Abstract

Our primary objective in this study was to design and implement the FAME Lab PHS Calculator software (PHSFL) (www.famelab.gr/research/downloads), a free tool to calculate the predicted heat strain of an individual based on ISO 7933:2018. Our secondary objective was to optimize the practicality of the PHSFL by incorporating knowledge from other ISO standards and published literature. The third objective of this study was to assess: (i) the criterion-related validity of the PHSFL by comparing its results against those obtained using the original ISO 7933:2018 code; and (ii) the construct validity of the PHSFL by comparing its results against those obtained via field experiments performed in human participants during work in the heat. Our analysis for criterion validity demonstrates that PHSFL provides valid results within the required computational accuracy, according to Annex F of ISO 7933:2018. The construct validity showed that root mean square errors (RMSE) and 95% limits of agreement (LOA) were minimal between measured and predicted core temperature (RMSE: 0.3°C; LOA: 0.06 ± 0.58°C) and small between measured and predicted mean skin temperature (RMSE: 1.1°C; LOA: 0.59 ± 1.83°C). In conclusion, the PHSFL software demonstrated strong criterion-related and construct-related validity.

Keywords: Predicted heat strain (PHS), Hyperthermia, Heat stress, Occupation, Work, Labor, Thermal

Introduction

It is well-established that human capacity to perform both physical and mental tasks is impaired in hot environments and that this relationship is driven by core (Tc) and mean skin (Tsk) temperatures as well as hydration status1,2,3,4). For instance, a study in agriculture workers showed that there is a 2.1% increase in irregular work breaks for every degree Celsius increase in Tsk5). Furthermore, a recent systematic review showed that 35% of workers experience occupational heat strain during a work shift under heat stress, while 15% of the workers who frequently work under occupational heat stress experience kidney disease or injury3). However, despite these important health ramifications associated with work or exercise in hot environments, it is not always possible to perform the necessary physiological assessments in workers due to, for instance, lack of equipment, expertise, resources, time, and/or inability to recruit volunteers. Consequently, over the last century more than 160 thermal stress indices have been developed to estimate the thermal stress and/or strain experienced by a person6, 7). However, the majority of those thermal indices take into account only exogenous (e.g., environmental conditions) parameters without considering endogenous factors (e.g., metabolic heat production and clothing)6, 8). Therefore, the results derived using these indices may not accurately correspond to the thermal strain experienced by a person9,10,11).

The ISO 7933:1989 was developed to determine and interpret thermal stress by calculation of the required sweat rate for heat balance12). Subsequently, a European Union project (BMH4-CT96-0648)13) was funded to address some of the shortcomings14, 15) of the ISO 7933:1989 and to improve its prediction accuracy. The resulting standard (ISO 7933:200416)) was updated using large datasets collected from different laboratories15). The ISO 7933:2004 introduced the programming code for the Predicted Heat Strain (PHS) model, which was designed to predict the heat strain experience by a group of individuals under a set of known environmental and physiological conditions13). Recently, the ISO committee published the ISO 7933:20182) “…for the analytical determination and interpretation of the thermal stress (in terms of water loss and core temperature) experienced by a subject in a hot environment and to determine the “maximum allowable exposure times”, with which the physiological strain is acceptable for 95% of the exposed population”.

The popularity of the PHS is increasing until today, primarily due to the afore-mentioned complexities for performing physiological assessments in human participants. Since its inception, a total of 611 articles have used and/or referred to the PHS model (metrics taken on Jan 11, 2019 from Google Scholar). The same statistics demonstrate that about three scientific articles used and/or referred to the PHS model every two weeks during 2018. Despite the increasing popularity of the PHS model, the calculations described in the ISO 7933:2018 are cumbersome and time-consuming. For instance, it has been stated that the first ISO 7933:1989 “…was so sophisticated that it was simply not understood nor used in industry” and that “…this situation was likely to be worse as the complexity increased for the Predicted Heat Strain”14).

To address the limited practicality of the PHS and to increase its usage in industry, our primary objective in this study was to design and implement the FAME Lab PHS Calculator software (PHSFL), a new software to calculate the PHS of a group of individuals based on ISO 7933:2018. Our secondary objective was to optimize the practicality of the PHSFL by making it easy for physiologists, industrial hygienists, and occupational physicians to calculate the required environmental and physiological parameters through other ISO standards (7726:199817), 8996:200418), and 7730:199419)) and published literature20, 21). The third objective of this study was to assess: (i) the criterion-related validity of the PHSFL by comparing its results against those obtained using the original ISO 7933:2018 code16); and (ii) the construct validity of the PHSFL by comparing its results against those obtained via field experiments performed in human participants during work in the heat.

Subjects and Methods

Design and implementation of the PHSFL software (objective 1)

The PHSFL software was developed using the Visual Basic programming language (Microsoft; USA). In its core, the software is based on equations and formulas elaborated in the ISO 7933:20182).

Optimizing the practicality of the PHSFL software (objective 2)

After developing the basic code of the PHSFL, published information was used to make certain additions to improve the user friendliness of the software. These additions are described in detail in the following sub-sections. It is important to note that all modifications of the original software described in ISO 7933:2018 are optional, as the user can choose which features he/she wants to use and which not.

Additions to the ISO 7933:2018 programming code

i) Metabolic rate using heart rate (ISO 8996:2004)

We added an option to predict metabolic rate as a function of an individual’s heart rate, age, sex, and body mass according to the ISO 8996:200418) (Table 1). It is important to note that, according to ISO 9886:200422) “the increase of heart rate due to thermal strain is on the average 33 beats·min−1 per degree of temperature rise of the body core”. Therefore, we modified our code to subtract the thermal cardiac reactivity from the user-defined heart rate (using the user-defined core temperature) in the calculation of metabolic rate. Though correcting heart rate for thermal cardiac reactivity is advisable for the unbiased estimation of metabolic rate, the above-mentioned value of 33 beats/min/°C may vary between individuals from 17 to 60 beats/min/°C22,23,24).

