Abstract

The experiments of contact ultrasound-assisted far-infrared radiation (FIR) drying on potato slices were conducted to investigate the effects of ultrasonic power on drying characteristics and quality properties. The results showed that contact ultrasound was helpful for accelerating mass transfer of the samples, and the improvement of ultrasonic power could significantly shorten drying time. The ultrasonic reinforcement effect on drying rate declined along with the decrease in moisture content. Deff values were within 1.15 × 10−10 and 1.96 × 10−10 m2/s, and improved with an increase in ultrasound power. Compared with FIR dried ones, more and larger pore size of microcapillaries in the samples’ tissue structure could be observed with contact ultrasound application, and higher ultrasonic power produced more microtunnels. Contact ultrasound in FIR drying could reduce the color difference of dried potato slices, and decrease the hardness and brittleness values. Higher TPC and TFC could be achieved as ultrasonic power increased.

Keywords: Contact ultrasound, Drying, Far-infrared radiation, Potato slices, Quality properties

Introduction

Ultrasonic wave is the mechanical wave with a frequency of higher than 20 kHz (Chemat et al., 2011). It can be propagated in gas, liquid and solid, with the characteristics of good direction, great penetration ability and strong vibration (Schössler et al., 2012). When ultrasound wave transfers through a certain medium, very rapid vibration could be irritated in the material, and it is subjected to iterative stretch and contraction. Ultrasound could produce cavitation and mechanical effects and then reduce the moisture adhesion and decrease the water migration resistance, thus enhancing the mass transfer effect inside treated materials (Cárcel et al., 2007). At present, applying ultrasound technology in food drying is also getting more and more attention (Carlos and Byron, 2015; Fernandes et al., 2015; Gamboa-Santos et al., 2014; Liu et al., 2019; Riera, 2007). Ultrasound pretreatment before drying process is a commonly used method to reduce drying time by loosening material’s organizational structure (Carlos and Byron, 2015). However, ultrasound pretreatment has no direct effect on drying process and the enhancement on drying rate is unsatisfactory. Airborne ultrasound, another kind of ultrasound strengthening method, could also reduce drying time significantly (Gamboa-Santos et al., 2014). But the airborne ultrasound energy is easily attenuated in a large amount in the air medium before reaching dried material’s surface, resulting in low drying efficiency during drying process. Therefore, if the ultrasound energy can transfer into the objects directly without any air medium, named as contact ultrasound, ultrasound energy attenuation can be reduced and the energy utilization rate can be improved effectively, which is beneficial to accelerating dehydration as well as increasing energy utilization. Riera (2007) investigated the effect of contact ultrasound on mushrooms, carrots and apples during hot air drying, and verified that contact ultrasound could promote dehydration and shorten drying period significantly. Fernandes et al. (2015) explored contact ultrasound-assisted hot air drying on cherry tomatoes, and the results showed that not only the effective diffusivity of water increased by 33–89%, but also the carotenoids in dried products could be retained by using ultrasound. Hence, the application of contact ultrasound strengthening method is very promising in food drying industry.

In recent years, far-infrared radiation (FIR) has been widely used in drying process because of its significant thermal effect. When an FIR plate releases energy to penetrate the surface of the material, the surface and the interior of the material could be simultaneously heated to achieve uniform internal heating and fast water dehydration (Pawar and Pratape, 2017; Sun et al., 2017). The researches on FIR drying showed that FIR drying technology has the advantages of uniform heating, fast drying speed and good product quality compared with traditional drying technology (Kim et al., 2012; Riadh et al., 2015). However, FIR heating doesn’t have significant reinforcement effect on internal mass transfer although it has obvious thermal effect during drying.

In short, FIR drying can improve internal heat transfer of materials, and contact ultrasound technology can promote the internal mass transfer during drying process. Therefore, the application of ultrasound technology in FIR drying can theoretically promote the heat and mass transfer of materials synchronously, thereby significantly improving dehydration rate. However, there is no detailed research about the effect of contact ultrasound on the quality properties of FIR dried materials. Since ultrasonic power is the most important factor of contact ultrasound strengthening method for drying, the target of this research was to explore the effects of contact ultrasound power on FIR drying of potato which was a familiar and favorite food and was chosen as dried object. The effects of ultrasound power on drying process and Deff values of potato slices were to be studied. The internal microstructure changes of dried potato slices with contact ultrasound treatment were to be analyzed by scanning electron microscopy (SEM). Moreover, several quality attributes including texture, color, total phenolic content (TPC) and total flavonoid content(TFC) of potato products dried under different ultrasonic powers were to be discussed.

Materials and methods

Preparation of samples

Fresh potato materials were bought from a Dazhang supermarket in Luoyang City, Henan, China. The moisture content of fresh potato was determined as 567 ± 8% (dry base) by the vacuum oven drying method of the literature (Schössler et al., 2012). Before each experiment, fresh potatoes were washed, peeled, and cut into slices with the dimensions of 40 × 40 × 4 mm using a food slicer. The 10 pieces of potato slices were taken for each drying experiment. In order to effectively inhibit enzymatic browning during drying, potato slices were blanched in boiling water for 2 min before each drying process. After the potato slices were taken out of the water, they were wiped by tissue paper and then were uniformly put on the ultrasonic radiation disk for drying experiment.

Contact ultrasound equipment

The ultrasound equipment applied in this work was manufactured by Henan University of Science and Technology, and the corresponding appearance and structure could be seen in the literature (Liu et al., 2016). The resonant frequency of the ultrasonic equipment is 28 ± 0.5 kHz, the resonant impedance is 0–20 Ω, and the maximum power is 60 W.

