Abstract

Tropical fruits rich in polyphenols, ascorbic acid, and high antioxidant capacity can enhance the functional composition, flavor as well as the overall acceptance of their juices. The aim of this study was to evaluate the effects of pasteurization and storage time on the physical, chemical, and sensory quality parameters of two formulations of tropical fruit juice blends with high antioxidant capacity. Two formulations with different concentrations of acai, camu-camu, acerola, cashew apple, yellow mombin, and pineapple were pasteurized at 85 °C for 30 s, hot-filled in glass bottles, and stored in refrigerated conditions (5 °C). Analyses for color, total antioxidant activity, total polyphenols, carotenoids, ascorbic acid, and sensory quality were performed before and after pasteurization as well as at 90 and 180 day of storage. Pasteurization did not negatively affect the concentration of functional components and sensory properties. However, the storage time negatively influenced the sensory quality and reduced the ascorbic acid content of both the formulations. Further, the acceptability and the nutritional quality were still high in these products after 180-days of storage, thus, not preventing their consumption.

Keywords: Pasteurization, Antioxidant activity, Sensory evaluation, Colorimetry, Malpighia emarginata, Anacardium occidentale, Spondias mombin, Ananas comosus, Euterpe oleracea, Myrciaria dubia

Introduction

Tropical fruits are an important source of bioactive compounds such as polyphenols, anthocyanins, flavanols, carotenoids, and vitamins. Good manufacturing practices contribute towards avoiding the loss of functional components during exposure to oxygen, light, and heat during storage (Nayak et al. 2015). The degradation of ascorbic acid by thermal treatments has been investigated for several juices such as cashew apple (Damasceno et al. 2008), orange (Tiwari et al. 2009; Remini et al. 2015), pomegranate (Paul and Ghosh 2012), and others. Silva et al. (2016) reported that when appropriate thermal operational conditions were used, the loss of anthocyanins in acerola pulp was less than 1%. Zepka et al. (2014) studied the thermal stability of carotenoids in cashew apple juice and investigated how the thermal degradation of these carotenoids influences the aroma and flavor of cashew apples. Furthermore, due to the synergistic and antagonistic effects of different compounds, the composition of bioactive compounds may possess different antioxidant capacity when a fruit product is alone or is together with other fruits and vegetables (Pereira et al. 2015).

Embrapa has developed formulations of mixed tropical fruit juices using acerola, acai, cashew apple, yellow mombin, camu-camu, and pineapple. The purpose of this mixture was to enhance the antioxidant capacity of the final product by virtue of the functional compounds of each fruit and, at the same time, improve the flavor and overall acceptance (Pereira et al. 2015). Juices were pasteurized and hot-filled in glass bottles. The formulations were optimized by the response surface methodology based on total polyphenols (TP), total antioxidant capacity (TAC), ascorbic acid content, and sensory acceptance. Camu-camu, acerola, and acai were the major factors that influenced the antioxidant potential of the juice and the yellow mombin showed a positive effect on the acceptance of the tropical juice (Pereira et al. 2015). All products presented functional appeal due to the ascorbic acid and polyphenol content, and total antioxidant activity (Pereira et al. 2015; Wurlitzer et al. 2015) as shown by in vitro assays. One of the formulations evaluated by in vivo assays also demonstrated beneficial effects in terms of the antioxidant potential as well as antimutagenic and antiproliferative potential (Carvalho-Silva et al. 2014); this is of great interest for the control of oxidative stress.

The aim of the present study was to evaluate the effects of pasteurization and storage under refrigeration on the chemical and sensory quality of the two formulations that have shown the best acceptance.

Materials and methods

Juice preparation

For the preparation of juice blends, frozen pulps were used due to the differences in seasonality and production area among the chosen fruits: acerola cherry (Malpighia emarginata D.C.), cashew apple (Anacardium occidentale L.), yellow mombin (Spondias mombin), pineapple (Ananas comosus L.), acai (Euterpe oleracea), and camu-camu (Myrciaria dubia). The frozen pulps were purchased from the local market (Fortaleza-Brazil), except for camu-camu, which originated from Belém, Brazil.

As shown in Table 1, two formulations of tropical juices (F1 and F2) were prepared using different percentages of fruit pulps, which were optimized to high vitamin C, polyphenols, antioxidant capacity, and sensory acceptability, according to Pereira et al. (2015) and Wurlitzer et al. (2015). Pulps were defrosted, mixed in an industrial blender in the proportions indicated for each formulation, and were then subjected to pasteurization. A control sample of each formulation (not pasteurized) was stored at − 18 °C until further analysis. Formulation F1_control had pH 3.44 ± 0.03, soluble solids (SS) 11.2 ± 0.50 °Brix, and titratable acidity (TA) 0.36 ± 0.01 g citric acid L−1. Formulation F2_control had pH 3.95 ± 0.01, SS 10.0 ± 0.1, °Brix and TA 0.23 ± 0.01 g citric acid L−1. Microbiological analyses were performed after pasteurization and during storage to avoid the interference in the results. All microbiological analyses indicated samples as acceptable with microbiologically stable conditions; E. coli, Salmonella pathogens as well as fecal coliforms were absent. The fungi and yeast counts were lower than two log cycles in six-month storage. The high acidity (pH < 4.0) of tropical juices limits the growth of pathogenic and deteriorating bacteria. The absence of pathogenic microorganisms during the storage complied with the microbiological safety criteria recommended for juice.

Table 1.

