Zhong 2017), confirming the values obtained at work.

Thermogravimetric analysis

Thermogravimetric analysis (TGA) is performed to verify the mass loss of a material as a function of the temperature variation at which it is exposed, providing information about its thermal stability. The relevance of this information is in the applied operations to the given material, involving heat exchange, such as pasteurization, furnishing and cooking (Lechevalier et al. 2017; Mohamed et al. 2016).

Based on Fig. 4, it is possible to verify that the weight loss of the lemongrass oil starts at 40 °C and has a peak around 150 °C, temperatures above 150 °C virtually all oil is lost. This result demonstrates the oil’s vulnerability to temperature and, therefore, the importance of protecting it. For all treatments, it was observed weight loss of more than 10% when exposed to temperatures higher than 200 °C, considering that losses between 92 and 105 °C are relative to the water content (Oliveira et al. 2014). The wall materials presented similar degradation profile. The partial replacement of gum arabic by the materials studied does not cause substantial changes in the thermal stability of the microparticles. Gum arabic was considered the material that present the higher thermal stability, however, the substitution of gum arabic by modified starches, in general, contributed to lower the thermal stability of the microparticles, based on the dTG results, where corn maltodextrin DE20 treatment showed the lower stability.

Fig. 4.

Thermal analyzes of the lemongrass oil in nature form and for bulk wall materials (a) and for the microparticles produced using the different wall materials (b)

Conclusion

The wall material combinations used, in this work, demonstrated the potential to encapsulate lemongrass oil through the technique of spray drying. Solubility, moisture content and oil composition profile, important factors to distinguish the best composition of wall material, did not present differences. The treatments Mcor20 and OSA-starch presented lower wettability, because they had higher wetting times. Replacement of gum by modified starches showed a decrease in the yield of the process, especially with maltodextrin of equivalent dextrose 20 and also contributed to lower thermal stability. On the other hand, the use of modified starches contributed to reduce the hygroscopic characteristic of microparticles when compared to gum arabic only. OSA-starch microparticles showed greater roughness and folds on the microparticles’ surface. These results evidenced the potential of using modified starches partially replacing gum arabic in microencapsulation process by spray drying due to their cost and new properties.

Acknowledgements

The authors thank FAPEMIG (Minas Gerais State Agency for Research and Development) (Process No. CAG-APQ-02487-16) and CNPq (National Council for Scientific and Technological Development) for the financial support. This study was financed in part by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (CAPES)—Finance Code 001.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Contributor Information

Gabriel Ribeiro Carvalho, Email: carvalho.gabrielr@gmail.com.

Regiane Victória de Barros Fernandes, Email: regiane.botrel@dqi.ufla.br.

Priscila de Castro e Silva, Email: prihkstro@gmail.com.

Anelise Lima de Abreu Dessimoni, Email: anelisedessimoni@dqi.ufla.br.

Cassiano Rodrigues Oliveira, Email: cassiano.oliveira@ufv.br.

Soraia Vilela Borges, Email: sborges@dca.ufla.br.

Diego Alvarenga Botrel, Phone: +55 035 3829-4610, Email: diegobotrel@dca.ufla.br.

References

- Association of Official Analytical Chemists—AOAC . Official methods of analysis. 17. Maryland: AOAC; 2007. [Google Scholar]

- Bae EK, Lee SJ. Microencapsulation of avogado oil by spray drying using whey protein and maltodextrin. J Microencapsul. 2008;25(8):549–560. doi: 10.1080/02652040802075682. [DOI] [PubMed] [Google Scholar]

- Bajaj R, Singh N, Kaur A. Properties of octenyl succinic anhydride (OSA) modified starches and their application in low fat mayonnaise. Int J Biol Macromol. 2019;131:147–157. doi: 10.1016/j.ijbiomac.2019.03.054. [DOI] [PubMed] [Google Scholar]