Drying

The samples of drying and the ultrasonic radiation disk were together put in FIR dryer (Model 766-0AS, Shanghai Hasuc Instrument Co., Shanghai, China). During drying experiments, the ultrasonic powers were set as 0, 15, 30, 45 and 60 W (corresponding ultrasonic power density values were 0, 0.09, 0.17, 0.27 and 0.36 W/cm2), respectively. For the better investigation on the effects of ultrasound power on FIR drying and quality of potato, the temperature inside FIR dryer was fixed as 50 °C in each drying experiment. The samples were weighed every 30 min by a digital balance (DT-2000E, Hengjia Co., Ningbo, China) until the end of drying. The experiments of potato drying were performed in triplicates.

The sample’s moisture content in drying process was obtained as follows (Ruiz Celma et al., 2009):

| 1 |

where M is moisture content (%, dry base), m is sample mass (g), and md is the mass of dry matter (g).

The drying rate calculation was as following (Kek et al., 2013):

| 2 |

where DR is drying rate of the process (%/min), and Mt1 and Mt2 are the moisture contents at drying time t1and t2, respectively (%, dry base).

The calculation of Deff values were conducted based on Fick’s second diffusion equation described in the literatures (Liu et al., 2014; Midilli, 2001).

Scanning electron microscopy (SEM)

A scanning electron microscopy (TM3030, Hitachi Co., Hitachi, Japan) was used to observe the microstructure of dehydrated samples. A small specimen was cut from the dried potato samples and placed on stainless stub, sputtered immediately. The specimens were observed at 200 × magnifications.

Texture Analysis

A texture analyzer (TA.XT., Stable Micro Systems Ltd, Cardiff, U.K.) was used to investigate textural properties of dried potato slices. Test conditions: the pre-speed and test speed are 1 mm/s, the post-speed is 10 mm/s, the trigger force is 0.1 N, and each sample was tested for eight times. During the test, the hardness (N) is the maximum force required to break the sample, and the brittleness (millimeter) is the distance at the point of brake, and the sample breaks at a very short distance has a high fracture capacity (Vega-Gálveza et al., 2012).

Color measurement

A colorimeter (Color i5, X-Rite, Granville, USA) was used for measuring the color of the surfaces of the dried and fresh potato samples. The color values of the samples, which were L*, a*, and b*, represented darkness–lightness, greenness–redness, and blueness–yellowness, respectively. Total color difference (ΔE) was calculated as following (Vega-Gálveza et al., 2010):

| 3 |

where , and represent the color values of the fresh potato samples while L*, a*, and b* represent the color values of dried samples. Five randomly selected samples were repeated three times in each group.

Determination of TPC and TFC

Some dried potatoes were grounded into powders and weighed for 1 g. The samples were put into 70% ethanol solution (60 mL) and treated by an ultrasonic cleaner (SB-120DT, Xingzhi Co. Ningbo, China) at 25 °C for 30 min. The extracts were filtered in a centrifugal tube and were centrifuged by a centrifuge (TG16-WS, Xiangyi Co., Changsha, China) at 4000 × g for 20 min. The supernatants were added to the test tube for the determination of TPC and TFC. The TPC of the samples was determined using the Folin-Ciocalteu colorimetric method (Kim et al., 2003), and the results were expressed as milligram gallic acid equivalent in 100 g of dried sample (mg GAE/100 g). The TFC of the samples was determined using colorimetric method (Bouayed et al., 2011), and the results were expressed as milligram rutin equivalent in 100 g of dried sample (mg RE/100 g). All measurements were done in triplicate.

Data analysis

Data analysis and ANOVA were conducted with Origin 8.5 software.