Tropical fruit juice blend formulations

| Ingredientsa | (%) | |

|---|---|---|

| F1 | F2 | |

| Camu-camu | 5.0 | – |

| Acerola | 10.0 | 10.0 |

| Acai | 5.0 | 10.0 |

| Cashew apple | 5.0 | – |

| Yellow mombin | 5.0 | 10.0 |

| Pineapple | 20.0 | 20.0 |

| Sucrose | 6.9 | 6.6 |

| Water | 43.1 | 43.4 |

aEach formulation had 50% of fruit pulp

Pasteurization

Juices were pasteurized in an Armfield FT74 tubular heat exchanger at 85 °C for 30 s followed by hot-filling in 210 mL glass bottles previously sanitized with chlorine solution (100 ppm). After the bottles were filled and closed with plastic screw caps, they were positioned lying-down for the pasteurization of the cap for 2–3 min, cooled in a water bath, labeled, and then stored under refrigeration (5 °C ± 2 °C) until further analysis. The experiments were performed in three repetitions. A total of 15 samples (bottles) were collected for sensory attributes, physical, chemical and microbiological analyses, before and after the pasteurization, and at each storage time point (0, 90, and 180 days).

Analysis of physical and chemical attributes

Color measurement

Color coordinates L*, a*, and b* were obtained from a chromameter (CR-300, Minolta, Ramsey, USA). The L* coordinate denotes lightness on a 0–100 scale from black to white; and on a − 60 to + 60 scale for a* green (−) to red (+); b* blue (−) to yellow (+). From the color coordinates, the hue angle (h*, Eq. 1), chroma (C*, Eq. 2), and color difference (ΔE, Eq. 3) were obtained. The hue angle is the color tone, starting at the + a* axis and is expressed in degrees. For example, 0° would be + a* (red), 90° would be + b* (yellow). The value of chroma C* is the color saturation. It starts at the center of the CIELAB space (zero) and increases according to the distance from the center. ΔE is the global difference between two samples, and was calculated with respect to the control sample (fresh, not pasteurized juice).

| 1 |

| 2 |

| 3 |

Ascorbic acid (AA)

The ascorbic acid was quantified by titration with DFI solution (2,6 dichlorophenolindophenol 0.02%) according the specifications of AOAC (2005).

Total carotenoids

Carotenoids were quantified following the recommendations of Rodriguez-Amaya (2001) i.e. after the extraction with acetone and Hyflo Supercel (Celite®), and partition with petroleum ether.

Total extractable polyphenols (TEP)

TEP were determined using the Folin–Ciocalteu reagent and by using a standard curve of gallic acid as a reference according to the methodology described by Larrauri et al. (1997), in a methanol/water (50:50, v/v) extraction.

Total antioxidant activity (TAA)

The total antioxidant activity was determined by the ABTS free radical capture method as well as the FRAP reduction method. Both the methods were employed along with the modifications proposed by Rufino et al. (2010). The methanol/water (50:50 v/v) hydrophilic extracts were used for the analysis.

Sensory analyses

The protocols of sensory tests were previously approved by the Ethics Research Committee of the State University of Ceará (Protocol No. 147,279). Before every experiment, informed consent was obtained from each panelist.

Descriptive analysis

A trained panel, using descriptive sensory profiling (Stone and Sidel 2004), evaluated the tropical fruit juice blends. The panel consisted of 12 assessors screened for their sensory ability by basic tastes and odor detection tests as well as their ability to describe and discriminate food products. The generation of descriptors followed the Grid Method using samples of F1 formulation prepared in the laboratory, before and after pasteurization. During eight working sessions, the panelists, under the supervision of a moderator selected the descriptors that characterized the samples and established their definitions and references (Table 2). Panel validation consisted of the evaluation of three samples of F1 formulation: fresh, pasteurized, and overcooked. Descriptors were then quantified with a 9 cm non-structured linear scale, anchored on the extremes with terms that expressed their intensities. For each sample, the results were subjected to ANOVA, with two sources of variation viz. samples and repetitions, in order to check their discriminatory ability, repeatability, and consensus with the group.

Table 2.

Sensory descriptors, definitions and references used in descriptive analysis of tropical fruit blends

| Descriptor | Definition | References |

|---|---|---|

| Appearance | ||

| Visible solids (VSOL) | Visually perceived particles adhering to the walls of the glass | Weak Acerola pulp (Ali Polpa®) diluted with grape nectar (Dell Valle®) 1:3 (v/v) |

| Strong Acerola pulp (Ali Polpa®) diluted with grape nectar (Dell Valle®) 1.5:1 (v/v) | ||

| Oil on the surface (OS) | Presence of oil that may appear as spots/droplets on the juice surface | Weak Acerola pulp (Ali Polpa®) diluted with grape nectar (Dell Valle®) 1:1 (v/v) plus 15 µL passion fruit oil, homogenized in Turax for 45 s |

| Strong Acerola pulp (Ali Polpa®) diluted with grape nectar (Dell Valle®) 1:1 (v/v) plus 90 µL passion fruit oil, homogenized in Turax for 45 s | ||

| Aroma | ||

| Sweet aroma (SWA) | Sweet aroma associated with fruit that has been heated | Weak Same preparation as the strong reference, diluted with water 1:2 (v/v) |

| Strong 50 mL of mixed fruit nectar (Jandaia®) added with 1 mL of an aqueous solution of brown sugar (Nuntrin G®, 1:2 w/v) and heated for 1.5 min in the microwave (1000 W) | ||

| Acid aroma (ACA) | Aroma pungent associated with the acidity of the fruits | Weak Same preparation as the strong reference, diluted with water 1:1 (v/v) |

| Strong 100 mL of aqueous lemon juice solution 1:100 (v/v) added with 60 μL of pineapple essence (Duas Rodas®) | ||

| Mixed fruits aroma (MFA) | Characteristic aroma of a mixture of ripe fruits | Weak Same preparation as the strong reference, diluted with water 1:4 (v/v) |

| Strong Mixed fruit nectar (Jandaia®) blended with pineapple for 1 min (1:1 v/w) | ||

| Flavor | ||

| Ácid taste (ACT) | Characteristic acid taste of an aqueous solution of citric acid | Weak 0.02 g of citric acid in 100 mL of water |

| Strong 0.2 g of citric acid in 100 mL of water | ||

| Sweet taste (SWT) | Characteristic sweet taste of an aqueous solution of sucrose | Weak 2 g of sucrose in 100 mL of water |

