Highlights

-

•

UASB was proposed for RPMW anaerobic treatement under mesophilic conditions.

-

•

Start-up up of the UASB reactor was completed in the 24 days.

-

•

80,76 % COD and 90 % TS were removed at an OLR of 7,27 g COD/L d.

-

•

At optimal OLR of 8.31 g COD/L d was required to produce 62.51 L/d biogas.

-

•

For HRT 15.14 h, after reactor start-up 80.63 % of COD was removed.

-

•

The average biogas composition was 72.98 % CH4, 19.76 % CO2, 0.9 % O2.

Keywords: Anaerobic digestion, Biogas, HRT, OLR, Up flow - anaerobic sludge blanket, Reactor and RPMW

Abstract

The anaerobic digestion (AD) has become an alternative source and an attractive treatment method. Up-flow Anaerobic Sludge Blanket (UASB) digester has been designed to treat the Recycled paper mill wastewater (RPMW) in Morocco. This paper provides a research on anaerobic digestion of RPMW using UASB technology. The UASB digester was designed following the characterization of wastewater and the feed rate, with the volume of 70 liters. The UASB reactor treating the RPMW was operated for 130 days with minimal overload problems. The experiments were carried out in the mesophilic temperature (37 °C) at different organic loading rates (OLR). A daily analysis was performed to ensure the efficiency of the digester. In this study, the AD experiment was performed in continuous mode with an effluent inlet flow rate equal to 1 L/h. Using the optimal OLR value 5.18 g COD/Ld and with an effluent 5,7 g COD/L, a biogas yield of 92 N mL/g COD removed (at normal temperature and pressure) was obtained during the RPMW anaerobic treatment. The reactor was operated at an optimal hydraulic retention time (HRT) of 15.14 h with a biogas production volume of the optimal value 62.5 L/d. These results indicate that RPMW can be effectively treated in a UASB reactor with the advantage of producing biogas. We tested our system with RPMW, to see the production capacity of the UASB system, which the objective is to develop the system for the industrial scale.

1. Introduction

The paper and pulp industry is a big consumer of energy and water. Its industrial process produces significant amounts of organic wastewater with a high chemical oxygen demand (COD) concentration [1]. According to the raw material used in the process there are two kinds of paper manufacturing industry: the virgin pulp paper and recycled old paper. In this work we focused on the recycled paper industry wastewater. The huge quantity of organic waste matter produced from recycled paper industry may be converted to biomethane and valorized to a renewable energy [2,3].

There are several treatment methods of pulp and paper wastewater, physicochemical treatment methods such as (sedimentation and floatation, coagulation and precipitation, filtration, reverse osmosis, adsorption, wet oxidation, ozonation and other advanced oxidation processes) and Biological treatment methods, such as (Anaerobic digestion, Aerobic treatment and Fungal treatment) [4]. Among these techniques there is anaerobic digestion, which is considered as a stable process for wastewater treatment. In fact, it provides a significant reduction in the input material mass [5] and reduces COD concentration compared to activated sludge process [6]. This technique has more advantages than aerobic and physicochemical processes in terms of simplicity of design and lower energy requirement [7]. Note that in aerobic treatment case, a concentrated sludge generated in large quantities by the wastewater treatment facilities of paper recycling plants is a serious disposal problem requiring an urgent solution, the degradation process is effective compared to more conventional aerobic processes and produces only 5–10 % sludge. This saves considerably on cost and associated with sludge disposal [1,8,9].

Furthermore, digester UASB can be applicable on the small and large scale [8,10]. Many different types of anaerobic reactors have been studied such as Up-flow anaerobic filter, Up-flow anaerobic sludge blanket (UASB)+partially recirculation, submerged anaerobic membrane bioreactor (SAnMBR) and Modified anaerobic baffled reactor (MABR) [[11], [12], [13], [14]]. The most commonly used for industrial and municipal wastewaters treatment is UASB digester, which is operationally stable and energetically efficient [15,16]. Indeed, The UASB reactor where at its bottom there is a bed of granular sludge, is a encouraging system as it can provide relatively high COD removal efficiencies and energy production in the form of methane [9,17]. Due to low biogas yields, anaerobic processing of biosludge has not yet been carried out in pulp mills [18]. The efficiency of COD removal is significantly improved by the formation of concentrated granular sludge recovered at a relatively high height from the biological filter in the digester [19]. Furthermore, one of the basic conditions for the success of high rate the anaerobic digestion process is effective in UASB reactors is the development of granular sludge, a highly settleable sludge with high methanogenic activity [1]. The feasibility of the UASB reactor has been sufficiently demonstrated for treating mainly soluble wastewaters [20].

The objective of this research is to design a high-flow anaerobic digester; UASB type. The process was evaluated according to its COD and VFA removal efficiency and operated at different hydraulic retention times. The results were presented for a better understanding of the process. The digester is started by a bed of anaerobic granular sludge recovered from a biogas plant. For the separation of the liquid and gaseous phase, a phase separator has been installed at the top of the digester. This system can be an appropriate solution for the treatment of industrial wastewater in the community. In addition, we tested our system with recycled paper mill wastewater (RPMW), to see the production capacity of the UASB system with the objective is to develop the system for the industrial scale.

2. Material and methods

2.1. Experimental setup and procedure

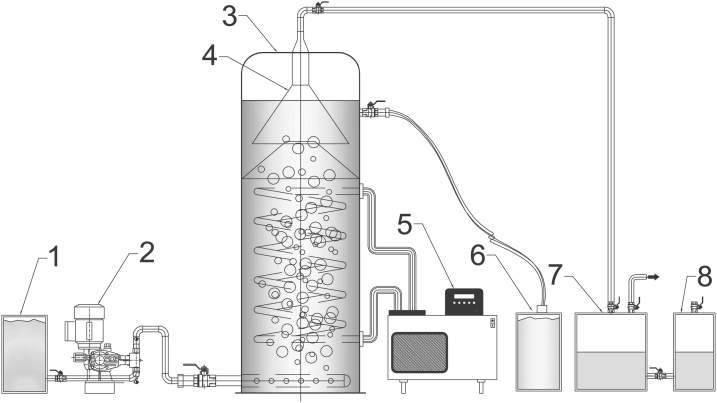

Fig. 1. Shows the experimental setup which it’s composed of an influent storage buffer tank installed before the UASB digester; the role of the buffer tank is to control and adjust the influent physicochemical parameters before it’s feeding into the reactor. A peristaltic pump maintains the digester feeding with a flow rate from 0.5 to 4.5 L/h. The design results of the digester were a total volume of 70 liters a height of 1 m and a diameter of 0.30 m. The top of UASB digester includes a gas-liquid-solid separator with a height of 0.30 m. This device allows the biogas recovery. In order to maintain the mesophilic conditions of the process, a helical exchanger has been fixed inside the digester [21].

