Abstract

The aim of the research was to verify the influence of macro and micronutrients present in the peanut waste (hulls and nuts) for supplementation of Pleurotus ostreatus substrate. The raw materials for base substrate preparation were Brachiaria dictyoneura, sugarcane bagasse (bulk material), rice and wheat bran, calcitic limestone, and gypsum. The following supplement formulations were used as treatments: (1) 100% peanut hulls, (2) 80% peanut hulls + 20% nuts, (3) 60% peanut hulls + 40% nuts, (4) 40% peanut hulls + 60% nuts, (5) 20% peanut hulls + 80% nuts, and (6) 100% nuts. A commercial supplement was also used as an additional treatment. The supplementation was done at spawning using the rates of 1% and 2% wet weight of the substrate. Positive correlations amongst yield and N content, and weight of mushroom and P and K content were verified with 1% supplement. A positive correlation between yield and Cu content, and a negative correlation between yield and Mn content were observed with 2% supplement. The use of peanut waste can be used as supplement for the production of P. ostreatus increasing biological efficiency up to 61%. A better combination can be reached with 20% peanut hulls + 80% nuts or 100% nuts. The addition of 2% supplement in the substrate provided greater yield than 1%.

Keywords: Pleurotus ostreatus, Macronutrient, Micronutrient, Bioconversion, Food quality

Introduction

Globally, developed regions are concerned about the quality of the ecosystem and sustainability seeking alternatives to close the food production cycle, avoiding the emission of CO2, producing high quantities, with maximum quality of food and avoiding the generation of waste.

Sugarcane (Saccharum officinarum) is an important crop for the production of biofuels. In Brazil between 2015 and 2016, 658 million tons were harvested [1]. The planting of Brachiaria dictyoneura has been growing significantly and has been the best option for the development of tropical livestock. In the last 3 years, residues from these two plant crops are the main bulk materials used for the production of Pleurotus ostreatus mushroom substrate [2], due to their great abundance and low price.

Peanut (Arachis hypogaea, Leguminosae) is the fourth most planted and consumed oilseed worldwide. It also provides a good option for crop rotation [3, 4]. Currently, several sugar cane reform areas are cultivated with peanut with the aim of improving the physical, chemical, and biological conditions of the soil.

In addition to peanuts planted for the improvement of soil quality, they are widely used for the production of oil, milk, peanut butter, confectionery, roasted peanuts, snack products, extenders in meat product formulation, soups, and desserts [5]. Peanuts are consumed all over the world in a wide variety of forms, being used as the complete dietary source for people on expeditions to diverse areas like Antarctica, space, and trekking [5]. It has notably been the source of elimination of malnutrition amongst the population in many African countries in recent years [6].

With all these applications, the domestic consumption of peanuts in Brazil is high. Even though the export scenario of this product has been growing fast, exports are accompanied by a series of quality standards that the peanut must possess, to ensure the product is exported with the highest quality. Because of these standards and depending on the exporting country, a series of products and by-products are generated after the processing and selection. This may include those grades of poor quality nuts (grain) with and without skin (attacked by pests and diseases) and peanut hulls. The literature reports the applications given to this bulky waste generated in peanut-producing countries, which are often burned, dumped, or left to deteriorate naturally [7].

In the recent past, environmental concerns have led to an interest in using peanut waste for a variety of purposes: fuel, mulch, carrier for chemicals and fertilizers, bedding for livestock and poultry, pet litter, soil conditioners, etc. [8]. Despite several applications of the use of peanut waste, no literature reported the influence of macro and micronutrient of this sub-product to supplement mushroom substrates.

Mushroom production in Brazil and South America is increasing very fast due to the nutritional benefits of mushroom as a food and as a source of economic income. In spite of this rapid growth in the last few decades, the international companies of supplements and spawns of mushrooms have not made any representation in order to make their products available in Brazil and South America. Supplements have been used successfully to improve mushroom yield [9, 10] and the use of alternative supplements in developing countries could be a good strategy.

Research has already shown an increase of 34.4% in yield, in addition to increasing precocity, thus reducing the length of the crop cycle [11, 12]. The range of supplement composition is characterized by the amount of protein (24 to 62%) and fat (0.8 to 19%) of the material used as base supplement [13]. The peanut wastes have about 25.8% protein and 49.2% fat in the nuts, while the peanut hulls have 7.3% protein and 1.4% fat [14, 15].

In addition to the amount of protein and fat, several authors have also detailed the amount of carbohydrates, fibers, and ashes in the supplements and their possible influence on mushroom yields [16, 17]. Studies have been performed highlighting the importance of the proximate analysis (ash, fibers, fats, proteins, and carbohydrates) of the supplements, but no research was carried out referring to which macro and micronutrients were necessary and essential for the selection of a supplement of high quality. So the aim of this research is to verify the influence of macro and micronutrients present in the waste of the peanut industry (peanut hulls and nuts) and the agronomic viability to use different formulations to supplement the substrate for the production of Pleurotus ostreatus (oyster mushroom).

Material and methods

Substrate

P. ostreatus substrate was prepared using a short method of composting, totaling 8 days of substrate preparation, 6 days for phase I and 2 days for phase II (semi-composted system). During phase I process, Brachiaria dictyoneura and sugarcane bagasse (bulk material) were moistened for 2 days. On the 3rd day, the pile was assembled, and on the 4th day, the pile was turned and, then, the additional materials (rice and wheat bran, calcitic limestone, and gypsum) were added. Afterwards, two more turns were performed and at the 7th day the substrate was transferred to a pasteurization chamber (phase II). The substrate was pasteurized between 65 and 72 °C during 20 h and subsequently conditioned between 55 and 48 °C for 1 day. Table 1 presents the chemical characteristics of the substrate after the phase II process. For each nutrient, three substrate samples were analyzed.