Results and discussion

Drying characteristics

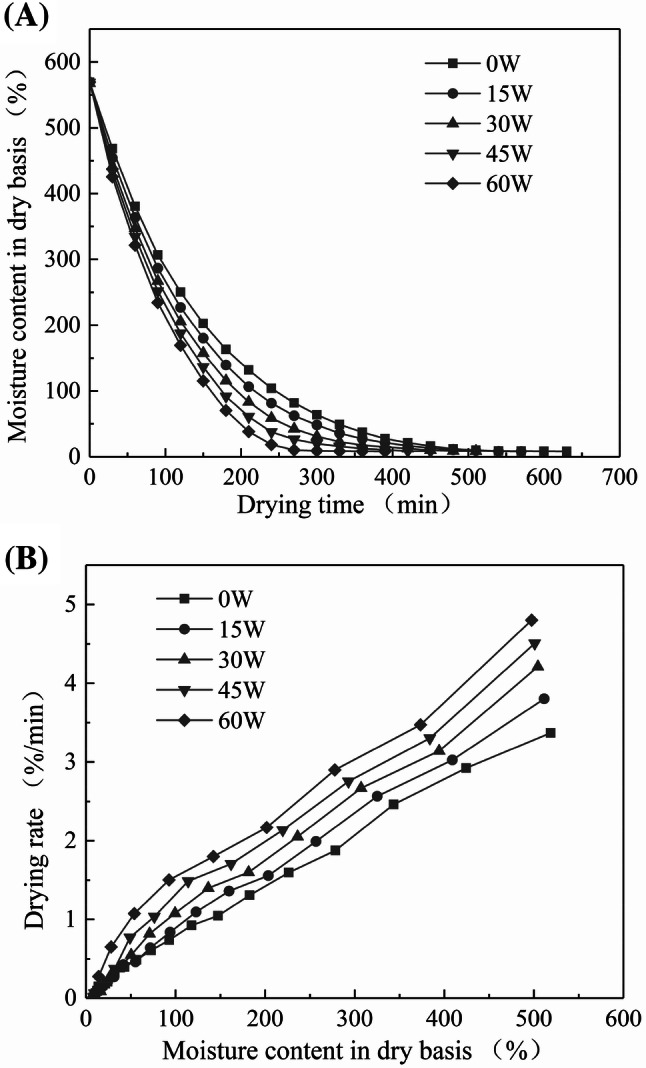

The drying experiments of potato slices by contact ultrasound-assisted FIR was carried out at ultrasonic powers of 0, 15, 30, 45 and 60 W, respectively. The corresponding drying curves and drying rate curves are shown in Fig. 1.

Fig. 1.

Drying curves and drying rate curves of potato slices dried at different ultrasound powers. (A) Drying curves. (B) Drying rate curves

It can be seen from the figure that contact ultrasound application could significantly reduce drying time and promote drying rate. The drying time without ultrasound application was 630 min, while the drying times decreased as 570, 510, 450 and 390 min at ultrasound powers of 15, 30, 45 and 60 W, with the declination ratios of 9.5%, 19.0%, 28.6% and 38.1%, respectively. Compared with the average drying rate of 0.89%/min at ultrasonic power of 0 W, the average drying rates rose to 0.98, 1.10, 1.25 and 1.44%/min when ultrasound powers were 15, 30, 45 and 60 W, with the rising ratios of 10.1%, 23.6%, 40.4% and 61.8%, respectively. An explanation for this fact may be that the ultrasound energy radiated from the ultrasound board could penetrate directly inside the samples when the potato slices were put on the ultrasound board during drying process. Because of the rapid compression and expansion of the internal structure caused by the high-frequency vibration of ultrasound, a large number of micro-bubbles are generated, and strong kinetic energy and compression energy are produced when the bubbles burst instantaneously (Wiktor et al., 2016). These energies reduce the adhesion of water molecules closely bounded to the wall of micro-tubes, enhance moisture mobility and accelerate water diffusion and migration. On the other hand, the cavitation effect of ultrasound could also affect the pore structure of the material, and the size and connectivity of the micro-channels are increased, which could significantly improve moisture transfer rate (Nowacka et al., 2012). It can be seen from drying rate regulations that the drying process of potato slices by contact ultrasound-assisted FIR drying only exists falling-rate drying periods, which indicates that the drying process is internal moisture diffusion-controlled process. With contact ultrasound application, it is obvious that ultrasound enhancement technology is conducive to accelerating the drying rate of FIR dried potatoes, and the greater the ultrasonic power, the more significant the enhancement effect. Sabarez et al. (2012) announced that the drying time of apple without ultrasound was about 7.8 h in the study of ultrasound combined convection drying, and the drying times were about 3.3 h at ultrasonic power of 90 W. The results revealed that the drying rate could be accelerated significantly with the rise in ultrasound power level, which is consistent with the conclusions obtained in this study. With the rise in ultrasonic power and the enhancement of internal vibration of materials, ultrasound energy could produce stronger reinforcement effects, which is conducive to the turbulence and diffusion of water, so that drying could be completed quickly and drying rate could be increased.

In addition, according to the drying rate curves in Fig. 1, the drying rates show a declining trend as moisture content reduced continuously. In the initial stage of drying, the average drying rates increased by 25.9% and 43.4% at ultrasonic powers of 30 and 60 W, respectively, compared with single FIR drying. When the moisture content of the material was dropped by half, the corresponding average drying rates increased by 23.4% and 39.1% at 30 and 60 W, respectively, compared with single FIR drying. When the moisture content of the material dropped to about one-fourth of the initial value, the corresponding average drying rates increased by 20.3% and 35.8% at 30 and 60 W, respectively, compared with the FIR drying without ultrasound application. When the moisture content was below 35%, all drying rate curves tended to coincide. The above phenomena revealed that the enhancement effect of ultrasound is closely related to moisture content, and decreases with moisture reduction. In the initial period of potato drying, the higher moisture content of the material represented more free water and faster ultrasound transmission. At this time, the attenuation coefficient of the ultrasound wave and the internal transmission resistance were small, which were beneficial for the ultrasound waves to penetrate into the material and produce strong strengthening effect (Schössler et al., 2012). As the rising in ultrasound power, the corresponding enhancement effects became stronger and water removal rate was further accelerated. However, during drying, the internal moisture content of the material decreased, which lead to the increase of ultrasound attenuation, the corresponding ultrasonic enhancement effect became weak, and the ultrasound energy utilization rate for enhancing mass transfer was significantly reduced.

