Abstract

This study was conducted to develop a self-assembled direct competitive enzyme-linked immunosorbent assay (dcELISA) kit for the detection of deoxynivalenol (DON) in food and feed grains. Based on the preparation of anti-DON monoclonal antibodies, we established a standard curve with dcELISA and optimized the detection conditions. The performance of the kit was evaluated by comparison with high-performance liquid chromatography (HPLC). The minimum detection limit of DON with the kit was 0.62 ng/mL, the linear range was from 1.0 to 113.24 ng/mL and the half-maximal inhibition concentration (IC50) was 6.61 ng/mL in the working buffer; there was a limit of detection (LOD) of 62 ng/g, and the detection range was from 100 to 11324 ng/g in authentic agricultural samples. We examined four samples of wheat bran, wheat flour, corn flour and corn for DON recovery. The average recovery was in the range of 77.1% to 107.0%, and the relative standard deviation (RSD) ranged from 4.2% to 11.9%. In addition, the kit has the advantages of high specificity, good stability, a long effective life and negligible sample matrix interference. Finally, wheat samples from farms in the six provinces of Henan, Anhui, Hebei, Shandong, Jiangsu and Gansu in China were analyzed by the kit. A total of 30 samples were randomly checked (five samples in each province), and the results were in good agreement with the standardized HPLC method. These tests showed that the dcELISA kit had good performance and met relevant technical requirements, and it had the characteristics of accuracy, reliability, convenience and high-throughput screening for DON detection. Therefore, the developed kit is suitable for rapid screening of DON in marketed products.

Keywords: deoxynivalenol, dcELISA kit, performance measurement, development

1. Introduction

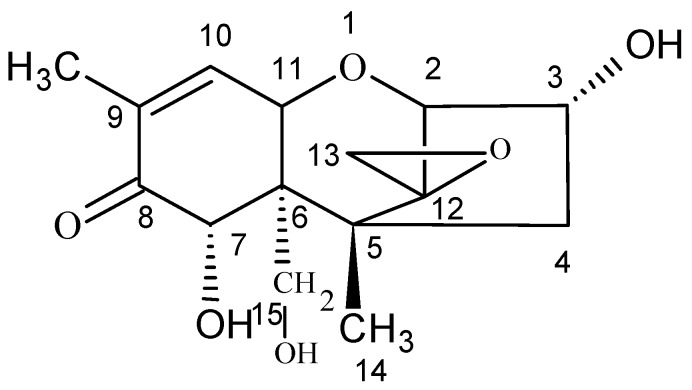

Deoxynivalenol (DON), also known as vomitoxin, is a highly toxic secondary metabolite produced by Fusarium graminearum and Fusarium culmorum; DON belongs to the B-group of trichothecenes and widely exists in various agricultural products, food, and animal feed, especially in wheat, maize, and other cereal crops [1,2,3,4]. DON readily acts as an animal antifeedant and shows immunotoxicity, organ toxicity, inhibition of protein synthesis, and teratogenicity. These symptoms are closely related to immune suppression, Keshan disease, oesophageal cancer and other diseases [5,6,7]. Moreover, DON is heat-stable, and general cooking and processing cannot destroy its toxicity. Young et al. [8] found that grain processed into pet food still contained DON. Therefore, DON pollution poses a great threat to human and livestock health and has attracted the attention of countries around the world [9]. At present, at least 100 countries have mandatory limits on DON levels in food and feed. In view of its serious toxic effects, in the preliminary draft of the DON maximum levels (MLs), the Codex Alimentarius Food (FAO) Committee recommended the following limits: 2 mg/kg in unprocessed cereals, 1 mg/kg in semi-processed products using wheat, corn and barley as raw materials, and 0.5 mg/kg in cereals for infants and young children [10,11]. In China, the ML of DON in maize, wheat, and their products is regulated at 1 mg/kg [12,13]. The molecular formula of DON is C15H20O6, and its molecular weight is 296.32 [14]. Its structure is shown in Figure 1:

Figure 1.

Molecular structure of deoxynivalenol (DON).

At present, the main physical and chemical methods for detecting DON contamination in food and feed are thin-layer chromatography (TLC), high-performance liquid chromatography (HPLC), gas chromatography (GC), mass spectrometry (MS), gas chromatography-mass spectrometry (GC-MS), high-performance liquid chromatography–mass spectrometry (HPLC–MS), high-performance liquid chromatography–tandem mass spectrometry (HPLC–MS/MS), and others [15,16,17]. These methods have high precision and sensitivity, but the sample pretreatment is rigorous, the instruments are expensive, the detection range is small, and, as the analysts often need special training, the cost is high. These methods are only suitable for large enterprises, scientific research institutes, or testing institutions that require high detection sensitivity, and they are not suitable for the demand of DON pollution detection in the feed industry. Therefore, increasing attention has been paid to the simple, rapid, sensitive, low-cost enzyme-linked immunosorbent assay (ELISA), which is suitable for large-scale sample screening. For example, the traditional immunosorbent assay (ELISA) [18], chemiluminescence enzyme immunoassay (CLEIA) [19], fluorescence polarization immunoassay (FPIA) [20], time-resolved fluorescence immunoassay (TRFIA) [21], colloidal gold immunochromatography (GICA) [22,23], surface plasmon resonance (SPR) immunoassay [24], silver-stained GICA [25], nanobody-based ELISA [26], and immunosensor, among others, can be used to detect DON. Therefore, due to the prevalence of DON contamination and the large number of samples that need to be analyzed, ELISA kits have been considered a suitable detection tool, and their development and application has grown rapidly in recent years because they do not need special instruments and equipment, are suitable for the field and are suitable for high-throughput screening.

The purpose of this experiment is to assemble and optimize a new DON dcELISA kit. The performance of the ELISA kit was tested, and its accuracy was verified by HPLC, which laid a foundation for the development of ELISA kits with high sensitivity, specificity, and good quantification suitable for screening a large number of DON-contaminated samples.