Fig. 1.

Schematic of a UASB digester, designed to treat wastewater from recycled pulp and paper industry.

Fig. 1 Illustrates the designed UASB digester used in this work, influent tank (1), influent feed pump (2), UASB cylinder tank digester (3) with a total volume of 70 L, "solid-liquid-gas" separator (4), including thermostat heating water (5) for mesophilic conditions (37°) C, effluent tank (6), Gazometer (7), graduated tube (8) for measuring the water volume displaced from the gazometer.

The volume of biogas produced during the process was measured using a water tank of 16 L, connected to the reactor (Boyle-Mariotte reservoir). The biogas volume displaced an equal measurable volume of water from the tank. The biogas volumes are standardized taking into account the effect of the pressure and temperature at laboratory scale, and expressed under normal conditions (0 °C and 760 mm Hg).

2.2. Experimental procedure

The mesophilic UASB digester was inoculated with a granular sludge from a full-scale UASB digester, treating industrial wastewater. During the UASB startup, the digester was continuously fed with the RPWM using a peristaltic pump. The feeding flow was under 0.5 L/h, this step lasted 15 days. The UASB digester feeding with a low flow was to adapt the granular sludge to the new temperature (37 ± 2 °C) conditions, and to avoid their deterioration during this first phase, in order to accelerate the reactor startup. The heating of the digester was maintained by a recirculation of hot water using a helical exchanger inside the digester (Fig. 1). The experiment was carried out in a continuous mode introducing RPWM gradually. The experiment has gone through nine stages; from a stage to another we increase the flow rate by a 0.5 L/h, from 0.5 to 4.5 L/h.

2.3. Chemical analysis

The following parameters were analyzed at laboratory scale mainly pH, moisture, alkalinity (Alk), total solids (TS), mineral solids (MS), volatile solids (VS) and volatile fatty acid (VFA). All analyses were carried out according to ” Standard Methods for the Examination of Water and Wastewater” [22]. The COD was determined using the HACH Reactor Digestion Method (HACH Spectrophotometer DR2010, USA) and the biomass concentration in the reactor was measured using the MLSS Standard Method [22,23]. For the determination of TS, the samples were dried at 105 °C for 24 h, for measure the MS concentration, the dried matters were heated at 550 °C for 2 h. The volatile solid contents were calculated from the differences between total and mineral solids. Alkalinity was determined by a titration method at pH 4.5. Biogas composition (CO2 and CH4) was determined using Gas Analyzer (GeoTech 2000).

2.3.1. Granular sludge bed

The reactor was inoculated with 25 L of granular sludge. The granular sludge bed used in this experiment was recovered from a full scale UASB digester. This last treats the soda industry wastewater. Table 1 shows the characteristics of granular sludge bed used in this study.

Table 1.

Physicochemical characteristics of the granular sludge bed.

| Parameter | Unit | Average value |

|---|---|---|

| pH | – | 7.4 |

| COD (Chemical oxygen demand) | mg/L | 5330.5 |

| Alk (alkalinity) | mgCaCO3/L | 3250 |

| TS (total solid) | g/L | 32.99 |

| VS (volatile solid) | g/L | 27.28 |

| MS (mineral solid) | g/L | 5.71 |

| % TS | % | 3.21 |

| VS (%TS) | % | 82.70 |

| Moisture (%) | % | 96.79 |

| Diameter | mm | 1–1.5 |

| Color | – | Black |

The initial granular sludge had respectively 27.28 and 32.99 g/L as VS and TS value, and the COD equals to 5330.5 mg/L. In General, the alkalinity varies from 1000 to 5000 mg/L as CaCO3 in anaerobic [24].

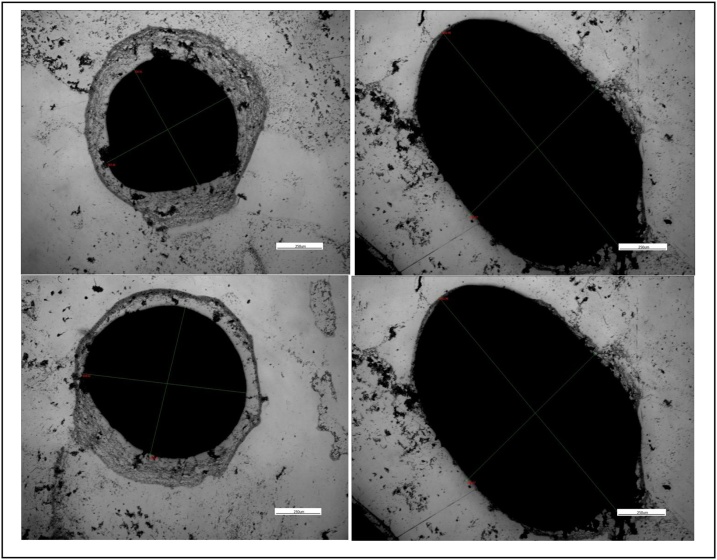

The biogranules formation technique is not fully understood. The role of inert microparticles as granulation initiators has been identified. The importance of calcium concentration (more than 100 mg/L) in granule consolidation phenomena is often reported. The presence of starch is also a favorable element. The settling properties of these granules are excellent (15–80 m/h), which allows them to be used in a sludge bed through which the liquid to be treated flows from bottom to top without significant entrainment. This process, known as UASB, is nowadays the most widespread process in waste methanisation. This allows the charges to be removed 1–15 g COD/L d (Fig. 2).

Fig. 2.

Biogranule photo by microscope.

2.3.2. Influent characterization

In order to characterize the input influent, a physicochemical analysis was carried out for various parameters as illustrated in Table 2. All analysis was carried out according to the ”standard methods for the Examination of Water and Wastewater” [22]. The results show that RPWM contains organic and inorganic matters required for biological growth. The BOD5/COD ratio of 1.4 shows that the influent is rich in biodegradable organic matter [7], which means that it can be suitable for anaerobic treatment. The BOD5/COD ratio of 0.5 shows that this wastewater is of high strength organic type [7].