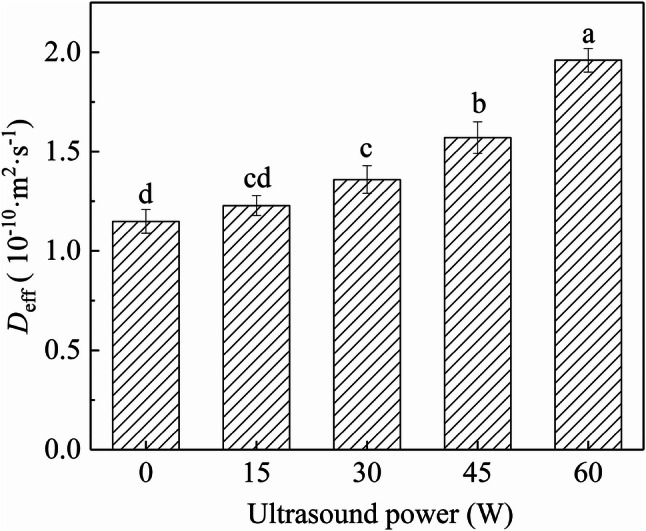

Effective moisture diffusivity

The variation of effective moisture diffusivity of potatoes at different ultrasound powers was shown in Fig. 2. From the figure, it could be found that Deff values increased significantly with an increase in ultrasound power. For example, when ultrasound powers at 30 and 60 W were applied, the increase ratios of Deff values were 18.26% and 70.43%, respectively, compared with that of the FIR drying without ultrasound assistance. This indicated that ultrasound could significantly reduce the internal diffusion resistance of drying and improve the mass transfer rate. Increasing the ultrasound power could enhance cavitation generation and fragmentation and moisture turbulence, resulting in the formation of micro-channels in the material. Furthermore, it also weakened the adhesive force and binding force of the material structure to water. Thus, the moisture turbulence inside the material was enhanced to increase the water molecule movement rate and the effective water diffusion coefficient. Ortuño et al. (2010) studied ultrasound application in convective drying of orange peel and showed that applying ultrasound could evidently improve the mass transfer coefficient and water diffusion ability of drying. Liu et al. (2015) discussed the effect of ultrasound combined with hot air drying on honeysuckle, and the conclusion showed that the Deff values could be increased with the rising in ultrasonic power.

Fig. 2.

The Deff values of potato slices by FIR drying at different ultrasound powers. Note: Values with different letters represent significant difference at the level of p < 0.05

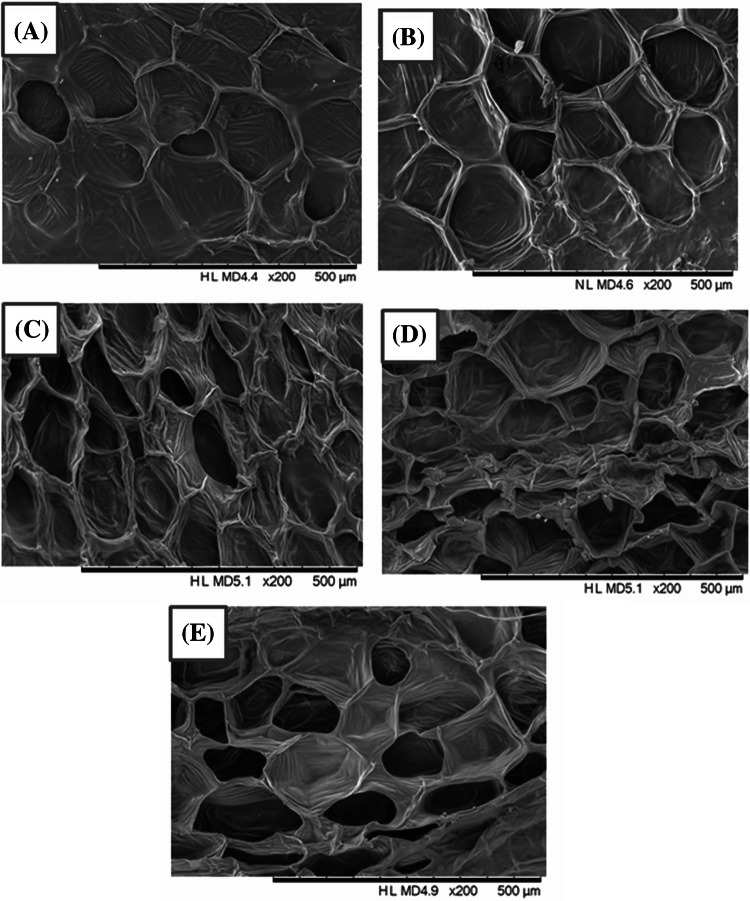

Scanning electron microscopy

The structure of material has an important influence on the internal water diffusion property during drying process (Kantrong et al., 2014). To further explore the influence of ultrasonic power on inside moisture diffusion, the microstructures of potato slices dried by contact ultrasound-assisted FIR were examined and analyzed by SEM. Figure 3 shows the SEM photographs of surface microstructure of potato slices contacting with the ultrasound board. Obvious microstructure differences were observed with different ultrasonic powers. The structure of materials with no ultrasound assistance was compact and dense. It could be explained by the continuous shrinkage of materials during FIR dehydration process, which lead to less and small capillary channels for water flow. By increasing ultrasound power to 15 W, the surface microstructure of potato slices was still compact. It can be concluded that ultrasound power of 15 W had a positive effect on moisture migration, but it was not strong enough to change the structure of potato chips and expand microchannels. When ultrasound power of 30 W was applied, a large number of micro-channels were generated on the surface treated by ultrasound and the diameter of pores also increased gradually. Because of the cavitation effect of the ultrasound waves, the microbubble blasting had a strong impact and destruction on the tissue structure, and new micropores appeared (Ortuño et al., 2010). Moreover, rapid oscillation irritated by ultrasound led to rapid and repeated extrusion and shearing of material’s structure, expanded the original microcapillaries. After ultrasound powers of 45 and 60 W were applied, the surface structure of potato slices was loose and the pore size and number of microcapillaries continued to increase, which verified that the rising in ultrasonic power was helpful for the enhancement effects, leading to more obvious expansion and generation of microcapillaries. Garcia-Perez et al. (2012) discussed the microstructural changes of orange peel by high-intensity ultrasound during drying, and the results showed that ultrasound could promote the water transfer performance of materials and promote moisture transfer during drying.

