Abstract

An analytical method for furan in semi-solid and paste-type food products that have been widely used consumed in Korea was presented using headspace solid-phase microextraction by gas chromatography-mass spectrometry. Total 131 food samples were analyzed and categorized into 11 groups. The validation parameters such as linearity, limit of detection (LOD), limit of quantitation (LOQ), precision (RSD) and accuracy were verified. The linearity with regression coefficients was obtained from 0.9962 to 0.9996 and the values of LOD and LOQ were 0.18 ng/g and 0.54 ng/g, respectively. The recoveries were obtained from 88.03 to 105.06%. The analysis of furan in such matrix was qualified and quantified by using the developed validation method. Dry cereals, pickled cucumbers, and oyster sauces contained high furan contents with average values 8.60, 6.45, and 4.40 ng/g, respectively.

Keywords: Furan, Monitoring, Paste matrix, Validation, Analysis

Introduction

Furan (C4H4O) is a colorless compound having a strong volatility (boiling point 31 °C), containing one oxygen and four carbon atoms. It is classified as “possibly carcinogenic to humans” (Group 2B) by the International Agency for Research on Cancer (IARC, 1995; Kim et al., 2015). Also, National Toxicology Program (NTP) classified furan as “reasonably anticipated to be human carcinogen”, and European Union classified as C2 for “substances which should be regarded carcinogenic to humans” (Seok et al., 2015). Previously reported toxicity related to furan focused on oral toxicity, carcinogenicity, and genotoxicity and considerable evidences were reported related to this matter (Burka et al., 1991; Gill et al., 2010). It has particular attention to the occurrence of furan in foods because it has been found in various foods which undergone thermal processing such as cooking, roasting, baking, and sterilization. Though furan is odorless, there are a lot of furan derived volatile compounds such as furfurals in foods. Thus it could contribute to the flavor in foods. Thermal processing is an important role in ensuring food safety from microbial contamination and preserving food quality (Nie et al., 2013).

In 2004, U.S. FDA analyzed the concentration of furan in the commercial canned and jarred foods, which typically involved thermal processing. Since then, the methods of analyzing furan in food products have been developed world widely, in that the detectability of furan has increased significantly. Because public concerns raised on risk of furan in common foods, many international agencies have conducted the monitoring and accumulated database for exposure of furan. EFSA has collected data on furan concentrations in heat-treated food products to estimate dietary exposure since 2004. The analysis contains a total of 5050 results for the levels of furan detected in foods from 20 countries in Europe (EFSA, 2004). FDA has also posted the public information regarding monitoring of furan in various food products since 2004. Subsequently, FDA also issued an action plan for furan in 2005, which is expanding the furan databases to over 600 food samples to accumulate the databases on furan content in alcoholic beverages in the U.S. (FDA, 2008). Especially, FSA conducted the monitoring of furan levels in various foodstuffs in England from 2011 to 2013, which presents the significance of the direct comparison of furan levels in each year (FSA, 2014).

In addition, there have been various reports on furan contents in food products by headspace or SPME coupled with GC/MS. In Taiwan, furan levels of total 101 food samples were analyzed in 2010 (Liu and Tsai, 2010). In China, furan concentrations ranged between not-detectable in infant formula and 210.7 ng/g in soy sauce (Sijia et al., 2014). In studies of Chile, wheat crackers had more dark color than those from European countries and this color difference could be accounted for high levels (259 ng/g) of furan in the Chilean product (Mariotti et al., 2013). In Korea, furan levels in commercial heat-processed foods were monitored by the optimized analytical methods using SPME-GC/MS in 2009 (Kim et al., 2009).

The previous studies could not represent the furan concentration in all foods consumed in Korea because the samples analyzed in that study were only canned and jarred foods. There is pressing need for monitoring furan in various food categories to make a policy to control occurrence, dietary exposure assessment of furan and find ways to furan reduction. The objective of the present study is to accumulate the monitoring data in Korean foods served as paste or semi-solid phase. The analytical method for furan in semi-solid or paste status was validated and the furan levels of total 131 food samples were analyzed.