Table 1. Calculation of metabolic rate as a function of an individual’s heart rate, sex, age, and body mass.

| Age (yr) | Body mass (kg) | |||||

|---|---|---|---|---|---|---|

| 50 | 60 | 70 | 80 | 90 | ||

| Women | ||||||

| 20 | 2.9*HR-150 | 3.4*HR-181 | 3.8*HR-210 | 4.2*HR-237 | 4.5*HR-263 | |

| 30 | 2.8*HR-143 | 3.3*HR-173 | 3.7*HR-201 | 4.0*HR-228 | 4.4*HR-254 | |

| 40 | 2.7*HR-136 | 3.1*HR-165 | 3.5*HR-192 | 3.9*HR-218 | 4.3*HR-244 | |

| 50 | 2.6*HR-127 | 3.0*HR-155 | 3.4*HR-182 | 3.7*HR-207 | 4.1*HR-232 | |

| 60 | 2.5*HR-117 | 2.9*HR-145 | 3.2*HR-170 | 3.6*HR-195 | 3.9*HR-219 | |

| Men | ||||||

| 20 | 3.7*HR-201 | 4.2*HR-238 | 4.7*HR-273 | 5.2*HR-307 | 5.6*HR-339 | |

| 30 | 3.6*HR-197 | 4.1*HR-233 | 4.6*HR-268 | 5.1*HR-301 | 5.5*HR-333 | |

| 40 | 3.5*HR-192 | 4.0*HR-228 | 4.5*HR-262 | 5.0*HR-295 | 5.4*HR-326 | |

| 50 | 3.4*HR-186 | 4.0*HR-222 | 4.4*HR-256 | 4.9*HR-288 | 5.3*HR-319 | |

| 60 | 3.4*HR-180 | 3.9*HR-215 | 4.5*HR-249 | 4.8*HR-280 | 5.2*HR-311 | |

All information included in Table 1 was obtained from the ISO 8996:2004.

ii) Metabolic rate using heart rate

We added an option to predict metabolic rate as a function of an individual’s sex, age, body mass, body stature, mean heart rate, and heart rate at rest, according to ISO 7933:20182, 23, 25). As mentioned above, this part of the code is modified to subtract the thermal cardiac reactivity from the user-defined heart rate in the calculation of metabolic rate.

iii) Metabolic rate using the compendium of physical activities

We added an option to predict the metabolic rate using the compendium of physical activities26). The compendium of physical activities presents all activities in metabolic equivalents; we converted those values to W/m2 by multiplying them with 58.15, as descripted in ISO 7730:199419).

iv) Clothing insulation using previous literature

We added an option to predict clothing insulation based on the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE)27) to describe the clothing insulation of various garments such as, shirts, sweaters, jackets, trousers, skirts, dresses, sleepwear, robes, and underwear.

v) Mechanical efficiency and power

Mechanical efficiency (η) represents the fraction of the overall metabolic energy converted to external mechanical power (work), while the remaining metabolic energy (1−η) is converted to internal heat warming up the body.21) The ISO 7933:20182, 16) states that “in most industrial situations, the effective mechanical power is small and can be neglected”. However, Fiala21) concluded that “…the human mechanical efficiency is not constant in reality, but rises with increasing activity levels”. In this light, we added an option in the PHSFL to calculate the mechanical efficiency based on a formula provided by Fiala21), as well as an automatic computation of mechanical power using the following formula:

η=mechanical efficiency (%)

act=activity (W/m2)

Fiala’s equation has been modified to calculate activity in W/m2, instead of metabolic equivalent. The transformation between metabolic equivalent and activity in W/m2 (1 MET=58.15 W/m2) was obtained from ISO 7730:199419).

It is important to note that, effective mechanical power is of great importance as it is a main parameter of the heat balance equation and neglecting it can lead to erroneous diagnosis and decisions. For instance, in a hypothetical case where a construction worker (body stature: 180 cm; body mass: 75 kg) repairs a roof, which is equal to a metabolic rate of 232.6 W/m2 2626), in a hot (air temperature: 30°C; globe temperature: 45°C) and humid (relative humidity: 60%) environment, he will reach 39°C Tc after 200 min of work. On the other hand, if we take into account the effective mechanical power, which in this case is equal to 34 W/m2, his Tc after 200 min will be 37.8°C, resulting in a Tc difference of 1.2°C between the two identical scenarios.

vi) Different time periods

It is logical to assume that the environmental, physiological, and/or clothing parameters included in the PHS calculations may vary throughout the simulated exposure time. For instance, an individual performs work in the morning (when environmental heat stress is low) and continues working until the afternoon (when environmental heat stress is high). To this effect, we added an option to calculate the PHS for successive time periods that may include different environmental, physiological, and/or clothing parameters. To calculate the PHS during separate time periods, the last values of each time period are used as initial data in the subsequent period, the new input values are considered, while the remaining properties of the software (i.e., equations and code) remain unchanged. Hence, this approach predicts heat strain during different time periods by continuously performing the calculation with dynamically varying input parameters (environmental, clothing, and physiological).

