Abstract

Aflatoxins are wide-spread harmful carcinogenic secondary metabolites produced by Aspergillus species, which cause serious feed and food contaminations and affect farm animals deleteriously with acute or chronic manifestations of mycotoxicoses. On farm, both pre-harvest and post-harvest strategies are applied to minimize the risk of aflatoxin contaminations in feeds. The great economic losses attributable to mycotoxin contaminations have initiated a plethora of research projects to develop new, effective technologies to prevent the highly toxic effects of these secondary metabolites on domestic animals and also to block the carry-over of these mycotoxins to humans through the food chain. Among other areas, this review summarizes the latest findings on the effects of silage production technologies and silage microbiota on aflatoxins, and it also discusses the current applications of probiotic organisms and microbial products in feeding technologies. After ingesting contaminated foodstuffs, aflatoxins are metabolized and biotransformed differently in various animals depending on their inherent and acquired physiological properties. These mycotoxins may cause primary aflatoxicoses with versatile, species-specific adverse effects, which are also dependent on the susceptibility of individual animals within a species, and will be a function of the dose and duration of aflatoxin exposures. The transfer of these undesired compounds from contaminated feed into food of animal origin and the aflatoxin residues present in foods become an additional risk to human health, leading to secondary aflatoxicoses. Considering the biological transformation of aflatoxins in livestock, this review summarizes (i) the metabolism of aflatoxins in different animal species, (ii) the deleterious effects of the mycotoxins and their derivatives on the animals, and (iii) the major risks to animal health in terms of the symptoms and consequences of acute or chronic aflatoxicoses, animal welfare and productivity. Furthermore, we traced the transformation and channeling of Aspergillus-derived mycotoxins into food raw materials, particularly in the case of aflatoxin contaminated milk, which represents the major route of human exposure among animal-derived foods. The early and reliable detection of aflatoxins in feed, forage and primary commodities is an increasingly important issue and, therefore, the newly developed, easy-to-use qualitative and quantitative aflatoxin analytical methods are also summarized in the review.

Keywords: aflatoxin, Aspergillus, storage conditions, mitigation strategies, livestock

Introduction

Mycotoxins are harmful secondary metabolites produced by a variety of mold species that represent serious health risks to both humans and household animals (Beardall and Miller, 1994) and, not surprisingly, they cause both acute and chronic diseases called mycotoxicoses. The chronic pathological conditions develop over a longer period of time through the consumption of both cereals and animal products, e.g., milk, meat, and eggs. They represent a risk factor to human health directly in the food chain and through biological transformations as well. Mycotoxinogenic fungi are present mainly in small grains like wheat, barley, rye, rice, triticale, and corn (Miller, 2008; Gacem and El Hadj-Khelil, 2016; Udovicki et al., 2018) and also in different feedstuffs. In fact, aflatoxins were first discovered following a severe livestock poisoning incident in England involving turkeys (e.g., Amare and Keller, 2014; Keller, 2019). In addition, aflatoxins may also occur in peanuts, figs, pistachios, Brazil nuts and cottonseeds.

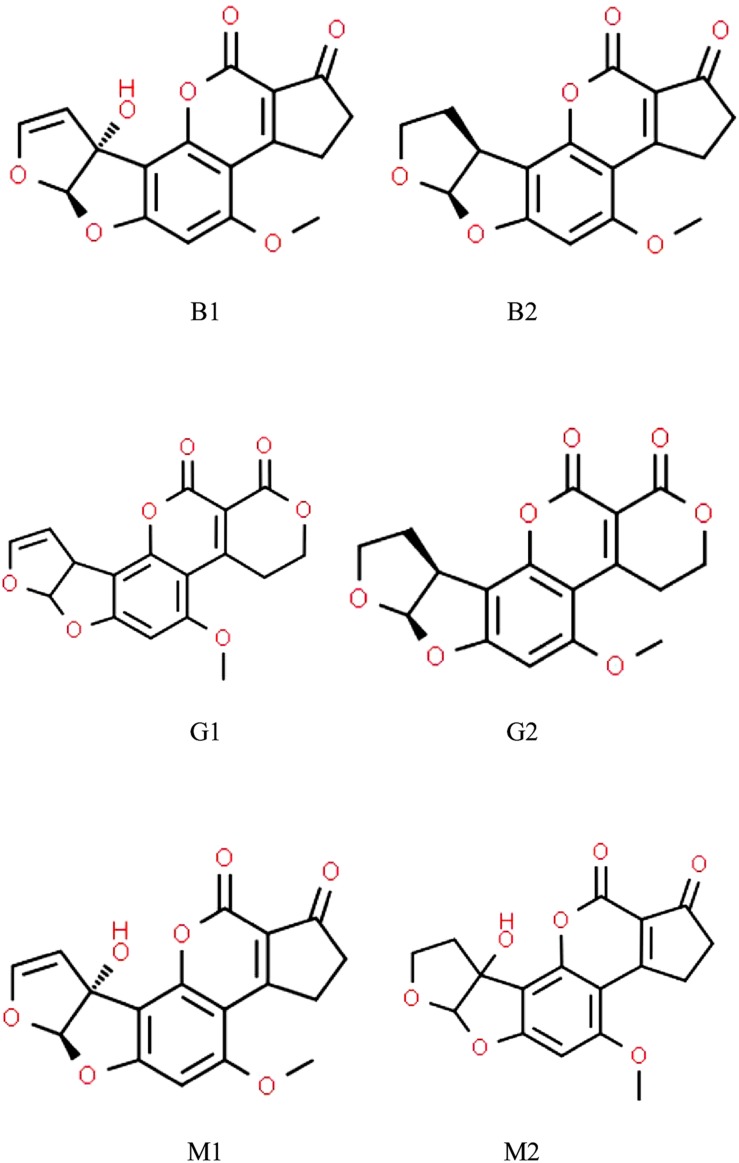

A number of Aspergillus spp. belonging to sections Flavi, Ochraceorosei and Nidulantes have the ability to produce the harmful, carcinogenic difuranocoumarin derivatives called aflatoxins (Varga et al., 2015; Chen A.J. et al., 2016; Niessen et al., 2018; Frisvad et al., 2019). Aspergillus flavus, Aspergillus parasiticus, and Aspergillus nominus are the most often detected aflatoxigenic Aspergilli in feed (Table 1). Aflatoxin producer Aspergilli are of paramount importance because the aflatoxins synthesized by them are among the strongest naturally occurring carcinogenic substances (Kumar et al., 2008). Considering their chemical structures, aflatoxins are furanocoumarin derivatives (Figure 1), of which aflatoxin M1 (AFM1), a hydroxylated derivative of aflatoxin B1 (AFB1), occurs in milk and in various dairy products (Prandini et al., 2009; Giovati et al., 2015). AFM1 is a distinguished target in on-going mycotoxin-related research, because AFM1 consumption may be exceptionally dangerous for children especially at younger ages (Udomkun et al., 2017; Rodríguez-Blanco et al., 2019; Ojuri et al., 2019).

TABLE 1.

Aflatoxin producer Aspergillus species detected in feed.

| Country | Type of feed | Isolated Aspergillus spp. | References |

| Argentina | Maize silage, corn grains, cotton seed, finished feed | A. flavus, A. parasiticus | Alonso et al., 2009 |

| Argentina | Maize silage | A. flavus, A. parasiticus | González Pereyra et al., 2011 |

| Brazil | Concentrated feed and maize silage | A. parasiticus, A. nomius | Variane et al., 2018 |

| Egypt | Maize silage | A. flavus | El-Shanawany et al., 2005 |

| France | Maize silage | A. parasiticus | Garon et al., 2006 |

| Ghana | Corn grain | A. flavus | Dadzie et al., 2019 |

| Indonesia | Maize of livestock feed | A. flavus | Sukmawati et al., 2018 |

| Iran | Silage, concentrate, hay, TMR | A. flavus | Davari et al., 2015 |

| Malaysia | Corn grains | A. flavus | Zulkifli and Zakaria, 2017 |

| Malaysia | Wheat and barley | A. flavus | Reddy and Salleh, 2010 |

| Pakistan | Feed samples | A. flavus, A. parasiticus | Usman et al., 2019 |

| Saudi Arabia | Animal feedstuff samples | A. flavus, A. parasiticus, A. nomius | Gherbawy et al., 2019 |

| Serbia | Corn, wheat, barley, soybean and sunflower grains | A. flavus | Lević et al., 2013 |

| Spain | Barley grains | A. flavus, A. parasiticus | Mateo et al., 2011 |

| Tanzania | Corn grains | A. flavus | Manoza et al., 2017 |

FIGURE 1.

Chemical structures of aflatoxins most frequently found in animal husbandry.

The risks associated with mycotoxins have an enormous economic impact, which heavily supports the need for further research in this field (Gnonlonfin et al., 2013). The scope of future mycotoxin-linked studies should be broadened and should focus more on the prevention of mycotoxin production and the reduction of their deleterious effects. One of the major objectives of current investigations is the breeding and cultivation of novel plant varieties/hybrids more resistant to infections by mycotoxin producer fungi. Another major goal focuses on the accuracy of the storage of crops and crop products, especially silage, to control the production of mycotoxins more tightly (Driehuis et al., 2018; Ogunade et al., 2018; Glamočić et al., 2019). A further important step in mycotoxin control would be to make feeding practices more rigorous to prevent mycotoxins from entering the body of animals in the first place (Aslam et al., 2016; Shanakhat et al., 2018). Furthermore, countermeasures may also include the application of various mycotoxin binding agents mixed with the feed (De Mil et al., 2015; Vila-Donat et al., 2018). Besides agricultural and technological approaches combating aflatoxins successfully, we also need to develop more sensitive and more reliable analytical methods (Kos et al., 2016).