Table 2.

RPWM physicochemical characteristics.

| Parameters | Unit | Minimum value | Maximum value | Mean value |

|---|---|---|---|---|

| T | °C | 18 | 21 | 19.5 |

| pH | – | 6.6 | 7 | 6.8 |

| COD | mg/L | 3896 | 6351 | 5123.5 |

| BOD5 | mg/L | 3125 | 4037 | 3581 |

| COD/BOD5 | -- | 1.24 | 1.57 | 1.4 |

| Alk | mgCaCO3/L | 1250 | 2250 | 1750 |

| TS | mg/L | 5822 | 9050 | 7436 |

| VS | mg/L | 1759 | 7242 | 4500.5 |

| MS | mg/L | 4063 | 1080 | 2571.5 |

| Na | mg/L | 231.6 | 357.9 | 294.75 |

| K | mg/L | 22.5 | 31.25 | 26.87 |

| Ca | mg/L | 41 | 90 | 65.5 |

| VFA | mg/L | – | – | 2700 |

| NH4+ | mgNH4+ /L | – | – | 1.75 |

This result is consistent with the literature results. In fact, recent studies show that the paper mill effluents COD varies from 3348 to 3765 mg/L, TS from 3067 to 3307 mg/L and the pH varies from 6.32 to 7.6 [25]. Another study summarizes physicochemical characterization of recycled paper mill wastewater, it gives that the COD varies between 3380–4930 mg COD/L, the BOD varies between 1650−2565 mg/L and TS is between 3530−6163 mg/L [7]. The influent also had relatively neutral pH between 6.2 and 7.6, which was used without any alkaline adjustment. The characterization results of this substrate are higher than the results found by the characterization of pulp and paper wastewater [26,27].

2.4. Reactor operation

2.4.1. Hydraulic retention time (HRT)

The HRT is considered as an important parameter which controls the UASB digester performance [28]. The HRT during the experiment was calculated using the following formula:

With:

V l: Volume of liquid in the reactor; volume used (53 L)

Q: Flow rate (L/h)

2.4.2. Organic loading rate (OLR)

As HRT, OLR is a very important parameter which controls the UASB digester performance [28]. The OLR was calculated using the relation:

With:

Q: Flow rate (L/h)

S0: Influent substrate concentration (g COD/L)

V l: Volume of liquid in the reactor; volume used (53 L)

3. Results and discussion

The results concern the stability parameters of the process, and the UASB bioreactor performance. The objective of the stability parameters monitoring is to control and ensure the process operation. The main control parameters are: pH evolution, alkalinity (Alk), volatile faty acid (VFA), VFA/Alk ratio and chemical oxygen demand (COD).

3.1. Stability parameters

3.1.1. pH evolution

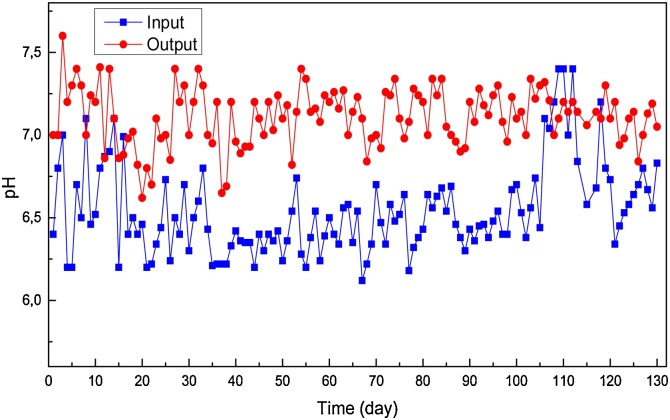

The pH is an essential parameter used to control the anaerobic digestion process stability. Fig. 3 shows the input influent and output effluent pH fluctuation as a function of time during the experiment, the mean value of the input and output pH during the process reached respectively 7 and 7.4. The pH fluctuation was in the neutral range, which confirms the correct functioning of the process and the UASB digester stability. In fact, several studies reported that most of the anaerobic bacteria especially methanogens enhance the biogas production at pH range of 6.5–7.5 [29]. A previous study on RPMW treatment using the modified anaerobic baffled reactor (MABR), reported that the pH slightly decreased from 7.3 to 6.2 during the process [7,30].

Fig. 3.

Input–Output pH evolution during the process.

3.1.2. Alkalinity and VFA/Alk ratio evolution

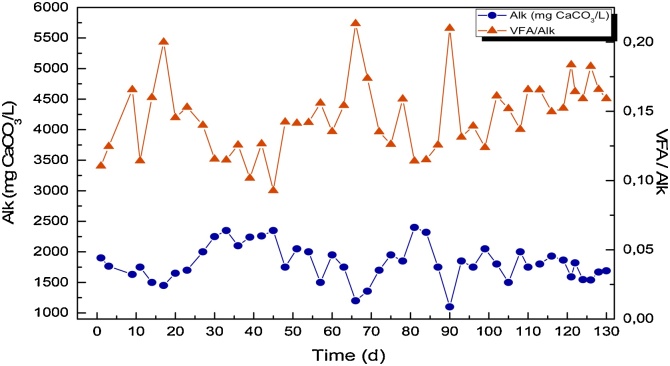

Fig. 4 shows the input and output effluent Alk and VFA/Alk fluctuation as a function of time during the experiment, high concentrations of VFA play a disruptive role in all stages of biochemical degradation. Their accumulation caused an imbalance in the different microbial metabolism. Moreover, VFA accumulation is a simple way to detect a biochemical dysfunction of the anaerobic digestion process. Monitoring these compounds is, therefore, a way of controlling the functioning of the digesters [31,32].

Fig. 4.

Alk and VFA/Alk evolution during the process.

The results show that the Alk varies from 1100 to 2500 mg CaCO3/L as illustrated in Fig. 4. In General, the alkalinity varies from 1000 to 5000 mg/L as CaCO3 in anaerobic [24]. Moreover, the indicator parameter of stability (VFA/Alk) ratio was less than 0.2 during the experiment. This favorable value corresponds to a good process operation, which stabilize the digester in order to avoid inhibition phenomenon.

