Abstract

Availability and consumption of eggs, especially in Sub‐Saharan Africa and Asia, is low despite their apparent benefits. We investigated constraints in egg production in four countries; Kenya, Ethiopia, Malawi, and India and identified five business models that are viable and sustainable. They are (a) micro‐franchising, (b) microfinancing, (c) co‐operative farming, (d) enterprise development, and (e) out‐grower model. All of them involve smallholder farmers to increase egg production. These farmers have access to soft loans and use improved inputs and extension services to varying degrees. Inputs include resilient breeds of day‐old chicks or point‐of‐lay hens, feed, vaccines, medicines, and housing. Outgrower and enterprise development models have a significant potential of rapidly increasing egg yields, achieve self‐sufficiency, operate at or near scale, and provide a high income for the farmers. This study shows how a range of actors in commercial, not‐for‐profit and microfinance sectors with specialized skills, can facilitate the transformation of the egg production sector. Specific skills include brooding (hatchery operations), feed milling, aggregation, and training of smallholder farmers or large‐scale rearing. The five archetypes we describe here are promising ways to increase egg availability in rural areas.

Keywords: business models, East Africa, eggs, India, rural, smallholders

Key messages.

There are five archetypes of business models involving smallholder farmers that can increase egg availability in rural areas.

Those with larger flock sizes can rapidly achieve high egg yields while ensuring the smallholder farmers have a good income.

All of the models have access to soft loans and use improved inputs to varying degrees.

Favourable policies are needed for diverse actors: commercial, not‐for‐profit, and microfinance institutions, to transform the egg production sector in rural areas.

1. INTRODUCTION

Eaten since the beginning of time, eaten almost everywhere in the world, relatively easy to obtain, adaptable to many different types of cooking techniques and an affordable source of highly digestible protein, the egg offers a high potential to improve maternal and child nutrition. In a recent study, all nine essential amino acids were significantly lower in stunted children compared with non‐stunted Malawian children (Semba et al., 2016). This finding is important because it suggests that stunted children are not receiving sufficient quality protein from their diets. Studies promoting egg consumption for women and children as part of broader dietary improvements in low‐ and middle‐income countries (LMICs) show that child growth indicators are significantly improved in the intervention group compared with control (Iannotti et al., 2017; Iannotti, Lutter, Bunn, & Stewart, 2014). Despite the apparent benefits of eggs, their availability and consumption in these countries, especially in Sub‐Saharan Africa and Asia, is low (Iannotti et al., 2014).

In LMICs, extensively raised chicken or village poultry (flock size of less than 50) contribute to most of the poultry population and are owned by most rural households (Alders & Pym, 2009; Gilbert et al., 2015). Despite low productivity levels (30 to 80 eggs per bird per year), such backyard production systems have been beneficial as they provide supplemental income and insurance to vulnerable groups of society through the sale of eggs and birds using almost negligible inputs (Wong et al., 2017). However, several critical barriers to production need to be addressed to improve and maximize their contribution to food and nutrition security. These include high losses due to disease and predation, high and volatile feed prices, inadequate nutrition, housing, access to affordable vaccines and medicines, veterinary services, and flock management practices (Wong et al., 2017)—all of which are elements of an intensive production system. Intensive poultry systems have a minimum flock size of 100 birds, operate as commercial farms with much higher productivity levels ranging from 200 to 340 eggs per bird per year (Chatterjee & Rajkumar, 2015; Pym, Guerne Bleich, & Hoffmann, 2006). In rural areas, intensifying production through aggregation of smallholders as contract farmers or through cooperatives are known to improve productivity for several foods such as cereals, dairy, fruits, vegetables, and chicken meat (Prowse, 2012). However, published literature for egg production models is sparse. We, therefore, conducted a value chain assessment in three countries in East Africa and India to explore organizations that address the constraints in egg production and analysed their approaches that resulted in identifying five business models that are viable and sustainable. In this paper, we describe these five archetypes all of which involve smallholder farmers in Kenya, Ethiopia, Malawi, and India.

2. METHODS

We followed an empirical approach to profile business models with a comprehensive literature review and discussion with experts in the poultry sector, donors, and impact investors in agriculture in Kenya, Ethiopia, Malawi, and India. We selected these four countries based on the priority geographies of the funding institution and our prior experience in India. Through 160 key informant interviews with farmers, input suppliers, integrators, women self‐help groups, and poultry social enterprises, we mapped the poultry ecosystem and documented the initiatives of nongovernmental organizations (NGOs), small and medium enterprises, large corporations, and government entities. After an extensive due diligence of 21 initiatives involved in rural egg production, we applied four criteria, (a) impact, (b) relevance, (c) sustainability, (d) scale, and shortlisted six organizations for an in‐depth assessment. Impact: interventions that aim to solve deep‐rooted challenges and empower rural communities to make a lasting positive change in their lives have a high impact. Relevance: an initiative's offering is relevant if it increases the smallholder farmer's ability to adapt quickly. Sustainability: sustainable programs rely less on donor funds and create revenue streams for the organization to be self‐sufficient. Scale: an initiative can continue to scale up if it can increase profits by adding additional farmers, or an initiative can scale up rapidly if the cost of reaching a new farmer decreases as the number of farmers increase. We then developed case studies of these six organizations including qualitative and quantitative indicators of operational and financial performance, their approaches to scale, and sustainability. We conducted a comparative analysis of their performance, practices, and critical success factors for sustainability. Based on this assessment, we clustered their approaches into five archetypes or business models (Table 1). All local currencies were converted to US Dollars (USD), using the currency's 12‐month average conversion rate (January 2017 to December 2017).

