Abstract

This research was initiated to evaluate the physicochemical property of crude oil from Moringa stenopetala (M. Stenopetala) seed collected from three locations (Damba Gofa, Shelle and Konso) which wasextracted with two solvents (hexane and petroleum ether). Physical properties of crude oil varied from 34.8- 44.3%, 0.8–0.9, 0.8–0.9gcm3and 1.4–1.5 at 40 °C for yield, specific gravity, relative density and refractive index, respectively. The chemical properties of the crude oil varied from 0.1 – 0.3mg KOHg−1, 76.5–91.6g I2 100g−1, 17.6–20.6 mEqKg−1, 154.0–199.3mg KOHg−1 oil and 0.2–0.4mgg−1for Free fatty acid(FFA), iodine value, peroxide value, saponification value and acid value respectively. Two-way interaction effect of all physical and chemical properties showed a significant difference (p < 0.05) except the refractive index. The finding indicates that oil extracted with Hexane from Konso had a better quality. The extraction of oil using hexane from M. stenopetala seed could be of great importance in edible crude oil production. Further investigation should be done on oxidative stability of crude oilof M. Stenopetala.

Keywords: Agriculture, Physical chemistry, Crude oil, Solvent extraction, Physico chemical properties

Agriculture, Physical Chemistry, Crude oil, solvent extraction, physico chemical properties.

1. Introduction

There are many underutilized plants in Ethiopia which have the potential to bring a lot of prosperity and most of which has remained unexploited. Moringa is one of the underutilized crops by a rural community in southern Ethiopia (Glærum, 2012). The Moringaceae is a single-genus family of oilseed trees with 14 known species (Rashied et al., 2008). It is a crop that tolerates harsh environmental conditions including prolonged drought periods, poor soil and achieving harvest in a short amount of time (Meitzner and prince, 1996; Abuye et al., 2003). Due to its drought tolerance and appear towards the end of the dry season when few other sources of green vegetables are available; it is regarded as a priority crop in Ethiopia to attain food security (Mekonnen, 2003).

M. stenopetala grows widely in many parts of the world tropics including Ethiopia. Similar to M. oleifera, M. stenopetalais currently introduced in several tropical countries for its popular uses but its origins are the southern regions of Ethiopia and Northern Kenya. It is known by different names with different languages such as shiferaw (amharic), halako (Gamo/wolayita), kallanki (Benishangul), Shalchade (Konso), Haleko (Burji) and cabbage tree (English) (Nzikou et al., 2009).

M. stenopetala has large edible leaves and seeds and is a multi-purpose tree of significant economic importance as it has a vital nutritional, industrial and medicinal application (Eyasu, 2012; Abdull et al., 2014; Leone et al., 2016; Boukandoul et al., 2018; Tilahun, 2018). While many parts of M. stenopetala trees are deemed useful, the seeds are especially prized for their medicinal powers. The seeds contain edible oil that can be used for cooking and as salad dressings. The leaves and fruits are also consumed as vegetables as they are rich in proteins, essential amino acids, calcium, iron, phosphorous as well as vitamin A and C. In addition to nutritional importance, The medicinal properties of the M. stenopetala seed are well documented in the scientific literature (Adegbe et al., 2016; Fahey, 2005; Hsu, 2006; Kasolo et al., 2010) and are further supported by the experiences of generations of traditional Ayurvedic practitioners (Siddique et al., 2010).

Physicochemical properties of M. olifera seeds oil recorded that it had a promising potential application in human nutrition (Gore, 2018). The oil extracted from Moringa is known as Ben oil and reported that it has physical and chemical properties equivalent to that of olive oil, contains a large number of tocopherols (Tsaknis et al., 1999) and 70% of oleic acid, an 18carbon long monounsaturated fatty acid (MUFA). Hence the oleic acid has good oxidative stability compared to polyunsaturated fatty acids (PUFAs), it has been used in the food industry, as it allows for longer storage and high-temperature frying processing. The higher content of unsaturated fatty acids may present a healthy impact of Moringa seeds oil in human nutrition (Kasolo et al., 2010). Many people in Taiwan or China have been using the seed of Moringa as herbal medicine to treat athlete's foot and tinea (Lalas et al., 2006).

