Abstract

With the aim of improving the loss of quality in retorted vegetables, experiments on pretreatment inactivation using microwaves were carried out to allow the heating intensity to be reduced during retorting. Microwave heating reduced the bacteria level by 103 CFU/g, and was a more effective method considering the short processing time of 3 min and the required energy being 70–80% of that when using steam. The inactivation effect was due to dielectric heat generation by the high-frequency microwaves. The inactivation effect for heat-resistant Bacillus amyloliquefaciens was indicated by a reduction of 102 CFU/g after 3 min of microwave heating. The total bacteria counts for peeled potato and spicy sauce with vegetables decreased by 3–4 log CFU/g after 3 min using microwaves, and heat-resistant microorganisms were reduced by 2 log CFU/g. Combining microwave heating and mild retorting is expected to produce higher quality vegetable foodstuffs compared to conventional retorting.

Keywords: Microwave heating, Vegetable foodstuffs, Pretreatment inactivation, Dielectric, Retort

Introduction

Various vegetables represent important materials in processed foods. But their weak structural characteristics during heating limit manufacturing methods to processes such as low-temperature heating, drying, and freezing so as to minimize the deterioration of sensory quality. Inactivation methods for vegetables based on heating include blanching for several tens of seconds at 100 °C and pasteurization for 10–30 min at 85 °C (Choi et al., 2018). But this type of mild heating makes it difficult to inactive the heat-resistance microorganisms that are associated with decreased organoleptic quality and safety. However, a loss of quality is inevitable when applying retorting at 121 °C to kill spores on vegetable foodstuffs (Gokhale and Lele, 2014; Kwak and Chang, 2001; Lee et al., 2012).

Hot-air drying is another widely used method for the long-term storage of vegetables. However, such drying is associated with various restrictions due to the generation of off-flavors, tough texture, and browning reactions (Hwang and Rhim, 1994). Freeze-drying at a low temperature can minimize the disadvantages of hot-air drying, but it results in a brittle structure and is more expensive than other methods. The quality of frozen vegetables is degraded during defrosting, and they are not convenient to store (Choi et al., 2015). Other inactivation methods such as adding natural antimicrobial agents including alcohol, organic acid, surfactant, calcium, and bacteriocin are relatively ineffective at controlling microorganisms, and their use is limited by the deterioration of taste, aroma, and color (Cho et al., 1994; Choi et al., 2018). Choi et al. (2013) reported on the use of ultrahigh pressure (a nonthermal inactivation method), but spores are not killed and can only be applied to refrigeration products such as sauces, jam, and processed meat and fish. In summary, the current processing and inactivation methods are not able to adequately control the levels of microorganisms in various vegetable foodstuffs while maintaining good quality, and so a new inactivation method is required that also exhibits the characteristic of a uniform temperature distribution.

One way to minimize excessive heating during sterilization is to reduce the retort conditions via pretreatment inactivation with microwave heating. Microwaves are used in the various food industries for cooking, pasteurization, drying, and thawing (Campañone et al., 2010; Chandrasekaran et al., 2013). Microwave heating occurs via dielectric loss due to the polarization of dipoles by electromagnetic waves with frequencies from 300 MHz to 300 GHz (Bae and Lee, 2010; Choi and Koh, 1993). In the case of foodstuffs, rapid internal heating due to the vibration of water molecules induced by microwaves can kill microorganisms with only a slight loss of sensory quality within a short time compared to conventional conduction heating. While the mechanism of microwave inactivation has been identified as microbial death by rapid dielectric heating at high frequency, the nonthermal inactivation effects of electromagnetic fields have not been clearly revealed (Curet et al., 2013; van Remmen et al., 1996). Previous studies of microwave inactivation have been restricted to applying pasteurization for pathogenic and spoilage microorganisms in chilled products, and the inactivation of enzymes (Bows, 2000; Kang et al., 2013). There have been few detailed studies of the important factors influencing microwave inactivation, such as the energy consumption, initial temperature, and physical properties of the foods and packaging materials (Knoerzer et al., 2007; Kwak and Chang, 2001).

As a result of considering the relevant research literature, there were relatively few studies on the sterilization of room temperature distribution foods using microwave heating. Therefore, the aim of the present study was to develop a novel technology for the inactivation of microorganisms in instant-cooking foods containing various vegetables and stored for a long time at room temperature, based on microwaves as a new heating method that can enhance the inactivation effect on heat-resistant microorganisms.

