Abstract

Background

The aim of this study was to evaluate the precision of correlation between intraoral scanners and computer aided design (CAD) software programs used during scanning and designing phases of digital dentistry. In the present study, CAD software programs that accept data in Standard Tessellation Language (STL) and proprietary format have been evaluated and data loss has been examined in the scanned data.

Material/Methods

A single unit crown preparation was conducted for maxillary right first molar on a fully dentulous model. The prepared tooth was scanned with a high precision industrial scanner (ATOS Core 80) and the reference digital model was obtained. The dental model was further scanned 10 times using 3 different intraoral scanners (CEREC Omnicam AC, TRIOS 3 Color Pod, and Aadva IOS 100). The data obtained from the reference scanner and intraoral scanners were transferred to different CAD programs (CEREC inLab, TRIOS Design Studio, Exocad) and digital crowns were designed for each scanned data-CAD combination. After that, the data losses that occurred between these transfers were evaluated by superimposition technique in a special software (VR Mesh v7.5) (α=0.05).

Results

Among the all combinations of scanner and software, Omnicam AC-InLab was determined to be the most precise combination through the full digital workflow since the Omnicam AC-Exocad combination showed the highest deviations.

Conclusions

Within the limitations of this in vitro study, it was determined that the combinations of scanners and associated CAD programs yielded more accurate results, and data loss was revealed when the scanned data converted from the proprietary format to the STL format.

MeSH Keywords: Analog-Digital Conversion, Computer-Aided Design, Dental Clinics

Background

Nowadays, in addition to the increased aesthetic expectations in dental treatments, more ease is also sought in routine treatment procedures for the practitioner, and also for the patient. In this emerging technology age, the solutions required for this target provide more options. Computer-aided design and computer-aided manufacturing (CAD-CAM) technology in dentistry was introduced for single-unit restorations 30 years ago, and technological advances make it possible to produce complex multi-unit rehabilitations and implant restorations [1].

When the CAD-CAM concept started to be used in prosthetic dental treatments, intraoral scanning concept were introduced in the early 1980s [2]. Especially with the entry of intraoral scanners into the market, digital impression techniques have shown many innovations and developments; and these developments brought with them easier and reliable manipulations at many stages of treatments. All intraoral scanners are based on a variety of non-contact imaging techniques and principles [3].

CAD-CAM systems using intraoral scanners provide easier and patient-friendly planning of a wider range of acceptable cases, easier communication with laboratories, and shorter treatment times [4–6]. Over the last decade, many intraoral scanners have been developed with different technologies. The correct choice of a scanner system for individual cases is a pivotal factor for the long-term success of definitive restoration [5].

The use of intraoral scanning devices for digital impressions is increasing in dental implant cases as well as in the case of fixed prosthesis on natural tooth abutments. This fully digitized workflow has many advantages over conventional impression techniques such as increasing patient comfort, time saving, accuracy, precision, and productivity, as well as extraoral digital measurement techniques [7]. Intraoral digital impression acquisition also allows 3-dimensional data of all dento-gingival tissues to be obtained [8,9].

The data obtained by intraoral scanner acquisitions in digital workflows are transferred to various software programs in order to create 3-dimensional digital design. Some of the scanners have open systems that export output data in the Standard Tessellation Language (STL) format; while some have closed systems that only export output data in proprietary formats. Scanners with an open system, can be read by all design programs. In the closed systems, the special formatted output data obtained from scanning is transferred directly to the corresponding software of associated system, allowing digital design. If the data is obtained from a scanner with a closed system, a step of conversation from proprietary to STL format must be done to make it possible for the other programs to access and read these data [10]. The data loss that can occur during these transfers made with these conversation steps, can affect the final adaptation and success of the definitive restoration [11].

It was the aim of this current study to evaluate the data loss from scanning phase to design phase and thereby to present documentation about precision of different scanning systems. The null hypothesis was that transferred data formats and conversions would not influence the precision of different scanner systems.