Table 1.

Macro and micronutrients (g kg−1) of the supplements without being mixed and mixed at a ratio of 1% (w/w) to substrate (1st experiment) and at a ratio of 2% (w/w) to substrate (2nd experiment)

| Treatments | N | P | K | Ca | Mg | S | B | Cu | Fe | Mn | Zn |

|---|---|---|---|---|---|---|---|---|---|---|---|

| g kg−1 | mg kg −1 | ||||||||||

| 1 | 13 ± 0.04 | 0.5 ± 0.02 | 6 ± 0.01 | 3 ± 0.2 | 1.3 ± 0.08 | 0.7 ± 0.002 | 25 ± 0.6 | 11 ± 0.1 | 781 ± 3 | 63 ± 4.2 | 27 ± 0.5 |

| 2 | 19.8 ± 0.1 | 0.8 ± 0.02 | 6.4 ± 0.04 | 3 ± 0.2 | 1.42 ± 0.02 | 0.76 ± 0.008 | 25 ± 0.2 | 11.8 ± 0.03 | 818.8 ± 5 | 65.4 ± 3.6 | 31.8 ± 0.7 |

| 3 | 26.6 ± 0.1 | 1.26 ± 0.04 | 6.8 ± 0.03 | 3 ± 0.1 | 1.54 ± 0.04 | 0.82 ± 0.004 | 25 ± 0.5 | 12.6 ± 0.04 | 856.6 ± 6 | 67.8 ± 4 | 36.6 ± 0.2 |

| 4 | 33.4 ± 0.3 | 1.64 ± 0.03 | 7.2 ± 0.07 | 3 ± 0.3 | 1.66 ± 0.03 | 0.88 ± 0.007 | 25 ± 0.2 | 13.4 ± 0.09 | 894.4 ± 5 | 70.2 ± 3 | 41.4 ± 0.3 |

| 5 | 40.2 ± 0.2 | 2.02 ± 0.08 | 7.6 ± 0.02 | 3 ± 0.2 | 1.78 ± 0.06 | 0.94 ± 0.002 | 25 ± 0.2 | 14.2 ± 0.1 | 932.2 ± 2 | 72.6 ± 5 | 46.2 ± 0.5 |

| 6 | 47 ± 0.3 | 2.4 ± 0.05 | 8 ± 0.1 | 3 ± 0.1 | 1.9 ± 0.04 | 1 ± 0.003 | 25 ± 0.3 | 15 ± 0.08 | 970 ± 8 | 75 ± 6.8 | 51 ± 0.4 |

| 7 | 44 ± 0.14 | 3.4 ± 0.07 | 17 ± 0.06 | 7 ± 0.2 | 2.4 ± 0.05 | 1 ± 0.005 | 26 ± 0.2 | 11 ± 0.04 | 334 ± 5 | 22 ± 0.8 | 48 ± 0.6 |

| Substrate + 1% of supplements | |||||||||||

| 1 | 10.08 ± 0.1 | 1.18 ± 0.05 | 6.0 ± 0.02 | 19.53 ± 0.4 | 2.47 ± 0.02 | 2.06 ± 0.05 | 16.2 ± 0.4 | 6.14 ± 0.04 | 358 ± 2 | 338.1 ± 10 | 42.5 ± 1 |

| 2 | 10.27 ± 0.3 | 1.19 ± 0.03 | 6.01 ± 0.04 | 19.53 ± 0.1 | 2.47 ± 0.05 | 2.06 ± 0.03 | 16.25 ± 0.3 | 6.16 ± 0.07 | 359 ± 5 | 338.2 ± 2 | 42.6 ± 0.3 |

| 3 | 10.46 ± 0.2 | 1.20 ± 0.03 | 6.02 ± 0.03 | 19.53 ± 0.2 | 2.47 ± 0.04 | 2.06 ± 0.06 | 15.25 ± 0.5 | 6.18 ± 0.05 | 360 ± 8 | 338.2 ± 5 | 42.8 ± 0.8 |

| 4 | 10.65 ± 0.4 | 1.21 ± 0.08 | 6.03 ± 0.07 | 19.53 ± 0.3 | 2.48 ± 0.08 | 2.07 ± 0.02 | 16.25 ± 0.8 | 6.21 ± 0.04 | 361 ± 4 | 338.3 ± 7 | 42.9 ± 0.6 |

| 5 | 10.84 ± 0.2 | 1.22 ± 0.04 | 6.04 ± 0.06 | 19.53 ± 0.1 | 2.48 ± 0.04 | 2.07 ± 0.09 | 16.25 ± 0.4 | 6.23 ± 0.02 | 362 ± 9 | 338.3 ± 14 | 43.09 ± 0.2 |

| 6 | 11.03 ± 0.4 | 1.23 ± 0.03 | 6.06 ± 0.04 | 19.52 ± 0.4 | 2.48 ± 0.06 | 2.07 ± 0.02 | 16.25 ± 0.1 | 6.25 ± 0.06 | 363 ± 7 | 338.4 ± 9 | 43.2 ± 2 |

| 7 | 10.94 ± 0.5 | 1.26 ± 0.08 | 6.3 ± 0.07 | 19.64 ± 0.3 | 2.50 ± 0.08 | 2.07 ± 0.05 | 16.28 ± 0.8 | 6.14 ± 0.01 | 345 ± 5 | 337.0 ± 27 | 43.1 ± 1.2 |