2. Materials and Methods

2.1. Reagents and Materials

The standards of DON, 3-Ac-DON, 15-Ac-DON, Nivalenol (NIV), Fusarenon-X, T-2 toxin, Zearalenone (ZEN), and Aflatoxin B1 (AFB1) were purchased from Sigma-Aldrich Co., Ltd. (Augsburg, Germany). Bovine serum albumin (BSA), chicken ovalbumin (OVA), N,N′-carbonyldiimidazole (CDI), anhydrous tetrahydrofuran (THF), N,N-dimethylformamide (DMF), horseradish peroxidase (HRP), 1-ethyl-3-(3-dimethylamino)propyl) carbodiimide hydrochloride (EDC), Freund’s complete adjuvant (FCA), and Freund’s incomplete adjuvant (FIA) were provided by Pierce. PEG-1500 (polyethylene glycol) was purchased from Roche. GaMIgG was purchased from Huamei Biotechnology Company (Shanghai, China). In addition, 96-well microtiter plates as well as 24-well and 96-well cell culture plates were purchased from Iwaki Co., Ltd. (Dalian, China); 3,3,5,5-Tetramethylbenzidine (TMB), phenacetin and urea peroxide were purchased from Sigma. Foetal bovine serum (FBS) was purchased from Gibco. Female Balb/c mice (6 to 8 weeks old) were provided by Beijing SPF Biotech Co., Ltd. (Beijing, China) and were raised under strict control in our laboratory animal house.

Phosphate-buffered saline (PBS), carbonate-buffered saline (CBS), washing buffer (PBST, PBS containing 0.05% Tween-20), blocking buffer (SPBST, PBST containing 5% goat serum), color substrate solution (TMB), stopping solution (2 M H2SO4), Glucose sodium chloride potassium chloride solution (GNK), complete medium, Hypoxantin Aminopterin and Thymidin (HAT) medium, Hypoxantin and Thymidin (HT) medium, were all made in-house in our laboratory.

A Galaxy S-type CO2 cell incubator was purchased from Biotech. A Multiskan MK3 microplate reader was purchased from Thermo (Waltham, Ma, USA) and used for 450 nm absorbance measurements. An inverted MIC 00949 microscope was purchased from Nikon Corporation. A DK-8D water bath was provided by Yiheng Instrument Co., Ltd. (Shanghai, China). A BS124S electronic balance was purchased from the German Sartorius Group. Purified water was prepared using a Milli-Q purification system (Millipore Corporation, Bedford, MA, USA). An A11 basic analytical mill was provided by IKA (Staufen, Germany). A Legend Micro 17 centrifuge was provided by Thermo (Waltham, MA, USA). Glass microfiber filter paper was purchased from Whatman (Maidstone, UK). The reliability of the ELISA kit was confirmed using an Agilent 1260 HPLC equipped with a diode array detector (DAD) (Agilent Technologies, Wilmington, DC, USA).

2.2. Preparation of the Antigen and Anti-DON Monoclonal Antibody (mAb)

According to the molecular structure of DON, the artificial antigen DON-BSA was synthesized by the carbonyl diimidazole (CDI) procedure outlined in a previously published method by Maragos et al. [14], with slight modifications. The synthesis of coated DON-OVA was improved by referring to the method of Li et al. [27]. DON was derivatized by maleic anhydride, and then the hapten was coupled with OVA to coat the original DON-OVA by implementation of the carbodiimide (EDC) procedure. Preparation of anti-DON mAb was achieved with classical hybridoma technology [28]. After obtaining DON mAb hybridoma cell lines, this experiment adopted an in vivo induced ascites method [29] to mass produce DON mAb, which was then purified from ascites by an octanoic acid/ammonium sulfate precipitation method [30]. The DON mAb was then stored at −20 °C until the dcELISA kit was assembled.

2.3. Development of the DON dcELISA Kit

We prepared the enzyme-labeled hapten (horseradish peroxidise-DON) and determined its working concentration as follows.

The enzyme-labeled hapten (HRP-DON) was prepared by a carbonyl diimidazole (CDI) method. DON standard (5 mg) was dissolved in 1 mL THF, 60 mg CDI was added, and the reaction proceeded for 4 h in a dry environment at 70 °C. The solvent of the reaction products was evaporated, and 500 μL DMF was added to the remaining products and completely dissolved. Then, 2 mg of HRP was added dropwise (the HRP was dissolved in 2 mL 0.01 mol/L pH 7.4 PBS solution) and stirred for 24 h at 4 °C in the dark. The reaction products were dialyzed in PBS for 72 h, the fluids were replaced 9 times during dialysis, and the dialysate, which was the enzyme-labeled hapten HRP-DON, was collected.

It is well known that the working concentration of the coated antigen and antibody is the key to determine the sensitivity of an ELISA kit. To determine the optimum dilution of RaMIgG, anti-DON mAb, and HRP-DON, chessboard titration tests were carried out. HRP-DON was added to 50% glycerol and stored at −20 °C.

2.4. Components of the ELISA Kit

The optimum conditions of the kit were very important for improving detection technology. The components and parameters of the kit are shown in Table 1 [31]:

Table 1.

Components and parameters of the direct competitive enzyme-linked immunosorbent assay (dcELISA) kit.

| Number | Composition | Quantity | Unit | Parameters |

|---|---|---|---|---|

| 1 | ELISA microplates | 1 | board | coated 96-well transparent microplates |

| 2 | Mab solution | 1 | tube | 6 mL (concentration of 1:6400 diluted in PBS) |

| 3 | DON standard | 1 | tube | 1 mg/mL |

| 4 | HRP-DON | 1 | tube | 3 mL (concentration of 1:800 diluted in PBS) |

| 5 | 1 × Working buffer | 1 | bottle | 50 mL (5% methanol, 0.5 mol/L Na+, pH 7.4 in PBS) |

| 6 | 10 × Washing buffer | 1 | bottle | 50 mL (10 × PBST, pH 7.4) |

| 7 | Color substrate buffer | 1 | bottle | 15 mL (0.4 mmol/L TMB and 3 mmol/L H2O2 diluted in citrate buffer, pH 5.0) |

| 8 | Stop buffer | 1 | bottle | 10 mL (2 mol/L H2SO4 diluted in H2O) |

2.5. Establishment of the Kit Standard Curve

The standard curve was established by dcELISA. The inhibition rate B/B0 of a series of concentrations of DON standards against DON mAb was taken as the ordinate, and the logarithmic value of a series of concentrations of DON standards was taken as the abscissa. The standard curve was analyzed and fitted using Origin Program 7.0 software (OriginLab Co., Northampton, MA, USA), and the linear regression was established. The theoretical detection limit and linear detection range of the kit were calculated by the regression equation.

