Abstract

Purpose

3D printing technology provides an excellent capability to manufacture customised implants for patients. Now, its applications are also successful in bone tissue engineering. This paper tries to provide a review of the applications of 3D printing in bone tissue engineering.

Methods

Searching by keywords, from the Scopus database, to identify relevant latest research articles on 3D printing in bone tissue engineering, through “3D printing” “bone tissue engineering”. This study makes a bibliometric analysis of the identified research articles and identified major applications and steps.

Results

3D printing technology creates innovative development in bone tissue engineering. It involves the manufacturing of a scaffold with the combination of cells and materials. We identified a total number of 257 research articles through bibliometric analysis by searching through keywords “3D printing” “bone tissue engineering”. This paper studies 3D printing technology and its significant contributions, benefits and steps used for bone tissue engineering. Result discusses the essential elements of bone tissue engineering and identifies its five significant advancements when 3D printing is used. Finally, ten useful applications of 3D printing in bone tissue engineering are identified and studied with a brief description.

Conclusion

In orthopaedics, bone defects create a high impact on the quality of life of the patient. It leads to a higher demand for bone substitutes for replacement of bone defect. Bone tissue engineering can help to replace a critical defect bone. 3D printing is a useful technology for the fabrication of scaffolds critical in bone tissue engineering. There are different binders which can create bone scaffolds with requisite mechanical strength. These binders are used to create excellent osteoconductive, bioactive scaffolds. Computed tomography (CT) and Magnetic resonance imaging (MRI) help to provide images of specific defects of an individual patient, and these images can further be used for 3D printing the detective object. A bone defect caused by specific disease is sorted out by transplantation in clinical practice. Now a day bone tissue engineering opens a new option for this treatment of bone defects with the manufacturing of porous bone scaffold using 3D printing technology.

Keywords: 3D printing, Advancement, Additive manufacturing (AM), Application, Bone tissue engineering, Orthopaedics, Scaffold

1. Introduction

Bone tissue engineering is an interdisciplinary approach which utilizes cells and combination of biomaterials to restore required functions of tissues. Scaffolds are an essential part of bone tissue engineering. They are 3D structures which provide a template for cell attachment in bone tissue formation.1 There are various critical parameters to define the performance of scaffolds; these include, pore-volume, pore size, chemical properties and mechanical strength. It is made as per the understanding of bone mechanics, bone structure, and tissue formation for new functional bone tissues. There are varieties of methods extensively used for making porous bone scaffolds. These methods are chemical foaming, freeze-drying, solvent casting and foam-gel.2,3

3D printing is first introduced to create a prototype for the development of products of specific industries. This technology is part of additive manufacturing (AM) which is used to create parts, layer by layer from the 3D Computer-Aided Design (CAD) model. In printing scaffold, using Polyjet printing, parameters are optimised to obtain appropriate quality, these include powder flowability, binder drop volume, powder packing dentistry and layer thickness. There are different types of 3D printing technology, each having its capability to print parts and are materials specific. These technologies use, material such as gypsum powder, plastics, resins, aluminide, ceramics, sand, metal, Polyether ether ketone (PEEK), graphene and other materials to create the required part. Inkjet 3D printing technology provides disruptive innovation for bone tissue engineering. It facilitates the requisite distribution of cells in the scaffold. It also uses bioink for efficient regeneration and part reconstruction.4,5

3D printing technology creates advancement in the field of bone regeneration medicine by fabricating biological tissues or organs. 3D bones tissue are easily created using bioink to overcome the challenges. This bioink is in the form of hydrogels and viscous fluid. Bioink is used to manufacture cell-laden 3D structures. Thus, 3D printing and bioink are successfully used to manufacture tissue of bone and considers different parameters for developing specific bioink such as printability, mechanical integrity etc.6,7

This emerging field aims for the treatment of bone disease. There is a vital role in cell adhesion, differentiation, proliferation, migration, and mineralized bone tissue formation. Bone consists of cancellous, while cortical bone has two different structures. Cancellous is the inner part of the bone, and cortical is the outer part of the bone. These two collectively have capabilities of self-healing to restore normal operations. Also, there are options of autograft and allograft, by which bone tissue engineering provides the capability to restore and improve its functions. This review based article provides a study on 3D printing as adopted in bone tissue engineering and addresses the following issues:

Issue 1: to study the 3D printing technology, its significant contributions and significant benefits for bone tissue engineering;

Issue 2: to briefly describe the concepts of bone tissue engineering with its basic elements;

Issue 3: to identify steps of 3D printing in bone tissue engineering;

Issue 4: to study different advancement in bone tissue engineering using 3D printing;

Issue 5: to study and analyse the research status of 3D printing in bone tissue engineering;

Issue 6: to identify significant applications of 3D printing in bone tissue engineering;

Issue 7: to study the miRNA therapy integration with 3D printing technology.

