Abstract

Purpose:

To evaluate the influence of extrinsic pigmentation on the biaxial flexural strength and surface topographic of translucent Y-TZP (InCoris TZI - Sirona - USA) subjected to several surface treatments.

Methods and Materials:

Sintered zirconia discs-shaped specimens (n=120) (ø:12 mm; thickness:1.2 mm; ISO 6872) were prepared and divided (n=15) according to various factors: “extrinsic pigmentation” (n:without; p:with) and “surface treatments” (C: control - as sintered; A: abraded with silica-coated alumina particles (30μm); G: glazed with a thin film of low-fusing porcelain glaze; GH: glazed and etched with 10% hydrofluoridric acid for 60s. Mechanical cycling (1.2×106 cycles, 200N, 3.8Hz) and flexural strength test (1mm/min - 1000kg cell) were performed. Two-way ANOVA and Tukeýs were used for statistical test (α=0.05). Weibull analysis was used to evaluate the strength reliability. Samples were analyzed via (1) an optical profilometer to determine the surface roughness (Ra); (2) an x-ray diffraction (XRD) to evaluate phase transformations; and (3) a SEM equipped with an energy dispersive x-ray spectroscopy (EDX) to elucidate morphological properties and chemical compositions.

Results:

Regardless of the surface treatment (p = 0.5459) (Cn:560.16 MPa; Gn:573.36 MPa; An:643.51 MPa; GHn:542.94 MPa; Cp:628.04 MPa; Gp:641.90 MPa; Ap:554.47 MPa; GHp:602.84 MPa) and extrinsic pigmentation (p = 0.1280) there was no difference in the flexural strength among the experimental groups. According to the XRD analysis, phase transformations occurred in the An group (t→m) and in Ap group (t→c). Surface roughness was affected by surface treatments (An - p=0.001) and extrinsic pigmentation (Gp – p=0.001).

Conclusions:

The biaxial flexural strength of the tested samples was not affected neither by surface treatments nor by pigmentation, although it can cause phase transformation and promote surface roughness.

Keywords: Zirconia surface treatment, biaxial flexural strength, phase transformation, surface characterization

1. Introduction

Y-TZP ceramic (Yttria-stabilized tetragonal zirconia polycrystal) has a large number of indications, in both restorative and implant dentistry [1]. It can be used as a framework or monolithic restoration for fixed dental prostheses (FDPs) and single crowns, implants and abutments, inlays and onlays [2]. Y-TZP has excellent biocompatibility and mechanical properties [3], most notably high fracture toughness [4] and remarkable load-bearing capacity [5]. Although concern has been expressed with regard to the survivability of such restorations compared to their metal ceramic counterparts (particularly FDPs), a recent clinical survey revealed similar survival rates for such restorations as compared with metal ceramic ones [6].

Whilst clinical studies have demonstrated limited complications related to the Y-TZP frameworks [7], veneered zirconia restorations can create clinical issues such as chipping or fracture of the veneering ceramic [8], being the most reported reason for the failure of such restorations [9]. Porcelain fracture and chipping has been reported with annual rates from 1% to 8% [10]. To avoid such complications, the use of anatomic contour zirconia FDPs (monolithic restoration) without additional veneering ceramic has been proposed [5, 11, 12]. While it is still the strongest and toughest ceramic ever used in dentistry, its low translucence remains as a major drawback [13]. As the color of conventional zirconia is white, obtaining a natural tooth color may be difficult to achieve even after veneering. For these reasons, using a stained or shaded zirconia may facilitate a more natural appearance. External characterization with staining seems to be a good esthetic alternative. However, staining can also significantly increase surface roughness, which may cause bacterial biofilm accumulation [14] and periodontal inflammation [15]. Another approach available to obtaining a shaded zirconia is to infiltrate a green-stage framework with specific coloring liquids. As an alternative, sintered zirconia can be painted with liners that require firing in a traditional dental ceramic furnace. However, doping with coloring substances—usually metal oxides—has been reported to decrease the mechanical properties of zirconia [4, 16]. With the introduction of high translucent Y-TZP coupled with the use of individualized staining techniques enables the esthetics to be sufficiently improved, making this material an attractive alternative for restorative dental treatments [17]. Adhesion of resin-based cement to zirconia is also an important issue for the long-term success of the restoration [18]. A crucial aspect about Y-TZP is its high crystalline content, becoming impossible for acids and silane coupling agents to provide micro-retentions and chemical bonds. A reliable bonding would bring better clinical uses for Y-TZP [19, 20]. Some surface treatments have been proposed to improve zirconia adhesion such as: tribochemical silicatization [21], 10-methacryloyloxydecyl dihydrogen phosphate (MDP) base primers [22] and glazing, glass-infiltration, or vitrification [23, 24, 25]. Airborne-particle abrasion, which consists of air-abrasion with silica-coated alumina particles followed by silanization [26], is one of the most efficient methods for promoting micromechanical retention and consequently improving bond strength at the zirconia-cement interface [27]. Although abrasion protocols are widely used in clinical practice, reports in the current literature on their effects on the mechanical properties and structural stability of Y-TZP remain unclear [28]. Thus, the scientific community is still cautious regarding its use, because this treatment may cause surface damage and phase transformation (t→m) [23, 29]. The surface modification of the Y-TZP by vitrification consists of the application of a thin film of low-fusing porcelain glaze (rich in silicon oxide) on the intaglio surface, which can be selectively conditioned by hydrofluoric acid and silane application, changing the topography and creating micro retentions and chemical reactivity similar to the bonding mechanisms of silica-based ceramics [30, 31]. On the other hand, surface glass-infiltration is set to infiltrate a high melting temperature glass into the zirconia intaglio surface, producing a glass-rich graded surface [32]. These methods significantly improved the adhesion between Y-TZP and resin cement [25]. In addition, this etching would increase the ceramic surface energy and its adhesive potential, a necessary condition to obtain a stable and durable bonding of the resin cement to the substrate [33]. This technique showed promising results with significant improvements of the bond strength between resin cements and Y-TZP [2].