- Balakrishnan B, Paramasivam S, Arulkumar A. Evaluation of the lemongrass plant (Cymbopogon citratus) extracted in different solvents for antioxidant and antibacterial activity against human pathogens. Asian Pac J Trop Dis. 2014;4:S134–S139. doi: 10.1016/S2222-1808(14)60428-X. [DOI] [Google Scholar]

- Basu S, Shivhare US, Mujumdar AS. Models for sorption isotherms for food: a review. Drying Technol. 2006;24(8):917–930. doi: 10.1080/07373930600775979. [DOI] [Google Scholar]

- Binsi PK, Nayak N, Sarkar PC, Jeyakumari A, Muhamed Ashraf P, Ninan G, Ravishankar CN. Structural and oxidative stabilization of spray dried fish oil microencapsulates with gum arabic and sage polyphenols: characterization and release kinetics. Food Chem. 2017;219:158–168. doi: 10.1016/j.foodchem.2016.09.126. [DOI] [PubMed] [Google Scholar]

- Bisinella RZB, Ribeiro JCB, Oliveira CS, Colman TAD, Schnitzler E, Masson ML. Some instrumental methods applied in food chemistry to characterise lactulose and lactobionic acid. Food Chem. 2017;220:295–298. doi: 10.1016/j.foodchem.2016.10.018. [DOI] [PubMed] [Google Scholar]

- Cai YZ, Corke H. Production and properties of spray-dried Amaranthus betacyanin pigments. J Food Sci. 2000;65:124–125. doi: 10.1111/j.1365-2621.2000.tb10273.x. [DOI] [Google Scholar]

- Campelo PH, Sanches EA, Fernandes RVB, Botrel DA, Borges SV. Stability of lime essential oil microparticles produced with protein-carbohydrate blends. Food Res Int. 2018;105:936–944. doi: 10.1016/j.foodres.2017.12.034. [DOI] [PubMed] [Google Scholar]

- Domian E, Cenkier J, Gorska A, Brynda-Kopytowska A. Effect of oil content and drying method on bulk properties and stability of powdered emulsions with OSA starch and linseed oil. LWT Food Sci Technol. 2018;88:95–102. doi: 10.1016/j.lwt.2017.09.043. [DOI] [Google Scholar]

- Fan M, Hu T, Zhao S, Xiong S, Xie J, Huang Q. Gel characteristics and microstructure of fish myofibrillar protein/mandioca starch composites. Food Chem. 2017;218:221–230. doi: 10.1016/j.foodchem.2016.09.068. [DOI] [PubMed] [Google Scholar]

- Farooq M, Sagbas S, Sahiner M, Siddiq M, Turk M, Aktas N, Sahiner N. Synthesis, characterization and modification of Gum Arabic microgels for hemocompatibility and antimicrobial studies. Carbohydr Polym. 2017;156:380–389. doi: 10.1016/j.carbpol.2016.09.052. [DOI] [PubMed] [Google Scholar]

- Fernandes RVB, Silva EK, Borges SV, Oliveira CR, Yoshida MI, Silva YF, Carmo EL, Azevedo VM, Botrel DA. Proposing novel encapsulating matrices for spray-dried ginger essential oil from the whey protein isolate-inulin/maltodextrin blends. Food Bioprocess Technol. 2016;10:115–130. doi: 10.1007/s11947-016-1803-1. [DOI] [Google Scholar]

- Fontes GC, Calado VMA, Rossi AM, da Rocha-Leao MHM. Characterization of antibiotic-loaded alginate-OSA starch microbeads produced by ionotropic pregelation. Biomed Res Int. 2013;2013:1–11. doi: 10.1155/2013/472626. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Fuchs M, Turchiuli C, Bohin M, Cuvelier ME, Ordonnaud C, Payrat-Maillard MN, Dumoulin E. Encapsulation of oil in powder using spray drying and fluidised bed agglomeration. J Food Eng. 2006;75:27–35. doi: 10.1016/j.jfoodeng.2005.03.047. [DOI] [Google Scholar]

