Abstract

Background:

Self-disinfecting impression materials would reduce time and energy needed for impression disinfecting process in clinic. The aim of this study was to evaluate the antimicrobial effect of alginate mixed with nanosilver solution at a concentration of 500 ppm and 1000 ppm on common oral microorganisms and assess changes in working time, setting time, and surface detail reproduction.

Materials and Methods:

In this in vitro study, three groups were assigned. The first group was alginate, the second group was alginate mixed with 500 ppm nanosilver, and the third group was alginate mixed with 1000 ppm nanosilver. Antimicrobial effect on Escherichia coli, Staphylococcus aureus, and Candida albicans was studied using direct contact test in each group (n = 10). Working time (n = 10), setting time (n = 10), and surface detail reproduction (n = 10) were evaluated separately using the ISO 21563 protocol. Descriptive tables were used to describe the data. Kruskal–Wallis test used to determine significant differences in the number of colonies was counted in antimicrobial test (α = 0.05).

Results:

No adverse effects observed in working time, setting time, and surface detail reproduction of alginate impressions. Alginate mixed with silver nanoparticles showed no inhibitory effect on S. aureus and C. albicans, but the number of E. coli colonies were counted in the group 1000 ppm was significantly lower than 500 ppm (P = 0.001).

Conclusion:

Antimicrobial effect of alginate mixed with silver nanoparticles is not clinically indicated. Nevertheless, its physical features did not change significantly.

Key Words: Dental impression materials, microbiologic, nanotechnology

INTRODUCTION

Alginate impression material has a widespread use in dentistry.[1] The oral cavity is a host to many microbial agents, and it is shown that oral fluid could mix into the impressions.[2] Therefore, they are capable of making cross infection.[3]

Many studies evaluated various methods to disinfect impression materials.[4,5,6,7] Among disinfectant agents, chlorhexidine (CHX) and quaternary ammonium salts were reported to have superior antimicrobial activity against oral microorganism.[1,5,6,7,8]

The most widespread methods for disinfecting impressions are using spray and immersing. However, these methods are time-consuming and have negative effect on mechanical properties of alginate.[1]

Silver and its derivatives are employed as antimicrobial agent, and especially nanosilver products have been used in various medical applications.[9,10,11] Therefore, incorporation of nanosilver particles in alginate impression material may be useful.

Despite the widespread use of nanosilver products, few studies have examined the effect of nanosilver on antimicrobial and mechanical properties of impression materials. Therefore, the null hypothesis of this study was that adding of nanosilver particles to alginate has no effect on mechanical and antimicrobial properties of the materials.

MATERIALS AND METHODS

In this in vitro study, three groups were assigned. The first group was alginate, the second group was alginate mixed with 500 ppm nanosilver particles, and the third group was alginate mixed with 1000 ppm nanosilver particles. Varying concentrations (500 and 1000 ppm) of silver nanoparticles (prepared in School of Pharmacy, Mashhad University of Medical Sciences, Mashhad, Iran) of 90–100 nm size were added to a dust-free alginate (Iralgin, Golchi, Iran) and its properties were evaluated.

Preweighed alginate powder and silver nanoparticles were dispended in a container and mixed uniformly. Alginate without silver nanoparticles was tested as control group.

Alginate with or without nanoparticles was prepared by mixing powder with a premeasured volume of deionized water as recommended by the manufacturer (23 g powder with 50 ml water).