To eradicate or at least to decrease mycotoxins considerably in the feed and food chain is undoubtedly a high-complexity and highly prestigious aim, which absolutely requires the effective cooperation of experts working in different fields. Such expanding co-operations will hopefully help on-going research obey the “from farm to fork” principle more. In this case, this concept means that we need to deal not only with production, storage and processing issues but also their impacts on human health as well (Fink-Gremmels, 2008b; Ogunade et al., 2014; Asemoloye et al., 2017).

In this review, we focus on special parts of the feed and food chain like silage production and mitigation of mycotoxins by microbial products. A special attention will be paid to novel findings, which may help the feed management in animal husbandry to prevent and alleviate aflatoxin contamination. Other major issues tackled by this review include new pieces of information on the deleterious physiological effects of aflatoxins on domestic animals, which help us further in proper risk assessment and management. Moreover, up-to-date analytical tools and methods to measure aflatoxins precisely both on farms and analytical laboratories will also be covered. We hope that shedding light on the high-complexity relations between aflatoxin producer Aspergilli, aflatoxin contaminations in feeds and feeding practices in animal husbandry will also give us new hints on the efficient control of aflatoxin contaminations in feeds and minimizing the carry-over of these harmful myctotoxins to humans through the food chain.

Aflatoxin Production in Fungi: Biosynthesis and Regulation

Considering the aflatoxin biosynthetic pathway acetate molecules are converted to norsoloinic acid at first by two fatty acid synthases, a polyketide synthase and a monooxygenase (Ehrlich et al., 2010; Yu, 2012; Roze et al., 2013). The biosynthesis proceeds through the intermediates averantin, averufin, versiconal and branches at versicolorin B to give rise to aflatoxin B1 and G1 via the versicolorin A/sterigmatocystin and to aflatoxin B2 and G2 via the versicolorin B/dehydrosterigmatocystin pathways, respectively (Yu, 2012). The letters B and G stand for the blue and green fluorescence of these compounds observable under ultraviolet light, when separated by thin-layer chromatography (Yu, 2012). The aflatoxin biosynthetic gene cluster is sophisticatedly regulated by both local (AflR and AflS) and global (Velvet Complex) regulatory elements (Amaike and Keller, 2011; Alkhayyat and Yu, 2014; Amare and Keller, 2014; Gil-Serna et al., 2019; Keller, 2019). Environmental factors like the availability of carbon and nitrogen sources, changing pH, temperature and light conditions as well as variations in the redox status of the fungal cells all have their impacts on aflatoxin production (Alkhayyat and Yu, 2014). Among environmental stresses, oxidative stress seems to play a pivotal role in the initiation of aflatoxin production (Reverberi et al., 2010; Hong et al., 2013; Roze et al., 2013; Amare and Keller, 2014). Plant–fungus interactions also affect the biosynthesis of aflatoxins e.g., through oxylipin production, which have been reviewed e.g., by Pusztahelyi et al. (2015). Undoubtedly, a deeper understanding of the elements and regulation of the aflatoxin biosynthetic gene clusters operating in aflatoxigenic fungi is an important prerequisite for the development of novel and successful mycotoxin control strategies in the future (Alkhayyat and Yu, 2014; Gil-Serna et al., 2019).

Fungal Activity and Aflatoxin Production in Stored Grains

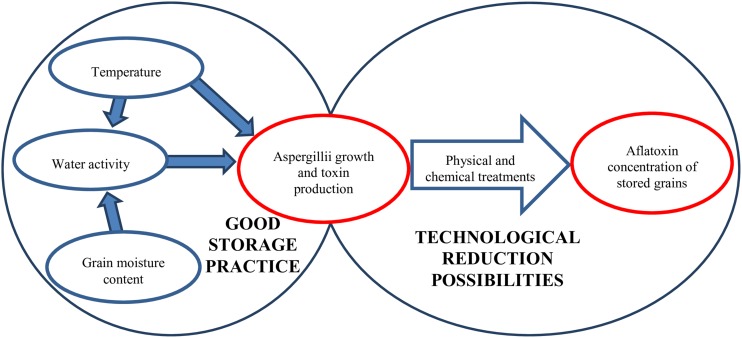

Aflatoxin-producing Aspergilli (Varga et al., 2015; Chen A.J. et al., 2016; Niessen et al., 2018; Frisvad et al., 2019) may originate from crop fields but post-harvest infections have also been reported (Gachara et al., 2018). Aflatoxin production cannot be linked strictly to any specific phase of growth or processing status although poorly managed post-harvest conditions during drying and storage can result in rapid increase in mycotoxin concentrations (Hell et al., 2010; Chulze, 2010). Grain drying is costly but selecting a variety or hybrid optimal for a given crop field can help farmers to harvest cereals with lower than 13–15% kernel moisture contents, which is required for safe storage (Magan and Aldred, 2007) (Figure 2). Nevertheless, artificial drying is unsurmountablein most cases.

FIGURE 2.

Factors influencing the aflatoxin content of grains during storage.

Obeying quality regulations, the recommended drying temperature is less than 65°C for most feed cereals and below 90°C for corn (Hellevang, 2013). Of course, these high drying temperatures will also have on impact on the Aspergillus spp., which contaminate grains. A. flavus has an outstandingly high heat tolerance in comparison to other fungi with an upper tolerance limit of 40°C (Neme and Mohammed, 2017). Prencipe et al. (2018) also found that while the growth of A. flavus was suboptimal above 40°C this relatively high temperature resulted in the most intensive aflatoxin synthesis on chestnut. Hawkins et al. (2005) found that 60°C drying temperature still had no adverse effect on A. flavus thriving on corn kernels but raising the temperature up to 70°C significantly decreased fungal infection. Favorable effects of high drying temperature in the restriction of fungal growth were also reported for rice (Hell and Mutegi, 2011).

Unfortunately, the aflatoxin molecules are highly heat-stable as their decomposing temperature is 268–269°C (Peng et al., 2018). As a result, simple drying technologies cannot decrease aflatoxin concentrations significantly in stored grains. On the other hand, elongated high-temperature treatments may have beneficial effects (Lee et al., 2015).

The temperature, kernel moisture content and relative humidity during storage all influence the physiological processes of fungi. As demonstrated, 18 – 19°C temperature and 12 – 13% moisture content were the limiting factors for the growth and activity of the Aspergilli (Villers, 2014; Mwakinyali et al., 2019), although lower temperature (8 – 10°C) may also be permissive for growth and mycotoxin production when the grain moisture content is higher (Mannaa and Kim, 2017). Although these values are accepted widely in good storage practices under continental climatic conditions the relative humidity of grain silos are higher during the cold months, which results in higher water binding by the grains. Nevertheless, the lower temperature hinders increases in microbial activity, and the tolerable water activity is 0.70 for the different Aspergillus species (Mannaa and Kim, 2017). It is important to note that ‘hot spots’ can develop in grain heaps because of insects or increased grain physiological activity and the released heat and moisture can support fungal growth. Therefore, maintaining good hygienic practice and controlling the temperature of the grain heaps are adequate and necessary measures during storage (Magan et al., 2003; Peng et al., 2018).

There are several procedures applicable to decrease fungal infection and mycotoxin production in kernels during storage (Table 2). Size separation by sieving and density separation by gravity table are useful measures as the lighter, smaller and broken kernels and the small components of heap may be infected or damaged by fungi and, therefore, they can be starting points for further deterioration. Not surprisingly, their removal significantly decreases aflatoxin contamination (De Mello and Scussel, 2007; Shi et al., 2014; Peng et al., 2018).

TABLE 2.

Summary of possibilities and examples for the reduction of the aflatoxin content of stored grains.

| Method | Effect | References | |

| Removal | Cleaning and sorting by size and density | Only small Brazil nuts (smaller than 36.6 mm length and 6.3 g weight) contained AFB1 | De Mello and Scussel, 2007 |

| Corn particles passed 5.16 mm sieve contained 46 times higher more toxin than the over fraction and lower density kernels contain 50 times higher aflatoxin | Shi et al., 2014 | ||

| Sorting by color | UV light, fluorescent and multi spectral analysis can be used to detect contaminated kernels | Pasikatan and Dowell, 2001; Vasishth and Bavarva, 2016; Stasiewicz et al., 2017; Tao et al., 2018 | |

| Removal of contaminated part by dehulling and polishing | Dehulling removed 92% of the initial aflatoxin content from corn kernel | Siwela et al., 2005 | |

| Aflatoxin residuals in corn after crushing and dehulling was almost negligible | Fandohan et al., 2005 | ||

| Dehulling decreased AF content of corn by 5.5–70% | Mutungi et al., 2008 | ||

| Dehulling and whitening of rice kernel resulted 96% decrease in AF content in polished broken grains and 79% in polished whole kernels | Castells et al., 2007 | ||

| Dehulling of corn kernels resulted in 88 and 92% reduction in AFB1 and AFB2 levels | Matumba et al., 2015 | ||

| Reduction, destruction | Thermal treatment for a long time | Heating at 100 and 150°C for 90 min decreased the AFB1 content of soybean 41.9 and 81.2%, respectively | Lee et al., 2015 |

| Oxidation by ozone | 2.8 and 5.3 mg/l ozone concentration applied for 4 hours resulted 76–84% decrease in AFB1 content of poultry feed | Torlak et al., 2016 | |

| 66–95% AFB1 reduction in peanut, corn and wheat kernel | Ismail et al., 2018 | ||

| Irradiation by ionizing and non-ionizing radiation | 25 kGy gamma irradiation resulted 43% decrease, microwave heating for 10 min at 1.45 kW resulted 32% decrease, direct solar irradiation for 3–30 h resulted 25–40% decrease in AFB1 content of poultry feed | Herzallah et al., 2008 | |

| 4, 6, and 8 kGy gamma irradiation doses resulted 15–56% reduction in aflatoxin content for corn, wheat and rice kernels | Mohamed et al., 2015 | ||