2. 3D printing

In 1980, 3D printing technology was introduced, and today it is providing extensive benefits over traditional manufacturing technologies. It can manufacture different parts with different and unconventional materials. The applications of 3D printing are growing, and now it has uses in the field of bone tissue engineering. Here, this technology provides excellent capabilities to print porous scaffolds with required shape and size using layer by layer technique. 3D printing is becoming popular due to its capability manufacturing of the customised parts at lesser cost and time. For printing any part, first, step is the importing of the 3D digital CAD file and converting to Standard Triangulate Language (STL) file format, for facilitating 3D printing of the part. After that setup files for printing are provided with proper orientation of the part in 3D Print software.8 Finally, the part is printed with selected material. Post-processing is done as per the requirements of quality and strength of part.9,10

AM also plays a vital role in product development and provides a modified concept in the industry. The design and development of the medical implants, tool, instrument and devices are easily possible by using this technology. It increases the efficiency and quality of the product, but there is a reduction in development cycle time and cost of the product. 3D printing provides incremental innovation in medical, dentistry, cardiology, orthopaedics, engineering, research, food, agriculture, automobile, architecture, aerospace and various other fields.11, 12, 13, 14, 15

3. Bone tissue engineering

Bone tissue engineering is an essential technique, where a scaffold for the cell is manufactured using a biomaterial having suitable biochemical and physicochemical properties. It is used to replace or improve bone with surrounding tissues. It is used to create advancement in the orthopaedics field. Thus, bone tissue engineering, with its extensive capability of formation of bone structure provides significant progress.16

3D printing provides an excellent opportunity by creating scaffolds for bone tissue engineering. It enhances bone formation for cell culture to optimize osteogenesis. Bone tissue engineering is now becoming feasible in today medical field. This technique is used successfully for grafting of bone, by which a surgeon can repair the bone of a patient. Scientists and researcher use scaffolds for bone tissue. It resembles bone and has required porosity and composition. A scaffold is created according to the desired area, which has to be repaired using cells. Two methods are used to produce bone tissues, either these tissues are taken from existing bone or stem cells. These are used successfully for bone in the scaffold.17,18

4. Essential elements of bone tissue engineering

The important part of tissue engineering is to repair a bone defect, may be caused by fracture or trauma. In conventional techniques, there is a change in structure and function by biological substitutes when used for repairing of damaged tissue.19,20 Thus, to sort out bone defects, 3D printing is used to construct artificial bone with required shape, size, properties and mechanical strength. This technology is more suitable as compared to other traditional manufacturing technique and consists of the following elements:

-

•

Bone Scaffolds

-

•

Cells

-

•

Growth factors

4.1. Bone scaffold

Scaffolds are mainly applied to make a physical and mechanical stable bone-like structure. In clinical medicine, it has an excellent capability to rebuilt organs with normal function. It allows attachment and migration of the cell to retain biochemical and other required biological properties. Scaffolds help all cells to integrate and fulfil the requirements of bone tissue treatment. This scaffold is created by using AM (3D printing) technologies as per the required shape and size of the individual customer. It helps to treat the disease/fracture successfully, by fulfilling the challenge to regenerate and growth of new tissue for medical applications, thereby improving patient survival.21

4.2. Cells

In living beings, cells are the basic building blocks and are specific to the body part. These cells provide structure to the body and help carry out specialized functions. Cells perform different functions and provide shape to the body part. 3D printing is introduced to assist localized cell growth as per the specifications.22,23

4.3. Growth factors

There are different growth factors like fibroblast growth factor, vascular endothelial growth factor and bone morphogenic proteins also are required in bone tissue engineering. 3D printed scaffold minimizes the side effect.24

5. Major contributions of 3D printing

3D printing is used for the development in different fields and provides better flexibilities to achieve improved accuracy. This technology explores the manufacturing of complex products as per the customer’s requirements. There are different capabilities, advantages and limitations of this technology during its practical implementation. Its applications areas include medical, dentistry, engineering, food, agriculture and related fields. There are different types of 3D printing, with different material, processes and part property. These technologies now provide excellent surface resolution, surface finish, colour 3D parts, recycling of waste materials, lightweight parts, lesser maintenance cost, environmentally friendly production and capability to make parts with different types of material.25,26 Coming subsections provide major areas wise contributions of 3D printing.

5.1. Academia

3D printing technology helps students, researchers and teachers to study facts in detail with lesser risks and with the quicker fabrication of prototype before starting commercial production. It contributes to the innovative application in education and training for students to develop concepts. For medical students, it is the best tool by which they can plan and perform mock surgery before the actual surgery. Complex medical cases are easily understandable by manufacturing a patient-specific replica.

5.2. Industry

It plays a vital role to enhance the design and development ability of a conceived product in different interdisciplinary fields. It can quickly help identify the mistakes in assembly. In industries, it provides better ideas for product design, development, and manufacturing. This technology speeds up the first stages of product development with quicker production of prototypes. It helps creative ideation for the manufacturing of challenging to make a product. This technology provides complex geometries/lightweight parts at a lower cost.

5.3. Research and development

This technology shortens research & development (R&D) time for new products/applications. The design and development of any product can be done effectively as per the requirements such as ergonomics, aesthetics and aerodynamics. It helps to do quicker modification in R&D of industrial products. In the medical industry, it has a significant contribution because every patient data is not the same. Thus, it is used for the development of implants, tool, instruments and various other devices as per the requirements of the patient.