Table 1.

Comparison of business model elements in micro‐franchising, microfinancing, co‐operative farming, enterprise development, and outgrower models to backyard poultry

| Backyard poultry operationsa | Model 1: Micro‐franchising | Model 2: Microfinancing | Model 3: Co‐operative farming | Model 4: Enterprise development | Model 5: Outgrower model | |

|---|---|---|---|---|---|---|

| Model characteristics | ||||||

| Description | A low‐input and low‐output system; birds are reared in household backyards where they scavenge on kitchen and farm waste. | Hatchery sells day‐old‐chicks to micro‐franchisee agents who rear them until they are 4 to 6 weeks old; agents in turn sell them to backyard and smallholder farmers. | Microfinancing institution procures inputs and distributes them to its smallholder farmer clients with tailored loan packages. | Many farmers co‐own and run a poultry enterprise and share profits and benefits. Each member operates a small farm on their own land. The co‐operative buys inputs and services for its members. | An input supplier aggregates a group of five backyard farmers to set up and own the farm. Eggs produced are sold in communities; excess eggs are collected by the input supplier and sold to other markets. | Contract between a company and independent farms; the company sells inputs and services to the farms and guarantees buy‐back of eggs. |

| Beneficiaries | Households rearing backyard vpoultry | Households rearing backyard poultry | Small‐scale farmers | Small‐scale farmers | Smallholder farmer groups | Medium‐scale farmer or smallholder farmer groups |

| No. of farmers owning each farm | 1 | 1 | 1 | 1 | 5 | 1 |

| Flock size (No. of birds per farm) | 20 | 20 | 50 | 800 | 5,000 | 5,000 |

| Productivity (eggs per bird per year) | 40 | 100 | 200 | 220 | 290 | 290 |

| Mortality | 60% | 25% | 20% | 15% | 7% | 7% |

| Input and services adopted | None | Point of lay birds, improved feed | Input package, loans, training, extension services, and access to markets | Input package, infrastructure, training, loans, and access to markets | Input package, credit, training, and access to markets | Input package, technical and veterinary assistance, and regular farm visits |

| Frequency of use of inputs | Never | Rarely | Sometimes | Regular | Regular | Regular |

| Access to extension services | Never | Sometimes | Sometimes | Regular | Regular | Regular |

| Extent of biosecurity | Low | Low | Low | Medium | High | High |

| Access to markets | Households, communities, and village markets | Barter and sell within village community | Sold in village markets | Sold through own retail shops | Sold in village markets, communities; excess eggs bought by the integrator | Bought by the commercial entity |

| Economic characteristics | ||||||

| Start‐up capitalb required per farm (USD) | 10 | ~70 | ~600 | 2,500 | ~30,000 | ~30,000 |

| Recurring capitalc per laying cycle (USD) | 10 | 60 | 150 | ~1000 | ~9,000 | ~9,000 |

| Minimum no. of farms required to set up the model | n/ad | 120 | 15 | 30 | 1 | 1 |

| Minimum capital required to set up the model (USD excl. program management costs) | n/a | ~8,000 | ~8,000 | 75,000 | ~30,000 | ~30,000 |

| Number of eggs produced per farm per year | 320 | 1500 | 8000 | ~0.15 million | ~1.35 million | ~1.35 million |

| Start‐up capitalb required per egg produced (USD) | 0.031 | 0.044 | 0.069 | 0.017 | 0.022 | 0.022 |

| Recurring capitalc required per egg produced (USD) | 0.0313 | 0.04 | 0.0188 | 0.0074 | 0.0065 | 0.0065 |

| Program cost per egg produced (USD) | n/a | 0.24 | Data not available | 0.02 | 0.03 | 0.03 |

| Each farmer's net annual income (USD) | ~40 | ~75 to 150 | 600 | ~600 to 800 | ~1,700 | ~2,200 to 5,000e |

Note. USD: US Dollars.

Akinola & Essien, 2011.

Money required to start a poultry farm: includes infrastructure (building and cages) and starter pack. For Model 3 and backyard poultry, includes starter pack only.

Money required to repopulate chickens after one laying cycle. Farmers typically use sales proceeds to buy next cycle of chickens.

n/a: not applicable.

