Abstract

Workers in several industries are occupationally exposed to flame retardants. This study characterizes flame retardant exposure for nine industries through air and hand wipe measures for 105 workers. Specifically, we analyzed 24 analytes from three chemical classes: organophosphate flame retardants (OFRs), poly-brominated diphenyl ethers (PBDEs), and non-PBDE brominated flame retardants (NPBFRs). The industries were: carpet installation, chemical manufacturing, foam manufacturing, electronic scrap, gymnastics, rigid board installation, nail salons, roofing, and spray polyurethane foam. Workers wore personal air samplers for two entire workdays and provided hand wipe samples before and after the second work day. Bulk products were also analyzed. The air, hand wipe and bulk samples were evaluated for relevant flame retardants. Spray polyurethane foam workers’ tris(1-chloro-2-propyl) phosphate air (geometric mean=48,500 ng/m3) and hand wipe (geometric mean=83,500 ng per sample) concentrations had the highest mean industry concentration of any flame retardant analyzed in this study, followed by triphenyl phosphate air concentration and tris(1,3-dichloro-2-propyl) phosphate hand wipe concentration from chemical manufacturers. Overall, OFR air and hand wipe concentrations were higher and more prevalent than PBDEs or non-PBDE brominated flame retardants. Some industries including spray polyurethane foam application, chemical manufacturing, foam manufacturing, nail salons, roofing, and rigid polyiso board installation had high potential for both air and hand exposure to OFRs. Carpet installers, electronic scrap workers, and gymnastic workers had exposures to all three classes of flame retardants including PBDEs, which were phased out of production in 2013. Air and dermal exposures to OFRs are prevalent in many industries and are replacing PBDEs in some industries.

Keywords: Organophosphate flame retardants (OFRs), construction workers, roofers, gymnasts, electronic scrap, nail salons

1. INTRODUCTION

Flame retardants (FRs) are added to materials to slow and/or stop flame production. Specifically, poly-brominated diphenyl ethers (PBDEs) are FRs historically used in consumer products like electronics, foam furniture, and padding.(Brown et al., 2014) PBDEs accumulate in humans, have been associated with altered hormone regulation and possible neurobehavioral effects, and are listed in California Proposition 65 as potentially carcinogenic.(EPA, 2017; Linares et al, 2015; Park et al., 2015) Due to health concerns, penta- and octa- PBDEs were restricted globally when they were added to the Persistent Organic Pollutants (POPs) list at the 2009 Stockholm Convention, and the deca-formulation was added in 2017. (House, 2017) In part due to these restrictions, penta- and octa- PBDE production within the U.S. ended in 2004 and deca-PBDE production ended in 2013. However, PBDEs will continue to be released during end-of-life activities for products manufactured before 2013 like carpet and electronics. Manufacturers have primarily replaced PBDEs with non-PBDE brominated flame retardants (NPBFRs) or organophosphate flame retardants (OFRs), though some manufacturing companies have removed FRs from consumer products due to California 117–2013 and California SB-1019.(CDCA 2013 a; b) Specifically, 2,3,4,5–tetrabromobenzoate (TBB) and 2,3,4,5–tetrabromophthalte (TBPH) replaced penta-BDEs(Brown et al., 2014; Covaci et al., 2011; Stapleton et al., 2008) for polyurethane foams while triphenyl phosphate (TPP) was used before and after the PBDE phaseout. Deca-PBDEs have been replaced by decabromodiphenyl ethane (DBDPE) (CECBP, 2008) for acrylonitrile-butadiene-styrene (ABS) and high impact polystyrene (HIPS) plastics. These replacement FRs are expected to be safer due to a lack of bioavailability in comparison to PBDEs, but their fate in the environment is relatively unknown.(EPA, 2014a; b)

More information is needed to fully characterize the physiological effects of these replacement FRs. However, OFRs tris(2-chloroethyl) phosphate (TCEP) and tris(1,3-dichloro-2-propyl) phosphate (TDCPP) are currently listed in California Prop 65 as potentially carcinogenic.(EPA, 2017) One study found OFRs were associated with cytotoxicity(Behl et al., 2016) and another study found TDCPP may affect neurodevelopment.(Dishaw et al., 2011) At high concentrations, tris(1-chloro-2-propyl) phosphate (TCPP) may be toxic to human cells.(An et al., 2016; Li et al., 2017) Triphenyl phosphate (TPP) has been found to affect development in zebrafish.(Isales et al., 2015) Endocrine disruption has been observed for NPBFRs bis (2-ethylhexyl)-2,3,4,5tetrabromophtalate (TBPH) and 2-ethylhexyl-2,3,4,5-tetrabromobenzoate (TBB).(Saunders et al., 2013) Tetrabromobisphenol-A (TBBPA) is classified as a 2A, probably carcinogenic to humans by the International Agency for Research on Cancer (IARC). (WHO, 2018)

Use of FRs in various industries is changing with the phasing out of PBDEs and the subsequent increased use of OFRs and NPBFRs. From an occupational perspective, workers can be exposed to FRs during primary production (e.g. chemical manufacturing), secondary production (e.g. foam production), downstream usage (e.g. spray polyurethane foam application, roofers, and nail salon workers), and decommissioning (e.g. electronic scrap workers and carpet workers). An assessment of FR occupational exposure will aid in determining exposure path (air or dermal), relationship to urinary biomarkers, and for use in animal models.

Some exposure assessments have been conducted on FRs in some of these industries, primarily focusing on dust, air, blood or urine and often focusing on only certain FRs. Gravel et al (2019) recently conducted a thorough literature review of occupational exposure to FRs and reported mean and max air levels for three PBDEs, TPP, TDCPP, TBBPA aind HBCDs. (Gravel et al., 2019) Electronic scrap workers were found to have the highest reported levels for BDE-47, BDE-209, TPP, TDCPP and TBBPA. Studies have reported high concentrations of TCPP for personal air samples during spray polyurethane foam applications and lower concentrations of other OFRs like TDCPP and TPP.(Marlow et al., 2017; Marlow et al., 2014; Wood, 2017) Bello et al. also evaluated spray polyurethane foam workers and found high TCPP air concentrations and high glove dosimeters concentrations that were significantly associated with post-shift urinary TCPP biomarkers.(Bello et al., 2018) Hand wipe concentrations have also been evaluated among gym workers and electronic scrap workers.(Beaucham et al., 2019; Ceballos et al., 2018; Makinen et al. 2009) PBDE exposures have been well documented for gymnastic studio workers(Carignan et al., 2013; Ceballos et al., 2018; La Guardia and Hale, 2015), electronic scrap workers(Beaucham et al., 2019; Rosenberg et al., 2011; Sjodin et al., 2001) with more limited work on carpet installers.(Stapleton et al., 2008)

Due to the decreased use of PBDEs, foam manufacturers and installers of new roof and wall board are likely exposed to OFRs and NPBFRs. Long-term users of foam like gymnastics workers may be exposed to PBDEs in addition to NPBFRs and OFRs. Indeed, a gymnastic coach’s TDCPP and TBB personal air concentrations from a gymnastic studio were significantly higher compared to samples collected at home.(La Guardia and Hale, 2015) Another study conducted in 2013 found penta-BDEs, TBB, and TBPH air concentrations were higher in gymnastic studios than in residences.(Carignan et al., 2013) A more recent study in 2018 found TDCPP concentrations on hand wipe samples taken from gymnastic workers increased significantly during the work day.(Ceballos et al., 2018) From the same study, penta-BDEs concentrations on hand wipe samples were much lower, but above the limit of detection (LOD). Carpet installers may also be exposed to PBDEs during removal of older carpet padding or carpet padding with recycled foam and NPBFRs and OFRs during installation of newer carpet padding.

Electronic scrap (i.e. dismantling of plastic housing or electronics) workers are expected to have the highest exposure to PBDEs because the products they breakdown were often manufactured before 2013. In 2001, a study examining FR air concentrations at an electronic scrap site found PBDEs and NPBFRs at orders of magnitude higher than other work environments. (Sjodin et al., 2001) More recently, a study detected several organophosphates at electronic scrap facilities including TPP, TCPP, and TDCPP in addition to PBDEs. (Makinen et al., 2009; Rosenberg et al., 2011) In 2019, Beaucham et al. examined hand wipes at an electronics scrap facility and found relatively high concentrations of BDE-209, demonstrating PBDE exposure for electronic scrap workers may still be significant. (Beaucham et al., 2019)

Industrial workers are likely exposed to various FRs through air or hand contact. We sought to determine exposure levels to 24 FRs among workers from nine industries, some of which have not been studied recently, by evaluating bulk, air and hand wipe concentrations and comparing differences among industries.

2. METHODS

2.1. Study Design

This was a convenience sample, and 19 companies across nine industries were recruited to participate from 2015–2017. A literature search determined which industries were likely using FRs. Companies from those industries were sent a letter and called to request a site visit. If a business responded and was interested in participating, a site visit or walkthrough was scheduled. Table 1 explains the type of work the sampled workers conducted within each industry. By conducting a walkthrough of the business, reviewing safety data sheets, or discussing with managers, we determined which of 24 FRs (Table 2) were being used by the business.

Table 1.

Description of the Industries

| Industry | Industry Designation | Number of Businesses | Description of worker tasks |

|---|---|---|---|

| Carpet Installation | Decommissioning | 1 | Removed old carpet and padding from residences and replaced it with new carpet and padding. Foam and padding were recycled. |

| Chemical Manufacturing | Primary Production | 1 | Monitored control center, conducted sampling and added ingredients in a process room and conducted maintenance. Workers added ingredients to vessel by altering valves, not pouring. They did grab approximately one cup for occasional tests. |

| Electronic Scrap | Decommissioning | 2 | Manually disassembled, sorted, or shipped electronics, drove forklift trucks, loaded or maintained shredders, or conducted data destruction (de-gaussing). |

| Foam Manufacturing | Secondary Production | 2 | Operated control panels, conducted quality control in a laboratory, replaced paper rolls, drove forklift truck, occasionally cleaned nozzles or extra foam in the process to make high density polyiso board. |

| Gymnastics | Decommissioning | 1 | Coached children to perform exercises on trampoline, floormats, bars, pommel horse, etc., in a large gymnasium with multiple foam pits. Foam was recycled. |

| Rigid Polyiso Board Installation | Downstream Usage | 1 | Cut, fit, and installed exterior insulation (rigid cellular polyisocyanaurate thermal insulation) onto outside of a building that was being constructed and was not yet enclosed. Cutting was conducted with razor blades. |

| Nail Salon | Downstream Usage | 4 | Removed old polish, messaged, applied moisturizers, applied base coatings, new polish and top coatings on hands or feet. Rarely, performed eyebrow sculpting. |

| Roofing | Downstream Usage | 1 | Removed old materials, cleaned and prepared the surface, applied bonding adhesive, installed thermoplastic membrane, installed gypsum board, cut, fit and installed high density polyiso board, then covered with a white ultraply membrane on an industrial roof. |

| Spray Polyurethane Foam | Downstream Usage | 6 | Prepared area with protective tarps, sprayed polyurethane foam, cut newly sprayed foam, cleaned area at various commercial or residential job sites. |

Table 2.