Even though it has been demonstrated to have the potential to be integrated into the marginal, drought-prone farming systems of the country and important food security crop as sources of phytonutrients and raw materials in different chemical industries still it remains underutilized. Ethiopia is importing oil from abroad for chemical, cosmetics and pharmaceutical use. Moreover, peoples of our country use these crops only when there is a serious shortage of food affecting all strata of the population from the poorest to the richest. When there is a serious shortage of food its leaves are consumed by Gofa, Konso, Burji and Gamo tribes as vegetable especially during the dry season (Yisehak et al., 2011). So far from 14 species of Moringa, only Moringa oleifera has been accorded research and development attention.

Unlike M. oleifera, very little scientific research project has been conducted on the properties and potential uses of M. stenopetala seed oil. As a result, its application in antioxidant, aromatherapy, perfumery, soap and other related industries are limited due to lack of adequate research on the chemical and biological potential of its raw materials. To our knowledge extraction and characterizationof physicochemical property of oil from M. stenopetala seed has not been reported yet in the study area. Therefore this research focuses on investigating the possibility of extraction and evaluation of physicochemical property of M. stenopetala seed oil produced in three locations using two solvent extractions. This could put the mile stone for further research on physicochemical characteristics of M. Stenopetila seed oil.

2. Materials and methods

2.1. Description of study site

M. Stenopetala seed was collected from three locations (DambaGofa, Arba Minch zuriya and Konso) in GamoGofa and Segen area Zone, Southern part of Ethiopia, located at a distance of 514 km from Addis Ababa. Laboratory analyses took place at Arba Minch University Chemistry Department Laboratory and Ethiopian conformity assessment center.

2.2. Sample collection and preparation

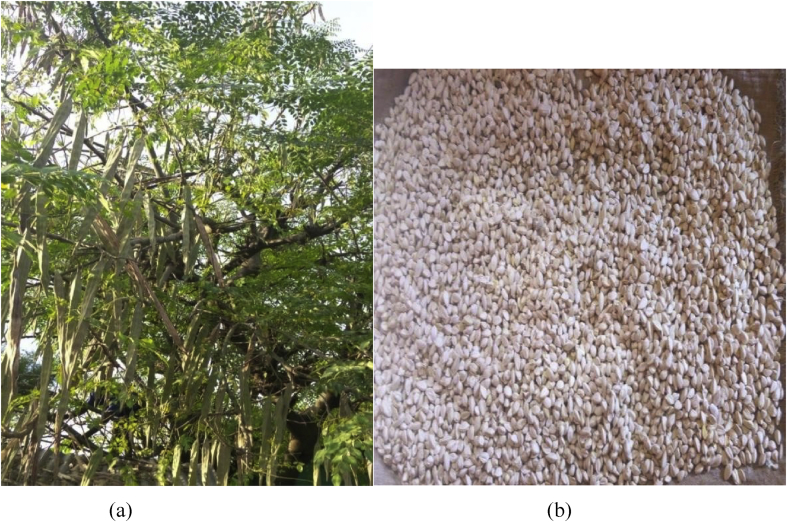

The matured pods of similar color were collected from M. stenopetala tree (Fig. 1) from two zones in South nation and nationalities of Ethiopia. Gamo Gofa Zone (Gofa and Shelle Districts) and Segen area zone (Konso District). The selection of both zones and Districts were made based on availability and abundance of M. stenopetala seed. The seeds were separated from the pods by removing the barks and removed from the pods. Then seeds were cleaned and only those with the uniform overall appearance, size, and shape were selected for this study. The seeds also had extra seed husk which was separated after sun drying to facilitate the separation of husk and seed kernels. Finally, the powder was obtained using grinding mill and kept for further oil extraction experiments.

Fig. 1.