Materials and methods

Materials

The vegetables used as foodstuffs in sauces tested in this study, such as potato, carrot, onion, and red pepper, were purchased at a local market in Seoul, Korea. The samples were stored at 4 °C in a refrigerator to minimize any changes in quality such as taste, flavor, and appearance.

Microwave heating

Thermoduric bacteria that survive pasteurization at 63 °C for 30 min or 72 °C for 15 s are Bacillus, Clostridium, Microbacterium, and Micrococcus. Among these thermostable bacteria, Bacillus spp. is a soil-derived microorganism, which is present in many vegetables. The presence of heat-resistant bacteria in processed food products containing vegetables is important since they degrade the quality and present sanitary problems. Therefore, the inactivation effect of microwave heating against Bacillus amyloliquefaciens, which is a typical heat-resistant microorganism, was investigated.

To examine the inactivating effect of microwave heating in food material against heat-resistant bacteria, a 1-mL suspension of B. amyloliquefaciens was mixed with 110 g of sterilized soaked rice and 80 mL of distilled water in a sterilized transparent vinyl pouch made of PP (polypropylene) material, and then heated in a household microwave oven (RE-C21VW, 700 W, Samsung Electronics Co., Ltd., Seoul, Korea) with high frequency generation on three sides for 0, 3, 4, or 5 min.

In addition, unpeeled and peeled cubes (1.5 cm × 1.5 cm × 1.5 cm) of washed potato, and model foodstuffs such as sauces containing vegetables, spices, and seasonings were packed in a standing vinyl pouch with heat-resistance and heated by microwaves of 100 °C for 3 min. Potato is a typical vegetable used as a food raw material, and the main growth microorganism is a heat-resistant Bacillus spp. Considering this fact, potato was selected as a sample for inactivation experiment in this study. The temperature of the sample in the microwave oven was measured using a fiber optic temperature sensor (OPTOCON TS3, Weidmann Inc., Dresden, Germany), and used for setting of heating temperature and calculation of amount of heat generated.

Atmospheric and superheated steaming were used as control methods in this study at processing conditions of 100 °C for 20 min and 350 °C for 8 min, respectively. Superheated and atmospheric steaming were done in a superheated steamer (DFC-240W, Naomoto, Osaka, Japan) by adjustment of heating temperature and treatment time.

In the experiments, the temperature and time conditions on microwave and steam heating were determined through preliminary experiments. Each of the atmospheric steam, superheated steam, and microwave heating conditions applied to the experiment was firstly selected in consideration of the heating temperature and time range in which the characteristic flavor and color of the sample potato were not changed. Then, the final application temperature and time were selected considering the conditions that could be applied in the production line with commercialized equipment. The heating energy in microwave and steam heating was calculated by using the specific heat, mass and the temperature of the food materials. And the microwave energy was calculated by using output power of microwave oven and processing time.

Combination with retorting

In order to improve the quality of the retorted vegetables by reducing the heating intensity during retorting, the effect of combining pretreatment sterilization using microwaves and retorting was investigated in this study.

Retorting was performed after microwave heating using a pilot-scale, one-basket, water-cascading retort (Water Cascading Retort, Stock Pilot-Rotor 900, Hermann Stock Maschinenfabrik, Neumünster, Germany). A sterilization temperature of 121.1 °C and a steam pressure of 2.1 kgf/cm2 were used in each experiment. Considering the temperature and time at which the vegetable base foods could reach the sterilized state, the retort conditions using the control were set at 121 °C for 20 min by preliminary experiment.

Each experiment was repeated at least five times, and the obtained data were subjected to statistical analysis. The temperature profile of the samples during each sterilization process were monitored using an F0 sensor (TrackSense Prosensor, Ellab, Hilleroed, Denmark).

Measurement of microbial inactivation effects

The B. amyloliquefaciens strain was incubated on nutrient agar at 30 °C for 1 week. A suspension of cultured vegetative cells containing endospores was then collected by centrifugation (12,000×g for 2 min) and washed by repeated centrifugation/resuspension in sterile distilled water at 4 °C. Plastic cryopreservation tubes containing 1 mL of suspension (108 CFU/mL) were stored at − 70 °C until used. In general, Bacillus spp. that grows in vegetables is mixed with vegetative cell and endospore forming vegetative cell with heat resistance. Therefore, in the experiment, Bacillus spp. was prepared mixed type with vegetative cell and spore similar to actual environment.