| Strong 5.5 g of sucrose in 100 mL of water | ||

| Mixed fruits flavor (MFF) | Flavor that reminds a mixture of fruits | Weak Mixed fruit nectar (Jandaia®) blended with pineapple for 1 min (1:1 v/w) and then diluted with water 1:4 (v/v) |

| Strong 100 mL mixed fruit nectar (Jandaia®) blended with pineapple for 1 min (1:1 v/w) and added by 15 µL of pineapple essence (Duas Rodas®) | ||

| Texture | ||

| Consistency (CON) | Characteristic related to the juice being more or less fluid, perceived when putting the product in the mouth | Weak Acerola pulp (Ali Polpa®) diluted with grape nectar (Dell Valle®) 1:3 (v/v) |

| Strong Acerola pulp (Ali Polpa®) diluted with grape nectar (Dell Valle®) 1.5:1 (v/v) | ||

| Solids in the mouth (SOL) | Particles perceived when putting the product in the mouth | Weak Guava nectar (Jandaia®) |

| Strong Acerola pulp (Ali Polpa®) diluted with grape nectar (Dell Valle®) 1.5:1 (v/v) | ||

Subsequently, the two formulations of mixed juices (F1 and F2), before and after pasteurization, were evaluated in triplicate, following the experimental design of balanced complete blocks. Approximately 40 mL of juice was served at room temperature in glass cups covered with watch glass and coded with three-digit random numbers. Water was provided to cleanse the palate, and remove the residue of the juice. Tests were performed in individual acclimatized booths (22 °C) under controlled lighting (white day light, fluorescent). The booths were equipped with computer terminals for automatic data collection/retrieval of responses using FIZZ software version 2.40A.

Affective tests

Acceptance test was carried out with the tropical juice blends under the same conditions described above, with a difference that the juices were served cold (16 °C). The panel consisted of 50 untrained individuals, who were either employees or students from Embrapa Tropical Agroindustry. Panelists were regular juice consumers and non-smokers. Sixty percent of the panelists were women with 90% of the total panelists aged 20–35 years. Overall acceptability was calculated using a nine-point hedonic structured scale where 9 was designated as ‘like extremely’ and 1 was designated as ‘dislike extremely’ (Meilgaard et al. 2006).

As the storage period was too long to keep the panel trained, a Check-All-That-Apply (CATA) test was performed to evaluate the storage effect. A list with the descriptive terms generated in QDA plus two terms related to the color of the juices (red and brown) was provided and the consumers were asked to check all the terms that applied to the given sample.

Statistical analyses

Physical, chemical, and acceptability data were subjected to the analysis of variance (ANOVA) in completely randomized designs and Tukey test was applied at α = 0.05 for comparison of mean values. For descriptive sensory analysis, data points were subjected to Grubs test to remove the outliers. ANOVA was then applied to individual descriptors using samples (S) and panelists (J) (blocks) as main effects and the interaction between them (S vs. J) as random effect, in order to get an indication of the signal/noise ratio of the variables. The CATA counts were summed for each product and the resulting contingency table was subjected to the multivariate Correspondence Analysis. Statistical analyses were performed using SAS program v.6.1 and XLSTAT software v.18.1.

Results and discussion

Antioxidant capacity of non-pasteurized fruit juices (control samples)

Despite the differences in the control formulations (F1 and F2), the results for both the non-thermal juices showed high antioxidant activity with similar values (p > 0.05) as measured by ABTS (8.66 μMol Trolox/g in average) and FRAP (21.93 μMol FeSO4/g in average). Considering a 200 mL-portion (1732 µMol Trolox), this is half the amount of antioxidants recommended for daily intake according to the Mediterranean diet based on bioactive compounds, as studied by Saura-Calixto and Goñi (2009).

Effect of the thermal treatment on bioactive compounds, color, and sensory quality of the tropical fruit juice formulations

The first objective of this study was to evaluate the effects of the pasteurization and hot-filling process on the bioactive compounds, color, and sensory quality parameters of two formulations of tropical fruit juice with high antioxidant activity, namely F1 and F2, as compared to the control (before thermal treatment) non-pasteurized samples. Results indicated that the pasteurization process did not affect the total polyphenol content and antioxidant activity (FRAP and ABTS methods) of both the formulations, but caused a significant depletion of the ascorbic acid content (Table 3). The thermal process used (85 °C for 30 s) decreased the ascorbic acid by approximately 7% in F1 and F2. Sánchez-Moreno et al. (2005), while evaluating the effects of thermal treatments on the antioxidant capacity of orange juice (using DPPH method), showed that the pasteurization using 90 °C for 60 s decreased the antioxidant capacity of the juice only by 6.6%. The authors also reported a less than 9% degradation of ascorbic acid. Odriozola-Serrano et al. (2008), showed statistical differences between the antioxidant capacity of pasteurized and non-pasteurized strawberry juices. However, this difference was less than 4% when 90 °C was used for 30 s. These authors also reported less than 8% differences in the phenolic acids contents between the treatments.

Table 3.

Mean values of quality parameters of two tropical fruit juice formulations (blends) before and after pasteurization (day 0)

| Parameters | F1 | F2 | ||

|---|---|---|---|---|

| Control | Pasteurized | Control | Pasteurized | |

| TAA—ABTS (μMol Trolox/g) | 8.66 ± 1.58 a | 8.93 ± 0.58 a | 8.67 ± 0.74 a | 8.56 ± 0.73 a |

| TAA—FRAP (μMol FeSO4/g) | 21.30 ± 1.99 a | 22.02 ± 2.29 a | 22.55 ± 0.24 a | 22.34 ± 0.92 a |

| Ascorbic acid (mg/100 g) | 155.47 ± 2.50 a | 143.57 ± 2.42 b | 102.37 ± 2.85 a | 95.83 ± 2.38 b |

| TEP (mg AG eq/100 g) | 141.20 ± 1.15 a | 135.39 ± 5.51 a | 101.13 ± 2.40 a | 99.72 ± 1.23 a |

| Carotenoids (μg/100 g) | 3.51 ± 0.35 b | 5.88 ± 0.50 a | 7.93 ± 0.48 a | 7.65 ± 0.63 a |