USD 2,200 per farmer if it is a group of five farmers and USD 5,000 for a single farmer managing a flock size of 5,000 birds.

We now define key terms commonly used in the poultry sector and in subsequent sections. “Integrators” are commercial entities who have operations across the value chain. They distribute input packages, operate layer farms and sell eggs through their own shops. An “input package” comprises of young chicks, feed for chickens, medicines and vaccines, and housing for the hens. Young chicks are procured either as “day‐old chicks” (DOCs) or “point of lay” chicken (17 to 20 weeks old). Eggs are hatched into DOCs in “hatchery” units. These chicks are then raised in “brooding units” with high quality of care, nutritious diets, and additional warmth to raise them into point of lay chicken. At this stage, they are ready to lay eggs. “Para‐veterinarians” supervise birds for disease outbreaks and administer vaccines and medicines through “extension services.”

3. RESULTS

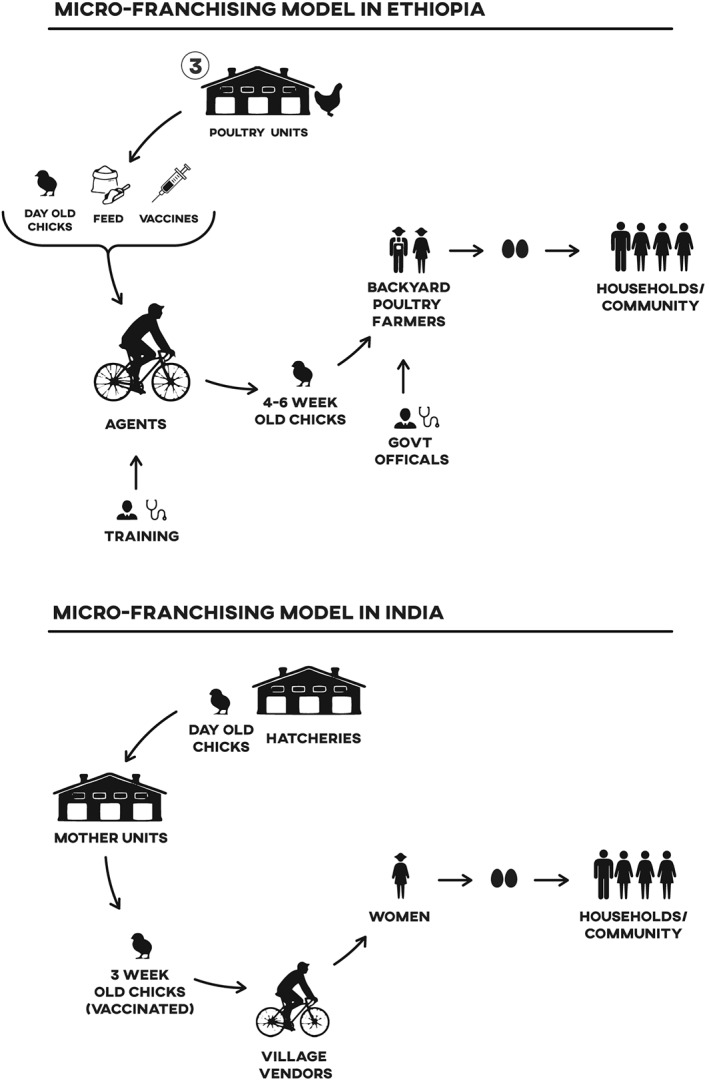

3.1. Model 1: Micro‐franchising

In this business model, a hatchery sells DOCs, together with vaccines and feed to agents (micro‐franchisees). Agents breed the chicks till they are 4 to 6 weeks old, thus ensuring they are resilient when introduced to extensive or backyard rearing. They then sell these chicks to the backyard and smallholder farmers, sometimes together with feed. In Ethiopia and India, for example, two private companies created a vast agent network and a replicable distribution model to reach rural households (Figure 1). They developed a commercial breed that is agile and has high resistance to diseases when compared with the indigenous variety. The Ethiopian company, in a public–private partnership with the government, operates state‐owned poultry breeding farms at higher efficiency and profitability. The Indian company has a hatchery, and DOCs are transported to mother units located across the country where they are vaccinated and raised for 3 weeks. Micro‐franchisees, who are independent entrepreneurs, buy the 3‐week‐old chicks and transport them to rural areas on their bicycles where they sell these chicks to backyard farmers (mainly village women). They are also called “brooding entrepreneurs” or “agents.” They would need to invest on their own or use credit from the company. Each micro‐franchisee can cover between 120 and 150 households and is responsible for brooding up to 3,000 chicks. Village women raise the chicks on low‐cost household and agricultural waste. Not more than 20 birds can be raised at a time, beyond which the farmer sees diminishing returns. Backyard farmers make a net supplemental income between USD 72 and USD 144 per year because of improved productivity of 100 eggs per bird (vs. 40 eggs per bird) and reduced mortality. In an optimistic scenario, where a farmer buys three batches of 20 birds each per year, the micro‐franchisee or the brooding entrepreneur has a net annual income of USD 1,600 and can recover his capital investment in 2 to 3 years. Net margin for the micro‐franchise is 20%. Nearly 40% of the costs is for DOC, 35% for feed, and the remaining for vaccines and other medicines. This model is laborious to set up as it requires hiring and training of several agents. A significant share of the revenue of eggs in the value chain is with the micro‐franchisee and not the backyard farmer, and since the birds continue to grow in the suboptimal backyard environment, productivity is still low. As a result, the backyard farmers make less than a 10th of the income of farmers in the Models 4 and 5.