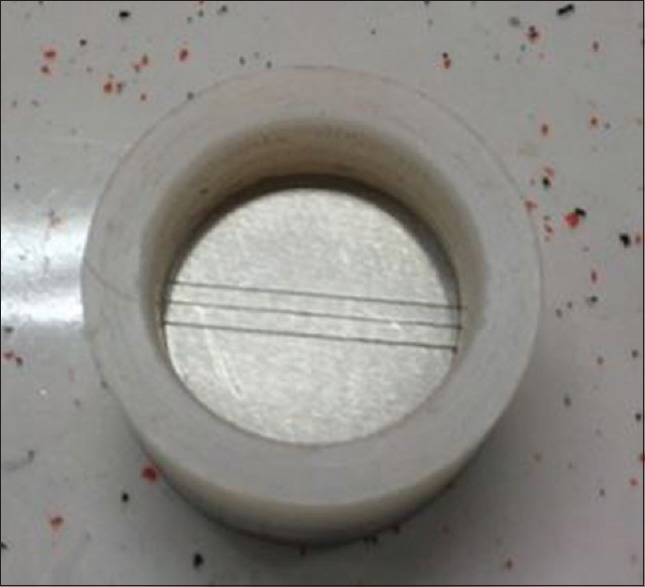

Alginates were mixed for 45 s using a rubber bowl and alginate mixing spatula by a single operator. At the end of the mixing time, the material was filled into an orthodontic gypsum mold of 30 ± 0.2-mm internal diameter and 16 ± 0.1-mm height. Working time was measured using indentation methods. Seventy seconds after mixing the alginate, a needle (weighed 50 g) was released. Using Universal testing Machine device (SANTAM, Iran), the amount of remained alginate under the needle was measured. This measurement should not be <0.25 mm according to the ISO 21563 protocol.[12] This process was performed ten times for each group [Figure 1]. To measure primary setting time similar to the working time, the mold was fulfilled with alginate and 5 s before the manufacturer's instruction (2 min and 30 s), and the rod was placed in contact with the surface of alginate. This procedure was repeated at 10 s intervals until the impression material no longer adhered to the rod (n = 10). To evaluate surface details reproduction, a grooved mold was used [Figure 2]. Fifteen seconds before termination of working time, the mold was fulfilled by alginate and a glass plate was placed on top of this mixture. The surface of specimens was examined by stereomicroscope (Olympus, Leica, EZ4D, Italy) and reproduction of 20-μ groove was considered acceptable (n = 6 for each group). The results were reported according to Culhaoglu et al.'s rating.[13]

Figure 1.

Designed device to measure working time.

Figure 2.

The mold for evaluating surface detail reproduction.

Rating 1: Well defined, sharp detail, continuous line

Rating 2: Continuous line but with loss of sharpness

Rating 3: Poor detail or loss of continuity of the line

Rating 4: Marginally or not discernible.

Antimicrobial activity on Escherichia coli, Staphylococcus aureus, and Candida albicans assessed using direct contact test. In each group, 10 alginate specimens were prepared in molds (2-cm diameter and 0.7-cm height). All the specimens were placed in autoclavable container and were sterilized in 121°C and 15 Psi. After that, 100 μl from the bacterial or fungal solution were added and remained for 1 h. The lawn cultures of all the three microorganisms tested were made with a bacterial or yeast suspension, matching the turbidity of a 0.5 McFarland standard. After 1 h, the solution was collected from alginate specimens by a sampler and was cultured in a blood agar medium and incubated at 37°C for 24 h. Then, the number of colonies was counted. Data were analyzed by Kruskal–Wallis test using SPSS software (ver. 16, IBM, New York, USA), and the statistical significance level was 0.05 (α = 0.05).

RESULTS

Working time

The mean measured depths for control, 500 ppm nanosilver incorporated alginate, and 1000 ppm nanosilver incorporated groups were 15.82 ± 0.13 mm, 15.89 ± 0.08, and 15.93 ± 0.03, respectively [Table 1].

Table 1.

Penetration depth of needle and setting times in groups

| Group | Mean±SD |

|

|---|---|---|

| Penetration depth (mm) | Setting time (s) | |

| Control | 15.82±0.13 | 161±9.16 |

| 500 ppm | 15.89±0.08 | 166±5.38 |

| 1000 ppm | 15.93±0.03 | 157±7.48 |

SD: Standard deviation

According to ISO 21563, the measured depth >15.75 mm is standard. Therefore, in all groups, the working time was standard.

Setting time

As shown in Table 1, the mean measured setting time for control, 500 ppm nanosilver, and 1000 ppm nanosilver groups was 161 ± 9.16 s, 166 ± 5.38 s, and 157 ± 7.48 s, respectively. According to ISO 21563,[12] the setting time 20% more or less than the time mentioned by manufacturer is acceptable (120–180 s). Therefore, all specimens showed acceptable setting time.

Surface detail reproduction

Six samples were prepared for each group. In all specimens, the 20-μm line was evident by stereomicroscope. None of the specimens showed rating 4 [Table 2].

Table 2.

Surface reproduction details of samples

| Groups | n | Control | 500 ppm | 1000 ppm |

|---|---|---|---|---|

| Rating | 1 | 1 | 2 | 1 |

| 2 | 1 | 2 | 2 | |

| 3 | 1 | 1 | 3 | |

| 4 | 1 | 2 | 2 | |

| 5 | 1 | 1 | 2 | |

| 6 | 1 | 1 | 1 |

Antimicrobial activity

To test antimicrobial activity, direct contact test was used for E. coli, S. aureus, and C. albicans.

There were no significant differences in S. aureus count among groups (P = 0.617). Furthermore, C. albicans count showed no significant differences among groups (P = 0.086). However, there were statistically significant differences in E. coli count among groups (P = 0.008). Post hoc test showed that the counted colonies in the concentration of 1000 ppm nanosilver were significantly < 500 ppm nanosilver concentration (P = 0.008) [Table 3].