2.6. Pretreatment of Samples

The wheat samples came from farms in six Chinese provinces: Henan, Anhui, Hebei, Shandong, Jiangsu and Gansu. A total of 30 samples were randomly checked (5 samples from each province). After the samples were ground, 5 g of each sample was accurately weighed (accurate to 0.01 g) and placed in a bottle. Distilled water (25 mL) was added, and extracted by sonication for 10 min. The mixture was evenly mixed for a few minutes. The supernatant was centrifuged at 8000 rpm/min for 5 min. Finally, 500 μL of the supernatant was added to 500 μL of the sample diluent, which is the extract solution of the sample to be tested. In addition, the pH of the sample extract was adjusted from 6 to 8. If needed, samples were diluted with the working buffer before being analyzed with the kit.

2.7. Operating Procedure of the Kit

-

(1)

Addition of anti-DON mAb: anti-DON mAb at a working concentration was added (50 μL/well), set as the negative and blank control, incubated for 15 min at 37 °C, and then washed.

-

(2)

Addition of HRP-DON and the sample to be tested: HRP-DON at a working concentration was added (50 μL/well), the sample to be tested was added at the same volume, the plate was incubated for 25 min at 37 °C, and then washed.

-

(3)

Coloration: the TMB-containing color substrate solution (50 μL/well) was added, and the plate was placed in the dark for 5 min at room temperature (RT).

-

(4)

Termination: a 2 mol/L H2SO4 termination solution was added (50 μL/well).

-

(5)

Measurement with the microplate reader: the absorbance was measured at 450 nm, and the inhibition rate was calculated.

2.8. Characteristics of the DON dcELISA Kit

2.8.1. Sensitivity Determination

According to the method of Hayashi et al. [32], the sensitivity of competitive ELISA is B/B0% = 83.3%; the sensitivity of the kit was calculated according to the standard curve regression equation, and the detection limit was also determined.

2.8.2. Accuracy and Precision Determination

In this study, the accuracy and precision of the kit were determined with recovery experiments and expressed as recovery (%) and relative standard deviation (RSD%), respectively. The wheat bran, wheat flour, maize flour, and maize were first treated with 1% Na2CO3 for detoxification [33]. Then, 5 g of each sample was spiked with DON at 200, 500 and 1000 ng/g and stirred for 2 h at room temperature (RT). Next, the spiked samples were added to 10 mL of working buffer containing 20% methanol, and extracted by sonication for 10 min. The supernatant was centrifuged at 8,000 rpm/min for 5 min. Finally, 500 μL of the supernatant was added to 500 μL of the working buffer, which is the extract solution of the sample to be tested. Then, each sample was tested three times, and the recovery (%) and RSD% were calculated:

| Recovery (%) = the measured value/the actual added value × 100% | (1) |

| (2) |

2.8.3. Specificity Determination

The specificity of the cross-reactions between the kit and other mycotoxins was evaluated, and the formula of cross-reaction rate (CR%) is [34]:

| CR (%) = [IC50 (DON)/IC50 (Structural Analogue)] × 100% | (3) |

2.8.4. Stability Determination

The stability of the kit was evaluated by the changes in B0 (the value of absorbance without the DON standard) and B/B0 (%) (the ratio value of absorbance with 5 ng/mL DON and without the DON standard) during storage (2 to 8 °C).

2.8.5. Matrix Effect Determination

To analyze the effect of the sample matrix on the sensitivity of the kit, the DON standard solution was dissolved in four samples of wheat bran, wheat flour, corn flour, and corn. These samples were then diluted with sample diluent, and the curve was generated according to the operation of the kit.

2.9. Confirmation of the DON dcELISA Kit with HPLC

The wheat samples from farms in the six provinces of Henan, Anhui, Hebei, Shandong, Jiangsu and Gansu in China were tested using the assembled DON dcELISA kit and HPLC. A total of 30 samples were randomly checked (5 samples from each province), and the correlation between the kit and HPLC was evaluated by comparing the results of detection [35]. Sample extraction and HPLC analysis were performed according to the method of the national standard of China GB5009.111-2016 [36], with slight modifications. After the samples were ground, 5 g of each sample was accurately weighed (accurate to 0.01 g) and placed in a clean and capped wide-mouth bottle. Twenty-five milliliters of acetonitrile-H2O (20:80, v/v) and 2 g polyethylene glycol were added. The bottle was capped and extracted by sonication for 30 min. The mixture was evenly mixed for a few minutes. The samples were centrifuged at 6000 rpm/min for 10 min. Finally, the supernatants were filtered through glass microfiber filters to clarify the extract solution of the sample to be tested. Then, the supernatants were purified through DON immunoaffinity columns. The extracted phases were collected and analyzed by HPLC. The HPLC analysis was performed using an Agilent 1260 HPLC equipped with a diode array detector (DAD). Separation was performed on a C18 liquid chromatographic column (150 mm × 4.6 mm × 5 μm) or equivalent, the mobile phase was methanol:water (20:80, v/v), the flow rate was 0.8 mL/min, the column temperature was 35 °C, the injection volume was 50 μL, and the detection wavelength was 218 nm.

3. Results

3.1. Development of the DON dcELISA Kit

For the determination of the working concentrations of RaMIgG, anti-DON mAb and HRP-DON using the chessboard titration tests, ELISA microplates were coated with 10 ng/mL RaMIgG. The working concentrations of the anti-DON mAb and HRP-DON were determined as 1:6400 (1.56 ng/mL) and 1:800 (28.5 ng/mL), respectively, when the value of B0 reached 1.0.