Materials and methods

Chemicals and reagents

Furan (+99%, purity) and d4-furan (98%, purity) were purchased from Sigma-Aldrich Corporation (St. Louis, MO, USA). HPLC-grade acetone, methanol, hexane, and water (J. T. Baker, Phillipsburg, NJ, USA) were used. Due to high volatility, all vials containing stock and working solution were stored in completely closed with silicone/polytetrafluoroethylene (PTFE) septum and aluminum seal.

Food samples collection and preparation

The selected food samples are derived for Total Dietary Studies in Korea that is supported from Ministry of Food and Drug Safety, Korea. The list of food was completed based on some criterions such as intake amounts considering how commonly and frequently consumed in Korea by Korea Health Industry Development Institute (KHDI). The raw materials of selected food were purchased from eighteen stores in nine major cities in Korea such as Seoul, Busan, Incheon, Daegu, Daejeon, Kwangju, Ulsan, Changwon and Suwon where the population is upper one million. The stores to purchase raw materials are selected upon considerations such as the number of stores in the area and sales figures. Food samples are collected and preprocessed within 2–3 days from purchase. The purchased raw materials were poured to be a composite that can cover the intakes of whole country.

Sample preparation was performed in a cold room to prevent the loss of furan by evaporation. Reagents were also kept cool prior to use. Depends on matrix state of the sample, the sampling ways are slightly different. The samples were weighed 1 g for solid matrix sample and 5 g for semi-solid or liquid matrix sample into chilled 20 mL headspace vials. Then it is mixed with 9 mL and 5 mL of HPLC grade water each. After sealing with aluminum cap using crimper, the vials are stored in 4 °C until analysis. The internal standard (d4-furan) was spiked into the vials just before adsorption. The adsorption to SPME fiber is processed that the vial is heated 50 °C in a double boiler for 20 min, 300 rpm. After the adsorption, the SPME fiber is finally injected into the injection port of GC to be analyzed.

Standard solutions

Nature furan and d4-furan were stored in the freezer and cooler compartment each. Stock and intermediate stock solutions at concentration of 10,000 ppm, 100 ppm were prepared in methanol. Working solutions at concentration of 1 ppm were prepared in water. All vials of stock, intermediate stock and working solutions were stored sealing with silicone-PTFE septa, aluminum seals at 4 °C until analysis. Stock solutions of furan and d4-furan were prepared in headspace vials (20 mL) each by adding 100 µL of native solutions using 100 µL gastight syringe with HPLC-grade methanol. Stock solutions were stored at 4 °C for about a week. Intermediate stock standards of furan and d4-furan were prepared by transferring 100 µL of stock solution with 100 µL gastight syringe. It was contained 10 mL of HPLC-grade methanol. After sealing with silicone-PTFE septa and aluminum seals, it was mixed by vortex mixer. The intermediate stock solutions of furan and d4-furan are stable up to a week. A 100 µL of intermediate stock solutions were transferred using 100 µL gastight syringe to 20 mL headspace vial. It was filled with HPLC-grade water and mixed by vortex mixer. Working solution was prepared daily.

Headspace-solid phase micro-extraction (SPME) followed by gas chromatography/mass spectrometry (GC–MS)

The SPME analytical method was well in accordance with the previous study published in 2009 (Kim et al., 2009). SPME analysis was carried out using 75 µm Carboxen/Polydimethylsiloxane (CAR/PDMS) fibers purchased from Supelco, Bellefonte, PA, USA. Before the analysis of furan, the SPME fiber is supposed to be optimized through conditioning for an hour at 300 °C. A stainless steel needle was inserted into the vial septum for absorption. The fiber was exposed to the headspace in vials (1.5 cm in depth) for 20 min at 50 °C. After extraction, the fibers were taken out from the vial and immediately injected into the injection port of GC to process for desorption of furan (4 cm in depth). Before the next analysis, it needs to remove residual from the fiber. Therefore the fiber was baked for 10 min at 250 °C. This analysis was carried out in triplicate each sample.