Software description

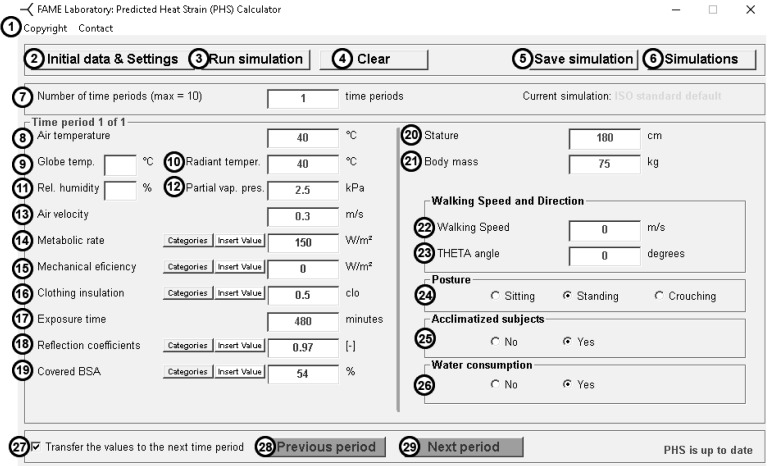

The developed PHSFL software package can be freely downloaded using the following link: www.famelab.gr/research/downloads. It runs using Microsoft Windows operating systems (XP/Vista/Win7/Win10). With the use of Windows emulators, the PHSFL software can also run on Linux and Apple Macintosh platforms. The home screen includes 29 buttons and input-boxes (Fig. 1), which are described in detail in Table 2. According to the ISO 7933:2018, the PHSFL software provides minute-by-minute values for rectal temperature (°C) and total water loss (g).

Fig. 1.

Main screen of the FAME Lab Predicted Heat Strain software.

Numbers indicate the 29 different options/buttons on the main screen that are explained in Table 2.

Buttons entitled “Categories” open a new window providing additional options; the buttons entitled “Insert value” enables the user to insert a specific value.

Table 2. Explanation of the 29 different options/buttons provided on the main screen of the PHS software, as shown in Fig. 1.

| # | Name | Description |

|---|---|---|

| 1 | Copyright | Opens a new window which provides general information about the copyright of the present software. |

| 2 | Initial data & settings | Opens a new window which allows the user to change the initial data and settings of the software. |

| 3 | Calculate | Calculates the predicted heat strain and opens a new window which shows the calculated results. |

| 4 | Clear | Clears all changes including results. By clicking the “Yes” button, all changes, including results, will be lost. |

| 5 | Save simulation | Saves all variables including time periods and initial data. |

| 6 | Simulations | Opens a new window which provides four options: a) import a preexisted simulation from a file; b) export the selected simulation; c) delete the selected simulation; d) load a saved simulation. |

| 7 | Number of time periods | Indicates the number of different simulation phases. Each time period can have different input parameters. The maximum number of allowed time periods is 10. |

| 8 | Air temperature | Represents the temperature of the air around the human body. |

| 9 | Globe temperature | Measured using a black globe temperature sensor. |

| 10 | Mean Radiant temperature | Describes the average radiant temperature of all the surrounding surfaces. |

| 11 | Relative humidity | Describes the ratio between the partial pressure of water vapour in humid air and the water vapour saturation pressure at the same temperature and the same total pressure. |

| 12 | Vapour pressure | Describes the actual amount of water in the air. |

| 13 | Air velocity | Describes the wind speed. |

| 14 | Metabolic rate | Describes the metabolic rate. |

| 15 | Mechanical efficiency | Describes the efficiency of a task. |

| 16 | Clothing insulation | Describes the thermal insulation provided by clothing. |

| 17 | Exposed time | Represents the amount of time (minutes) spent on the simulated work task. |

| 18 | Reflection coefficients | Describes the emissivity of the reflective clothing. |

| 19 | Covered BSA | Describes the fraction of the body surface area covered by reflective clothing. |

| 20 | Stature | Represents the height (cm) of the simulated individual. |

| 21 | Body mass | Represents the weight (kg) of the simulated individual. |

| 22 | Walking speed | Describes the walking/movement speed of the simulated individual. |

| 23 | THETA angle | Describes the angle between walking direction and wind direction. |

| 24 | Posture | Describes the body position of the simulated individual. |

| 25 | Acclimatized subjects | Describes the acclimatization status of the simulated individual. It is important to note that a human being needs up to two weeks of daily exposure to be fully acclimatized. |

| 26 | Water consumption | Describes the ability of the simulated individual to drink water freely during the exposure time. |

| 27 | Transfer the values to the next time period | Enabling this option results in all values being transferred to the next time period when pressing “Next period”. |

| 28 | Previous period | Moves to the previous time-period, if available. |

| 29 | Next period | Moves to the next time-period, if available. If option #27 is enabled, all values will be transferred to the next time period. |

To improve its usefulness, the PHSFL also provides minute-by-minute results for Tc and Tsk. These values were included within the original code of the ISO 7933:2018, yet the final outputs did not provide these predictions. The data are provided in numeric format as well as in charts and can be exported in *.csv, *.txt, and *.bmp formats.

Assessing the criterion-related validity of the PHSFL (objective 3a)

The criterion-related validity (comparing a measurement against some known quantity)28) of the PHSFL was assessed by comparing its results against those obtained using the original ISO 7933:2018 code16). For this purpose, we compared the results of the of the PHSFL and the PHS when simulating five different scenarios (Table 3), as descripted in the Annex F of ISO 7933:20182). Also, we slightly modified the programming code of the ISO 7933:201816)—without making any changes to the computations and formulas—to generate minute-by-minute data, instead of producing only the last value of each scenario. Specifically, mean differences (bias) and root mean squared errors (RMSE) were used to examine potential differences in all outputs between PHSFL and the code described in the Annex E of the ISO 7933:2018. Statistical analyses were conducted using Excel spreadsheets (Microsoft Office, Microsoft, Washington, USA).