Material and Methods

A full dentulous dental model (AG-3 WOK, Frasaco, Tettnang, Germany) was used in this study. On this model, only a tooth number 16 was prepared to simulate a single crown case. During the preparation, a supra-gingival finishing line was applied in order to protect the gingival tissues and make it possible to capture better scans on the finishing line. Moreover, black, red, and yellow chamfer burs (Hager and Meisinger GmbH, Germany) were preferred for preparation, respectively. To ensure standardization of the step width, all burs were chosen to be 1 mm wide.

During the scans, teeth number 14, 15, 16, 17, and 18, which create the scanning area, were completely fixed by applying a small amount of acrylic resin (Self Cure Dental Acrylic, Rapid Repair, Melio Dent, Heraeus Kulzer, Germany) with the help of a fine application brush into the sockets to prevent possible minimal movements of the teeth that are held in place by the screws.

The prepared master model was first scanned with a professional industrial scanner (ATOS Core 80 5MP, GOM, Braunschweig, Germany) to obtain reference scans. During this scanning, coating spray was not used in order to achieve standardization. Surface of the prepared tooth was left roughed with the aid of the burs and none of the polishing processes were applied. Also, acid (Bisco, uni-etch 32% phosphoric acid etchant with benzalkonium chloride, Schaumburg, USA) was applied to the surface to better eliminate the risk of reflection during scanning procedure as roughed surface provides a sensitive scan.

Thereafter, the master model was scanned with 3 different intraoral scanners (CEREC Omnicam AC, Sirona, York, USA, software version: CEREC SW 4.4.4; 3 shape TRIOS 3 Color Pod, Copenhagen Denmark, software version: TRIOS 1.4.7.5; Aadva IOS 100 GC, Belgium, software version: IOS 100 2018). The software programs of all intraoral scanners included in the study were used with their current software versions. While the scanning procedures, the master model was placed on phantom head to better simulate the clinical conditions and all scanning procedures were completed with a single operator. The operator was a clinician who had experience with various intraoral scanners, including CEREC Omnicam AC, TRIOS 3 Color Pod and Aadva IOS 100 for at least 2 years.

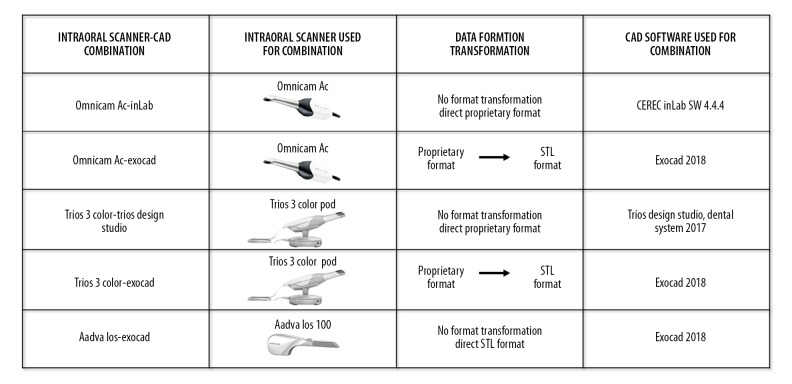

In order to mimic clinical conditions, 3900 K light and 500 lux were used in each scanning procedure. This environment was standardized for all scanning procedures. To obtain the standardization of the scanned areas, a minimum of 2 mesial and 2 distal teeth from the prepared tooth were included in the scanning area. The same scanning strategy was carried out when performing all scans. During the scans, the procedure was started at occlusal surfaces, moving towards the palatal side, and returning from the buccal side. The scanning procedures were repeated 10 times with each intraoral scanner (n=10/intraoral scanner). After all scans were obtained from each intraoral scanner, excess soft tissue areas and all areas out of the crown preparation area were cropped. To ensure that all scans were cropped identically, a custom adjustment of cropping and trimming options was applied to all scans. While these adjustments, considering the tip of the cusps which were used as landmarks for superimposition processes, the region between the third molars distal and first molars mesial were protected. Since the area to be used in superimpositions would be limited to the prepared surface of tooth number 16, it was ensured that the finish line and surface area of tooth number 16 were completely traceable after adjustments for each scan. And then all obtained data were transferred to the different CAD software programs, as depicted in Figure 1.