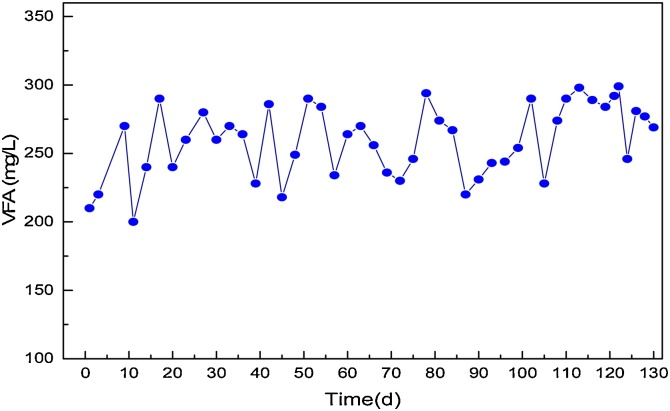

3.1.3. Volatile fatty acid evolution

Fig. 5 Shows the volatile fatty acid content is a fundamental parameter to monitor the anaerobic digestion process. The accumulation of VFA causes a displacement of bicarbonate to the dissolved CO2 and the CO2 will partly pass in the gas phase. Their accumulation in the digester leads to an organic overload and an acidification of the digester content, which leads to a failure of the process.

Fig. 5.

VFA evolution during the process.

Several studies show that the organic overload in digesters is due to the VFA accumulation, and often the acetate accumulates the first, the total VFA concentrations slightly or steady increased when the COD loading rate increased to 9.93 g/L d [33]. Fig. 5 shows that the VFA concentration during the experiment varies between 200−320 mg/L, this concentration shows a good operation of the digester [32]. These results we can conclude that in the case of recycled paper mill wastewater, the digester is operating well when the VFA in the outlet effluent are less than 0.4 g/L.

3.2. Digester performance

The UASB bioreactor performance results are summarized in Table 3. The digester performance was evaluated according to several parameters such as removal COD efficiency, biogas production, HRT and the applied OLR, which depend on the input flow rate.

Table 3.

Performance results of UASB reactor.

| HRT (h) | Flow (L/h) | OLR (g COD/L d) | CODI (mg/L) | CODE (mg/L) | Removel effciency % | Biogas production (L/d) | V(mL biogas/g COD removed) |

|---|---|---|---|---|---|---|---|

| 106 | 0.5 | 1 | 4420 | 1331.5 | 70 | 0.97 | 24.6 |

| 53 | 1 | 2.1 | 4656 | 1198 | 74.3 | 4.3 | 52 |

| 35.33 | 1.5 | 4 | 5907.2 | 1246 | 78.9 | 11.7 | 69.7 |

| 26.5 | 2 | 5.2 | 5726 | 1175.5 | 79.5 | 20 | 92 |

| 21.2 | 2.5 | 6 | 5330.2 | 1088 | 79.6 | 37 | 145.4 |

| 17.66 | 3 | 7.3 | 5353 | 1030 | 80.7 | 52 | 167.1 |

| 15.14 | 3.5 | 8.3 | 5240.9 | 1015 | 80.6 | 62.5 | 176.1 |

| 13.25 | 4 | 8.4 | 4650.8 | 1018.6 | 78.1 | 61.5 | 176.4 |

| 11.78 | 4.5 | 10 | 4887.2 | 1034.8 | 78.8 | 35.3 | 84.9 |

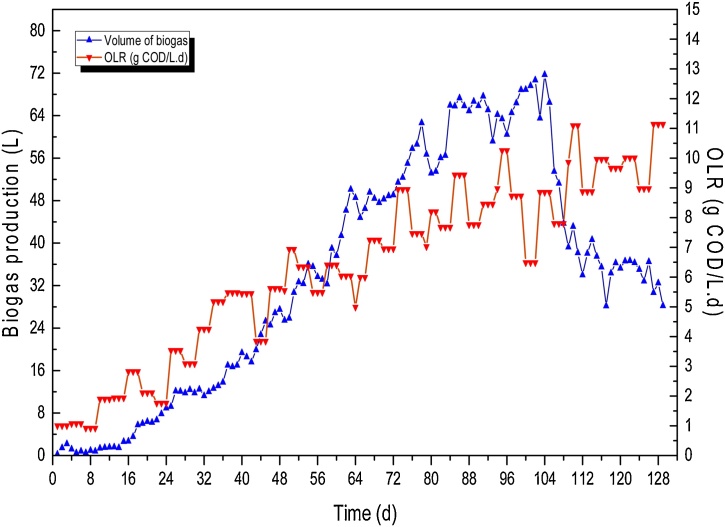

Table 3 shows that the UASB digester performance increases proportionally with the OLR growth, and the biogas production enhances when the removal efficiency increases according to the OLR. Fig. 5 shows the biogas production as a function of applied OLR during the experiment. The produced biogas volume varies significantly in the first stage of the process and stabilizes during the operational period. The maximum biogas production reaches 62.51 L/d. The reactor was started in a continuous mode introducing RPWM at an OLR of g COD/L d and operated for 106 h until the reactor was stabilized. Subsequently, OLR was increased to 2.1 g COD/L d. During the first stage, the reactor performance in terms of COD reduction was between 70 and 74.3 %, biogas production was 4.3 L/d (52 mL biogas/g COD removed) and the flow rate 1 L/h.

The performance of the reactor in terms of COD removal and biogas production at various OLR is in Table 3. Biogas volume was in the range of 0.97–62.5 L/d for a COD reduction of 70–80.7 % until an OLR value of 8.3 g COD/L d. However the biogas production dropped down to 35.3 L/d for the OLR of 10 g COD/L d with a COD reduction of 78.82. This value is higher than the one reported by Haider et al., this study results shows a remarkable digester performance of high COD removal efficiency up to 71 % [7]. The fall in the substrate removal rates at higher OLR might be attributed to the accumulation of organic matter inside the digester and inhibition of biomass activity [34,35]. Further, when the reactor OLR was conducted at OLR of 8.1 g COD/L d, the biogas production reaches the optimum with 62.5 L/d and the COD reduction rose to 80.6 %, respectively. It was concluded that the UASB reactor for the RPWM could work effectively for 8.3 g COD/L d.