Table 3. Tested conditions during the criterion-related validity simulations.

| Parameters (Units) |

Simulated scenario | ||||

|---|---|---|---|---|---|

| 1st | 2nd | 3rd | 4th | 5th | |

| Acclimatization | Yes | No | No | No | Yes |

| Posture | Standing | Standing | Standing | Standing | Sitting |

| Duration | 480 | 480 | 480 | 480 | 480 |

| Ta (°C) | 40 | 35 | 30 | 30 | 35 |

| Tg (°C) | 40 | 35 | 45 | 30 | 50 |

| Va (ms-1) | 0.30 | 0.10 | 0.10 | 1.00 | 1.00 |

| RH (%) | 35 | 60 | 35 | 45 | 30 |

| M (W) | 300 | 300 | 300 | 450 | 250 |

| W (W) | 0 | 0 | 0 | 0 | 0 |

| Icl (clo) | 0.5 | 0.5 | 0.8 | 0.5 | 1.0 |

| Tr (°C) | 40.0 | 35.0 | 52.0 | 30.0 | 74.6 |

| Pa (kPa) | 2.58 | 3.37 | 1.48 | 1.91 | 1.69 |

| Ap (fraction %) | ‒ | ‒ | 30 | ‒ | 20 |

| Fr (-) | ‒ | ‒ | 0.15 | ‒ | 0.15 |

The five hypothetical scenarios presented in Table 3 were obtained from ISO/DIS 7933:2018. As mentioned in Annex F of ISO/DIS 7933:2018, in all cases stationary or undefined walking conditions are assumed. Ta: air temperature; Tg: globe temperature; Va: air velocity; RH: relative humidity; M: metabolic rate; W: effective mechanical power; Icl: clothing insulation; Tr: mean radiant temperature; Pa: vapor pressure; Ap: fraction of the body surface area covered by reflective clothing; Fr: emissivity of the reflective clothing.

Assessing the construct validity of the PHSFL (objective 3b)

The construct validity [the property of a measurement being associated with variables assessing the same (or similar) characteristic]28) of the PHSFL was assessed by comparing its results against those obtained via field experiments performed in human participants during work in the heat. The experimental protocol for these field experiments was approved by the National Bioethical Committee of Cyprus in accordance with the Declaration of Helsinki (NBCC 27.01.61). The study involved monitoring a group of five experienced (8–16 yr of work experience) and acclimatized (i.e., continuously living in the area for the ≥90 previous days and performing other agriculture jobs on a daily basis) grape-picking workers during one full work-shift. Prior to their participation in the study, written informed consent was obtained from all volunteers after detailed explanation of all the procedures involved.

Baseline data [self-reported age; body stature (Seca 213; seca GmbH & Co. KG; Hamburg, Germany) and body mass (BC1000, Tanita corporation, Tokyo, Japan)] were collected one day prior to the experiment. During the field study, continuous heart rate, Tc and Tsk data were collected using wireless heart rate monitors (Polar Team2. Polar Electro Oy, Kempele, Finland), telemetric capsules (BodyCap, Caen, France), and wireless thermistors (iButtons type DS1921H, Maxim/Dallas Semiconductor Corp., USA), respectively. Skin temperature data were collected from four sites (chest, arm, thigh, and leg) and were expressed as Tsk according the formula of Ramanathan (Tsk=[0.3 (chest + arm) + 0.2 (thigh + leg)])29). Furthermore, continuous environmental data [air temperature (°C), globe temperature (°C), relative humidity (%), and air velocity (m/s)] were collected using a portable weather station (Kestrel 5400FW, Nielsen-Kellerman, PA, USA). Thereafter, these environmental data were utilized to compute mean radiant temperature (by using air temperature, globe temperature, and air velocity) and partial vapor pressure (by using air temperature and relative humidity) based on formulas incorporating in the PHS code (Annex E) found in ISO 7933:20182).

Video recordings using a video camera (Hero 5 black, GoPro, CA, USA) installed in close proximity (up to 40 m) to the volunteers was used to calculate other parameters such as clothing insulation, covered body surface area, body posture, walking speed, and metabolic rate throughout the work shift. For this purpose, second-by-second video analysis was conducted using previous methodology5). More precisely, all clothes worn by volunteers were video-recorded and matched with known clothing insulation values found in the literature27). The same video recordings were used to calculate the fraction of the covered body surface area of workers by summing the regions of their body found to be covered by garments. The ratios of the area of the different body regions to the total body surface area were obtained from ISO 7933:20182). Metabolic rate was set to 327 W for males and 258 W for females according to previous literature30); individual characteristics for body mass and body stature were utilized to calculate body surface area using Dubois’ formula31) and to express metabolic rate as W/m2. Video analysis was used to identify when major changes in metabolic rate (i.e, lunch break) took place. Lunch break was characterized by 1.5 metabolic equivalents (87.2 W/m2) according to the MET code 13030 of the compendium of physical activities26). The effective mechanical power (W/m2) of the workers throughout their work shift was calculated using the method described under the section “additions to the ISO 7933:2018 programming code”.

The raw data collected were used to calculate hourly mean values. These averages were used to conduct five (i.e., one simulation per worker) eight-period (i.e., each period lasting one hour) simulations using the PHSFL software. Pearson’s correlation coefficient was used to examine the relationship between the recorded minute-by-minute Tc and Tsk values and those predicted via the PHSFL. Paired-samples t-tests were used to detect potential differences between the recorded minute-by-minute Tc and Tsk values and those predicted via the PHSFL. Furthermore, mean differences and root mean square errors were used to examine potential differences in Tc and Tsk between the recorded and those predicted via the PHSFL. Finally, the Bland-Altman 95% limits of agreement and associated percent coefficient of variation were used to further assess and visualize the between-method differences. Statistical analyses were conducted using both the SPSS v25.0 (IBM, Armonk, NY, USA) and Excel spreadsheets (Microsoft Office, Microsoft, WA, USA). The level of significance for these analyses (construct validity) was set at p<0.05.