M. stenopetala tree and matured pods (a) and M. Stenopetala seed (b) collected for the experiment.

2.3. Experimental design

Experiments were carried out using completely Randomized Design (CRD) having three M. stenopetala producer districts (Demba Gofa, Shelle and Konso) and two extraction solvents (hexane and petroleum ether) in three replicated times.

2.4. Data collected

2.4.1. Extraction and oil yield percentage determination

The oil was extracted following the method described by Adejumo et al. (2013) which uses solvent extraction method using Soxhlet apparatus with the semi-continuous process for the extraction of lipids from foods. Accordingly, grounded Moringa seed samples were placed in porous cellulose thimble and oil were extracted by repeated washing (percolation) with two organic solvents (hexane, and petroleum ether). The flask containing solvent and lipid was removed at the end of the extraction process, then the solvent in the flask was evaporated in Rota vapor and the mass of the oil remaining was measured and the percentage oil yield was calculated using the following formula:

2.4.2. Physical property determination

Density, specific gravity and refractive index of extracted oil were determined using standard analytical methods of AOAC (2000) (method 969. 18)

2.4.3. Chemical property determination

Saponification and peroxide value were determined following the method described by Akpan et al. (2006). Iodine value was determined using titration following the method described by Garcia (2010) and calculated using the following equation.

where; B = Volume consumed by Blank, A = Volume consumed by Sample, 1ml of 0.025 N2S2O3 = 0.0 0317g.

Peroxide value was determined following the method described by Farooq et al. (2006) and expressed as the percentage of free fatty acid calculated as oleic acid. The dish containing 5g of the oil sample was accurately weighed, poured into a conical flask and re-weighed, thus obtaining the actual weight of the oil taken. Fifty milliliters of hot neutral alcohol was added with a few drops of phenolphthalein and shaken vigorously. The solution was titrated with 0.5 M sodium hydroxide (NaOH) solution with constant shaking until the pink color remains constant. From the quantity of 0.5M alkali used, the percentage of acid present calculated, stating the result in terms of oleic acid (Farooq et al., 2006).

2.4.3.1. Determination of acid value

Acid value was determined using titration following the method described by Gatar et al. (2012) and calculated using the following equation

where: V=Volume of the KOH solution used N= Normality of KOH m = Mass of oil sample.

2.5. Statistical analysis

Data analysis was conducted using Minitab version 16 and analysis of variance (ANOVA) to determine the significant differences in physicochemical properties of samples. All diagnostic tools were tested prior to data analysis and indicated that the residuals of all parameters were normally distributed. Differences between the sample means were conducted using Tukey's test at α = 0.05 level for parameters showed a significant difference.

3. Result and discussion

3.1. M. stenopetela seed oil yield and physical property

Table 1 shows the range of values for oil yield and physical properties of M. stenopetela seed crude oil as affected by production locations and extraction solvents. The minimum and maximum values of yield, specific gravity, relative density, and refractive index value vary from 34.8-44.3, 0.8–0.9, 0.8–0.9 and 1.4–1.5 respectively. Oil yield, specific gravity and relative density of M. stenopetela seed oil were significantly (P < 0.05) affected by production locations and extraction solvents.

Table 1.

Oil yield and physical properties of Moringa stenopeta seed crude oil.

| Extraction solvent | Locations | Oil Yield (%) | Specific gravity | Relative density (gml−1) | Refractive index |

|---|---|---|---|---|---|

| Hexane | Gofa | 34.8c | 0.9a | 0.9a | 1.4a |

| Shelle | 42.3ab | 0.8b | 0.9a | 1.4a | |

| Konso | 42.3ab | 0.9a | 0.9a | 1.4a | |

| Petroleum Ether | Gofa | 35.3bc | 0.8b | 0.8b | 1.4a |

| Shelle | 44.0a | 0.8b | 0.9a | 1.5a | |

| Konso | 44.3a | 0.9a | 0.9a | 1.5a |

Results are mean values of triplicate determination and means with the different letters across the column are significantly different (p < 0.05).