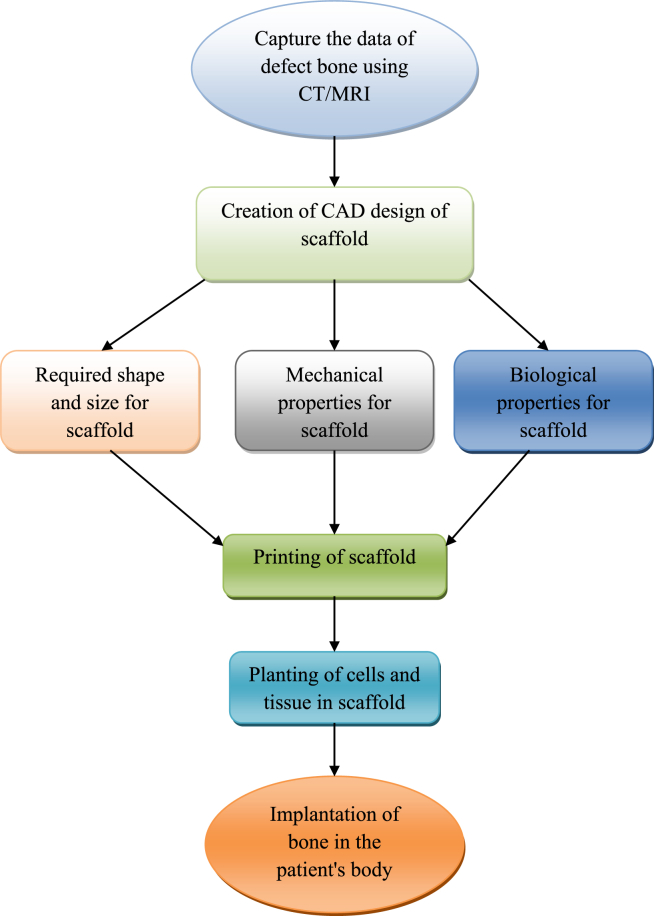

6. Steps used in 3D printing for bone tissue engineering

Bone tissue engineering with the help of additive manufacturing provides a promising solution for the treatment of orthopaedics patients. It provides scaffolds as per the required shape and size and uses a process similar to natural bone regeneration. Fig. 1 provides different steps as required for bone tissue engineering in conjunction with additive manufacturing.

Fig. 1.

Steps used by Additive Manufacturing for bone tissue engineering.

In bone tissue engineering, the first step is to capture the data of defective bone of individual patient using CT/MRI. Different software like 3D slicer, 3D doctors, magics, mimics etc. are used to convert this data in 3D CAD form and create a precise design of the scaffold. During manufacturing of scaffold, it requires the exact shape, size, mechanical and biological properties to improve the reliability of the patient outcome after the surgery. Then digital CAD data is exported in 3D printing technology in STL format and is printed with the required material. After printing of the scaffold, cells and tissues are planted on the scaffold.7 Finally, it is implanted in the body of the patient through a successful surgery.

7. Material properties required 3D printed scaffold

Scaffolds are produced by using varieties of biomaterials which are helpful to regenerate the organs and tissue in the body.27,28 There different properties of material required for 3D printed scaffold used for bone tissue engineering are:

7.1. Mechanical properties

Scaffold required specific mechanical properties to be implanted successfully during a practical perspective. It must be strong so that it can be handled easily during the surgical situation/during implantation. It has to be appropriate for bone or cartilage.

7.2. Chemical properties

It consists of bioceramics, polymers and hybrid materials which supports the growth of cells in scaffolds. These provide the ability to create complex shape and improve attachment of cells. Scaffold with excellent chemical properties overcome different complications in bone tissue engineering.

7.3. Biological properties

Scaffold requires biological and nontoxicity properties so that cells can grow and reproduce a new matrix. It produces perfect and complete regeneration of bone tissue. The perfect biological properties significantly create an interaction of scaffolds with organs and tissue. It promotes proper cellular interaction, differentiation/migration and incorporates cells in scaffolds.

7.4. Biodegradability

It should be biodegradable, which helps to construct tissue from their body cells. A scaffold is not a permanent implant as it allows to produce own extracellular matrix from cells. It plays a prominent role in clinical practice and research areas.

7.5. Biocompatible material

A biocompatible material is required to create scaffolds helps cells to perform routine functions. These materials reduce reaction in the body and increase efficiency after implantation.

7.6. Precise shape and size of scaffold

3D printing is applicable to manufacture scaffolds for bone tissue engineering as per required shape and size. CT/MRI is used to capture the data of the patient. This technique is suitable for manufacturing of patient-specific scaffolds. It is to be cost-effective than a customised scaffold which is used generally in bone tissue engineering.

7.7. Porous structure

Scaffolds should be highly porous and should have an interconnected pore structure to ensure cellular penetration. It creates an extracellular matrix from the cells and exit from the body without any interference of surrounding tissue and organs.

8. Advancement of 3D printing for bone tissue engineering

Accurate designing of scaffold is essential for proper implantation in the patient body. It has to support the vascular growth to meet the requirement of bone regeneration mechanical requirement. There are highly dynamic and diverse tissues in bone with both structurally and functionality. Table 1 discusses the significant advancement of 3D printing for bone tissue engineering.

Table 1.

Advancement of 3D printing for bone tissue engineering.

| SNo | Advancement | Description | Reference/s |

|---|---|---|---|

| 1 | Biomaterials |

|

Butscher et al., 201129; Javaid and Haleem, 201830 |

| 2 | Hydrogels |

|

Bose et al., 201331; Liu et al., 201732 |

| 3 | Bioceramic scaffolds |

|

Castilho et al., 201533; Ma et al., 201834 |

| 4 | Calcium Phosphate Ceramics |

|

Trombetta et al., 201635; Jammalamadaka and Tappa, 201836 |

| 5 | Living tissue |

|

Holmes, 201637; Egan, 201938; Tamay et al., 201939 |

3D printing creates various advancements by the printing of smart biomaterials which can perform desired functions. There are different Hydrogels used to create innovations in bone tissue engineering filed. Bioceramic scaffolds are made with different biocompatible materials. This technology creates advancements by printing living tissues which have broader applications in the medical field.