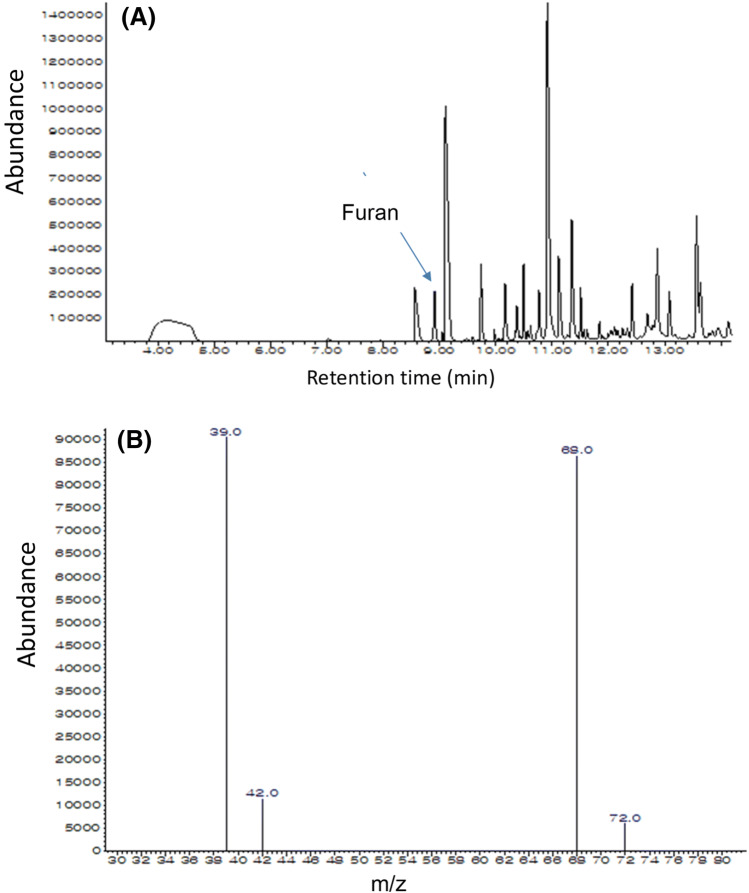

Furan analysis was done by Agilent Technologies 6890 N network gas chromatograph (GC) system coupled with Agilent Technologies 5977 inert mass selective detector (Agilent, Santa Clara, CA, USA). A column was selected to HP PLOT-Q (15 m, 0.32 mm I.D., 20 µm film thicknesses, J & W Scientific, Folsom, CA, USA). PLOT (porous layer open tubular) column with bonded polystyrene-divinylbenzene separates small volatile molecules well. The GC oven was set initially at 50 °C holding for 5 min to 230 °C at 25 °C/min and holding for 2 min. The total run time is 14.2 min and the post run is processed at 230 °C for 5 min. Helium was used as a carrier gas at 1.5 mL/min under the constant flow mode. The GC inlet temperature was maintained at 250 °C under the splitless mode. Analysis was processed under the selective-ion monitoring mode (SIM) mode, and the mass spectrometer was operated in positive electron impact ionization mode (EI+, 70 eV). The monitored ions were m/z 68 [M]+ as a quantification ion and m/z 39 [M_CHO]+ as a qualification ion for furan. In case of d4-furan, there are m/z 72 [M]+ as a quantification ion and m/z 42 [M_CHO]+ as a qualification ion.