The key parameters were studied to guarantee the ideal sensitivity and performance of the kit for detecting DON. Under the criteria of a higher value of B0/half-maximal inhibition concentration (IC50) and lower value of IC50, the working buffer, which could greatly affect the sensitivity of the kit, was adjusted. Finally, 5% methanol, 0.5 mol/L Na+, and pH 7.4 in the working buffer were selected as the optimal working buffer for the kit (Table 2).

Table 2.

Key parameters for the proposed kit.

| Factor | Parameter | Factor | Parameter |

|---|---|---|---|

| RaMIgG | 10 ng/mL | Methanol (v/v, %) | 5 |

| anti-DON mAb | 1:6400 (1.56 ng/mL) | Na+ (mol/L) | 0.5 |

| HRP-DON | 1:800 (28.5 ng/mL) | pH | 7.4 |

3.2. Generating and Fitting the Standard Curve of the Kit

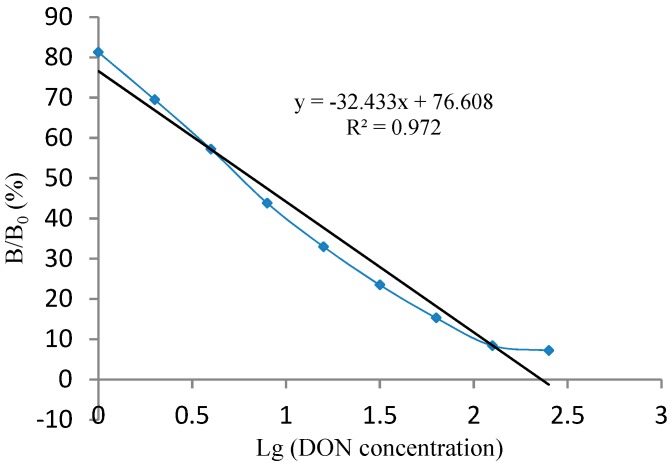

The standard curve of the kit is shown in Figure 2. By analyzing the curve, the regression equation y = −32.433x + 76.608, correlation coefficient R2 = 0.972, and IC50 = 6.61 ng/mL was obtained, and the detection range (IC10 to IC80) was 1.0 to 113.24 ng/g.

Figure 2.

Calibration curve of the dcELISA kit.

3.3. Performance Measurements of the Kit

3.3.1. Sensitivity Determination

When B/B0 = 83.3%, the corresponding DON concentration was 0.62 ng/g, indicating a sensitivity of 0.62 ng/g, which was obtained by substituting the B/B0 value into the standard curve regression equation. However, considering the need for positive detection and the error of user operation, the detection limit of the competitive ELISA kit was determined to be 1.0 ng/g.

3.3.2. Accuracy and Precision Measurement

Table 3 shows the four feed samples of wheat bran, wheat flour, corn flour, and corn with the recoveries. The average recovery was in the range of 77.1% to 107.0%, and the RSD ranged from 4.2% to 11.9%. The dcELISA kit meets the requirements of national accuracy and precision, indicating that the kit can be used for the detection of actual samples.

Table 3.

Recoveries of DON in different samples by the dcELISA kit (n = 3).

| Samples | Spiked (ng/g) | Mean Recovery ± SD (%) | RSD (%) | |

|---|---|---|---|---|

| 200 | 89.2 ± 6.2 | 7 | ||

| Wheat bran | 500 | 88.1 ± 5.7 | 6.5 | |

| 1000 | 79.4 ± 7.5 | 9.4 | ||

| 200 | 77.1 ± 9.2 | 11.9 | ||

| Wheat flour | 500 | 81.7 ± 5.6 | 6.8 | |

| 1000 | 96.5 ± 4.1 | 4.2 | ||

| 200 | 104.4 ± 5.8 | 5.5 | ||

| Corn meal | 500 | 96.4 ± 6.3 | 6.5 | |

| 1000 | 107.0 ± 7.6 | 7.1 | ||

| 200 | 103.7 ± 4.6 | 4.4 | ||

| Corn | 500 | 95.0 ± 5.3 | 5.6 | |

| 1000 | 98.4 ± 7.3 | 7.4 | ||

3.3.3. Specificity Determination

Table 4 shows that the cross-reactions between the kit and other mycotoxins were negligible. The cross-reaction rate with 3-Ac-DON was 4.7% and that with other mycotoxins was less than 0.2%, indicating that the kit has high specificity.

Table 4.

Cross-reactivity of the DON dcELISA kit with other related mycotoxins.

| Compounds | IC50 (ng/mL) | Cross-Reactivity (%) |

|---|---|---|

| DON | 6.61 | 100 |

| 3-Ac-DON | 142.1 | 4.7 |

| 15-Ac-DON | >5 × 103 | <0.2 |

| DON-3-G | >1 × 104 | <0.1 |

| NIV | >1 × 104 | <0.1 |

| Fusarenon-X | >1 × 104 | <0.1 |

| T-2 toxin | >1 × 104 | <0.1 |

| ZEN | >1 × 104 | <0.1 |

| AFB1 | >1 × 104 | <0.1 |

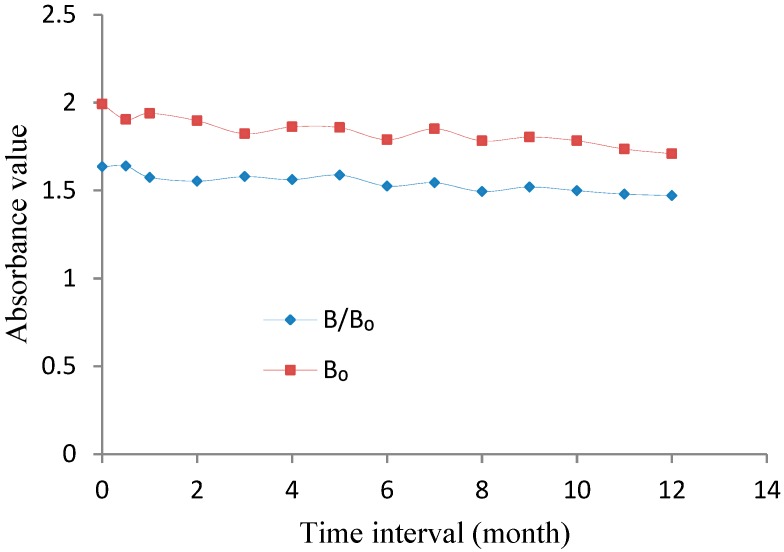

3.3.4. Stability Determination

As shown in Figure 3, the values of B0 (the value of absorbance without DON standard) and B/B0 (%) (the ratio value of absorbance with 5 ng/mL DON and without DON standard) showed acceptable decreases during storage. The results showed that the kit had good stability and that its effective life was at least 12 months.