9. Research status on 3D printing in bone tissue engineering

Research on 3D printing in bone tissue engineering is rapidly increasing. By searching keywords as “3D printing” bone tissue engineering”, a total of 257 research articles are identified up to September 2019. In the year 2004, the first article on this specific area was published and this year, only one research article was published. In 2005, three articles and in 2006, again no article was published. One research article published in year 2007 and 2008. In 2009, two, in 2010, one and in 2011 no research article published. In 2012 (1), 2013 (7), 2014 (13), 2015 (29), 2016 (21), 2017 (54), 2018 (60), and in year 2019, total 64 research articles are published so far up to September.

There are different journals and sources publishing research articles on 3D printing in bone tissue engineering. Out of these, we have reported the top five journals. These are: “Materials Science and Engineering C″ which has published a maximum number of research articles (14). Whereas, “ActaBiomaterialia” and “Materials” each published nine research articles. Journal “ACS Applied Materials and Interfaces” and “Biofabrication” again published an equal number of publications (8). Other sources and journals also have provided an excellent contribution to the research on 3D printing in bone tissue engineering.

In area wise contribution to this valuable area, “Materials Science” field has a maximum contribution of 27%. In contrast, other fields provide engineering (25%), Biochemistry, Genetics and Molecular Biology (13%), Chemical Engineering (10%), Medicine (6%), Physics and Astronomy (6%), Chemistry (5%) and 8% of contribution, these include Computer Science, Pharmacology, Toxicology and Pharmaceutics, Dentistry, Mathematics, Agricultural and Biological Sciences, Environmental Science, Immunology and Microbiology, Energy, Health Professions, Multidisciplinary, Neuroscience, Social Sciences and Veterinary fields.

We have analysed from the Scopus databases that the applications of 3D printing are increasing in bone tissue engineering. Researchers from the different fields are providing a significant contribution to this innovative field. In the upcoming days, more research will be carried out in this field to create advancement.

10. 3D printing applications in bone tissue engineering

3D printing technology gains attraction in the field of bone tissue engineering due to its extensive capability of higher precision, ease of use and cost-effectiveness for customised requirements. The results show that this technology allows the reproducing of the required structure. Table 2 discusses different applications of 3D printing in bone tissue engineering.

Table 2.

3D Printing applications in bone tissue engineering.

| S No | Applications | Description | References |

|---|---|---|---|

| 1 | Repair of bone defects |

|

Bendtsen et al., 201740; Qasim et al., 201941 |

| 2 | Cell planting |

|

Kim et al., 201342; Xu et al., 201543 |

| 3 | Biological functions |

|

Park et al., 201244; Demirtaş et al., 201745 |

| 4 | Restoration of the functions of tissue |

|

Wang et al., 201646; Yu et al., 201647; Byambaa, 201748 |

| 5 | Functioning scaffolds |

|

Do et al., 201549; Ma et al., 201950 |

| 6 | A functional gradient of cells |

|

Xia et al., 201351; Dong et al., 201752; Tao et al., 201953 |

| 7 | Bone graft |

|

Kim et al., 201342; Nandi et al., 201854 |

| 8 | Scaffold with desired mechanical properties |

|

Duan et al., 201055; Barak et al., 201856 |

| 9 | Biocompatible material printing |

|

Luo et al., 201357; Haleem and Javaid, 201958; Turnbull et al., 201759 |

| 10 | Treatment |

|

Venkatesan et al., 201560; Javaid and Haleem, 201961; Mastrogiacomo et al., 201962 |

3D printing provides extensive applications towards repairing of bone defects and is helpful to perform precise surgery. It is helpful in the planting of cells which are used to perform required biological functions.63,64 This technology can respond to different types of input materials for enhancing the mechanical properties of the scaffold. It is used for the various innovative applications aimed at better treatment of the patient.

11. miRNA therapy integration with 3D printing technology

In recent times, there has been a surge in integrating miRNA therapy with 3D printing technology. miRNAs are small non-coding RNAs that can regulate gene expression at the post-transcriptional level by binding to complementary sites on target messenger RNAs. miRNA cannot easily cross the cell membrane; hence, vectors are required to protect and deliver miRNAs into cells. Recently, three-dimensional printed hybrid scaffolds were engineered with ex-situ miR-148b expressing delivery system for osteogenic induction of ‘rat bone marrow stem cells; (rBMSCs) in vitro, and also in vivo in critical-sized rat calvarial defects which improved calvarial bone regeneration in rats. Scaffolds are designed as highly porous structures and then loaded into collagen gel that was subsequently used to infill a 3D printed polymeric frame which enabled the loading of a high number of cells laden in collagen compared to conventional 3D printed scaffolds, where cells can be only loaded on the surface of filaments. This collagen-infilled 3D printed hybrid scaffolds, expressing significant levels of osteogenic markers, improved bone regeneration.65, 66, 67 In another study, a versatile material poly-lactide was used as a 3D printing filament labelled with fluorescent dye rhodamine-conjugated and functionalized with poly-amidoamine dendrimers to create a multifunctional scaffold for cell proliferation and transfection with miRNAs.68 These studies could pave a way of controlled delivery of genes in bone engineering.