Fig. 3.

SEM photos of microstructure of potato slice surface in contact with the ultrasound radiation board at different ultrasound powers. (A) 0 W. (B) 15 W. (C) 30 W. (D) 45 W. (E) 60 W

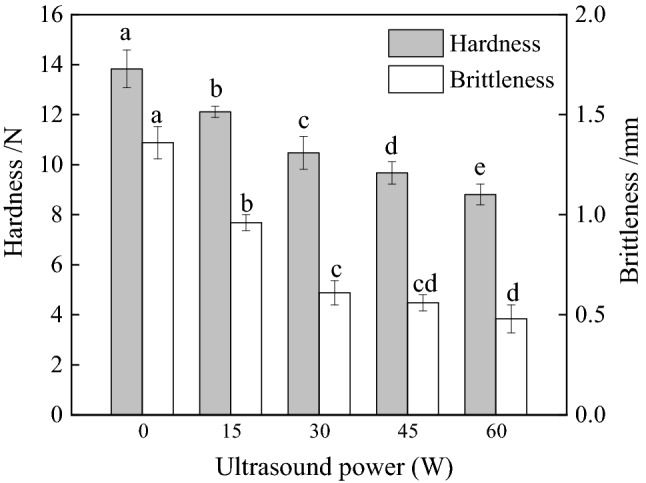

Texture analysis

The hardness and brittleness values of dried potato samples at different ultrasound powers are showed Fig. 4. After drying, the hardness values of the products were in the range of 8.81 ± 0.65 to 13.83 ± 0.75 N, and the brittleness values were in the range of 0.48 ± 0.06 to 1.36 ± 0.18 mm. ANOVA results showed that ultrasonic power can affect hardness and brittleness significantly. Compared with the single FIR drying, the hardness and brittleness of potato slices were significantly reduced after the application of contact ultrasound, which indicated that ultrasound application could make potato slices softer and crisper. The textural properties of vegetables are closely related to the integrity of cell wall components (Pei et al., 2014). Garcia-Perez et al. (2010) compared the effects of ultrasound with non-ultrasound drying on the microstructure of eggplant, and clarified that ultrasound assistance was helpful in slowing down the degradation of microstructures. According to this study, the structural degradation degree during drying may be related to long-term exposure without ultrasound. Dujmić et al. (2013) explored the effects of pretreatment with different intensity ultrasound on the texture characteristics of dried pear slices, and verified that the hardness values of samples reduced with a rise in ultrasonic intensity. With ultrasound treatment, the mechanical strength of the tissue by the stress-related enzymes activity in the potato tissue was increased, and thus the cell wall integrity under those conditions was enhanced. According to the microstructure SEM photos of dried potato slices, more micropores were generated inside the material after ultrasound application, which indicated that the high-frequency vibration of the contact ultrasound could make looser internal structure.

Fig. 4.

The values of hardness and brittleness of potato slices by FIR drying at different ultrasound powers. Note: Values with different letters represent significant difference at the level of p < 0.05

Color

The color of dried potato slices is generally considered to be one of the most relevant quality traits. The effect of ultrasonic powers on the color of potato slices dried by contact ultrasound-assisted FIR drying is presented in Table 1. Fresh samples showed L* of 45.61 ± 1.23, a* of -1.62 ± 0.14, and b* of 23.97 ± 0.72. Compared with fresh potatoes, the L* and b* values of dried potatoes decreased significantly, while the a* values increased slightly, indicating that drying could reduce the brightness and yellowness of the materials. The color of the samples dried by ultrasound-assisted FIR drying was highly different from those that dried by single FIR drying. After applying ultrasound during FIR drying, the L* values of the samples were increased, a similar change regulation was observed in b* values. Besides, the ΔE values reduced obviously as ultrasonic power increased. The above phenomena showed that ultrasound application had a remarkable effect on the color of potatoes. In other words, ultrasound assistance could improve the brightness of products and reduce the color difference. Salehi et al. (2016) pointed out that ΔE values reduced significantly during high temperature drying process because of the browning reaction. High temperature enhanced the molecular fluidity and activity, leading to the acceleration of browning. However, applying ultrasound could help slow the rate of browning reaction and preserve the original color of the sample. Deng and Zhao (2008) found that ultrasound treatment could inhibit the oxidase reaction in air drying. In addition, when the potatoes were dried by single FIR drying, due to the rich phenolic substances and long drying time, the materials contacted with more oxygen in the drying medium, which made it easier to brown. Contact ultrasound assistance could reduce the exposure time to FIR drying by shorten drying time greatly, thus protecting the color of dried products.

Table 1.