| L* | 33.59 ± 0.84 b | 35.35 ± 0.44 a | 33,87 ± 1.15 a | 32.20 ± 0.48 b |

| a* | 7.16 ± 0.35 a | 6.99 ± 0.31 a | 7.04 ± 0.42 a | 7.48 ± 0.54 a |

| b* | 2.48 ± 0.40 a | 2.67 ± 0.46 a | 2.43 ± 0.38 a | 2.72 ± 0.26 a |

| h* | 0.33 ± 0.04 a | 0.36 ± 0.05 a | 0.33 ± 0.04 a | 0.35 ± 0.02 a |

| C* | 7.58 ± 0.45 a | 7.49 ± 0.43 a | 7.45 ± 0.49 a | 7.96 ± 0.59 a |

| ΔE | – | 1.77 | – | 1.74 |

Means values in each line (comparison between the control and pasteurized treatments of each formulation) followed by different letters differ significantly in Tukey’s test (p < 0.05)

Control = fresh, not pasteurized; TAA = total antioxidant activity; TEP = total extractable polyphenols; L*, a*, b* = color coordinates; h* = hue angle; C* = chroma; ΔE = color difference between fresh and pasteurized juices of each blend

Paul and Ghosh (2012), while evaluating the effect of thermal treatment, observed 31% ascorbic acid degradation in a very long heat treatment comprised of heating at 70 °C for 90 min in pomegranate juice. Ascorbic acid is a labile molecule whose concentration could be decreased during processing or storage due to enzymatic or non-enzymatic degradation. Heat treatments are used to inactivate oxidative enzymes. Munyaka et al. (2010), while evaluating the ascorbic acid stability, observed 21% and 43% less vitamin in broccoli after heating at 70 °C and 90 °C for 15 min, respectively. The same authors registered that l-ascorbic acid is first oxidized to dehydroascorbic acid (DHAA), which is less stable and can be rapidly and irreversible hydrolyzed to 2,3-diketogulonic acid (2,3-DKG), losing its functional properties. However, the 7% reduction that we observed in our analysis, although statistically significant, can be considered low, as the remaining ascorbic acid content of the pasteurized samples of both the formulations was still very high. The recommended daily intake (RDI) of vitamin C (as ascorbic acid) is 45 mg; a 200 mL juice portion would provide two or three times higher vitamin C than RDI.

An increase in the carotenoids after thermal treatment would appear to be a contradictory result. However, similar effects have been well documented elsewhere (Muzhingi et al. 2008; Khachik et al. 1992). It has been suggested that food processing such as cooking or grinding might improve the extractability of the carotenoids. In addition, Khachik et al. (1992) found that the carotenoid concentration in several green vegetables increased with conventional blanching and cooking. Granado et al. (1992) also reported that the boiling of vegetables resulted in an increase in the amount of some of the carotenoids. Khachik et al. (1992) suggested that the increase in carotenoid concentration is suspected to be due to the increased chemical extractability of carotenoids as a result of the breakdown of the food matrix. A combination of homogenization and heat treatment disrupts cell membranes and protein–carotenoid complex, making carotenoids more accessible for the extraction.

According to the objective evaluation, the color of both the formulations were of red tonality as indicated by the low values of angle hue (h*); this is due to the presence of acai, a fruit rich in anthocyanin. However, the colors were not pure as apparent by low C* (chroma) that indicates the color saturation; it tended to be brown. Color parameters a* and b* were not affected by the thermal treatment.

Lightness was the only parameter that was affected by pasteurization (p < 0.05) as compared with the control treatments (before pasteurization) and after pasteurization, for both F1 and F2 juice formulations; a small but noticeable difference in color (ΔE near 1.75) was observed. Mokrzycki and Tatol (2011) have stated that with ΔE between 1 and 2, only an expert observer can notice the difference. The two juice formulations showed opposite behaviors. For F1, the pasteurized sample had higher L* values (clearer) than non-pasteurized juice, while for F2 the pasteurized sample showed lower values, indicating that the juice became darker after pasteurization. Albarici and Pessoa (2012), while studying the effects of heat treatment and storage temperature on the use of acai drink, concluded that the pasteurization process could improve the preservation of anthocyanin in the pulp.

Table 4 summarizes mean intensities of all sensory descriptors, since interaction samples × panelists was not significant (p > 0.05) for most descriptors. Besides, no significant interactions were apparent. This Table also presents the global acceptability reached by each sample in the hedonic tests. Regarding the sensory profile (Table 4), F1 was observed to be more stable to heating as there was no significant difference in the perception of any of the descriptors (p > 0.05) between control (fresh, non-pasteurized) and pasteurized juice. Acceptability of F1 also remained unaltered, reaching the category ‘like moderately’ in the middle of the acceptance region of the hedonic scale. As compared to both mixed juices (F1 and F2), control samples only differed from each other for ‘oil on the surface’ (p = 0.014). F2, richer in yellow mombin and acai (Euterpe oleracea), presented higher frequency of oil drops floating on the juice surface. Acai is a fruit with relative high lipid content (1.83–9.74%) (Yuyama et al. 2011). However, when sample F2 was pasteurized, this visual perception decreased. As a function of heating over 45 °C, the oil-water emulsion was partially broken, generating smaller droplets that were hatched into the pulp mass (Tangsuphoom and Coupland 2009). Comparing the control treatments of F1 and F2 formulations, it can be observed in Table 4 that F1 has a higher intensity for “acid taste”, possibly due to the proportion of camu-camu pulp. F2 has a higher intensity for the descriptors “visible solids”, “oil in the surface”, and “solids in the mouth”, possibly due to the proportion of acai pulp used in this formulation.

Table 4.