| 5 and 10 kGy irradiation doses resulted in 69.8 and 94.5% decreases in AFB1 content, respectively | Markov et al., 2015 | ||

| Pulsed light treatment (0.52 J/cm2/pulse in spectrum of 100–1100 nm with a xenon flash lamp) resulted 75–90% decreases in AFB1 and AFB2 contents of rice and rice bran | Wang et al., 2016 | ||

| 6 and 10 kGy gamma irradiation doses resulted 90 and 95% reduction in AFB1, respectively | Serra et al., 2018 | ||

| In peanuts, 5–9 kGy gamma irradiation doses result 20–43% decrease in aflatoxins, microwave radiation at 360, 480, and 600 W resulted 59–67% decrease, combined treatments have higher than 95% efficiency | Patil et al., 2019 | ||

| Destruction by cold plasma | Hazelnuts, peanuts, and pistachio nuts treated with air gases plasma for 20 min resulted 50% decrease in total aflatoxins, SF6 plasma application resulted only 20%reduction | Basaran et al., 2008 | |

| Atmospheric plasma generated with 400–1150 W power for 1–12 min resulted 46–71% decrease in AFB1 in peanuts | Siciliano et al., 2016 | ||

| High voltage atmospheric cold plasma applied for 1 and 10 min resulted 62 and 82% reduction in AFs levels of corn. | Shi et al., 2017 | ||

| Atmospheric and low pressure cold plasma reduced the AFB1 content of hazelnut by 72–73% | Sen et al., 2019 |

Hand sorting based on visible fungal infections is a very useful tool to decrease the aflatoxin B1 (AFB1) content of corn kernels but obviously this is not a viable option in industrial scale (Matumba et al., 2015). Another possibility is optical sorting because A. flavus contaminated corn kernels emit bright greenish-yellowish light when illuminated by UV light enabling separation using suitable optical equipment. Unfortunately, such light emission does not occur in each case and hidden, internal fungi contaminations have no visible effects either. Nevertheless, a sorting method based on the evaluation of red and green light reflectance was also developed to separate aflatoxin containing peanuts and another one for cleaning pecans, based on fluorescence (Pasikatan and Dowell, 2001). It is noteworthy that a low cost multi-spectral analyzer was manufactured to screen single corn kernels at nine distinct wavelengths in the 470 – 1550 nm region for qualitative use (Stasiewicz et al., 2017). Although fluorescent optical techniques have higher sensitivities and specificities than near infrared spectroscopy-based and hyperspectral imaging methods near infrared spectroscopic evaluations seem to have greater capabilities to reveal both aflatoxin and fungal contaminations. Most importantly, these techniques have already been applied in automatic sorters (Tao et al., 2018). Color analyses can be combined easily with other visible properties. For example, the Raspberry Pi optical analytical equipment (Vasishth and Bavarva, 2016) is able to sort peanuts based on their color, size, edge length and area of kernel with more than 40 kg/h sorting capacity. It is foreseeable that recent improvements in computing techniques will open new ways for visual analyses in combating both fungi and their mycotoxins.

Dehulling, the removal of external layers of kernel surface, can be an effective tool to decontaminate grains from toxigenic fungi and significantly decreases the aflatoxin content of grains (Siwela et al., 2005; Peng et al., 2018). This beneficial effect could be improved further by floating and washing before application (Fandohan et al., 2005; Mutungi et al., 2008; Matumba et al., 2015; Hadavi et al., 2017). Polishing rice kernels is also effective to reduce aflatoxin and, hence, more than nine-fold decrease in contamination was recorded (Castells et al., 2007).

Application of ozone during cereal storage is a relatively new method to improve storage conditions, based on the combined antifungal and insecticide effects of this reactive gas (Isikber and Athanassiou, 2015). Importantly, ozone treatments reduce mycotoxin contaminants without any negative effect on the quality of the grains (Tiwari et al., 2010; Zhu, 2018), and eliminate aflatoxins with high efficiency (66–95% of the original toxin concentration) in cereal grains and flours, as well as in soybean and peanut (Torlak et al., 2016; Ismail et al., 2018).

Another physical method to reduce aflatoxin contaminations is irradiation. Several radiation sources have been evaluated thus far and many of them were found to be effective. For example, the advantageous effects of UV in liquid phase (Patras et al., 2017), gamma irradiation in corn (Markov et al., 2015; Serra et al., 2018), in other cereal kernels (Mohamed et al., 2015), in peanuts (Patil et al., 2019) and in poultry feed (Herzallah et al., 2008) have been reported in a number of publications. Direct sunlight was also effective in aflatoxin reduction in poultry feed (Herzallah et al., 2008) and, in addition to exposures to direct light, the applicability of pulsed light has also been tested and evaluated, and it has already been employed in new decontamination technologies (Moreau et al., 2013). Meanwhile exposure to pulsed light was effective in liquid medium (Moreau et al., 2013) pulsed polychromatic light applied with a simple xenon flash lamp also resulted in significant decreases in the aflatoxin content in cereal kernels (Wang et al., 2016).

Cold plasma treatment is another possible physical treatment against pathogens and fungal toxins. Cold plasma is generally a result of atmospheric dielectric discharge, and the effects of pressure (atmospheric or vacuum), air composition, humidity and flow rate, discharging power and treatment time are under continuous evaluation nowadays in different cereals and nuts (Basaran et al., 2008; Siciliano et al., 2016; Shi et al., 2017; Misra et al., 2019; Sen et al., 2019). Cold plasma treatments are cost effective, ecologically neutral and have only a negligible effect on the quality of the grains when compared to classical detoxification methods (Hojnik et al., 2017).

Fungal Activity and Aflatoxin Production in Silage

Climate change has a major impact on agriculture in many ways and, thereby, many studies have already been published on the effects of climate change on the growth, spread and toxin production of mycotoxigenic fungi on economically important crops (Magan et al., 2011; Paterson and Lima, 2011; Wu et al., 2011; Battilani et al., 2012, 2016).

Aflatoxin contaminations of maize, wheat, etc. have become a major safety issue in the European agricultural industry (Battilani et al., 2016), and aflatoxin producer Aspergillus spp. have also been detected in temperate Europe (Dobolyi et al., 2013). As a consequence, mycotoxins including the Aspergillus-derived harmful aflatoxins may also contaminate European agricultural products – a foreseeable threat, which we should by no means neglect (Magan et al., 2011; Battilani et al., 2012, 2016; Dobolyi et al., 2013).

Maize silage, one of the most important components in the feeding of dairy cows in Europe and worldwide, can be contaminated by several mycotoxin-producer fungi entering the feed production chain at various stages (Ogunade et al., 2018). Not surprisingly, aflatoxin contaminations can be detected occasionally both before and after ensiling (Storm et al., 2014; Gallo et al., 2015; Ogunade et al., 2018; Peng et al., 2018). Therefore, the rigorous control of the growth of aflatoxigenic fungi is of pivotal importance, if the production of aflatoxin-free silage is to be guaranteed (Borreani and Tabacco, 2010; Ogunade et al., 2018).

Although microaerophilic conditions and low pH, which are typical features of silage fermentations, may prevent the growth of the majority of molds, some species of the genera Aspergillus, Byssochlamys, Monascus, Penicillium, and Trichoderma are able to survive even under ensiling conditions (Mansfield and Kuldau, 2007; Pereyra et al., 2008). To make things even worse, the aflatoxigenic capacity of the Aspergillus section Flavi strains derived from silage samples is remarkable. For example, del Palacio et al. (2016) demonstrated that 27.5% of these strains produced AFB1, 17.5% of them aflatoxin G2 (AFG2) and 10% synthesized aflatoxin G1 (AFG1). Interestingly, only 5% of the strains produced AFB2 (del Palacio et al., 2016). In another study concomitantly performed in Pakistan (Sultana et al., 2017), A. niger, A. flavus, A. fumigatus, A. ochraceous, and A. terrus were identified in both fresh fodder and corn silage. Importantly, the authors also found AFB1 in 37.5% of the fresh fodder and in 41.7% of the corn silage samples with average AFB1 concentrations of 9.5 and 8.4 μg/kg, respectively, meanwhile AFB2 was present in only two samples (1.2 and 1.3 μg/kg), and none of the analyzed samples was contaminated by AFG1 or AFG2 (Sultana et al., 2017). In Southern Brazil, aflatoxigenic A. parasiticus and A. nomius strains have been detected in the tested silage and concentrated feed samples (Variane et al., 2018).

Considering the world-wide occurrence of aflatoxin contaminations (Table 3), AFB1 has been reported in corn silage in Argentina (González Pereyra et al., 2008, 2011), in Brazil (Keller et al., 2013; Schmidt et al., 2015), and in France (Richard et al., 2009). Total aflatoxin contaminations have also been determined in silage samples collected in Iran (Hashemi et al., 2012) and in Uruguay (del Palacio et al., 2016).

TABLE 3.

Worldwide occurrence of aflatoxins in silage.

| Country | Mycotoxin | Sample | No. of samples | No. of positive sample (Incidence%) | Mean concentration (μg/kg) | Range (μg/kg) | References |

| Argentina | AFB1 | Corn silage | 35 | 6(17.0%) | – | 1.4 – 155.8 | González Pereyra et al., 2008 |

| Argentina | AFB1 | Trench silo | 43 | 6(14.0%) | – | 1.0 – 190.0 | González Pereyra et al., 2011 |

| Argentina | AFB1 | Silo bag | 35 | 19(54.3%) | – | 5.8 – 47.4 | González Pereyra et al., 2011 |

| Brazil | AFB1 | Corn silage | 116 | 15(13.0%) | 33.0 | 2.0 – 61.0 | Keller et al., 2013 |

| Brazil | AFB1 | Corn silage | 327 | 3(0.9%) | 3.0 | 1.0 – 6.0 | Schmidt et al., 2015 |

| France | AFB1 | Corn silage | – | – | 28.0 | 7.0 – 51.3 | Richard et al., 2009 |

| Iran | Total AF | Silage | 42 | 7(16.7%) | 1.24 | 1.1 – 27.3 | Hashemi et al., 2012 |

| Uruguay | Total AF | Wheat silage | 220 | – | 17.0 | 6.1 – 23.3 | del Palacio et al., 2016 |

–, not evaluated data.