Flame Retardants Measured in Air, Hand Wipe, and Bulk Sample

| Analyte | CAS number |

|---|---|

| Organophospate flame retardants (OFRs) | |

| Triphenyl phosphate (TPP or TPhP) | 115–86–6 |

| Tris(1,3-dichloro-2-propyl) phosphate (TDCPP) | 13674–87–8 |

| Tricresyl phosphate (TCP) | 1330–78–5 |

| Tris(1-chloro-2-propyl) phosphate (TCPP, TCIPP) | 13674–84–5 |

| Tris(2-chloroethyl) phosphate (TCEP) | 115–96–8 |

| Non-PBDE-brominated (NPBFRs) | |

| 2-Ethylhexyl 2,3,4,5-tetrabromobenzoate (TBB) | 183658–27–7 |

| 1,2-bis (2,4,6-tribromophenoxy) ethane (BTBPE) | 37853–59–1 |

| Decabromodiphenylethane (DBDPE) | 84852–53–9 |

| Di (2-ethylhexyl)-2,3,4,5-tetrabromophthalate (TBPH) | 26040–51–7 |

| Heaxabromocyclododecane (α-, β-, γ-HBCD) | 25637–99–4 |

| Tetrabromobisphenol-A (TBBPA) | 79–94–7 |

| Polybrominated diphenyl ethers (PBDEs) | |

| BDE-28, -47, and -66 | 41318–75–6, 5436–43–1, 189084–61–5 |

| BDE-85, -99, and -100 | 182346–21–0, 60348–60–9, 189084–64–8 |

| BDE-153, -154, and -183 | 68631–49–2, 207122–15–4, 207122–16–5 |

| BDE-206 and -209 | 63387–28–0, 1163–19–5 |

Sampling methods were similar for all industries and flame retardant categories, and were explained in a previous paper documenting only spray polyurethane foam workers. (Estill et al., 2019) Briefly, researchers collected two air and hand wipe samples over a period of two sampling days from each participant. Air sampling was conducted on two consecutive days for each participant, while hand wipe sampling was conducted before and after the work shift on the second day. Bulk samples of products were collected.

We did not analyze for all classes of chemicals for some industries. Sometimes, we initially analyzed for a class of chemicals and did not analyze for that class on subsequent visits to companies in that particular industry, e.g. if more than 50% of hand wipe and air samples were below the LOD.

Of the 24 FRs being evaluated in this study, only TPP, TCP, and PBDE-209 have US occupational exposure limits (OEL) for air concentrations. TPP has a Threshold Limit Value of 3 mg/m3 established by the American Conference of Governmental Industrial Hygienists. (ACGIH, 2018) TCP has an Occupational Safety and Health Administration (OSHA) permissible exposure limit (PEL) of 0.1 mg/m3.(NIOSH, 2010) PBDE-209 has a Workplace Environmental Exposure Level of 5 mg/m3. (AIHA, 2013) In addition, the People’s Republic of China established an OEL for TCP of 0.3 mg/m3. (IFA, 2015)

2.2. Recruiting Participants

All workers performing job tasks with target FRs at each business were invited to participate in the study. Participants signed an informed consent and were given a brochure explaining the project. Participants were also asked demographic and career-related questions to better understand their exposures.

2.3. Bulk Samples

Bulk samples of products of potential exposure were collected during site visits to businesses in each industry, excluding electronic scrap facilities. Bulk products varied in type based on industry but consisted of liquid or foam materials that workers were handling or using. The products used at the electronic scrap facilities were too varied to make it useful to collect and analyze these products. Specific products from each business were documented and safety data sheets were collected. All bulk products were analyzed for OFRs (nail products only TPP and TCP) and TBBPA while gymnastics foam and carpet padding were also analyzed for the other NPBFRs and the PBDEs.

2.4. Air Samples

Workers wore AirChek 5000 (SKC Inc., Eighty Four, PA) personal air samplers on two sequential days, operated at sample flow rates of 1 L/min. An OSHA Versatile Sampler (OVS) with XAD-2 sorbent and glass wool separator sampling media was used. The sampling was conducted for each workers’ entire shift. Samplers were worn on the collar outside of respirators. All pumps were calibrated before and after use to within ten percent of 1 L/min using a low or medium flow DryCal Defender (MesaLabs, Lakewood, CO). Investigators recorded the number of minutes the personal air sampling pumps were running per day, equivalent to the total time that the workers spent on the job site, and respirator use was observed and recorded.

2.5. Hand Wipe Samples

On the second day of sequential sampling, pre-shift and post-shift hand wipe samples were collected from worker’s hands. Two 3”× 3” sterile gauze pads (Dynarex, Orangeburg, NY) were placed in 120 mL amber glass jars (Fisher Scientific, Pittsburgh, PA). Each jar included 6 mL of 99% HPLC grade isopropanol (Fisher Scientific) using an automatic pipette. The jars were then tightly sealed, and stored at approximately 5°C for up to seven days. Samples were collected in a break room or conference room before and after the work shift. During sample collection participants were instructed to grab one of the gauze pads and wipe both sides of their bare hands (the area from the bend of the wrist to the fingertips) for 30 seconds. Then they were instructed to grab the other wipe and repeat the process. Both gauze pads were placed into the same jar, sealed, and stored at refrigerated temperatures until analyzed. At the end of the day, workers were asked how many times they washed their hands that work day and glove use was observed and recorded.

2.6. Sample Analysis

Air, hand wipe, and bulk samples were analyzed for FRs at Virginia Institute of Marine Sciences, College of William and Mary. The analysis was completed by ultra-performance liquid chromatography (UPLC) - atmospheric pressure photoionization (APPI) tandem mass spectrometry adapted from La Guardia and Hale. (La Guardia and Hale, 2015)

At least one field blank per ten hand wipe and air samples was collected during each site visit. Surrogate standards including deuterated TDCPP (dTDCPP) for TDCPP, TCEP, TCPP, and TBBPA, deuterated triphenyl phosphate (d15-TPP) for TCP and TPP and 2,3,4,4’,5,6-hexabromodiphenyl ether (BDE-166) for TBB, BTBPE, DBDPE, TBPH, α-, β-, γ-HBCD, and all PBDEs were used to estimate extraction recoveries, and those recovery values were used to correct each respective FR levels. Briefly, 6000 ng/sample dTDCPP, 600 ng of d15-TPP, and 500 ng of BDE-166 were added to samples when analytes of interest were evaluated. dTDCPP, d15-TPP and BDE-166 levels were also evaluated, and the result was a percentage of the “spiked” amount. All samples were adjusted by dividing by the recovery percentage and subtracting any lab processing media blank or field blank amount. In the event both a media and field blank were above the LOD, the highest blank value was used for correction.

2.7. Statistical Analysis

Data from air and hand wipe samples were transformed using the natural logarithms. LOD divided by square root of two was assigned to concentrations not detected. (Hornung and Reed, 1990) Descriptive statistics were presented as frequency (%), mean ± standard deviation (SD), median, and range for study subjects characteristics by industry. In addition, percentage above LOD, geometric mean and standard deviation (GSD), and median were provided for air and hand wipe concentrations by industry.

Air sampling concentrations from two consecutive sampling days were averaged using the time-weighted average (TWA) method. Multiple comparisons were conducted to determine significant differences of TWA air and post-shift hand wipe analyte concentrations between industries. All statistical tests were two-sided at the 0.05 significance level. Analyses were performed in SAS version 9.4 (SAS Institute, Cary, NC). Note that we used Principal component analysis (PCA) for post-shift hand wipes that had high detection rates (> 50%) in most PBDEs, and identified new latent and uncorrelated variables (principal components (PCs)) and common patterns of exposure (results shown in the Supplemental Table S5).

3. RESULTS

3.1. Demographics

One hundred eleven workers from 19 companies representing nine industries agreed to participate in the study. However, six participants were excluded due to missing both hand wipe samples. Overall, 105 participants were included in this analysis, and characteristics of the participants are shown in Table 3

Table 3.

Characteristics of Study Participants by Industry, N=105

| Industry | Carpet Installation | Chemical Manufacturing | Electronic Scrap | Foam Manufacturing | Gymnastics | Rigid Board Installation | Nail Salon | Roofing | Spray Polyurethane | Total |

|---|---|---|---|---|---|---|---|---|---|---|

| (N = 2) | (N = 10) | (N = 19) | (N = 11) | (N = 9) | (N = 3) | (N = 12) | (N = 10) | (N = 29) | (N=105) | |

| Characteristic | No. (%) | No. (%) | No. (%) | No. (%) | No. (%) | No. (%) | No. (%) | No. (%) | No. (%) | No. (%) |

| Gender | ||||||||||

| Male | 2 (100) | 9 (90) | 13 (68) | 11 (100) | 2 (22) | 3 (100) | 2 (17) | 10 (100) | 29 (100) | 81 (77) |

| Female | 0 | 1 (10) | 6 (32) | 0 | 7 (78) | 0 | 10 (83) | 0 | 0 | 24 (23) |

| Age, years | ||||||||||

| Mean ± SD | 40 ± 12 | 41 ± 9 | 38 ± 12 | 41 ± 10 | 29 ± 8 | 36 ± 11 | 46 ± 8 | 25 ± 8 | 30 ± 8 | 35 ± 11 |

| Median | 40 | 37 | 39 | 39 | 26 | 38 | 46 | 22 | 29 | 34 |

| Range | 31 – 48 | 28 – 54 | 19 – 57 | 28 – 55 | 18 – 43 | 24 – 46 | 35 – 64 | 18 – 45 | 20 – 51 | 18 – 64 |

| Race | ||||||||||

| White | 2 (100) | 10 (100) | 11 (58) | 10 (91) | 9 (100) | 3 (100) | 0 | 10 (100) | 26 (90) | 81 (77) |

| Black | 0 | 0 | 2 (10) | 1 (9) | 0 | 0 | 0 | 0 | 3 (10) | 6 (6) |

| Asian | 0 | 0 | 0 | 0 | 0 | 0 | 12 (100) | 0 | 0 | 12 (11) |

| Other | 0 | 0 | 6 (32) | 0 | 0 | 0 | 0 | 0 | 0 | 6 (6) |

| Ethnicity | ||||||||||

| Hispanic or Latino | 0 | 0 | 4 (21) | 0 | 0 | 0 | 0 | 1 (10) | 1 (3) | 6 (6) |

| Other | 2 (100) | 10 (100) | 15 (79) | 11 (100) | 9 (100) | 3 (100) | 12 (100) | 9 (90) | 28 (97) | 99 (94) |

| Hand washed | ||||||||||

| No | 0 | 0 | 0 | 1 (9) | 1 (11) | 3 (100) | 0 | 8 (80) | 16 (55) | 29 (28) |

| Yes | 2 (100) | 10 (100) | 19 (100) | 9 (82) | 8 (89) | 0 | 12 (100) | 2 (20) | 13 (45) | 75 (71) |

| Missing | 0 | 0 | 0 | 1 (9) | 0 | 0 | 0 | 0 | 0 | 1 (1) |

| Glove worn | ||||||||||

| No | 2 (100) | 1 (10) | 1 (5) | 1 (9) | 9 (100) | 0 | 7 (58) | 6 (60) | 5 (17) | 32 (31) |

| Intermittent | 0 | 1 (10) | 17 (90) | 2 (18) | 0 | 3 (100) | 2 (17) | 0 | 15 (52) | 40 (38) |

| Yes | 0 | 8 (80) | 1 (5) | 8 (73) | 0 | 0 | 3 (25) | 4 (40) | 9 (31) | 33 (31) |

| Respirator worn | ||||||||||

| None | 2 (100) | 10 (100) | 17 (89) | 11 (100) | 9 (100) | 3 (100) | 7 (58) | 10 (100) | 8 (28) | 77 (73) |

| Surgical | 0 | 0 | 2 (11) | 0 | 0 | 0 | 5 (42) | 0 | 0 | 7 (7) |

| Half | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 10 (34) | 10 (10) |

| Full | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 3 (10) | 3 (3) |

| Supplied air | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 8 (28) | 8 (8) |