Mean values of color parameters, sensory descriptors and acceptability of two tropical fruit juice formulations before and after pasteurization

| Attributes | F1 | F2 | ||

|---|---|---|---|---|

| Control | Pasteurized | Control | Pasteurized | |

| Visible solids | 4.86 ± 1.50 a | 5.16 ± 1.69 a | 5.84 ± 1.31 a | 5.70 ± 1.25 a |

| Oil on the surface | 5.13 ± 1.54 a | 5.11 ± 1.50 a | 6.39 ± 1.76 a | 4.70 ± 1.48 b |

| Sweet aroma | 5.08 ± 1.69 a | 5.06 ± 1.82 a | 5.21 ± 1.59 b | 5.68 ± 1.24 a |

| Acid aroma | 4.64 ± 1.47 a | 4.48 ± 1.35 a | 4.02 ± 1.67 a | 4.26 ± 1.27 a |

| Fruity aroma | 4.82 ± 1.57 a | 4.99 ± 1.62 a | 5.18 ± 1.43 b | 5.64 ± 1.58 a |

| Acid taste | 5.70 ± 1.41 a | 5.64 ± 1.40 a | 5.19 ±1.63 a | 5.16 ± 1.57 a |

| Sweet taste | 4.88 ± 1.38 a | 4.89 ± 1.49 a | 4.68 ± 1.63 a | 4.55 ± 1.23 a |

| Fruity flavor | 5.42 ± 1.38 a | 5.61 ± 1.21 a | 5.26 ± 1.48 a | 5.48 ± 1.63 a |

| Consistency | 5.40 ± 1.77 a | 5.65 ± 1.56 a | 5.05 ± 1.48 a | 5.20 ± 1.48 a |

| Solids in the mouth | 4.39 ± 1.94 a | 4.75 ± 1.98 a | 4.68 ± 1.83 a | 5.17 ± 1.53 a |

| Global acceptability | 7.0 ± 1.4 a | 6.8 ± 1.7 a | 6.01 ± 1.8 b | 7.0 ± 1.4 a |

Means values in each line (comparison between the control and pasteurized treatments of each formulation) followed by different letters differ significantly in Tukey’s test (p < 0.05)

Control = fresh, not pasteurized

The thermal treatment did not impair the aroma and flavor of the juices. These results agree those of Garruti et al. (2010), who observed that in general, the volatile compounds were resistant to pasteurization process, with the sensory profile of processed juice being very similar to that of the fresh juice while studying the changes in the key odor-active compounds and sensory profile of cashew apple juice. Facundo et al. (2010), in a similar study with pineapple juice, also reported that extraction, finishing, centrifugation, and pasteurization steps did not modify the flavor profile of the juice substantially. Major changes in flavor attributes were observed in the concentrated pineapple juice, which showed an increased intensity of undesirable descriptors such as the cooked fruit aroma, flavor, and an artificial aroma. In the present work, on the contrary, in sample F2, perception of ‘sweet aroma’ increased. Heating could liberate volatile compounds that were trapped in the oil phase. According to Neiens et al. (2017), the most powerful odor-active compounds of yellow mombin are ethyl butanoate and 4-hydroxy-2,5-dimethylfuran-3-one; these compounds are described as fruity, sweet, and caramel-like. In acai berry, Lim et al. (2016) found beta-damascenone and 2-phenylethanol to be among the strongest aroma-active compounds, both with sweet-like odors (rose and honey). We note that the main changes provoked in the sensory profile of F2 juice by the pasteurization process such as decrease in ‘oil on the surface’ and increase in ‘sweet’ and ‘fruity’ aroma, improved its acceptability from 6 (like slightly) to 7 (like moderately); both of the ratings correspond to acceptable juices.

Effect of storage on bioactive compounds, color, and sensory quality of the tropical fruit juice formulations

The storage effect was evaluated with chemical and sensory analyses and the results are presented in Table 5. Ascorbic acid was the chemical parameter that was most affected by storage time, while total polyphenols, carotenoids, and antioxidant activity presented almost a stable behavior during the storage. The ascorbic acid degradation was 30% and 40% for formulations F1 and F2, respectively, as compared to the control at 0 days of storage. Freitas et al. (2006), while working with pasteurized acerola juice, obtained 23% and 12% ascorbic acid reduction after 200 days of storage, respectively, when comparing the aseptic and hot-fill processes. The same authors also evaluated carotenoids and observed a 12% reduction after 200 days of storage; this is similar to the 17% reduction we observed for F1 and is 4% more than what was observed for F2. Total polyphenols presented a stable amount during storage for F2, with no significant difference. Total polyphenols observed to have decreased by 24% for F1. Nevertheless, the ascorbic acid content was still high at the end of storage time, averaging at the same or more than the usual values for lemon (74 mg/100 g), grape fruit (23 mg/100 g), kiwi (65 mg/100 g), and orange (83 mg/100 g) (Lee and Kader 2000), which are the well-known fruits for good vitamin C supplies.

Table 5.

Mean values of quality parameters of two pasteurized tropical fruit juice blends during 180-day storage

| Parameters | F1 | F2 | ||||

|---|---|---|---|---|---|---|

| 0 | 90 | 180 | 0 | 90 | 180 | |

| TAA—ABTS (μMol Trolox/g) | 8.93 ± 0.58 a | 8.22 ± 0.46 b | 8.64 ± 0.57 ab | 8.56 ± 0.73 a | 8.77 ± 0.43 a | 8.32 ± 0.53 a |

| TAA—FRAP (μMol FeSO4/g) | 22.02 ± 2.29 a | 20.78 ± 1.55 a | 21.82 ± 2.85 a | 22.34 ± 0.92 a | 20.08 ± 1.15 b | 20.86 ± 1.82 ab |

| Ascorbic acid (mg/100 g) | 143.57 ± 2.42 a | 100.73 ± 2.63 b | 115.54 ± 2.63 b | 95.83 ± 2.38 a | 85.76 ± 2.79 b | 50.99 ± 2.76 c |

| TEP (mg AG eq./100 g) | 135.39 ± 5.51 b | 160.87 ± 8.70 a | 102.58 ± 3.89 c | 99.72 ± 1.23 a | 96.52 ± 3.68 a | 101.05 ± 9.73 a |

