Abstract

Effect of sonication on the quality parameters of juçara, banana and strawberry smoothie was evaluated using a rotational central composite design with power (73.5–250.0 W) and time (7–36 min) as independent variables. The sonicated smoothie was evaluated regarding anthocyanins, instrumental color and rheological and physicochemical parameters. Within the evaluated processing conditions, 86% of anthocyanins were retained. The pH and acidity of the smoothie wasn’t affected by the independent variables. Regarding instrumental color parameters, only luminosity was affected by the operational conditions. The cavitation phenomenon decreased the apparent viscosity of the smoothie. The sonicated smoothie presented non-Newtonian behavior, with characteristics of a pseudoplastic fluid (n < 1) in all treatments and control. Taking into account that the highest anthocyanin retention was observed at 147 W for 2 min, this condition was the most recommended for the processing of the product.

Keywords: Euterpe edulis martius, Anthocyanins, Viscosity, Instrumental color

Introduction

Brazil produces several native fruits rich in antioxidant compounds of great interest regarding their potential benefits to health such as functional compounds, including those associated with pigments, which are considered to have impact in reducing the incidence of chronic diseases caused by oxidative stress (Rufino et al. 2010; Zhao et al. 2015).

The cultivation of many of these fruits is practiced on a small-scale, or even through extractive agricultural models, which reduces their commercial availability. In addition, it is important to emphasize that due to certain sensory attributes, some of these fruits present low acceptance when consumed in nature (Schulz et al. 2016; Ribeiro et al. 2018). In this sense, the development of new products becomes an important alternative aiming to add value and to increase the consumption of these fruits (Bhardwaj and Pandey 2011).

Juçara, a typical Atlantic Rainforest fruit, mainly sold as frozen pulp, contains high anthocyanin concentrations, the phenolic compound responsible for its purple coloration and high antioxidant power. Due to these characteristics, juçara pulp is considered an important ingredient for the development of new products with potential functionality. In addition, since it does not have a sweet taste due to its low soluble solids content, the combination of juçara pulp with other fruits can increase its sensory acceptance (Schulz et al. 2016). For example, Moreira et al. (2017) reported the sensory acceptance of a probiotic juçara and mango-based blend. In the present study, juçara pulp was used as an ingredient in the development of a smoothie with banana and strawberry.

In order to meet the current demand of the consumer market that wishes to consume healthier products with sensory characteristics similar to fresh products, many studies have been conducted applying non-conventional conservation methods. Ultrasound, due to the cavitation phenomenon, is a technique that allows the microorganism destruction and enzymatic inactivation, with reduced impact on the sensory characteristics and bioactive compounds of the product when compared to pasteurization (Tiwari et al. 2009; Keenan et al. 2012).

However, its efficiency depends on several factors, such as the physical and chemical characteristics of the food matrix and the microbial load present in the food, among others. Thus, each product requires different processing conditions, and specific studies are required for the full knowledge of sonication effects on its characteristics (Chemat and Khan 2011).

In this context, the aim of the present study was to evaluate the effect of sonication on the main physical and chemical characteristics of a juçara, banana and strawberry smoothie, applying a rotational central composite experimental design, with power and processing time as the evaluated factors.

Materials and methods

Raw materials and smoothie development

Strawberry and juçara pulps, both frozen and unpasteurized, were obtained, respectively, from local market at Rio de Janeiro city and from the processing industry, in Espírito Santo state. The juçara pulp was pretreated in a Centrifuge with 100 μm nylon mesh (Centrifugal IEC - Model K7165, USA) to remove suspended solids and reduce lipid fraction, as it contributes to oxidation. The banana pulp was obtained by depulping of fruits from nanica variety, purchased in Rio de Janeiro local market, in a horizontal depulper (Itametal, Brazil) comprising 1.5 mm stainless steel sieve and polyethylene blades. The bananas were used at maturity stage 6, with full yellow peels. All pulps were stored at − 18 °C until the experiments were performed.

Smoothie formulated with juçara (20%), banana (40%) and strawberry (40%) pulps was standardized in a pilot blender. This product was developed according to data reported by Ribeiro et al. (2018). These authors considered both sensory acceptance and antioxidant capacity as parameters for selection of this formulation. After mixing, the smoothie was homogenized in an APV homogenizer (Gaulin, USA) at 60 MPa (control), maximum equipment pressure. The homogenized smoothie was then subjected to sonication assays.