| Substrate | 10 ± 0.3 | 1.2 ± 0.02 | 6 ± 0.03 | 20 ± 0.2 | 2.5 ± 0.07 | 2.1 ± 0.04 | 16 ± 0.5 | 6 ± 0.02 | 346 ± 2 | 346 ± 23 | 43 ± 0.5 |

| Substrate + 2% of supplements | |||||||||||

| 1 | 10.16 ± 0.4 | 1.16 ± 0.05 | 6.0 ± 0.08 | 19.09 ± 0.7 | 2.44 ± 0.02 | 2.02 ± 0.05 | 16.48 ± 0.7 | 6.27 ± 0.06 | 369 ± 6 | 330 ± 7 | 42.1 ± 2.8 |

| 2 | 10.53 ± 0.7 | 1.18 ± 0.09 | 6.02 ± 0.02 | 19.08 ± 0.2 | 2.44 ± 0.07 | 2.03 ± 0.07 | 16.49 ± 0.6 | 6.31 ± 0.07 | 371 ± 7 | 330.8 ± 3 | 42.4 ± 1.4 |

| 3 | 10.90 ± 0.3 | 1.20 ± 0.02 | 6.04 ± 0.05 | 19.08 ± 0.4 | 2.45 ± 0.04 | 2.03 ± 0.1 | 16.49 ± 0.3 | 6.36 ± 0.2 | 373 ± 9 | 330.9 ± 11 | 42.6 ± 1.1 |

| 4 | 11.27 ± 0.2 | 1.22 ± 0.07 | 6.07 ± 0.04 | 19.08 ± 0.5 | 2.45 ± 0.05 | 2.03 ± 0.06 | 16.49 ± 0.7 | 6.40 ± 0.09 | 375 ± 5 | 331.0 ± 6 | 42.9 ± 2.8 |

| 5 | 11.64 ± 0.5 | 1.24 ± 0.05 | 6.09 ± 0.08 | 19.07 ± 0.8 | 2.46 ± 0.02 | 2.04 ± 0.02 | 16.49 ± 0.5 | 6.45 ± 0.2 | 377 ± 1 | 331.1 ± 18 | 43.18 ± 1.6 |

| 6 | 12.01 ± 0.3 | 1.27 ± 0.03 | 6.11 ± 0.06 | 19.07 ± 0.1 | 2.47 ± 0.09 | 2.04 ± 0.08 | 16.49 ± 0.8 | 6.49 ± 0.03 | 379 ± 4 | 331.2 ± 28 | 43.4 ± 3.1 |

| 7 | 11.83 ± 0.6 | 1.32 ± 0.06 | 6.59 ± 0.07 | 19.30 ± 0.6 | 2.49 ± 0.2 | 2.04 ± 0.08 | 16.54 ± 0.1 | 6.27 ± 0.04 | 345 ± 8 | 328.5 ± 9 | 43.27 ± 0.7 |

| Substrate | 10.3 ± 0.09 | 1.9 ± 0.04 | 7 ± 0.09 | 20 ± 0.3 | 2.8 ± 0.06 | 1.6 ± 0.06 | 15 ± 0.2 | 6 ± 0.05 | 362 ± 12 | 321 ± 11 | 42 ± 1 |

Treatment 1, 100% hulls of peanut; 2, 80% hulls of peanut + 20% nuts of peanut; 3, 60% hulls of peanut + 40% nuts of peanut; 4, 40% hulls of peanut + 60% nuts of peanut; 5, 20% hulls of peanut + 80% nuts of peanut; 6, 100% nuts of peanut; 7, Spawn Mate II SE ®; substrate, control (without supplement). Each value is expressed as mean ± standard deviation (n = 3)

Supplement

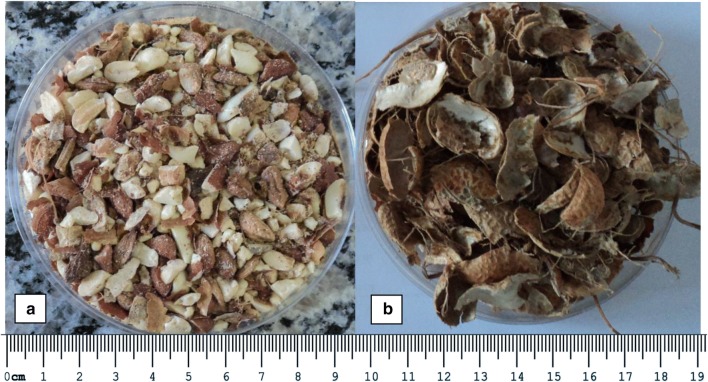

Peanut hulls and nuts were used as a supplement in the present study (Fig. 1). The runner cultivar was used because it is widely planted in Brazil. The hulls and nuts were dried at 68 °C for 24 h (which serve as heat treatment), until they reached 4–6% moisture, then they were crushed with a sieve to < 0.5 mm. The formulations used as treatments were (1) 100% hulls of peanut, (2) 80% hulls of peanut + 20% nuts, (3) 60% hulls of peanut + 40% nuts, (4) 40% hulls of peanut + 60% nuts, (5) 20% hulls of peanut + 80% nuts, and (6) 100% nuts. As a reference, two more treatments were used, the first one was an international commercial supplement (Spawn Mate II SE®—recommended for the production of P. ostreatus) and the second was the substrate control (without supplement), used to compare the viability of the formulations and the efficiency of the technique of substrate supplementation. The supplements with peanut waste and Spawn Mate were added to the substrate in two doses (1 and 2% wet weight of the substrate). The supplement rates used followed the recommendation of the commercial product (treatment 7) and the values reported in the literature [11, 12, 18]. Table 1 presents the chemical characteristics of the supplements. The contents of macro and micronutrients of the supplements and substrate were evaluated, following the methodology presented by Bell and Ward [19] and Sonneveld and van Elderen [20]. For each nutrient, three repetitions were performed.