L*, a*, b* and ΔE values of potato slices dried by FIR drying at different ultrasound powers

| Ultrasound power (W) | L* | a* | b* | ΔE |

|---|---|---|---|---|

| 0 | 32.13 ± 1.03bc | − 1.24 ± 0.19c | 11.96 ± 0.28c | 18.06 ± 0.55a |

| 15 | 31.87 ± 1.21c | − 1.15 ± 0.19b | 13.85 ± 0.37bc | 17.41 ± 0.66b |

| 30 | 32.10 ± 0.89bc | − 1.19 ± 0.18bc | 16.39 ± 0.26a | 15.50 ± 0.47c |

| 45 | 33.45 ± 0.72b | − 1.03 ± 0.24a | 15.63 ± 0.25ab | 14.89 ± 0.71cd |

| 60 | 35.15 ± 1.08a | − 1.05 ± 0.15a | 14.59 ± 0.42b | 14.06 ± 0.64d |

Values with different letters represent significant difference at the level of p < 0.05

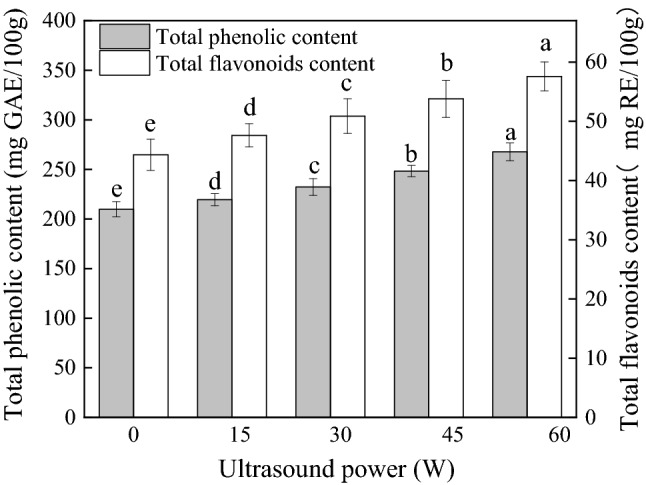

TPC

The TPC values of dried potatoes at different ultrasonic powers are illustrated in Fig. 5. It can be seen from the figure that TPC increased with the rise in ultrasonic power. After applying ultrasound of 15 W, the TPC increased from 209.87 to 219.59 mg GAE/100 g, and the TPC continued to increase when ultrasound increased to 60 W. Phenolic substances have strong activity and are easily oxidized and degraded during drying. The contact ultrasound application would benefit for TPC retention, and the higher the ultrasound power is, the more significant the protective effect is. Applying ultrasound treatment in the FIR drying could remarkably shorten drying time, thus reducing the degradation of phenolic substances. Tekin and Baslar (2018) studied ultrasound-vacuum drying on the quality of red pepper. The results revealed that ultrasound assistance had a positive effect on the bioactive content of red pepper. During traditional FIR drying process, lower radiation temperature leads to long-term drying. In the drying medium, potato samples are exposed to phenolic compounds and oxygen for a long time. The phenolic compounds of potato samples exposed to oxygen for a long time in a dry medium are readily oxidized and degraded due to enzymatic catalysis. The rising in ultrasound power could reduce drying time as well as the oxidation time of phenolic components, so as to better retain the TPC.

Fig. 5.

TPC and TFC values of FIR dried potato slices at different contact ultrasound powers. Note: Values with different letters represent significant difference at the level of p < 0.05

TFC

The TFC values of dried potatoes at different ultrasonic powers are illustrated in Fig. 5. It can be seen from the figure that TFC increased with the improvement of ultrasonic power. After applying ultrasound of 15 W, the TFC increased from 44.35 to 47.62 mg RE/100 g, and when ultrasound increased to 60 W, the TFC continued to increase. The increasing trend is similar to that of TPC. The above phenomenon indicated that applying ultrasound could shorten drying time, improve dehydration rate, reduce the reaction time of flavonoid degradation, and contribute to the improvement of TFC. And the higher the ultrasound power, the shorter the drying time, which means that the time for degradation of the flavonoids was shortened and the rate was slowed down. Rodríguez et al. (2014) found that under certain conditions, the total flavonoid loss ratio of apple dried by ultrasound enhanced hot air drying was 35.5%, which was lower than that of apple dried by single hot air (38.8%). Therefore, in the process of FIR drying, the content of total flavonoids could be retained by applying ultrasound.

In summary, contact ultrasound application could promote dehydration process and then reduce drying time of FIR drying significantly. The decrease in moisture content could reduce the reinforcement effect of contact ultrasound. During drying process, Deff values increased along with the rising in ultrasonic power. SEM results showed that the microstructure of potato slices was significantly different at different ultrasound powers. The rise in ultrasonic power could enlarge micropores and increase the number of microtunnels in the potato tissue structure, which could facilitate the diffusion of moisture inside the material and increase drying rate. The ultrasonic power could significantly affect texture, color, TPC and TFC. Compared with FIR dried potato slices, contact ultrasound-assisted FIR dried potato products showed less color change, and texture characteristics were softer and crisper. The TPC and TFC values improved with the rise of ultrasonic power. Therefore, it could be concluded that contact ultrasound application in FIR drying could accelerate drying rate and protect the quality of dried potato slices effectively. In further studies, the effect of ultrasound power on other nutrients’ retention and functional evaluation of dried products may be investigated and discussed.

Acknowledgements

The authors thank for the financial support from the College Innovation Talents Program of Henan (19HASTIT013), the Chinese College Students’ Innovative Training Program (201810464010) and Henan College Students’ Research Training Program (2018151).

Compliance with ethical standards

Conflict of interest

The authors declare that they have no conflict of interest.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Contributor Information

Huihan Xi, Email: 1143012924@qq.com.

Yunhong Liu, Email: lyunhong@hotmail.com.

Linge Guo, Email: 1097114892@qq.com.

Runrun Hu, Email: 1179498239@qq.com.