Sonication processing

Sonication was carried out in batches using an Ultrasonic UIP-1000hd processor from Hielscher (Teltow, Germany) (frequency 20 kHz–220 V) with power intensity of 200 W cm−2, equipped with a titanium transducer (IP65), Buster B4 1.8 with an area of 2.5 cm2, and a BS2d18 sonotrode, the latter submerged 20 mm in the sample.

For each process, 200 mL of the smoothie was placed in a jacketed glass reactor, coupled to a thermostatic bath set at 10 °C aiming to decrease the temperature during processing. A rotational central composite experimental design was applied, in which power and processing time were the independent variables, taking into account literature data (Table 1) (Chemat and Khan 2011; Keenan et al. 2012; Costa et al. 2013). It is also shown energy intensity and amplitude in order to gather details about the processing. These variables are directly related to the applied power and to the probe used. The temperature gradient (ΔT), given by the difference between the final and initial temperature of the samples, was recorded in all assays.

Table 1.

Rotational central composite experimental design for sonication of juçara, banana and strawberry smoothie

| Assay | Coded variables (actual values) | Parameters associated to sonication | ||

|---|---|---|---|---|

| Time (min) | Power (W) | Energy intensity (W/cm2) | Amplitude (%) | |

| 1 | − 1 (7) | − 1 (73.5) | 29 | 29 |

| 2 | 1 (31) | − 1 (73.5) | 29 | 31 |

| 3 | − 1 (7) | 1 (220) | 88 | 89 |

| 4 | 1 (31) | 1 (220) | 88 | 90 |

| 5 | 0 (19) | 0 (147) | 59 | 64 |

| 6 | 0 (19) | 0 (147) | 59 | 64 |

| 7 | 0 (19) | 0 (147) | 59 | 64 |

| 8 | − 1.41 (2) | 0 (147) | 59 | 65 |

| 9 | 1.41 (36) | 0 (147) | 59 | 62 |

| 10 | 0 (19) | − 1.41 (43.5) | 17 | 28 |

| 11 | 0 (19) | 1.41 (250) | 100 | 100 |

Analytical methods

Total monomeric anthocyanins

Total monomeric anthocyanins were quantified using the differential pH method, applying cyanidin-3-glucoside as reference. The obtained extracts were diluted in buffers, at pH 1.0 and pH 4.5, separately, and after 30 min of stabilization, absorbances were determined at 510 and 700 nm (Giusti and Wrolstad 2001).

Instrumental color

The instrumental color analysis was performed on a colorimeter (ColorQuest XE, Hunterlab) using the coordinate CIELab/CIELCH system of L*, a*, b*, chroma (C*) and Hue angle (H°) (Ferreira 1981).

Physicochemical characteristics

The determinations were carried out following the methodologies proposed by AOAC (2006). An adequately calibrated automatic titrator (785 DMP Titrino, Metrohm) was used for the pH and titratable acidity measurements. Soluble solids determinations were performed using a digital refractometer (Pal-3, Atago).

Rheological characteristics

Rheological analyses in steady state were performed on a HaakeMARS II Rheometer (Thermo Electron Corporation) (Karlsruhe, Germany), using a plate–plate device (PP60Ti) and 1 mm gap. The time for each experimental determination was 3 min, obtaining 90 deformation points (0–600 s−1) (Gouvêa et al. 2017).

The Power Law model (Eq. 1) was adjusted to experimental data of shear stress versus shear rate by means of a non-linear regression, using the Statistica software, version 12.

| 1 |

where τ is the shear stress (Pa), k is the consistency index (Pa sn), γ is the shear rate (s−1) and n is the flow behavior index.

Data analysis

The results of the dependent variables adopted as responses were presented as the average value of assays and analyses carried out in triplicate. Statistical analyses of the experimental data were performed using the Statistica software, version 12 (Statsoft Inc., Tulsa, OK, USA). The analysis of variance and F-test were used to estimate the significance of the observed effects.