3.2. Bulk Results

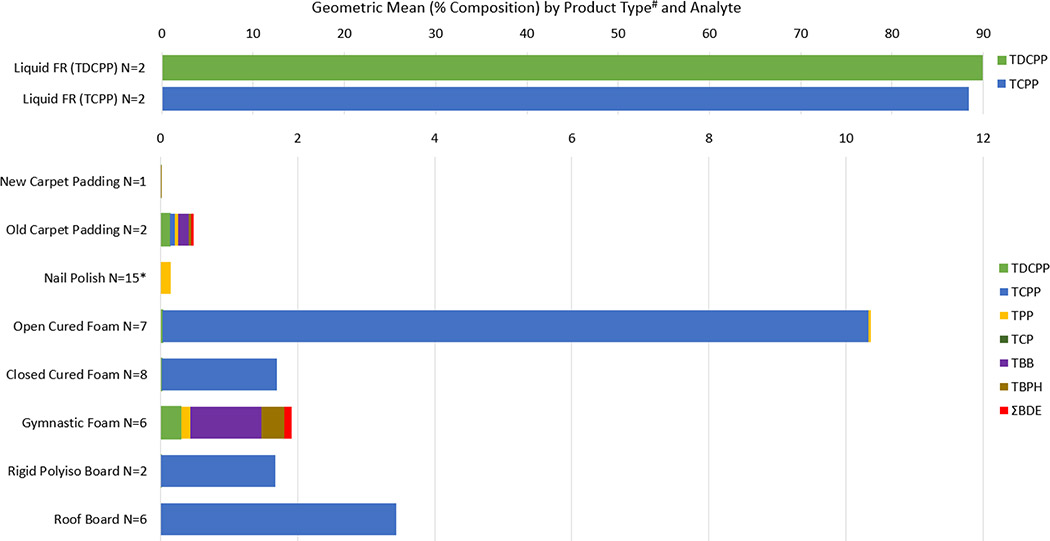

Figure 1 and Supplemental Table S1 present bulk sampling results for OFRs, NPBFRs, and PBDEs by % weight. All samples analyzed for TCPP were above the LOD. As expected, liquid TCPP FR from the chemical manufacturing plant had a very high percentage of TCPP. Similarly, liquid TDCPP FR produced by the chemical manufacturing plant had a very high level (89.9%) of TDCPP. Downstream usage products like roof boards, spray polyurethane, and rigid board foam had TCPP geometric means from 1.67% to 10.3%, while products from decommissioning industries like carpet padding and gymnastic foam had very low percentages (< 0.08%). Among samples collected from spray polyurethane sites, cured open-cell foam had higher TCPP concentrations than closed-cell (Supplemental Table, S1). When examining TPP, only three product types had 50% of samples above the LOD for TPP including nail products, gymnastic foam, and old carpet padding. Gymnastic foam contained many FRs, while rigid board foam mainly contained TCPP. Of nine types of bulk samples analyzed, only new carpet padding contained TCP or TBBPA above the LOD, but the levels were low at 0.005% and 0.00002%, respectively. Of all sample types, only decommissioning products like old carpet padding contained TCEP. By product type, old carpet padding had greater percentage weight FR concentrations compared to new carpet padding for all analytes tested. Supplemental Table S2 shows decommissioning product gymnastic foam had greater geometric mean PBDE concentrations than old carpet padding. Gymnastic foam also had the highest geometric means of TBB and TBP concentrations (1.04% and 0.34%). New carpet did not have any PBDE analytes above the LOD, and only had very low levels (< 0.01%) of other FRs tested.

Figure 1.

Geometric Mean Percent Composition in Bulk Samples by Product Type and Analyte (color required)

# For liquid FR, we measured TDCPP and TCPP; for carpet padding and gymnastic foam, we measured all analytes; for cured foam, rigid polyiso board, and roof board, we measured TDCPP, TCPP, TPP, and TCP.

* Only TPP and TCP were measured in nail polishes.

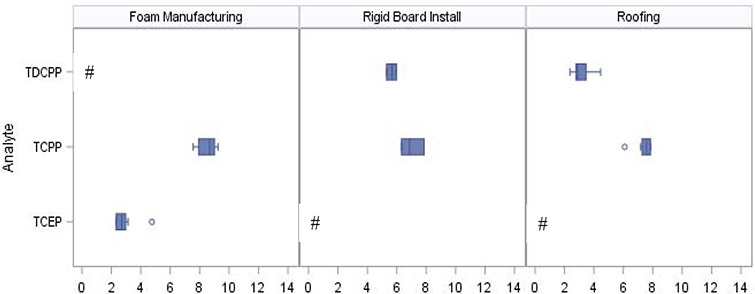

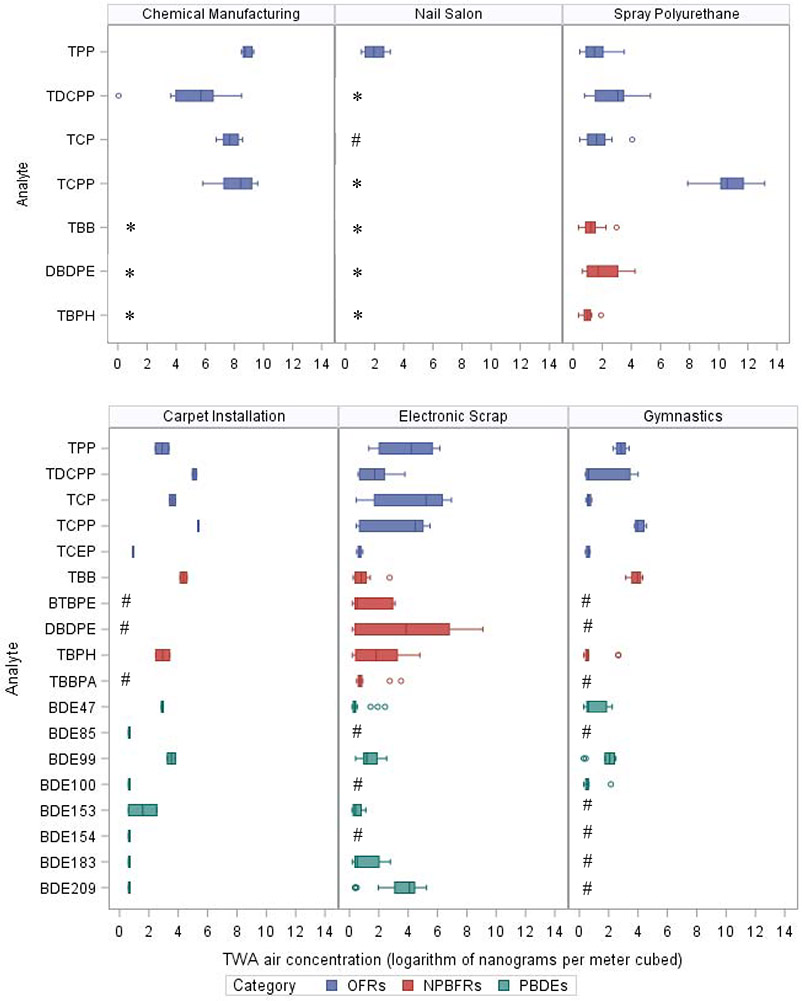

3.3. Air Results

Air sampling results are provided in Table 4 and Figure 2. TWA personal air concentrations of TPP collected from chemical manufacturing workers were significantly higher (Geometric Mean = 7170 ng/m3) than all other measured industry groups, while electronic scrap workers were found to have greater concentrations than those from nail salon and spray polyurethane foam industries. Decommissioning and primary production industries had the highest air TPP air concentrations. TCP air concentrations were highest for primary production chemical manufacturers (Geometric Mean = 2200 ng/m3), and significantly greater than other industries. Air concentrations of TDCPP were highest for workers across all industry designations including installing rigid polyiso board, (Geometric Mean = 285 ng/m3) chemical manufacturers, (Geometric Mean = 188 ng/m3) and carpet installers (Geometric Mean = 165 ng/m3). Moreover, the workers from these three industries had statistically higher TDCPP concentrations compared to gymnastic and foam manufacturing industries. Less than half of TDCPP concentrations were above the LOD for downstream users roofing and spray polyurethane foam industries, and gymnastic facilities. TCPP air concentrations for workers in primary and secondary production as well as downstream usage industries. In particular, the spray polyurethane foam industry (Geometric Mean = 48500 ng/m3) were nine-times higher than the other industries. Additionally, TCPP concentrations from foam and chemical manufacturing, roofing, and rigid polyiso board installation had Geometric Means above 1100 ng/m3. All industries tested had 100% of TCPP air samples above the LOD except electronic scrap (58%). Other decommissioning industries carpet installers and gymnastic workers had higher TBB air concentrations than those from spray polyurethane foam and electronic scrap industries. No industry tested had BTBPE or TBBPA air concentrations above the LOD for more than 50% of the workers. Electronic scrap and spray polyurethane foam workers had air concentrations above the LOD for DBDPE. All air, hand, and bulk samples tested for α-, β-, γ-HBCD were below the LOD.

Table 4.