Figure 3.

Stability of the dcELISA kit.

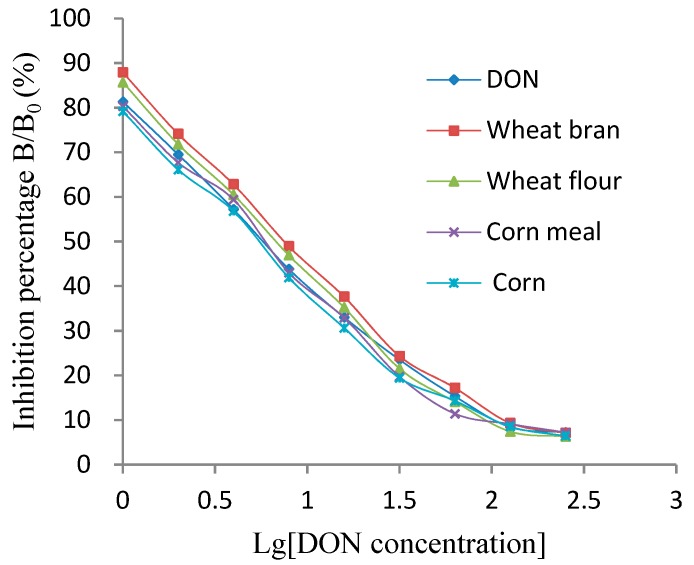

3.3.5. Matrix Effect Determination

As shown in Figure 4, the curves of the spiked samples of wheat bran, wheat flour, corn flour and corn were close to the DON standard curve by dilution of the extract solution multiple times, and their IC50 values were 8.81, 7.59, 6.22 and 5.7 ng/mL, respectively, indicating that the matrix interference was negligible. Therefore, the kit is functional for different substrates and can be used for detecting subsequent samples.

Figure 4.

Effect of different samples’ matrixes on the dcELISA kit.

3.4. Confirmation of the DON dcELISA Kit with HPLC

Table 5 shows that a total of 30 wheat samples from different provinces in China were tested using the assembled DON dcELISA kit and HPLC. The average value of detection with HPLC was in the range of 560.4 to 1049.1 ng/g, and the RSD ranged from 12.4% to 43.4% (the results of HPLC were corrected by a recovery of 85.7%). The average value of detection with the kit was in the range of 580.5 to 1020.3 ng/g, and the RSD ranged from 13% to 43.8%. The results showed that the test results of the kit were generally higher than those of HPLC. However, the test results of the kit in its linear range were in good agreement with those of HPLC.

Table 5.

Comparison of screening results of 30 wheat samples detected by two different methods.

| Province | dcELISA Kit | HPLC | ||||

|---|---|---|---|---|---|---|

| Range (ng/g) | Average Value ± SD% | RSD (%) | Range (ng/g) | Average Value ± SD% | RSD (%) | |

| Henan | 309.5–1243.8 | 933.4 ± 324.1 | 34.7 | 277.1–1231.4 | 918.1 ± 304.7 | 33.2 |

| Anhui | 378.9–1230.7 | 810.5 ± 276.3 | 34.1 | 350.5–1218.4 | 796.6 ± 268.5 | 33.7 |

| Hebei | 696.4–1087.9 | 853 ± 119.4 | 14 | 681.9–1023.1 | 834.3 ± 103.1 | 12.4 |

| Shandong | 741.9–1258.4 | 1020.3 ± 168.2 | 16.5 | 752.8–1235.6 | 1049.1 ± 158.2 | 15.1 |

| Jiangsu | 591.2–891.2 | 713.4 ± 93 | 13 | 583.5–870.3 | 703.9 ± 92.4 | 13.1 |

| Gansu | 254.7–1080.5 | 580.5 ± 254.3 | 43.8 | 236.1–991.6 | 560.4 ± 243.3 | 43.4 |

Thirty samples of wheat were detected with the kit, 22 of which were found to contain DON, with a concentration range of 254.7to 1258.4 ng/g. Four of the 30 samples were false suspect, with a false suspect rate of 13.3% (Table 6).

Table 6.

Test results of wheat samples from different provinces by the kit and HPLC.

| Province | Samples (Wheat) | dcELISA Kit | HPLC |

|---|---|---|---|

| 1 | + | + | |

| 2 | + | + | |

| Henan | 3 | - | - |

| 4 | + | + | |

| 5 | + | - | |

| 1 | + | + | |

| 2 | - | + | |

| Anhui | 3 | + | - |

| 4 | + | + | |

| 5 | + | + | |

| 1 | + | + | |

| 2 | + | + | |

| Hebei | 3 | - | - |

| 4 | + | + | |

| 5 | - | + | |

| 1 | - | - | |

| 2 | + | + | |

| Shandong | 3 | + | + |

| 4 | + | + | |

| 5 | - | - | |

| 1 | + | + | |

| 2 | + | + | |

| Jiangsu | 3 | - | - |

| 4 | - | - | |

| 5 | + | + | |

| 1 | + | - | |

| 2 | + | + | |

| Gansu | 3 | + | + |

| 4 | + | + | |

| 5 | + | - |

+, positive; -, negative; +, false negative; -, false suspect.