Results and discussion

Anthocyanins

The sonication process reduced the anthocyanin content of the smoothie, regardless of the operational conditions. Relating to the control, the sample with the highest degradation of these pigments (T4), obtained at 220 W for 31 min, still retained 86% of these compounds (Table 2). It is known that cavitation that occurs during the sonication process can cause degradation of bioactive compounds (Chemat and Khan 2011), which is corroborated in the present study. The formation and collapse of cavitation bubbles, which leads to temperature and pressure increases into medium favors the degradation of pigments (Tiwari et al. 2010). In addition, anthocyanin interactions with free radicals, for example, formed during sonication, facilitate the breakdown of the pigment’s structure (Sadilova et al. 2007).

Table 2.

Total monomeric anthocyanins, instrumental color, physicochemical and rheological characteristics of juçara, banana and strawberry sonicated smoothie and control smoothie

| Assay | TMAa | L* | a* | H° | pH | Acidityb | SS | η (Pa s−1) | n | k | ∆t (°C) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Control | 14.0 ± 0.5 | 35.8 ± 0.6 | 9.3 ± 0.3 | 359 ± 0 | 4.2 ± 0.1 | 0.44 ± 0.02 | 11.5 ± 0.1 | 0.24 ± 0.02 | 0.30 | 6.2 | – |

| T1 (73.5 W/7 min) | 13.5 ± 0.1 | 35.7 ± 0.2 | 9.0 ± 0.1 | 359 ± 0 | 4.2 ± 0.1 | 0.44 ± 0.01 | 11.4 ± 0.4 | 0.19 ± 0.01 | 0.30 | 4.7 | 12 |

| T2 (73.5 W/31 min) | 13.5 ± 0.4 | 35.8 ± 0.2 | 9.1 ± 0.0 | 359 ± 0 | 4.2 ± 0.1 | 0.44 ± 0.01 | 11.6 ± 0.1 | 0.16 ± 0.01 | 0.34 | 3.4 | 14 |

| T3 (220 W/7 min) | 13.6 ± 0.2 | 36.2 ± 0.5 | 9.5 ± 0.1 | 360 ± 0 | 4.2 ± 0.1 | 0.41 ± 0.01 | 11.6 ± 0.1 | 0.14 ± 0.01 | 0.36 | 2.8 | 43 |

| T4 (220 W/31 min) | 12.0 ± 0.1 | 36.6 ± 0.7 | 8.9 ± 0.5 | 359 ± 0 | 4.2 ± 0.1 | 0.41 ± 0.01 | 11.1 ± 0.1 | 0.12 ± 0.01 | 0.34 | 2.5 | 44 |

| T5 (147 W/19 min) | 12.6 ± 0.2 | 36.0 ± 0.1 | 9.3 ± 0.1 | 360 ± 0 | 4.2 ± 0.0 | 0.44 ± 0.00 | 11.6 ± 0.1 | 0.14 ± 0.00 | 0.32 | 3.3 | 32 |

| T6 (147 W/19 min) | 13.0 ± 0.1 | 36.1 ± 0.3 | 9.2 ± 0.1 | 359 ± 0 | 4.4 ± 0.0 | 0.41 ± 0.01 | 11.6 ± 0.1 | 0.14 ± 0.00 | 0.35 | 2.7 | 33 |

| T7 (147 W/19 min) | 12.8 ± 0.2 | 36.3 ± 0.2 | 9.5 ± 0.4 | 360 ± 0 | 4.2 ± 0.0 | 0.44 ± 0.00 | 11.5 ± 0.1 | 0.14 ± 0.00 | 0.32 | 3.2 | 30 |

| T8 (147 W/2 min) | 13.9 ± 0.2 | 35.6 ± 0.1 | 8.9 ± 0.0 | 359 ± 0 | 4.2 ± 0.0 | 0.44 ± 0.01 | 11.5 ± 0.1 | 0.19 ± 0.01 | 0.32 | 4.4 | 24 |

| T9 (147 W/36 min) | 12.3 ± 0.3 | 36.2 ± 0.1 | 9.2 ± 0.1 | 359 ± 0 | 4.3 ± 0.0 | 0.42 ± 0.00 | 11.5 ± 0.1 | 0.12 ± 0.01 | 0.33 | 2.7 | 36 |

| T10 (43.5 W/19 min) | 13.5 ± 0.0 | 36.2 ± 0.2 | 9.4 ± 0.1 | 360 ± 0 | 4.2 ± 0.0 | 0.43 ± 0.00 | 11.5 ± 0.1 | 0.21 ± 0.00 | 0.30 | 5.6 | 18 |

| T11 (250 W/19 min) | 12.8 ± 0.2 | 36.6 ± 0.4 | 9.5 ± 0.2 | 360 ± 0 | 4.2 ± 0.0 | 0.44 ± 0.01 | 11.8 ± 0.1 | 0.15 ± 0.02 | 0.29 | 4.2 | 50 |