- Gaonkar R, Yallapa S, Dhananjaya BL, Hegde G. Development and validation of reverse phase high performance liquid chromatography for citral analysis from essential oils. J Chromatogr B. 2016;1036:50–56. doi: 10.1016/j.jchromb.2016.10.001. [DOI] [PubMed] [Google Scholar]

- Gharib R, Auezova L, Charcosset C, Greige-Gerges H. Drug-in-cyclodextrin-in-liposomes as a carrier system for volatile essential oil components: application to anethole. Food Chem. 2017;218:365–371. doi: 10.1016/j.foodchem.2016.09.110. [DOI] [PubMed] [Google Scholar]

- Hadjilouka A, Mavrogiannis G, Mallouchos A, Paramithiotis S, Mataragas M, Drosinos EH. Effect of lemongrass essential oil on Listeria monocytogenes gene expression. LWT Food Sci Technol. 2017;77:510–516. doi: 10.1016/j.lwt.2016.11.080. [DOI] [Google Scholar]

- Hategekimana J, Masamba KG, Ma J, Zhong F. Encapsulation of vitamin E: effect of physicochemical properties ofwall material on retention and stability. Carbohydr Polym. 2015;124:172–179. doi: 10.1016/j.carbpol.2015.01.060. [DOI] [PubMed] [Google Scholar]

- He H, Hong Y, Gu Z, Liu G, Cheng L, Li Z. Improved stability and controlled release of CLA with spray-dried microcapsules of OSA-modified starch and xanthan gum. Carbohydr Polym. 2016;147:243–250. doi: 10.1016/j.carbpol.2016.03.078. [DOI] [PubMed] [Google Scholar]

- Kugapreethan R, Umasuthan N, Wan Q, Thulasitha WS, Kim C, Lee J. Comparative analysis of two thioredoxin-like genes in black rockfish Sebastes schlegelii and their possible involvement in redox homeostasis and innate immune responses. Dev Comp Immunol. 2017;67:43–56. doi: 10.1016/j.dci.2016.10.012. [DOI] [PubMed] [Google Scholar]

- Lechevalier V, Guerin-Dubiard C, Anton M, Beaumal V, Briand ED, Gillard A, Gouar YL, Musikaphun N, Tanguy G, Pasco M, Dupont D, Nau F. Pasteurisation of liquid whole egg: optimal heat treatments in relation to its functional, nutritional and allergenic properties. J Food Eng. 2017;195:137–149. doi: 10.1016/j.jfoodeng.2016.10.007. [DOI] [Google Scholar]

- Liolios CC, Gortzi O, Lalas S, Tsaknis J, Chinou I. Liposomal incorporation of carvacrol and thymol isolated from the essential oil of Origanum dictamnus L. and in vitro antimicrobial activity. Food Chem. 2009;112(1):77–83. doi: 10.1016/j.foodchem.2008.05.060. [DOI] [Google Scholar]

- Martysiak-Żurowska D, Puta M, Barczak N, Dabrowska J, Malinowska-Panczyk E, Kielbratowska B, Kolodziejska I. Effect of high pressure and sub-zero temperature on total antioxidant capacity and the content of vitamin C, fatty acids and secondary products of lipid oxidation in human milk. Pol J Food Nutr Sci. 2017;67(2):117–122. doi: 10.1515/pjfns-2016-0011. [DOI] [Google Scholar]

- Mohamed NA, El-Ghany NAA, Fahmy MM. Thermogravimetric analysis in the evaluation of the inhibition of degradation of rigid poly (vinyl chloride) using biologically active phthalimido aromatic hydrazide derivatives. Polym Degrad Stab. 2016;128:46–54. doi: 10.1016/j.polymdegradstab.2016.02.014. [DOI] [Google Scholar]

- Muzaffar M, Kumar P. Moisture sorption isotherms and storage study of spray dried tamarind pulp powder. Powder Technol. 2016;291:322–327. doi: 10.1016/j.powtec.2015.12.046. [DOI] [Google Scholar]