Table 3.

Comparison of counted colonies among the groups

| Microorganism | Groups | Mean±SD | Kruskal–Wallis test χ2, P |

|---|---|---|---|

| Staphylococcus aureus | Control | 40.00±37.00 | 0.964, 0.617 |

| 500 ppm | 33.10±26.24 | ||

| 1000 ppm | 47.39±0.72 | ||

| Candida albicans | Control | 26.00±21.66 | 4.90, 0.086 |

| 500 ppm | 36.00±27.57 | ||

| 1000 ppm | 12.29±16.00 | ||

| Escherichia coli | Control | 122.75±125.18 | 9.70, 0.008 |

| 500 ppm | 122.89±81.19 | ||

| 1000 ppm | 26.10±31.02 |

P<0.05 is statistically significant. SD: Standard deviation

DISCUSSION

The null hypotheses were rejected; adding of nanosilver particles to alginate had effect on mechanical and antimicrobial properties of the materials.

One way against cross infection in dental office is disinfection of impression materials. It has been reported that bacillus tuberculosis, hepatitis B, herpes virus, and other microorganisms could transfer by impression materials. Surface disinfection of impressions may inhibit this cross infection.[14] Spraying and immersing the impressions are the most common methods to disinfect these materials.[1] However, these methods may have negative effects on physical properties of impressions.[1,14] It has been shown that incorporation of disinfectant agents into the impression materials is an effective method.[4,5,15]

Recently, nanoparticles, especially nanosilver as an antimicrobial agent, have been widely used.[11,16] In this study, we added two concentrations of nanosilver particles (500 ppm and 1000 ppm) and then antimicrobial and mechanical properties were evaluated. The antimicrobial activity was measured using direct contact test. The advantage of this method to disc diffusion and agar well method is that the procedure is more similar to clinical condition. In our study, three microorganisms S. aureus (g+), E. coli (g−), and C. albicans (fungi) were evaluated. Furthermore, Ginjupalli et al.[7] in their study examined these three microorganisms.

Our results showed that nanosilver addition to alginate has no adverse effect on its mechanical properties; however, there was no significant difference in counted colonies of S. aureus and C. albicans among the groups. Although for E. coli, there were significant less colonies in 1000 ppm nanosilver group in comparison with 500 ppm group. However, even existence of one colony indicates the inability of nanosilver with concentrations of 1000 ppm and 500 ppm to hinder the microorganisms. Ginjupalli et al.[7] showed that alginate incorporated by silver nanoparticles had a proper antimicrobial effect on S. aureus, E. coli, and C. albicans.

These differences may be as a result of the difference in the methods. Ginjupalli et al.[7] used disc diffusion method; however, we used direct contact test to count the colonies. Moreover, Ginjupalli et al.[7] and Jafari et al.[4] showed that the silver-incorporated irreversible hydrocolloids exhibited dose-dependent antimicrobial activity. However, in our study, it was true only for E. coli. Sondi and Salopek-Sondi showed that nanosilver particles have a limited use as antimicrobial agent.[17]

Flanagan et al.[18] and Kollu et al.[14] showed that CHX-incorporated alginate was capable of destroying 99% of microorganism. Consequently, it can be said that this method is better than incorporation of silver nanoparticles.

CONCLUSION

Incorporation of silver nanoparticles in concentrations of 500 ppm and 1000 ppm did not have the ability to completely hinder growth of E. coli, S. aureus, and C. albicans existed on the surface of alginate. Nevertheless, its physical properties (working time, setting time, and reproduction of surface details) did not change significantly.

Financial support and sponsorship

Nil.

Conflicts of interest

The authors of this manuscript declare that they have no conflicts of interest, real or perceived, financial or nonfinancial in this article.

Acknowledgment

The authors would like to extend their appreciation to the Vice-Chancellor for Research of Mashhad University of Medical Sciences for the financial support.