The lowest oil yields (34.8%) was observed in M. stenopetela seed collected from Gofa district and extracted with hexane, while the highest oil yield (44.3%) was observed in moringa seed collected from Konso and extracted with petroleum ether even though it's statistically similar with oil obtained from Shelle district. The oil yield obtained in this study is similar with the result reported by Essayas (2012) who reported the M. stenopetala oil yield in the range of 39.3–44.5%. Variation in oil yield with location and extraction solventmight be attributed to theindiversity of natural habitats, agro climatic andconstraintsripening stage. Different authors reported significant oil yield variation among Moringa seed varieties. Oil yield of (49.8–54.3%) recorded for M. peregrine (Somali et al., 1984; Tsaknis 1999) and (40.5–44.9%) for M. stenopetala(Lalas et al., 2003). Moreover, it could be due to the variation among capacity of solvent used to extract the oil from the seed. Sayyar et al., (2009) stated that n-hexane as a more preferable solvent for extraction of Jatropha seed oil as compared to petroleum ether, the extraction yield with n-hexane is about 1.3% more than that of petroleum ether (47.3% and 46.0% wt. respectively) under similar conditions. Banat et al. (2013) also obtain the highest oil yield by n-hexane. The range of oil content (34.8–44.3%) of M. stanopetala seeds in the present analyses was found to exceed those of cotton seed (15.0–24.0 %) and soybean (17.0–21.0 %) and comparable with those of safflower (25.0–40.0 %). The high oil yield allows the possibility of economic exploitation which Results in lower operation costs compared to some other oil seeds.

The Specific gravity of M. stenopetala seed oil was found to be in the range of 0.80–90gmL−1. The maximum specific gravity (0.9%) was observed in moringa seed collected from Konso district regardless of extraction solvent although it is not significantly different from Gofa district extracted with hexane. The obtained value for specific gravity is in agreement with the value recorded for M. Oleifera seed oil (0.9050) by FAO/WHO (2009) international standard for edible oil cited in (Adegbe et al., 2016).

The relative density of M. stenopetala seed oil was found to be in the range of 0.80–90gmL−1. Similar values were recorded for all treatments in terms of relative density except the lowest value (0.8gmL−1) recorded for seed collected from Gofa district and extracted with petroleum Ether. The relative density observed in this study is in better agreement with the value recorded (0.903 gmL−1) by Ejigu et al. (2008) for M. stenopetala seed oil. It's also consistent with the finding of Meta (2018) who reported the average density of M. stenopetala oil 0.907.

The refractive index (RI) of oil is related to the degree of saturation and distinctive for each type of oil and is indicative of oil purity. The refractive index of the oil was in the range of 1.4–1.5. There was no significant difference among treatments in terms of refractive index. The refractive index of the M. stenopetala seed oil recorded in this study is comparable with reports of different authors, Manzoor et al. (2007) reported the RI of M. oliefera oil of 1.4648 and Anwar et al. (2006) reported 1.4581.

3.2. Chemical properties

Table 2 shows the range of values for the chemical property of M. stenopetala seed crude oil as affected by production locations and extraction solvents. The minimum and maximum values of FFA, iodine value, peroxide value, saponification value and acid values varies from 0.1– 0.3, 76.5–91.6, 17.6–20.6, 154.0–199.3 and 0.2–0.4 respectively. The chemical properties of the oil showed significantly (P < 0.05) influenced by the interaction effect of extraction solvents and production locations.

Table 2.

Chemical properties of Moringa stenopetala seed crude oil.

| Extraction solvent | Locations | FFA (mgKOHg−1) | Iodine value (g I/100g) | Peroxide value (meqkg−1) | Saponification Value (mgKOHg−1) | Acid value (mgKOHg−1) |

|---|---|---|---|---|---|---|

| Hexane | Gofa | 0.2ab | 87.9ab | 18.5ab | 175.7ab | 0.4a |

| Shelle | 0.3a | 83.8ab | 20.6a | 192.3a | 0.4a | |

| Konso | 0.1b | 80.0ab | 17.6b | 199.3a | 0.3ab | |

| Petroleum Ether | Gofa | 0.1b | 91.6a | 18.9ab | 159.0b | 0.3ab |

| Shelle | 0.2ab | 76.5b | 19.1ab | 154.0b | 0.2b | |

| Konso | 0.1b | 84.3ab | 18.5ab | 177.0ab | 0.2b |

Results are mean values of triplicate determination and means with the different letters across the column are significantly different (p < 0.05).