Fig. 1.

Peanut waste used for substrate supplementation. a Nuts. b Hulls

Inoculation

POS 16/01 strain of Pleurotus ostreatus var. Florida was used. This strain was obtained from a commercial grower in the city of Mogi-das-Cruzes in the São Paulo State (Brazil). This strain was selected in function of the scale of the mushroom production by the grower/company (amount superior to 5 tons of fresh mushrooms harvested per month). The procedures adopted by Zied et al. [21] and Zied et al. [22] were followed for spawn production. The strain was deposited in the public culture collection of São Paulo State University, Campus de Dracena, with open access to other researchers who are interested.

After phase II process or “at spawning”, the substrate cooled down and then was mixed with supplements (rate of 1 and 2% of the wet substrate) and the spawn (2% of the wet substrate) homogeneously. The mixture was packed into plastic bags (4 kg wet substrate) and subsequently incubated for 13 days in the greenhouse used specifically for P. ostreatus growth, at 75 ± 5% relative humidity, and without ventilation. Under these conditions, the substrate temperature was kept at 28 ± 1 °C.

Growing cycle

The first flush started after 16 days of spawn run, the second after 29 days, and the third after 37 days, with the growing cycle lasting a total of 45 days. The temperature and relative humidity during the harvest phases were 24 ± 3 °C and 80 ± 10%, respectively. The mushrooms were collected twice a day during each flush, weighed and counted for the analysis of the production parameters.

Parameters evaluated

The following production parameters were evaluated: (i) the yield calculated as 100 times the fresh weight (f.w.) of mushrooms divided by the f.w. of substrate, expressed as a percentage (1st, 2nd, and 3rd flush and total yield); (ii) the number of mushrooms harvested; (iii) the weight per mushroom, expressed in grams (total fresh weight harvested during the cycle divided by the number of mushrooms); (iv) the number of clusters harvested; and (v) biological efficiency calculated as 100 times the f.w. of mushrooms divided by the dry weight of substrate, expressed as a percentage, as previously described by Royse [23] and Pardo-Giménez et al. [12].

Statistical analyses

Two experiments were performed in a completely randomized blocks design (8 treatments: 6 supplements based with peanut waste + commercial supplement + control), with 6 replicates per treatment (a plastic bag with 4 kg wet weight). The only difference between 1st and 2nd experiment was the amount of supplement added to the substrate (1 and 2% wet weight or 40 and 80 g of the supplement per bag). The means of each production parameter were compared by the least significant difference (LSD) test at p < 0.05. Sigma Stat 3.5 software was used to calculate linear correlations amongst the values for yield, number and weight of mushroom, and the macro- and micronutrients content of the treatments.

Results

Comparing the amount of macro and micronutrients in the supplements and in the substrate “control,” we verified that the supplements had superior amounts of N, B, Cu, and Fe (except the commercial supplement that had a Fe value of 334 mg kg−1, close to that observed in the substrate, 1st experiment: 346 mg kg−1 and 2nd experiment: 362 mg kg−1). On the other hand, the substrate has a superior amount of Ca, Mg, S, and Mn (except the commercial supplement that had a Mg value of 2.4 g kg−1, close to that observed in the substrate, 1st experiment: 2.5 g kg−1 and 2nd experiment: 2.8 g kg−1). In relation to values between hulls of peanut and substrate, it was verified that the hulls of peanut had a lower amount of P and Zn and similar content of K (Table 1).

The application of supplements in the 1st experiment (supplement’s 1% w.w.) provided different results compared with the production parameters (Table 2). In the 1st flush, treatment 3 provided the superior yield; in 2nd flush, treatments 1, 5, and 6 provided superior yields; and finally in 3rd flush, treatments 2, 3, 4, 5, and 6 provided superior yield. Neither the commercial supplement nor the substrate control provided superior yield when comparing the flushes separately (1st, 2nd, and 3rd).

Table 2.

Production parameters of the treatments supplemented with 1% of wet weight of the substrate

| Treatments | 1st flush (%) | 2nd flush (%) | 3rd flush (%) | Yield (%) | Number of mushrooms (u) | Weight of mushrooms (g) | Cluster of mushrooms (u) |

|---|---|---|---|---|---|---|---|

| 1 | 8.65abc | 8.83a | 2.67b | 20.28ab | 147 | 2.87b | 11.33 |

| 2 | 6.55c | 7.97ab | 6.85a | 21.37ab | 153 | 3.02ab | 13.66 |

| 3 | 12.51a | 2.21c | 6.00a | 20.78ab | 151 | 2.86b | 12.60 |

| 4 | 9.75abc | 3.73bc | 6.58a | 20.07ab | 142 | 3.92a | 11.75 |

| 5 | 11.09ab | 8.43a | 5.81a | 25.39a | 161 | 3.15ab | 14.66 |

| 6 | 8.01bc | 8.72a | 7.00a | 23.75ab | 159 | 3.18ab | 12.0 |

| 7 | 10.39abc | 6.76ab | 4.86ab | 22.01ab | 136 | 3.97a | 11.33 |

| 8 | 7.95bc | 6.03ab | 5.2ab | 19.18b | 151 | 2.69b | 15 |

| Mean | 9.43 | 5.93 | 5.57 | 21.41 | 149 | 3.10 | 12.37 |

Treatment 1, 100% hulls of peanut; 2, 80% hulls of peanut + 20% nuts of peanut; 3, 60% hulls of peanut + 40% nuts of peanut; 4, 40% hulls of peanut + 60% nuts of peanut; 5, 20% hulls of peanut + 80% nuts of peanut; 6, 100% nuts of peanut; 7, Spawn Mate II SE ®; 8, substrate control (without supplement). Values followed by different lowercase letters within a column are significantly different at p < 0.05