Thus, to our knowledge, no published studies have evaluated the influence of the surface treatments and the application of extrinsic pigmentation on the flexure strength of translucent Y-TZP. The hypotheses tested were: (1) the flexural strength and surface topography are affected by the extrinsic pigmentation; (2) surface treatments can affect the flexural strength and surface topographic of ZrO2; and (3) extrinsic pigmentation and surface treatment promote phase transformations (t-m).

Materials and methods

The materials, commercial names and manufacturer used in this study are presented in Table 1.

Table 1 –

The materials along with their brand names and manufacturers used in this study.

| Material | Brand name | Manufacturer | Batch numbers |

|---|---|---|---|

| Y-TZP Ceramic | InCoris TZI | Dentsply Sirona, York, PA, USA | 2015326815; 2015286550; 2015417321. |

| Low-fusion porcelain | Vita Akzent | Vita Zahnfabrik, Bad Säckingen, Germany | A0764 |

| 30 μm alumina particles coated with sílica | Rocatec®Soft | 3M ESPE, Irvine, CA, USA | 1511007637 |

| Fluoridric acid 10% | Condac Porcelana | FGM, Joinville, SC, Brazil | 310316 |

| Pigmentation liquid | InCoris TZI Colouring Liquid | Dentsply Sirona, York, PA, USA | 91026 |

Specimen preparation

Disk-shaped zirconia (InCoris TZI, Dentsply Sirona, USA) were sectioned with a diamond disc (Extec, Enfield, CT) in a cutting machine (Isomet® 1000 Precision Saw, Buehler, Lake Bluff, IL) under water irrigation. 120 specimens were obtained at dimensions suggested by ISO 6872 [34] (ø=15 mm; thickness: 1.6 mm). Discs were polished with #180, #600 and #1200 grit silicon carbide abrasive papers for 5 min each under water-cooling and ultrasonically cleaned in isopropyl alcohol for 8 min. The specimens were sintered in a Zyrcomat T furnace (Vita Zahnfabrik, Bad Säckingen, Germany) at a temperature of 1510° C for 120 min. The final dimensions of the disks were ø12×1.2 mm (ISO 6872).

Half of the specimens (n = 60) received extrinsic pigmentation (InCoris TZI Coloring Liquid A3.5, Dentsply Sirona, USA) (p) through an immersion technique for 5 minutes, according to the manufacturer’s instructions. The other half of the specimens (n = 60) did not receive pigmentation (n).

Surface treatment

The groups p (n = 60) and n (n = 60) were divided into four groups (n = 15), according to the surface treatment:

(C) Control: as sintered

(A) Abraded: (one side) with 30 μm silica-coated alumina particles (Rocatec Soft, 3M ESPE, Minnesota, USA) at 2.8 bar for 15 seconds using a specific apparatus (Dento-Prep™, RØNVIG A/S).

(G) Glazed: low-fusing porcelain glaze (powder/liquid) (Vita Akzent, Vita Zahnfabrik, Germany), (0.2g / 8 drops) were applied with a disposable brush (TechNew, Rio de Janeiro, Brazil) and then placed in Vita Vacumat 6000 MP (Vita Zahnfabrik, Germany) for the glaze firing process, following the manufacturer’s instructions.

(GH) Glazed + Hydrofluoric acid etched: after receiving the glaze application, as described above, samples were treated with 10% hydrofluoric acid (Condac Porcelana 10%, FGM, Brazil) for 60 seconds on the glazed face.

Optical profilometer

Ten measurements were made to evaluate the surface morphology. The digital optical profilometer (Wyko, Model NT 1100, Veeco, Tucson, USA) connected to a PC with image software (Vision 32, Veeco, USA) was used for surface micrographs (qualitative analysis of 3D geometry) and surface roughness measurements. The software used to obtain the images provides arithmetic mean (Ra) data, based on peaks and valleys presented in the analyzed area.

X-ray diffraction analysis

In order to determine phase transformations induced by surface treatments, x-ray diffraction analysis was performed (Model X’pert Powder, PANalytical, Almelo, Netherlands) for two specimens of each group (Cu-Kα, ƛ=1.54060 Å, 45 kV, 40 mA, 25–80°, 0.02° step size, integration time: 25 s). Each crystalline phase presents a set of characteristic peaks.

Energy dispersive x-ray and scanning electron microscopy (SEM) analysis

Morphological and chemical analysis was performed on one specimen from each group using SEM (5,000 X, TESCAN, model MIRA 3 and VEGA 3) equipped with an energy dispersive x-ray spectroscopy (EDX) (Bruker, Spirit 1.0 software). The specimens were analyzed under SEM at a high vacuum (20 kV, working distance: 12 mm).

Mechanical aging

The samples were subjected to a mechanical cycling test in a mechanical fatigue simulating machine (ERIOS, Model: ER-11000, São Paulo, Brazil) for 1.2×106 cycles (200 N load and 3.8 Hz). The load was applied in the center of the specimens by a stainless steel piston with a rounded tip and 1.5 mm curvature radius. The load was applied to the non-treated face.

Biaxial flexural strength test

According to ISO 6872 [34], disc-shaped specimens were subjected to biaxial flexural test (1 mm/min, 100kgf load cell, in water) using a universal tester (Emic DL-1000, Emic, São José dos Pinhais, PR, Brazil). The samples were positioned with the treated surface facing downwards (tensile surface) on three supporting balls (Ø = 3.2 mm) placed 120° apart from each other, forming a support circle with a diameter of 10 mm. The assembly was immersed in water, and a flat circular tungsten piston (Ø=1.6 mm) was used to apply a monotonically increasing load (1 mm/min) until catastrophic failure occurred. Before the test, adhesive tape (12 mm × 10 mm, 3M ESPE) was placed on the compression side of the discs to provide better piston-sample contact as well as avoid fragment spreading. The biaxial flexural strength (σ) (MPa) of the discs was determined according to the ISO 6872 standard:

where P is the fracture load (N), X and Y are parameters related to the elastic properties of the material [Poisson’s ratio and elastic module], and b is thickness of the specimen at the fracture origin in mm.

Statistical analysis

The numerical values obtained through the optical profilometer and the biaxial flexural strength data were subjected to two-way ANOVA and Tukey multiple comparison tests (α = 0.05).