Results and discussion

Validation of the analytical method for furan using SPME

For accurate quantification of furan, samples are categorized to paste matrix which is represented as rice porridge. The representive matrix is selected based on physical status not ingredients. The validation parameters were included linearity (R2), limit of detection (LOD), limit of quantitation (LOQ), precision (RSD, %) and accuracy. Linearity (R2) was estimated from the calibration curve at eight different points (0.5, 1, 2, 5, 10, 20, 50 and 100 ng). As shown in Table 1, the results were obtained as 0.9962 which is adoptable to quantify the levels of furan. LOD is defined as the minimal concentration of an analyte, furan, it can be detected and distinguished from the noise for a given matrix. LOQ is defined as the minimal analytical concentration that can be quantified. The LOD and LOQ are determined from the analysis of water samples and those were calculated by the 3.3 × sigma (σ)/slope factor and the 10 × sigma (σ)/slope factor each. Sigma is standard deviation of water samples which were analyzed 5 times. Calculated LOD and LOQ are 0.18 and 0.54 ng/g each. The results are lower than the results of previous study, which were determined 0.5 ng/g for LOD and 1.5 ng/g for LOQ in canned jam for semi-solid samples (Nie et al., 2013). However, these values were similar with those obtained in our laboratory such as 0.037 ng/g and 0.123 ng/g for LOD and LOQ in canned and jared food matrices (Kim et al., 2010), 0.079 ng/ml for LOD and 0.26 ng/ml for LOQ in orange juice matrix (Kim et al., 2016). Precisions were evaluated by calculating the relative standard deviation (RSD) based on five replicates in three different concentration points: 10, 50 and 100 ng. It was determined by inter-day (RSD, %) for 5 days and intra-day (RSD, %) for 5 repetitions within a day. The results of precisions are ranged from 12.03 to 14.86% in inter-day and from 5.81 to 14.92% in intra-day. The results are demonstrated in Table 2, showing proper reproducibility. Previous studies analyzing furan in various food products showed that the RSD ranges from 2.59 to 8.01% in soy sauce model system (Kim et al., 2015), 4.8–11.47% in orange juice (Kim et al., 2016), 1.38–5.39% in coffee matrix (Han et al., 2017), and 3.77–5.80% in semi-solid food products (Kim et al., 2010). The RSD collected in this study was within the range reported in previous furan analysis work. The accuracy was obtained by confirming the recoveries in three different concentration levels which is the same as precisions. All the samples are analyzed 5 times. The recoveries were calculated by this formula: Recovery, % = (ng furan detected/ng furan added) × 100. The results of recoveries are shown in Table 2.

Table 1.

Equation, linearity (R2), limit of detection and limit of quantification for furan in paste matrix

| Food type | Matrix | Method | Equation | Linearity (R2) | LODa (ng/g) | LOQb (ng/g) |

|---|---|---|---|---|---|---|

| Semi-solid | Rice porridge | Manual | y = 0.202x + 1.1725 | 0.9962 | 0.18 | 0.54 |

aThe LOD(Limit of detection) was calculated by 3.3 standard deviation(σ) divided by the slope factor of the standard curve

bThe LOQ(Limit of quantification) was calculated by 10 standard deviation(σ) divided by slope factor of standard curve

Table 2.

Precision and accuracy results for furan in paste matrix

| Matrix | Spiked amount (ng) | Precision (RSD %, n = 5)a | Recovery (%, n = 5)b | ||

|---|---|---|---|---|---|

| Intra-day | Inter-day | Intra-day | Inter-day | ||

| Rice porridge | 10 | 13.59 | 12.03 | 105.06 | 104.87 |

| 50 | 5.81 | 14.25 | 94.35 | 97.38 | |

| 100 | 14.92 | 14.86 | 88.03 | 97.15 | |

aThe RSD(relative standard deviation) is the percentage of standard deviation divided by the mean

bThe recovery is the percentage of the analyzed furan amount divided by the spiked furan amount

Determination of furan in food samples

For determination of furan in food samples, GC–MS was utilized, and Fig. 1(A) showed the typical chromatogram of furan detected in the representative sample (A), and the mass spectrum of furan peak (B). In this study, total 131 food samples were analyzed and the samples were categorized to 11 groups such as marine foods (14 samples), grain (8 samples), grain products (19 samples), seasonings (7 samples), root and tuber crops (3 samples), processed products of root and tuber crops (2 samples), vegetables (42 samples), processed vegetables (5 samples), fruits (17 samples), fruit products (4 samples), and Kimchi (Korean traditional food) (10 samples). The detection rate was remarkably different depends on food categories. Furan was not detected at all in some food categories including marine foods, grain, root and tuber crops, processed root and tuber crops, vegetables, fruits, fruit products, and Kimchi. All the results are summarized in Table 3.

Fig. 1.

TIC chromatogram of furan, (A) furan detected in oyster sauce. (B) Mass spectrum of furan

Table 3.