Microbial Biocontrol and Microbial Detoxification Products for Mycotoxin Mitigation in Animal Husbandry

In recent decades, several feasible and cost-effective strategies have entered the market aiming to mitigate the effects of feed mycotoxin contamination in animal husbandry, especially in the dairy industry. Technologies to reduce the incidence of mold and mycotoxin contaminations of silages can be employed in one of the three main phases (preharvest, harvest, ensiling) of silage production. During the preharvest phase, the appropriate agronomic practices may rely on (i) the use of crop varieties or hybrids, which are resistant to fungal infections, (ii) the application of pesticides and fungicides, (iii) adequate management of weeds and crop residues, (iv) the use of appropriate crop rotation, tillage, fertilization and irrigation and (v) the application of biocontrol agents, e.g., bacteria, yeasts, or atoxigenic strains of A. flavus or A. parasiticus (Gallo et al., 2015; Pfliegler et al., 2015; Ogunade et al., 2018; Peng et al., 2018). During the harvest phase, the most important factors that should be taken into consideration are proper harvest timing (maturity stage) and cutting height (to minimize soil contamination), as well as immediate storage of harvested feeds (Gallo et al., 2015; Ogunade et al., 2018; Peng et al., 2018).

Pre-harvest biocontrol microbes represent a promising and already widely applied method to lower mycotoxin risks in food and feed by protecting plants from pathogens and inhibiting the growth of molds during postharvest conditions. They both reduce economic loss caused by fungal infections and lower toxin levels in products (e.g., Pfliegler et al., 2015). Biocontrol agents compete for nutrients and space, may secrete antifungals or even parasitize molds, and can also stimulate host plant resistance (Liu et al., 2013) and, thereby, they mitigate the risk of plant infections and their undesirable consequences. Regarding Aspergilli infection and aflatoxin contamination, non-aflatoxigenic biocontrol Aspergillus flavus strains are most commonly applied to crops (Ehrlich, 2014; Weaver and Abbas, 2019), while biocontrol yeasts species are also effective, such as the 2-phenylethanol producing Wickerhamomyces anomalus (Hua et al., 2014). These biocontrol agents are mostly applied to protect plants directly used in food production but may exert their effects on plant parts that are to be ensiled for feed production concomitantly.

In the ensiling phase, attention must be payed to adequate particle size, proper silo size, immediate rapid filling, proper compaction, complete sealing (to maintain strictly anaerobic conditions), and the use of acid-based additives or microbial inoculants, e.g., lactic acid bacteria (Gallo et al., 2015; Ogunade et al., 2018; Peng et al., 2018). Some specific strains in the Lactobacillus (L. buchneri, L. fermentum, L. hilgardii, L. plantarum, L. reuteri, L. rhamnosus), Lactococcus (L. lactis), Leuconostoc, and Pediococcus (P. pentosaceus) genera can inhibit or can even prevent completely the growths of various mycotoxigenic molds and their mycotoxin productions as well (Dalié et al., 2010; Cavallarin et al., 2011; Queiroz et al., 2012; Dogi et al., 2013; Ahlberg et al., 2015; Ma et al., 2017; Gallo et al., 2018; Zielińska and Fabiszewska, 2018; Ferrero et al., 2019). It is noteworthy that there is a wide spectrum of environmental factors which influence the antifungal activity of LAB, including the type of the matrix and culture medium, the availability of nutritional compounds, the incubation time and temperature (Dalié et al., 2010; Ahlberg et al., 2015; Leyva Salas et al., 2017). In addition, some biological (e.g., the natural microbiota), and chemical (e.g., pH, water activity) parameters will also affect the antifungal activity in a species-specific manner (Dalié et al., 2010; Ahlberg et al., 2015; Leyva Salas et al., 2017). Species- and strain-specific factors are noteworthy, for example both L. rhamnosus and L. plantarum were efficient against A. parasiticus only L. rhamnosus reduced the AFB1 levels produced by A. parasiticus (Dogi et al., 2013). Quite unexpectedly, the A. parasiticus – L. plantarum interaction even stimulated aflatoxin B1 production, which makes the use of L. plantarum undesirable as a silage inoculant.

In another study, a mixture of P. pentosaceus and L. buchneri reduced the adverse effects of rust infestation during ensiling and also decreased aerobic spoilage and aflatoxin production in maize silages with high levels of southern rust infestation (Queiroz et al., 2012). Importantly, L. buchneri increased the aerobic stability of the silage as well (Cavallarin et al., 2011). Inoculation of corn silage with a combined inoculant of L. buchneri and Lactococcus lactis improved the aerobic stability of the silage, and the higher silage density increased the stability further (Gallo et al., 2018). The interaction of L. buchneri, L. reuteri, L. plantarum, and L. fermentum strains reduced the AFB1 level, improved the stability and, furthermore, the microbiological and chemical purity of maize silage (Zielińska and Fabiszewska, 2018). In a most recent study by Ferrero et al. (2019), the authors examined the effect of L. buchneri, Lactobacillus hilgardii, and their combination on A. flavus contaminants and their aflatoxin production in maize silage. The results showed that the inoculation of corn silage with L. buchneri and L. hilgardii increased the aerobic stability and delayed the beginning of aerobic microbial degradation of maize silage, and indirectly reduced the risk of A. flavus emergence and aflatoxin B1 level after silage opening.

Ma et al. (2017) examined the AFB1 binding capacity of various silage bacteria including L. plantarum, L. buchneri, P. acidilactici, and P. pentosaceus and found that high concentration of silage bacteria could bind the AFB1 content of maize silage but population, strain, viability, and medium acidity have all affected the efficacy of binding.

Antifungal compounds produced by LAB also reduce the mycotoxin production of molds (Ahlberg et al., 2015). These LAB-produced compounds cover organic acids (e.g., acetic, lactic, and propionic acid), carboxylic acids, phenolic compounds, including phenolic acids (gallic acid, tannins, benzoic acids, phenyllactic acid, hydroxyphenyllactic acid), fatty acids (caproic acid, decanoic acid, 3-hydroxydecanoic acid, coriolic acid, ricinoleic acid), volatile compounds (e.g., diacetyl, acetoin), cyclopeptides [e.g., cyclo(Phe-Pro), cyclo(L-Leu-L-Pro), cyclo(L-Met-L-Pro), cyclo(L-Tyr-L-Pro)], hydrogen peroxide, ethanol, reuterin, and proteinaceous compounds (Dalié et al., 2010; Li et al., 2012; Crowley et al., 2013; Le Lay et al., 2016; Leyva Salas et al., 2017).

Considering the mechanisms of actions of these antifungals, the dissociated forms of organic acids can decrease the intracellular pH within the cells, can increase the permeability of the cytoplasmic membrane, and finally can lead to the death of the fungal cells (Leyva Salas et al., 2017). In addition, H2O2 oxidizes directly the cellular proteins and the lipid components of the cellular membranes (Dalié et al., 2010). Nevertheless, the mechanisms of the antifungal actions of hydroxy fatty acids and proteinaceous compounds have remained yet to be elucidated (Dalié et al., 2010).

Silage decontamination may also be applied if measures to avoid contamination were proven ineffective. Such strategies are primarily based on the adsorbents. Advantages of using adsorbent feed additives over decontamination of the final product, e.g., milk, are their safety and inexpensiveness, and that they may simply be mixed into animal feed to achieve the desired effect. These products may lower the bioavailability of mycotoxins and can help to decrease toxic effects, as well as the amount of toxin detectable in the final product (meat or milk). Such strategies may involve the use of live microbial (LAB or yeast) cultures (usually termed microbial enterosorption, biosorption), microbial or plant extracts, other organic/inorganic materials such as activated carbons or charcoals, hydrated sodium calcium aluminosilicates, and various clay-based products (Kutz et al., 2009; Giovati et al., 2015). LAB can not only inhibit the growth of molds but are also able to bind aflatoxins in different matrices (Table 4; Ahlberg et al., 2015; Muck et al., 2018), thereby reducing the health risks of aflatoxins. Environmental conditions have a great impact on the aflatoxin binding capabilities of LAB (Dalié et al., 2010; Ahlberg et al., 2015; Ma et al., 2017), which is highly species-specific (Gomah et al., 2010; Dogi et al., 2013; Ahlberg et al., 2015). Some studies demonstrated that non-viable LAB cells had better binding capability for aflatoxin than viable LAB cells (Ahlberg et al., 2015; Damayanti et al., 2017; Ma et al., 2017). On the contrary, Liew et al. (2018) reported on a higher binding efficiency by living cells. Regardless of alive or dead bacterial cells, the aflatoxin binding seems to be reversible and the bound mycotoxins are released slowly over time (Verheecke et al., 2016).

TABLE 4.