3.2.1. Biogas production

The biogas average volume produced increases 24.6–176.1 mL biogas/g COD removed (24.6–176.1 L/kg COD removed), the highest biogas volume of 176.1 L/kg COD removed was obtained with an OLR of 8.3 g COD/L d and an HRT of 15.14 h. d. Biogas production for different organic loads applied in the digester are shown in Fig. 6. Biogas production increases significantly in the first run (HRT) and stabilizes during the operational period. After that we observe an important drop in produced volume of biogas. According to the bibliography, the biogas production of the wastewater form a mill for recycling paper was lower than from pulp and paper industry effluent. However the COD removal efficiency was in the same range. A study of anaerobic digestion using UASB digester with a Bagasse wash wastewater from agro-based pulp and paper mill, shows that the efficiency ranged between 80–85 % and the biogas production reached 520 L/kg COD [36].

Fig. 6.

Biogas production and applied organic load for different operational periods.

Another study review was carried out for the anaerobic treatment of industrial wastewater, reported that for the anaerobic digestion of effluents from the pulp and paper industry, the efficiency was about 80 % in terms of COD reduction and the methane production was 340 L/kg COD. However, the effluent from cellulose washings, the COD reduction was only 20–30 % and the methane yield was 270−360 L/kg COD removed [35,37]. As well, Gangagni et al., have found a methane production in the range of 310–330 L/kg COD removed, treating dilueted pre-hydrolysate liquor from pulp and paper effluent, with a COD removal efficiency of 70–75 % [35]. UASB digester gives an excellent result in terms of wastewater treatment at high concentration up to 10 g COD/L, elimination rate reaches 81 %, and the hydraulic retention time was 12 h. However, a study by Hasnidah et al. in which they developed a laboratory scale granular activated carbon sequencing reactor to treat wastewater from a recycled paper mill. In this study, COD removals were in the range of 53–92%, the longest observed HRT is 48 h [38]. The maximum volume of biogas is about 62.2 L/day, which is higher than that of a previous literature study which showed that under optimal conditions the HRT was of the order of 23 h, the percentage of COD elimination is about 84.3 % and the biogas production is 21.2 L/d [39].

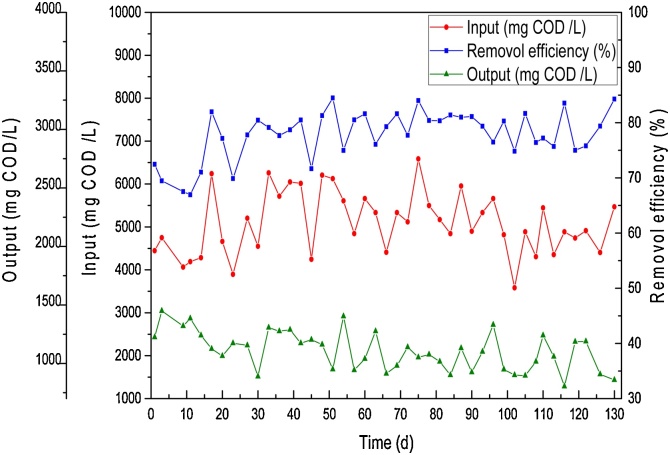

3.2.2. Chemical oxygen demand evolution

Fig. 7 shows the input-output COD fluctuation as a function of HRT during the experiment. The results obtained show a decrease in COD output compared to the input one, in which the COD removal efficiency reached 80.63 %. This value is lower compared with study conducted by Shreeshivadasan et al., that reported the average COD reduction efficiency of 95 % for an HRT of 1.6 days and an OLR of 1.560 kg COD/m3d [30]. Moreover, the results obtained are encouraging in terms of COD reduction, which is due to RPWM degradation by granular sludge bed inside the digester. This COD removal efficiency achieved by the process allows a good digester operation without risk of biogas inhibition.

Fig. 7.

Input and output COD of the reactor and COD removal efficiency for different operation times.

The efficiency of COD removal obtained in this study reached 80 %. It was higher than their achieved in other anaerobic treatment studies of recycled paper mill effluents using UASB full-scale reactor. In a study by Möbius et al., COD removal efficiency is strongly related to wastewater composition, but can be expected to be between 60 % and 70 % [40]. Moreover, COD removal efficiency increases to 78° for pulp and paper wastewater using a UASB digester with partial recirculation [41,6]. Our UASB is designed to treat high concentrations of wastewater and a minimum HRT of less than 12 h.

In this study, the digester design mainly depends on the effluent characteristics, in terms of the concentration of organic matter. Knowing that the digester design parameters have been calculated based on the chemical oxygen demand and the flow rate of the input influent [42]. The study results indicate that the UASB digester designed had a good performance, in terms of biogas production and the efficiency of COD removal. Our UASB digester of 1 m in high and 0.32 m in diameter was effective for the treatment of effluents from the recycling paper wastewater industry in Morocco. The other digesters and several studies done for the UASB digester give a digester characteristic based on height than 3 m [42]. As well, in this research we have chosen to heat the UASB digester with water recirculation, using a cooper exchanger fixed inside the digester. The exchanger is connected to a thermostat that controls mesophilic temperature conditions inside the reactor. The research results shows, that we can use the heating exchanger technique, instead the most popular technique of heating UASB digesters using a thermostatic bath (double membrane jacket).

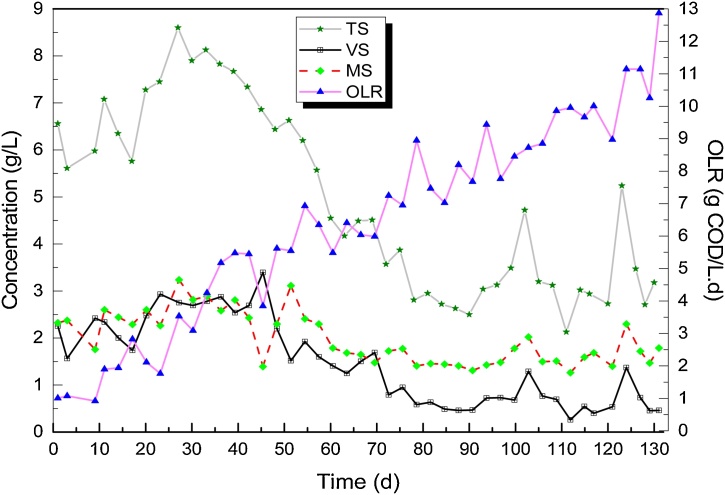

3.2.3. Organic matter evolution

The following Fig. 8 shows the evolution of the amount of TS, VS, and MS during the experiment of each organic load rate as a function of time. The organic loading rate is one of the most important parameters, operating an anaerobic digester. It is defined as the application amount of volatile organic matter per digester volume per day. This parameter gives an indication of biological degradation of the substrates i.e.; it describes the efficiency of the anaerobic digester.