- Oliveira EF, Paula HCB, Paula RCM. Biointerfaces Alginate/cashew gum nanoparticles for essential oil encapsulation. Colloids Surf B. 2014;113:146–151. doi: 10.1016/j.colsurfb.2013.08.038. [DOI] [PubMed] [Google Scholar]

- Qu B, Zhong Q. Casein-maltodextrin conjugate as an emulsifier for fabrication of structured calcium carbonate particles as dispersible fat globule mimetics. Food Hydrocolloids. 2017;66:61–70. doi: 10.1016/j.foodhyd.2016.12.022. [DOI] [Google Scholar]

- Rajabi H, Ghorbani M, Jafari SM, Mahoonak AS, Rajabzadeh G. Retention of saffron bioactive components by spray drying encapsulation using maltodextrin, gum Arabic and gelatin as wall materials. Food Hydrocolloids. 2015;51:327–337. doi: 10.1016/j.foodhyd.2015.05.033. [DOI] [Google Scholar]

- Rezende YR, Nogueira JP, Narain N. Microencapsulation of extracts of bioactive compounds obtained from acerola (Malpighia emarginata DC) pulp and residue by spray and freeze drying: chemical, morphological and chemometric characterization. Food Chem. 2018;254:281–291. doi: 10.1016/j.foodchem.2018.02.026. [DOI] [PubMed] [Google Scholar]

- Rutz JK, Borges CD, Zambiazi RC, Crizel-Cardozo MM, Kuck LS, Noreña CPZ. Microencapsulation of palm oil by complex coacervation for application in food systems. Food Chem. 2017;220:59–66. doi: 10.1016/j.foodchem.2016.09.194. [DOI] [PubMed] [Google Scholar]

- Shamaei S, Seiiedlou SS, Aghbashlo M, Tostsa E, Kharaghani A. Microencapsulation of walnut oil by spray drying: effects of wall material and drying conditions on physicochemical properties of microcapsules. Innov Food Sci Emerg Technol. 2017;39:101–112. doi: 10.1016/j.ifset.2016.11.011. [DOI] [Google Scholar]

- Shenoy P, Xanthakis E, Innings F, Jonsson C, Fitzpatrick J, Ahrné L. Study of effect of composition and water content on mixture quality of binary food powder mixtures. J Food Eng. 2015;149:229–236. doi: 10.1016/j.jfoodeng.2014.10.019. [DOI] [Google Scholar]

- Tharaneedhar V, Kumar PS, Saravanan A, Ravikumar C, Jaikumar V. Prediction and interpretation of adsorption parameters for the sequestration of methylene blue dye from aqueous solution using microwave assisted corncob activated carbon. Sustain Mater Technol. 2017;11:1–11. [Google Scholar]

- Valdes A, Cifuentes A, Leon C. Foodomics evaluation of bioactive compounds in foods. TrAC Trends Anal Chem. 2017;96:2–13. doi: 10.1016/j.trac.2017.06.004. [DOI] [Google Scholar]

- Yang J, Xiao JX, Ding LZ. An investigation into the application of konjac glucomannan as a flavor encapsulant. Eur Food Res Technol. 2009;229:467–474. doi: 10.1007/s00217-009-1084-2. [DOI] [Google Scholar]

- Zambrano MV, Dutta B, Mercer DG, MacLean HL, Touchie MF. Assessment of moisture content measurement methods of dried food products in small-scale operations in developing countries: a review. Trends Food Sci Technol. 2019;88:484–496. doi: 10.1016/j.tifs.2019.04.006. [DOI] [Google Scholar]

- Zhang S, Chen J, Yin X, Wang X, Qiu B, Zhu L, Li Q. Microencapsulation of tea tree oil by spray-drying with methyl cellulose as the emulsifier and wall material together with chitosan/alginate. J Appl Polym Sci. 2017;134(13):1–10. doi: 10.1002/app.44662. [DOI] [Google Scholar]