| Carotenoids (μg/100 g) | 5.88 ± 0.50 a | 4.76 ± 0.33 b | 4.91 ± 0.55 b | 7.65 ± 0.63 a | 7.50 ± 0.43 a | 7.35 ± 0.34 a |

| L* | 35.35 ± 0.44 a | 29.88 ± 0.90 b | 30.74 ± 0.22 b | 32.20 ± 0.48 a | 27.75 ± 0.80 b | 28.60 ± 0.72 b |

| a* | 6.99 ± 0.31 a | 6.41 ± 0.69 b | 6.84 ± 0.32 ab | 7.48 ± 0.54 b | 7.43 ± 0.77 b | 9.17 ± 0.40 a |

| b* | 2.67 ± 0.46 c | 5.92 ± 0.92 b | 6.77 ± 0.30 a | 2.72 ± 0.26 c | 4.49 ± 0.59 b | 6.96 ± 0.53 a |

| h* | 0.36 0.05 b | 0.74 ± 0.05 a | 0.78 ± 0.01 a | 0.35 ± 0.02 c | 0.54 ± 0.04 b | 0.65 ± 0.03 a |

| C* | 7.49 ± 0.43 c | 8.74 ± 1.07 b | 9.63 ± 0.43 a | 7.96 0.59 b | 8.90 ± 0.89 b | 11.52 ± 0.57 a |

| ΔE | – | 6.39 | 6.17 | – | 4.80 | 5.82 |

| Global acceptability | 7.11 ± 1.21 a | 6.87 ± 1.45 ab | 6.16 ± 1.83 b | 7.26 ± 1.02 a | 7.08 ± 1.04 a | 6.87 ± 1.31 a |

Means values in each line (comparison among the storage time of each formulation) followed by different letters differ significantly in Tukey’s test (p < 0.05)

TAA = total antioxidant activity; TEP = total extractable polyphenols; L*, a*, b* = color coordinates; h* = hue angle; C* = chroma; ΔE = color difference between two samples calculated with respect to day zero

The color parameters presented significant differences (p < 0.05) with increase in values for b*, h*, and C*, while luminosity (L*) was reduced with storage time. As the differences among the parameter values were very small, the color difference (ΔE) was calculated. Both the formulations presented ΔE values much higher than two units, considered as a noticeable threshold for the common people, after 90 days of storage. It can be observed that ΔE was more pronounced in F1 formulation, with the color going from a strong red to a brown color. However, the color in F1 was stabilized after 90 days while it continued to change in F2. This alteration of color could be related to a decrease in pigments carotenoids and anthocyanins (Table 5). Tarazona-Díaz and Aguayoa (2013), while evaluating the effects of centrifugation and storage time (30 days) on pasteurized watermelon juices found that in non-centrifuged (NC) juice, hue values (h*) decreased during storage, while in the centrifuged juice h* tended to increase until day 20 and then remained constant until the end of storage. Authors attributed the variation in the red color to a decrease in lycopene. In fact, Liao et al. (2007) have reported that a long storage time (6 months) yielded a great loss of carotenoids and color in carrot juices.

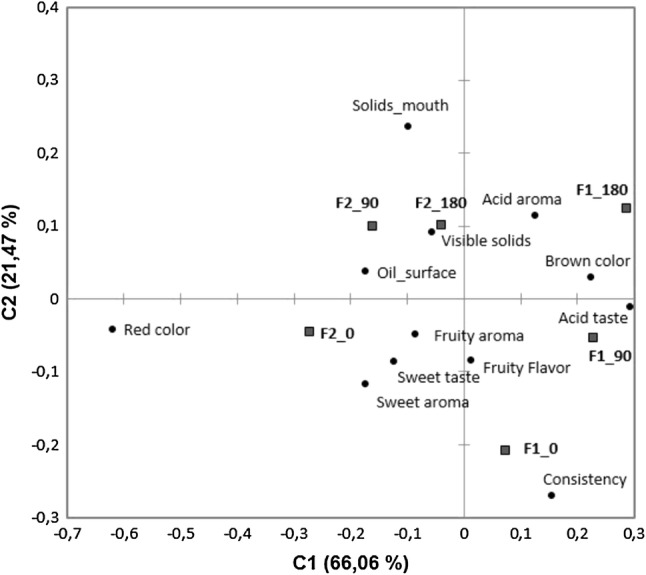

When applying a multivariate statistical analysis (CA) to the frequency of all sensory descriptive terms reported by consumers to both juice samples at different storage times, the first two axis accounted for 87.53% of the total variability (Fig. 1). The first axis (A1) was associated with the parameters related to appearance and flavor, segregating the formulations. Juice F1 was observed to be brown and with more intense acid aroma than juice F2, which in turn was red with more oil drops on the surface and presented higher intensity of sweet and fruity aromas. Samples also differed in basic tastes, with juice F1 being always more acidic than juice F2. The second axis (A2) was associated with the parameters related to texture, distributing the samples according to storage time. Juices from time zero were located on the negative side of axis A2, while samples from later times were located at an upper position in the graph. We have noted that juice F1_0 was thicker than F2_0, however the consistency decreased with storage time for both the formulations. It is also clear that the presence of drops of oil, visible solids, and solids on the mouth, together with the brown color increased over time. The samples from the end of storage were poorer in fruity and sweet aroma, making the acid aroma more evident. These changes in the sensory profile caused a significant decrease in the F1 acceptance; however, in the consumer’s opinion, these were not as important in F2, for which the global acceptability remained unchanged until the end of storage. When studying the effect of thermal treatment and storage (60 days) on the physical and sensory properties of grapefruit juice, Igual et al. (2014) have observed that color saturation and grapefruit smell were the attributes impaired but the preference did not show statistically significant differences.

Fig. 1.