The inactivation effect of microwave heating against B. amyloliquefaciens was measured using standard colony counting on tryptic soy broth agar (TSB, Difco Laboratories, Detroit, MI, USA) plates. And the inactivation effect of pretreatment in microwave heating was quantified based on the total bacterial growth on plate count agar (PCA, Difco Laboratories, Detroit, MI, USA) (Choi et al., 2018; Kwak and Chang, 2001). And heat-resistant bacteria were counted on trypticase soy agar (TSA, Difco Laboratories, Detroit, MI, USA) plates by analysis of total bacterial count after heating the ground sample mixed with sterile distilled water at 90 °C for 10 min.

Sensory evaluation

The organoleptic characteristics of the samples were determined by a trained panel such as 20 researchers who are in charge of processed food development. After completing three training sessions relate to descriptive profiling, hedonic testing, and perception, sensory attributes were evaluated based on the degree of overall acceptability of the treated potatoes and spicy sauce based on consideration of the taste, color, flavor, and texture. The panelists rated the preference of sensory attributes of each sample on a 5-point hedonic scale from 1 (extremely bad) to 5 (extremely good).

Statistical analysis

All of the data are expressed as mean and SD values of five replicate measurements. The significance of differences between the samples was assessed using analysis of variance and Duncan’s multiple-range test with Minitab software (MTB13, Minitab Inc., State College, PA, USA). The threshold for statistical significance was set at p < 0.05.

Results and discussions

Microbial inactivation effect of pretreatment methods

Methods of pretreatment inactivation using microwaves and steam were considered for improving the quality of heated vegetables by reducing the heating intensity in this study. The microwave and superheated steam heating methods, which have the advantages of rapid heating, were selected as effective pretreatment methods to avoid the excessive heat sterilization strength of retort which causes quality deterioration of vegetables. Peeled potatoes were heated with conventional atmospheric steam, superheated steam, and microwaves, for which the heating conditions were 100 °C for 20 min, 350 °C for 8 min, and 100 °C for 3 min, respectively.

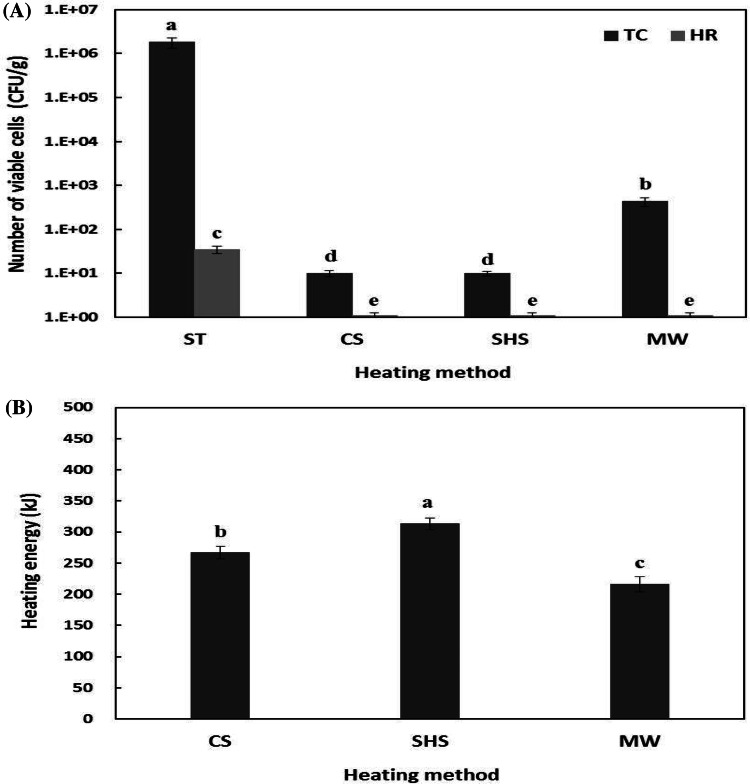

The experimental results are shown in Fig. 1. Each method showed an inactivation effect as a reduction of 103–104 CFU/g in the total number of cells, and there were no marked differences in the inactivation efficacy between the pretreatment methods. All three methods produced a killing effect of 99.9–99.99%, which is statistically significant (p < 0.05) compared to the untreated control. From these experimental results, it can be seen that atmospheric steam, superheated steam, and microwave heating could be utilized as methods of pretreatment inactivation in retorting [Fig. 1(A)].