The detection amount of furan in foods

| Food categories | Food sample | Average (ng/g) | Range (ng/g) |

|---|---|---|---|

| Marine foods | Tuna | nd | nd |

| Gray mullet | nd | nd | |

| Spoon worm (Gae-bull) | nd | nd | |

| Manila clam | nd | nd | |

| Octopus ocellatus | nd | nd | |

| Pen shell | nd | nd | |

| Hizikia fusiforme | nd | nd | |

| Corbicula | nd | nd | |

| Sea bream | nd | nd | |

| Pomfret | nd | nd | |

| Rock fish | nd | nd | |

| Sea squirt | nd | nd | |

| Freshwater eel | nd | nd | |

| Sea eel | nd | nd | |

| Grain | Millet | nd | nd |

| Unhulled barley | nd | nd | |

| Mixed grain | nd | nd | |

| Sorghum | nd | nd | |

| Brown rice | nd | nd | |

| Black rice | nd | nd | |

| Brown glutinous rice | nd | nd | |

| Glutinous rice | nd | nd | |

| Grain products | Buckwheat noodles | nd | nd |

| Dried buckwheat noodles | nd | nd | |

| Flour | nd | nd | |

| Korean pancake powder | nd | nd | |

| Korean frying powder | nd | nd | |

| Plain noodles | nd | nd | |

| Spaghetti noodle | nd | nd | |

| Uncooked noodle | nd | nd | |

| Buckwheat jelly | nd | nd | |

| Acorn jelly | nd | nd | |

| Five-grain rice (Ogokbap) | nd | nd | |

| Multi-grain rice (Japgokbap) | nd | nd | |

| Bar rice cake (Garaetteok) | nd | nd | |

| Steamed white rice cake (Baekseolgi) | nd | nd | |

| Pounded rice cake (Jeolpyeon) | nd | nd | |

| Korean traditional rice cake 1 (Injeolmi) | nd | nd | |

| Popcorn | nd | nd | |

| Instant noodle (Ramen) | nd | nd | |

| Dry cereal | 8.60 | 7.29–10.70 | |

| Seasonings | Chili sauce | nd | nd |

| Sauce for barbecued meat | nd | nd | |

| Oyster sauce | 4.40 | 3.79–4.77 | |

| Seasoning powders | nd | nd | |

| Mustard sauce | nd | nd | |

| Salt | nd | nd | |

| Powdered wasabi | nd | nd | |

| Root and tuber crops | Potatoes | nd | nd |

| Sweet potatoes | nd | nd | |

| Kudzu root | nd | nd | |

| Processed products of root and tuber crops | Starch | nd | nd |

| Cellophane (yam) noodle | nd | nd | |

| Vegetables | Corn | nd | nd |

| Sweet potato vines | nd | nd | |

| Curled mallow | nd | nd | |

| Pepper leaves | nd | nd | |

| Taro stem | nd | nd | |

| Pleurotus eryngii (Saesongi Mushroom) | nd | nd | |

| Bracken | nd | nd | |

| Shishito Pepper (kkwarigochu) | nd | nd | |

| Green chilli | nd | nd | |

| Perilla leaf | nd | nd | |

| Shepherd’s purse | nd | nd | |

| Carrot | nd | nd | |

| Balloon flower root | nd | nd | |

| Garlic | nd | nd | |

| Stem of garlic | nd | nd | |

| The green part of a radish | nd | nd | |

| Dried chinese radish | nd | nd | |

| Cabbage | nd | nd | |

| Chinese cabbage | nd | nd | |

| Chives | nd | nd | |

| Broccoli | nd | nd | |

| Lettuce | nd | nd | |

| Ginger | nd | nd | |

| Bean sprouts (Sukjunamul) | nd | nd | |

| Spinach | nd | nd | |

| Crown daisy | nd | nd | |

| Cabbage lettuce | nd | nd | |

| Onion | nd | nd | |

| Lotus root | nd | nd | |

| Cucumber | nd | nd | |

| Burdock | nd | nd | |

| Chwinamul | nd | nd | |

| Bean sprouts (Congnamul) | nd | nd | |

| Green onion | nd | nd | |

| Paprika | nd | nd | |

| Bell pepper | nd | nd | |

| Young squash | nd | nd | |

| Oyster mushroom | nd | nd | |

| Agaricus bisporus (button mushroom) | nd | nd | |

| Enoki mushroom | nd | nd | |

| Lentinus edode (fragrant mushroom) | nd | nd | |

| Dried jujube | nd | nd | |

| Processed vegetable products | Pickled vegetable | nd | nd |

| Cucumber, pickled | 6.46 | 5.74 – 7.38 | |

| Canned olive | nd | nd | |

| Canned corn | nd | nd | |

| Steamed corn | nd | nd | |

| Fruits | Heavenly peach | nd | nd |

| White peach | nd | nd | |

| Strawberry | nd | nd | |

| Apple | nd | nd | |

| Mandarin | nd | nd | |

| Melon | nd | nd | |

| Chinese yellow peaches | nd | nd | |

| Water melon | nd | nd | |

| Orange | nd | nd | |

| Plum | nd | nd | |

| Korean melon | nd | nd | |

| Campbell early grape | nd | nd | |

| Kyoho grape | nd | nd | |