Weibull analysis was performed to evaluate the reliability of the flexural strength, with the Weibull parameter (m) and the characteristic strength (σo), with a confidence interval of 95%, being determined in a lnσc–ln [ln 1/(1-F(σc)] diagram (according to ENV 843–5):

The characteristic strength represents the strength at a failure probability of approximately 63.2%, and the Weibull modulus m is used as a measure of the strengths distribution, which indicates the structural homogeneity of the material.

Statistical analysis was performed using a software (Minitab software, version 17, 2013, Minitab, State College, PA). The level of significance was 5%.

Results

Surface Roughness, SEM, and EDX analysis

The surface roughness (Ra) data (μm) obtained from the optical profilometer analysis are described in Table 2.

Table 2 –

Mean and standard deviation of the surface roughness. Different upper case letters indicate statistical difference in the column.

| Group | Mean (Ra)μm |

|---|---|

| C | 0.38 (0.05) C |

| A | 0.78 (0.33) B |

| G | 0.30 (0.09) C |

| GH | 0.45 (0.09) C |

| Cp | 0.51 (0.05) B C |

| Ap | 0.47 (0.02) B C |

| Gp | 1.33 (0.28) A |

| GHp | 1.40 (0.15) A |

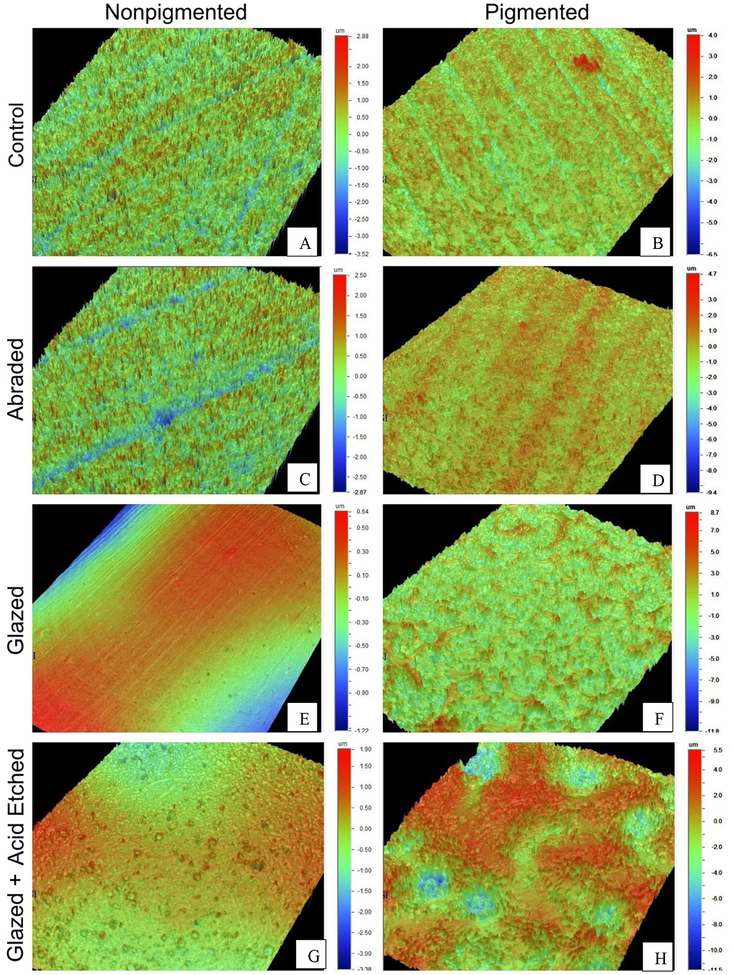

The surface treatment and pigmentation altered the surface roughness (p = 0.001). In the n groups (Figs. 1 – A to D), it was observed that the A group showed the highest surface roughness, differing statistically from the others (p = 0.001). Within the pigmented groups (Figs. 1 – E to H), the GH group showed the highest surface roughness, differing statistically from the A group that presented the lowest Ra mean values (p = 0.001). When the pigmentation factor was verified, it increased the Ra average values of all but the A group. Thus, hypotheses 1 and 2 were partially rejected.

Figure 1a-h –

Digital profilometer images.

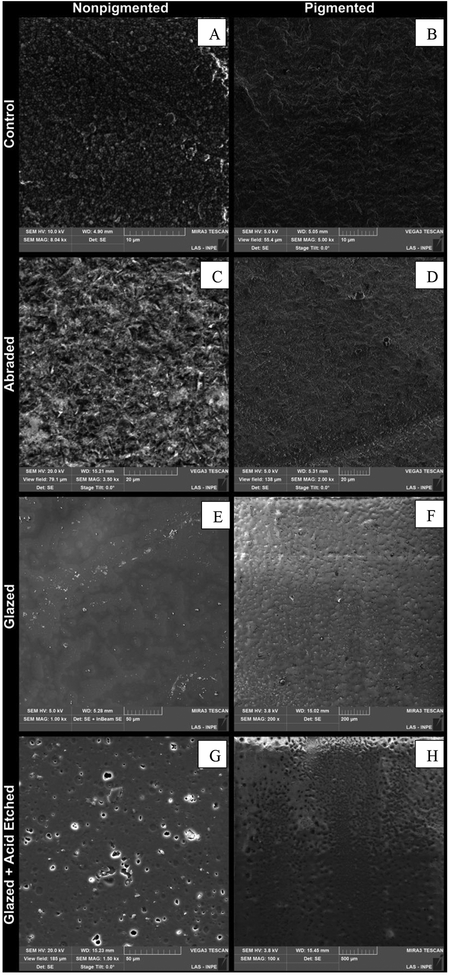

SEM images of the Cn and Cp groups (Figs. 3A and E) revealed a homogeneous surface and the zirconia grains, measuring 0.4 μm (Cn) and 0.3 μm (Cp) average. In the Sn group (Fig. 3B), a slight increase in roughness is observed due to the action of the silica-coated particles sandblasted under pressure. However, such roughness is not apparent in the Ap group (Fig. 3 – F). The images of the Gn and Gp groups do not exhibit the zirconia grains, since they were covered by glaze (Figs. 3C and G). There was also a distinct aspect between these two groups, indicating that the pigmentation interferes in its appearance, generating a rougher surface. In the GHn and GHp groups, it is possible to verify the partial degradation of the glaze layer (Figs. 3D and H) from the increase in its roughness. However, acid etching is unable to remove the entire glaze layer, so it is not possible to identify zirconia grains. The EDX results are listed in Table 3.