Total yield of the supplemented substrate with peanut waste varied from 20.28 to 25.39% while the commercial supplement provided a yield of 22.01%. Both of these results were superior when compared with the substrate without supplement (treatment 8). The only treatment that differed significantly was treatment 5 (20% hulls of peanut + 80% nuts of peanut) when compared with treatment 8 (substrate control), due to the high yield in the 1st, 2nd, and 3rd flush. Separating the obtained results of statistical analysis amongst the treatments, two groups varied in yield values of 20.07 to 25.39% (group a) and of 19.18 to 23.75% (group b); in this sense, it was verified that all treatments that were supplemented are in group a, providing positive physiological responses.

The number of mushrooms and clusters of mushroom did not present a significant difference between treatments. However, the mushroom weight differed, so treatments 4 and 7 presented higher mushroom size than treatments 1, 3, and 8. The substrate non-supplemented provided a high number of clusters, though inferior in mushroom size.

In the 2nd experiment (supplement’s 2% w.w.), treatment 3 provided the superior yield in the 1st flush; treatments 4, 6, and 7 provided superior yield in the second flush; and finally treatment 5 provided superior yield in the 3rd flush. In both experiments, treatment 3 presented a superior yield at 1st flush and treatment 5 at 3rd flush (Table 3).

Table 3.

Production parameters of the treatments supplemented with 2% of wet weight of the substrate

| Treatments | 1st flush (%) | 2nd flush (%) | 3rd flush (%) | Yield (%) | Number of mushrooms (u) | Weight of mushrooms (g) | Cluster of mushrooms (u) |

|---|---|---|---|---|---|---|---|

| 1 | 10.07ab | 7.35ab | 4.76c | 22.18ab | 167ab | 2.70b | 15.75 |

| 2 | 8.27b | 5.20ab | 5.81abc | 19.29b | 116b | 3.70a | 11.66 |

| 3 | 13.06a | 4.38ab | 6.60abc | 24.05a | 186a | 2.67b | 15.83 |

| 4 | 7.01b | 7.91a | 6.95abc | 21.88ab | 136ab | 3.40ab | 12.66 |

| 5 | 8.80ab | 5.67ab | 8.53a | 23.00ab | 150ab | 3.15ab | 15.40 |

| 6 | 10.90ab | 7.85a | 7.27abc | 26.04a | 171a | 3.06ab | 14.66 |

| 7 | 8.55ab | 7.83a | 5.21bc | 21.60ab | 151ab | 2.89ab | 11.25 |

| 8 | 9.11ab | 2.68b | 4.33c | 16.12c | 120ab | 2.79ab | 11.66 |

| Mean | 9.47 | 5.89 | 6.60 | 21.96 | 152 | 3.05 | 13.61 |

Treatments 1, 100% hulls of peanut; 2, 80% hulls of peanut + 20% nuts of peanut; 3, 60% hulls of peanut + 40% nuts of peanut; 4, 40% hulls of peanut + 60% nuts of peanut; 5, 20% hulls of peanut + 80% nuts of peanut; 6, 100% nuts of peanut; 7, Spawn Mate II SE ®; 8, substrate control (without supplement). Values followed by different lowercase letters within a column are significantly different at p < 0.05

Statistical significant differences were verified in treatments 1, 3, 4, 5, 6, and 7 with a high total yield comparable to substrate control (without supplement). The inferior total yield of the substrate without supplement was due to the low yield in 2nd and 3rd flush, which indicates the 2% supplement improved yields in the 2nd and 3rd flush. The treatments that obtained superior yield resulted in a higher number of mushrooms harvested, with a positive correlation (r = 0.829 and p = 0.0108). In both experiments, treatment 3 showed inferior sizes of mushroom.

The supplements based with peanut waste combinations provided superior total yields than a commercial supplement, although not statistically significant. Treatments with higher percentages of nuts (5 and 6) provided superior total yields when compared with treatments with a higher percentage of hulls (1 and 2). When results referring to total yield and biological efficiency for various treatments were compared, they were congruent and presented similar (statistically significant) differences (Table 4).

Table 4.

Biological efficiency and increase in biological efficiency due to supplementation with 1 and 2% of wet weight of the substrate

| Experiment | Biological efficiency (%) | Increase in biological efficiency* (%) | Biological efficiency (%) | Increase in biological efficiency* (%) |

|---|---|---|---|---|

| Treatments | 1% supplement (1st experiment) | 2% supplement (2nd experiment) | ||

| 1 | 131.9ab | 5 | 144.2ab | 38 |

| 2 | 139.1ab | 11 | 125.4b | 20 |

| 3 | 135.2ab | 8 | 156.6a | 49 |

| 4 | 130.6ab | 4 | 142.3ab | 36 |

| 5 | 165.1a | 32 | 149.8ab | 42 |

| 6 | 154.7ab | 24 | 169.3a | 61 |

| 7 | 143.3ab | 15 | 140.1ab | 34 |

| 8 | 124.7b | 0(substrate control) | 104.8c | 0(substrate control) |

| Mean | 139.4 | – | 142.9 | – |

Treatments 1, 100% hulls of peanut; 2, 80% hulls of peanut + 20% nuts of peanut; 3, 60% hulls of peanut + 40% nuts of peanut; 4, 40% hulls of peanut + 60% nuts of peanut; 5, 20% hulls of peanut + 80% nuts of peanut; 6, 100% nuts of peanut; 7, Spawn Mate II SE ®; 8, substrate control (without supplement).Values followed by different lowercase letters within a column are significantly different at p < 0.05. *Percentage of increase in the biological efficiency of the supplemented treatments in relation to the substrate without supplement