Free fatty acid value varied from 0.1 to 0.3 and the maximum free fatty acid was recorded from a sample collected from Shelle district and extracted with hexane solvent. The minimum free fatty acid content was obtained from seed collected from Konso and extracted with hexane solvent. There is a significant difference among treatments in terms of free fatty acid contents of the M. stenopetala seed crude oil. Free Fatty Acids are produced by the hydrolysis of oils and fats and it is not desired in the oil meant for consumption. It measures the extent to which glycerides in the oil have been decomposed by lipase action. The free fatty acid recorded in this study is moderately low and indicated that the oil from M. stenopetala seed can be used for human consumption.

The Iodine Number gives a measure of the average degree of unsaturation of oils and fats: the higher the iodine value, the greater the number of C=C double bonds. The highest iodine value (91.6 g I/100g) was recorded from seed collected from Gofa and extracted using petroleum ether and the lowest iodine value (76.5g I/100g) was recorded from seed collected from shelle and extracted using petroleum ether. The recorded iodine values are in line with the value reported by Lalas et al. (2003) (65.8 g I/100 g) and that of iodine value reported by Ejigu et al. (2008) (69gI/100g). The result indicated that M. stenopetala oils are relatively stable to oxidation when compared to, sunflower (125-140gI/100g), linseed (170-180gI/100g) and soybean oil (128-143gI/100g) (Gunstone, 2009). Aremu et al. (2006) reported that the lower the iodine value the lesser the number of unsaturated bonds; thus the lower the susceptibility of such oil to oxidative rancidity. A similar observation was also stressed by Aremu et al. (2006) reported that the lower the iodine value the lesser the number of unsaturated bonds; thus the lower the susceptibility of such oil to oxidative rancidity. The variation observed among treatments could be duet to mineral contents of the soil of different location where the plants are grown and the extraction solvent used.

Peroxide values measures the content of hydroperoxides in the oil (Kapoor et al., 2009). Its low value indicates high resistance to oxidation. The peroxide value of M. stenopetala crude oil of the current finding ranged from 17.6 to 20.6 meqkg−1 with a different location and extraction solvent used. Peroxide value of crude oil of M. stenopetala seed showed a significant difference between location and extraction solvent. The minimum peroxide value was recorded at Konso and extracted with hexane and the maximum was recorded at Shelle and extracted with hexane. The recorded peroxide values were high in this study and could be due to the oil is not refined and because of high temperature during extraction that leads to fatty acid oxidation. A similar study was reported, oxidation of fatty acids at high temperature and exposure to oxygen during the extraction process high peroxide value (Allen and Hamilton, 1994).

The Saponification values of the oils were ranged from 154 to 199.3mgKOHg−1 with different locations and extraction solvents. The maximum value (199.3) was recorded from a sample collected from Konso and extracted with hexane solvent and the minimum value was recorded M. stenopetala from Shelle and extracted with a petroleum solvent. The value obtained for the oil of M. stenopetala (154–199.3 mg KOHg−1 oil) in this study was comparable with those reported by Anwar and Bhanger (2006) (186 mgKOHg−1oil), Anwar et al. (2006) (184 mg KOHg−1oil), and Manzoor et al. (2007) (179 mg KOHg−1oil) in the oil of M. oleifera cultivated in Pakistan. A similar result was also reported by Rekha and Leema (2017) that the saponification value for the Moringa Oleifera seed oil was 164. Since saponification value is an indicator of molecular weight or size as a function of the chain lengths of the constituent fatty acid (Tilahun, 2018), the value of around 195 indicates that oil contains mainly fatty acid of high molecular mass while the oils having high saponification value (around 300) have mainly fatty acids of low molecular mass and are useful for soap making (Boukandoul et al., 2018). The present result indicated that oil from M. stenopetala seed contains fatty acid of high molecular mass and mainly useful for consumption rather than soap making.