OFRs, NPBFRs, and PBDEs Time-Weighted Average of Air Concentrations* (ng/m3)

| Analyte† | Industry | N | > LOD (%) | Geometric Mean (GSD) | Median | Multiple Comparisons of Industries‡ (significant differences in means of log-concentrations are listed) | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| TPP | All | 68 | 77 | 21.32 (8.91) | 12.05 | |||||

| Chemical Mfg. | 5 | 100 | 7169.6 (1.46) | 6227.2 | ||||||

| Electronic Scrap | 19 | 100 | 50.85 (5.66) | 67.80 | CM-ES | |||||

| Carpet Installation | 2 | 100 | 18.17 (1.90) | 20.08 | CM-CI | |||||

| Gymnastics | 9 | 100 | 17.18 (1.47) | 17.33 | CM-G | |||||

| Nail Salon | 12 | 100 | 7.39 (2.06) | 7.16 | CM-NS | ES-NS | ||||

| Spray Polyurethane | 21# | 24 | 4.96 (2.47) | 4.37 | CM-SP | ES-SP | ||||

| TDCPP | All | 93# | 43 | 17.25 (5.63) | 17.00 | |||||

| Rigid Board Installation | 3 | 100 | 285.4 (1.40) | 291.8 | ||||||

| Chemical Mfg. | 10 | 90 | 188.2 (10.75) | 303.3 | ||||||

| Carpet Installation | 2 | 100 | 165.2 (1.22) | 166.8 | ||||||

| Roofing | 10# | 30 | 22.64 (1.82) | 18.13 | CM-R | |||||

| Spray Polyurethane | 29# | 35 | 15.31 (3.63) | 21.53 | RB-SP | CM-SP | ||||

| Electronic Scrap | 19 | 53 | 5.18 (2.76) | 5.57 | RB-ES | CM-ES | CI-ES | |||

| Gymnastics | 9# | 33 | 4.96 (4.94) | 1.88 | RB-G | CM-G | CI-G | |||

| Foam Mfg. | 11# | 0 | ||||||||

| TCP | All | 68 | 57 | 11.58 (11.94) | 4.53 | |||||

| Chemical Mfg. | 5 | 100 | 2218.9 (2.09) | 2145.3 | ||||||

| Electronic Scrap | 19 | 79 | 50.53 (13.63) | 185.1 | CM-ES | |||||

| Carpet Installation | 2 | 100 | 36.96 (1.32) | 37.66 | CM-CI | |||||

| Spray Polyurethane | 21 | 76 | 5.31 (2.34) | 5.01 | CM-SP | ES-SP | ||||

| Gymnastics | 9# | 11 | 1.91 (1.15) | 1.89 | CM-G | ES-G | ||||

| Nail Salon | 12# | 0 | ||||||||

| TCPP | All | 93 | 91 | 1669.9 (25.46) | 2579.0 | |||||

| Spray Polyurethane | 29 | 100 | 48512 (3.63) | 39564 | ||||||

| Foam Mfg. | 11 | 100 | 4989.6 (1.80) | 5876.9 | SP-FM | |||||

| Chemical Mfg. | 10 | 100 | 3391.7 (3.62) | 4706.5 | SP-CM | |||||

| Roofing | 10 | 100 | 1687.7 (1.71) | 1958.7 | SP-R | |||||

| Rigid Board Installation | 3 | 100 | 1114.5 (2.18) | 962.0 | SP-RB | |||||

| Carpet Installation | 2 | 100 | 214.0 (1.04) | 214.0 | SP-CI | |||||

| Gymnastics | 9 | 100 | 59.71 (1.39) | 53.03 | SP-G | FM-G | CM-G | R-G | RB-G | |

| Electronic Scrap | 19 | 58 | 22.74 (9.08) | 88.41 | SP-ES | FM-ES | CM-ES | R-ES | RB-ES | |

| TCEP | All | 93# | 1 | 5.28 (3.49) | 2.59 | |||||

| Foam Mfg. | 11# | 9 | 17.12 (2.00) | 14.96 | ||||||

| Spray Polyurethane | 29# | 0 | ||||||||

| Chemical Mfg. | 10# | 0 | ||||||||

| Roofing | 10# | 0 | ||||||||

| Rigid Board Installation | 3# | 0 | ||||||||

| Carpet Installation | 2# | 0 | ||||||||

| Gymnastics | 9# | 0 | ||||||||

| Electronic Scrap | 19# | 0 | ||||||||

| TBB | All | 42 | 64 | 6.08 (4.14) | 3.34 | |||||

| Carpet Installation | 2 | 100 | 78.41 (1.39) | 80.54 | ||||||

| Gymnastics | 9 | 100 | 46.26 (1.52) | 52.15 | ||||||

| Spray Polyurethane | 12# | 25 | 3.75 (2.05) | 3.39 | CI-SP | G-SP | ||||

| Electronic Scrap | 19 | 68 | 2.41 (1.81) | 2.22 | CI-ES | G-ES | ||||

| BTBPE | All | 42# | 21 | 2.84 (2.46) | 1.91 | |||||

| Electronic Scrap | 19# | 47 | 4.25 (3.33) | 1.70 | ||||||

| Carpet Installation | 2# | 0 | ||||||||

| Gymnastics | 9# | 0 | ||||||||

| Spray Polyurethane | 12# | 0 | ||||||||

| DBDPE | All | 42# | 40 | 11.45 (13.57) | 2.45 | |||||

| Electronic Scrap | 19 | 58 | 44.81 (24.71) | 47.22 | ||||||

| Spray Polyurethane | 12 | 50 | 7.37 (3.47) | 6.15 | ||||||

| Carpet Installation | 2# | 0 | ||||||||

| Gymnastics | 9# | 0 | ||||||||

| TBPH | All | 42# | 48 | 4.60 (3.43) | 2.87 | |||||

| Carpet Installation | 2 | 100 | 18.92 (1.95) | 21.09 | ||||||

| Electronic Scrap | 19 | 68 | 7.23 (4.32) | 6.15 | ||||||

| Spray Polyurethane | 12# | 25 | 2.71 (1.48) | 2.66 | ||||||

| Gymnastics | 9# | 22 | 2.62 (2.62) | 1.77 | ||||||

| TBBPA | All | 93# | 2 | 3.85 (2.93) | 2.06 | |||||

| Electronic Scrap | 19# | 11 | 2.57 (2.20) | 1.98 | ||||||

| Spray Polyurethane | 29# | 0 | ||||||||

| Foam Mfg. | 11# | 0 | ||||||||

| Chemical Mfg. | 10# | 0 | ||||||||

| Roofing | 10# | 0 | ||||||||

| Rigid Board Installation | 3# | 0 | ||||||||

| Carpet Installation | 2# | 0 | ||||||||

| Gymnastics | 9# | 0 | ||||||||

| BDE-47 | All | 42# | 29 | 2.83 (2.64) | 1.85 | |||||

| Carpet Installation | 2 | 100 | 18.43 (1.09) | 18.46 | ||||||

| Spray Polyurethane | 12# | 25 | 4.13 (3.11) | 3.09 | ||||||

| Gymnastics | 9# | 44 | 2.97 (2.12) | 1.85 | CI-G | |||||

| Electronic Scrap | 19# | 16 | 1.79 (1.87) | 1.47 | CI-ES | SP-ES | ||||

| BDE-85 | All | 42# | 10 | 1.78 (1.48) | 1.61 | |||||

| Spray Polyurethane | 12# | 17 | 2.63 (1.66) | 2.39 | ||||||

| Carpet Installation | 2 | 100 | 1.93 (1.07) | 1.93 | ||||||

| Gymnastics | 9# | 0 | ||||||||

| Electronic Scrap | 19# | 0 | ||||||||

| BDE-99 | All | 42 | 71 | 4.94 (2.68) | 3.77 | |||||

| Carpet Installation | 2 | 100 | 34.10 (1.47) | 35.37 | ||||||

| Gymnastics | 9 | 78 | 5.90 (2.30) | 7.87 | ||||||

| Spray Polyurethane | 12# | 25 | 5.00 (3.78) | 3.09 | CI-SP | |||||

| Electronic Scrap | 19 | 95 | 3.67 (1.73) | 3.25 | CI-ES | |||||

| BDE-100 | All | 42# | 14 | 2.02 (2.00) | 1.61 | |||||

| Spray Polyurethane | 12# | 25 | 3.67 (2.60) | 2.80 | ||||||

| Gymnastics | 9# | 11 | 1.99 (1.76) | 1.77 | ||||||

| Carpet Installation | 2 | 100 | 1.93 (1.07) | 1.93 | ||||||

| Electronic Scrap | 19# | 0 | ||||||||

| BDE-153 | All | 42# | 26 | 2.09 (1.83) | 1.85 | |||||

| Carpet Installation | 2 | 100 | 4.82 (3.91) | 7.24 | ||||||

| Spray Polyurethane | 12# | 17 | 2.89 (2.24) | 2.39 | ||||||

| Electronic Scrap | 19# | 37 | 1.70 (1.38) | 1.52 | ||||||

| Gymnastics | 9# | 0 | ||||||||

| BDE-154 | All | 42# | 7 | 1.72 (1.32) | 1.61 | |||||

| Spray Polyurethane | 12# | 8 | 2.32 (1.31) | 2.24 | ||||||

| Carpet Installation | 2 | 100 | 1.93 (1.07) | 1.93 | ||||||

| Electronic Scrap | 19# | 0 | ||||||||

| Gymnastics | 9# | 0 | ||||||||

| BDE-183 | All | 42# | 29 | 2.55 (2.01) | 1.91 | |||||

| Electronic Scrap | 19# | 47 | 3.35 (2.57) | 1.70 | ||||||

| Spray Polyurethane | 12# | 8 | 2.32 (1.31) | 2.24 | ||||||

| Carpet Installation | 2 | 100 | 1.93 (1.07) | 1.93 | ||||||

| Gymnastics | 9# | 0 | ||||||||

| BDE-209 | All | 42# | 48 | 8.49 (6.40) | 2.90 | |||||

| Electronic Scrap | 19 | 84 | 33.50 (4.61) | 59.59 | ||||||

| Spray Polyurethane | 12# | 17 | 4.11 (5.13) | 2.75 | ES-SP | |||||

| Carpet Installation | 2 | 100 | 1.93 (1.07) | 1.93 | ES-CI | |||||

| Gymnastics | 9# | 0 | ||||||||

| Sum§ | All | 42 | 42.83 (2.65) | 37.60 | ||||||

| Carpet Installation | 2 | 68.83 (1.39) | 70.74 | |||||||

| Electronic Scrap | 19 | 61.74 (2.23) | 77.15 | |||||||

| Spray Polyurethane | 12 | 38.15 (3.58) | 24.70 | |||||||

| Gymnastics | 9 | 20.78 (1.51) | 20.77 | ES-G | ||||||

The concentrations below LOD were imputed at LOD/.

Other analytes measured with all results below the LOD were: α-, β-, γ-HBCD, BDE-28, -66, and -206 and they were measured in carpet installation, electronic scrap, gymnastics, and some spray polyurethane foam workers.

The abbreviations in the Multiple Comparisons of Industries are: Carpet Installation (CI), Chemical Manufacturing (CM), Electronic Scrap (ES), Foam Manufacturing (FM), Gymnastics (G), Nail Salon (NS), Rigid Board Installation (RB), Roofing (R), and Spray Polyurethane (SP). If the means of log-concentrations for two industries were significantly different, the comparison of the two industries would be presented in the table. For example, “CM-ES” means that the mean of log-concentrations for chemical manufacturing was significantly different from electronic scrap.

Samples above LOD were less than 50%.