TMA Total monomeric anthocyanins, L* luminosity, a* red intensity, H° Hue angle, SS soluble solids expressed in °Brix, n flow behavior index, k consistency index expressed in Pa sn, η Apparent viscosity at 100 s−1 expressed in Pa s, ∆t temperature gradient

aResults expressed in mg of cyanidin-3-glucoside per 100 g

bResults expressed in grams of citric acid per 100 g

Tiwari et al. (2009) observed a 5% degradation of the anthocyanin content in blackberry juice when using the most drastic sonication condition. In that case, the amplitude, time and theoretical intensity applied were 100%, 10 min and 18.75 W cm−2, respectively. Mohideen et al. (2015), in the processing of blueberry juice by continuous ultrasound at 24 mL min−1 and 93.5 mL min−1, applying an amplitude range of 40–100%, observed no significant degradation in anthocyanin content. Thus, the higher anthocyanin loss (14%) observed in this study was higher than the data reported in the literature. This difference was due to the applied power intensity, which, in the present study, was 10-fold higher than that reported by Tiwari et al. (2009), and the use of batch processing, without agitation, which increases the contact time of the product with the probe, favoring the degradation of this pigment in comparison to the continuous mode processing adopted by Mohideen et al. (2015). In addition, it can also be due to the different fruit matrices.

It can be noted that anthocyanins exhibit certain stability to sonication in different processing conditions, as observed in the aforementioned studies, demonstrating that this technology can be a potential alternative for processing of fruit juices, especially those rich in anthocyanins.

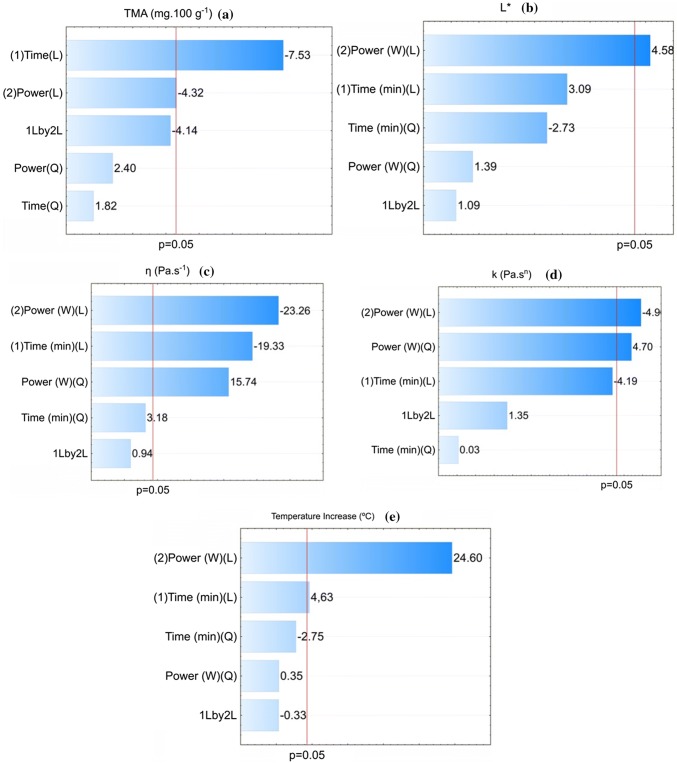

Regarding the effects of the independent variables on the smoothie anthocyanin content, Pareto chart indicates that the linear effects of time and processing power were significant and negative (p < 0.05), reinforcing that long processing times and high power affect smoothie anthocyanin content (Fig. 1a).

Fig. 1.