Fig. 8.

The output TS, VS and MS evolution with OLR applied during the experiment process as a function of time.

Fig. 8 shows the evolution of the output volatility and total solid in the digester. We observe a decrease in the output TS and VS as a function of time compared to the OLR applied to the digester, which increases during the experiment reaching an average value of 10 (g COD/L d) in nearly 11.78 h. These results indicate an important biodegradation of RPMW in the digester by microorganism. Knowing that this great biodegradability allows the applying OLR in the digester to increase and improve its performance. The designed digester shows that the AD of RPWM, for OLR varying from 1 to 10 g COD/L d, allows to a stable digester performance. These results are consistent with several other studies, which conclude that the optimum OLR is about 5 g COD/L d in a UASB digester treating wastewater from pulp and paper industry [1].

3.2.4. Buswell method

According to El Bari study [43], the Table 4 below represent the elementary analysis of RPWM: the percentage of carbon, hydrogen, oxygen, sulphur and nitrogen. From these results and the Buswell equation, we can calculate the theoretical amount of biogas of biogas and biomethane production and the percentage of each gas in the biogas [43].

Table 4.

Theoretical amount of biogas and biomethane from the Buswell equation.

| %C | %H | %O | %N | %S | Empirical formula | ||

|---|---|---|---|---|---|---|---|

| 46 | 6 | 44 | 0.37 | 3.63 | C332H520O238N22S | 0.86 | 0.42 |

The elementary analyses give an idea on the composition of the biogas and the theoretical quantity of methane and carbon dioxide, according to the Buswell equation. Table 4, Table 5 presents respectively the elementary analyses and the results of the biogas volume estimation about 0.86 m3/kg VS. The experimental results can be compared with the theoretical results obtained. The best result obtained in our elementary analyses was the use of sludge obtained from RPM wastewater by settling, maximum methane production potential of 421.5 N mL CH4/gVS, our result is higher than that of the researcher [44] who gives the maximum production potential of pulp paper sludge is in the order of 417 NmLCH4/gVS.

Table 5.

Biogas compositions from the Buswell equation.

| Gas | VTh (Nm3 CH4/Ton VS) | Biogas composition (%) |

|---|---|---|

| CH4 | 421.511 | 46.50 |

| CO2 | 424.172 | 46.79 |

| NH3 | 58.119 | 6.41 |

| H2S | 2.592 | 0.29 |

3.2.5. Statistics for biogas composition analysis

Table 6 presents descriptive statistics of data on the composition and flow rate of biogas produced in the UASB reactors, obtained by RPWM anaerobic digestion. During the monitoring period, the wastewater flow rate applied to the digester was between 0.5–4.5 L/d. The average biogas composition during this analysis was 73 % CH4, 19.76 % CO2, 0.9 % O2 and a mixture of other components of 6.18 %, in which the H2S concentration was 0.16 %. The CH4 gas concentrations were within the range reported by Lin et al. in cake sludge and bulk sludge cases between 62–75 % for CH4 and 22–30 % for CO2 [11]. The results obtained from the experimental analyses are superior to the theoretical results obtained by author El Bari [43]. These results were given by the Buswell method equation. The theoretical biogas composition results theoretical calculation is 46.5 % CH4 and 46.79 % CO2. It is clear that UASB digester granules are effective in converting organic matter from wastewater to biogas. The reactor appears to support high organic loads. However, when the used water is sent to the reactor, the AD process works without inhibition problems.

Table 6.

Descriptive statistics on the composition of biogas obtained from RPWM.

| Test | Biogas flow (L/h) | CH4 (%) | CO2 (%) | O2 (%) | H2S (%) | Others (%) |

|---|---|---|---|---|---|---|

| 1 | 1.25 | 71.7 | 18.8 | 1.2 | 0.1 | 8.2 |

| 2 | 1.50 | 75 | 21.8 | 0.6 | 0.2 | 2.4 |

| 3 | 1.76 | 73 | 19.4 | 0.9 | 0.3 | 6.4 |

| 4 | 2.60 | 73.2 | 17.9 | 1.0 | 0.1 | 7.8 |

| 5 | 3.40 | 70.8 | 20.9 | 1.0 | 0.1 | 7.2 |

The optimal flow rate of our digester was 3.5 L/h of RPMW. Biogas production reaches 62.5 L/d with an organic loading rate of 8.3 g COD/L. The COD reduction reached 80.6 % in this experiment. According to the data of the biogas composition an average percentage value of methane is equal to 73 % and the concentration of H2S of about 0.16 %. The results obtained in this work show that RPWM treatment by AD using a UASB digester designed in our laboratory has a high performance in terms of COD efficiency and biogas production. This technique offers an excellent opportunity to exploit the economic benefits of the produce energy from this process, which could contribute to develop more efficient and sustainable systems. During the long period of reactor operation, the AD process was adapted to the used flow rate.

4. Conclusion

It is clear that UASB digester granules are effective in converting organic matter from wastewater to biogas. The reactor appears to support high organic loads. However, when the used water is sent to the reactor, the AD process works without inhibition problems. The optimal flow rate of our digester was 3.5 L/h of RPMW. Biogas production reaches 62.5 L/d with an organic loading rate of 8.3 g COD/L. The COD reduction reached 80.6 % in this experiment. According to the data of the biogas composition an average percentage value of methane is equal to 73 % and the average concentration of H2S of about 0.16 %.The results obtained in this work show that RPWM treatment by anaerobic digestion using a UASB digester designed in our laboratory has a high performance in terms of COD efficiency and biogas production. This technique offers an excellent opportunity to exploit the economic benefits of the produced energy from this process, which could contribute to develop more efficient and sustainable systems. During the long period of reactor operation, the AD process was adapted to the used flow rate.

Declaration of Competing Interest

None.