12. Discussion

The human body is affected due to damaging of parts/organs. To fulfil this innovative requirement, the replacement of these parts/organs is essential to minimize the risk and to satisfy biomedical needs. Tissue engineering is used to regenerate and replace tissue/organs damaged by injury, disease or any other congenital anomalies. These damaged tissue/organs are repaired with scaffolds. AM is used to manufacture scaffold having biocompatible properties as tissue they regenerate. It allows manufacturing of precise and cheap 3D scaffolds in lesser time without any requirement of tools and fixture. 3D printing creates surgical guides which can provide improved efficiency than that of the existing one. Medical model printed by this technology is useful for training, surgery planning, and diagnosis. It is a suitable technique used in many industries to save cost and production time. In orthopaedics, bone tissue engineering is a developing field used to combine tissue engineering, material science and regenerative medicine to repair bone. This technique is used in clinical practice to restore significant bone defects. This bone defect regeneration is a significant challenge in the orthopaedics, which is now being taken up through AM technologies.

13. Limitations and future scope

There are various issues in 3D printing technologies such as material changing option, the strength of the part, post-processing cost, skilled human resources and layer thickness changing option. It is only beneficial for the manufacturing of a customised product. So, only limited products are being manufactured by this technology. Post-processing is also an essential requirement, which involves extra cost.

In future, 3D printing will become a versatile tool for bone tissue engineering for the customised patient match. It provides an opportunity to print with varied materials which are still a big challenge. By changing input material, a qualitative change in the scaffold can be evaluated for different cells/tissues. In upcoming years, its demand will increase to make custom medical devices to accomplish the goal. This technology will create technological change by printing multiple objects with multiple materials, including smart medical implants. This technology will come up with some significant innovations in future, the printing & testing of mixed and new materials.

14. Conclusion

Bone tissue engineering is an innovative approach which is directly used to repair bone defects/tissue for transplantation. In this process, biomaterials play an important role to support regenerative cells and regeneration of tissue. Additive manufacturing is a disruptive innovation, which uses different types of scanning, printing and associated software support. It is used to manufacture complex shapes customised scaffolds from images in lesser time and cost. In bone tissue engineering, it is successfully used to repair and regeneration of bone. It provides essential knowledge of bone biology and its development. In the medical field, this technology is introduced to manufacture customised patient-specific parts. In orthopaedics, it is developed in many ways for the manufacturing of customised human hard tissue in a cost-effective manner. It is also suitable for the manufacturing of living tissue, stem cells, hearing aids, craniofacial disfigurement and dental delivery devices. 3D printing is concerned with the creation of substitute implantable bone for critical application. During orthopaedics and craniofacial surgery, these are the most common defects as bone loss due to infection, trauma and tumour resection. In future, 3D printing will create disruptive innovation for the bone tissue engineering in which cells and bioactive molecules will be directly seeded into 3D biomaterials scaffolds.

Declaration of competing interest

None.

Contributor Information

Abid Haleem, Email: haleem.abid@gmail.com, https://scholar.google.co.in/citations?hl=en&user=4047148AAAAJ.

Mohd Javaid, Email: mohdjavaid0786@gmail.com, https://scholar.google.co.in/citations?user=rfyiwvsAAAAJ&hl=en.

Rizwan Hasan Khan, Email: rizwanhkhan1@gmail.com, https://scholar.google.co.in/citations?user=5CzfvLkAAAAJ&hl=en.

Rajiv Suman, Email: raje.suman@gmail.com, https://scholar.google.co.in/citations?hl=en&user=A3tEW98AAAAJ.

References

- 1.Vaishya R., Vijay V., Vaish A., Agarwal A.K. Computed tomography-based 3D printed patient-specific blocks for total knee replacement. J Clin Orthop Trauma. 2018;9:254–259. doi: 10.1016/j.jcot.2018.07.013. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 2.Bose S., Tarafder S., Bandyopadhyay A. Effect of chemistry on osteogenesis and angiogenesis towards bone tissue engineering using 3D printed scaffolds. Ann Biomed Eng. 2017;45(1):261–272. doi: 10.1007/s10439-016-1646-y. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.Witte T.M.D., Fratila-Apachitei L.E., Zadpoor A.A., Peppas N.A. Bone tissue engineering via growth factor delivery: from scaffolds to complex matrices. Regen Biomater. 2018;5(4):197–211. doi: 10.1093/rb/rby013. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.De AzevedoGonçalvesMota R., da Silva E., de Lima F., de Menezes L., Thiele A. 3D printed scaffolds as a new perspective for bone tissue regeneration: literature review. Mater Sci Appl. 2016;7:430–452. [Google Scholar]

- 5.Sa M.W., Nguyen B.B., Moriarty R.A., Kamalitdinov T., Fisher J.P., Kim J.Y. Fabrication and evaluation of 3D printed BCP scaffolds reinforced with ZrO2 for bone tissue applications. Biotechnol Bioeng. 2018;115:989–999. doi: 10.1002/bit.26514. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 6.Seitz H., Rieder W., Irsen S., Leukers B., Tille C. Three-dimensional printing of porous ceramic scaffolds for bone tissue engineering. J Biomed Mater Res B Appl Biomater. 2005;74:782–788. doi: 10.1002/jbm.b.30291. [DOI] [PubMed] [Google Scholar]