Fig. 1.

Comparisons of the number of viable cells (A) and heating energy (B) for peeled potatoes when using steam or microwave heating. ST: no treatment, CS: conventional steam, SHS: superheated steam, MW: microwave heating, TC: total cell count, HR: heat-resistant microorganism. Bar data are mean and standard-deviation values; those marked with different letters differ significantly by ANOVA with Duncan’s multiple-range test at p < 0.05

Though all three methods produced effective inactivation, microwave heating was a more sufficient method when considering the sensory quality, cost, and commercial applications associated with a short processing time of 3 min and the heating energy required being 70–80% of that when using steam [Fig. 1(B)]. The reason that the heat energy was consumed low in the microwave heating as compared with the steam heating would be due to the rapid dielectric heating in the food inside by the high frequency vibration energy (Chandrasekaran et al., 2013; Park et al., 2017; Resurreccion et al., 2014). Therefore, the subsequent experiments were performed using microwave heating.

Inactivation by microwaves against heat-resistant bacteria

Bacillus amyloliquefaciens is a species of bacterium in genus Bacillus and α-amylase from B. amyloliquefaciens is often used in starch hydrolysis. It is also a source of subtilisin, which catalyzes the breakdown of proteins. This enzyme activity originated from the B. amyloliquefaciens causes damages on the quality of processed vegetable foods, so B. amyloliquefaciens has been selected as a target microbial for inactivation in this study.

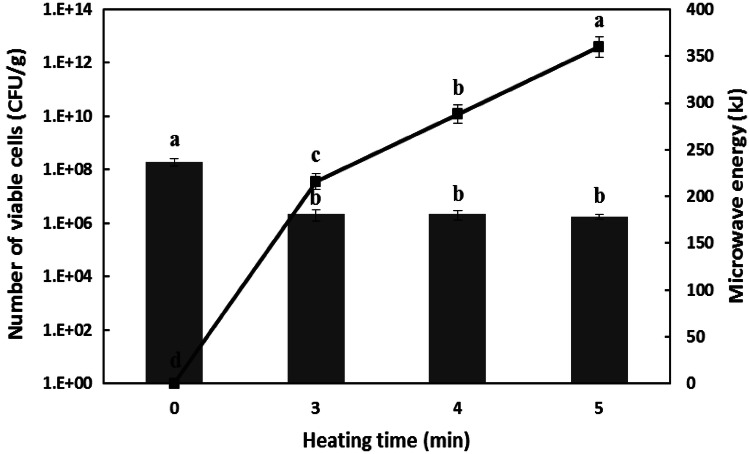

Microwave heating showed an inactivation effect of a reduction of 102 CFU/g after 3 min, but the killing intensity did not increase when the heating time was increased to 4–5 min (Fig. 2). Although this lengthening of the treatment time increased the applied thermal energy by 1.3- to 1.7-fold, it is assumed that the temperature of microwave heating did not rise above 100 °C and the inactivation effect does not increase all the time. This is because the microwave chamber is not in a sealed state where pressure can be applied during microwave heating.

Fig. 2.

Temporal changes in viable cell counts and microwave energy for heat-resistant B. amyloliquefaciens during microwave heating. “filled square”: heating energy. Bar data are mean and standard-deviation values; those marked with different letters differ significantly by ANOVA with Duncan’s multiple-range test at p < 0.05

The vegetative cell of Bacillus spp. form endogenous spores when depleted of nutrients required for propagation, and have heat resistance that does not sterilize at 100 °C. Therefore, if the heat-resistant bacteria of Bacillus species capable of forming endogenous spores in vegetable foods can be killed in advance by pre-treatment, the heat sterilization conditions of retort for storage at room temperature can be alleviated and the sensory quality can be improved. And also, considering that the level of heat-resistant bacteria in processed foods from either the ingredients or contamination is typically 102–103 CFU/g, the microwave heating could be applied as a pre-inactivation method for reducing the requirements of the retorting process (Lim, 1996; Luan et al., 2016).

In addition, if a sealed pressurized heating system capable of heating at high temperature and high pressure using microwave heating could be constructed, it will be possible to sterilize even heat resistant spores (Malyshev et al., 2019; Park et al., 2017).