Figure 1.

Micro‐franchising model

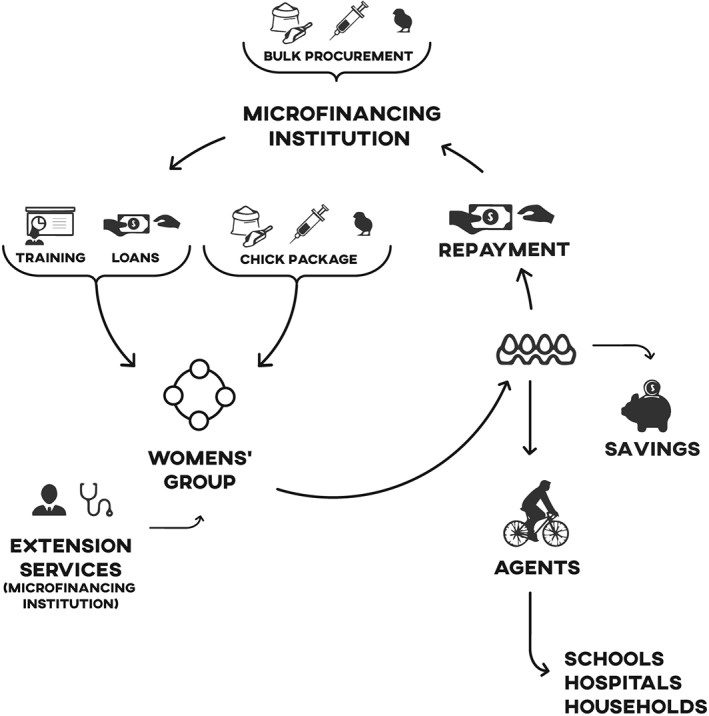

3.2. Model 2: Microfinancing

In this model, a microfinancing institution (MFI) procures inputs from a supplier and distributes them to micro‐entrepreneurs along with loans, training on backyard poultry, and extension services. Women rear hens and sell eggs within the community and to institutions while repaying the loan (Figure 2). Interest from the loans is income for the MFI which, after covering its costs, is used to expand its coverage to other locations. We found two MFIs in Kenya and Malawi providing asset‐backed loans for small‐scale poultry farmers. Their group lending structure, working through self‐help groups, minimizes risk for default. The MFI also advises the farmers on good suppliers of assets and inputs: brings technical partners to provide training to farmers while giving the farmers the flexibility to select where to sell or where to invest in the business process. Informal saving groups are common in Kenya, and hence this model is relatively more straightforward to set up compared with the previous models. For example, in Kenya, the MFI reaches more than 32,000 farmers across 14 counties whereas the one in Malawi covers 86,000 clients across 17 districts. Moreover, microfinance is a familiar concept among farmers. In the Kenya model, a farmer starts with a small loan of approximately USD 400. She earns USD 600 per year with 50 chickens. Through regular payments, she can graduate to a more substantial loan amount, which she invests to expand flock size. Farmers typically expand from 50 chickens to 100 and then to 200 chickens reaching productivity levels of 200 eggs per bird. They also expand their ownership in the value chain by setting up their own hotels or food kiosks in the village that buy the eggs produced by their own farms. Critical success factors in this model are encouraging farmers to diligently save earnings however small it may be; weekly meetings where farmers learn about new products, practices, share ideas, and support each other; and farmer groups organized to bargain for better deals with input suppliers and distributors to markets.

Figure 2.