4. Discussions

4.1. Pretreatment of Biotoxin Samples

The pretreatment of samples increases the accuracy of HPLC and ELISA analyses. The samples were extracted and detected for DON; the pretreatment of samples for detection by ELISA was relatively simple, and direct filtration after extraction was sufficient for detection, while the pretreatment of samples for detection with HPLC required an immunoaffinity column. Yang et al. reported [37] that, the recovery rate of DON in ELISA was higher than 75%, and the RSD was 4.7% to 10.6% after the sample was filtered directly, while after passing through the immunoaffinity column, the recoveries of DON in HPLC and ELISA were the same when the spiked concentration of the standard was higher. It is concluded that the DON kit simplifies the process of sample pretreatment and purification. The results are accurate and reliable, and the detection steps are simple. It is very suitable for the rapid detection of a large number of samples. Moreover, ELISA detection technology has the advantages of limited interference, strong specificity, and short enzymatic reaction times, which shortens the whole detection time.

4.2. Determination of dcELISA Kit Performance

In this study, the dcELISA kit was assembled with an in-house-developed homemade high-affinity anti-DON monoclonal antibody. The kit performance metrics included sensitivity, accuracy, precision, specificity, stability and matrix effect, among others. Sensitivity determination can be calculated according to the method of Hayashi et al. [32]. The sensitivity of competitive ELISA is B/B0 = 83.3%, which can also be calculated by the formula of limit of detection LOD (%) = [(X − 2SD)/X] × 100%. The method of B/B0 = 83.3% was adopted in this experiment. The sensitivity was determined as 0.62 ng/mL, the detection limit was 1.0 ng/mL, and the detection range (IC10 to IC80) was 1.0 to 113.24 ng/mL in the working buffer. According to the procedures of authentic sample pretreatment and extraction, the DON levels of samples were equivalent to a 100-fold dilution and the matrix effects were negligible. Thus, for the analysis of wheat samples, with a sensitivity of 62 ng/g, an LOD of 100 ng/g, and a detection range from 100 to 11,324 ng/g in authentic agricultural samples, the cross-reaction rate with 3-Ac-DON and 15-Ac-DON was 4.7%, less than 0.2%, respectively. The DON ELISA method established by the Ministry of Health in China has a detection limit of 5 ng/mL, and the detection range was 5 to 1000 ng/mL. It had been approved as the national recommended standard detection method of China. Therefore, the DON dcELISA kit assembled in our laboratory meets the domestic detection range and sensitivity standard requirements of DON analysis in food and feed. Compared with the commercial kits, the sensitivity and specificity is higher (3 ng/mL in the working buffer), the DON levels of samples were equivalent to a 100-fold dilution with an LOD of 300 ng/g in authentic agricultural samples, and the cross-reaction rate with 3-Ac-DON and 15-Ac-DON was less than 70%, less than 1%, respectively. Compared with the kit that was developed by Li et al. [12], it has higher sensitivity and specificity (4.9 ng/mL in the working buffer), the DON levels of samples were equivalent to a 40-fold dilution with an LOD of 200 ng/g in authentic agricultural samples, and the cross-reaction rate with 3-Ac-DON and 15-Ac-DON was 5.7%, less than 0.5%, respectively. Accuracy and precision are measured by spiked sample recovery (%) and relative standard deviation (RSD%). Generally, the recovery rate is between 70% and 140%. The average recovery was in the range of 77.1% to 107.0%, and the RSD was 4.2% to 11.9% in this experiment, which meets the national accuracy and precision test requirements, indicating that the kit could be used for the detection of actual samples. Therefore, by evaluating the recoveries and determining the DON content in wheat samples, it is proved that the developed dcELISA kit is accurate, reliable, and simple, and that it requires less instrumentation, and involves simple experimental steps for detecting DON content in food and feed. Compared with commercial kits, it is a more advanced detection method in China and abroad, providing a highly sensitive, economical and safe DON detection method.

4.3. Comparison of the Results of the dcELISA Kit and HPLC

The kit test results were generally higher than those of HPLC. The wheat samples from the farms in the six provinces of Henan, Anhui, Hebei, Shandong, Jiangsu and Gansu in China were analyzed for DON content using both the kit and HPLC. A total of 30 samples were randomly checked (five samples from each province). The average value of detection with HPLC was in the range of 560.4 to 1049.1 ng/g, and the RSD ranged from 12.4% to 43.4%. The average value of detection with the kit was in the range of 580.5 to 1020.3 ng/g, and the RSD ranged from 13% to 43.8%. Therefore, the results showed that the test results of the kit were generally higher than those of the HPLC. However, the test results of the kit in its linear range were in good agreement with those of HPLC. Therefore, the kit can be used for the determination of DON in food and feed. Antibodies are the basis of the ELISA kit detection method, which may lead to false positive or false negative results, while HPLC is commonly used as an accurate verification method. There were two main reasons why the kit test results were generally too high. First, high or low pH of the sample solution will affect the test results. Therefore, it is necessary to adjust the pH of the sample solution before detection. Some studies have found that when the pH of a sample extract is lower than 5, the structure of the enzyme in an enzyme-labeled antigen changes irreversibly, and most of its activity is lost, resulting in a reduced color reaction, which leads to false-positive results. The pH of the extracted solution was from 6 to 8 when the samples were purified in this experiment, which met the detection requirements of the kit. Therefore, the pH of the samples did not need to be adjusted when samples were detected. Second, the loss of sample in the pretreatment process of HPLC leads to low detection results (the results of HPLC in this experiment were corrected by a recovery of 85.7%).

5. Conclusions

In this experiment, a dcELISA kit method was established by using an anti-DON monoclonal antibody developed in our laboratory. The working concentrations of RaMIgG, anti-DON mAb and HRP-DON were optimized, and the performance of the developed kit was tested. Finally, a comparison of the results of the kit with those of HPLC shows that the developed kit has the same detection ability as HPLC. Therefore, the kit can be widely used for DON detection in food and feed.

Author Contributions

W.-J.Z. and Z.-L.W. designed the research and interpreted the results. L.H. and Y.-T.L. conducted the experiments and drafted the manuscript. Y.Z. and J.-M.L. collected and processed data. J.-Q.J., R.-F.L. and G.-Y.F. revised the manuscript. All authors have read and agreed to the published version of the manuscript.