Results

Assessing the criterion-related validity of the PHSFL (objective 3a)

The developed PHSFL software predicts four variables (rectal temperature, Tc, Tsk, and total water loss), while the ISO 7933:2018 predict two variables (rectal temperature and total water loss). Also, both methods calculate the maximum allowable exposure times (maximum tolerable Tc and water loss not exceeded by 95% of the exposed people).

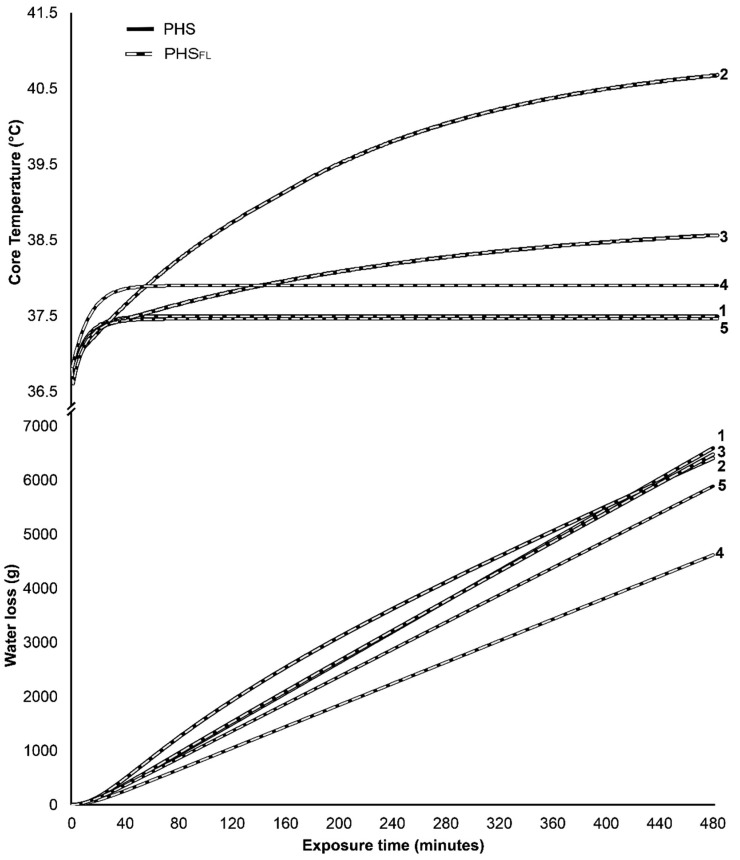

There were no differences (bias=0°C; RMSE=0°C) between the PHSFL and the programming code obtained from Annex E of ISO 7933:2004 (Fig. 2). Furthermore, our analysis demonstrated that PHSFL provides correct results within the required computational accuracy of 0.1°C for the predicted Tc and 1% for water loss, according to Annex F of ISO 7933:20182).

Fig. 2.

Core temperature (top graph) and water loss (bottom graph) during the criterion-related validity scenarios presented in Table 3, as estimated using the two Predicted Heat Strain software packages (ISO 7933:2018 and PHSFL).

Solid black and dashed white lines represent the ISO 7933:2018 and PHSFL values, respectively (these lines overlap completely in all cases).

Assessing the construct validity of the PHSFL (objective 3b)

Five grape-picking workers [3 females (age: 46.0 ± 6.9 yr; height: 157.9 ± 8.5 cm; weight: 55.9 ± 2.0), 2 males (age: 31.0 ± 14.1 yr; height: 177.6 ± 5.1 cm; weight: 81.5 ± 0.6 kg)] worked for eight consecutive hours in environmental temperature (28.5 ± 3.3°C) ranging from 18.6°C to 35.1°C. Heart rate (103.5 ± 12.6 bpm; range 75–172 bpm), Tc (37.4 ± 0.3°C; range 36.7–38.2°C), and Tsk (34.6 ± 1.5°C; range 30.9–36.6°C) suggested a moderate-to-high level of work intensity. Second by second video analysis showed that workers spent 81.4% of their work shift crouching, 12.0% standing, and 6.6% sitting. Furthermore, all of them wore clothes equal to 0.90 clo, while the clothing coverage (0.89 ± 0.2% of body surface area) ranged from 0.88% to 0.93% of their body surface area. All workers had an average walking speed of approximately 0.035 m/s (total walking distance/work shift duration→up to 1,000 m/28,800 s), throughout the work shift.