Acknowledgements

This research work was funded by the Institute of Research in Solar Energy and New EnergiesIRESEN agency. I would like to thank Professor Hassan El Bari and Dr. Fadoua Karouach for their help and contributions in conducting this study.

References

- 1.Badshah M., Parawira W., Mattiasson B. Anaerobic treatment of methanol condensate from pulp mill compared with anaerobic treatment of methanol using mesophilic UASB reactors. Bioresour. Technol. 2012;125:318–327. doi: 10.1016/j.biortech.2012.08.109. [DOI] [PubMed] [Google Scholar]

- 2.Bakraoui M., Karouach F., Ouhammou B., Aggour M., Essamri A., El Bari H. Kinetics study of the methane production from experimental recycled pulp and paper sludge by CSTR technology. J. Mater. Cycl. Waste Manag. 2019;21(6):1426–1436. [Google Scholar]

- 3.Torsten M., Elizabeth A.E. Anaerobic digestion of pulp and paper mill wastewater and sludge. Water Res. 2014:321–349. doi: 10.1016/j.watres.2014.07.022. [DOI] [PubMed] [Google Scholar]

- 4.Mohammadreza K., Khodaparast Z. Review on recent developments on pulp and paper mill wastewater treatment. Ecotoxicol. Environ. Saf. 2015;114:326–342. doi: 10.1016/j.ecoenv.2014.05.005. [DOI] [PubMed] [Google Scholar]

- 5.Bakraoui Mohammed, Hazzi Mohammed, Karouach Fadoua, Ouhammou Badr, El Bari Hassan. Experimental biogas production from recycled pulp and paper wastewater by biofilm technology. Biotechnol. Lett. 2019;41:1299–1307. doi: 10.1007/s10529-019-02735-w. [DOI] [PubMed] [Google Scholar]

- 6.Pontual L., Mainier F.B., Lima G.B.A. The biogas potential of pulp and paper mill wastewater: an essay. Am. J. Environ. Eng. 2015;5(3):53–57. [Google Scholar]

- 7.Haider M.Z., Siti R.H., Nastaein Q.Z., Hamidi A.A., Irvan D. The start-up performance of modified anaerobic baffled reactor (MABR) for the treatment of recycled paper mill wastewater. J. Environ. Chem. Eng. 2013:61–64. [Google Scholar]

- 8.Verma A.K., Kumar S. Department of Civil Engineering National Institute of Technology; Rourkela: 2013. Characterization of Sewage and Design of a UASB Reactor for its Treatment. [Google Scholar]

- 9.Valentine N.N., Marika M. Biogas production from wheat straw in batch and UASB reactors: the roles of pretreatment and seaweed hydrolysate as a co-substrate. Bioresour. Technol. 2013;128:164–172. doi: 10.1016/j.biortech.2012.10.117. [DOI] [PubMed] [Google Scholar]

- 10.Ouhammou Badr, Aggour Mohammed, Frimane Âzeddine, Bakraoui Mohammed, Bari HassanEl, Essamri Azzouz. A new system design and analysis of a solar bio-digester unit. Energy Convers.Manage. 2019;198 [Google Scholar]

- 11.Lin H., Liao B.Q., Chen J., Gao W., Wang L., Wang F., Lu X. New insights into membrane fouling in a submerged anaerobic membrane bioreactor based on characterization of cake sludge and bulk sludge. Bioresour. Technol. 2011;102:2373–2379. doi: 10.1016/j.biortech.2010.10.103. [DOI] [PubMed] [Google Scholar]

- 12.Zwain H.M., Hassan S.R., Zaman N.Q., Aziz H.A., Dahlan I. The start-up performance of modified anaerobic baffled reactor (MABR) for the treatment of recycled paper mill wastewater. J. Environ. Chem. Eng. 2013;1:61–64. [Google Scholar]

- 13.Buzzini A.P., Pires E.C. Evaluation of a upflow anaerobic sludge blanket reactor with partial recirculation of effluent used to treat wastewaters from pulp and paper plants. Bioresour. Technol. 2007;98:1838–1848. doi: 10.1016/j.biortech.2006.06.030. [DOI] [PubMed] [Google Scholar]

- 14.Deshmukh N.S., Lapsiya K.L., Savant D.V., Chiplonkar S.A., Yeole T.Y., Dhakephalkar P.K., Ranade D.R. Upflow anaerobic filter for the degradation of adsorbable organic halides (AOX) from bleach composite wastewater of pulp and paper industry. Chemosphere. 2009;75:1179–1185. doi: 10.1016/j.chemosphere.2009.02.042. [DOI] [PubMed] [Google Scholar]

- 15.Chen C., Liang J., Yoza B.A., Li Q.X., Zhan Y., Wang Q. Evaluation of an up-flow anaerobic sludge bed (UASB) reactor containing diatomite and maifanite for the improved treatment of petroleum wastewater. Bioresour. Technol. 2017:620–627. doi: 10.1016/j.biortech.2017.06.171. [DOI] [PubMed] [Google Scholar]

- 16.Yu W., Qinghong W., Min L., Yingnan Y., Wei H., Guangxu Y., Shaohui G. An alternative anaerobic treatment process for treatment of heavy oil refinery wastewater containing polar organics. Biochem. Eng. J. 2016:44–51. [Google Scholar]

- 17.Jeong-Geol N., Mo-Kwon L., Yeo-Myeong Y., Chungman M., Mi-Sun K., Dong-Hoon K. Microbial community analysis of anaerobic granules in phenol-degrading UASB by next generation sequencing. Biochem. Eng. J. 2016:241–248. [Google Scholar]

- 18.Bonilla S., Choolaei Zahra, Meyer Torsten, Edwards Elizabeth A., Yakunin Alexander F., Grant Allen D. Evaluating the effect of enzymatic pretreatment on the anaerobic digestibility of pulp and paper biosludge. Biotechnol. Rep. 2018;17:77–85. doi: 10.1016/j.btre.2017.12.009. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 19.Heng L., Kezeng H., Zhipeng L., Jinfeng Z., Hua L., Yaohua H., Liang S., Qingbiao L., Yuanpeng W. Performance, granule conductivity and microbial community analysis of upflow anaerobic sludge blanket (UASB) reactors from mesophilic to thermophilic operation. Biochem. Eng. J. 2018:59–65. [Google Scholar]