Symmetric plot representing correspondence analysis (CA) from CATA tests corresponding to sensory analyses of two pasteurized tropical fruit juice formulations during 180-day of storage

Conclusion

In general, pasteurization (85 °C for 30 s) followed by hot-filling does not present deleterious effects to functional components, sensory quality, and acceptability of mixed tropical juices. On the contrary, for formulations with higher concentrations of acai and yellow mombin (F2), pasteurization improved the sensory profile and acceptability. Storage time did impair the appearance, aroma, ascorbic acid content, polyphenols, and carotenoids, especially in sample F1, which is formulated with camu-camu and cashew apple. However, the acceptability and the nutritional quality were still high in these products after 180-day of storage, thus, not preventing their consumption.

Acknowledgements

We thank Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq) for the student scholarships.

Funding

This work was supported by Embrapa—Empresa Brasileira de Pesquisa Agropecuária (Brazilian Agricultural Research Corporation).

Compliance with ethical standards

Conflict of interest

The authors declare that they have no conflict of interest.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Contributor Information

Nédio Jair Wurlitzer, Email: nedio.jair@embrapa.br.

Ana Paula Dionísio, Email: ana.dionisio@embrapa.br.

Janice Ribeiro Lima, Email: Janice.lima@embrapa.br.

Deborah dos Santos Garruti, Email: Deborah.garruti@embrapa.br.

Idila Maria da Silva Araújo, Email: idila.araujo@embrapa.br.

Renier Felinto Julião da Rocha, Email: hfelinto@gmail.com.

Johnnathan Lima Maia, Email: johnnathanlm89@gmail.com.

References

- Albarici TR, Pessoa JDC. Effects of heat treatment and storage temperature on the use of açaí drink by nutraceutical and beverage industries. Food Sci Technol (Campinas) 2012;32:9–14. doi: 10.1590/S0101-20612012005000026. [DOI] [Google Scholar]

- AOAC – Association of Official Analytical Chemists . Official methods of analysis. 18. Gaithersburg: AOAC; 2005. [Google Scholar]

- Carvalho-Silva LB, Dionísio AP, Pereira ACS, Wurlitzer NJ, Brito ES, Bataglion GA, Brasil IM, Eberlin MN, Liu RH. Antiproliferative, antimutagenic and antioxidant activities of a Brazilian tropical fruit juice. LWT Food Sci Technol. 2014;59:1319–1324. doi: 10.1016/j.lwt.2014.04.002. [DOI] [Google Scholar]

- Damasceno LF, Fernandes FAN, Magalhães MMA, Brito ES. Non-enzymatic browning in clarified cashew apple juice during thermal treatment: kinetics and process control. Food Chem. 2008;106:172–179. doi: 10.1016/j.foodchem.2007.05.063. [DOI] [Google Scholar]

- Facundo HVV, Souza Neto MA, Maia GA, Narain N, Garruti DS. Changes in flavor quality of pineapple juice during processing. J Food Process Preserv. 2010;34:508–519. doi: 10.1111/j.1745-4549.2008.00356.x. [DOI] [Google Scholar]

- Freitas CAS, Maia GA, Costa JMC, Figueiredo JWR, Sousa PHM, Fernandes AG. Estabilidade dos carotenoides, antocianinas e vitamina C presentes no suco tropical de acerola (Malpighia emarginata DC.) adoçado envasado pelos processos hot-fill e asséptico. Ciênc agrotec. 2006;30:942–949. doi: 10.1590/S1413-70542006000500018. [DOI] [Google Scholar]

- Garruti DS, Facundo HVV, Souza Neto MA, Wagner R. Changes in the key odour-active compounds and sensory profile of cashew apple juice during processing. In: Blank I, Wüst M, Yeretzian C, editors. Expression of multidisciplinary flavour science. Meißenheim: Zürcher; 2010. pp. 215–219. [Google Scholar]

- Granado F, Olmedilla B, Blanco I, Rojas-Hidalgo E. Carotenoid composition in raw and cooked Spanish vegetables. J Agric Food Chem. 1992;40:2135–2140. doi: 10.1021/jf00023a019. [DOI] [Google Scholar]

- Igual M, Contreras C, Camacho MM, Martínez-Navarrete N. Effect of thermal treatment and storage conditions on the physical and sensory properties of grapefruit juice. Food Bioprocess Technol. 2014;7:191–203. doi: 10.1007/s11947-013-1088-6. [DOI] [Google Scholar]

- Khachik F, Goli MB, Beecher GR, Holden J, Lusby WR, Tenorio MD, Barrera MR. Effect of food preparation on qualitative and quantitative distribution of major carotenoid constituents of tomatoes and several green vegetables. J Agric Food Chem. 1992;40:390–398. doi: 10.1021/jf00015a006. [DOI] [Google Scholar]

- Larrauri JA, Rupérez P, Saura-Calixto F. Effect of drying temperature on the stability of polyphenols and antioxidant activity of red grape pomace peels. J Agric Food Chem. 1997;45:1390–1393. doi: 10.1021/jf960282f. [DOI] [Google Scholar]

- Lee SK, Kader AA. Preharvest and postharvest factors influencing vitamin C content of horticultural crops. Postharvest Biol Technol. 2000;20:207–220. doi: 10.1016/S0925-5214(00)00133-2. [DOI] [Google Scholar]

- Liao HM, Sun Y, Ni YY, et al. The effect of enzymatic mash treatment, pressing, centrifugation, homogenization, deaeration, sterilization and storage on carrot juice. J Food Process Eng. 2007;30:421–435. doi: 10.1111/j.1745-4530.2007.00118.x. [DOI] [Google Scholar]

- Lim S-H, Nam H, Baek H-H. Aroma characteristics of acai berry. Korean J Food Sci Technol. 2016;48:122–127. doi: 10.9721/KJFST.2016.48.2.122. [DOI] [Google Scholar]

- Meilgaard M, Civille GV, Carr BT. Sensory evaluation techniques. 4. Boca Raton: CRC Press; 2006. [Google Scholar]

- Mokrzycki W, Tatol M. Color difference delta E: a survey. Mach Graph Vis. 2011;20:383–411. [Google Scholar]