Microfinancing model

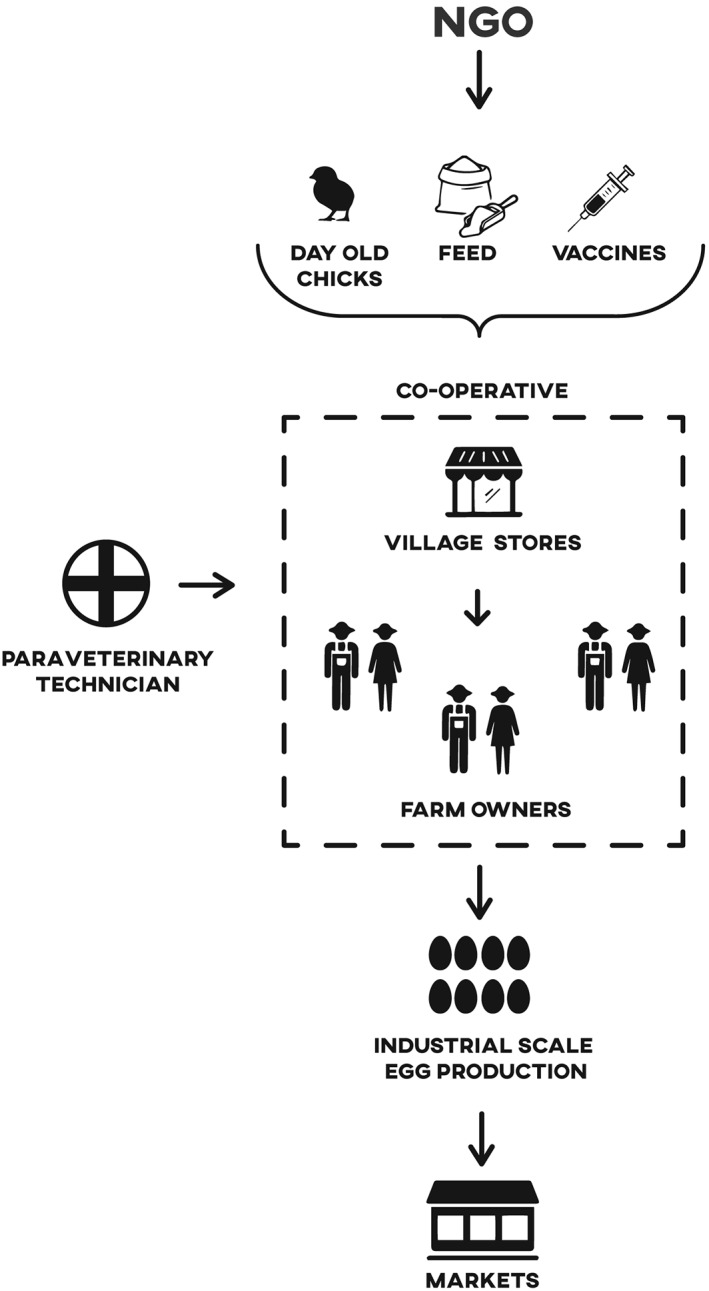

3.3. Model 3: Co‐operative farming

In a co‐operative farming model, many farmers own and jointly run the enterprise and share the profits and benefits (Figure 3 ). A not‐for‐profit organization in central India has pioneered the co‐operative model for poultry farming successfully with nearly 10,000 farmer‐owners in two units. Most of the farmer‐owners are women belonging to vulnerable communities who were engaged in manual labour and wood collection before the establishment of the co‐operative. Interested women were organized into groups and provided training in poultry rearing and management practices. Once the training was over, farmers were provided with part loan and part grant amount for construction of sheds. Each entrepreneur started operations with 300 to 400 chicks and currently operate 600 to 1000 birds per batch with productivity levels of 220 eggs per bird per year. About 25 to 30 such sheds are located within a tight cluster, enabling the enterprise to achieve production and cost efficiencies usually seen in large‐scale production. Each cluster is supported by a para‐veterinary technician hired with a small fixed fee and performance‐based variable pay and a village store for delivery of inputs at the doorstep. The co‐operative is vertically integrated, owns and operates hatcheries, feed mills, procurement, and retail outlets. The enterprise has a collective turnover of USD 58 million. Each farmer has a net income of USD 620 to USD 780 for 200 working days as a part‐time engagement.

Figure 3.