Antifungal activity of lactic acid bacteria (LAB).

| LAB | Strain | Effect | References |

| Lactobacillus buchneri | NCIMB 40 788 | Decreased mold count, decreased AFB2 and increased aerobic stability of the silage | Cavallarin et al., 2011 |

| Lb. buchneri | 40788 | Decreased the population of spoilage fungi, and aflatoxin production in silages | Queiroz et al., 2012 |

| Lb. buchneri | R1102 | Bound AFB1 | Ma et al., 2017 |

| Lb. buchneri | LB1819 | Enhanced the fermentation and aerobic stability of maize silage | Gallo et al., 2018 |

| Lb. buchneri | A KKP 2047 p | Reduced mold count and decreased AFB1 amount | Zielińska and Fabiszewska, 2018 |

| Lb. buchneri | NCIMB 40788 | Reduced the risk of Aspergillus flavus outgrowth and AFB1 production after silage opening | Ferrero et al., 2019 |

| Lactobacillus fermentum | N KKP 2020 p | Reduced mold count and decreased AFB1 amount | Zielińska and Fabiszewska, 2018 |

| Lactobacillus hilgardii | CNCM I-4785 | Reduced the risk of Aspergillus flavus outgrowth and AFB1 production after silage opening | Ferrero et al., 2019 |

| Lactobacillus plantarum | RC009 | Reduce Aspergillus parasiticus growth rate | Dogi et al., 2013 |

| Lb. plantarum | PT5B | Bound AFB1 | Ma et al., 2017 |

| Lb. plantarum | K KKP 593 p, S KKP 2021 p | Reduced mold count and decreased AFB1 amount | Zielińska and Fabiszewska, 2018 |

| Lactobacillus reuteri | M KKP 2048 p | Reduced mold count and decreased AFB1 amount | Zielińska and Fabiszewska, 2018 |

| Lactobacillus rhamnosus | RC007 | Reduce Aspergillus parasiticus growth rate | Dogi et al., 2013 |

| Lactococcus lactis | O224 | Enhanced the fermentation and aerobic stability of maize silage | Gallo et al., 2018 |

| Pediococcus pentosaceus | 12455 | Decreased the population of spoilage fungi and aflatoxin production in silages | Queiroz et al., 2012 |

| Pediococcus acidilactici | R2142, EQ01 | Bound AFB1 | Ma et al., 2017 |

Based on various microbe species, sources, manufacturers, and formulations, live yeast products include several categories: yeast probiotics, Saccharomyces cerevisiae fermentation products (SCFP), dried yeast products (DY or DYP), brewery yeasts (BY), and active dry S. cerevisiae (ADSC) (Pizzolitto et al., 2012; Poppy et al., 2012; Gonçalves et al., 2017). Compared to live bacteria-based products, these yeast products are considered and employed as direct feed additives in most cases and are not applied at the ensiling phase (Giovati et al., 2015). Some bacterial species, e.g., Nocardia corynebacteroides (NC) are also added as direct feed additives for poultry (Tejada-Castañeda et al., 2008). Microbe-derived feed additive products are also based on yeasts, and include autolyzed yeast (AZ), inactivated yeast cells (IY), distillery yeast sludge, and yeast cell wall (YCW) products (Gonçalves et al., 2017; Plaizier et al., 2018).

Live yeast or bacterial cells intended to colonize the gastrointestinal tract (GIT) of humans, or in some cases, poultry or laboratory rodents, are occasionally termed probiotics (Śliżewska and Smulikowska, 2011; Pizzolitto et al., 2012; González Pereyra et al., 2014). However, especially in the case of ruminants, the use of live cells may not necessarily result in gastrointestinal colonization. The rumen’s own microbiota is also to be taken into account, as it can contribute to aflatoxin detoxification and degradation (e.g., biotransformation to aflatoxicol) (Upadhaya et al., 2009; Jiang et al., 2012). Aflatoxin B1 is absorbed in the rumen mainly at acidic pH (Pantaya et al., 2014), and the degradation of aflatoxins in rumen depends on both the animal species and feed type (Upadhaya et al., 2009). However, it must be noted that rumen colonization by A. flavus has also been recorded, leading to toxin production in rumen liquor (Nidhina et al., 2017).

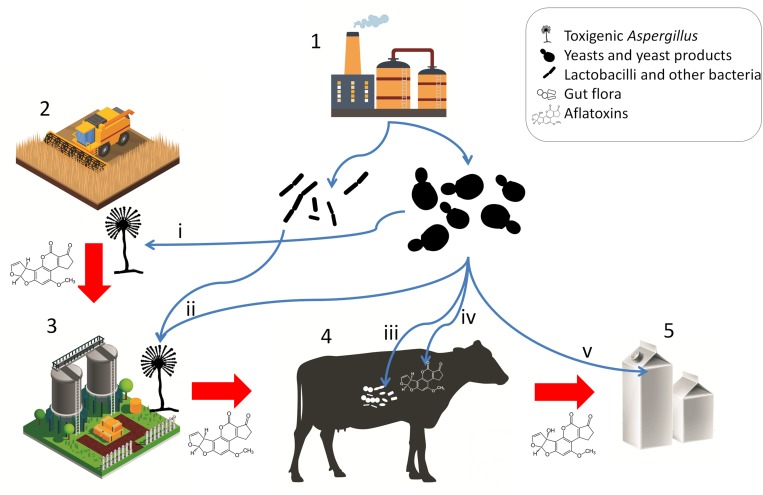

The products SCFP, DY, BY, and ADSC consist of yeast cells, the nutrient medium on which the yeasts were grown, and the metabolites produced by the yeasts and have been shown to increase DMI, milk yield, as well as milk fat and protein yield in lactating dairy cows (Poppy et al., 2012). However, these positive effects are attributed to adsorption of toxic substances and the modulation of the gut (prokaryote) microbiota, not to long-term gut colonization by the yeasts. Yeasts in fact are thought to play a negligible role in the microbiome of ruminants, although they may survive gastrointestinal conditions and retain their aflatoxin B1 binding ability under gastrointestinal conditions (Dogi et al., 2011). Various studies have shown the effects of these live yeast products on the microbiota of the cows, however, uncovering the underlying mechanisms and a holistic understanding of dairy cow gastrointestinal health still requires further research (Zhu et al., 2017; Huebner et al., 2019). Interestingly, YCW has also been shown to positively modulate the gut health in broiler chicken challenged with AFB1 or with Clostridium infection (Liu et al., 2018). These observations raise the possibility that yeast products, whether live or not, generally contribute to animal health both as bioadsorbents and as modulators of the gut prokaryote microbiota, as well as the immune status of the animal. Such positive effects may not only prevent toxicosis but result in increased feed intake and production (Pasha, 2008). In poultry feedstuff, S. cerevisiae strains have been tested and made commercially available as a probiotic microbe. It must be noted though, that the intended effect of the yeasts is not necessarily gut colonization and microbiome modulation, but aflatoxin adsorption (Śliżewska and Smulikowska, 2011; Pizzolitto et al., 2012), a role, which yeasts can effectively fulfill. The applications of microbes and microbial products for mycotoxin risk mitigation are summarized in Figure 3.

FIGURE 3.

Microbial products for mycotoxin mitigation in animal husbandry and their applications. Red arrows represent potential carry-over of mycotoxins or toxigenic Aspergilli. Blue arrows represent applications of microbes and microbe-derived products. (1) Fermentation and animal feed supplement industries; (2) crop production; (3) preparation and storage of silage and other feedstuffs; (4) livestock; (5) product; (i) pre-harvest biocontrol; (ii) antagonism in silage and feed; (iii) host gut microbiota and immune modulation, probiotic effect; (iv) enterosorption; (v) bioadsorption from product (milk). [Stock image credits: Freepik, macrovector, and vectorpocket].

Yeast cell wall β-D-glucans, glucomannans and mannan-oligosaccharides are responsible for the mycotoxin binding abilities of these products (Pfliegler et al., 2015). Some purified cell wall components have been tested in animal husbandry, such as mannan-oligosaccharides supplemented into the diet of Japanese quails affected by aflatoxicoses (Oguz and Parlat, 2005). However, no direct correlation between the amount of individual components and toxin binding are evident (Joannis-Cassan et al., 2011). Structural integrity and amount of the yeast cell wall is crucial in binding efficacy, while viability is not: heat-treatment can even increase adsorption capacity (Bueno et al., 2007; Joannis-Cassan et al., 2011). Toxin binding can reach saturation rapidly and is reversible, and mycotoxins are not modified chemically during the process (Bueno et al., 2007). It must be noted that some yeasts (reviewed by Pfliegler et al., 2015) and bacteria (Wang Y. et al., 2018) are known to be able to enzymatically degrade mycotoxins if applied in viable form.

A novel approach for the microbiological detoxification of animal feed is the screening of isolates from various environmental sources (Intanoo et al., 2018), instead of using the most widespread species, S. cerevisiae. Various bacteria and yeasts may exhibit toxin-binding or even toxin-degrading abilities, as well as biocontrol effects on toxigenic molds (Pfliegler et al., 2015) and these may be directly applied to supplement animal feed (Intanoo et al., 2018). Novel yeast species in this field include members of the genera Kluyveromyces and Pichia, both related to the widely used Saccharomyces. P. kudriavzevii has been successfully applied as a bioadsorbent feed additive to ameliorate the negative effects of AFB1 contamination on broiler chicken performance (Magnoli et al., 2017). Novel isolates of K. marxianus have also been proposed as bioadsorbents based on in vitro characterization (Intanoo et al., 2018). However, Battacone et al. (2009) found no evidence for AFB1 detoxification in ewes fed with Kluyveromyces lactis DYP, highlighting the need for rigorous testing of novel strains in different setups and with multiple animal species.

Apart from novel microbial strains, combined treatments of microbial and inorganic products constitute a promising strategy in ameliorating mycotoxin contamination. Recently, Jiang et al. (2018) found that both dietary clay and clay + SCFP reduced transfer of dietary AFB1 to milk as well as milk aflatoxin M1 (AFM1) concentration, while the combined treatment was the only one that also prevented the decrease in milk yield caused by AFB1. Thus, the potent adsorbing capability of inorganic products may act synergistically with the adsorbent, gut health-promoting and immunomodulatory effects of yeast products.