- 20.Rosa A.P., Chernicharo C.A.L., Lobato L.C.S., Silva R.V., Padilha R.F., Borges J.M. Assessing the potential of renewable energy sources (biogas and sludge) in a full-scale UASB-based treatment plant. Renew. Energy. 2017:21–26. [Google Scholar]

- 21.Ouhammou B., Naciri M., Aggour M., Bakraoui M., Karouach F., El Bari H. Design and analusis of integrating the solar thermal energy in anaerobic digester using TRNSYS: application kenitra-Morocco. Energy Procedia. 2017:13–17. [Google Scholar]

- 22.APHA . 21st ed. American Public Health Association; Washington, D.C: 2005. Standard Methods for the Examination of Water and Wastewater. [Google Scholar]

- 23.Li J., Carlson B.E., Lacis A.A. A study on the temporal and spatial variability of absorbing aerosols using total ozone mapping spectrometer and ozone monitoring instrument aerosol. J. Geophys. Res. 2009:114. [Google Scholar]

- 24.Veluchamy C., Kalamdhad S.A. Influence of pretreatment techniques on anaerobic digestion of pulp and paper mill sludge: a review. Bioresour. Technol. 2017:1206–1219. doi: 10.1016/j.biortech.2017.08.179. [DOI] [PubMed] [Google Scholar]

- 25.Birjandi N., Younesi H., Bahramifar N. Treatment of wastewater effluents from paper-recycling plants by coagulation process and optimization of treatment conditions with response surface methodology. Appl. Water Sci. 2014 [Google Scholar]

- 26.Paolo D., Estefania P., Aino-Maij L., Gavin C., Piet N.L.L. Temperature control as key factor for optimal biohydrogen production from thermomechanical pulping wastewater. Biochem. Eng. J. 2018:214–221. [Google Scholar]

- 27.Ram C., Rachna S. Decolourisation and detoxification of rayon grade pulp paper mill effluent by mixed bacterial culture isolated from pulp paper mill effluent polluted site. Biochem. Eng. J. 2012:49–58. [Google Scholar]

- 28.Kaviyarasan K. Application of UASB reactor in industrial wastewater treatment: a review. Int. J. Sci. Eng. Res. 2014:584. [Google Scholar]

- 29.Nayono S.E. Scientific Publishing; 2010. Anaerobic Digestion of Organic Wastes for Energy; p. 720. [Google Scholar]

- 30.Chelliapan S., Mahat S.B., Din M.D.F., Yuzir A., Othman N. Anaerobic digestion of paper mill wastewater. Iran. J. Energy Environ. 2012;3:85–90. ISSN 2079-2115. [Google Scholar]

- 31.Nielsen H.B., Uellendahl H., Ahring B.K. Regulation and optimization of the biogas process: propionate as a key parameter. Biomass Bioenergy. 2007:820–830. [Google Scholar]

- 32.Rathaur R., Dhawan S.H., Ganguly A., Mandal M.K., Halder G. Methanogenesis of organic wastes and their blend in batch anaerobic digester: experimental and kinetic study. Process. Saf. Environ. Prot. 2018;1 1 3:413–423. [Google Scholar]

- 33.Achiraya J.T., Kiatchai M., Sumaeth C. Production of biogas from cassava wastewater using a three-stage upflow anaerobic sludge blanket (UASB) reactor. Renew. Energy. 2019:191–205. [Google Scholar]

- 34.Clàudia E.T.C., Magali C.C., Alcina M.F.X. Slaughter house wastewater treatment: evaluation of a new three-phase separation system in a UASB reactor. Bioresour. Technol. 2002;81 doi: 10.1016/s0960-8524(01)00070-0. [DOI] [PubMed] [Google Scholar]

- 35.Gangagni R.A., Bapat A.N. Anaerobic treatment of pre-hydrolysate liquor (PHL) from a rayon grade pulp mill: pilot and full-scale experience with UASB reactors. Bioresour. Technol. 2006:2311–2320. doi: 10.1016/j.biortech.2005.10.033. [DOI] [PubMed] [Google Scholar]

- 36.Chinnaraj S., Venkoba R.G. Implementation of an UASB anaerobic digester at bagasse-based pulp and paper industry. Biomass Bioenergy. 2006:273–277. [Google Scholar]

- 37.Medhat M., Saleh A., Usama F.M. Anaerobic digestion technology for industrial wastewater treatment. International Water Technology Conference; Egypt; 2004. p. 345. iwtc8. [Google Scholar]

- 38.Hasnidah W.W.O., Rozaimah S.S.A., Mohamad A.B., Kadhum A.A.H., Rakmi A.R. Simultaneous removal of AOX and COD from real recycled paper wastewater using GAC-SBBR. J. Environ. Manage. 2013;121:80–86. doi: 10.1016/j.jenvman.2013.02.005. [DOI] [PubMed] [Google Scholar]

- 39.Mohammadreza K., Borazjani S.A.A., Khodaparast Z., Khalaj M., Jahanshahi A., Costa E., Capela I. Additive and additive-free treatment technologies for pulp and paper mill effluents: advances, challenges and opportunities. Water Resour. Ind. 2019;21:100109. [Google Scholar]

- 40.Möbius C.H. Books on Demand GmbH; 1. Aufl. Norderstedt: 2006. Water Use and Wastewater Treatment in Paper Mills. [Google Scholar]

- 41.Buzzini A.P., Pires E.C. Evaluation of a upflow anaerobic sludge blanket reactor with partial recirculation of effluent used to treat wastewaters from pulp and paper plants. Bioresour. Technol. 2007;98:1838–1848. doi: 10.1016/j.biortech.2006.06.030. [DOI] [PubMed] [Google Scholar]

- 42.Lettinga G., Hulshoff P.L.W., Zeeman G. Wageningen Agricultural University. Biological Wastewater Treatment; 1996. Anaerobic Wastewater Treatment. Lecture Notes; p. 123. [Google Scholar]

- 43.El Bari H., Bakraoui M., Karouach F. Book of Ecological Sustainable Waste Management; Morocco: 2018. Energetic Potentiel of Recycled Pulp and Paper Sludge. [Google Scholar]

- 44.Lopes A.C.P., Silva C.M., Pereira A.R., Rodrigues F.Á. Biogas production from thermophilic anaerobic digestion of kraft pulp mill sludge. Renew. Energy. 2018;124:40–49. [Google Scholar]