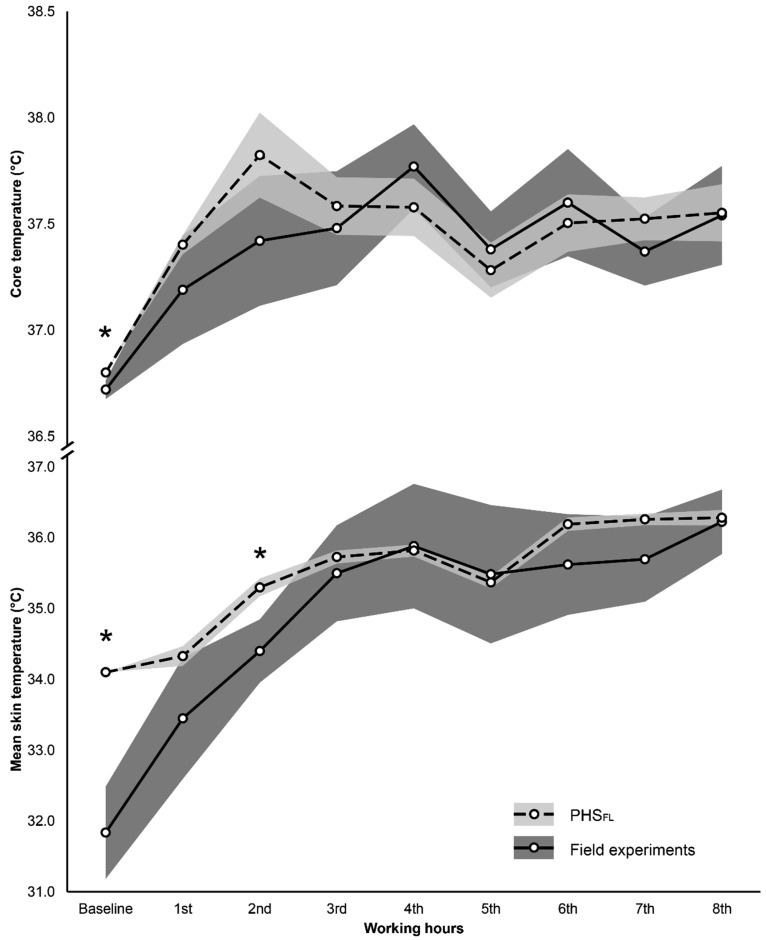

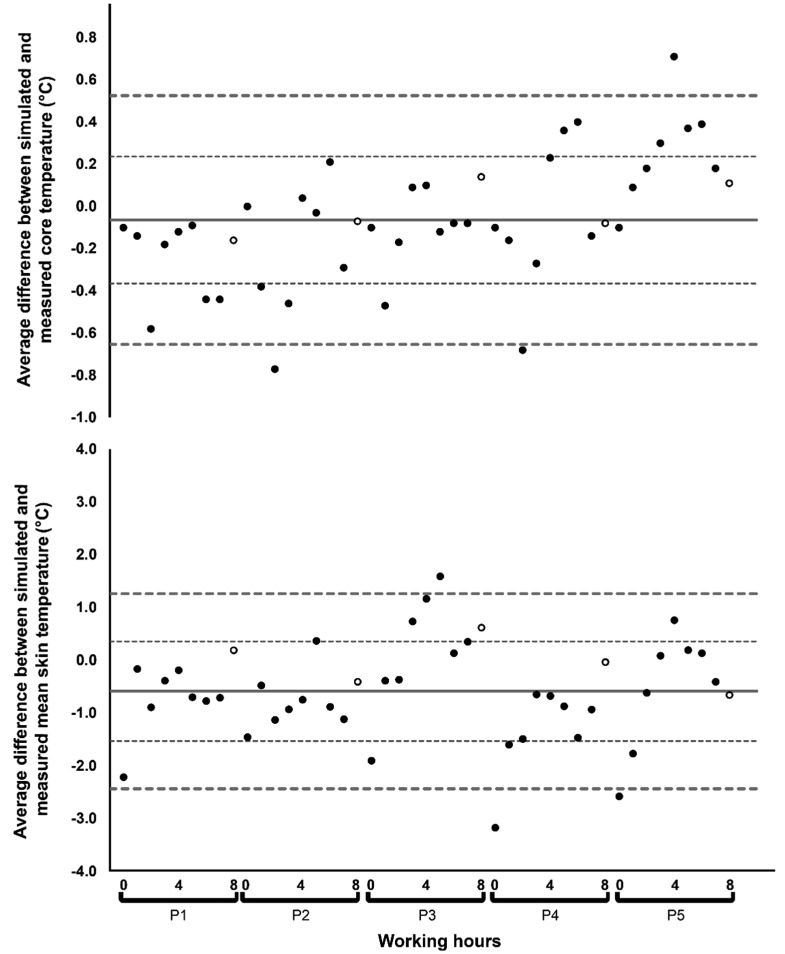

Both Tc and Tsk were strongly related with the predicted Tc (r=0.573, p<0.001) and Tsk (r=0.850, p<0.001) values (Fig. 3). No statistically significant differences were identified between the predicted Tc (37.4 ± 0.3°C) and the hourly measured Tc (37.4 ± 0.3°C) (p>0.05), throughout the work shift (Fig. 3). Importantly, no differences were found between the hourly predicted Tc (37.6 ± 0.1°C) and hourly measured Tc (37.6 ± 0.2°C) (p=0.847), during the last hour of the work shift (Fig. 3). On the other hand, we found statistically significant differences between the measured Tsk (34.9 ± 1.5°C) and predicted Tsk (35.5 ± 0.8°C) (p<0.001). However, it is important to note that there were no statistically significant differences between the measured and predicted Tsk values, throughout the majority of work duration (i.e., 1st, 3rd, 4th, 5th, 6th, 7th, and 8th working hours) (Fig. 3). Root mean square errors were minimal for Tc (0.3°C) and small for Tsk (1.1°C). The 95% limits of agreement between measured and predicted Tc and Tsk (Fig. 4) were 0.06 ± 0.58°C and 0.59 ± 1.83°C, respectively, indicating overestimation. The corresponding percentage coefficients of variation between measured and predicted Tc and Tsk were 0.8% and 2.6%, respectively.

Fig. 3.

Core (top graph) and mean skin (bottom graph) temperature (mean ± SD) as measured (solid lines with dark grey shading) during field studies or simulated (dashed lines with light grey shading) using the FAME Lab Predicted Heat Stain (PHSFL) software.

Asterisks indicate statistically significant differences at p<0.05.

Fig. 4.

Average differences between simulated and measured core (top graph) and mean skin (bottom graph) temperatures.

Solid grey lines represent bias (average difference between the two methods). Fine dashed lines represent the standard deviations. Thick dashed lines represent the 95% limits of agreement. The full colored circles represent the hourly differences between simulated and measured temperature. White-filled circles correspond to the differences between simulated and measured temperature at the end of the work shift. Horizontal axis corresponds to the five 8-h work shifts [i.e., one per participant (P1, P2, P3, P4, and P5)] used in the study.