- Munyaka AW, Makule EE, Oey I, Loey AV, Hendrick M. Thermal stability of l-ascorbic acid and ascorbic acid oxidase in Broccoli (Brassica oleraceae var. italic) J Food Sci. 2010;75:336–340. doi: 10.1111/j.1750-3841.2010.01573.x. [DOI] [PubMed] [Google Scholar]

- Muzhingi T, Yeum K-J, Russell RM, Johnson EJ, Qin J, Tang G. Determination of carotenoids in yellow maize, the effects of saponification and food preparations. Int J Vitam Nutr Res. 2008;78:112–120. doi: 10.1024/0300-9831.78.3.112. [DOI] [PubMed] [Google Scholar]

- Nayak B, Liu RH, Tang J. Effect of processing on phenolic antioxidants of fruits, vegetables, and grains—a review. Crit Rev Food Sci Nutr. 2015;55:887–918. doi: 10.1080/10408398.2011.654142. [DOI] [PubMed] [Google Scholar]

- Neiens S, Geiblitz S, Steinhaus M. Aroma-active compounds in Spondias mombin L. fruit pulp. Eur Food Res Technol. 2017;243:1073–1081. doi: 10.1007/s00217-016-2825-7. [DOI] [Google Scholar]

- Odriozola-Serrano I, Soliva-Fortuny R, Martín-Belloso O. Phenolic acids, flavonoids, vitamin C and antioxidant capacity of strawberry juices processed by high-intensity pulsed electric fields or heat treatments. Eur Food Res Technol. 2008;228:239. doi: 10.1007/s00217-008-0928-5. [DOI] [PubMed] [Google Scholar]

- Paul R, Ghosh U. Effect of thermal treatment on ascorbic acid content of pomegranate juice. Indian J Biotechnol. 2012;11:309–313. [Google Scholar]

- Pereira ACS, Wurlitzer NJ, Dionísio AP, Soares MVL, Bastos MSR, Alves RE, Brasil IM. Synergistic, additive and antagonistic effects of fruit mixtures on total antioxidant capacities and bioactive compounds in tropical fruit juices. Arch Latinoam Nutr. 2015;65:119–127. [PubMed] [Google Scholar]

- Remini H, Mertz C, Belbahi A, Achir N, Dornier M. Degradation kinetic modelling of ascorbic acid and colour intensity in pasteurised blood orange juice during storage. Food Chem. 2015;173:665–673. doi: 10.1016/j.foodchem.2014.10.069. [DOI] [PubMed] [Google Scholar]

- Rodriguez-Amaya DB. A guide to carotenoid analysis in foods. Washington, D.C.: ILSI Press; 2001. [Google Scholar]

- Rufino MSM, Alves RE, Brito ES, Perez-Jimenez J, Saura-Calixto F, Mancini-Filho J. Bioactive compounds and antioxidant capacities of 18 nontraditional tropical fruits from Brazil. Food Chem. 2010;121:996–1002. doi: 10.1016/j.foodchem.2010.01.037. [DOI] [Google Scholar]

- Sánchez-Moreno C, Plaza L, Elez-Martínez P, De Ancos B, Olga Martín-Belloso O, Cano MP. Impact of high pressure and pulsed electric fields on bioactive compounds and antioxidant activity of orange juice in comparison with traditional thermal processing. J Agric Food Chem. 2005;53:4403–4409. doi: 10.1021/jf048839b. [DOI] [PubMed] [Google Scholar]

- Saura-Calixto F, Goñi I. Definition of the Mediterranean diet based on bioactive compounds. Crit Rev Food Sci Nutr. 2009;49:45–152. doi: 10.1080/10408390701764732. [DOI] [PubMed] [Google Scholar]

- Silva NL, Crispim JMS, Vieira RP. Kinetic and thermodynamic analysis of anthocyanin thermal degradation in acerola (Malpighia emarginata D.C.) pulp. J Food Process Preserv. 2016;41:1–7. doi: 10.1111/jfpp.13053. [DOI] [Google Scholar]

- Stone H, Sidel JL. Sensory evaluation practices. 3. London: Elsevier; 2004. [Google Scholar]

- Tangsuphoom N, Coupland JN. Effect of thermal treatments on the properties of coconut milk emulsions prepared with surface-active stabilizers. Food Hydrocoll. 2009;23:1792–1800. doi: 10.1016/j.foodhyd.2008.12.001. [DOI] [Google Scholar]

- Tarazona-Díaz MP, Aguayoa E. Influence of acidification, pasteurization, centrifugation and storage time and temperature on watermelon juice quality. J Sci Food Agric. 2013;93:3863–3869. doi: 10.1002/jsfa.6332. [DOI] [PubMed] [Google Scholar]

- Tiwari BK, O’Donnell CP, Muthukumarappan K, Cullen PJ. Ascorbic acid degradation kinetics of sonicated orange juice during storage and comparison with thermally pasteurized juice. LWT Food Sci Technol. 2009;42:700–704. doi: 10.1016/j.lwt.2008.10.009. [DOI] [Google Scholar]

- Wurlitzer NJ, Dionisio AP, Lima JR, Bastos MSR, Pereira ACS, Modesto ALG. Obtenção de Sucos Mistos de Frutas Tropicais com Alto Teor de Polifenóis e Capacidade Antioxidante. Fortaleza: Embrapa Agroindústria Tropical (Comunicado Técnico 213); 2015. [Google Scholar]

- Yuyama LKO, Aguiar JPL, Silva Filho DF, Yuyama K, Varejão MJ, Fávaro DIT, Vasconcelos MBA, Pimentel SA, Caruso MSF. Caracterização físico-química do suco de açaí de Euterpe precatoria Mart. oriundo de diferentes ecossistemas amazônicos. Acta Amaz. 2011;41:545–552. doi: 10.1590/S0044-59672011000400011. [DOI] [Google Scholar]

- Zepka LQ, Garruti DS, Sampaio KL, Mercadante AZ, da Silva MAAP. Aroma compounds derived from the thermal degradation of carotenoids in a cashew apple juice model. Food Res Int. 2014;56:108–114. doi: 10.1016/j.foodres.2013.12.015. [DOI] [Google Scholar]