Linear correlations of the production parameters and macro and micronutrients content of the treatments in the 1st experiment showed a positive correlation between yield and N content (r = 0.744 and p = 0.034), and amongst weight of mushrooms and P (r = 0.867 and p = 0.0005) and K contents (r = 0.960 and p = 0.0002). In the 2nd experiment, a positive correlation existed between the mushroom yield and Cu content (r = 0.875 and p = 0.004), while a negative correlation between yield and Mn content (r = 0.7171 and p = 0.045) were also observed (Table 4).

Discussion

Currently the amount of peanut waste (hulls and nuts) has been increasing due to the strict classification made to meet the maximum quality in the export standard of the peanut. Often this classification discards hulls and broken and defective grains (nuts with and without skin). These residues are currently being used for animal feeding [24], and human feeding is not indicated due to the presence of impurities and even aflatoxin [25, 26]. In this sense, it is fundamental to search for practices that convert these wastes into food quality (closing the cycle of production) for the population, e.g., the bioconversion in fungi protein, known popularly as mushroom.

P. ostreatus is the most commonly produced mushroom in Brazil and the 3rd most-produced mushroom in the world, representing approximately 19% of the total world production [27]. In this sense, the application of peanut waste for the supplementation of the substrate at spawning can be an important alternative of food generation, due to the efficiency in the production parameters of this mushroom, as verified in this manuscript, especially in countries where commercial supplements are not available.

Philippoussis et al. [28] studying the use of residues of economic importance in subtropical and temperate countries evaluated the possibility of adding peanut hulls in the substrate formulation of Pleurotus spp. production. The authors verified a low biological efficiency, with values of 13.57% for P. ostreatus, 18.46% for Pleurotus pulmonarius, and 15.31% for Pleurotus eryngii. Therefore, in our work, we proposed the use of peanut residues as a supplement, not in the substrate formulation, and we have observed a positive effect.

Increased biological efficiency by 5, 11, 8, 4, 32, and 24% in the 1st experiment and by 38, 20, 49, 36, 42, and 61% in the experiment 2 were verified, for treatments 1, 2, 3, 4, 5, and 6 respectively, when compared with biological efficiency obtained in the substrate control (Table 4). Commercial supplements also provided yield increases, for example, in the 1st experiment (15%) and 2nd experiment (33%). The rate of 2% supplement showed better results in biological efficiency than 1% supplement. Royse et al. [29] studying the effect of the commercial supplement Campbell’s S41 at various levels verified increasing values of biological efficiency from 90.5% (substrate control) to 102.6% using the supplement at a rate of 3%. As supplement level increased up to 3%, the biological efficiency decreased.

Depending on the origin of the waste material and on the supplement rate, authors have published different results. Narh Mensah et al. [30] obtained biological efficiency of 78.8% using powdered pineapple rind supplement and 65.2% with substrate control. Pardo-Gimenez et al. [31] reported biological efficiency of 100.3, 109.8, 126.9, and 127.6%, respectively, for the control substrate (without supplement) and supplemented with a defatted almond meal at a rate of 0.5%, 1.0%, and 1.5%.

It is important to note that the peanut residue is a material found in some countries (China, India, Nigeria, USA, Indonesia, Brazil, Argentina, and others) with low commercial value, or even with no commercial value. The only treatment that must be performed for its utilization as a supplement is drying (at a temperature of 68 °C for 24 h) and crushing. The drying process, besides being used to remove moisture excess from hulls and nuts, also serves as pasteurization (or heat treatment), reducing the possible presence of contaminants and pests that may influence the mushroom cultivation. Thus, we suggest the use of peanut residue in countries that do not have companies with commercial representation of substrate supplements for mushroom production. Countries with commercial representation may also use peanut residue for substrate supplementation (Fig. 2).

Fig. 2.

Possibility of application of the technology in several countries that produce peanuts and oyster mushrooms

There is a small change in the amount of micro and macronutrient in the final substrate mixed to the supplements (1 and 2%). The N content in the supplement is very high compared with the substrate, while the commercial supplement has 44 g kg−1 of N, the substrate has only 10 g kg−1 of N; so in the 1st experiment, the N content of treatment 7 increased by 0.94 g kg−1 with the addition of commercial supplement. A positive correlation was found in the 1st experiment, which showed much greater N availability improved yields, but in the 2nd experiment we doubled the amount of supplement and not found a correlation between yield and N content, although the yield gains were greater than those obtained in 1st experiment.

The supplementation of compost with soybean base products is common in the cultivation of A. bisporus. The majority of modern supplements are based on protein-rich vegetable-based raw materials with contents rich in N [18]. As a result of this, we understand that N content that is important for mushroom growth, but there are also other nutrients involved during the cultivation.

The positive correlation was found between the weight of mushrooms and the amount of P and K of the treatments (1st experiment), showing the importance of the macronutrients in the nutrition of fungi. Micronutrients can also improve or reduce yield which was verified with the positive and negative correlations found in the 2nd experiment. The values of Cu and Mn ranged from 6 to 6.49 mg kg−1 and 127–331.2 mg kg−1, respectively between the treatments. Consequently supplements rich in Cu and poor in Mn should be used, but the same correlations with micronutrients were not found in the 1st experiment.