Discussion

In this paper we designed and implemented the PHSFL, a new free software to estimate the heat strain of an individual under pre-known environmental conditions based on ISO 7933:2018. The PHSFL software generates results identical to the ISO 7933:2018 code. According to our construct validity analyses, the PHSFL estimates are comparable to those obtained via field experiments performed in human participants during work in the heat.

The PHSFL software includes a number of features to optimize practicality and user-friendliness, including a method to simulate the heat strain of an individual who is exposed to varying environmental and/or physiological stress. In turn, our simulations showed that there were no statistically significant differences in Tc between the predicted and measured data. On the other hand, we showed that there were significant differences between the predicted and measured Tsk during the baseline measurements and the 2nd hour of the work shift. Despite these differences, we found strong linear relationships between the predicted and measured Tc and Tsk values. Moreover, the 95% limits of agreement suggest that a Tc of 38°C when measured with a gastrointestinal thermistor during field work in the heat would be estimated as low as 37.4°C or as high as 38.6°C using the PHSFL. Similarly, a Tsk of 32°C when measured with skin thermistors during field work in the heat would be estimated as low as 29.3°C or as high as 33.5°C using the PHSFL. These estimation limits are considerable (which is why actual measurements are vital for an accurate assessment), yet they provide a fairly good approximation of the heat strain experienced when working or exercising in the heat.

The PHS model was developed using a large dataset of field and laboratory tests13). The initial study conducted to develop and validate the PHS model13) reported a moderate correlation coefficient (r=0.594) between the observed and predicted rectal temperatures in field experiments. In laboratory experiments, where clothing and environmental conditions are more tightly controlled, the PHS has shown a strong association between the measured and predicted rectal temperatures (r=0.659)13). A subsequent study reported that the PHS model underestimates rectal temperature by 0.38°C (males: 0.18°C; females: 0.57°C) but provides an accurate estimate of Tsk (males: 0.05°C; females: 0.26°C)32). Given these extensive validation studies, we considered the PHS being validated, and we aimed to investigate the validity of the PHSFL; that is, the added features of the PHSFL (eg., time periods) that are not included in the PHS. Our field study results showed strong associations between the measured and predicted values from the PHSFL for both Tc (r=0.573) and Tsk (r=0.850). Despite these positive results on construct validity, it is important to note that the PHSFL is based on the ISO/DIS 7933:2018 code that was not developed to predict heat strain during successive sequences of exposure and incorporates a known error when a work period (Period 1) is followed by a prolonged period (Period 2) characterized by comparatively cooler environmental conditions and/or lower metabolic rate. In such conditions, the predicted rectal and core temperatures may (falsely) not return to baseline levels during Period 2. Additionally, it is important to note that the opposite may happen as well, since unrealistic Tc decline during resting breaks has been also observed8). Moreover, the ISO 7933 reports that the PHS model is not applicable in cases where protective clothing is worn2), and this has been demonstrated by Wang et al33). Thus, the results from the PHSFL during successive periods of exposure and/or when protective clothing is worn may incorporate errors.

Unfortunately, we were unable to investigate potential differences in sweat rate between predicted and collected data because our grape-picking workers consumed large amounts of grapes during their work shift which would introduce errors in our estimations. Also, our analysis is limited by the fact that our Tc and Tsk were calculated as hourly averages to minimize the influence of instantaneous events (eg., drinking cold water, dropping cold water on the body, eating grapes, moving to a different environment for limited amount of time).

In conclusion, we designed and implemented the PHSFL, a free software (www.famelab.gr/research/downloads) and user-friendly software to estimate the heat strain of an individual under known and varying environmental conditions based on ISO 7933:2018. The PHSFL software demonstrated strong criterion-related and construct-related validity. However, it is important to note that conducting simulations with the PHSFL without the necessary basic understanding in thermal physiology may lead to misuse of the software and the potential generation of recommendations that can endanger the health of individuals exposed to heat. We hope that this software will help physiologists, industrial hygienists, and occupational physicians to optimize workers’ health and enhance work effort and productivity.

Acknowledgments

This work was supported by funding from the European Union’s Horizon 2020 research and innovation programme under the grant agreement no. 645710 (ICI-THROUGH project).

References

- 1.Piil JF, Lundbye-Jensen J, Christiansen L, Ioannou L, Tsoutsoubi L, Dallas CN, Mantzios K, Flouris AD, Nybo L. (2018) High prevalence of hypohydration in occupations with heat stress—perspectives for performance in combined cognitive and motor tasks. PLoS One 13, e0205321. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 2.ISO/DIS 7933. 2018,Ergonomics of the thermal environment—Analytical determination and interpretation of heat stress using the predicted heat strain model.International Organization for Standardization, Geneva.

- 3.Flouris AD, Dinas PC, Ioannou LG, Nybo L, Havenith G, Kenny GP, Kjellstrom T. (2018) Workers’ health and productivity under occupational heat strain: a systematic review and meta-analysis. Lancet Planet Health 2, e521–31. [DOI] [PubMed] [Google Scholar]

- 4.Flouris AD, Schlader ZJ. (2015) Human behavioral thermoregulation during exercise in the heat. Scand J Med Sci Sports 25 Suppl 1, 52–64. [DOI] [PubMed] [Google Scholar]

- 5.Ioannou LG, Tsoutsoubi L, Samoutis G, Bogataj LK, Kenny GP, Nybo L, Kjellstrom T, Flouris AD. (2017) Time-motion analysis as a novel approach for evaluating the impact of environmental heat exposure on labor loss in agriculture workers. Temp Austin 4, 330–40. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 6.de Freitas CR, Grigorieva EA. (2017) A comparison and appraisal of a comprehensive range of human thermal climate indices. Int J Biometeorol 61, 487–512. [DOI] [PubMed] [Google Scholar]