Microbial inactivation effect of microwaves on various foods

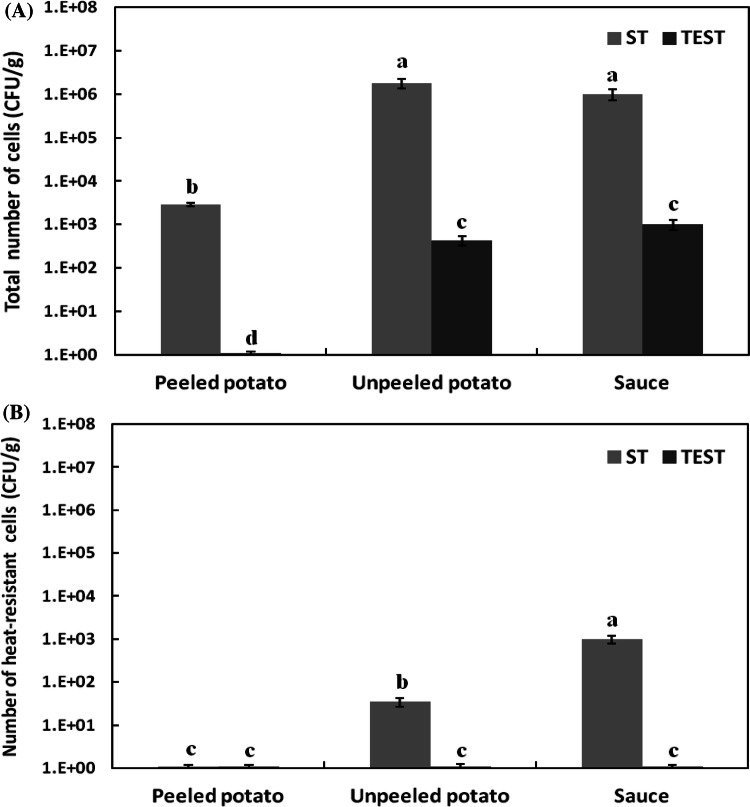

Peeled and unpeeled potatoes were heated by microwaves, respectively as representative samples for the detailed investigation of the inactivation effect on vegetables. The total bacteria counts of the peeled potato decreased by 3–4 log CFU/g after 3 min of microwave heating [Fig. 3(A)]. This indicates that peeled vegetables can be completely sterilized by microwave heating. In the case of unpeeled potato, the total cell count was around 6 log CFU/g, and so 3 log higher than for peeled potato. This meant that a cell count of 3 log CFU/g remained after the 3 log reduction produced by 3 min of microwave heating [Fig. 3(A)]. Regardless of whether the potato was peeled or unpeeled, the number of heat-resistant cells was reduced by 101–102 CFU/g [Fig. 3(B)].

Fig. 3.

Comparison of total number of viable cells (A) and number of heat-resistant viable cells (B) for potatoes and sauce with vegetables by microwave heating. ST: no treatment, TEST: microwave heating. Data are mean and standard-deviation values; those marked with different letters differ significantly by ANOVA with Duncan’s multiple-range test at p < 0.05

The inactivation effect of microwave was caused by dielectric heat generation by the high-frequency energy (Lim, 1996; Pandit and Prasad, 2003; Zhu et al., 2018). The microwave heating of potatoes was associated with reductions in the deterioration of odor and discoloration, in addition to the excellent bactericidal effects. Moreover, microwave heating can control the moisture content and significantly (p < 0.05) improve the quality of processed potatoes compared to when using water blanching (Lim, 1996; Pandit and Prasad, 2003; Resurreccion et al., 2014; Xu and Shi, 2017).

To investigate the effect of microwave inactivation on processed food, experiments were performed with spicy sauce consisting of various foodstuffs such as potato, carrot, onion, garlic, and pepper. The total bacterial count was decreased to 3 log CFU/g after 3 min of microwave heating, compared to a level of 6 log CFU/g in the controls without treatment, while heat-resistant microorganisms were reduced by 2 log CFU/g (Fig. 3).

The results of this study indicate the improvement in sensory qualities obtained by using microwaves rather than conventional heating with steam or hot water. The organoleptic qualities of a sauce such as its taste, flavor, color, and texture were significantly (p < 0.05) better after microwave treatment than after conventional conduction heating. The scores for the organoleptic characteristics were higher by 0.2–0.4 points for microwave heating (p < 0.05). Especially, when microwave heating inactivated, the taste and flavor related to spicy characteristic of the sauce were excellent as around 4.0 points. Moreover, microwave inactivation has several advantages such as energy efficiency due to the shorter processing time.