The acid value of M. stenopetala seed oils was ranged from 0.2 to 0.4 mg KOHg−1 and it is within acceptable acid value limit for edible oil which is less than 1 (Sampson, 2005). The low-level acid values being viewed as a testimony to the freshness of the crude oil and that show that the oil is not degraded from the processing stage (Ochigbo and Paiko, 2011). This could be attributed to the presence of natural antioxidants in the seeds such as vitamins C and A as well as other possible phytochemicals like flavonoids. The value of acidity (0.2–0.4 mg KOHg−1) obtained in this study was considerably lower than M. oleifera oil from Pakistan which is 0.8 (Anwar and Rashid, 2006). The low acid value obtained in result indicated that, M. stenopetala seed oil could be acceptable for edible applications.

4. Conclusion

M. stenopetala is one of the underutilized plants in Ethiopia which have the potential to bring a lot of prosperity. Oil seed collected from all locations were showed almost similar physicochemical property with literature values of commercially sold oils for human consumption. From treatment evaluated,oil extracted with Hexane from Konso has better physicochemical properties. Furthermore, physicochemical properties of moringastenopetala seed oil in this study indicates high iodine and saponification value which implies high unsaturated to saturated fatty acids ratio and might be an acceptable substitute for high saturated oils such as olive oil and palm oil. The current finding demonstrated that the oil has great potential to be utilized as a source of new vegetable oil for human consumption and its full potential should be exploited. Generally, the quality of the oil obtained in this study is comparable with other commercial edible oil. In the search for alternative oil sources, particularly those rich in unsaturated fatty acids, Moringa stenopetala seed oil has valuable promise. Therefore, the production of useful oil from its seed could be of great economic importance in substituting foreign currency for importing oil for Ethiopia. Further investigation is needed on refiningof M. Stenopetala seed crude oil and characterizing of fatty acid.

Declarations

Author contribution statement

Haile T Duguma: Conceived and designed the experiments; Performed the experiments; Analyzed and interpreted the data; Wrote the paper.

Meseret Haile: Conceived and designed the experiments; Performed the experiments; Wrote the paper.

Gebiremedhine Chameno, Chala G. Kuyu: Conceived and designed the experiments; Performed the experiments; Analyzed and interpreted the data; Contributed reagents, materials, analysis tools or data; Wrote the paper.

Funding statement

This work was supported by Arba Minch University, Sawla Campus, Ethiopia.

Competing interest statement

The authors declare no conflict of interest.

Additional information

No additional information is available for this paper.

References

- Abdull Razis A.F., Ibrahim M.D., Kntayya S.B. Health benefits of moringaoleifera. Asian Pac. J. Cancer Prev. APJCP. 2014;15(20):8571–8576. doi: 10.7314/apjcp.2014.15.20.8571. [DOI] [PubMed] [Google Scholar]

- Abuye C., Urga K., Knapp H., Selmar D., Omwega A.M., Imungi J.K., Winterhalter P. A compositional study of Moringastenopetala leaves. East Afr. Med. J. 2003;80(5):247–252. doi: 10.4314/eamj.v80i5.8695. [DOI] [PubMed] [Google Scholar]

- Adegbe A.A., Larayetan R.A., Omojuwa T.J. Proximate analysis, physicochemical properties and chemical constituents characterization of Moringaoleifera (Moringaceae) seed oil using GC-MS analysis. Am. J. Chem. 2016;6(2):23–28. [Google Scholar]

- Adejumo B.A., Alakowe A.T., Obi D.E. Effect of heat treatment on the characteristics and oil yield of moringaoleiferaseeds. Int. J. Eng. Sci. 2013;2(1):232–239. [Google Scholar]