Summation of BDE-47, BDE-85, BDE-99, BDE-100, BDE-153, BDE-154, BDE-183, and BDE-209. Note that except for the carpet installation industry, the concentrations below LOD were imputed. The electronic scrap samples had more than 50% detection for BDE-99 and BDE-209, while the gymnastics samples had more than 50% detection for BDE-99 only.

Figure 2.

Boxplots of TWA Air Concentrations by Analyte and Industry (color required)

* Not measured. # No samples were above the LOD.

Although a majority of PBDE concentrations were below the LOD (Table 4 and Figure 2), we note that BDE-99 air concentrations were generally above the LOD (71%) and statistically significant differences were found between carpet installers (Geometric Mean = 34.1 ng/m3), and spray polyurethane foam and electronic scrap workers. Overall, decommissioning industries had the highest PBDE air concentrations. Specifically, carpet installers were above the LOD for all PBDEs except BDE-28, −66, and −206, though the sample size was small (N = 2). BDE-99 air concentrations were above the LOD for the majority of electronic scrap workers (95%), and their corresponding concentrations (Geometric Mean = 3.67 ng/m3) were notably less than the carpet installers. BDE-28, −66, −206, and α-, β-, γ-HBCD were measured in carpet installation, electronic scrap, gymnastics, and some spray polyurethane workers, and all samples were below the LOD. All air concentrations were orders of magnitude below the few relevant OELs.

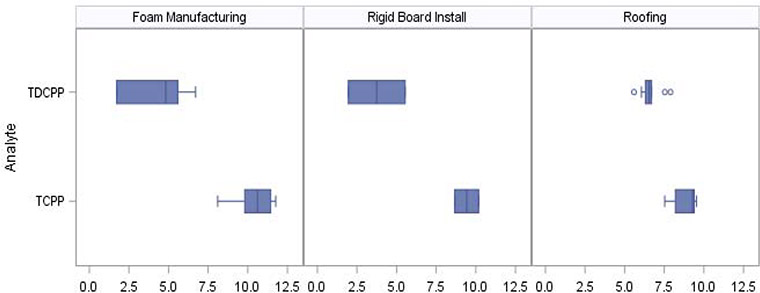

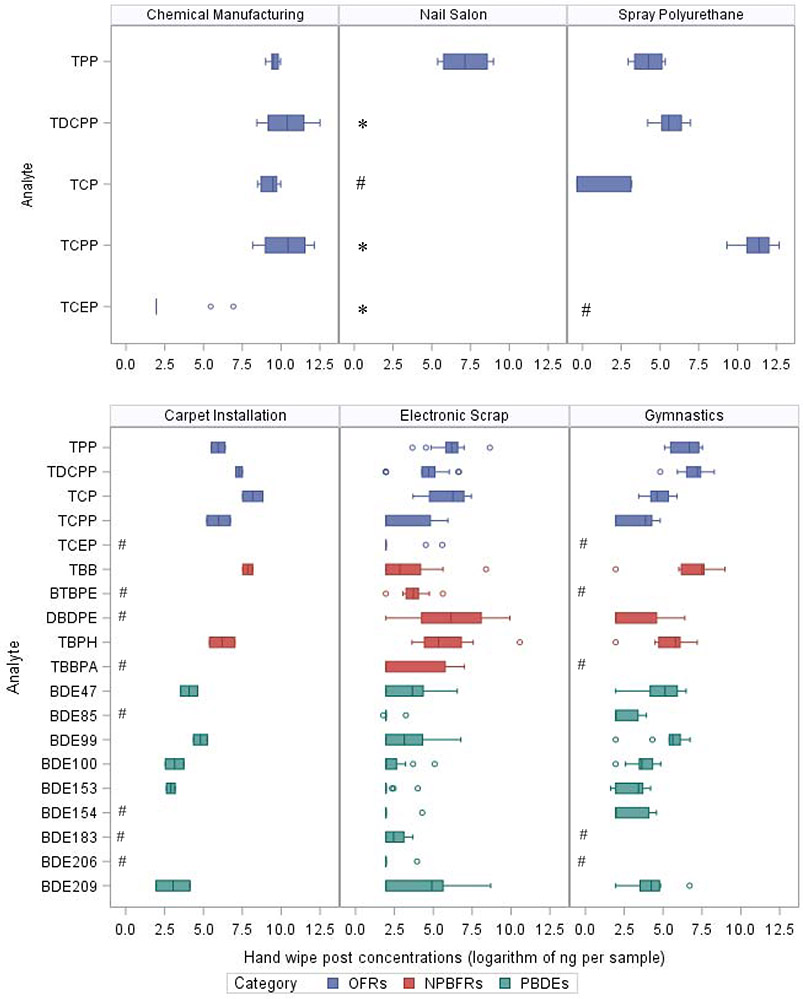

3.4. Hand Wipe Results

Table 5 and Figure 3 show results regarding OFRs and NPBFRs post-shift hand wipe concentrations. TPP and TDCPP concentrations were highest for chemical manufacturers (Geometric Mean = 13,800 and 32,800 ng/sample, respectively) working in primary production of FRs, and were significantly higher than other industries evaluated. In addition, chemical manufacturers had significantly greater TCP hand wipe concentrations (Geometric Mean = 10,700 ng/sample) than downstream usage industry workers in spray polyurethane foam and nail salons and decommissioning industry workers in electronic scrap and gymnastic studios. Overall, TCPP post-shift hand wipe concentrations were higher than for other analytes tested in this study. Primary and secondary production industries including foam and chemical manufacturers had high TCPP hand wipe concentrations (Geometric Mean = 35,900 and 31,200 ng/sample, respectively) that were significantly higher compared to roofers and decommissioning industries like carpet installers, and gymnastics and electronic scrap workers. Spray polyurethane foam workers had the highest TCPP hand wipe concentrations (Geometric Mean = 83,500 ng/sample) and significantly greater concentrations than the workers from all industries including roofing, carpet installation, gymnastics, and electronic scrap Only chemical manufacturing and electronic scrap workers had any workers with detectable hand wipe concentrations of TCEP and TBBPA. Carpet installers and gymnastic workers had higher TBB hand wipe concentrations than electronic scrap workers.

Table 5.

OFRs and NPBFRs Post-Shift Hand Wipe Concentrations* (ng/sample)

| Analyte† | Industry | N | > LOD (%) | Geometric Mean (GSD) | Median | Multiple Comparisons of Industries‡ (significant differences in means of log-concentrations are listed) | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| TPP | All | 53 | 100 | 635.6 (5.25) | 596.5 | ||||||

| Chemical Mfg. | 5 | 100 | 13843 (1.46) | 13267 | |||||||

| Nail Salon | 11 | 100 | 1350 (4.00) | 1264 | CM-NS | ||||||

| Gymnastics | 9 | 100 | 649.9 (2.65) | 796.1 | CM-G | ||||||

| Electronic Scrap | 19 | 100 | 431.7 (2.81) | 485.8 | CM-ES | ||||||

| Carpet Installation | 2 | 100 | 383.2 (1.87) | 421.3 | CM-CI | ||||||

| Spray Polyurethane | 7 | 100 | 69.16 (2.37) | 70.93 | CM-SP | NS-SP | G-SP | ES-SP | |||

| TDCPP | All | 78 | 87 | 386.7 (11.16) | 350.8 | ||||||

| Chemical Mfg. | 10 | 100 | 32759 (3.80) | 36531 | |||||||

| Carpet Installation | 2 | 100 | 1467 (1.35) | 1499 | |||||||

| Gymnastics | 9 | 100 | 979.5 (2.83) | 1358 | CM-G | ||||||

| Roofing | 10 | 100 | 756.5 (1.95) | 697.4 | CM-R | ||||||

| Spray Polyurethane | 15 | 100 | 291.4 (2.39) | 261.2 | CM-SP | ||||||

| Electronic Scrap | 19 | 79 | 81.37 (4.34) | 110.3 | CM-ES | G-ES | R-ES | ||||

| Foam Mfg. | 11 | 55 | 44.20 (7.68) | 124.7 | CM-FM | CI-FM | G-FM | R-FM | SP-FM | ||

| Rigid Board Installation | 2 | 50 | 42.44 (12.61) | 130.9 | CM-RB | ||||||

| TCP | All | 53 | 72 | 67.73 (27.42) | 109.0 | ||||||

| Chemical Mfg. | 5 | 100 | 10676 (1.90) | 13000 | |||||||

| Carpet Installation | 2 | 100 | 3531 (2.50) | 4301 | |||||||

| Electronic Scrap | 19 | 100 | 398.3 (3.13) | 524.0 | CM-ES | ||||||

| Gymnastics | 9 | 100 | 120.9 (2.29) | 100.7 | CM-G | CI-G | |||||

| Spray Polyurethane | 7# | 43 | 2.96 (6.01) | 0.71 | CM-SP | CI-SP | ES-SP | G-SP | |||

| Nail Salon | 11# | 0 | |||||||||

| TCPP | All | 92 | 85 | 3770 (38.11) | 13062 | ||||||

| Spray Polyurethane | 29 | 100 | 83523 (2.54) | 88696 | |||||||

| Foam Mfg. | 11 | 100 | 35884 (2.90) | 40516 | |||||||

| Chemical Mfg. | 10 | 100 | 31193 (3.95) | 34682 | |||||||

| Rigid Board Installation | 2 | 100 | 12393 (2.90) | 16076 | |||||||

| Roofing | 10 | 100 | 6931 (2.05) | 10742 | SP-R | FM-R | |||||

| Carpet Installation | 2 | 100 | 394.0 (2.89) | 510.3 | SP-CI | FM-CI | CM-CI | R-CI | |||

| Gymnastics | 9 | 67 | 32.31 (3.25) | 47.67 | SP-G | FM-G | CM-G | RB-G | R-G | ||

| Electronic Scrap | 19# | 42 | 23.02 (4.61) | 7.07 | SP-ES | FM-ES | CM-ES | RB-ES | R-ES | CI-ES | |

| TCEP | All | 78# | 5 | 7.11 (2.51) | 7.07 | ||||||

| Chemical Mfg. | 10# | 20 | 16.50 (6.17) | 7.07 | |||||||

| Electronic Scrap | 19# | 11 | 9.79 (2.69) | 7.07 | |||||||

| Carpet Installation | 2# | 0 | |||||||||

| Gymnastics | 9# | 0 | |||||||||

| Roofing | 10# | 0 | |||||||||

| Spray Polyurethane | 15# | 0 | |||||||||

| Foam Mfg. | 11# | 0 | |||||||||

| Rigid Board Installation | 2# | 0 | |||||||||

| TBB | All | 30 | 80 | 108.7 (11.63) | 57.73 | ||||||

| Carpet Installation | 2 | 100 | 2564 (1.57) | 2696 | |||||||

| Gymnastics | 9 | 89 | 913.2 (7.65) | 1808 | |||||||

| Electronic Scrap | 19 | 74 | 28.43 (4.97) | 17.27 | CI-ES | G-ES | |||||

| BTBPE | All | 30 | 60 | 21.64 (2.86) | 25.80 | ||||||

| Electronic Scrap | 19 | 95 | 41.34 (2.12) | 41.25 | |||||||

| Carpet Installation | 2# | 0 | |||||||||

| Gymnastics | 9# | 0 | |||||||||

| DBDPE | All | 30 | 63 | 130.4 (13.99) | 136.3 | ||||||

| Electronic Scrap | 19 | 84 | 418.6 (11.28) | 464.4 | |||||||

| Gymnastics | 9# | 33 | 21.26 (5.61) | 7.07 | ES-G | ||||||

| Carpet Installation | 2# | 0 | |||||||||

| TBPH | All | 30 | 97 | 273.4 (4.96) | 234.5 | ||||||

| Carpet Installation | 2 | 100 | 496.0 (3.16) | 669.5 | |||||||

| Electronic Scrap | 19 | 100 | 285.4 (5.58) | 209.2 | |||||||

| Gymnastics | 9 | 89 | 218.8 (4.62) | 331.3 | |||||||

| TBBPA | All | 78# | 17 | 10.39 (4.28) | 7.07 | ||||||

| Electronic Scrap | 19# | 47 | 44.11 (8.01) | 7.07 | |||||||

| Chemical Mfg. | 10# | 40 | 18.26 (3.63) | 7.07 | |||||||

| Carpet Installation | 2# | 0 | |||||||||

| Gymnastics | 9# | 0 | |||||||||

| Roofing | 10# | 0 | |||||||||

| Spray Polyurethane | 15# | 0 | |||||||||

| Foam Mfg. | 11# | 0 | |||||||||

| Rigid Board Installation | 2# | 0 | |||||||||

The concentrations below LOD were imputed at LOD/.