- 7.Haleem A., Javaid M. Role of CT and MRI in the design and development of orthopaedic model using additive manufacturing. J Clin Orthop Trauma. 2018;9(3):213–217. doi: 10.1016/j.jcot.2018.07.002. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8.Negi S., Dhiman S., Sharma R.K. Basics and applications of rapid prototyping medical models. Rapid Prototyp J. 2014;20:256–267. [Google Scholar]

- 9.Brunello G., Sivolella S., Meneghello R. Powder-based 3D printing for bone tissue engineering. Biotechnol Adv. 2016;34:740–753. doi: 10.1016/j.biotechadv.2016.03.009. [DOI] [PubMed] [Google Scholar]

- 10.Hoang D., Perrault D., Stevanovic M., Ghiassi A. Surgical applications of three-dimensional printing: a review of the current literature & how to get started. Ann Transl Med. 2016;4(23):456. doi: 10.21037/atm.2016.12.18. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 11.Gómez-Ciriza G., Hussain T., Gómez-Cía T., Valverde I. Potential of 3D-printed models in planning structural interventional procedures. Interv Cardiol. 2015;7:1–5. [Google Scholar]

- 12.Qasim M., Chae D.S., Lee N.Y. Advancements and frontiers in nano-based 3D and 4D scaffolds for bone and cartilage tissue engineering. Int J Nanomed. 2019;14:4333–4351. doi: 10.2147/IJN.S209431. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 13.Javaid M., Haleem A. 4D printing applications in medical field: a brief review. Clin Epidemiol Glob Health. 2019;7(3):317–321. [Google Scholar]

- 14.Haleem A., Javaid M. Polyether ether ketone (PEEK) and its 3D printed implants applications in the medical field: an overview. Clin Epidemiol Glob Health. 2019;7(4):571–577. [Google Scholar]

- 15.Javaid M., Haleem A. Current status and applications of additive manufacturing in dentistry: a literature-based review. J Oral Biol Craniofac Res. 2019;9:179–185. doi: 10.1016/j.jobcr.2019.04.004. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 16.Amini A.R., Laurencin C.T., Nukavarapu S.P. Bone tissue engineering: recent advances and challenges. Crit Rev Biomed Eng. 2012;40(5):363–408. doi: 10.1615/critrevbiomedeng.v40.i5.10. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 17.Fielding G., Bose S. SiO2 and ZnO dopants in three-dimensionally printed tricalcium phosphate bone tissue engineering scaffolds enhance osteogenesis and angiogenesis in vivo. Acta Biomater. 2013;9:9137–9148. doi: 10.1016/j.actbio.2013.07.009. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 18.De Mori A., Peña Fernández M., Blunn G. 3D printing and electrospinning of composite hydrogels for cartilage and bone tissue engineering. Polymers (Basel) 2018;10:285. doi: 10.3390/polym10030285. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 19.Chen G. 3D scaffolds with different stiffness but the same microstructure for bone tissue engineering. ACS Appl Mater Interfaces. 2015;7(29):15790–15802. doi: 10.1021/acsami.5b02662. [DOI] [PubMed] [Google Scholar]

- 20.Hamlet S.M., Vaquette C., Shah A., HutmacherDW, Ivanovski S. 3-dimensional functionalized polycaprolactone-hyaluronic acid hydrogel constructs for bone tissue engineering. J Clin Periodontol. 2017;44:428–437. doi: 10.1111/jcpe.12686. [DOI] [PubMed] [Google Scholar]

- 21.Gao G., Schilling A.F., Yonezawa T., Wang J., Dai G., Cui X. Bioactive nanoparticles stimulate bone tissue formation in bioprinted three-dimensional scaffold and human mesenchymal stem cells. Biotechnol J. 2014;9:1304–1311. doi: 10.1002/biot.201400305. [DOI] [PubMed] [Google Scholar]

- 22.Duarte Campos D.F., Blaeser A., Buellesbach K. BioprintingOrganotypic hydrogels with improved mesenchymal stem cell remodeling and mineralization properties for bone tissue engineering. Adv Healthc Mater. 2016;5:1336–1345. doi: 10.1002/adhm.201501033. [DOI] [PubMed] [Google Scholar]

- 23.Cidonio G., Glinka M., Dawson J.I., Oreffo R.O.C. The cell in the ink: improving biofabrication by printing stem cells for skeletal regenerative medicine. Biomaterials. 2019;209:10–24. doi: 10.1016/j.biomaterials.2019.04.009. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 24.Ji K., Wang Y., Wei Q. Application of 3D printing technology in bone tissue engineering. Bio-Des Manuf. 2018;1:203. [Google Scholar]

- 25.Javaid M., Haleem A. Additive manufacturing applications in medical cases: a literature-based review. Alexandria J Med. 2018;54(4):411–422. [Google Scholar]

- 26.Chadha A., UlHaq M., Raina A., Singh R., Penumarti N., Bishnoi M. Effect of fused deposition modelling process parameters on mechanical properties of 3D printed parts. World J Eng. 2019 [Google Scholar]

- 27.O’Brien F.J. Biomaterials & scaffolds for tissue engineering. Mater Today. 2011;14(3):88–95. [Google Scholar]

- 28.Eltom A., Zhong G., Muhammad A. Scaffold techniques and designs in tissue engineering functions and purposes: a review. Adv Mater Sci Eng. 2019 [Google Scholar]