Pareto chart showing the effects of independent variables on total monomeric anthocyanins (TMA) (a), luminosity (L*) (b), apparent viscosity (η) (c), consistency index (k) (d) and temperature increase (e) of juçara, banana and strawberry sonicated smoothie

Instrumental color

Little variation was observed in luminosity (L*), red intensity (a*) and Hue angle (H°) of the smoothie samples subjected to different sonication conditions. Among these responses, only luminosity was significantly affected by the treatment, as showed in the Pareto chart (Fig. 1b), in which the linear effect of power was positive (p < 0.05), indicating that increased power leads to luminosity increase. There was an increase in smoothie luminosity when power was superior than 180 W. This may be due to the breakdown of the cellular structure of the fruit pulps by the cavitation effect, triggering various chemical and physical reactions, resulting in greater product luminosity (Chemat and Khan 2011). Tiwari et al. (2010) and Dias et al. (2015) also reported that red grape and soursop juices treated with ultrasound presented higher luminosity values than the control juices. According to these authors, this is due, initially, to the precipitation of suspended particles in the juice due to sonication.

However, in practical terms, the overall color changes were very small, and would not be perceptible by naked eye, mainly regarding a* (red intensity) and H° (Hue angle), which represents the product global color observed by the consumer.

Physicochemical characteristics

In practical terms, the differences among pH, acidity and soluble solids parameters of the smoothie are mainly due to the very low analytical error of the applied analysis methods. Therefore, the sonication conditions did not affect these characteristics. These results are in agreement with the data reported by Chitgar et al. (2017) when evaluating sonication effects on the physicochemical parameters of barberry juice, and by Bhat and Goh (2017), regarding the sonication of strawberry juice.

Rheological characteristics

As expected, the apparent viscosity of the smoothie was affected by sonication. Table 2 shows the apparent viscosity values at a shear rate of 100 s−1, which corresponds to the majority of processes applied in the fruit juice industry (Steffe 1996), as well as flow behavior index (n) and consistency index (k) values of the sonicated samples at different times and power.

The greatest decrease in apparent viscosity (51%) was observed during the longer treatments, of 31 and 36 min. However, from an industrial point of view, such reduction can be considered positive because a less viscous fluid presents less resistance during flow, which reflects in lower energy costs during processing (Steffe 1996; Costa et al. 2013).

The cavitation phenomenon was responsible for the decreased viscosity of the smoothie, since it acts on cellular structures breaking them due to extreme conditions, mainly pressure. According to Costa et al. (2013), who also observed viscosity decreasing of sonicated pineapple juice, which is considered a fibrous material containing high amounts of pectin, viscosity reduction is due to the breakdown of pectic molecules, leading to a decrease in the molecular weight of the carbohydrates present in the juice. The same behavior was observed by Keenan et al. (2012) during the sonication of a fruit smoothie.

The Pareto chart (Fig. 1c) indicates that the apparent viscosity decrease was significantly influenced by power and time. Reduction of apparent viscosity of the smoothie was observed when applying high power and long processing time.

The parameters related to the Power Law model, obtained by fitting the experimental data of the sonicated smoothie and the control, are displayed in Table 2. The model well fitted the data for all evaluated samples, presenting coefficient of determination values (R2) over 0.99 and p < 0.05 (Fcalc/Ftab ≫ 102).

All sonicated smoothies and control presented flow behavior index values lower than 1, which classifies them as non-Newtonian pseudoplastic fluids (Steffe 1996). Similar behavior has been observed for tomato puree, umbu pulp and mango suspensions (Tan and Kerr 2015; Gouvêa et al. 2017; Mahawar et al. 2018).

The consistency index (k) of the smoothie presented the same behavior as the apparent viscosity, decreasing after sonication. This indicates that the observed decrease in viscosity, caused by the possible breakdown of polysaccharides, direct impacts the consistency index of the samples, since the packaging degree of the product particles was decreased. The processed samples presented lower k values compared to the control, confirming that the cavitation phenomenon was responsible for these results. Tan and Kerr (2015) also associated the decreases observed in the particles size of tomato juice to the cavitation zones formed during the homogenization processes, which lead to increased pressure and temperature.