| Tomato | nd | nd | |

| Pear | nd | nd | |

| Kiwi | nd | nd | |

| Pineapple | nd | nd | |

| Fruit products | Strawberry, jam | nd | nd |

| Dried grape | nd | nd | |

| Tomato paste, canned | nd | nd | |

| Pineapple, canned | nd | nd | |

| Kimchi (Korean traditional food) | Young radish kimchi (Yeolmukimchi) | nd | nd |

| Young radish kimchi (Chonggakkimchi) | nd | nd | |

| Radish water kimchi (Nabak kimchi) | nd | nd | |

| Stuffed cucumber pickles (Oisobaki) | nd | nd | |

| Diced radish kimchi (Kkakdugi) | nd | nd | |

| Leaf mustard kimchi (Gatkimchi) | nd | nd | |

| Green onion kimchi | nd | nd | |

| Ripened kimchi | nd | nd | |

| Cabbage kimchi | nd | nd | |

| Water-based radish kimchi (Dongchimi) | nd | nd |

Furan in marine foods selected in this study was not detected at all. Some previous reports showed the furan levels in fish, which were ranged from 1.5 to 75.2 ng/g (Hasnip et al., 2006; Liu and Tsai, 2010). However, these previously reported results are limited to comprehensively cover the levels of furan found in food products. In order to be a valid database, it should be accumulated not only in canned and jarred foods in which contained considerable amounts of furan, but also in the raw food samples in which consumed by Korean consumers on a regular basis. Grain and its processed products play significant roles in Korean daily diet. The food samples analyzed in this study are included raw materials of grain, noodles, powders, jelly made by grain, rice cake, popcorn and cereals. Furan in the raw materials of grain was not detected at all. In the category of grain products, furan was detected only in ‘dry cereal’ ranged between 7.29 and 10.70 ng/g which was included in the result of previous reports ranged from 9.2 to 65.3 ng/g (EFSA, 2004; Liu and Tsai, 2010; Mariotti et al., 2013; Scholl et al., 2012). Furan was detected only in the sample of ‘oyster sauce’ in the category of seasoning. It was detected between 3.79 and 4.77 ng/g (average at 4.40 ng/g) in oyster sauce. It was significantly low level of furan compared to the result of previous report which was ranged from 35.2 to 43.8 ng/g (Kim et al., 2010). Three samples of root and tuber crops were not detected for furan at all. It was reported that furan was detected at very low level from not detectable to 2 ng/g in potatoes which is one of the major agricultural crops and has been popular in snacks all over the world (Hasnip et al., 2006).

The samples categorized to vegetables in this study were not detected for furan at all. There are previous reports which demonstrated the detection amounts of carrot, broccoli, spinach, lettuce and onion. In those raw materials, furan was detected from not detectable to 2 ng/g (Becalski et al., 2003; Lachenmeier et al., 2009; Zoller et al., 2007). In the category of processed vegetable products, furan was detected only in the sample of ‘cucumber, pickled’ which was ranged from 5.74 to 7.38 ng/g. The results were much lower than those of furan determined in another study showing the levels between 76.1 and 126.6 ng/g (Sijia et al., 2014). Fruits and processed fruit products were not detected for furan at all in this study. According to previous reports, there were no results of the raw fruits but processed fruit products. The reported detection amounts of furan were ranged from 2.9 to 3.1 ng/g in peach marmalade, from 3.24 to 7.59 ng/g in orange juice, from 2.62 to 9.19 ng/g in grape juice, from 2.2 to 15.2 ng/g in strawberry jam, from 4 to 12 ng/g in tomato paste and from 2.8 to 46.7 ng/g in fruit beverage (Hasnip et al., 2006; Kim et al., 2010; Liu and Tsai, 2010; Mariotti et al., 2013). In this study strawberry (jam) and tomato paste does not have any furan. This could be various thermal temperature for sterilization in food processing. In addition different species of the fruits could be one of the reason.