- Akpan U.A., Jimoh A., Mohammod Extraction, characterization and modification of caster seed oil. Leonardo J. Sci. 2006;1(8):43–52. [Google Scholar]

- Allen J.C., Hamilton R.J. third ed. Chapman and Hall Ltd; 1994. Rancidity in Foods. [Google Scholar]

- Anwar F., Zafar S.N., Rashid U. Characterization of Moringaoleifera seed oil from drought and irrigated regions of Punjab, Pakistan. Grasas Aceites. 2006;57(2):160–168. [Google Scholar]

- AOAC Official Methods of Analysis . In: Firestone D., editor. Association of the Official Analytical Chemists INC. Virginia; USA): 2000. pp. 951–952. [Google Scholar]

- Aremu M.O., Olaofe O., Akintayo E.T. Chemical composition and physicochemical characteristics of two varieties of Bambara groundnut (Vignasubterrenea) flours. J. Appl. Sci. 2006;6(9):1900–1903. [Google Scholar]

- Banat F., Pal P., Jwaied N., Al-Rabadi A. Extraction of olive oil from olive cake using soxhletapparatus. AJOCT. 2013;1(4):1–8. [Google Scholar]

- Boukandoul S., Casal S., Zaidi F. The potential of some moringa species for seed oil production. Agriculture. 2018;8(10):150. [Google Scholar]

- Ejigu A.A. Moringastenopetala seed oil as a potential feed stock for biodiesel production in Ethiopia. J. Env’t. Sc. 2008 [Google Scholar]

- Eyasu S. Physico-chemical properties of moringastenopetala (Haleko) seeds. J. Bio. Sc. 2012;12(3):197–201. [Google Scholar]

- Fahey J.W. Moringaoleifera: a review of the medical evidence for its nutritional, therapeutic, and prophylactic properties. Part 1. Trees life J. 2005;1(5):21205–22185. [Google Scholar]

- Farooq A., Syeda N.Z., Umer R. Characterization of MoringaOleifera Seed Oil from Drought and Irrigated Regions of Punjab, Pakistan. Department of Chemistry, University of Agriculture. 2006;57(20):160–168. Faisalabad-38040, Pakistan. [Google Scholar]

- García-Fayos B., Arnal J.M., Verdú G., Sauri A. International conf on food innovation. 2010, October. Study of Moringaoleifera oil extraction and its influence in primary coagulant activity for drinking water treatment; pp. 1–5. [Google Scholar]

- Gatar M.K., Itodo A.U., Warra A.A., Abdulahi L. Extraction and physicochemica determination of garlicl (Allium Sativum L) oil. Int. J. nutrition Sc. 2012;1(2) [Google Scholar]

- Glærum N. University of Agder; 2012. Usage and Acceptance of Moringastenopetala in the Diet in Ethiopia (Master's Thesis, Universitetet I Agder. [Google Scholar]

- Gore M. Extraction and physicochemical characterization of oil from Maringa Stenopetala Seeds. J. Appl. Chem. 2018;11(6):01–07. [Google Scholar]

- Gunstone F. John Wiley & Sons; 2009. The Chemistry of Oils and Fats: Sources, Composition, Properties and Uses. [Google Scholar]

- Hsu R. National Herbarium; Leiden, The Netherlands: 2006. Moringaoleifera Medicinal and Economic uses.International Course on Economic Botany. [Google Scholar]

- Kapoor I.P.S., Singh B., Singh G., De Heluani C.S., De Lampasona M.P., Catalan C.A. Chemistry and in vitro antioxidant activity of volatile oil and oleoresins of black pepper (Piper nigrum) J. Agric. Food Chem. 2009;57(12):5358–5364. doi: 10.1021/jf900642x. [DOI] [PubMed] [Google Scholar]

- Kasolo J.N., Bimenya G.S., Ojok L., Ochieng J., Ogwal-Okeng J.W. Phytochemicals and uses of Moringaoleiferaleaves in Ugandan rural communities. J. Med. Plants Res. 2010;4(9) [Google Scholar]