Combination of microwave heating and retorting

The sterilization effect obtained by combining microwave heating as preheating followed by retorting was confirmed by a reduction in the total cell count of 106 CFU/g for unpeeled potatoes and spicy sauce (Table 1), and the heating sterilization time for the retorting phase was reduced by 50% (i.e., 10 min, versus 20 min for traditional retorting). The combination of microwave heating and mild retorting was expected to result in a higher food quality during complete sterilization compared to using conventional retorting at 121 °C, because heat-resistant bacteria appeared to be inactivated after applying the microwave pretreatment.

Table 1.

Sterilization effects on potatoes and spicy sauce for the combination of microwave heating and retorting compared with other methods

| Sterilization method | |||||

|---|---|---|---|---|---|

| Control (no treatment) | Microwave heating | Retorting | Microwave heating + retorting | ||

| Sterilization conditions | Temperature | – | 100 °C | 121.1 °C | 100 °C, 121.1 °C |

| Time | – | 5 min | 20 min | 5 min, 10 min | |

| Total number of cells1 | Unpeeled potatoes | 1.8 ± 0.2×106a | 4.3 ± 0.4×102c | 0d | 0d |

| Peeled potatoes | 1.3 ± 0.1×103b | 0d | 0d | 0d | |

| Spicy sauce | 1.0 ± 0.1×106a | 0.0 ± 0.1×102c | 0d | 0d | |

Different superscript letters indicate values that differ significantly by ANOVA with Duncan’s multiple-range test at p < 0.05

1Data are mean ± standard-deviation values (n = 10)

The results obtained in this study suggest that microwave inactivation can be useful for improving the organoleptic qualities and microbial safety of various vegetable-based processed foods as a pretreatment process or in combination with retorting (Coronel et al., 2007; Malyshev et al., 2019). When the microwave heating is applied to vegetable foods, the temperature rise is faster than the hot water and steam heating in blanching, cooking and pasteurization, thus shortening the heating time which is advantageous in quality improvement and preservation of nutrients (Malyshev et al., 2019; Park et al., 2017).

Compliance with ethical standards

Conflict of interest

The authors declare that they have no conflict of interest.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Contributor Information

Won-Il Cho, Email: wonil.cho@cj.net.

Myong-Soo Chung, Email: mschung@ewha.ac.kr.

References

- Bae YM, Lee SY. Effect of microwave treatment and packaging methods on extending the shelf-life of RTE rice balls at room temperature. Korean J. Food Cook. Sci. 2010;26:165–170. [Google Scholar]

- Bows JR. A classification system for microwave heating of food. Int. J. Food Sci. Technol. 2000;35:417–430. doi: 10.1046/j.1365-2621.2000.00401.x. [DOI] [Google Scholar]

- Campañone LA, Paola CA, Mascheroni RH. Modeling and simulation of microwave heating of foods under different process schedules. Food Bioprocess Tech. 2010;5:738–749. doi: 10.1007/s11947-010-0378-5. [DOI] [Google Scholar]

- Chandrasekaran S, Ramanathan S, Basak T. Microwave food processing–a review. Food Res. Int. 2013;52:243–261. doi: 10.1016/j.foodres.2013.02.033. [DOI] [Google Scholar]

- Cho SH, Chung JH, Ryu CH. Inhibitory effects of natural antimicrobial agent on postharvest decay in fruits and vegetables under natural low temperature. J. Korean Soc. Food Nutr. 1994;23:315–321. [Google Scholar]

- Choi OJ, Koh MS. Changes in physico-chemical properties of potato starch by microwave heating methods. Korean J. Food Sci. Technol. 1993;25:461–467. [Google Scholar]

- Choi Y, Oh JH, Bae IY, Cho EK, Kwon DJ, Park HW, Yoon S. Changes in quality characteristics of seasoned soy sauce treated with superheated steam and high hydrostatic pressure during cold storage. Korean J. Food Cook. Sci. 2013;29:387–398. doi: 10.9724/kfcs.2013.29.4.387. [DOI] [Google Scholar]

- Choi JB, Chung MS, Cho WI. Pretreatment method of texture improvement on high fiber vegetables of freeze drying. Food Eng. Prog. 2015;19:285–290. doi: 10.13050/foodengprog.2015.19.4.285. [DOI] [Google Scholar]

- Choi JB, Cheon HS, Chung MS, Cho WI. Pretreatment sterilization of garlic and ginger using antimicrobial agents and blanching. Korean J. Food Sci. Technol. 2018;50:172–178. [Google Scholar]