Kimchi is a Korean traditional fermented food made of vegetables with various seasonings. There are hundreds of varieties of kimchi made from cabbage, radish, green onion, or cucumber as a main ingredient. In this study, 10 types of Kimchi were analyzed and furan was not detected at all from the samples. The studies on furan detection from Kimchi have not also been reported yet.

The lethal concentration of furan in the air was reported as 34,400 ppm in Merck index in the case of rat (Kim et al., 2010). While toxicity of furan has consistently reported in various government organizations, high volatility of furan could minimize the risk associated with furan. Previous study on furan analysis in coffee reported that the levels of furan in fact decrease significantly if coffee was served in a cup without a lid (Han et al., 2017). Their work emphasized that the common coffee handling conditions in different types of coffee including canned coffee, brewed coffee and instant coffee, could decrease the exposure to furan, hence reduce the furan toxicity-related risk. As such, proper handling conditions, including home cooking in an open space and serving canned foods few minutes after opening the can and/or jars may decrease the amount of human ingestion through processed food products, hence, decrease the overall risk associated with furan toxicity.

In conclusion, this study showed the analytical method for furan in paste matrix which is represented as a rice porridge. The method of this study was confirmed to be rapid, and sensitive for the analysis of parts-per-billion existence of furan in foods. The results of validation parameters were obtained clearly. Total 131 food samples were analyzed and divided to 11 food groups to demonstrate easily. Only five samples are positive for furan among the food samples. The furan levels in 11 food groups were ranged from not detected to 10.70 (dry cereal) ng/g. Analyzed food samples which are not-detected or low level can be considered as free and safe foods from furan. Consequently the results of this study would be useful as a database for the future studies of Korean diet. The further study should determine how the furan levels change upon cooking method.

Acknowledgements

This research was supported by a Grant (13162MFDS049) from the Ministry of Food and Drug Safety, the Basic Science Research Program through the National Research Foundation of Korea (NRF-2018R1A2B6002634), and the Agriculture, Food and Rural Affairs Research Center Support Program, Ministry of Agriculture, Food and Rural Affairs, Republic of Korea.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Contributor Information

Yun-Jeong Seok, Email: yunjung0314@naver.com.

Kwang-Geun Lee, Email: kwglee@dongguk.edu.

References

- Becalski A, Forsyth D, Casey V, Lau BY, Pepper K, Seaman S. Development and validation of a headspace method for determination of furan in food. Food Addi. Contam. 2003;22:535–540. doi: 10.1080/02652030500129170. [DOI] [PubMed] [Google Scholar]

- Burka LT, Washburn KD, Irwin RD. Disposition of [14C]furan in the male F344 rat. J. Toxicol. Environ. Health. 1991;34:245–257. doi: 10.1080/15287399109531564. [DOI] [PubMed] [Google Scholar]

- European Food Safety Authority (EFSA). Report of the scientific panel on contaminants in the food chain on provisional findings on furan in food. The EFSA J. 137: 1-20 (2004)

- Food Standards Agency (FSA). Acrylamide and furan in a range of UK retail foodstuffs. Available from: http://www.food.gov.uk/science/research/surveillance/food-surveys/food-survey-information-sheets-2014/acrylamide-and-furan. Accessed Oct. 18, 2018

- Gill S, Bondy G, Lefebvre DE, Becalski A, Kavanagh M, Hou Y, Turcotte AM, Barker M, Weld M, Vavasour E, Cooke GM. Subchronic oral toxicity study of furan in Fischer-344 rats. Toxicol. Pathol. 2010;38:619–630. doi: 10.1177/0192623310368978. [DOI] [PubMed] [Google Scholar]

- Han JS, Kim MK, Lee KG. Furan levels and sensory profiles of commercial coffee products under various handling conditions. J. Food Sci. 2017;82:2759–2766. doi: 10.1111/1750-3841.13933. [DOI] [PubMed] [Google Scholar]

- Hasnip S, Crews C, Castle L. Some factors affecting the formation of furan in heated foods. Food addi. Contam. 2006;23:219–227. doi: 10.1080/02652030500539766. [DOI] [PubMed] [Google Scholar]