- 29.Butscher A., Bohner M., Hofmann S., Gauckler L., Müller R. Structural and material approaches to bone tissue engineering in powder-based three-dimensional printing. Acta Biomater. 2011;7:907–920. doi: 10.1016/j.actbio.2010.09.039. [DOI] [PubMed] [Google Scholar]

- 30.Javaid M., Haleem A. Additive manufacturing applications in orthopaedics: a review. J Clin Orthop Trauma. 2018;9(3):202–206. doi: 10.1016/j.jcot.2018.04.008. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 31.Bose S., Vahabzadeh S., Bandyopadhyay A. Bone tissue engineering using 3D printing. Mater Today. 2013;16(2):496–504. [Google Scholar]

- 32.Liu M., Zeng X., Ma C. Injectable hydrogels for cartilage and bone tissue engineering. Bone Res. 2017;5:17014. doi: 10.1038/boneres.2017.14. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 33.Castilho M., Rodrigues J., Pires I. Fabrication of individual alginate-TCP scaffolds for bone tissue engineering by means of powder printing. Biofabrication. 2015;7 doi: 10.1088/1758-5090/7/1/015004. [DOI] [PubMed] [Google Scholar]

- 34.Ma H., Feng C., Chang J., Wu C. 3D-printed bioceramic scaffolds: from bone tissue engineering to tumor therapy. Acta Biomater. 2018;79:37–59. doi: 10.1016/j.actbio.2018.08.026. [DOI] [PubMed] [Google Scholar]

- 35.Trombetta R., Inzana J.A., Schwarz E.M., Kates S.L., Awad H.A. 3D printing of calcium phosphate ceramics for bone tissue engineering and drug delivery. Ann Biomed Eng. 2017;45(1):23–44. doi: 10.1007/s10439-016-1678-3. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 36.Jammalamadaka U., Tappa K. Recent advances in biomaterials for 3D printing and tissue engineering. J Funct Biomater. 2018;9(1):22. doi: 10.3390/jfb9010022. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 37.Holmes B. A synergistic approach to the design, fabrication and evaluation of 3D printed micro and nano featured scaffolds for vascularized bone tissue repair. Nanotechnology. 2016;27(6) doi: 10.1088/0957-4484/27/6/064001. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 38.Egan P.F. Integrated design approaches for 3D printed tissue scaffolds: review and outlook. Materials (Basel) 2019;12(15):2355. doi: 10.3390/ma12152355. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 39.Tamay D.G., DursunUsal T., Alagoz A.S., Yucel D., Hasirci N., Hasirci V. 3D and 4D printing of polymers for tissue engineering applications. Front Bioeng Biotechnol. 2019;7:164. doi: 10.3389/fbioe.2019.00164. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 40.Bendtsen S.T., Quinnell S.P., Wei M. Development of a novel alginate-polyvinyl alcohol-hydroxyapatite hydrogel for 3D bioprinting bone tissue engineered scaffolds. J Biomed Mater Res A. 2017;105:1457–1468. doi: 10.1002/jbm.a.36036. [DOI] [PubMed] [Google Scholar]

- 41.Qasim M., Haq F., Kang M.H., Kim J.H. 3D printing approaches for cardiac tissue engineering and role of immune modulation in tissue regeneration. Int J Nanomed. 2019;14:1311–1333. doi: 10.2147/IJN.S189587. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 42.Kim M., Jung W.-K., Kim G. Bio-composites composed of a solid free-form fabricated polycaprolactone and alginate-releasing bone morphogenic protein and bone formation peptide for bone tissue regeneration. Bioproc Biosyst Eng. 2013;36:1725–1734. doi: 10.1007/s00449-013-0947-x. [DOI] [PubMed] [Google Scholar]

- 43.Xu T., Miszuk J.M., Zhao Y., Sun H. Electrospunpolycaprolactone 3D nanofibrous scaffold with interconnected and hierarchically structured pores for bone tissue engineering. Adv Healthc Mater. 2015;4(15):2238–2246. doi: 10.1002/adhm.201500345. [DOI] [PubMed] [Google Scholar]

- 44.Park S.H., Park D.S., Shin J.W. Scaffolds for bone tissue engineering fabricated from two different materials by the rapid prototyping technique: PCL versus PLGA. J Mater Sci Mater Med. 2012;23:2671–2678. doi: 10.1007/s10856-012-4738-8. [DOI] [PubMed] [Google Scholar]

- 45.Demirtaş T.T., Irmak G., Gümüşderelioğlu M. A bioprintable form of chitosan hydrogel for bone tissue engineering. Biofabrication. 2017;9:35003. doi: 10.1088/1758-5090/aa7b1d. [DOI] [PubMed] [Google Scholar]

- 46.Wang X., Ao Q., Tian X. 3D bioprinting technologies for hard tissue and organ engineering. Materials (Basel) 2016;9(10):802. doi: 10.3390/ma9100802. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 47.Yu Y., Hua S., Yang M. Fabrication and characterization of electrospinning/3D printing bone tissue engineering scaffold. RSC Adv. 2016;6:110557–110565. [Google Scholar]