References

- Bouayed J, Hoffmann L, Bohn T. Total phenolics, flavonoids, anthocyanins and antioxidant activity following simulated gastro-intestinal digestion and dialysis of apple varieties: Bioaccessibility and potential uptake. Food Chem. 2011;128:14–21. doi: 10.1016/j.foodchem.2011.02.052. [DOI] [PubMed] [Google Scholar]

- Cárcel JA, García-Pérez JV, Riera E, Mulet A. Influence of High-Intensity Ultrasound on Drying Kinetics of Persimmon. Dry. Technol. 2007;25:185–193. doi: 10.1080/07373930601161070. [DOI] [Google Scholar]

- Carlos ARJ, Byron DYV. Ultrasound as pretreatment to convective drying of Andean blackberry (Rubus glaucus Benth) Ultrason. Sonochem. 2015;22:205–210. doi: 10.1016/j.ultsonch.2014.06.011. [DOI] [PubMed] [Google Scholar]

- Chemat F, Huma Z, Khan MK. Applications of ultrasound in food technology: Processing, preservation and extraction. Ultrason. Sonochem. 2011;18:813–835. doi: 10.1016/j.ultsonch.2010.11.023. [DOI] [PubMed] [Google Scholar]

- Deng Y, Zhao Y. Effect of pulsed vacuum and ultrasound osmopretreatments on glass transition temperature, texture, microstructure and calcium penetration of dried apples (Fuji) LWT Food Sci. Technol. 2008;41:1575–1585. doi: 10.1016/j.lwt.2007.10.018. [DOI] [Google Scholar]

- Dujmić F, Brnčić M, Karlović S, Bosiljkov T, Ježek D, Tripalo B, Mofardin I. Ultrasound-Assisted Infrared Drying of Pear Slices: Textural Issues. J. Food Process Eng. 2013;36:397–406. doi: 10.1111/jfpe.12006. [DOI] [Google Scholar]

- Fernandes FAN, Rodrigues S, García-Pérez JV, Cárcel JA. Effects of Ultrasound-Assisted Air Drying on Vitamins and Carotenoids of Cherry Tomatoes. Dry. Technol. 2015;34:986–996. doi: 10.1080/07373937.2015.1090445. [DOI] [Google Scholar]

- Gamboa-Santos J, Montilla A, Cárcel JA, Villamiel M, Garcia-Perez JV. Air-borne ultrasound application in the convective drying of strawberry. J. Food Eng. 2014;128:132–139. doi: 10.1016/j.jfoodeng.2013.12.021. [DOI] [Google Scholar]

- Garcia-Perez JV, Puig A, Carcel JA, Perez-Munuera I. Enhancement of Water Transport and Microstructural Changes Induced by High-Intensity Ultrasound Application on Orange Peel Drying. Food Bioprocess Tech. 2012;5:2256–2265. doi: 10.1007/s11947-011-0645-0. [DOI] [Google Scholar]

- Garcia-Perez JV, Puig A, Perez-Munuera I, Carcel JA, Riera E. Kinetic and microstructural changes induced by power ultrasound application on convective drying of eggplant. In: Proceedings of the 20th International Congress on Acoustics (ICA 2010). August, Sydney, Australia. pp. 23-27 (2010)

- Kantrong H, Tansakul A, Mittal GS. Drying characteristics and quality of shiitake mushroom undergoing microwave-vacuum drying and microwave-vacuum combined with infrared drying. J. Food Sci. Technol. 2014;51:3594–3608. doi: 10.1007/s13197-012-0888-4. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kek SP, Chin NL, Yusof YA. Direct and indirect power ultrasound assisted pre-osmotic treatments in convective drying of guava slices. Food Bioprod. Process. 2013;91:495–506. doi: 10.1016/j.fbp.2013.05.003. [DOI] [Google Scholar]

- Kim DO, Jeong SW, Lee CY. Antioxidant capacity of phenolic phytochemicals from various cultivars of plums. Food Chem. 2003;81:321–326. doi: 10.1016/S0308-8146(02)00423-5. [DOI] [Google Scholar]

- Kim W-W, Ghimeray AK, Wu JC, Eom SH, Lee B-G, Kang W-S, Cho D-H. Effect of far infrared drying on antioxidant property, anti-inflammatory activity, and inhibitory activity in A549 cells of Gamguk (Chrysanthemum indicum L.) flower. Food Sci. Biotechnol. 2012;21:261–265. doi: 10.1007/s10068-012-0034-0. [DOI] [Google Scholar]

- Liu Y, Sun Y, Miao S, Li F, Luo D. Drying characteristics of ultrasound assisted hot air drying of Flos Lonicerae. J. Food Sci. Tech. 2015;52:4955–4964. doi: 10.1007/s13197-014-1612-3. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Liu Y, Sun Y, Yu H, Yin Y, Li X, Duan X. Hot air drying of purple-fleshed sweet potato with contact ultrasound assistance. Dry. Technol. 2016;35:564–576. doi: 10.1080/07373937.2016.1193867. [DOI] [Google Scholar]

- Liu Y, Wu J, Miao S, Chong C, Sun Y. Effect of a Modified Atmosphere on Drying and Quality Characteristics of Carrots. Food Bioprocess Tech. 2014;7:2549–2559. doi: 10.1007/s11947-014-1295-9. [DOI] [Google Scholar]