Microbial Detoxification Products to Counteract Aflatoxin Contamination in Dairy Products

Some studies have explored microbial aflatoxin decontamination strategies in dairy products, taking advantage of the high efficacy and relative ease of utilizing LAB and yeast, recently been reviewed by Assaf et al. (2019). Briefly, such microbial decontamination approaches rely on heat-killed or immobilized cells, and promising results were obtained when both LAB and yeasts were applied simultaneously. Heat-treatment of bacterial cells was found to improve binding capabilities in some studies (Pierides et al., 2000; Bovo et al., 2015; Assaf et al., 2018), while no such effect was reported by Kabak and Var (2008). Bacteria tested in the aforementioned studies include members of the genera traditionally considered probiotics and/or important in food production, as Bifidobacterium, Lactobacillus, or Pediococcus, and oddly, a potential pathogen, Enterococcus.

In UHT skim milk, both LAB and yeasts showed promising results (Corassin et al., 2013), and the binding of toxins to microbial cell walls was shown to be rapid, enabling short incubation times in potential industrial applications. Yeasts of the genera Saccharomyces and Kluyveromyces have been tested by Abdelmotilib et al. (2018), where the higher efficacy of heat-killed cells was also demonstrated for yeasts.

There are certain limitations on applying yeasts and bacteria for the decontamination of dairy products (Assaf et al., 2019), such as the need for their subsequent removal, reversibility of binding, or even legislations on tolerated number of live or dead microbial cells in products. Nevertheless, the high toxin binding capability and the safety of heat-killed cells toward consumers compared to chemical methods makes microbial decontamination a promising strategy.

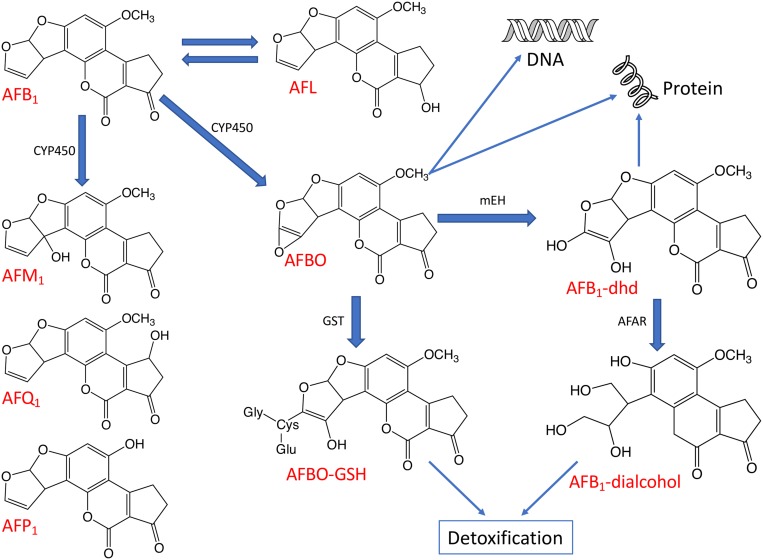

Aflatoxin Metabolism in Livestock

The toxicity of AFB1 is strictly related to the bioactivation and detoxification pathways operating animals in vivo (Figure 4). Indeed, AFB1 is a “pro-carcinogen” that is activated biologically by cytochrome P450 (CYP450), a microsomal enzyme of phase I detoxification (oxidation) to the extremely reactive and electrophilic AFB1-8,9-epoxide (AFBO). This harmful AFB1 derivative is able to covalently bind to macromolecules such as DNA and proteins, thereby forming adducts, which cause acute and chronic cytotoxicity, DNA mutations and eventually expressing carcinogenic activity (Diaz et al., 2010; Deng et al., 2018).

FIGURE 4.

The major metabolic pathways of AFB1. The aflatoxin derivatives presented here include aflatoxin B1 (AFB1), aflatoxin M1 (AFM1), aflatoxin Q1 (AFQ1), aflatoxin P1 (AFP1), AFB1-8,9-epoxide (AFBO), AFB1-8,9-dihydrodiol (AFB1-dhd) and aflatoxicol (AFL). Some enzymes taking part in the biotransformation and detoxification of aflatoxins are also indicated including cytochrome P450 (CYP450), glutathione-S-transferase (GST), microsomal epoxide hydrolase (mEH), and aflatoxin-aldehyde reductase (AFAR).

Moreover, AFBO can be hydrolyzed to AFB1-8,9-dihydrodiol (AFB1-dhd) by an epoxide hydrolase. AFB1-dhd is able to react with proteins causing cytotoxicity or, alternatively, AFBO can be metabolically detoxified via conjugation with glutathione (GSH) by glutathione S-transferase (GST), a phase II detoxification enzyme. This pathway is considered as one of the main routes of AFBO detoxification (Diaz et al., 2010; Deng et al., 2018). Microsomal epoxide hydrolase (mEH) and aflatoxin-aldehyde reductase (AFAR) can also transform reactive AFB1 to AFB1-dialcohol, a real detoxified AFB1 derivative, which can be excreted in urine (Guengerich et al., 2001; Deng et al., 2018).

It is important to note that several isoenzymes belonging to the CYP450 supergene family metabolize AFB1 through oxidative reactions, producing various metabolites with different carcinogenic potential.

In addition to the highly reactive and toxic AFBO, the main AFB1 metabolic pathways described in animals can also give rise to relatively less toxic metabolites such as aflatoxicol (AFL) by ketoreduction or AFM1 by hydroxylation and non-toxic metabolites such as AFB2a or aflatoxin Q1 (AFQ1) by hydroxylation or aflatoxic P1 (AFP1) by demethylation (Figure 4; Dohnal et al., 2014; Deng et al., 2018).

Current literature data indicate that the rates of the bioactivation and detoxification of AFB1 contribute greatly to the manifestation of its toxic effects. Furthermore, the metabolism of aflatoxins shows considerable interspatial differences and also significant variations among individuals belonging to the same species, depending for example on the age (Dohnal et al., 2014).

In conclusion, the largely different sensitivities of different animal species to the toxic effects of aflatoxins could be explained mainly with the remarkable variability of the metabolic pathways and enzymes that contribute to the bioactivation and detoxification of aflatoxins (Dohnal et al., 2014).

Poultry

Poultry are generally very sensitive to AFB1 and adverse health effects have been reported in turkeys, quail, chickens, and ducks but there is a great variability in species-specific sensitivities to aflatoxins (Klein et al., 2000; Diaz et al., 2010; Rawal et al., 2010). Several toxicological studies pointed at the existence of a sensitivity scale starting from the less resistant young duck and turkey, followed by quails, up to the more resistant chickens. Obviously, species-specific differences in the AFB1 biotransformation pathways, e.g., in AFB1 modifying hepatic microsomal enzymes, could explain the varying susceptibilities of the species (Lozano and Diaz, 2006). It has been reported in some works that the microsomal liver fractions produced only AFBO in avian species (Figure 4), unless these animals were stimulated with CYP450 inducers (Lozano and Diaz, 2006). However, the ability of poultry species to metabolize AFB1 to AFM1 was reported in other works, in which the AFM1 was detected in different tissues (Madden and Stahr, 1995; Wang H. et al., 2018). Lozano and Diaz (2006) reported that turkey microsomes produced 1.8–3.5 times more AFBO than quail and chicken microsomes. Furthermore, Diaz et al. (2010) suggested that the higher resistance of chicken to AFB1 in comparison to quail could be due to a lower activation rate of AFB1 to AFBO in chicken and also to a lower affinity for AFB1 of the chicken microsomal enzymes.

The high susceptibility of poultry to AFB1 appears to be a consequence of both the high activity of phase I microsomal detoxification enzymes to form AFBO, and to a low GST efficiency as well to conjugate AFBO with GSH (phase II detoxification). Some works reported that the partial or complete lack of GST-dependent detoxification of AFBO was the major reason for the exceptionally high susceptibility of poultry including turkeys to AFB1 (Klein et al., 2000; Rawal et al., 2010).

Another metabolic pathway that may contribute to the extreme susceptibility of poultry to aflatoxins could be the reduction of AFB1 to AFL via cytosolic reductase because the cytosolic metabolite AFL is produced in larger quantities in turkey and duck than in quail and chicken. This fact underlines that the formation of AFL cannot be regarded as a real detoxification pathway in these birds, moreover, microsomal dehydrogenase may oxidize AFL back to AFB1, increasing the physiological half life of AFB1 (Lozano and Diaz, 2006). Other aflatoxin metabolic pathways may also be involved in the manifestation of the high cytotoxicity of AFB1 in poultry species.

Furthermore, it has also been reported that AFB1 susceptibility correlated with age in both turkeys and broiler chickens. When livers obtained from 9, 45, and 61 day-old turkeys were compared, microsomes from younger birds were more active in AFB1 bioactivation than those from older ones (Klein et al., 2002). Moreover, Wang H. et al. (2018) underlined the efficient bioactivation of AFB1 by CYP enzymes and the deficient detoxification by GST enzymes in younger 7-day old broilers.

Aflatoxin residues were detected in various tissues mainly in liver, kidney, the organs where AFB1 is metabolized, but also in reproductive organs, in gizzard, breast and in legs (Herzallah et al., 2014). The metabolites AFB1, AFQ1, and AFL were excreted as such or as glucuronyl conjugates from bile in feces (Yunus et al., 2011). Some of these metabolites (AFM1 and AFL) have been found in liver, kidneys and thigh muscles (Micco et al., 1988). The concentrations of AFB1 residues decreased in the livers and muscles of all the birds after the suspension of mycotoxin feeding, and the elimination of AFB1 from tissues was faster in older than in younger birds (Yunus et al., 2011). The dietary exposure to aflatoxin of hens, even at low concentrations, may also cause contamination of eggs. AFB1 residues appeared in eggs after 5 days following the administration of AFB1 contaminated feedstuffs, and they accumulated in line with protracted feeding with contaminated grain (Hassan et al., 2012). However, the amount of mycotoxin contaminants was below 0.1% of the AFB1 intake owing to the AFB1 metabolism in the birds. Few works also demonstrated the presence of hydroxylated AFB1 derivatives (AFM1 and AFQ1) in eggs (Anfossi et al., 2015).