Figure 1.

A schematic illustration of the intraoral scanner-CAD software combinations used in the study and format conversions while the data transfers. CAD – computer aided design.

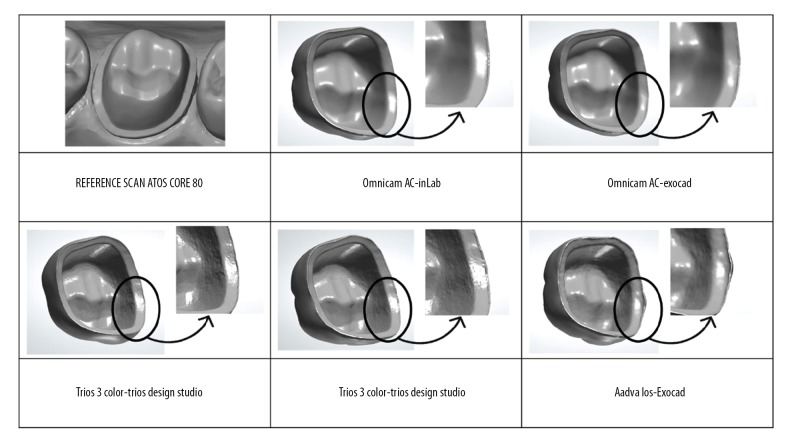

In each CAD software, all areas except the crown area to be evaluated were rechecked for the integrity of the scan images and the excess areas were cropped. Also, the die space was set to “0” for each CAD software. The aim of this setting was to make it possible to match the negative replicas of the digital crowns that were produced by CAD software programs and positive replicas of the reference scan. For each CAD software, the finishing lines of each crown design were corrected as needed. While the design adjustments, attention was paid to cover whole surface of the prepared tooth with full contour crown designs without any neglected parts because of decreasing the thickness of the design. Designs were left as far as possible without any excess adjustments of the corresponding program settings (Figure 2).

Figure 2.

Reference scan image of prepared tooth and crowns obtained from 5 different intraoral scanner-CAD software combinations. There is also a specific section of the crown image showing the differences in detail in the scans. CAD – computer aided design.

The reference scan and digital crown designs from each intraoral scanner-CAD combination were aligned observing the superposition of anatomic landmarks by a special software (VR Mesh v7.5, Bellevue, WA, USA). Anatomic landmarks were the tip of the first premolars buccal and palatal cusps and third molars mesiobuccal and mesiopalatal cusps. In the software, these points were marked and with the aid of fine alignment, superimpositions were conducted. When these superimpositions were conducted, areas with deviations of more than 0.2 mm were automatically extracted and eliminated from the matching process. The scans taken with each scanner (n=10/intraoral scanner) were matched with the reference scan and maximum, minimum, and average distance deviation values were obtained. To ensure the blinding of the operator about the origin of the files, instead of scanner names, different code names were used to label the scanner-CAD combinations.

The standard deviations were analyzed using a statistical software (GraphPad Prism 7.00). The one-way Analysis of Variance (ANOVA) test was used to test intragroup differences among the 5 intraoral scanner-software combinations.

In statistical analysis, the Brown-Forsythe test was used for the equality of group variances based on performing an ANOVA on a transformation of the response variables and the Bartlett’s test was used to test for homogeneity of variances. Also, the Tukey’s multiple comparison test was used to determine which means amongst a set of means differ from the rest. Statistical significance was set at P<0.05 for all tests (α=0.05).