- Lalas S., Tsaknis J., Sflomos K. Characterisation of Moringastenopetala seed oil variety “Marigat” from island Kokwa. Eur. J. Lipid Sci. Technol. 2003;105(1):23–31. [Google Scholar]

- Lalas S., Gortzi O., Tsaknis J. Frying stability of Moringastenopetala seed oil. Plant foods hum nutr. 2006;61(2):93–102. doi: 10.1007/s11130-006-0022-8. [DOI] [PubMed] [Google Scholar]

- Leone A., Spada A., Battezzati A., Schiraldi A., Aristil J., Bertoli S. Moringaoleifera seeds and oil: characteristics and uses for human health. Int. J. Mol. Sci. 2016;17(12):2141. doi: 10.3390/ijms17122141. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Manzoor M., Anwar F., Iqbal T., Bhanger M.I. Physicochemical characterization of Moringaconcanensis seeds and seed oil. J Am Oil Chem Soc. 2007;84(5):413–419. [Google Scholar]

- Meitzner L.S., Price M.L. Amaranth to zai holes: ideas for growing food under difficult conditions. Echo. 1996 [Google Scholar]

- Mekonnen Y. Institute of Pathobiology, Addis Ababa University; Addis Ababa, Ethiopia: 2003. The Multi-Purpose Moringa Tree: Ethiopia. [Google Scholar]

- Meta Memo Gore. Extraction and physicochemical characterization of oil from Maringa Stenopetala seeds. IOSR J. Appl. Chem. 2018;11:6–07. [Google Scholar]

- Nzikou J.M., Matos L., Moussounga J.E., Ndangui C.B., Kimbonguila A., Silou T.H., Desobry S. Characterization of Moringaoleifera seed oil variety CongoBrazzaville. J. Food Technol. 2009;7(3):59–65. [Google Scholar]

- Ochigbo S.S., Paiko Y.B. Effects of solvent blending on the characteristics of oils extracted from the seeds of chrysophyllumalbidium. Int J sci Nat. 2011;2:352–358. [Google Scholar]

- Rashid U., Anwar F., Moser B.R., Knothe G. Moringaoleifera oil: a possible source of biodiesel. Bioresour. Technol. 2008;99(17):8175–8179. doi: 10.1016/j.biortech.2008.03.066. [DOI] [PubMed] [Google Scholar]

- Rekha G., Leema R.,A. Extraction and characterization of moringaoleifera seed oil. International Journal of Current Research. 2017;9(01):45629–45631. [Google Scholar]

- Sampson W. Studying herbal remedies. N. Engl. J. Med. 2005;353(4):337. doi: 10.1056/NEJMp058130. [DOI] [PubMed] [Google Scholar]

- Sayyar S., Abidin Z.Z., Yunus R., Muhammad A. Extraction of Oil from Jatropha seeds-optimization and kinetics. Am. J. Appl. Sci. 2009;6(7):1390. [Google Scholar]

- Siddique B.M., Ahmad A., Ibrahim M.H., Hena S., Rafatullah M. Physicochemical properties of blends of palm olein with other vegetable oils. Grasas Aceites. 2010;61(4):423–429. [Google Scholar]

- Somali M.A., Bajneid M.A., Al-Fhaimani S.S. Chemical composition and characteristics ofMoringaperegrina seeds and seeds oil. J Am Oil Chem Soc. 1984;61(1):85–86. [Google Scholar]

- Tilahun G. 2018. Extraction, Kinetics Study and Characterization of MoringaStenopetala Seed Oil (Doctoral Dissertation, AAU) [Google Scholar]

- Tsaknis J., Lalas S., Gergis V., Dourtoglou V., Spiliotis V. Characterization of Moringaoleifera variety Mbololo seed oil of Kenya. J. Agric. Food Chem. 1999;47(11):4495–4499. doi: 10.1021/jf9904214. [DOI] [PubMed] [Google Scholar]

- Yisehak K., Solomon M., Tadelle M. Contribution of moringastenopetala. J. App. Sc. 2011;4:477–488. [Google Scholar]