Co‐operative farming model. NGO: nongovernmental organization

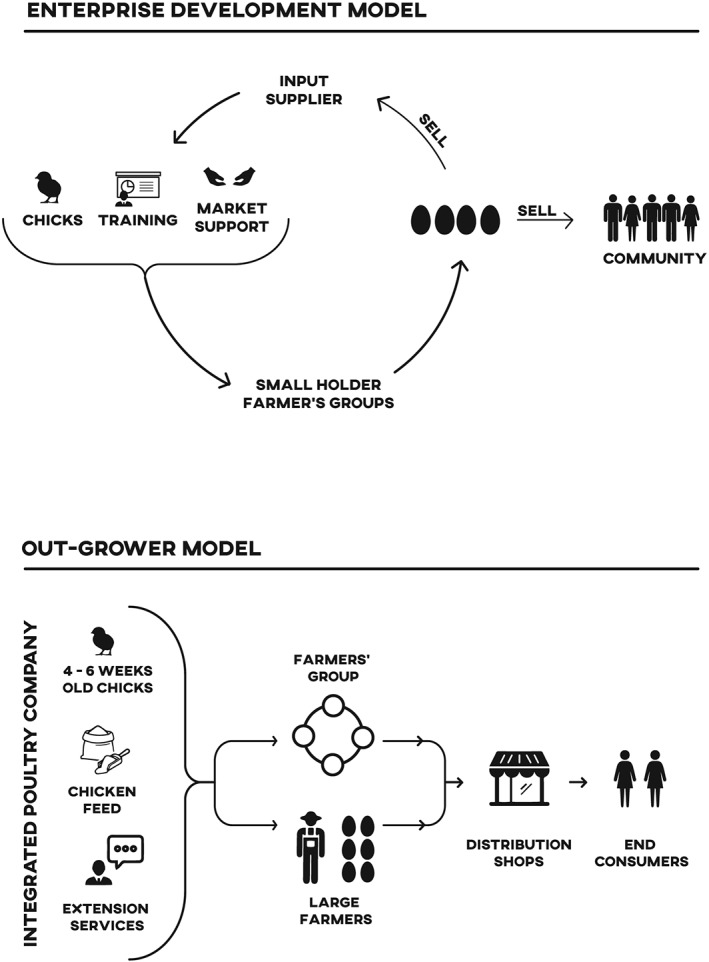

3.4. Model 4: Enterprise development

At the core of this model is an input supplier who organizes the backyard farmers into small groups and supports them to set up and develop an enterprise. Such support includes the provision of input package with credit, training, and access to markets to sell eggs. Farmer groups are encouraged to buy improved feed and other inputs from the supplier at wholesale rates. Farmers sell eggs primarily in their communities. Any excess eggs are transported to urban markets through the trucks of the input supplier that are used to deliver feed to the farmers (Figure 4 ). An example of this model is an integrated poultry company in Malawi. A breeder of DOCs, the company has extended its business to include commercial broiler and layer hatcheries and farms, poultry vaccines, extension services, and feed mill. The company aggregates five backyard or smallholder farmers into one group to establish a medium‐scale farm of 5,000 to 6,000 birds, that is, each farmer is supplied with 1,000 to 1,200 sixteen‐week‐old birds (near point‐of‐lay). Point‐of‐lay birds have lower mortality than DOCs. The risk for the farmer is lowered in this model as the company broods DOCs to point‐of‐lay birds in a high quality of care and temperature‐controlled environment. The company provides cages, biosecurity clothing, and inputs on credit for the first production cycle. Farmers are trained in flock, enterprise and financial management, marketing of eggs, and learn to save through a revolving fund to be able to buy inputs regularly. Productivity level of the hens starts at 70% (255 eggs per bird per year) and reaches at least 80% by the end of the second year. Capital expenditure, spent on land, shed, cages, and other assets, of nearly USD 29,000 incurred by the group of farmers, is recovered in 3 years. Recurring capital required for subsequent laying cycles is much lower, which is usually available to the group from sales of spent birds from the first cycle. Though the capital needed is high in this model, ongoing program costs are quite low. Every farmer makes a net income of USD 144 per month, which is 2.3 times more than Malawi's minimum wage rates.

Figure 4.

Enterprise development model and outgrower model

Two factors are critical to the success of this model. First, the model is feasible only when an integrator is committed to building robust technical capacity with farmer groups and sells inputs to them at wholesale prices. The integrator may not profit in the short‐term but benefits from sustainable gains in the long term as overall market size in rural areas increases. Second, frequent and adequate training and availability of low cost credit is necessary to improve farmer's initial adoption and consistent use of inputs and services (high‐quality feed, vaccine, and veterinary services) for subsequent laying cycles: a practice that is missing in small‐scale farms.

3.5. Model 5: Outgrower model

An outgrower model is a contract between independent farmer groups (five farmers managing 5,000 birds) or a single farmer with a minimum farm size of 5,000 birds and a commercial entity. The commercial entity provides chicks, input package, technical and veterinary assistance, and regularly visits the farmers, that is, two to three times a week to discourage from selling to others, assure quality, and ensure regular procurement of target quantity of eggs (Figure 4). The organizer buys back all eggs from the farmer groups and distributes them through its own retail channels. A medium size layer farmer in Kenya who also owns a feed mill is piloting this model to source eggs from contracted smallholder farmers for sale through its own branded retail stores in peri‐urban areas. The smallholders have a low risk in this model due to guaranteed price and quantity agreements and performance incentives for excess eggs. Capital requirements for the farmer and program costs for the company are the same as the enterprise development model. Outgrower farming can help increase production capacity of commercial players without significant capital investment as the farmer groups use their own farm for production. However, this model requires the commercial entity to have a sophisticated network of own or shared dealers and distributors to be able to transport fresh eggs quickly. The farmer groups and integrator need to be in close vicinity. Remotely located villages cannot be chosen since aggregation of eggs will become costly. Due to poor road infrastructure, transportation of eggs is usually limited to an area of 5,000 km2. To expand outgrower models to remote rural areas, a one‐stop hub for distribution of inputs, extension services, and eggs would be needed. The company usually invests in marketing of its branded eggs through community events, radio advertisements, banners, posters, wall paintings, and billboards. Due to constant checks and rigorous quality control procedures deployed by the company, the productivity of hens is high at 80% or more that also translated into more value for the farmers. Identifying committed and diligent farmers is a crucial factor for this model to succeed.