Results

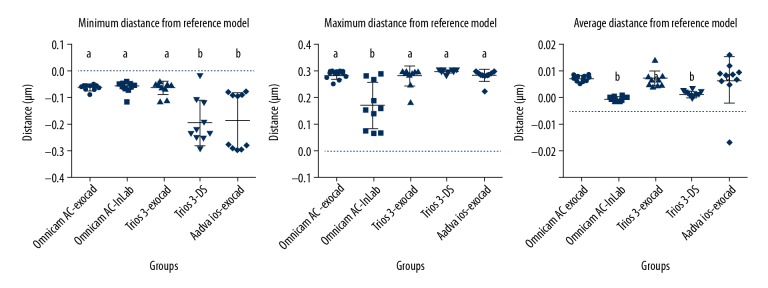

The average distance, minimum distance, and maximum distance results of the superimposition method for the model were given in the Table 1 and Figure 3. In accordance with the measurements of average distance, Omnicam AC-inLab combination exhibited the highest trueness with 368.3×10−5 mm±64.18×10−5 mm average distance, followed by TRIOS 3 Color-TRIOS Design Studio combination (495.1×10−5 mm±82.23×10−5 mm), Aadva IOS-Exocad combination (921.4×10−5 mm±697.4×10−5 mm), TRIOS 3 Color-Exocad combination (972×10−5 mm±228.7×10−5 mm), and Omnicam AC-Exocad combination (978.7×10−5 mm±91.44×10−5 mm) respectively. Whereas in accordance with the measurements of minimum and maximum distance only, Omnicam AC-inLab combination showed the smallest values, whereas the TRIOS 3 Color-TRIOS Design Studio indicated the highest values (Table 1).

Table 1.

The minimum, maximum and average distance results of the superimposition method for the model (mm).

| Intraoral scanner-CAD combination | Minimum distance Mean±SD* (10−5) |

Maximum distance Mean±SD* (10−5) |

Average distance Mean±SD* (10−5) |

|---|---|---|---|

| Omnicam AC – Exocad | −6075±1078a | 28450±1622a | 978.7±91.44a |

| Omnicam AC – inLab | −5967±2131a | 16870±8586b | 368.3±64.18b |

| Trios 3 Color – Exocad | −6156±2517a | 28030±3672a | 972.4±228.7a |

| Trios 3 Color – Trios Design Studio | −19400±8477b | 29580±622.7a | 495.1±82.23b |

| Aadva Ios – Exocad | −18540±10640b | 28210±2130a | 921.4±697.4a |

SD – standard deviation.

Letters ‘a’ and ‘b’ – The same letters in the same column indicate that there is no significant difference between the groups and the different letters indicate that there is significant difference between the groups.

Figure 3.

Minimum, maximum, and average distance deviation graphs obtained in GraphPad Prism 7.00 program after the analysis.

According to Tukey’s multiple comparisons test for average distance, statistically significant differences were found between the combinations of Omnicam AC-Exocad versus Omnicam AC-inLab, Omnicam AC-Exocad versus TRIOS 3 Color-TRIOS Design Studio, Omnicam AC-İnLab versus TRIOS 3 Color-Exocad, Omnicam AC-inLab versus Aadva IOS-Exocad, and TRIOS 3 Color-Exocad versus TRIOS 3 Color-TRIOS Design Studio. The statistically significant differences are shown in the Table 1.

Discussion

With respect to the aim of this study, a statistically significant influence of digital workflow on the precision of different intraoral scanner-CAD combinations was detected. Accordingly, the null hypothesis was rejected.

In addition to previous in vitro studies [12–14] investigating the precision of the intraoral scanners, there are also various studies [1,15,16] conducted in vivo conditions. According to one of the results of an in vivo study [16], factors such as light, salivation, heat, and experience of operator affected the success of intraoral scanners. In the present in vitro study, intraoral scanners were used in an environment free from oral conditions and, thereby, the influences of these factors were not evaluated in this study. Since the presence of saliva, body temperature, light reflections because of the intraoral tissues, and different patient position in the intraoral environment, it is envisaged that the present study might give different results when performed in the same conditions but within the oral environment. The main purpose of the present study was to evaluate the precision of intraoral scanner-CAD software combinations; clinical conditions have been ignored and more digital workflow precision was provided. Providing these intraoral conditions in the future studies, will make it possible to achieve more realistic results.