Other analytes measured with all results below the LOD were α-, β-, γ-HBCD, in which α-, β-, γ-HBCD which was measured in carpet installation, electronic scrap, and gymnastic workers.

The abbreviations in the Multiple Comparisons of Industries are: Carpet Installation (CI), Chemical Manufacturing (CM), Electronic Scrap (ES), Foam Manufacturing (FM), Gymnastics (G), Nail Salon (NS), Rigid Board Installation (RB), Roofing (R), and Spray Polyurethane (SP). If the means of log-concentrations for two industries were significantly different, the comparison of the two industries would be presented in the table. For example, “CM-ES” means that the mean of log-concentrations for chemical manufacturing was significantly different from electronic scrap.

Samples above LOD were less than 50%.

Figure 3.

Boxplots of Post-Shift Hand Wipe Concentrations by Analyte and Industry (color required)

* Not measured. # No samples were above the LOD.

Similar to air concentrations, PBDE hand wipe concentrations were highest for decommissioning industries. When evaluating PBDEs, gymnastic workers had higher post-shift hand wipe Geometric Mean concentrations, relative to electronic scrap workers among PBDE-47, 85, 99, 100, and 153, while electronic scrap workers had highest PBDE-209 hand wipe Geometric Mean concentration (Table 6 and Figure 3) but not significantly higher. Supplemental Table S3 and S4 present results with respect to OFRs, NPBFRs, and PBDEs averages of pre and post hand wipe concentrations.

Table 6.

PBDEs Post-Shift Hand Wipe Concentrations* (ng/sample)

| BDE† | Industry | N | > LOD (%) | Geometric Mean (GSD) | Median | Multiple Comparisons of Industries‡ (significant differences in means of log-concentrations are listed) |

|---|---|---|---|---|---|---|

| 47 | All | 30 | 73 | 47.77 (4.53) | 56.80 | |

| Gymnastics | 9 | 89 | 135.2 (4.22) | 167.6 | ||

| Carpet Installation | 2 | 100 | 58.95 (2.17) | 68.05 | ||

| Electronic Scrap | 19 | 63 | 28.55 (3.96) | 38.77 | G-ES | |

| 85 | All | 30# | 20 | 9.00 (1.79) | 7.07 | |

| Gymnastics | 9# | 44 | 13.95 (2.34) | 7.07 | ||

| Electronic Scrap | 19# | 11 | 7.50 (1.35) | 7.07 | G-ES | |

| Carpet Installation | 2# | 0 | ||||

| 99 | All | 30 | 73 | 55.59 (5.15) | 74.33 | |

| Gymnastics | 9 | 89 | 206.4 (4.26) | 276.8 | ||

| Carpet Installation | 2 | 100 | 122.3 (1.87) | 134.4 | ||

| Electronic Scrap | 19 | 63 | 27.49 (3.99) | 23.08 | G-ES | |

| 100 | All | 30 | 53 | 16.74 (2.80) | 10.91 | |

| Gymnastics | 9 | 89 | 38.81 (2.58) | 37.85 | ||

| Carpet Installation | 2 | 100 | 23.27 (2.32) | 27.49 | ||

| Electronic Scrap | 19# | 32 | 10.85 (2.31) | 7.07 | G-ES | |

| 153 | All | 30# | 40 | 11.52 (2.20) | 7.07 | |

| Gymnastics | 9 | 78 | 21.04 (2.69) | 30.56 | ||

| Carpet Installation | 2 | 100 | 18.16 (1.48) | 18.87 | ||

| Electronic Scrap | 19# | 16 | 8.25 (1.62) | 7.07 | G-ES | |

| 154 | All | 30# | 13 | 9.66 (2.25) | 7.07 | |

| Gymnastics | 9# | 33 | 15.41 (3.24) | 7.07 | ||

| Electronic Scrap | 19# | 5 | 8.00 (1.71) | 7.07 | ||

| Carpet Installation | 2# | 0 | ||||

| 183 | All | 30# | 33 | 10.22 (1.77) | 7.07 | |

| Electronic Scrap | 19 | 53 | 12.64 (1.88) | 11.57 | ||

| Carpet Installation | 2# | 0 | ||||

| Gymnastics | 9# | 0 | ||||

| 206 | All | 30# | 3 | 7.56 (1.44) | 7.07 | |

| Electronic Scrap | 19# | 5 | 7.85 (1.58) | 7.07 | ||

| Carpet Installation | 2# | 0 | ||||

| Gymnastics | 9# | 0 | ||||

| 209 | All | 30 | 73 | 73.90 (6.22) | 75.82 | |

| Electronic Scrap | 19 | 74 | 96.81 (7.35) | 135.3 | ||

| Gymnastics | 9 | 78 | 55.28 (4.39) | 69.13 | ||

| Carpet Installation | 2 | 50 | 20.98 (4.66) | 34.67 | ||

| Sum§BDE-47, -99, -100 and -153 | All | 30 | 144.0 (3.90) | 135.7 | ||

| Gymnastics | 9 | 423.0 (3.55) | 450.3 | |||

| Carpet Installation | 2 | 223.4 (1.95) | 248.9 | |||

| Electronic Scrap | 19 | 82.51 (3.15) | 84.24 | G-ES |

The concentrations below LOD were imputed at LOD/.

BDE-28 and BDE-66 were measured in carpet installation, electronic scrap, and gymnastic workers, and all results were below the LOD.

“Gymnastics-Electronic Scrap” means that the mean of log-concentrations for the gymnastics was significantly different from the electronic scrap.

Samples above LOD were less than 50%.

Summation of BDE-47, BDE-99, BDE-100, and BDE-153. Note that only the electronic scrap samples had less than 50% detection for BDE-100 and BDE-153.

4. DISCUSSION

The objective of the study was to characterize occupational exposures to FRs. It was difficult to find occupations where workers were exposed to PBDEs, because they were phased out in 2013 or earlier. (EPA, 2012; Health, 2006) Industries producing FRs in both a primary (chemical manufacturing workers) and secondary (foam manufacturing workers) fashion were included in the study. Several downstream usage industries were also included: spray polyurethane foam, nail salons, roofers, rigid board installation. Lastly, some decommissioning occupations with long-term and end-of-life use of PBDEs were included in the study: gym workers using foam cubes in pits, carpet workers removing and installing carpet padding, and electronic scrap. Site visits were conducted from 2015 to 2017, when many manufacturing companies had removed FRs from foam consumer products due to California 117–2013 or California SB-1019. (CDCA 2013a; b) California 117–2013, which took effect in 2014, changed the requirement for flammability testing in California and SB-1019 changed labeling requirements for FRs, resulting in many foam products no longer needing FRs. We analyzed for TBBPA in air and hand wipe samples for all industries except nail salons, and it was rarely detected. OFRs were found in many industries and workplaces, largely in supporting construction because construction flame retarding standards (Babrauskas et al., 2012) did not change during the study period. TCPP was the primary FR of interest in most of the industries evaluated, though other OFRs like TPP, TCP, and TDCPP were often detected as well.

The chemical manufacturing facility was a primary producer of FRs. Specifically, they produced TCPP and TDCPP liquid FRs during the two days of the site visit. Workers were adding to or sampling a large vessel of liquid FR held at 75–90 °C, conducting pipe maintenance, or monitoring control panels. Air and hand wipe sampling for TCPP and TDCPP at this facility were expected to be high because of the use of almost pure liquid FR. As expected, hand wipe concentrations of TCPP and TDCPP were higher (31,200 and 32,800 ng/sample, respectively) than TPP and TCP concentrations (13,900 and 10,700 ng/sample, respectively). Surprisingly, TPP and TCP air and hand wipe concentrations at the chemical manufacturing facility were statistically higher than most other industries tested. Although TPP and TCP were not being produced during our sampling visit, the plant may produce these at other times, or they may be an intermediate when producing TCPP or TDCPP. TPP air concentrations for chemical manufacturers (7,170 ng/m3) were greater than reported in other studies. Gravel et al (2019) conducted a systematic literature search for FR exposure studies and reported a finding from Makinen et al. (2009) as being the highest reported geometric mean concentration for TPP (850 ng/m3). A recent study reported TPP concentrations of 0.12 ng/m3 in residential homes and indoor areas, significantly lower than results found during occupational exposure assessments.(Kim et al., 2019) Chemical manufacturer TPP hand wipe concentrations in this study (13,900 ng/sample) were higher than a previous study examining TPP hand wipe concentrations (maximum of 1,230 ng/sample).(Hoffman et al., 2014) Air concentrations for chemical manufacturing workers were highest for TPP (7,170 ng/m3), TCPP (3,392 ng/m3), and TCP (2,219 ng/m3), compared to TDCPP (188 ng/m3).

Foam manufacturing workers were exposed to secondary production of FRs including liquid FR (99% TCPP) and polyiso boards (3.4% TCPP). They were found to have air and hand wipe exposures to TCPP. Air concentrations for these workers were an order of magnitude less than spray polyurethane foam workers, but higher than the other industries. They did not have any TDCPP air exposures above the limit of detection and were not tested for NPBFRs or PBDEs. Foam manufacturing workers’ TCPP hand wipe concentrations were statistically higher than roofers, carpet installers, gymnastic studio workers, and electronic scrap workers. Only 55% of foam manufacturing workers’ TDCPP hand wipe concentrations were above the LOD. However, pre hand wipe concentrations were higher than post concentrations for half the workers (data not shown), meaning workplace exposure to TDCPP for foam workers was likely low or nonexistent.