Rodriguez Estrada and Royse [32] verified the positive effect of the Cu; however, different from the present study, the Mn also presented a positive correlation when applied to the substrate on the yield of Pleurotus eryngii. Zied et al. [33] studying the effect of micronutrients in the supplementation of the Agaricus subrufescens production verified that Cu and Mn also showed a positive correlation with yield; nevertheless, the Mn values of compost were lower (141 ± 4.9 mg kg−1) than the present study.

No correlation was repeated between the eight treatments in the 1st and 2nd experiment regarding the production parameters and the macro and micronutrients specifically. It is difficult to understand the dynamics that occurred with the addition of the supplements in the substrate and hence further studies are recommended.

Conclusion

The use of peanut waste can be used as a supplement in the substrate during the production of P. ostreatus, allowing the closing cycle of quality food production. A better combination can be reached with a mix of 20% hulls and 80% or 100% nuts. The addition of 2% supplement in the substrate provided greater yield than 1% supplement.

Funding information

We would like to thank the Fundação de Amparo a Pesquisa do Estado de São Paulo for the financial support conceded (FAPESP 15/15306-3).

Footnotes

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- 1.Soccol CR, Neto CJD, Soccol VT, Sydney EB, Costa ESF, Medeiros ABP, Souza Vandenberghe LP. Pilot scale biodiesel production from microbial oil of Rhodosporidium toruloides DEBB 5533 using sugarcane juice: performance in diesel engine and preliminary economic study. Bioresour Technol. 2017;223:259–268. doi: 10.1016/j.biortech.2016.10.055. [DOI] [PubMed] [Google Scholar]

- 2.Iossi MR, Cobos JDV, Alegria FJG, Zied DC. Pleurotus spp. cultivation on Brachiaria sp. straw treatment with alkaline water. Braz J Microbiol. 2018;49:64–67. doi: 10.1016/j.bjm.2018.06.003. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.Meirelles PG, Ono MA, Ohe MCT, Maroneze DM, Itano EN, Garcia GT, Sugiura Y, Uenoy Ono EY. Detection of Fusarium sp. contamination in corn by enzyme-linked immunosorbent assay. Food Agric Immunol. 2006;17:79–89. doi: 10.1080/09540100600688754. [DOI] [Google Scholar]

- 4.Jaime-Garcia R, Cotty PJ. Crop rotation and soil temperature influence the community structure of Aspergillus flavus in soil. Soil Biol Biochem. 2010;42:1842–1847. doi: 10.1016/j.soilbio.2010.06.025. [DOI] [Google Scholar]

- 5.Arya SS, Salve AR, Chauhan S. Peanuts as functional food: a review. J Food Sci. 2016;53:31–41. doi: 10.1007/s13197-015-2007-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 6.Guimon J, Guimon P. How ready-to-use therapeutic food shapes a new technological regime to treat child malnutrition. Technol Forecast Soc Chang. 2012;79:1319–1327. doi: 10.1016/j.techfore.2012.04.011. [DOI] [Google Scholar]

- 7.Kerr TJ, Windham WR, Woodward JH, Benner R. Chemical composition and in-vitro digestibility of thermochemically treated peanut hulls. J Sci Food Agric. 1986;37:632–636. doi: 10.1002/jsfa.2740370706. [DOI] [Google Scholar]

- 8.Hill GM. Peanut by-products fed to cattle. Vet Clin North Am Food Anim Pract. 2002;18:295–315. doi: 10.1016/S0749-0720(02)00019-1. [DOI] [PubMed] [Google Scholar]

- 9.Estrada AR, Jimenez-Gasco M, Royse DJ. Improvement of yield of Pleurotus eryngii var. eryngii by substrate supplementation and use of a casing overlay. Bioresour Technol. 2009;100:5270–5276. doi: 10.1016/j.biortech.2009.02.073. [DOI] [PubMed] [Google Scholar]

- 10.Ruiz-Rodriguez A, Soler-Rivas C, Polonia I, Wichers HJ. Effect of olive mill waste (OMW) supplementation to oyster mushrooms substrates on the cultivation parameters and fruiting bodies quality. Int Biodeterior Biodegradation. 2010;64:638–645. doi: 10.1016/j.ibiod.2010.07.003. [DOI] [Google Scholar]

- 11.Zied DC, Savoie JM, Pardo-Giménez A Soybean the main nitrogen source in cultivation substrates of edible and medicinal mushrooms. In: El-Shemy HA (ed) Soybean and Nutrition, vol 2011. InTech Open Access Publisher, Rijeka, pp 433–452

- 12.Pardo-Giménez A, Catalán L, Carrasco J, Álvarez-Ortí M, Zied DC, Pardo JE. Effect of supplementing crop substrate with defatted pistachio meal on Agaricus bisporus and Pleurotus ostreatus production. J Sci Food Agric. 2016;96:3838–3845. doi: 10.1002/jsfa.7579. [DOI] [PubMed] [Google Scholar]

- 13.Wach MP, Wheeler DW. Mushroom supplements: what they are and why we use them. Mushroom News. 1998;46:10–16. [Google Scholar]

- 14.Boucque CHV, Fiems LO. II. 4. Vegetable by-products of agro-industrial origin. Livest Prod Sci. 1988;19:97–135. doi: 10.1016/0301-6226(88)90087-5. [DOI] [Google Scholar]

- 15.Ter GB, Warner K, Anderson RA, Bagley EB. Cornmeal/peanut flour blends and their characteristics. J Food Sci. 1978;43:1116–1120. doi: 10.1111/j.1365-2621.1978.tb15248.x. [DOI] [Google Scholar]