- Coronel P, Simunovic J, Sandeep KP, Cartwright GD, Kumar P. Sterilization solutions for aseptic processing using a continuous flow microwave system. J. Food Eng. 2007;85:528–536. doi: 10.1016/j.jfoodeng.2007.08.016. [DOI] [Google Scholar]

- Curet S, Rouaud O, Boillereaux L. Estimation of dielectric properties of food materials during microwave tempering and heating. Food Bioprocess Tech. 2013;7:371–384. doi: 10.1007/s11947-013-1061-4. [DOI] [Google Scholar]

- Gokhale SV, Lele SS. Retort process modelling for Indian traditional foods. J. Food Sci. Technol. 2014;51:3134–3177. doi: 10.1007/s13197-012-0844-3. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Hwang KT, Rhim JW. Effect of various pretreatments and drying methods on the quality of dried vegetables. Korean J. Food Sci. Technol. 1994;26:805–813. [Google Scholar]

- Kang HJ, Lee HY, Park JD, Kum JS. Effect of microwave treatment on the physicochemical and microbiological characteristics of beef loin during storage at 4°C. Korean J. Food Sci. Technol. 2013;45:161–166. doi: 10.9721/KJFST.2013.45.2.161. [DOI] [Google Scholar]

- Knoerzer K, Regier M, Schubert H. A computational model for calculating temperature distributions in microwave food applications. Innov. Food Sci. Emerg. Technol. 2007;9:374–384. doi: 10.1016/j.ifset.2007.10.007. [DOI] [Google Scholar]

- Kwak YS, Chang JK. Effect of various sterilization methods on growth of microorganism contaminated in ginseng powder. J. Food Hyg. Saf. 2001;16:221–226. [Google Scholar]

- Lee YR, Woo KS, Hwang IG, Kim HY, Lee SH, Lee JS, Jeong HS. Physicochemical properties and antioxidant activities of garlic (Allium sativum L.) with different heat and pressure treatments. J. Korean Soc. Food Sci. Nutr. 41: 278-282 (2012)

- Lim SI. Use of microwave in food industry. Sterilization of pathogens through the microwave. Food Sci. Ind. 32: 19-34 (1996)

- Luan D, Tang J, Pedrow PD, Liu F, Tang Z. Analysis of electric filed distribution within a microwave assisted thermal sterilization (MATS) system by computer simulation. J. Food Eng. 2016;188:87–97. doi: 10.1016/j.jfoodeng.2016.05.009. [DOI] [Google Scholar]

- Malyshev D, Williams CF, Lees J, Baillie L, Porch A. Model of microwave effects on bacterial spores. J. Appl. Phys. 2019;125:1–32. doi: 10.1063/1.5085442. [DOI] [Google Scholar]

- Pandit RB, Prasad S. Finite element analysis of microwave heating of potato–transient temperature profiles. J. Food Eng. 2003;60:193–202. doi: 10.1016/S0260-8774(03)00040-2. [DOI] [Google Scholar]

- Park HS, Yang J, Choi HJ, Kim KH. Effective thermal inactivation of the spores of Bacillus cereus biofilms using microwave. J. Microbiol. Biotechnol. 2017;27:1209–1215. doi: 10.4014/jmb.1702.02009. [DOI] [PubMed] [Google Scholar]

- Resurreccion FP, Luan D, Tang J, Liu F, Tang Z, Pedrow PD, Cavalieri R. Effect of changes in microwave frequency on heating patterns of foods in a microwave assisted thermal sterilization system. J. Food Eng. 2014;150:99–105. doi: 10.1016/j.jfoodeng.2014.10.002. [DOI] [Google Scholar]

- van Remmen HHJ, Ponne CT, Nijhuis HH, Bartels PV, Kerkhof PJAM. Microwave heating distributions in slabs, spheres and cylinders with relation to food processing. J. Food Sci. 1996;61:1105–1114. doi: 10.1111/j.1365-2621.1996.tb10941.x. [DOI] [Google Scholar]

- Xu XL, Shi RC. Effect of microwave treatment on the sterilization effect and quality of mango puree. Chin. J. Trop. Crops. 2017;38:572–579. [Google Scholar]

- Zhu X, YangY, Duan Z. Research progress on the effect of microwave sterilization on agricultural products quality. Earth Environ. Sci. 113: 1-5 (2018)