Spray polyurethane foam workers’ TCPP air concentrations were statistically and by an order of magnitude higher than all other industry workers tested. Bello et al. found higher results, confirming relatively high TCPP air concentrations for spray polyurethane foam workers. The high pressure application method (Estill et al., 2019; Wood, 2017) that aerosolizes spray foam likely contributes to increased exposures to TCPP for spray polyurethane foam workers. TCPP concentrations for indoor air environments including cars, theaters, offices, and electronic stores had maximum values of 260 ng/m3, orders of magnitude lower than found in our study. (Hartmann et al., 2004) TCPP hand wipe concentrations were also statistically higher than any industry tested except foam manufacturing, which was lower but not statistically so. Bello et al. used a glove dosimeter to sample dermal exposure for spray polyurethane foam workers and found even higher results, reporting TCPP geometric mean concentration of 18,800,000 ng/pair of gloves. Other OFRs were measured in air and hand wipes of spray polyurethane foam workers.

Other downstream usage industries like roofing and rigid board workers had work processes installing boards. Workers cut the boards to size and fastened them in place resulting in dust from cutting and handling of the boards. Roof boards contained about 3.5% TCPP, while the rigid polyiso boards contained about 1.5% TCPP and 0.001% TDCPP. Roofing and rigid board air concentrations of TCPP were not statistically different (1,700 and 1,100 ng/m3) and TCPP hand wipe concentrations were also not statistically different for roofers (6,900 ng/sample) and rigid polyiso board installers (12,400 ng/sample). TDCPP air concentrations for rigid polyiso board installers (285 ng/m3) were higher than spray polyurethane foam, electronic scrap, gyms, and foam manufacturing. Overall, rigid polyiso board installers’ TDCPP air concentrations were higher than any amount reported previously, according to a recent systematic review which found highest TDCPP geometric mean personal air concentrations (90 ng/m3) for e-waste workers in a study by Makinen et al (2009). (Gravel et al., 2019)

Other studies have focused on exposure to PBDE flame retardants in decommissioning industries like gymnastic studio workers (Carignan et al., 2013; Ceballos et al., 2018; La Guardia and Hale, 2015), electronic scrap workers (Beaucham et al., 2019; Rosenberg et al., 2011) and carpet installers. (Stapleton et al., 2008) PBDE hand wipe and air concentrations were lower than OFR concentrations for the industries measured. Carpet installers uncover and remove old carpet padding, aerosolizing padding particles, potentially contributing to their higher exposures. Neither carpet nor gym workers wore gloves or respirators. Carpet installers had greater air concentrations than gym workers for all analytes tested, however, the differences were statistically greater only for TDCPP and BDE-47. Carpet and gym workers had similar hand wipe concentrations for analytes measured except carpet workers had statistically higher levels of TCP compared to gym workers.

Gym workers in this study had higher PBDE (sum of −47, 99, 100, 153, 154) hand wipe concentrations than those in the Ceballos et al. (2018) study (423 versus 186 ng/samples) and similar when comparing NBPFRs and OPFRs. Gym workers FR air concentrations in this study were an order of magnitude lower than those reported by LaGuardia and Hale (2015) for most FRs, likely due to the weight percentage of FRs (1.2 to 2.4%) in the foam blocks compared to 0.5% in this study. Carignan (2013) measured hand wipe concentrations among collegiate gymnasts after practicing for 2–1/2 hours, and reported lower concentrations than post concentrations from gym workers in this study. One possible explanation for this difference is the gym worker’s length of time in the gym (3–1/2 to 7–1/2 hours per shift). (Carignan et al., 2013)

Although our study found BDE-209 air concentrations which were statistically higher for electronic scrap workers than carpet installation or gym workers, our levels were lower when compared to other research studies. Rosenberg et al (2011) evaluated electronic scrap facilities in 2008–09 and found BDE-209, TBBPA, and DBDPE to be the most abundant in personal air samples. (Rosenberg et al., 2011) Our study found TPP, TCP, DBDPE, and BDE-209 to be the most abundant in air. Makinen et al (2009) measured air and hand wipe concentrations in two electronic scrap companies and found geometric mean concentrations greater than this study for TPP, TCP, TCEP, TCPP, and TBBPA. This is especially true for TCEP, which was not detected in this study but were found at 1,050 and 450 ng/m3 in Makinen et al (2009), respectively. (Makinen et al., 2009) Beaucham et al. (2019) conducted hand wipe sampling of electronic scrap workers after their shift and reported results for the first gauze wipe concentration at much higher levels for TPP, TDCPP, TCP and BDE-209 than were found in this study. Differences could be related to change in FRs over time, the amount of automation, or different items being dismantled on the days of sampling. One of our electronic scrap facilities relied on only manual dismantling, the other had a very large shredder but only operated it on the first day of the survey.

When comparing bulk samples (Figure 1, Supplemental Tables S1 and S2), as expected, the liquid FR produced at the chemical company (TCPP 78.89%, N=1; TDCPP 89.87%, N=2) and the liquid FR that went into the foam product (TCPP 99.01%, N=1) had very high levels. Other TCPP bulk samples were 10% for open-cell spray polyurethane foam, 3.4% for roofing board and 1.7% for closed-cell spray polyurethane foam and rigid board. Open-cell spray polyurethane foam has a lower density compared with closed-cell foam, and generally has higher concentrations of TCPP compared to closed-cell (Estill, et al., 2019; Wood, 2017). Both are used in construction as insulation for buildings. These results focused the interest on TCPP at these workplaces. TPP was the chemical of interest for the nail salons and was found in their products at 0.15%. Of all the bulk samples tested, it is interesting that new carpet padding is the only sample that had levels above the LOD for TCP. Bulk sample weights for old carpet padding, new carpet padding, and gymnastic foam for all measured FRs were 0.5%, 0.01%, and 1.9%, respectively. Specifically, PBDEs weights were 0.04% in old carpet padding, not detected in new carpet padding, and 0.11% in gym foam. NPBFRs (TBB and TBPH) were not found in new carpet padding but found in old carpet padding (0.15 and 0.04%) and gym foam (1.04 and 0.33%). We do not have a record of the year the gymnastic foams were produced (collected in 2016) but they contained minimal PBDEs (ΣBDE 0.1%). Instead, they contained NBBFRs and OFRs with 1% TBB, 0.3% TBPH, 0.3% TDCPP, and <0.1% TPP and TCPP. Carignan et al (2016) measured for seven analytes of 28 gymnastic foams blocks purchased between 1971 and 2013, 71% had TPP and 25% had penta-BDE.(Carignan et al., 2016) LaGuardia and Hale (2015) found 1.2 to 2.6% overall in the foam blocks of various FRs with PBDEs ≤0.6%.(La Guardia and Hale 2015) Ceballos et al (2018) measured foam blocks in use before and after January 2015 and found that the new blocks did not contain PBDEs but two of four contained about 3% NPBFRs (TPP and TBPH).(Ceballos et al., 2018)

This study had a few limitations. We relied on a convenience sample to find sites and therefore, sites might not be representative of the industry. We did not analyze each bulk, air, and hand wipe sample for each FR, and instead employed targeted analyses for each industry. We have a small number of participants for some industries making comparison between industries difficult. We believe our results accurately represent each industry’s potential exposure, but a full analysis for each FR could have given us more information. Also, workers washed their hands as they normally would and therefore, some workers washed their hands before their post hand wipe sample was collected. We collected blood and urine samples from participants but did not provide these results in this paper. Blood and urine results will be shared in a subsequent modeling manuscript. Lastly, particle size collection efficiency of FRs for OVS is not known. A different sampling media (e.g. button sampler) could have given us more information on what was inhalable by the workers. However, OVS was chosen as the air sampling media because they are easily worn by the worker, minimizing the burden and allowing participants to complete their job tasks with little to no obstruction.

The literature on potential health outcomes in humans related to newer OFRs and NPBFR exposure is limited. And while our results are significantly below reported OELs, workers in these industries are nonetheless exposed to these chemicals. Future epidemiological studies examining health outcomes from exposure to FRs could recruit workers from these industries. This study characterizes exposure to FRs in various industries. Workers in primary and secondary production as well as downstream usage were more likely to be exposed to OFRs, while decommissioning industries had exposures to PBDEs, NPBFRs, and OFRs.

5. CONCLUSIONS

This study provided a broad understanding of FR use and exposures in various industries, including some industries where exposures have not been previously reported, e.g. chemical manufacturing, foam manufacturing, roofing, and rigid board installation. The FRs used in various materials continue to change and can take decades to be removed from some working environments, even after a phase out period. TCPP exposure (hand wipe and air concentrations) is high for spray polyurethane foam workers, foam manufacturers, chemical manufacturers, roofers and rigid board installers compared to other industries. TPP air concentrations measured for chemical manufacturing workers were the highest known mean exposures reported in the literature at 7,170 ng/m3, while highest known mean TDCPP air concentrations were documented for rigid polyiso board installation at 285 ng/m3. Overall, workers in primary and secondary production and downstream usage were exposed to OFRs, and decommissioning industries were exposed to lower concentrations of PBDEs, NPBFRs, and OFRs. Specifically, PBDE exposures still appear to be present but are declining among carpet installers, electronic scrap, and gymnastic workers compared to previous studies. Manufacturing industries could better enclose or ventilate processes involving FRs while other industries could improve glove or respirator use.

Supplementary Material

Highlights.

Several industries are occupationally exposed to flame retardants.

Exposure to organophosphate flame retardant (OFR) were higher than other flame retardants.

Workers in decommissioning industries had exposures to all classes of flame retardants.

6. ACKNOWLEDGEMENTS

Most of all, we thank the workers who participated in the study. We also thank Barb Alexander, Kelsey Babik, Catherine Beauchamp, Kenneth Fent, Reed Grimes, Myles O’Mara, Kaitlyn Phillips, Jessica Ramsey, Melissa Seaton and Ken Sparks for assistance in collecting, processing and submitting air and hand wipe samples for analysis. We thank Minhthu Le for interpreting at nail salons. We thank Bob Streicher, Jen Roberts, Fariba Nourian, and Jim Arnold for their assistance with understanding environmental sample results. We thank Steve Bertke and Annette Christianson for statistical advice. We thank Lian Luo for assistance with data management. This study was approved by the Institutional Review Board at NIOSH. This study was supported in part by an interagency agreement between NIOSH and the National Institute of Environmental Health Sciences (AES15002) as a collaborative National Toxicology Program research activity. The findings and conclusions in this paper are those of the authors and do not necessarily represent the official position of NIOSH, Centers for Disease Control and Prevention. Mention of any company or product does not constitute endorsement by NIOSH. This paper is Contribution No.xxxx of the Virginia Institute of Marine Science, College of William & Mary

Biography

Author Statement

Cheryl Estill: Conceptualization, Methodology, Writing, Original Draft, Investigation Jonathan Slone.: Conceptualization, Methodology, Writing- Original draft, Investigation. Alexander Mayer: Data Curation, Writing- Original Draft, Investigation, Validation. I-Chen Chen: Formal Analysis, Data Curation, Visualization, Writing-Original Draft: Mark LaGuardia: Investigation, Writing-Review and Editing.