Figure 3a-h –

Scanning electron microscopy (SEM) images. Note that C e Cp images presented irregular surfaces with distinct grain boundaries, which are not presented in A and Ap images due to blasting procedures altering surface patterns. Images G and Gp presented a glazed surface and images GH and GHp presented a deteriorated glazed surface.

Table 3 –

EDX analyses.

| O | Y | Zr | Al | Si | Na | K | Ca | Ba | Hf | C | Mg | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C | 21.97 | 4.18 | 73.85 | |||||||||

| A | 33.07 | 63.03 | 2.02 | 1.88 | ||||||||

| G | 42.03 | 4.17 | 39.26 | 4.47 | 3.22 | 4.64 | 2.22 | |||||

| GH | 43.22 | 3.93 | 38.11 | 4.55 | 3.21 | 4.80 | 2.18 | |||||

| Cp | 35.06 | 3.00 | 60.34 | 1.60 | ||||||||

| Ap | 32.82 | 3.27 | 58.75 | 2.92 | 2.24 | |||||||

| Gp | 66.62 | 1.60 | 2.21 | 14.06 | 4.19 | 0.37 | 0.24 | 10.40 | 0.31 | |||

| GHp | 67.20 | 1.80 | 11.14 | 4.15 | 15.70 |

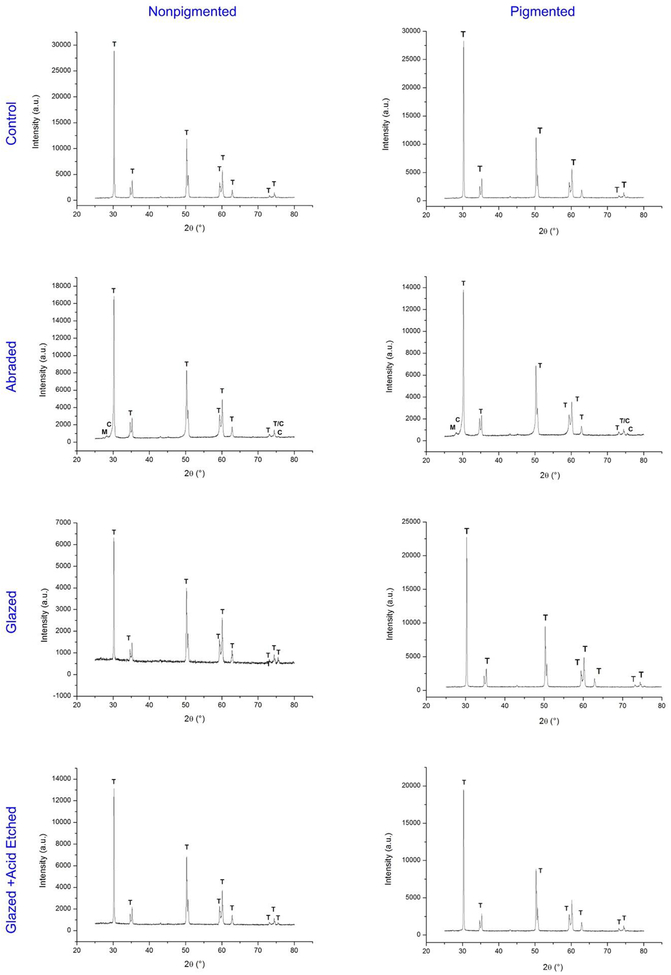

Phase Assemblage

The An and Ap groups (Figs. 2 – B and F) showed characteristic peaks of the tetragonal phases, which correspond to tetragonal t(101) and monoclinic (28° and 31.2°) crystallographic plane. These two peaks correspond to the monoclinic m(−101) and m(111) crystallographic planes, respectively. In addition, the PR group presents characteristic peaks of the cubic phase. Thus, hypothesis 3 was also partially rejected.

Figure 2 –

X-ray diffraction (XRD) spectra.

Biaxial flexural strength (BFS) and Weibull Analysis

The results of the data analysis are described in Table 4. Regardless of the surface treatments (p=0.5459) and extrinsic pigmentation (p=0.1280) there was no difference in the flexural strength among the experimental groups.

Table 4 –

Mean, standard deviation, and coefficient of variation of the biaxial flexural strength (MPa). Same upper case letters represent no statistical differences regarding surface treatments and pigmentation.

| Group | n | Mean MPa (SD) | Coefficient of variation (%) |

|---|---|---|---|

| C | 15 | 560.16(68.75) A | 12.28 |

| A | 15 | 643.51 (111.91) A | 17.44 |

| G | 15 | 573.36(80.96) A | 14.72 |

| GH | 15 | 542.94(80.96) A | 14.91 |

| Cp | 15 | 628.04(115.14) A | 18.33 |

| Ap | 15 | 554.47(86.83) A | 15.66 |

| Gp | 15 | 641.90(99.32) A | 15.47 |

| GHp | 15 | 602.84(110.36) A | 18.04 |

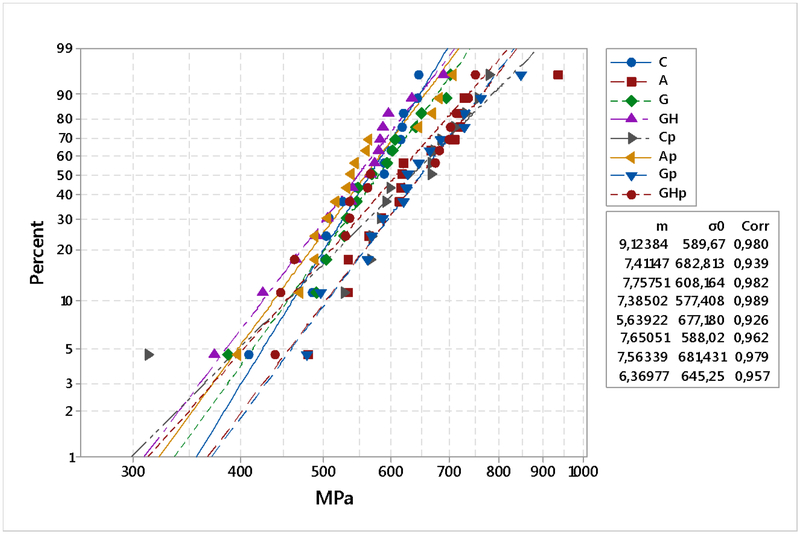

The Weibull analysis is displayed in Fig. 4. The Weibull modulus, the characteristic strength and their confidence interval (95%) are described in Table 5. The data were tested for equal modulus parameter (p = 0.967) and no differences were found.