Arakida et al. reported on the importance of ambient light during intraoral scanning; the conditions of 3900 K and 500 lux of ambient light is considered the most suitable condition, which is typical of clinical settings. Under these conditions, scanning can provide more true representation and scanning time can be reduced when compared with other ambient light conditions [17]. Therefore, considering the importance of ambient light, the aforementioned conditions were provided during scanning procedures in the current study. In order to prevent light reflections on the surface to be scanned, a surface coating process was applied while obtaining the image with the aid of some intraoral scanners. It has been shown that the surface coating process does not cause any statistical differences and as a result it was concluded that coating and non-coating procedures did not influenced the precision of the scanning systems [13]. Also, the aforementioned study authors stated that lower scanning deviations were found in the scanner system which uses laser triangulation technique. This situation contributed to the reflections on the scanned surface in some regions because of the non-coating system. Excessive coating also has no detrimental effect on the scans. In the present study, no surface coating was applied. Since the intraoral scanners evaluated in vitro, it is thought that there will not be any effect that can cause any reflection on the surface. Besides, in order to prevent possible reflections on the surfaces to be scanned on the model, the burial marks on the prepared tooth surface were not destroyed by any polishing process. In addition, acid (Bisco, uni-etch 32% phosphoric acid etchant with benzalkonium chloride, Schaumburg, USA) was applied to the prepared tooth surface on the model, to assure that no shiny area was left behind to cause reflection during the scanning procedures.

The accuracy of intraoral scanners can be affected by operator’s previous experiences with intraoral scanner use [16]. According to the literature, repeated experiences are required for effective clinical practice. In the present study, the operator had at least 2 years of experience on intraoral scanners and this might have contributed to obtaining precise results. Another issue as important as operator’s experience is the scanning strategy. The scanning strategy which might shows the more accurate results were determined according to information obtained from the literature. One study indicated the importance of scanning strategies, and the effects of scanning strategy on the impression accuracy were examined; it was found that scanning strategy that started from occlusal-palatal to opposite arch and then returned from buccal side gave better results [18].

In another study, the effect of the scanning strategy was evaluated by TRIOS 3 Color Pod, (which is one of the intraoral scanners used in the present study), and at the end of the study, the authors concluded that the same strategy which starts from occlusal-palatal and returns to buccal side gave the best results [19]. Thus, the scanning strategy in the present study was determined in accordance with the information obtained from available studies in the literature.

In the current study, a fully digital workflow was designed, which the authors believed would give more reliable results in order to eliminate the errors which can be encountered from the fabrication procedures of restorations. All the workflows were digitally conducted, leading to more reliable results, and thereby it was thought that a focused analysis of the scanning devices can be achieved. This has also been stated by a previous publication [20]. Further studies fabricating crowns by using the same data format conversion steps are required in order to better understand the effect of the data loss on the clinical conditions.

In most studies, while measuring the trueness and precision of the scanners, restorations were generated from digital models obtained regardless of the accuracy of the digital workflow itself, and final successes, such as marginal adaptation and path of insertion, were evaluated [21,22]. In the present study, we aimed to determine how the digital workflow could be used more accurately and efficiently, and how optimum intraoral scanner-CAD software combinations could be achieved. In the studies evaluating marginal and internal adaptation, certain die spaces were left between the teeth and crowns were designed for adaptation measurements. In the present study, as the positive of the reference models superimposed by the negatives of the crowns designed in different CAD software programs, no die space was left in the designs. Thereby, it was thought that more precise results could be achieved.

In our study, 2 of the most commonly used scanners providing design capability with associated CAD software in proprietary format and with open CAD programs in STL format were selected. GC Aadva IOS was introduced in our study since it is one of the latest systems introduced to the market and we obtained the scanned data directly in STL format, different from the others. The software versions of the existing intraoral scanners were continuously updating. With these updates, the aim was to perform more successful results. In one study, when the effect of the software versions on accuracy were examined, it was found that the use of the current version of software contributed to achieving more successful and precise results [23]. Therefore, for our purpose, the most recent software versions of scanners and CAD programs were used in the current study.