Pigs

Pigs are considered relatively susceptible to AFB1. Tulayakul et al. (2006) studied AFB1 metabolism in liver of different species in relation to the susceptibility to the toxic effects. The piglet’s liver showed a relatively lower cytosolic GST activity to convert AFB1-epoxide to AFB1-glutathione conjugate product, thus favoring the formation of AFB1-DNA adducts.

The metabolism and tissue distribution of AFB1 in pigs were studied by Lüthy et al. (1980), and the major excretory route was found to be the feces (51–65% of the dose administered) but also urine was also an important excretory route. Actually, both AFM1 and AFB1 were detected in pig urine samples and AFM1 was always found at higher concentrations in all studies (Thieu and Pettersson, 2009). In fact, urinary AFB1 and AFM1 are often used as biomarkers for aflatoxin exposure in pigs.

Ruminants

Ruminants are generally more resistant to the toxic effects of mycotoxins than monogastric animals, which could be explained mainly by AFB1 degradation or bioconversion by rumen microorganisms. Controversely, some studies reported on that aflatoxins were generally poorly bioconverted in the rumen, with an overall decrease of only 10% (Westlake et al., 1989). Moreover, AFB1 was incubated with intact rumen fluid or fractions of rumen protozoa and bacteria from sheep and cattle in the presence or absence of milled feed and the result clearly indicated that rumen fluid had no effect on AFB1 (Kiessling et al., 1984). Another study showed that AFB1 metabolism in rumen fluid was influenced by the animal species and the type of feed. In fact, rumen microbes from Korean native goats exhibited a greater degradation capacity for AFB1 in comparison to Holstein steers. These diverging observations might be the consequence of varying rumen microbe profiles (Upadhaya et al., 2009).

AFM1 is the most prominent metabolite formed in bovine hepatocytes within the first hours of incubation whereas AFB1-dhd becomes determinative after a prolonged incubation. These two metabolites are mainly formed by CYP1A and CYP3A hepatic monooxygenase activities (Kuilman et al., 2000). According to Larsson et al. (1994), several extrahepatic tissues of sheep can also bioactivate AFB1 very efficiently and can conjugate the bioactivated AFB1 with GSH as well.

Following the channeling of AFB1 in ruminants, the ingested aflatoxins may be degraded, at least in part, to AFL, AFM1 and many other hydroxylated metabolites by certain rumen microbes or may be sequestered by some rumen fluid components such as chlorophyllin structures as well as bacterial and yeast cell walls (Gallo et al., 2015). The remaining fraction is rapidly adsorbed in the gastro-intestinal tract by passive diffusion and then is extensively metabolized in the liver to AFM1, which enters the systemic circulation or is conjugated to glucuronic acid, and afterward excreted via bile, urine or milk (Kuilman et al., 2000; Rodrigues et al., 2019). Obviously, different levels of feed contamination may lead to different carry-over rates, which are also influenced by other physiological factors such the health status of animals including the status of the liver and its enzymatic activities. AFB1, AFM1 and AFL have been detected in liver, kidney and muscle tissue of bovine (Kuilman et al., 1998). AFM1 is excreted via urine at a greater extent than through milk but the physiological factors regulating the relative uptake by kidneys and mammary glands are still unknown (Rodrigues et al., 2019). AFM1 has been detected in both the milk and urine of cattle and dairy ewes 6 h after AFB1 ingestion (Helferich et al., 1986; Battacone et al., 2003), and its concentration decreased rapidly after withdrawal of aflatoxin from diets (Rodrigues et al., 2019). Fecal excretion of FB1 results from a lack of absorption by the GIT or a highly efficient elimination by the biliary system in the form of conjugated metabolites (Yiannikouris and Jouany, 2002; Jouany et al., 2009).

Goats were administrated with [14C]-AFB1, and urine, milk and feces were collected after 120 h. AFM1 was found in milk at the highest concentration meanwhile AFQ1 and AFL were found only in trace quantities in milk (Helferich et al., 1986). Other studies on goats also indicated that the absorption of AFB1 in the GIT of adult ruminants was very fast, as was its hydroxylation to AFM1 and release into the blood (Battacone et al., 2012). The short interval between AFB1 administration and the detection of its metabolite in milk confirmed that the absorption of the toxin took place already in the rumen in goats.

Aflatoxins in Foods of Animal Origin

Aflatoxins are generally considered as the most important mycotoxins due to their carcinogenic properties, their persistence in food commodities once formed, and the wide range of food commodities that may be contaminated by them (Fink-Gremmels and van der Merwe, 2019). Aflatoxins contaminating feeds pose a direct threat to livestock health and, indirectly, also affect human nutrition and health by reducing livestock productivity and via transfer from feed to foods of animal origin, namely milk, meat and eggs, even if milk is the only food of animal origin with relevant aflatoxin carry-over (Frazzoli et al., 2017).

Aflatoxins, particularly AFM1, are of public health concern because they are efficiently excreted into milk, even if they may also contaminate other foods of animal origin at low levels and, therefore, the associated risks are considered to be minor (Fink-Gremmels and van der Merwe, 2019). Not surprisingly, many countries have set maximum levels of aflatoxins (AFB1 or total aflatoxins, AFM1) in food commodities and animal feeds, with the main aims to protect animal health and to prevent aflatoxin contamination of animal-derived foods. This review does not provide a systematic overview on aflatoxins in foods of animal origin but summarizes the discussions on the potential public health concerns specifically related to aflatoxins residues in these food commodities. In livestock animals, the best estimate transfer factors for mycotoxins in kidney, liver, muscle, fat, milk and egg were reported by MacLachlan (2011), and they clearly showed that no significant residues coming from aflatoxin contaminants of livestock feed are present in meat and eggs.

In the case of human dietary exposure from dairy products, aflatoxins are considered the most important mycotoxins and, based on data belonging to Food and Feed Safety Alert, 93% of the overall mycotoxin notifications referred to aflatoxins, whereas dioxins, dioxin-like polychlorinated biphenyls and AFM1 were the most frequently reported chemical issues in dairy products (van Asselt et al., 2017). When ruminants were fed with contaminated feed, the AFB1 consumed by the animals was partly degraded by the forestomach before reaching the circulatory system, and the remaining part was transformed by the liver into monohydroxy derivative forms, mainly to AFM1, and, in smaller quantities, also to AFM2, AFM4 and AFL. Afterward, AFM1 was secreted into the milk through the mammary glands (Frazzoli et al., 2017). AFM1 has only from 2 to 10% of the carcinogenic potency of AFB1 but it possesses the same liver toxicity. The ability of ruminants to convert the AFB1 ingested with feedstuff to AFM1 and to excrete this derivative in milk varies within broad limits in large and small ruminants and ranges between 0.35 and 3% in cows, 0.018 and 3.1% in goats and between 0.08 and 0.33% in sheep (Virdis et al., 2014). This remarkable variability in AFB1 biotransformation observed in these species can be explained with differences in the activity of hepatic enzymes involved in the biotransformation and detoxification processes considering both their expression and catalytic activity (Becker-Algeri et al., 2016). The average conversion value was 2.5% (Veldman et al., 1992) in high yielding dairy cows, which produced a daily amount of about 40 L of milk, were tested. Importantly, Veldman et al. (1992) found a direct relationship between the carry-over rate and the milk yield with a maximal 6.2% carryover rate. AFM1 is the most commonly detected aflatoxin in milk and the excretion of AFM1 depends on a range of factors including diet composition, rumen degradation and liver biotransformation capacities, the duration of lactation (Fink-Gremmels and van der Merwe, 2019) as well as on the animal breed and udder health status (Masoero et al., 2007). In dairy cows ingesting AFB1 contaminated feedstuffs, the excretoin of AFM1 occured in 12 – 24 h and up to 2 – 3 days in milk, whereas the AFM1 clearance in milk depended on several factors, mainly on the amount of ingested AFB1 and the duration of mycotoxin consumption with an excretion for a variable period of about 5 – 7 days from the ending of AFB1 assumption by cows (Masoero et al., 2007).

Well-reported variations in AFM1 contamination were observed in milk worldwide, which were dependent on several factors like geographical area, environmental and climatic conditions including seasons and weather, as well as on the diversity and level of development of farming systems and the consumption of feed concentrates and green forage (Becker-Algeri et al., 2016). In recent years and independently of the type of commodity, the occurrence of AFM1 in milk and dairy products was lower in Europe (for example in Italy, Portugal, Turkia, and Croatia) than in Asia or South America, where higher mycotoxin frequencies up to 100% were reported (Filazi and Sireli, 2013; Becker-Algeri et al., 2016). In Europe, low levels of AFM1 contamination were reported in milk, and only 0.06% of the analyzed samples were above the European limit of 0.05 μg/kg milk. Nevertheless, when such incidents occur a widespread AFM1 contamination of milk may develop, which has to be taken into account and adequately considered and controlled (van Asselt et al., 2017). In addition, risk managers should also consider that aflatoxin concentrations in milk may vary within the year and may also depend on the geographical location and climatic conditions. Finally, AFM2 has also been investigated in milk with different outcomes varying from its absence to a not negligible occurrence in powdered, UHT and pasteurized milk samples (Becker-Algeri et al., 2016).