- IARC. IARC Monographs on the evaluation of carcinogenic risks to humans: Dry cleaning, some chlorinated solvents and other Industrial chemicals. International Agency for Research on Cancer. France (1995) [PMC free article] [PubMed]

- Kim JS, Her JY, Lee KG. Formation and reduction of carcinogenic furan in various model systems containing food additives. Food Chem. 2015;189:108–113. doi: 10.1016/j.foodchem.2014.10.128. [DOI] [PubMed] [Google Scholar]

- Kim TK, Kim S, Lee KG. Analysis of furan in heat-processed foods consumed in Korea using solid phase microextraction–gas chromatography/mass spectrometry (SPME–GC/MS) Food Chem. 2010;123:1328–1333. doi: 10.1016/j.foodchem.2010.06.015. [DOI] [Google Scholar]

- Kim TK, Lee YK, Kim S, Park YS, Lee KG. Furan in commercially processed foods: four-year field monitoring and risk assessment study in Korea. J. Toxicol. Envl. Health Part A. 2009;72:1304–1310. doi: 10.1080/15287390903212378. [DOI] [PubMed] [Google Scholar]

- Kim MK, Kim MY, Lee KG. Determination of furan levels in commercial orange juice products and its correlation to the sensory and quality charactersitics. Food Chem. 2016;211:654–660. doi: 10.1016/j.foodchem.2016.05.114. [DOI] [PubMed] [Google Scholar]

- Lachenmeier DW, Reusch H, Kuballa T. Risk assessment of furan in commercially jarred baby foods, including insights into its occurrence and formation in freshly home-cooked foods for infants and young children. Food Addi. Contam. 2009;26:776–785. doi: 10.1080/02652030802714018. [DOI] [PubMed] [Google Scholar]

- Liu YT, Tsai SW. Assessment of dietary furan exposures from heat processed foods in Taiwan. Chemosphere. 2010;79:54–59. doi: 10.1016/j.chemosphere.2010.01.014. [DOI] [PubMed] [Google Scholar]

- Mariotti MS, Toledo C, Hevia K, Gomez JP, Fromberg A, Granby K, Rosowski J, Castillo O, Pedreschi F. Are Chileans exposed to dietary furan? Food Addi. Contam. Part A. 2013;30:1715–1721. doi: 10.1080/19440049.2013.815807. [DOI] [PubMed] [Google Scholar]

- Nie SP, Huang JG, Zhang YN, Hu JL, Wang S, Shen MY, Li C, Marcone MF, Xie MY. Analysis of furan in heat-processed foods in China by automated headspace gas chromatography-mass spectrometry (HS-GC-MS) Food Control. 2013;30:62–68. doi: 10.1016/j.foodcont.2012.07.020. [DOI] [Google Scholar]

- Scholl G, Scippo ML, De Pauw E, Eppe G, Saegerman C. Estimation of furan contamination across the Belgian food chain. Food Addi. Contam. Part A. 2012;29:172–179. doi: 10.1080/19440049.2011.635158. [DOI] [PubMed] [Google Scholar]

- Seok YJ, Her JY, Kim YG, Kim MY, Jeong SY, Kim MK, Lee JY, Kim CI, Yoon HJ, Lee KG. Furan in thermally processed foods- a review. Toxicol. Res. 2015;31:241–253. doi: 10.5487/TR.2015.31.3.241. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Sijia W, Enting W, Yuan Y. Detection of furan levels in select Chinese foods by solid phase microextraction–gas chromatography/mass spectrometry method and dietary exposure estimation of furan in the Chinese population. Food Chem. Toxicol. 2014;64:34–40. doi: 10.1016/j.fct.2013.11.012. [DOI] [PubMed] [Google Scholar]

- US Food and Drug Administration (FDA). Exploratory Data on Furan in Food: Individual Food Products. Available from: http://www.fda.gov/Food/FoodborneIllnessConta-minants/ChemicalContaminants/ucm078439.htm. Accessed Oct. 18, 2018 (2008)

- Zoller O, Sager F, Reinhard H. Furan in food: headspace method and product survey. Food Addi. Contam. 2007;24:91–107. doi: 10.1080/02652030701447389. [DOI] [PubMed] [Google Scholar]