The result of our study found that Omnicam AC gave the most successful results among the evaluated combinations when it was used with its associated CAD software. According to the measurements of minimum and maximum distance deviations, Omnicam AC-in-Lab combination showed the least deviation values, whereas the TRIOS 3 Color-TRIOS Design Studio indicated the highest deviation values (Table 1). However, no statistically difference was found between these scanner-CAD combinations when average distance values were examined. When examining the difference of 2 surfaces, average data values might be efficient to determine the total precision of the final restoration, rather than the minimum and maximum distance deviation values. For average distance measurements, in accordance with the literature [24,25]. Omnicam AC and TRIOS 3 Color scanners showed the least deviations when associated CAD software programs of these scanners were used.

When Tukey’s multiple comparison test results were evaluated, a statistically significant difference was found between the Omnicam AC-inLab and the Omnicam AC-Exocad combinations. For the TRIOS 3 Color scanner, the average distance value was lower when it was used with its associated CAD software. For both scanners, when the same data were converted to STL format and processed in the Exocad software, the average distance value increased, which means that the accuracy was reduced. The combination of Aadva IOS-Exocad, as mentioned earlier, differs from the other scanners in the form of direct STL output format, and it can only be processed in open system CAD software programs. The combination of Aadva IOS-Exocad had the lowest sensitivity when compared with the TRIOS 3 Color and the Omnicam AC scanners which were not subjected to the STL conversion step (Omnicam AC-inLAB and TRIOS 3 Color-TRIOS Design Studio). There have been several studies involving Omnicam AC, TRIOS 3 Color, and Aadva IOS intraoral scanners [26,27] which presented different results from the current study in terms of the Aadva IOS scanner’s results. In the studies by Osnes et al. and Ferrari et al., Aadva IOS scanner exhibited similar results when compared to the TRIOS and the Omnicam scanners. However, unlike the current study, comparing the distance between 2 adjacent teeth [26] and signed mean distance measurement [27] were evaluated in those studies. In the current study, topographic surface details were evaluated by superimposition of the interior part of the crowns which were created by different digital workflows. Therefore, these dissimilar results can be explained by the different evaluation methodology of the aforementioned studies. With the best of our knowledge, this is the first study that evaluates the data loss during the transfer of intraoral scans to various CAD programs in different formats. Therefore, further studies regarding the data loss are needed in order to discuss the results of the current study. However, the results were found to be similar with Aadva IOS-Exocad values when these scanners (TRIOS 3 Color and Omnicam AC) subjected to format change and evaluated in an open system CAD software (Exocad). These contradictory results can be explained by the data loss which might have occurred during the conversion step that needs to be done for different CAD software programs. These results support the hypothesis that the data loss occurred when the scanned data were subjected to a format change from proprietary to STL. STL file format is supported by many other software packages; it is widely used for rapid prototyping and computer-aided manufacturing. STL files describe only the surface geometry of a 3-dimensional object without any representation of color, texture, or other common CAD model attributes [28]. In the study conducted by Ciobota, which was one of several studies evaluating the precision of the STL format in areas other than dentistry, the losses were determined about the STL files. In the Ciobota study, it was stated that in the near future, different formats will be put into use and the STL format will change with the new formats which will cause less data loss. This is in accordance with the present study. In the combination of Aadva IOS-Exocad there is no conversion of data format. However, because of the scanned data obtained by the Aadva IOS scanner, it is already in the STL format, and it is predicted to cause more precision than the Omnicam AC and TRIOS 3 Color scanners with an open system (Omnicam AC-Exocad and TRIOS 3 Color-Exocad).

Conclusions

According to the results of the current study, these conclusions can be drawn; 1) use of the CAD software is associated with the intraoral scanner exhibited better results. 2) Use of open system scanners that has an output of direct STL data can be recommended. 3) Data loss was observed when it was transferred from the proprietary format to STL.