Regarding the effect of the independent variables on the consistency index (k) of the sonicated smoothie, the Pareto chart (Fig. 1d) indicates that power had a higher influence on the decrease of this parameter, with its linear effect more dominant, i.e. increasing power leads to a decrease in smoothie consistency. However, there is a limit for it, because quadratic effect was also significant as shown in Fig. 1d.

Temperature variation

The increase in temperature during smoothie sonication confirms that the collapse of the bubbles formed by cavitation phenomenon is responsible for the generated heat. The statistical analysis carried out by analyzing the Pareto chart indicates that the linear effect of the power variable contributed most to the increase in processing temperature (Fig. 1e).

Since temperature increasing is inherent to the ultrasonic processing, it should be emphasized that heat can favor pigment degradation in food. Thus, the results obtained herein, especially those regarding smoothie anthocyanin content, can be explained by the synergistic effect between cavitation and heat. However, we emphasize once again that the degradation of anthocyanins, which can be considered a processing quality indicator, was low.

Conclusion

Sonication did not promote relevant changes in the physicochemical characteristics and instrumental color of the obtained smoothie. However, it significantly affected its viscosity. Over 86% anthocyanin retention was observed in the sonicated smoothie compared to the control. Taking into account that the highest anthocyanin retention was observed at 147 W/2 min, this condition is the most recommended for the processing of the juçara, banana and strawberry smoothie.

Acknowledgements

The authors are incredibly grateful to Federal University of Rio de Janeiro, Embrapa Agroindústria de Alimentos for support. Leilson O. Ribeiro acknowledge the Capes for his fellowship.

Compliance with ethical standards

Conflict of interest

The authors declare that they have no conflict of interest.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- AOAC . Official methods of analysis. Gaithersburg: Association of Official Analytical Chemists; 2006. [Google Scholar]

- Bhardwaj RL, Pandey S. Juice blends—a way of utilization of under-utilized fruits, vegetables, and spices: a review. Crit Rev Food Sci Nutr. 2011;51:563–570. doi: 10.1080/10408391003710654. [DOI] [PubMed] [Google Scholar]

- Bhat R, Goh KM. Sonication treatment convalesce the overall quality of hand-pressed strawberry juice. Food Chem. 2017;215:470–476. doi: 10.1016/j.foodchem.2016.07.160. [DOI] [PubMed] [Google Scholar]

- Chemat F, Khan MK. Ultrasonics sonochemistry applications of ultrasound in food technology: processing, preservation and extraction. Ultrason Sonochem. 2011;18:813–835. doi: 10.1016/j.ultsonch.2010.11.023. [DOI] [PubMed] [Google Scholar]

- Chitgar MF, Aalami M, Maghsoudlou Y, Milani E. Comparative study on the effect of heat treatment and sonication on the quality of barberry (Berberis vulgaris) juice. J Food Process Presev. 2017;41:e12956. doi: 10.1111/jfpp.12956. [DOI] [Google Scholar]

- Costa MGM, Fonteles TV, Jesus ALT, Almeida FDL, Miranda MRA, Fernandes FAN, Rodrigues S. High-intensity ultrasound processing of pineapple juice. Food Bioprocess Technol. 2013;6:997–1006. doi: 10.1007/s11947-011-0746-9. [DOI] [Google Scholar]

- Dias DRC, Barros ZMP, Carvalho CBO, Honorato FA, Guerra NB, Azoubel PM. Effect of sonication on soursop juice quality. LWT Food Sci Technol. 2015;62:883–889. doi: 10.1016/j.lwt.2014.09.043. [DOI] [Google Scholar]

- Ferreira VLP. Principles and applications of colorimetry in food. Campinas: ITAL; 1981. [Google Scholar]

- Giusti MM, Wrolstad RE. Characterization and measurement of anthocyanins by UV–visible spectroscopy. In: Wrolstad RE, editor. Current protocols in food analytical chemistry. New York: Wiley; 2001. pp. F.1.2.1–F1.2.13. [Google Scholar]

- Gouvêa RF, Ribeiro LO, Souza ÉF, Penha EM, Matta VM, Freitas SP. Effect of enzymatic treatment on the rheological behavior and vitamin C content of Spondias tuberosa (umbu) pulp. J Food Sci Technol. 2017;54:2176–2180. doi: 10.1007/s13197-017-2630-8. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Keenan DF, Tiwari BK, Patras A, Gormley R, Butler F, Brunton NP. Effect of sonication on the bioactive, quality and rheological characteristics of fruit smoothies. Int J Food Sci Technol. 2012;47:827–836. doi: 10.1111/j.1365-2621.2011.02915.x. [DOI] [Google Scholar]