Funding

This work was financially supported by the Modern Agricultural Science and Technology Tackling and Achievement Conversion Project of the Eighth Normal University [2018NY05]; the Twelfth Five-Year Plan of National Science and Technology Support Projects, “Research and Demonstration of Rapid Detection Technology for Hormone Drugs” [2014BAD13B05-01]; the Key Technological Research Projects of Henan Province in 2018 (Agriculture) [182102110222]; and the Program for Innovative Research Team (in Science and Technology) in University of Henan Province (20IRTSTHN025).

Conflicts of Interest

There are no conflict to declare.

Footnotes

Sample Availability: Samples of the compounds are not available from the authors.

References

- 1.Zuo H.G., Zhu J.X., Shi L., Zhan C.R., Guo P., Wang Y., Zhang Y.M., Liu J.P. Development of a novel immunoaffinity column for the determination of deoxynivalenol and its acetylated derivatives in cereals. Food Anal. Method. 2018;11:2252–2260. doi: 10.1007/s12161-018-1211-4. [DOI] [Google Scholar]

- 2.Jiang D., Chen J., Li F., Li W., Wang X. Deoxynivalenol and its acetyl derivatives in bread and biscuits in Shandong province in China. Food Addit. Contam. B. 2017;11:43–48. doi: 10.1080/19393210.2017.1402824. [DOI] [PubMed] [Google Scholar]

- 3.Dezhao K., Xiaoling W., Yue L., Liqiang L., Shanshan S., Qiankun Z., Hua K., Chuanlai X. Ultrasensitive and eco-friendly immunoassays based monoclonal antibody for detection of deoxynivalenol in cereal and feed samples. Food Chem. 2019;270:130–137. doi: 10.1016/j.foodchem.2018.07.075. [DOI] [PubMed] [Google Scholar]

- 4.Ennouari A., Sanchis V., Marín S., Rahouti M., Zinedine A. Occurrence of deoxynivalenol in durum wheat from morocco. Food Control. 2013;32:115–118. doi: 10.1016/j.foodcont.2012.10.036. [DOI] [Google Scholar]

- 5.Pestka J.J., Smolinski A.T. Deoxynivalenol: Toxicology and potential effects on humans. J. Toxicol. Environ. Heal B. 2005;8:39–69. doi: 10.1080/10937400590889458. [DOI] [PubMed] [Google Scholar]

- 6.Ji F., Li H., Xu J., Shi J. Enzyme-linked immunosorbent-assay for deoxynivalenol (DON) Toxins. 2011;3:968–978. doi: 10.3390/toxins3080968. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Liao Y., Peng Z., Chen L., Nüssler A.K., Liu L., Yang W. Deoxynivalenol, gut microbiota and immunotoxicity: A potential approach? Food Chem. Toxicol. 2018;112:342–354. doi: 10.1016/j.fct.2018.01.013. [DOI] [PubMed] [Google Scholar]

- 8.Young J.C., Fulcher R.G., Hayhoe J.H., Scott P.M., Dexter J.E. Effect of milling and baking on deoxynivalenol (vomitoxin) content of eastern canadian wheats. J. Agric. Food Chem. 1984;32:659–664. doi: 10.1021/jf00123a058. [DOI] [Google Scholar]

- 9.Tima H., Berkics A., Hannig Z., Ittzés A., Kecskésné Nagy E., Mohácsi-Farkas C., Kiskó G. Deoxynivalenol in wheat, maize, wheat flour and pasta: Surveys in hungary in 2008–2015. Food Addit. Contam. B. 2017;11:37–42. doi: 10.1080/19393210.2017.1397061. [DOI] [PubMed] [Google Scholar]

- 10.Arrúa Alvarenga A.A., Moura Mendes Arrua J., Cazal Martínez C.C., Arrúa Alvarenga P.D., Fernández Ríos D., Pérez Estigarribia P.E., Mohan Kohli M. Deoxynivalenol screening in wheat-derived products in Gran Asunción, Paraguay. J. Food Saf. 2018;39:51–56. doi: 10.1111/jfs.12580. [DOI] [Google Scholar]

- 11.Iqbal S.Z., Alim M., Jinap S., Arino A. Food Safety. Springer International Publishing; Basel, Switzerland: 2016. Regulations for Food Toxins. [DOI] [Google Scholar]

- 12.Li M., Sun M., Hong X., Duan J., Du D. Survey of Deoxynivalenol Contamination in Agricultural Products in the Chinese Market Using An ELISA Kit. Toxins. 2019;11:6. doi: 10.3390/toxins11010006. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 13.China Food and Drug Administration . China National Standard No. GB2761-2017. Ministry of Health of P. R. China; Beijing, China: 2017. [Google Scholar]

- 14.Maragos C.M., Mccormick S.P. Monoclonal antibodies for the mycotoxins deoxynivalenol and 3-acetyl-deoxynivalenol. Food Agric. Immunol. 2000;12:181–192. doi: 10.1080/09540100050140722. [DOI] [Google Scholar]

- 15.Wang X.Y. Determination of deoxynivalenol in maize by using gas chromatography-electron capture detector. J. Changzhi Univ. 2006;23:7–10. [Google Scholar]

- 16.Righetti L., Galaverna G., Dall’Asta C. Group detection of don and its modified forms by an elisa kit. Food Addit. Contam. A. 2016;34:248–254. doi: 10.1080/19440049.2016.1265671. [DOI] [PubMed] [Google Scholar]

- 17.Wang Z.P., Wang D.L., Feng Z.S., Yang J., Wang X.J., Chen X. Detection of deoxynivalenol in malting barley by immunoaffinity column clear up and high performance liquid chromatography. Food Ferment. Ind. 2008;34:137–139. doi: 10.1016/S1872-5813(08)60024-9. [DOI] [Google Scholar]

- 18.Dos Santos J.S., Takabayashi C.R., Ono E.Y.S., Itano E.N., Mallmann C.A., Kawamura O., Hirooka E.Y. Immunoassay based on monoclonal antibodies versus lc-ms: Deoxynivalenol in wheat and flour in southern brazil. Food Addit. Contam. A. 2011;28:1083–1090. doi: 10.1080/19440049.2011.576442. [DOI] [PubMed] [Google Scholar]