Footnotes

Source of support: Supported by grant no. SAG-2019-1-033 from Near East University, Scientific Research Projects Coordination Unit, Nicosia, Mersin 10, Turkey

Conflicts of interest

None.

References

- 1.Nedelcu R, Olsson P, Nyström I, et al. Accuracy and precision of 3 intraoral scanners and accuracy of conventional impressions: A novel in vivo analysis method. J Dent. 2018;69:110–18. doi: 10.1016/j.jdent.2017.12.006. [DOI] [PubMed] [Google Scholar]

- 2.Su T, Sun J. Comparison of repeatability between intraoral digital scanner and extraoral digital scanner: An in vitro study. J Prosthodont Res. 2015;59(4):236–42. doi: 10.1016/j.jpor.2015.06.002. [DOI] [PubMed] [Google Scholar]

- 3.Logozzo S, Zanetti EM, Fanceschini G, et al. Recent advances in dental optics. Part I: 3D intraoral scanners for restorative dentistry. Optics and Lasers in Engineering. 2014;54:203–21. [Google Scholar]

- 4.Richert R, Goujat A, Venet L, et al. Intraoral scanner technologies: A review to make a successful impression. J Healthc Eng. 2017;2017 doi: 10.1155/2017/8427595. 8427595. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 5.Alghazzawi TF. Advancements in CAD/CAM technology: Options for practical implementation. J Prosthodont Res. 2016;60(2):72–84. doi: 10.1016/j.jpor.2016.01.003. [DOI] [PubMed] [Google Scholar]

- 6.Gjelvold B, Chrcanovic BR, Korduner E, et al. Intraoral digital impression technique compared to conventional impression technique. A randomized clinical trial. J Prosthodont. 2016;25(4):282–87. doi: 10.1111/jopr.12410. [DOI] [PubMed] [Google Scholar]

- 7.Ting-shu S, Jian S. Intraoral digital impression technique: A review. J Prosthodont. 2014;24(4):313–21. doi: 10.1111/jopr.12218. [DOI] [PubMed] [Google Scholar]

- 8.Yuzbasioglu E, Kurt H, Turunc R, Bilir H. Comparison of digital and conventional impression techniques: Evaluation of patients perception, treatment comfort, effectiveness and clinical outcomes. BMC Oral Health. 2014;14:10. doi: 10.1186/1472-6831-14-10. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 9.Patzelt SBM, Lamprinos C, Stampf S, Att W. The time efficiency of intraoral scanners: An in vitro comparative study. J Am Dent Assoc. 2014;145(6):542–51. doi: 10.14219/jada.2014.23. [DOI] [PubMed] [Google Scholar]

- 10.Geng J. Structured-light 3D surface imaging: A tutorial. Adv Opt Photonics. 2011;3(2):128. [Google Scholar]

- 11.Baheti MJ, Soni UN, Gharat NV, et al. Intra-oral scanners: A new eye in dentistry. Austin Journal of Orthopedics & Rheumatology. 2015;2(3):1023. [Google Scholar]

- 12.Imburgia M, Logozzo S, Hauschild U, et al. Accuracy of four intraoral scanners in oral implantology: A comparative in vitro study. BMC Oral Health. 2017;17(1):92. doi: 10.1186/s12903-017-0383-4. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 13.Nedelcu RG, Persson AS. Scanning accuracy and precision in 4 intraoral scanners: An in vitro comparison based on 3-dimensional analysis. J Prosthet Dent. 2014;112(6):1461–47. doi: 10.1016/j.prosdent.2014.05.027. [DOI] [PubMed] [Google Scholar]

- 14.Miyoshi K, Tanaka S, Yokoyama S, et al. Effects of different types of intraoral scanners and scanning ranges on the precision of digital implant impressions in edentulous maxilla: An in vitro study. Clin Oral Implants Res. 2019 doi: 10.1111/clr.13548. [Epub ahead of print] [DOI] [PubMed] [Google Scholar]