Figure 4 –

Weibull plot for the flexural strength.

Table 5 –

Weibull modulus and characteristic strength (MPa) values both with a 95% confidence interval. Same upper case letters represent no statistical differences regarding Weibull modulus.

| Group | m | CI (lower-upper) | σ0 | CI (lower-upper) |

|---|---|---|---|---|

| C | 9.12 A | 5.47 – 15.19 | 589.67 | 556.26 – 625.08 |

| A | 7.41 A | 5.86 – 9.36 | 682.81 | 633.63 – 735.80 |

| G | 7.75 A | 5.02 – 11.98 | 608.16 | 567.75 – 651.45 |

| GH | 7.38 A | 4.72 – 11.53 | 577.40 | 537.18 – 620.64 |

| Cp | 5.63 A | 2.94 – 10.78 | 677.18 | 615.38 – 745.18 |

| Ap | 7.65 A | 5.42 – 10.78 | 588.02 | 547.90 – 631.08 |

| Gp | 7.56 A | 5.39 – 10.61 | 681.43 | 634.58 – 731.73 |

| GHp | 6.36 A | 4.11 – 9.85 | 645.25 | 593.39 – 701.64 |

Discussion

This study evaluated the influence of extrinsic pigmentation on surface roughness, biaxial flexural strength and phase transformation after several surface treatments. The hypotheses tested were rejected. The extrinsic pigmentation and the surface treatments affected only surface topography, and did not affect the flexural strength of Y-TZP. In addition, the extrinsic pigmentation did not promote phase transformation since only the grit blasted zirconia showed t-m phase transformation.

Surface Roughness, SEM, and EDX analysis

The Ra value describes the average roughness value for a surface using an arithmetical mean of the absolute values of peaks and valleys measured from a medium plane (mm) in a surface that has been traced by the profilometer [35, 36]. A lower Ra value indicates a smoother surface [37]. The level of acceptability for surface roughness is 0.5 μm, which is the level of perception of the tongue. According to the findings of this paper, the air-abraded group is the most rugged without the application of pigments. However, after characterization, air-abraded is the only group in which roughness would be acceptable.

The pigmentation affected the surface roughness according to the data found in this work (Figures 1a–h). As suggested by Yuan et al. [15], all groups had become rougher after pigmentation, except the air-abraded group which became smoother. Studies show that air-abrasion promotes higher surface roughness, which may even promote crack propagation by introducing flaws. But, the pigment layer must have filled these surface defects, making it smoother.

The values found here differ from those found in other studies, for example of Manziuc et al. [38] which demonstrated a significant reduction of the surface roughness after glazing zirconia without pigmentation. This happens because of methodological differences, zirconia grain sizes, pores, and flaw population. Although the roughness values do not represent clinical reality, the data associated with the other analyzes may contribute to the conclusions of the study. The readings are not performed throughout the sample area, but in addition to the SEM images for example, it is possible to have an overview of the surfaces. There are others parameters that evaluate the surface roughness, e.g. RSm and Rz [39]. However, Ra is the most commonly used parameter in dentistry.

SEM image analysis indicated that the non-pigmented group presented slightly larger grains than pigmented group (Figures 3b, 3d, 3f and 3h). Larger grains increase the surface roughness, as well as lead to an increase in the flaw size, which is deleterious to the mechanical properties of Y-TZP [40]. This information was not confirmed with the results of the present study, since there was no difference in the biaxial flexural strength among the tested groups. However, grain size is also related to translucency parameters. The smoothness of the surface correlates to the loss of incident light; in this sense, a smoother surface results in a lesser loss of the incident light. This reflects a greater ceramic translucency [41].

SEM images also corroborate the greater surface roughness for the glaze group; Dal Piva et al. [42] attributed the fact that the chemical bonding between glaze and zirconia is not ideal. Thus, the glaze accumulates irregularly on the surface, agglomerating in certain points as islands, which generates a greater roughness of the surface.

EDX analysis identifies the superficial chemical composition, but it is not possible to identify elements present in subsurface layers such as zirconia in glazed samples. Pigmentation liquid can be presented in either acidic or aqueous solutions. The acid solution usually contains 0.1 wt.% of hydrochloric acid (HCl), a strong acid that promotes staining by means of an acid-basic reaction. While aqueous pigmentation liquids are acid-free and deposit metal cations in the Y-TZP pores [40].

After pigmentation, all groups showed higher oxygen levels due to the metal oxides present in the pigmentation liquids. These metal oxides interact with zirconia particles, causing the grain size to decrease while promoting phase transformation. Such crystallographic and microstructural changes may influence the mechanical properties of zirconia [43, 44].

Phase Assemblage

An X-ray crystallographic analysis of the Ap group revealed the presence of the cubic phase, which according to Chevalier et al. [45], is detrimental to the flexural strength of Y-TZP. Cubic grains contain a higher amount of yttria, resulting in a depletion of yttria in the surrounding tetragonal grains. Preceding works have shown that transformation occurs by a nucleation and growth mechanism [46]. Transformation is thought to arise first in grains less stable than the average, then propagate to the neighbors due to large stresses and micro-cracks induced from the t→m transformation. The cubic grains can therefore act as nucleation sites for the transformation [45]. Air-abraded groups were the only specimens to show monoclinic phases, because the stress induced phase transformation [47].