The AFM1 contamination of dairy products is classified as an indirect contamination. For example, when the milk used in cheese-making was contaminated by aflatoxins, AFM1 unevenly distributes between whey and curd, because AFM1 prefers to bind to milk proteins, first of all to casein. For this reason, AFM1 is more concentrated in the curd and cheese than in the milk itself, which was used for cheese-making (Anfossi et al., 2012). Therefore, AFM1 levels were 3 – 8 times higher in certain dairy products than in the milk, and stable AFM1 residues were detected in the final dairy products like milk powder even after heat processing. In addition, the total amount of AFM1 does not change significantly during the cheese-making and cheese maturation processes but these steps influence the AFM1 and protein concentration ratios as a result of skimming and water loss (Anfossi et al., 2012). Although many studies on the contaminations of dairy products by AFM1 are available (Anfossi et al., 2012; Becker-Algeri et al., 2016) only few of them present any data estimating concentration factors for AFM1 in different cheeses. However, 2.5 – 3.3 and 3.9 – 5.8 times higher concentrations of AFM1 calculated on a weight basis were recorded in soft and hard cheeses, respectively, than those AFM1 concentrations found in the milk, from which these cheeses were made (Filazi and Sireli, 2013). In Europe, the food business operator has to justify and provide the specific concentration or dilution factors for AFM1 in the processed foodstuffs during official controls performed by the competent authority (EC Regulation, 1881/2016).

In this context, AFM1 contaminating milk should be unremitting to our attention and we should also take a special care of infants avoiding their exposures to AFM1 via milk and infant formulas (Fink-Gremmels and van der Merwe, 2019). Kerekes et al. (2016) emphasized the importance of regular control of produced milk and also the introduction of an appropriate action limit in combination with immediate corrective actions at the farm level. In fact, feed producers have to manage and control the feed ingredients intended for the production of feed for the lactating animals for risk mitigation. Feed ingredients should be selected based on their quality characteristics, whereas farmers, when the AFM1 content of milk exceeds the legal limit, have to withdraw milk consignments and also have to remove contaminated feedstuffs (Trevisani et al., 2014).

As far as the aflatoxin residues detected in edible tissues of bovine, pigs and poultry are concerned, these AFB1 entry routes do not contribute significantly to human aflatoxin exposures (Fink-Gremmels and van der Merwe, 2019). Nevertheless, data on the aflatoxin contents in the edible tissues of bovine species are scarce and it is generally assumed that aflatoxins are partly degraded in the rumen and they are rapidly metabolized in the liver after absorption from the intestines. The transfer rates of aflatoxins into the edible tissues of pigs are very low owing to the rapid pre-systemic and hepatic metabolisms, and the aflatoxin residues in pork are therefore not considered as of public health concern. Similarly, poultry with low levels of aflatoxin contaminations do not seem hazardous to humans although the presence of aflatoxin-residues in poultry liver is well-documented (Fink-Gremmels and van der Merwe, 2019). Importantly, a rapid decrease in AFB1 residues was observed in poultry muscles and liver after 3–7 days of uncontaminated dietary, significantly reducing the risk for human health (Filazi and Sireli, 2013). However, AFL is the main component of total AF residues in poultry with highest contents in liver (Frazzoli et al., 2017). In the case of laying hens, aflatoxins and their metabolites, particularly AFB1 itself and AFL, can also be carried over to eggs but very discrepant transmission ratios were reported in this case. Recent studies demonstrated very low amounts of aflatoxin residues in eggs, merely between 0.01% (Herzallah, 2013) and 0.07% (Hassan et al., 2012) of the aflatoxin intake. AFB1 residues appeared in eggs after 5 days of feeding with contaminated feedstuffs and the amount of AFB1 depended on the duration of feeding with contaminated grain. Similar to dairy products, the presence of aflatoxins in eggs may be indicative of the aflatoxins contamination of the feed.

Aflatoxicoses and Animal Susceptibility

In general, mycotoxicosis refers to syndromes appearing after ingestion, skin contact or inhalation of toxic secondary metabolites produced by toxigenic molds belonging to the genera Aspergillus, Fusarium, and Penicillium as well as to some other fungal taxa (Gallo et al., 2015). Within mycotoxicoses, aflatoxicosis refers to any disease caused by the consumption of foods and feeds contaminated with aflatoxins. It is well-known that AFB1 is a potent mutagenic, carcinogenic, teratogenic, and immunosuppressive fungal secondary metabolite and all these effects may be linked to the interference of AFB1 and its derivatives with the synthesis of proteins, the inhibition of various metabolic pathways or to the onset of oxidative stress. All these disadvantageous physiological effects will lead consequently to damages in various organs, especially in the liver, kidney, and the heart.

Aflatoxicoses may emerge in any livestock but literature reports on outbreaks mostly in poultry, pigs, equine, sheep, and cattle. The exposure of domestic animals to AFB1 mainly occurs through the ingestion of contaminated feeds, however, skin contacts or inhalation exposures might also contribute (Gallo et al., 2015). It is well-known that ruminants are among the least susceptible animals to the negative effects of mycotoxins in comparison to monogastrics. However, the rumen has a saturable capacity of detoxifying aflatoxins by microflora, depending on (i) variations in the diet, (ii) the consequences of metabolic diseases, such as rumen acidosis, (iii) rumen barrier alterations as a result of animal diseases, and also (iv) the actual concentrations of aflatoxins present in the animal feed (Fink-Gremmels, 2008a). Consequently, clinical manifestations of aflatoxicoses in ruminants are associated typically with aflatoxins that are not degraded at all or not completely degraded by the rumen microflora.

Most of the data we have already had in our hands on mycotoxin toxicity are coming from experimental studies with purified compounds in otherwise healthy animals, which knowledge may help us with the early and reliable diagnosis of mycotoxicoses. However, when natural episodes of mycotoxicoses occur, versatile signs of disease could appear depending on the environmental conditions and also on several other features of the animals involved, including nutrition, sex and breed. For this reason, the diagnosis of mycotoxicoses is often difficult but it should rely on observing the clinical symptoms on the affected animals and also on analyzing the feed involved in the intoxication (Council for Agricultural Science and Technology [CAST], 2003). Given aflatoxins could act in synergy with other mycotoxins and also with other disease-provoking agents and, therefore, additional apparently unrelated pathological symptoms and even diseases are observed and reported in the affected animals. Furthermore, most mycotoxicoses including aflatoxicoses may present non-pathognomonic features and, consequently, there are no definitive diagnostic symptoms to orient farmers and veterinarians to assign aflatoxin exposures unequivocally to the death of animals. Obviously, even other otherwise unrelated diseases may trigger similar responses in the domestic animals to those of aflatoxins (Richard, 2008).

Aflatoxins do not affect all animals uniformly. Some animal species are inherently more resistant, such as sheep, goats and cattle, whereas other animals are more susceptible like swine, chickens, turkeys, and ducklings. In addition, considerable breed differences are documented within a given species (Richard, 2008), and the physiological responses to the adverse effects of aflatoxins are also influenced by age (young animals are usually more sensitive than elder ones and, in particular, piglets and chicks), sex, diet, and weight, exposure to infectious agents, and the presence of other mycotoxins or other pharmacologically active substances (Zain, 2011). In addition, when mycotoxins are present simultaneously, some interactive effects, classified as additive, antagonistic or synergistic, could also occur (Gallo et al., 2015).

Animal Exposure to Aflatoxins

The exposure of animals to aflatoxins may trigger biological reactions that could be classified as acute, overt diseases with high morbidity and mortality, or, as it is usually the case, chronic, insidious disorders that impairs animal productivity (Bryden, 2012; Pierron et al., 2016). When livestock ingest aflatoxins the health effects could be acute, with severe consequences and evident signs of disease or even may be lethal when these toxins are abundantly consumed, even if this event is rare under farm conditions (Gallo et al., 2015). The timing of the proper diagnosis is a crucially important factor because the suspicious contaminated feed is likely consumed well before it can be tested (Council for Agricultural Science and Technology [CAST], 2003). The earliest clinical signs and lesions observed in turkey “X” disease, hepatitis “X” of dogs, and similar cases of acute aflatoxicoses were anorexia, lethargy, hemorrhages, hepatic necrosis, and bile duct proliferation (Miller and Wilson, 1994). Furthermore, the aflatoxins’ impact on animals should not be limited to the extreme effects of aflatoxicoses because it is related mainly to the chronic toxicity caused by the consumption of sublethal doses and to the fact that low levels of chronic exposures may result in cancer.

Considering the chronic effects of aflatoxins, hidden pathological alterations with reduced ingestion, productivity and fertility were implied, including lowered milk, meat, and egg productions, decreased weight gains and/or unclear changes in animal growth, feed intake reductions or feed refusals, alterations in nutrient absorption and metabolism, various typologies of damages to vital body organs, disadvantageous effects on the reproduction and endocrine systems and also suppression of the immune system with subsequently increased disease incidence. The economic consequences of chronic aflatoxicoses are many times larger than those of the rare acute cases with immediate morbidity and lethality (Council for Agricultural Science and Technology [CAST], 2003).

Hepatotoxic, Carcinogenic and Mutagenic Effects

Among the major devastating effects of aflatoxins on animals, these harmful metabolites specifically target the liver and, hence, are proved to be primarily hepatotoxic. In acute aflatoxicosis, the emerging clinical symptoms of acute hepatic injury include coagulopathy, increased capillary fragility, hemorrhage and prolonged clotting times. Gross liver changes are caused by hemorrhage, centrilobular congestion, and fatty changes in surviving hepatocytes. Death of the poisoned animal may occur within hours or a few days after exposure. In broiler chicks, hemorrhagic anemia syndrome develops as characterized by massive hemorrhagic lesions in major organs and musculature even if the anemia could be considered as a secondary effect of severe hypoproteinemia caused by primary liver damage (Council for Agricultural Science and Technology [CAST], 2003). However, changes in extrinsic coagulation factors as determined by increased fibrinogen concentration were also reported in lambs (Zain, 2011). In addition, in broiler chicks, other reported clinical signs of aflatoxicosis were glomerular hypertrophy, hydropic degeneration of tubuler epithelium in kidneys and increases in the number of mesengial cells, as well as atrophy and lymphoid depletion in the thymus and bursa of Fabricius (Ortatatli and Oguz, 2001).