Footnotes

Declaration of interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Publisher's Disclaimer: This is a PDF file of an unedited manuscript that has been accepted for publication. As a service to our customers we are providing this early version of the manuscript. The manuscript will undergo copyediting, typesetting, and review of the resulting proof before it is published in its final form. Please note that during the production process errors may be discovered which could affect the content, and all legal disclaimers that apply to the journal pertain.

7. REFERENCES

- ACGIH. Threshold limit values for chemical substances and physical agents and biological exposure indices 7th ed. American Conference of Governmental Industrial Hygienists; (2018) [Google Scholar]

- AIHA. Workplace Environmental Exposure Levels. AIHA; (2013) [Google Scholar]

- An J, Hu J, Shang Y, Zhong Y, Zhang X, Yu Z The cytotoxicity of organophosphate flame retardants on HepG2, A549 and Caco-2 cells. Journal of Environmental Science and Health, 51 (2016), pp. 980–988 [DOI] [PubMed] [Google Scholar]

- Babrauskas V, Lucas D, Eisenberg D, Singla V, Dedeo M, Blum A Flame Retardants in Building Insulation: A Case for Re-evaluating Building Codes. Building Research & Information, 40 (2012), pp. 738–755 [Google Scholar]

- Beaucham C, Ceballos D, Mueller C, Page E, LaGuardia M Field evaluation of sequential hand wipes for flame retardant exposure in an electronics recycling facility. Chemosphere, 219 (2019), pp. 472–481 [DOI] [PubMed] [Google Scholar]

- Behl M, Rice JR, Smith MV, Co CA, Bridge MF, Hsieh J, et al. Editor’s Highlight: Comparative Toxicity of Organophosphate Flame Retardants and Polybrominated Diphenyl Ethers to Caenorhabditiselegans. Toxicological Science, 154 (2016), pp. 241–252 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bello A, Carignan C, Xue Y, Stapleton H, Bello D Exposure to organophosphate flame retardants in spray polyurethane foam applicators: Role of dermal exposure. Environment International, 113 (2018), pp. 55–65 [DOI] [PubMed] [Google Scholar]

- Brown FR; Whitehead TP; Park JS; Metayer C; Petreas MX Levels of non-polybrominated diphenyl ether brominated flame retardants in residential house dust samples and fire station dust samples in California. Environmental research, 135 (2014), pp. 9–14 [DOI] [PMC free article] [PubMed] [Google Scholar]

- California Department of Consumer Affairs, B.o.E.a.A.R. Home Furnishings and Thermal Insultation. Initial Statement of Reasons for Proposed Regulations: New Flammability Standards for Upholstered Furniture 2013a

- California Department of Consumer Affairs, B.o.E.a.A.R. Home Furnishings and Thermal Insultation. Technical Bulletin 117–2013: Requirements, Test Procedure and Apparatus for Testing the Smolder Resistance of Materials Used in Upholstered Furniture. 2013b

- Carignan CC, Heiger-Bernays W, McClean MD, Roberts SC, Stapleton HM, Sjodin A, Webster TF Flame retardant exposure among collegiate United States gymnasts. Environmental science & technology, 47 (2013), pp. 13848–13856 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Carignan CC, Fang M, Stapleton HM, Heiger-Bernays W, MZcClean M et al. Urinary biomarkers of flame retardant exposure among collegiate U.S. gymnasts. Environmental International, 94 (2016), pp. 362–368 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ceballos D, Broadwater K, Page E, Croteau G, LaGuardia M Occupational exposure to polybrominated diphenyl ethers (PBDEs) and other flame retardant foam additives at gymnastics studios: Before, during and after the replacement of pit foam with PBDE-free foams. Environment international, 116 (2018), pp. 1–9 [DOI] [PMC free article] [PubMed] [Google Scholar]

- CECBP. Brominated and chlorinated organic chemical compounds used as flame retardants. California Environmental Contaminants. Biomonitoring Program Scientific Guidance Panel, (2008) [Google Scholar]

- Covaci A, Harrad S, Abdallah MA, Ali N, Law RJ, Herzke D, et al. Novel brominated flame retardants; a review of their analysis, environmental fate, and behavior. Environmental International, 37 (2011), pp. 532–556 [DOI] [PubMed] [Google Scholar]

- Dishaw LV, Powers CM, Ryde IT, Roberts SC, Seidler FJ, Slotkin TA, and Stapleton HM Is the PentaBDE replacement, tris (1,3-dichloro-2-propyl) phosphate (TDCPP), a developmental neurotoxicant? Studies in PC12 cells. Toxicology and Applied Pharmacology, 256 (2011), pp. 281–289 [DOI] [PMC free article] [PubMed] [Google Scholar]

- EPA. Polybrominated Diphenylethers (PBDEs) Significant New Use Rules (SNUR) in: Agency E.P, ed. Washington DC: Environmental Protection Agency; (2012) [Google Scholar]

- EPA. An Alternatives Assessment for polybrominated diphenyl ethers (PBDEs). (2014a)

- EPA. An Alternatives Assessment for the Flame Retardant Decabromodiphenyl ether (DecaBDE). 2014b

- EPA. Chemicals Known to the State to Cause Cancer or Reproductive Toxicity. in: EPA, ed. State of California; (2017) [Google Scholar]

- Estill C, Slone J, Mayer A, Phillips K, Lu J et al. Assessment of Spray Polyurethane Foam Workers Exposure to Organophosphate Flame Retardants Through Measures in Air, Hand Wipes and Urine. Journal of Occupational and Environmental Hygiene, 16 (2019), pp. 477–488 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Gravel S, Aubin S, Labreche F Assessment of Occupational Exposure to Organic Flame Retardants: A Systematic Review. Annals of Work Exposures and Health, 63 (2019), pp. 386–406 [DOI] [PubMed] [Google Scholar]

- Hartmann P, Burgi D, Giger W Organophosphate flame retardants and plasticizers in indoor air. Chemosphere, 57 (2004), pp. 781–787 [DOI] [PubMed] [Google Scholar]

- Health WSDo. Polybrominated Diphenyl Ether (PBDE) Chemical Action Plan: Final Plan. in: Washington State Department of Health D.o.E., ed; (2006) [Google Scholar]

- Hoffman K; Garantziotis S; Birnbaum LS; Stapleton HM Monitoring Indoor Exposure to Organophosphate Flame Retardants: Hand Wipes and House Dust. Environmental health perspectives (2014); [DOI] [PMC free article] [PubMed] [Google Scholar]

- Hornung R, Reed LD Estimation of Average Concentration in the Presence of Nondetectable Values. Applied Occupational and Environmental Hygiene, 5 (1990), pp. 46–51 [Google Scholar]

- House SC Information on the 16 chemicals added to the Stockholm Convention. (2017) [Google Scholar]

- IFA. GESTIS International Limit Values. Denmark: Institut fur Arbeitsschutz der Deutschen Gesetzlichen Unfllversicherung; (2015) [Google Scholar]

- Isales G, Hipszer R, Raftery T, Chen A, Stapleton H, et al. Triphenyl phosphate-induced development toxicity in zebrafish: Potential role of the retinoic acid receptor. Aquatic Toxicology, 161 (2015), pp. 221–230 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kim UJ, Wang Y, Li W, and Kannan K Occurrence of and human exposure to organophosphate flame retardants/plasticizers in indoor air and dust from various microenvironments in the United States. Environment international, 125 (2019), pp. 342–349 [DOI] [PubMed] [Google Scholar]

- La Guardia MJ; Hale RC Halogenated flame-retardant concentrations in settled dust, respirable and inhalable particulates and polyurethane foam at gymnastic training facilities and residences. Environment international, 79 (2015), pp. 106–114 [DOI] [PubMed] [Google Scholar]

- Li F, Wang L, Ji C, Wu H, Zhao J, Tang J Toxicological effects of tris(2-chloropropyl) phosphate in human hepatic cells. Chemosphere, 187 (2017), pp. 88–96 [DOI] [PubMed] [Google Scholar]

- Linares V, Bellés M, and Domingo JL Human exposure to PBDE and critical evaluation of health hazards. Archives of Toxicology, 89 (2015), pp. 335–356 [DOI] [PubMed] [Google Scholar]

- Makinen MS; Makinen MR; Koistinen JT; Pasanen AL; Pasanen PO; Kalliokoski PJ; Korpi AM Respiratory and dermal exposure to organophosphorus flame retardants and tetrabromobisphenol A at five work environments. Environmental science & technology, 43 (2009) pp. 941–947 [DOI] [PubMed] [Google Scholar]

- Marlow D, DeCapite, Joseph. Spray Polyurethane Foam Chemical Exposures during Spray Application. CDC Workplace Safety and Health; (2017), pp. 005–166 [Google Scholar]

- Marlow D, DeCapite J, Garcia A Spray Polyurethane Foam Chemical Exposures during Spray Application. CDC Workplace Safety and Health; (2014) [Google Scholar]

- NIOSH. Pocket Guide to Chemical Hazards. in: Barsen W, ed. Cincinnati, OH; (2010) [Google Scholar]

- Park JS; Voss RW; McNeel S; Wu N; Guo T; Wang Y; Israel L; Das R; Petreas M High exposure of California firefighters to polybrominated diphenyl ethers. Environ Sci Technol, 49 (2015), pp. 2948–2958 [DOI] [PubMed] [Google Scholar]

- Rosenberg C, Hameila M, Tornaeus J, Sakkinen K, et al. Exposure to Flame Retardants in Electronics Recycling Sites. The Annals of Occupational Hygiene, 55 (2011), pp. 658–665 [DOI] [PubMed] [Google Scholar]

- Saunders DM, Hagley EB, Hecker M, Mankidy R, Giesy JP In Vitro endocrine disruption and TCDD-like effects of three novel brominated flame retardants: TBPH, TBB, and TBCO. Chemosphere, 91 (2013) pp. 1386–1394 [DOI] [PubMed] [Google Scholar]

- Sjodin A, Carlsson H, Thuresson K, Sjolin S, Bergman A, Ostman C Flame retardants in indoor air at an electronics recycling plant and at other work environments. Environmental science & technology, 35 (2001), pp. 448–454 [DOI] [PubMed] [Google Scholar]

- Stapleton HM, Sjodin A, Jones RS, Niehuser S, Zhang Y, Patterson D, G. Jr. Serum levels of polybrominated diphenyl ethers (PBDEs) in foam recyclers and carpet installers working in the United States. Environmental science & technology, 42 (2008), pp. 3453–3458 [DOI] [PubMed] [Google Scholar]

- WHO. Agents Classified by the IARC Monographs. World Health Organization (WHO); (2018) [Google Scholar]

- Wood R Center for the Polyurethanes Industry summary of unpublished industrial hygiene studies related to the evaluation of emissions of spray polyurethane foam insulation. Journal of occupational and environmental hygiene, 14 (2017), pp. 681–693 [DOI] [PMC free article] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.