When Y-TZP is polished in a pre-sintered stage it presents only t phase after sintering. If polishing occurs after the sintering, larger amounts of m phase are observed [48]. Since the polishing and sintering protocols performed in this study were identical, it can be stated that the pigmentation and surface treatments played an important role.

Biaxial flexural strength (BFS) and Weibull Analysis

There is no consensus in the open literature about the influence of pigmentation liquids on Y-TZP flexural strength [49]. A study [50] evaluated the flexural strength and hardness of Y-TZP - pigmented and non-pigmented - and found no differences. It is noteworthy that the authors used different brands and protocols from those used in this study. Monteiro et al. [51], performed a study that analyzed the influence of ageing and pigmentation on the flexural strength of translucent Y-TZP. They concluded that ageing did not affect the flexural strength but pigmentation did. Moreover, the shade of the pigmentation played an important role as the coloring solutions used interacted with the material microstructure and affected its flexural strength [51]. The differences found among the present results and from other studies in the literature could be attributed in part to differences in composition of the zirconia blocks and the pigmentation liquids, as well as the techniques used for staining, which can cause diverse crystallographic alterations. Mahmood [44] noted the brush infiltration is more operator-dependent than immersion infiltration, which may lead to a decrease in zirconia strength. In addition, a prolonged immersion time (dipping time) may also decrease the fracture load of zirconia [52].

Shah et al. [16] evaluated the flexural strength using pigments containing cerium acetate, cerium hydrochloride and bismuth hydrochloride in different concentrations. They concluded that the flexural strength decreased with increasing concentrations of the cerium-containing compounds. The addition of metal oxides may accumulate at the grain boundaries, lowering the yttria content. With the reduction of the stabilizing agents, it can increase the t→m phase transformation, which will alter the mechanical properties of the zirconia [53].

The biaxial flexural strength data and the Weibull modulus did not show statistical differences. It was expected that the glazed group had the higher Weibull modulus because glaze has an ability to reduce many imperfections in the ceramic surface. During cooling, it also generates a compressive layer, which can help to improve the flexural strength and increasing the Weibull modulus. However, the data of this study does not confirm that tendency. Papia et al.[54] compared the flexural strength of Y-TZP after several surface treatments and found untreated zirconia has a higher strength than glass-modified zirconia. They also showed that grit blasting increases zirconia strength. However, their study was carried out using coarse alumina particles (100 μm) - a different treatment protocol from the current study. Pozzobon et al. [26] compared the fracture resistance of Y-TZP after glaze application and several etching times and concluded that when the vitrification technique is used, the strength decreased regardless of etching time. It should be noted that in none of these studies the specimens were pigmented. In this present study, it was found that after acid etching the biaxial flexural data decreased. This is due to the removal of the superficial glaze layer, which generates a defective area where it favors the stress concentration [55]. This fact was corroborated by Amaral et al. [2].

Despite these apparently contradictory results, there is no other study in the literature that correlates the presence/absence of pigmentation and surface treatment with biaxial flexural strength, especially in translucent zirconia ceramics. In order to reach a definitive conclusion, further studies altering pressure parameters, particles size, glaze layering conditions are needed.

Conclusions

Considering the limitations of this in vitro study, the following could be concluded:

Extrinsic pigmentation and surface treatments did not decrease the biaxial flexural strength, despite affecting the topography of the zirconia surface;

All air-abraded groups, with or without extrinsic pigmentation, showed the formation of m-phase. This occured due to the stress-induced phase transformation. However, the minor c-phase was only observed in the extrinsically pigmented and air-abraded group.

Acknowledgements

This study was supported by a FAPEMIG Grant (Fundação de Amparo à Pesquisa de Minas Gerais).

YZ would like to thank the United States National Institutes of Health, National Institute of Dental and Craniofacial Research (Grant No. R01DE026279 and Grant No. R01DE026772) for their support.

REFERENCES

- [1].Zhang Y, Lawn BR. Novel Zirconia Materials in Dentistry. J Dent Res 2018;97:140–7. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [2].Amaral M, Cesar PF, Bottino MA, Lohbauer U, Valandro LF. Fatigue behavior of Y-TZP ceramic after surface treatments. J Mech Behav Biomed Mater 2016;57:149–56. [DOI] [PubMed] [Google Scholar]

- [3].Chaiyabutr Y, McGowan S, Phillips KM, Kois JC, Giordano RA. The effect of hydrofluoric acid surface treatment and bond strength of a zirconia veneering ceramic. The Journal of Prosthetic Dentistry. 2008;100:194–202. [DOI] [PubMed] [Google Scholar]

- [4].Sedda M, Vichi A, Carrabba M, Capperucci A, Louca C, Ferrari M. Influence of coloring procedure on flexural resistance of zirconia blocks. J Prosthet Dent 2015;114:98–102. [DOI] [PubMed] [Google Scholar]

- [5].Stawarczyk B, Frevert K, Ender A, Roos M, Sener B, Wimmer T. Comparison of four monolithic zirconia materials with conventional ones: Contrast ratio, grain size, four-point flexural strength and two-body wear. J Mech Behav Biomed Mater 2016;59:128–38. [DOI] [PubMed] [Google Scholar]

- [6].Ozer F, Mante FK, Chiche G, Saleh N, Takeichi T, Blatz MB. A retrospective survey on long-term survival of posterior zirconia and porcelain-fused-to-metal crowns in private practice. Quintessence Int 2014;45:31–8. [DOI] [PubMed] [Google Scholar]

- [7].Flinn BD, Raigrodski AJ, Mancl LA, Toivola R, Kuykendall T. Influence of aging on flexural strength of translucent zirconia for monolithic restorations. J Prosthet Dent 2017;117:303–9. [DOI] [PubMed] [Google Scholar]

- [8].Passos SP, Linke B, Major PW, Nychka JA. Improving the compatibility of an Y-TZP/porcelain system using a new composite interlayer composition. J Mech Behav Biomed Mater 2017;65:11–9. [DOI] [PubMed] [Google Scholar]

- [9].Bankoglu Gungor M, Yilmaz H, Karakoca Nemli S, Turhan Bal B, Aydin C. Effect of surface treatments on the biaxial flexural strength, phase transformation, and surface roughness of bilayered porcelain/zirconia dental ceramics. J Prosthet Dent 2015;113:585–95. [DOI] [PubMed] [Google Scholar]