- Liu Y, Zeng Y, Wang Q, Sun C, Xi H. Drying characteristics, microstructure, glass transition temperature, and quality of ultrasound-strengthened hot air drying on pear slices. J Food Process. Preserv. 2019;43:e13899. doi: 10.1111/jfpp.13899. [DOI] [Google Scholar]

- Midilli A. Determination of pistachio drying behaviour and conditions in solar drying system. Int. J. Energ. Res. 2001;25:715–725. doi: 10.1002/er.715. [DOI] [Google Scholar]

- Nowacka M, Wiktor A, Śledź M, Jurek N, Witrowa-Rajchert D. Drying of ultrasound pretreated apple and its selected physical properties. J. Food Eng. 2012;113:427–433. doi: 10.1016/j.jfoodeng.2012.06.013. [DOI] [Google Scholar]

- Ortuño C, Pérez-Munuera I, Puig A, Riera E, Garcia-Perez JV. Influence of power ultrasound application on mass transport and microstructure of orange peel during hot air drying. Phys. Procedia. 2010;3:153–159. doi: 10.1016/j.phpro.2010.01.022. [DOI] [Google Scholar]

- Pawar SB, Pratape VM. Fundamentals of Infrared Heating and Its Application in Drying of Food Materials: A Review. J. Food Process Eng. 2017;40:e12308. doi: 10.1111/jfpe.12308. [DOI] [Google Scholar]

- Pei F, Shi Y, Mariga AM, Yang WJ, Tang XZ, Zhao LY, An XX, Hu QH. Comparison of Freeze-Drying and Freeze-Drying Combined with Microwave Vacuum Drying Methods on Drying Kinetics and Rehydration Characteristics of Button Mushroom (Agaricus bisporus) Slices. Food Bioprocess Tech. 2014;7:1629–1639. doi: 10.1007/s11947-013-1199-0. [DOI] [Google Scholar]

- Riadh MH, Ahmad SAB, Marhaban MH, Soh AC. Infrared Heating in Food Drying: An Overview. Dry. Technol. 2015;33:322–335. doi: 10.1080/07373937.2014.951124. [DOI] [Google Scholar]

- Riera E. Application of High-Power Ultrasound for Dehydration of Vegetables: Processes and Devices. Dry. Technol. 2007;25:1893–1901. doi: 10.1080/07373930701677371. [DOI] [Google Scholar]

- Rodríguez Ó, Santacatalina JV, Simal S, Garcia-Perez JV, Femenia A, Rosselló C. Influence of power ultrasound application on drying kinetics of apple and its antioxidant and microstructural properties. J. Food Eng. 2014;129:21–29. doi: 10.1016/j.jfoodeng.2014.01.001. [DOI] [Google Scholar]

- Ruiz Celma A, López-Rodríguez F, Cuadros Blázquez F. Experimental modelling of infrared drying of industrial grape by-products. Food Bioprod. Process. 2009;87:247–253. doi: 10.1016/j.fbp.2008.10.005. [DOI] [Google Scholar]

- Sabarez HT, Gallego-Juarez JA, Riera E. Ultrasonic-Assisted Convective Drying of Apple Slices. Dry. Technol. 2012;30:989–997. doi: 10.1080/07373937.2012.677083. [DOI] [Google Scholar]

- Salehi F, Kashaninejad M, Jafarianlari A. Drying kinetics and characteristics of combined infrared-vacuum drying of button mushroom slices. Heat Mass Transfer. 2016;53:1751–1759. doi: 10.1007/s00231-016-1931-1. [DOI] [Google Scholar]

- Schössler K, Jäger H, Knorr D. Effect of continuous and intermittent ultrasound on drying time and effective diffusivity during convective drying of apple and red bell pepper. J. Food Eng. 2012;108:103–110. doi: 10.1016/j.jfoodeng.2011.07.018. [DOI] [Google Scholar]

- Sun J, Zhao J, Fu D, Gu S, Wang D. Extraction, Optimization and antimicrobial activity of IWSP from oleaginous microalgae chlamydomonas sp YB-204. Food Sci. Technol. Res. 2017;23:819–826. doi: 10.3136/fstr.23.819. [DOI] [Google Scholar]

- Tekin ZH, Baslar M. The effect of ultrasound-assisted vacuum drying on the drying rate and quality of red peppers. J. Therm. Anal. Calorim. 2018;132:1–13. doi: 10.1007/s10973-018-6991-7. [DOI] [Google Scholar]

- Vega-Gálveza A, Ah-Hen K, Chacana M, Vergara J, Martínez-Monzó J, García-Segovia P, Lemus-Mondaca R. Empirical modeling of drying process for apple (cv. Granny Smith) slices at different air temperatures. J. Food Process. Preserv. 2010;32:972–986. doi: 10.1111/j.1745-4549.2008.00227.x. [DOI] [Google Scholar]

- Vega-Gálveza A, Ah-Hen K, Chacana M, Vergara J, Martínez-Monzó J, García-Segovia P, Lemus-Mondacaad R. Effect of temperature and air velocity on drying kinetics, antioxidant capacity, total phenolic content, colour, texture and microstructure of apple (var. Granny Smith) slices. Food Chem. 2012;132:51–59. doi: 10.1016/j.foodchem.2011.10.029. [DOI] [PubMed] [Google Scholar]

- Wiktor A, Sledz M, Nowacka M, Rybak K, Witrowa-Rajchert D. The influence of immersion and contact ultrasound treatment on selected properties of the apple tissue. Appl. Acoust. 2016;103:136–142. doi: 10.1016/j.apacoust.2015.05.001. [DOI] [Google Scholar]