- 15.Kuhra F, Schmidta A, Rehmanna P, et al. A new method for assessing the accuracy of full arch impressions in patients. J Dent. 2016;55:68–74. doi: 10.1016/j.jdent.2016.10.002. [DOI] [PubMed] [Google Scholar]

- 16.Lim JH, Park J-M, Kim M, et al. Comparison of digital intraoral scanner reproducibility and image trueness considering repetitive experience. J Prosthet Dent. 2018;119(2):225–32. doi: 10.1016/j.prosdent.2017.05.002. [DOI] [PubMed] [Google Scholar]

- 17.Arakida T, Kanazawa M, Iwaki M, et al. Evaluating the influence of ambient light on scanning trueness, precision, and time of intra oral scanner. J Prosthodont Res. 2018;62(3):324–29. doi: 10.1016/j.jpor.2017.12.005. [DOI] [PubMed] [Google Scholar]

- 18.Medina-Sotomayor P, Pascual-Moscardó A, Camps I. Accuracy of four digital scanners according to scanning strategy in complete-arch impressions. PLoS One. 2018;13(9):e0202916. doi: 10.1371/journal.pone.0202916. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 19.Müller P, Ender A, Joda T, Katsoulis J. Impact of digital intraoral scan strategies on the impression accuracy using the TRIOS Pod scanner. Quintessence Int. 2016;47(4):343–49. doi: 10.3290/j.qi.a35524. [DOI] [PubMed] [Google Scholar]

- 20.Seelbach P, Brueckel C, Wöstmann B. Accuracy of digital and conventional impression techniques and workflow. Clin Oral Invest. 2012;17:1759–64. doi: 10.1007/s00784-012-0864-4. [DOI] [PubMed] [Google Scholar]

- 21.Costa JB, Pelogia F, Hagedorn B, Ferracane JL. Evaluation of different methods of optical impression making on the marginal gap of onlays created with CEREC 3D. Oper Dent. 2010;35(3):324–29. doi: 10.2341/09-178-L. [DOI] [PubMed] [Google Scholar]

- 22.Ferrini F, Sannino G, Chiola C, et al. Influence of intra-oral scanner (IOS) on the marginal accuracy of CAD/CAM single crowns. Int J Environ Res Public Health. 2019;16(4) doi: 10.3390/ijerph16040544. pii: E544. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 23.Haddadi Y, Bahrami G, Isidor F. Effect of software version on the accuracy of an intraoral scanning device. Int J Prosthodont. 2018;31(4):375–76. doi: 10.11607/ijp.5781. [DOI] [PubMed] [Google Scholar]

- 24.Di Fiore A, Meneghello R, Graiff L, et al. Full arch digital scanning systems performances for implant-supported fixed dental prostheses: A comparative study of 8 intraoral scanners. J Prosthodont Res. 2019 doi: 10.1016/j.jpor.2019.04.002. [Epub ahead of print] [DOI] [PubMed] [Google Scholar]

- 25.Medina-Sotomayor P, Pascual-Moscardó A, Camps I. Relationship between resolution and accuracy of four intraoral scanners in complete-arch impressions. J Clin Exp Dent. 2018;10(4):e361–66. doi: 10.4317/jced.54670. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 26.Ferrari M, Keeling A, Mandelli F, et al. The ability of marginal detection using different intraoral scanning systems: A pilot randomized controlled trial. Am J Dent. 2018;31(5):272–76. [PubMed] [Google Scholar]

- 27.Osnes CA, Wu JH, Venezia P, et al. Full arch precision of six intraoral scanners in vitro. J Prosthodont Res. 2019 doi: 10.1016/j.jpor.2019.05.005. [Epub ahead of print] [DOI] [PubMed] [Google Scholar]

- 28.Ciobota ND. Standard Tessellation language in rapid prototyping technology. Materials and Mechanics. 2012;2:81–85. [Google Scholar]