4. DISCUSSION

More than 80% of chickens in East Africa and 50% in India are extensively raised, that is, in the backyards (Gilbert et al., 2015). Despite economic growth and known health benefits, availability of eggs per capita per year is very low: nine in Ethiopia, 27 in Malawi, 46 in Kenya, and 60 in India (FAOSTAT, 2013). Our analysis describes business models that engage smallholders in improving egg availability in these four countries. We found that these models were successful in improving hen productivity from an average of 40 eggs per bird in the backyard setting to a minimum of 100 eggs per bird in the micro‐franchising model (Model 1) and a maximum of 290 eggs per bird in the enterprise development and outgrower model. Models with flock size of more than 200 birds per farm could achieve self‐sufficiency in 3 years and thus become independent from investors and donors. However, to scale, flexible funding or patient capital would still be required. All of them have access to soft loans, use improved inputs, and extension services, to varying degrees. These inputs include resilient breeds of DOCs or point‐of‐lay hens, feed, vaccines, medicines, and housing. Integrators in Models 4 and 5 and NGOs as aggregators in Models 2 and 3 organize the value chain for smallholder farmers, lowering cost of reach and improving access to markets.

Model 1, micro‐franchising is an improved backyard situation. Despite light capital requirements, the micro‐franchising model struggles to breakeven or operates with slim margins. This model has the lowest productivity and the highest program costs as it must create a vast agent network to reach rural households and train individual backyard farmers. Moreover, weak extension services and nonavailability of inputs for subsequent laying cycles for backyard farmers make it difficult to sustain improved productivity. Therefore, this model must also service larger farms to sustain investment in developing the distribution network for inputs and services.

Microfinancing and cooperative farming offer encouraging alternatives for the micro‐franchising model where backyard farmers can instead be transitioned to own and rear up to 800 birds. This means hens would be more than an asset or insurance and be a primary source of income while also increasing egg production. In these two cases, farmers earn 5 times more than in Model 1. By aggregating farmers into small groups, recurring capital and program costs for each egg produced are significantly lower than the micro‐franchising business model.

The vast presence of microfinance organizations in LMICs is a promising channel to leverage for increased egg production in rural areas. Since NGOs and MFIs would not have poultry farming expertise, they would need to engage a wide range of partnerships from parastatals who often have veterinary and other extension services or subsidies for smallholders to input suppliers as an anchor buyer and coordinate activities along the value chain. The co‐operative model from India must be considered as a unique scenario and may not be feasible in Sub‐Saharan Africa. This is because India has a thriving and rapidly growing input industry, thus making procurement at affordable prices possible for NGOs. India is the third largest producer of eggs in the world, mostly driven by medium‐ and large‐scale farms (Mehta & Nambiar, 2007) leading to the development of a flourishing input industry around these larger farms.

Private companies developed Models 4 and 5. They are an input supplier of DOCs in Malawi and a large‐scale layer farmer in Kenya. These two models have stringent biosecurity measures, large flock sizes, follow best practices in flock and farm management, and hence have a very high and steady productivity of 70% or more. Despite heavy capital requirements, with each farm producing more than a million eggs every year, they are best placed to increase egg availability in rural areas and minimize losses due to a disease outbreak. Neither commercial player had any immediate, short‐term profit but would have long‐term sustainable gains through increased market share. Smallholder farmers in these two models spend up to 10 hr a day and have high annual incomes of nearly USD 2,000, that is, 2 to 15 times more than the farmers in the other models. Further, capital and program costs per egg is the lowest, thereby eggs produced can be made affordable to the consumer.

Favourable policies in the form of soft loans or subsidies are needed for the private sector to establish outgrower model or the enterprise development model in rural areas to rapidly increase egg production. Catalysing investments across the value chain, especially in the layer input sector would encourage NGOs to establish co‐operatives and MFIs to support the transition of backyard farmers to more economically viable, intensive production models.

There are a few limitations in our study. First, we rely on the information provided by the social enterprises themselves. Triangulating with a market study would make our analysis more robust. Further, an extensive due diligence is needed to assess their economic, social, and environmental impact in the communities they serve. Second, we have not explored whether increased productivity of the layer hens in these models leads to a steady supply of eggs at affordable prices throughout the year in the communities. Third and most importantly, future research should consider whether improving availability and affordability of eggs through such business models will increase consumption among the most vulnerable groups, women, and children. This is important because price is a significant predictor of consumption of eggs in children. Low supply of eggs in lower income countries due to low productivity of egg production and the perishable nature of shell eggs appears to contribute to high prices of eggs (Headey, Hirvonen, & Hoddinott, 2017).