- 19.Zhang R.S., Zhou Y.J., Zhou M.G. A sensitive chemiluminescence enzyme immunoassay for the determination of deoxynivalenol in wheat samples. Anal. Methods UK. 2015;7:2196–2202. doi: 10.1039/C4AY03079F. [DOI] [Google Scholar]

- 20.Li C.L., Wen K. A universal multi-wavelength fluorescence polarization immunoassay for multiplexed detection of mycotoxins in maize. Biosens. Bioelectron. 2016;79:258–265. doi: 10.1016/j.bios.2015.12.033. [DOI] [PubMed] [Google Scholar]

- 21.Zhang J., Gao L., Zhou B., Zhu L., Zhang Y., Huang B. Simultaneous detection of deoxynivalenol and zearalenone by dual-label time-resolved fluorescence immunoassay. J. Sci. Food Agric. 2011;91:193–197. doi: 10.1002/jsfa.4151. [DOI] [PubMed] [Google Scholar]

- 22.Yang X., Huang Z.B., He Q.H., Deng S.Z., Li L.S., Li Y.P. Development of an immunochromatographic strip test for the rapid detection of deoxynivalenol in wheat and maize. Food Chem. 2010;119:834–839. [Google Scholar]

- 23.Burmistrova N.A., Rusanova T.Y., Yurasov N.A., Goryacheva I.Y., De Saeger S. Multi-detection of mycotoxins by membrane based flow-through immunoassay. Food Control. 2014;46:462–469. doi: 10.1016/j.foodcont.2014.05.036. [DOI] [Google Scholar]

- 24.Kadota T., Takezawa Y., Hirano S., Tajima O., Maragos C.M., Nakajima T., Tanaka T., Kamata Y., Yoshiko S.K. Rapid detection of nivalenol and deoxynivalenol in wheat using surface plasmon resonance immunoassay. Anal. Chim. Acta. 2010;673:173–178. doi: 10.1016/j.aca.2010.05.028. [DOI] [PubMed] [Google Scholar]

- 25.Yu Q., Li H., Li C.L., Zhang S.X., Shen J.Z., Wang Z.H. Gold nanoparticles-based lateral flow immunoassay with silver staining for simultaneous detection of fumonisin B1 and deoxynivalenol. Food Control. 2015;54:347–352. doi: 10.1016/j.foodcont.2015.02.019. [DOI] [Google Scholar]

- 26.Qiu Y.L., He Q.H., Xu Y., Bhunia A.K., Tu Z., Chen B., Liu Y.Y. Deoxynivalenol-mimic nanobody isolated from a naïve phage display nanobody library and its application in immunoassay. Anal. Chim. Acta. 2015;887:201–208. doi: 10.1016/j.aca.2015.06.033. [DOI] [PubMed] [Google Scholar]

- 27.Li Y., Shi W., Shen J., Zhang S., Cheng L., Wang Z. Development of a rapid competitive indirect elisa procedure for the determination of deoxynivalenol in cereals. Food Agric. Immunol. 2012;23:41–49. doi: 10.1080/09540105.2011.589046. [DOI] [Google Scholar]

- 28.Jia-Jia T., Xiao-Bing L.I., Guo-Wen L., Tao K., Dong-Na L.I., Liang Z. Production of two anti-cadmium monoclonal antibodies by hock immunization. Chin. Vet. Sci. 2011;41:936–940. [Google Scholar]

- 29.Zeng K., Zou Y., Liu J., Wei W., Zhang M., Zhou J., Zhang Z., Gai Z.K. Enzyme-linked immunosorbent assay for triclocarban in aquatic environments. Water Sci. Technol. A J. Inter. Associ. Water Pollut. Res. 2015;72:1682–1691. doi: 10.2166/wst.2015.366. [DOI] [PubMed] [Google Scholar]

- 30.Kuang H., Xing C., Hao C., Liu L., Wang L., Xu C. Rapid and highly sensitive detection of lead ions in drinking water based on a strip immunosensor. Sensors. 2013;13:4214–4224. doi: 10.3390/s130404214. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 31.Xi J., Shi Q. Development of an indirect competitive elisa kit for the detection of soybean allergenic protein gly m bd 28k. Food Anal. Method. 2016;9:2998–3005. doi: 10.1007/s12161-016-0493-7. [DOI] [Google Scholar]

- 32.Hayashi Y., Matsuda R., Ito K., Nishimura W., Imai K., Maeda M. Detection limit estimated from slope of calibration curve: An application to competitive elisa. Anal. Sci. 2005;21:167–169. doi: 10.2116/analsci.21.167. [DOI] [PubMed] [Google Scholar]

- 33.Li H. Ph.D. Thesis. Nanjing Agricultural University; Nanjing, China: 2003. The Artificial Antigen Synthesis and Detection of Deoxynivalenol Using Indirect Competitive ELISA. [Google Scholar]

- 34.Sakamoto S., Nagamitsu R., Yusakul G., Miyamoto T., Tanaka H., Morimoto S. Ultrasensitive immunoassay for monocrotaline using monoclonal antibody produced by N, N’ -carbonyldiimidazole mediated hapten-carrier protein conjugates. Talanta. 2017;168:67–72. doi: 10.1016/j.talanta.2017.03.028. [DOI] [PubMed] [Google Scholar]

- 35.Niessen L., BoHm-Schrami M., Vogel H., Donhauser S. Deoxynivalenol in commercial beer – screening for the toxin with an indirect competitive elisa. Mycotoxin Res. 1993;9:99–109. doi: 10.1007/BF03192241. [DOI] [PubMed] [Google Scholar]

- 36.China Food and Drug Administration . China National Standard No. GB5009.111-2016. Ministry of Health of P. R. China; Beijing, China: 2016. [Google Scholar]

- 37.Yang D.N., Wang H.F. ELISA and HPLC for detection of DON in wheat. J. Anhui Agric. Sci. 2013;41:1269–1270. [Google Scholar]