REFERENCES

- 1.Wang J, Wan Q, Chao Y, Chen Y. A self-disinfecting irreversible hydrocolloid impression material mixed with chlorhexidine solution. Angle Orthod. 2007;77:894–900. doi: 10.2319/070606-277. [DOI] [PubMed] [Google Scholar]

- 2.Amalan A, Ginjupalli K, Upadhya N. Evaluation of properties of irreversible hydrocolloid impression materials mixed with disinfectant liquids. Dent Res J (Isfahan) 2013;10:65–73. doi: 10.4103/1735-3327.111795. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.Jennings KJ, Samaranayake LP. The persistence of microorganisms on impression materials following disinfection. Int J Prosthodont. 1991;4:382–7. [PubMed] [Google Scholar]

- 4.Jafari A, Bakhtiari R, Shahabi S, Nia JR, Mehrabadi JF, Yousefi B. antimicrobial activity of irreversible hydrocolloid impression against oral microorganisms. J Basic Appl Sci Res. 2013;3:397–401. [Google Scholar]

- 5.Casemiro LA, Pires-de-Souza Fde C, Panzeri H, Martins CH, Ito IY. In vitro antimicrobial activity of irreversible hydrocolloid impressions against 12 oral microorganisms. Braz Oral Res. 2007;21:323–9. doi: 10.1590/s1806-83242007000400008. [DOI] [PubMed] [Google Scholar]

- 6.Tobias RS, Browne RM, Wilson CA. An in vitro study of the antibacterial and antifungal properties of an irreversible hydrocolloid impression material impregnated with disinfectant. J Prosthet Dent. 1989;62:601–5. doi: 10.1016/0022-3913(89)90087-5. [DOI] [PubMed] [Google Scholar]

- 7.Ginjupalli K, Alla RK, Tellapragada C, Gupta L, Upadhya Perampalli N. Antimicrobial activity and properties of irreversible hydrocolloid impression materials incorporated with silver nanoparticles. J Prosthet Dent. 2016;115:722–8. doi: 10.1016/j.prosdent.2015.11.006. [DOI] [PubMed] [Google Scholar]

- 8.Rice CD, Dykstra MA, Feil PH. Microbial contamination in two antimicrobial and four control brands of alginate impression material. J Prosthet Dent. 1992;67:535–40. doi: 10.1016/0022-3913(92)90086-p. [DOI] [PubMed] [Google Scholar]

- 9.Kumar R, Münstedt H. Silver ion release from antimicrobial polyamide/silver composites. Biomaterials. 2005;26:2081–8. doi: 10.1016/j.biomaterials.2004.05.030. [DOI] [PubMed] [Google Scholar]

- 10.Parikh D, Fink T, Rajasekharan K, Sachinvala N, Sawhney A, Calamari T, et al. Antimicrobial silver/sodium carboxymethyl cotton dressings for burn wounds. Text Res J. 2005;75:134–8. [Google Scholar]

- 11.Panacek A, Kvítek L, Prucek R, Kolar M, Vecerova R, Pizúrova N, et al. Silver colloid nanoparticles: Synthesis, characterization, and their antibacterial activity. J Phys Chem B. 2006;110:16248–53. doi: 10.1021/jp063826h. [DOI] [PubMed] [Google Scholar]

- 12.Dentistry – Hydrocolloid Impression Materials ISO 21563 (E) Geneva, Switzerland: International Organization for Standardization; 2013. International Organization for Standardization. [Google Scholar]

- 13.Culhaoglu AK, Zaimoglu A, Dogan E, Ozkir SE. The influence of different mixing methods on the dimensional stability and surface detail reproduction of two different brands of irreversible hydrocolloids. Eur J Gen Dent. 2014;3:17. [Google Scholar]

- 14.Kollu VH, Kalyana Chakravarthy Pentapati S. Efficacy of chlorhexidine in reduction of microbial contamination in commercially available alginate materials–In-vitro study. Glob J Med Res. 2013;13:23–5. [Google Scholar]

- 15.Cserna A, Crist RL, Adams AB, Dunning DG. Irreversible hydrocolloids: A comparison of antimicrobial efficacy. J Prosthet Dent. 1994;71:387–9. doi: 10.1016/0022-3913(94)90100-7. [DOI] [PubMed] [Google Scholar]

- 16.Miri SA, Sadeghi GM, Rabiee M. Self disinfecting reversible hydrocolloid impression gels: Effect of composition and nanosilver on characteristic properties and gelation temperature. J Res Update Polym Sci. 2012;1:52. [Google Scholar]

- 17.Sondi I, Salopek-Sondi B. Silver nanoparticles as antimicrobial agent: A case study on E. coli as a model for gram-negative bacteria. J Colloid Interface Sci. 2004;275:177–82. doi: 10.1016/j.jcis.2004.02.012. [DOI] [PubMed] [Google Scholar]

- 18.Flanagan DA, Palenik CJ, Setcos JC, Miller CH. Antimicrobial activities of dental impression materials. Dent Mater. 1998;14:399–404. doi: 10.1016/s0300-5712(99)00013-5. [DOI] [PubMed] [Google Scholar]