In conclusion, this study contributes to the global literature on approaches and elements required for extensive or backyard poultry farmers to adopt semi‐intensive or intensive farming in LMICs. Four of the models we investigated have invested in the aggregation of smallholders to become more economically savvy trading partners and capitalize on economies of scale. These models are advanced by diverse actors: private companies, NGOs, and microfinance institutions. They developed specialized skills in brooding, feed milling, aggregation, and training of farmers or large‐scale rearing of hens to ensure that their business models are viable and profitable. The five archetypes we see are essential ways to increase egg availability in rural areas with the outgrower model showing remarkable promise for rapidly increasing egg production.

CONFLICTS OF INTEREST

The authors declare that they have no conflicts of interest.

CONTRIBUTIONS

KB and KK conceptualized the vision and the need to find viable models. KB designed the framework and participated in data collection, analysis, interpretation of findings, and drafting of the manuscript. SL assisted in data organization and drafting of the manuscript. KB, SL and KK contributed to the interpretation of findings and the critical revision of the manuscript for final submission. All authors approved the draft.

ACKNOWLEDGEMENTS

The authors would like to thank independent consultants Susan Otieno (East Africa) and Siddharth Tata (India) for data collection and Anne Milan for illustrations of the business models.

Beesabathuni K, Lingala S, Kraemer K. Increasing egg availability through smallholder business models in East Africa and India. Matern Child Nutr. 2018;14(S3):e12667 10.1111/mcn.12667

REFERENCES

- Akinola, L. , & Essien, A. (2011). Relevance of rural poultry production in developing countries with special reference to Africa. World's Poultry Science Journal, 67(4), 697–705. 10.1017/S0043933911000778 [DOI] [Google Scholar]

- Alders, R. G. , & Pym, R. (2009). Village poultry: Still important to millions, eight thousand years after domestication. World's Poultry Science Journal, 65(02), 181–190. [Google Scholar]

- Chatterjee, R. N. , & Rajkumar, U. (2015). An overview of poultry production in India. Indian Journal of Animal Health, 54(2), 89–108. [Google Scholar]

- Food and Agriculture Organization of the United Nations (2013). FAOSTAT statistics database. Rome, Italy: FAO. Retrieved on March 9, 2018 from http://www.fao.org/faostat/en

- Gilbert, M. , Conchedda, G. , van Boeckel, T. P. , Cinardi, G. , Linard, C. , Nicolas, G. , … Robinson, T. P. (2015). Income disparities and the global distribution of intensively farmed chicken and pigs. PLoS One, 10(7), e0133381 10.1371/journal.pone.0133381 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Headey D., Hirvonen, K. , & Hoddinott, J. (2017). Animal sourced foods and child stunting. December 23, 2fd017. IFPRI Discussion Paper 1695. Retrieved from SSRN: https://ssrn.com/abstract=3098491 [DOI] [PMC free article] [PubMed]

- Iannotti, L. L. , Lutter, C. K. , Stewart, C. P. , Gallegos Riofrío, C. A. , Malo, C. , Reinhart, G. , … Waters, W. F. (2017). Eggs in early complementary feeding and child growth: A randomized controlled trial. Pediatrics, 140(1), e20163459 10.1542/peds.2016-3459 [DOI] [PubMed] [Google Scholar]

- Iannotti, L. R. , Lutter, C. K. , Bunn, D. A. , & Stewart, C. P. (2014). Eggs: The uncracked potential for improving maternal and young child nutrition among the world's poor. Nutrition Reviews, 72, 355–368. 10.1111/nure.12107 [DOI] [PubMed] [Google Scholar]

- Mehta, R. , & Nambiar, R. G. (2007). The poultry industry in India In Theime O., & Pilling D. (Eds.), Poultry in the 21st century: Avian influenza and beyond. Rome: Food and Agriculture Organization (FAO). [Google Scholar]

- Prowse, M. (2012). Contract farming in developing countries: A review, February, p.13 Retrieved March 20, 2018, from http://www.afd.fr/webdav/shared/PUBLICATIONS/RECHERCHE/Scientifiques/A-savoir/12-VA-A-Savoir.pdf.

- Pym, R. , Guerne Bleich, E. , & Hoffmann, I. (2006). The relative contribution of indigenous chicken breeds to poultry meat and egg production and consumption in the developing countries of Africa and Asia. Presented at 12th European Poultry Conference, Italy, 10–14 September.

- Semba, R. D. , Shardell, M. , Sakr, A. , Fayrouz, A. , Moaddel, R. , Trehan, I. , … Manary, M. J. (2016). Child stunting is associated with low circulating essential amino acids. eBioMedicine, 6, 246–252. 10.1016/j.ebiom.2016.02.030 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Wong, J. T. , de Bruyn, J. , Bagnol, B. , Grieve, H. , Li, M. , Pym, R. , & Alders, R. G. (2017). Small‐scale poultry and food security in resource‐poor settings: A review. Global Food Security, 15, 43–52. 10.1016/j.gfs.2017.04.003 [DOI] [Google Scholar]