- 16.Dahlberg KR. Carboyhdrate-based mushroom supplements. Mushroom News. 2004;52:6–11. [Google Scholar]

- 17.Pardo-Giménez A, Zied DC, Álvarez-Ortí M, Rubio M, Pardo JE. Effect of supplementing compost with grapeseed meal on Agaricus bisporus production. J Sci Food Agric. 2012;92:1665–1671. doi: 10.1002/jsfa.5529. [DOI] [PubMed] [Google Scholar]

- 18.Carrasco J, Zied DC, Pardo JE, Preston GM, Pardo-Gimenez A. Supplementation in mushroom crops and its impact on yield and quality. AMB Express. 2018;8:146. doi: 10.1186/s13568-018-0678-0. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 19.Bell DT, Ward SC. Foliar and twig macronutrients (N, P, K, Ca and Mg) in selected species of Eucalyptus used in rehabilitation: sources of variation. Plant Soil. 1984;81:363–376. doi: 10.1007/BF02323051. [DOI] [Google Scholar]

- 20.Sonneveld C, van Elderen CW. Chemical analysis of peaty growing media by means of water extraction. Commun Soil Sci Plant Anal. 1994;25:3199–3208. doi: 10.1080/00103629409369258. [DOI] [Google Scholar]

- 21.Zied DC, Minhoni MTA, Kopytowski Filho J, Andrade MCN. Production of Agaricus blazei ss. Heinemann (A. brasiliensis) on different casing layers and environments. World J Microbiol Biotechnol. 2010;26:1857–1863. doi: 10.1007/s11274-010-0367-x. [DOI] [Google Scholar]

- 22.Zied DC, Penachio SM, Dias ES, Minhoni MTM, Ferraz RA, Vieites RL. Influence of productivity and processing method on physicochemical characteristics of white button mushrooms in Brazil. J Sci Food Agric. 2014;94:2850–2855. doi: 10.1002/jsfa.6624. [DOI] [PubMed] [Google Scholar]

- 23.Royse DJ. Influence of spawn rate and commercial delayed release nutrient levels on Pleurotus cornucopiae (oyster mushroom) yield, size, and time to production. Appl Microbiol Biotechnol. 2002;58:527–531. doi: 10.1007/s00253-001-0915-2. [DOI] [PubMed] [Google Scholar]

- 24.Fekete SG, Hullár I, Andrásofszky E, Kelemen F. Effect of different fiber types on the digestibility of nutrients in cats. J Anim Physiol Anim Nutr. 2004;88:138–142. doi: 10.1046/j.1439-0396.2003.00470.x. [DOI] [PubMed] [Google Scholar]

- 25.Lee NA, Wang S, Allan RD, Kennedy IR. A rapid aflatoxin B1 ELISA: development and validation with reduced matrix effects for peanuts, corn, pistachio, and soybeans. J Agric Food Chem. 2004;52:2746–2755. doi: 10.1021/jf0354038. [DOI] [PubMed] [Google Scholar]

- 26.van Egmond HP, Jonker MA. Worldwide regulations on aflatoxins - the situation in 2002. J Toxicol Toxin Rev. 2004;23:273–293. doi: 10.1081/TXR-200027844. [DOI] [Google Scholar]

- 27.Royse DJ, Baars J, Tan Q. Current overview of mushroom production in the world. In: Zied DC, Pardo-Gimenez A, editors. Edible and medicinal mushrooms: technology and applications. Chichester: Wiley; 2017. pp. 5–13. [Google Scholar]

- 28.Philippoussis A, Zervakis G, Diamantopoulou P. Bioconversion of agricultural lignocellulosic wastes through the cultivation of the edible mushrooms Agrocybe aegerita, Volvariella volvacea and Pleurotus spp. World J Microbiol Biotechnol. 2001;17:191–200. doi: 10.1023/A:1016685530312. [DOI] [Google Scholar]

- 29.Royse DJ, Rhodes TW, Ohga S, Sanchez JE. Yield, mushroom size and time to production of Pleurotus cornucopiae (oyster mushroom) grown on switch grass substrate spawned and supplemented at various rates. Bioresour Technol. 2004;91:85–91. doi: 10.1016/S0960-8524(03)00151-2. [DOI] [PubMed] [Google Scholar]

- 30.Narh Mensah DL, Addo P, Dzomeku M, Obodai M. Bioprospecting of powdered pineapple rind as an organic supplement of composted sawdust for Pleurotus ostreatus mushroom cultivation. Food Sci Nutr. 2018;6:280–286. doi: 10.1002/fsn3.551. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 31.Pardo-Giménez A, Carrasco J, Roncero JM, Álvarez-Ortí M, Zied DC, Pardo-González JE. Recycling of the biomass waste defatted almond meal as a novel nutritional supplementation for cultivated edible mushrooms. Acta Sci Agron. 2018;40:1–9. doi: 10.4025/actasciagron.v40i1.39341. [DOI] [Google Scholar]

- 32.Rodriguez Estrada A, Royse DJ. Yield, size and bacterial blotch resistance of Pleurotus eryngii grown on cottonseed hulls/oak sawdust supplemented with manganese, copper and whole ground soybean. Bioresour Technol. 2007;98:1898–1906. doi: 10.1016/j.biortech.2006.07.027. [DOI] [PubMed] [Google Scholar]

- 33.Zied DC, Caitano CEC, Pardo-Gimenez A, Dias ES, Zeraik ML, Pardo JE (2018) Using of appropriated strains in the practice of compost supplementation for Agaricus subrufescens production. Front Sustain Food Syst 2(26)