- 48.Byambaa B. Bioprinted osteogenic and vasculogenic patterns for engineering 3D bone tissue. Adv Healthc Mater. 2017;6(16):1700015. doi: 10.1002/adhm.201700015. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 49.Do A.V., Khorsand B., Geary S.M., Salem A.K. 3D printing of scaffolds for tissue regeneration applications. Adv Healthc Mater. 2015;4(12):1742–1762. doi: 10.1002/adhm.201500168. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 50.Ma C., Jiang L., Wang Y. 3D printing of conductive tissue engineering scaffolds containing polypyrrole nanoparticles with different morphologies and concentrations. Materials (Basel) 2019;12(15):2491. doi: 10.3390/ma12152491. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 51.Xia Y., Zhou P., Cheng X. Selective laser sintering fabrication of nano-hydroxyapatite/poly-epsilon-caprolactone scaffolds for bone tissue engineering applications. Int J Nanomed. 2013;8:4197–4213. doi: 10.2147/IJN.S50685. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 52.Dong L., Wang S.J., Zhao X.R., Zhu Y.F., Yu J.K. 3D-Printed poly(ε-caprolactone) scaffold integrated with cell-laden chitosan hydrogels for bone tissue engineering. Sci Rep. 2017;7:13412. doi: 10.1038/s41598-017-13838-7. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 53.Tao O., Kort-Mascort J., Lin Y. The applications of 3D printing for craniofacial tissue engineering. Micromachines (Basel) 2019;10(7):480. doi: 10.3390/mi10070480. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 54.Nandi S.K., Fielding G., Banerjee D., Bandyopadhyay A., Bose S. 3D-printed β-TCP bone tissue engineering scaffolds: effects of chemistry on in vivo biological properties in a rabbit tibia model. J Mater Res. 2018;33:1939–1947. doi: 10.1557/jmr.2018.233. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 55.Duan B., Wang M., Zhou W.Y., Cheung W.L., Li Z.Y., Lu W.W. Three-dimensional nanocomposite scaffolds fabricated via selective laser sintering for bone tissue engineering. Acta Biomater. 2010;6:4495–4505. doi: 10.1016/j.actbio.2010.06.024. [DOI] [PubMed] [Google Scholar]

- 56.Barak M.M., Black M.A. A novel use of 3D printing model demonstrates the effects of deteriorated trabecular bone structure on bone stiffness and strength. J Mech Behav Biomed Mater. 2018;78:455–464. doi: 10.1016/j.jmbbm.2017.12.010. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 57.Luo Y., Wu C., Lode A., Gelinsky M. Hierarchical mesoporous bioactive glass/alginate composite scaffolds fabricated by three-dimensional plotting for bone tissue engineering. Biofabrication. 2013;5 doi: 10.1088/1758-5082/5/1/015005. [DOI] [PubMed] [Google Scholar]

- 58.Haleem A., Javaid M. Additive manufacturing applications in industry 4.0: a review”. J Ind Integr Manag. 2019 [Google Scholar]

- 59.Turnbull G., Clarke J., Picard F. 3D bioactive composite scaffolds for bone tissue engineering. Bioact Mater. 2017;3(3):278–314. doi: 10.1016/j.bioactmat.2017.10.001. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 60.Venkatesan J., Bhatnagar I., Manivasagan P., Kang K.H., Kim S.K. Alginate composites for bone tissue engineering: a review. Int J Biol Macromol. 2015;72:269–281. doi: 10.1016/j.ijbiomac.2014.07.008. [DOI] [PubMed] [Google Scholar]

- 61.Javaid M., Haleem A. Current status and challenges of Additive manufacturing in orthopaedics: an overview. J Clin Orthop Trauma. 2019;10(2):380–386. doi: 10.1016/j.jcot.2018.05.008. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 62.Mastrogiacomo M., Campi G., Cancedda R., Cedola A. Synchrotron radiation techniques boost the research in bone tissue engineering. Acta Biomater. 2019;89:33–46. doi: 10.1016/j.actbio.2019.03.031. [DOI] [PubMed] [Google Scholar]

- 63.Javaid M., Haleem A. 3D printed medical parts with different materials using additive manufacturing. Clin Epidemiol Glob Health. 2019 [Google Scholar]

- 64.Li L., Yu F., Shi J. In situ repair of bone and cartilage defects using 3D scanning and 3D printing. Sci Rep. 2017;7(1):9416. doi: 10.1038/s41598-017-10060-3. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 65.Haleem A., Javaid M. 3D scanning applications in medical field: a literature-based review. Clin Epidemiol Glob Health. 2019;7(2):199–210. [Google Scholar]

- 66.Moncal K.K., Aydin R.S., Abu-Laban M. Collagen-infilled 3D printed scaffolds loaded with miR-148b-transfected bone marrow stem cells improve calvarial bone regeneration in rats. Mater Sci Eng C. 2019;105:110128. doi: 10.1016/j.msec.2019.110128. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 67.Tanataweethum N. Fabrication of poly-l-lactic acid/dicalcium phosphate dihydrate composite scaffolds with high mechanical strength-implications for bone tissue engineering. J Funct Biomater. 2015;6(4):1036–1053. doi: 10.3390/jfb6041036. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 68.Paolini A., Leoni L., Giannicchi I. MicroRNAs delivery into human cells grown on 3D-printed PLA scaffolds coated with a novel fluorescent PAMAM dendrimer for biomedical applications. Sci Rep. 2018;8(1):13888. doi: 10.1038/s41598-018-32258-9. [DOI] [PMC free article] [PubMed] [Google Scholar]