- [10].Marchack BW, Sato S, Marchack CB, White SN. Complete and partial contour zirconia designs for crowns and fixed dental prostheses: A clinical report. The Journal of Prosthetic Dentistry. 2011;106:145–52. [DOI] [PubMed] [Google Scholar]

- [11].Moon J-E, Kim S-H, Lee J-B, Han J-S, Yeo I-S, Ha S-R. Effects of airborne-particle abrasion protocol choice on the surface characteristics of monolithic zirconia materials and the shear bond strength of resin cement. Ceramics International. 2016;42:1552–62. [Google Scholar]

- [12].Zhang Y, Lee JJ, Srikanth R, Lawn BR. Edge chipping and flexural resistance of monolithic ceramics. Dent Mater 2013;29:1201–8. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [13].Zhang Y Making yttria-stabilized tetragonal zirconia translucent. Dent Mater 2014;30:1195–203. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [14].Alao AR, Stoll R, Song XF, Abbott JR, Zhang Y, Abduo J, et al. Fracture, roughness and phase transformation in CAD/CAM milling and subsequent surface treatments of lithium metasilicate/disilicate glass-ceramics. J Mech Behav Biomed Mater 2017;74:251–60. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [15].Yuan JC, Barão VAR, Wee AG, Alfaro MF, Afshari FS, Sukotjo C. Effect of brushing and thermocycling on the shade and surface roughness of CAD-CAM ceramic restorations. J Prosthet Dent 2017; pii: S0022–3913:30417–1. [DOI] [PubMed] [Google Scholar]

- [16].Shah K, Holloway JA, Denry IL. Effect of coloring with various metal oxides on the microstructure, color, and flexural strength of 3Y-TZP. Journal of Biomedical Materials Research Part B: Applied Biomaterials. 2008;87B:329–37. [DOI] [PubMed] [Google Scholar]

- [17].Johansson C, Kmet G, Rivera J, Larsson C, Vult Von Steyern P. Fracture strength of monolithic all-ceramic crowns made of high translucent yttrium oxide-stabilized zirconium dioxide compared to porcelain-veneered crowns and lithium disilicate crowns. Acta Odontol Scand 2014;72:145–53. [DOI] [PubMed] [Google Scholar]

- [18].Cura C, Ozcan M, Isik G, Saracoglu A. Comparison of alternative adhesive cementation concepts for zirconia ceramic: glaze layer vs zirconia primer. J Adhes Dent 2012;14:75–82. [DOI] [PubMed] [Google Scholar]

- [19].Everson P, Addison O, Palin WM, Burke FJ. Improved bonding of zirconia substructures to resin using a “glaze-on” technique. J Dent 2012;40:347–51. [DOI] [PubMed] [Google Scholar]

- [20].Hallmann L, Ulmer P, Wille S, Polonskyi O, Kobel S, Trottenberg T, et al. Effect of surface treatments on the properties and morphological change of dental zirconia. J Prosthet Dent 2016;115:341–9. [DOI] [PubMed] [Google Scholar]

- [21].Melo RM, Souza RO, Dursun E, Monteiro EB, Valandro LF, Bottino MA. Surface Treatments of Zirconia to Enhance Bonding Durability. Oper Dent 2015;40:636–43. [DOI] [PubMed] [Google Scholar]

- [22].Ozcan M, Bernasconi M. Adhesion to zirconia used for dental restorations: a systematic review and meta-analysis. J Adhes Dent 2015;17:7–26. [DOI] [PubMed] [Google Scholar]

- [23].Bottino MA, Bergoli C, Lima EG, Marocho SM, Souza RO, Valandro LF. Bonding of Y-TZP to dentin: effects of Y-TZP surface conditioning, resin cement type, and aging. Oper Dent 2014;39:291–300. [DOI] [PubMed] [Google Scholar]

- [24].Cotes C, Arata A, Melo RM, Bottino MA, Machado JP, Souza RO. Effects of aging procedures on the topographic surface, structural stability, and mechanical strength of a ZrO2-based dental ceramic. Dent Mater 2014;30:e396–404. [DOI] [PubMed] [Google Scholar]

- [25].Chai H, Kaizer MR, Chughtai A, Tong H, Tanaka CB, Zhang Y. On the Interfacial Fracture Resistance of Resin-Bonded Zirconia and Glass-Infiltrated Graded Zirconia, Dent. Mater 2015; 31:1304–1311. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [26].Pozzobon JL, Pereira GKR, Wandscher VF, Dorneles LS, Valandro LF. Mechanical behavior of yttria-stabilized tetragonal zirconia polycrystalline ceramic after different zirconia surface treatments. Mater Sci Eng C Mater Biol Appl 2017;77:828–35. [DOI] [PubMed] [Google Scholar]

- [27].Garcia Fonseca R, de Oliveira Abi-Rached F, dos Santos Nunes Reis JM, Rambaldi E, Baldissara P. Effect of particle size on the flexural strength and phase transformation of an airborne-particle abraded yttria-stabilized tetragonal zirconia polycrystal ceramic. J Prosthet Dent 2013;110:510–4. [DOI] [PubMed] [Google Scholar]

- [28].Aurelio IL, Marchionatti AM, Montagner AF, May LG, Soares FZ. Does air particle abrasion affect the flexural strength and phase transformation of Y-TZP? A systematic review and meta-analysis. Dent Mater 2016;32:827–45. [DOI] [PubMed] [Google Scholar]

- [29].Zhang Y, Lawn BR, Rekow ED, Thompson VP. Effect of sandblasting on the long-term performance of dental ceramics. J Biomed Mater Res B Appl Biomater 2004;71:381–6. [DOI] [PubMed] [Google Scholar]

- [30].Vanderlei A, Bottino MA, Valandro LF. Evaluation of resin bond strength to yttria-stabilized tetragonal zirconia and framework marginal fit: comparison of different surface conditionings. Oper Dent 2014;39:50–63. [DOI] [PubMed] [Google Scholar]