- Mahawar MK, Jalgaonkar K, Nambi VE, Bibwe B, Thirupathi V. Modelling of rheological properties of Mango (cv. Neelum) suspensions: effect of sample concentration and particle size. J Agric Eng. 2018;55:13–20. [Google Scholar]

- Mohideen FW, Solval KM, Li J, Zhang J, Chouljenko A, Chotiko A, Prudente AD, Bankston JD, Sathivel S. Effect of continuous ultra-sonication on microbial counts and physico-chemical properties of blueberry (Vaccinium corymbosum) juice. LWT Food Sci Technol. 2015;60:563–570. doi: 10.1016/j.lwt.2014.07.047. [DOI] [Google Scholar]

- Moreira RM, Martins ML, Júnior BRCL, Martins MFM, Ramos AM, Cristianini M, Campos ANR, Stringheta PC, Silva VRO, Canuto JW, Oliveira DC, Pereira DCS. Development of a juçara and Ubá mango juice mixture with added Lactobacillus rhamnosus GG processed by high pressure. LWT Food Sci Technol. 2017;77:259–268. doi: 10.1016/j.lwt.2016.11.049. [DOI] [Google Scholar]

- Ribeiro LO, Santos JGC, Gomes FS, Cabral LMC, Sá DGCF, Matta VM, Freitas SP. Sensory evaluation and antioxidant capacity as quality parameters in the development of a banana, strawberry and juçara smoothie. Food Sci Technol. 2018;38:653–660. doi: 10.1590/1678-457x.12017. [DOI] [Google Scholar]

- Rufino MSM, Alves RE, Brito ES, Pérez-Jiménez J, Saura-Calixto F, Mancini-Filho J. Bioactive compounds and antioxidant capacities of 18 non-traditional tropical fruits from Brazil. Food Chem. 2010;121:996–1002. doi: 10.1016/j.foodchem.2010.01.037. [DOI] [Google Scholar]

- Sadilova E, Carle R, Stintzing FC. Thermal degradation of anthocyanins and its impact on color and in vitro antioxidant capacity. Mol Nutr Food Res. 2007;51:1461–1471. doi: 10.1002/mnfr.200700179. [DOI] [PubMed] [Google Scholar]

- Schulz M, Silva GCB, Gonzaga LV, Costa ACO, Fett R. Juçara fruit (Euterpe edulis Mart.): sustainable exploitation of a source of bioactive compounds. Food Res Int 89. 2016;89(Part 1):14–26. doi: 10.1016/j.foodres.2016.07.027. [DOI] [PubMed] [Google Scholar]

- Steffe JF. Rheological methods in food process engineering. East Lansing: Freeman Press; 1996. [Google Scholar]

- Tan J, Kerr WL. Rheological properties and microstructure of tomato puree subject to continuous high pressure homogenization. J Food Eng. 2015;166:45–54. doi: 10.1016/j.jfoodeng.2015.05.025. [DOI] [Google Scholar]

- Tiwari BK, O’Donnell CP, Cullen PJ. Effect of sonication on retention of anthocyanins in blackberry juice. J Food Eng. 2009;93:166–171. doi: 10.1016/j.jfoodeng.2009.01.027. [DOI] [Google Scholar]

- Tiwari BK, Patras A, Brunton N, Cullen PJ, O’Donnell CP. Effect of ultrasound processing on anthocyanins and color of red grape juice. Ultrason Sonochem. 2010;17:598–604. doi: 10.1016/j.ultsonch.2009.10.009. [DOI] [PubMed] [Google Scholar]

- Zhao M, Wang P, Zhu Y, Liu X, Hu X, Chen F. Blueberry anthocyanins extract inhibits acrylamide-induced diverse toxicity in mice by preventing oxidative stress and cytochrome P450 2E1 activation. J Funct Foods. 2015;14:95–101. doi: 10.1016/j.jff.2015.01.035. [DOI] [Google Scholar]