- 7.de Freitas CR, Grigorieva EA. (2015) A comprehensive catalogue and classification of human thermal climate indices. Int J Biometeorol 59, 109–20. [DOI] [PubMed] [Google Scholar]

- 8.Bröde P, Fiala D, Lemke B, Kjellstrom T. (2018) Estimated work ability in warm outdoor environments depends on the chosen heat stress assessment metric. Int J Biometeorol 62, 331–45. [DOI] [PubMed] [Google Scholar]

- 9.Lamarche DT, Meade RD, D’Souza AW, Flouris AD, Hardcastle SG, Sigal RJ, Boulay P, Kenny GP. (2017) The recommended Threshold Limit Values for heat exposure fail to maintain body core temperature within safe limits in older working adults. J Occup Environ Hyg 14, 703–11. [DOI] [PubMed] [Google Scholar]

- 10.McGinn R, Poirier MP, Louie JC, Ioannou LG, Tsoutsoubi L, Sigal RJ, Boulay P, Hardcastle SG, Kenny GP. (2018) Screening criteria for increased susceptibility to heat stress during work or leisure in hot environments in healthy individuals aged 31–70 years AU − Flouris, Andreas D. Temperature 5, 86–99. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 11.Meade RD, Poirier MP, Flouris AD, Hardcastle SG, Kenny GP. (2016) Do the threshold limit values for work in hot conditions adequately protect workers? Med Sci Sports Exerc 48, 1187–96. [DOI] [PubMed] [Google Scholar]

- 12.ISO 7933 (1989) Hot environments—analytical determination and interpretation of thermal stress using calculation of required sweat rate. Geneva.

- 13.Malchaire J, Piette A, Kampmann B, Mehnert P, Gebhardt H, Havenith G, Den Hartog E, Holmer I, Parsons K, Alfano G, Griefahn B. (2001) Development and validation of the predicted heat strain model. Ann Occup Hyg 45, 123–35. [PubMed] [Google Scholar]

- 14.Malchaire JBM. (2006) Occupational heat stress assessment by the Predicted Heat Strain model. Ind Health 44, 380–7. [DOI] [PubMed] [Google Scholar]

- 15.Havenith G, Fiala D. (2015) Thermal indices and thermophysiological modeling for heat stress. Compr Physiol 6, 255–302. [DOI] [PubMed] [Google Scholar]

- 16.ISO 7933 (2004) Ergonomics of the thermal environment—analytical determination and interpretation of heat stress using calculation of the predicted heat strain.

- 17.ISO 7726 (1998) Ergonomics of the thermal environment—instruments for measuring physical quantities.

- 18.ISO 8996 (2004) Determination of metabolic rate.

- 19.ISO 7730 (1994) Moderate thermal environments—Determination of the PMV and PPD indices and specification of the conditions for thermal comfort.

- 20.National Weather Service Vapor Pressure (2018). https://www.weather.gov/media/epz/wxcalc/vaporPressure.pdf. Accessed February 12, 2018.

- 21.Fiala D (1998) Dynamic simulation of human heat transfer and thermal comfort. De Montfort University Leicester, UK. [Google Scholar]

- 22.ISO 9886 (2004) Ergonomics—E valuation of thermal strain by physiological measure ments, International Organization for Standardization, Geneva.

- 23.Bröde P, Kampmann B. (2019) Accuracy of metabolic rate estimates from heart rate under heat stress—an empirical validation study concerning ISO 8996. Ind Health 57, 615–20. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 24.Kamon E, Belding HS. (1971) Heart rate and rectal temperature relationships during work in hot humid environments. J Appl Physiol 31, 472–7. [DOI] [PubMed] [Google Scholar]

- 25.Malchaire J, d’Ambrosio Alfano FR, Palella BI. (2017) Evaluation of the metabolic rate based on the recording of the heart rate. Ind Health 55, 219–32. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 26.Ainsworth BE, Haskell WL, Whitt MC, Irwin ML, Swartz AM, Strath SJO, O’Brien WL, Bassett DR, Jr, Schmitz KH, Emplaincourt PO, Jacobs DR, Jr, Leon AS. (2000) Compendium of physical activities: an update of activity codes and MET intensities. Med Sci Sports Exerc 32 Suppl, S498–504. [DOI] [PubMed] [Google Scholar]

- 27.McCullough EA, Jones BW, Huck J. (1985) A comprehensive data base for estimating clothing insulation. Ashrae Trans 91, 29–47. [Google Scholar]

- 28.Bland JM, Altman DG. (2002) Statistics Notes: validating scales and indexes. BMJ 324, 606–7. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 29.Ramanathan NL. (1964) A new weighting system for mean surface temperature of the human body. J Appl Physiol 19, 531–3. [DOI] [PubMed] [Google Scholar]

- 30.Poulianiti KP, Havenith G, Flouris AD. (2019) Metabolic energy cost of workers in agriculture, construction, manufacturing, tourism, and transportation industries. Ind Health 57, 283–305. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 31.Du Bois D, Du Bois EF. (1916) Clinical calorimetry: tenth paper a formula to estimate the approximate surface area if height and weight be known. Archives of internal medicine, 17, 863–871. [Google Scholar]

- 32.Lundgren-Kownacki K, Martínez N, Johansson B, Psikuta A, Annaheim S, Kuklane K. (2017) Human responses in heat - comparison of the Predicted Heat Strain and the Fiala multi-node model for a case of intermittent work. J Therm Biol 70 Pt A, 45–52. [DOI] [PubMed] [Google Scholar]

- 33.Wang F, Kuklane K, Gao C, Holmér I. (2011) Can the PHS model (ISO7933) predict reasonable thermophysiological responses while wearing protective clothing in hot environments? Physiol Meas 32, 239–49. [DOI] [PubMed] [Google Scholar]