- [31].Antunes MCF, Miranda JS, Carvalho RLA, Carvalho RF, Kimpara ET, Assunção E Souza RO, Leite FPP. Can low-fusing glass application affect the marginal misfit and bond strength of Y-TZP crowns? Braz Oral Res 2018;32:e34. [DOI] [PubMed] [Google Scholar]

- [32].Zhang Y, Chai H, Lawn BR. Graded Structures for All-ceramic Restorations. Journal of Dental Research. 2010;89:417–421, 2010. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [33].Ntala P, Chen X, Niggli J, Cattell M. Development and testing of multi-phase glazes for adhesive bonding to zirconia substrates. J Dent 2010. October;38:773–81 [DOI] [PubMed] [Google Scholar]

- [34].International Organization for Standatization. Dental ceramic: amendment 1, ISO 6872. Genebra: ISO: 1998. [Google Scholar]

- [35].Advanced technical ceramics. Monolithic ceramics. General and texture properties. Part 4. Determination of surface roughness. The European Standard EN 623–4: 2004. [Google Scholar]

- [36].Prado RD, Pereira GKR, Bottino MA, Melo RM, Valandro LF. Effect of ceramic thickness, grinding, and aging on the mechanical behavior of a polycrystalline zirconia. Braz Oral Res 2017; 6;31:e82. [DOI] [PubMed] [Google Scholar]

- [37].Jones CS, Billington RW, & Pearson GJ, (2004) The in vivo perception of roughness of restorations British Dental Journal 2004;196:42–45. [DOI] [PubMed] [Google Scholar]

- [38].Manziuc MM, Gasparik C, Burde AV, Colosi HA, Negucioiu M, Dudea D. Effect of glazing on translucency, color, and surface roughness of monolithic zirconia materials. J Esthet Restor Dent 2019. June 2. [DOI] [PubMed] [Google Scholar]

- [39].Sachdeva A, Prabhu N, Dhanasekar B, Aparna IN. Effect of conventional and microwave glazing on surface roughness of metal ceramics: An atomic force microscopy analysis. Indian J Dent Res 2018;29:352–7. [DOI] [PubMed] [Google Scholar]

- [40].Nam J, Park M. Effects of aqueous and acid-based coloring liquids on the hardness of zirconia restorations. J Prosthet Dent 2017;117:662–8. [DOI] [PubMed] [Google Scholar]

- [41].Candido L, Miotto L, Fais L, Cesar P, & Pinelli L (2018). Mechanical and Surface Properties of Monolithic Zirconia. Oper Dent 2018;43:E119–E128. [DOI] [PubMed] [Google Scholar]

- [42].Dal Piva A, Contreras L, Ribeiro F, Anami L, Camargo S, Jorge A, & Bottino M Monolithic Ceramics: Effect of Finishing Techniques on Surface Properties, Bacterial Adhesion and Cell Viability. Oper Dent 2018;43:315–325. [DOI] [PubMed] [Google Scholar]

- [43].Sulaiman TA, Abdulmajeed AA, Shahramian K, Lassila L. Effect of different treatments on the flexural strength of fully versus partially stabilized monolithic zirconia. J Prosthet Dent 2017; 118:216–220. [DOI] [PubMed] [Google Scholar]

- [44].Mahmood DJH, Braian M, Khan AS, Shabaz A, Larsson C. Fracture load of colored and non-colored high translucent zirconia three-unit fixed dental prosthesis frameworks. Acta Biomater Odontol Scand 2018;4:38–43. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [45].Chevalier J, Deville S, Munch E, Jullian R, Lair F. Critical effect of cubic phase on aging in 3mol% yttria-stabilized zirconia ceramics for hip replacement prosthesis. Biomaterials. 2004;25:5539–45. [DOI] [PubMed] [Google Scholar]

- [46].Chevalier J, Cales B, Drouin JM. Low‐Temperature Aging of Y‐TZP Ceramics. J Am Ceram Soc 1999;82:2150–54. [Google Scholar]

- [47].Karakoca S, Yilmaz H. Influence of surface treatments on surface roughness, phase transformation, and biaxial flexural strength of Y-TZP ceramics. J Biomed Mater Res B Appl Biomater 2009;91:930–7. [DOI] [PubMed] [Google Scholar]

- [48].Hjerppe J, Närhi TO, Vallittu PK, Lassila LVJ. Surface roughness and the flexural and bend strength of zirconia after different surface treatments. J Prosthet Dent 2016;116:577–83. [DOI] [PubMed] [Google Scholar]

- [49].Druck CC, Pozzobon JL, Callegari GL, Dorneles LS, Valandro LF. Adhesion to Y-TZP ceramic: study of silica nanofilm coating on the surface of Y-TZP. J Biomed Mater Res B Appl Biomater 2015;103:143–50. [DOI] [PubMed] [Google Scholar]

- [50].Pittayachawan P, McDonald A, Petrie A, Knowles JC. The biaxial flexural strength and fatigue property of Lava Y-TZP dental ceramic. Dent Mater 2007;23:1018–29. [DOI] [PubMed] [Google Scholar]

- [51].Monteiro KN, Correia YP, Genova LA, Cesar PF. Effect of shade and ageing on strength of translucent Y-TZP. Dental Mater 2016;32:e9–e10. [Google Scholar]

- [52].Orhun E The effect of coloring liquid dipping time on the fracture load and color of zirconia ceramics. J Adv Prosthodont 2017;9:67–73. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [53].Tuncel I, Turp I, Usumez A. Effect of color shading procedures and cyclic loading on the biaxial flexural strength of zirconia. Niger J Clin Pract 2018;21:7–12 [DOI] [PubMed] [Google Scholar]

- [54].Papia E, Jimbo R, Chrcanovic BR, Andersson M, Vult von Steyern P. Surface structure and mechanical properties of impaction-modified Y-TZP. Dent Mater 2014;30:808–16. [DOI] [PubMed] [Google Scholar]

- [55].Kaizer MR, Gierthmuehlen PC, Dos Santos MB, Cava SS, Zhang Y. Speed sintering translucent zirconia for chairside one-visit dental restorations: Optical, mechanical, and wear characteristics. Ceram Int 2017;43:10999–1005. [DOI] [PMC free article] [PubMed] [Google Scholar]