Abstract

This research provided a new way to improve the quality of tofu using lactic acid bacteria combined with salt coagulants. In this study, the effect of Lactobacillus casei (L. casei) combined with salt coagulants (MgCl2, MgSO4, CaCl2, CaSO4) on the yield, water-holding capacity (WHC), texture, sensory factors, microstructure and flavour were analysed to evaluate the quality characteristics of fermented tofu. The results showed that the yield of tofu was significantly increased by the fermentation of L. casei (24.75–31.26%). There was no significant difference in the WHC of the tofu, and the value range of WHC was 77.32–80.52%. Fermentation increased the hardness of the tofu and made the tofu structure uniform. In L. casei + MgSO4 tofu, 10 flavour compounds were detected, and the relative content (54.29%) of the four main flavour compounds was highest. L. casei + MgSO4 had the highest sensory value (23.26). The fermentation of L. casei combined with salt coagulants significantly improved the quality characteristics of tofu.

Keywords: Tofu, Fermented, Lactobacillus casei, Coagulation, Quality

Introduction

Tofu is a traditional food in China and is loved, because tofu is nutrient-rich, easy-to-manufacture and delicious in taste (Lee et al. 2019; Li et al. 2017; Poudyal et al. 2019; Yasin et al. 2019). In recent years, tofu has become increasingly popular in the western world. Processing of tofu is diverse, and tofu has been used to make almost any Western style food, such as cheesecake and pies (O’Toole 2016). The health function of tofu is achieved mainly by high quality protein, beneficial lipids, vitamins and minerals, as well as other biologically active compounds such as isoflavones, soy saponins and others (Zhang et al. 2016). Regular consumption of tofu helps reduce the incidence of many diseases such as hypertension, hyperlipidaemia, hypercholesterolemia, arteriosclerosis (Fung et al. 2008), coronary heart disease (He and Chen 2013), breast cancer and others (Riciputi et al. 2016). Tofu is produced from water-extracted and hydrochloric acid-precipitated soybean in the form of a curd (Zhu et al. 2016). The processing of coagulation, which is affected by the type of coagulants, is the key step in determining the yield and quality (Prabhakaran et al. 2006). The main coagulant of tofu is salt, such as nigari, CaCl2, MgSO4, and CaSO4. According to Kao et al. (2003), MgCl2, CaCl2 and MgSO4 result in soy curd with coarse, hard, and granular texture due to their quick coagulating power. By contrast, CaSO4 can produce tofu with soft, smooth, and homogeneous texture. However, tofu with a CaSO4 coagulant has an unpleasant taste, especially a beany flavour and bitterness.

Several recent research studies have focussed on ways to improve the quality of tofu. Zhu used a water-in-oil emulsion to control the release of magnesium ions in the aqueous phase, slowing the gelation rate of the tofu to obtain high yield and uniform texture of the tofu (Zhu et al. 2016). Cao found tofu acidified with 0.14 g/100 mL organic acid exhibited excellent physical properties, as indicated by high storage modulus, hardness, water-holding capacity, and non-freezable water content (Cao et al. 2017). Fermentation by Lactobacillus can improve the flavour and quality of soymilk. Study has shown that lactic acid bacteria (LAB) were able to grow well in soymilk, and if used for fermentation, could increase the content of some bioactive substances (Li et al. 2012). Li et al. found that the organic acids produced by Lactobacillus plantarum (L. plantarum) slowly released hydrogen ions, making the tofu have good flavour and texture (Li et al. 2017). Serrazanetti et al. found that LAB-fermented tofu can prolong the shelf life of tofu due the production of some antibacterial substances, such as acetic acid and limonene, during the fermentation process (Serrazanetti et al. 2013). Fermenting soymilk increased the amount of isoflavone aglycones (Maki et al. 2018). As a new type coagulant of tofu to improve the quality of tofu, LAB fermentation can not only improve tofu nutritional value but also reduce the unpleasant flavours. However, fermenting tofu using LAB combined with these different salt coagulants has not been investigated.

This work was aimed to evaluate fermented tofu prepared by combining salt coagulants with Lactobacillus casei (L. casei). The yield, water-holding capacity (WHC), texture, microstructure and the flavour of tofu were studied. This research has important application value and broad development prospects.

Materials and methods

Materials

Soybean was purchased from local market in Heilongjiang Province (China); MgCl2·6H2O, MgSO4·7H2O, CaCl2·2H2O and CaSO4·2H2O were obtained from Tianjin Tianli Chemical Reagent Co., Ltd. (Tianjin, China). All other reagents were analytical grade.

Strain

Lactobacillus casei (L. casei) was isolated from traditional fermented milk in China, which was preserved in the food Laboratory of Northeast Agricultural University. The strain was inoculated into the MRS medium at 37 °C. The cultures were collected by centrifugation (7000 g × 5 min) and then washed and suspended in sterile water.

Tofu preparation

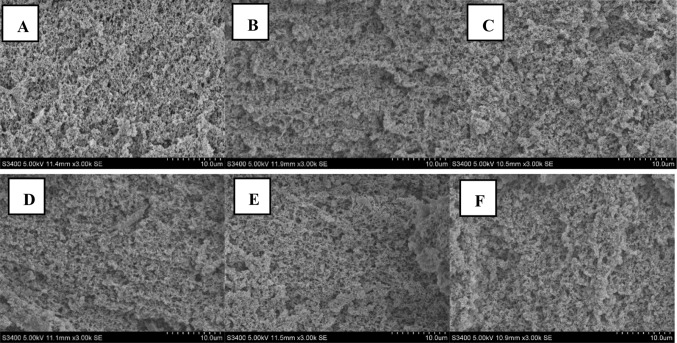

The tofu was prepared as in previous methods with some modifications (Serrazanetti et al. 2013). A flow chart describing the production of fermented tofu is presented in Fig. 1. The soybeans were soaked for 12 h in distilled water, ground (20% soy beans and 80% water) by a soybean milk machine (Joyoung, JYL-92, China) at medium speed for 1 min, and filtered through a screen (100 mesh). The raw soymilk was sterilized at 115 °C for 10 min.

Fig. 1.

Flow chart of producing fermented tofu

The culture (4%) incubated in the prepared soymilk at 37 °C for 5 h, the pH decreased to 5.07 ± 0.31. The fermented tofu was homogenized at 750 rpm for 1 min at 75 °C, the coagulant (2.0 M, 2%) was added, and the mixture was then kept warm for 20 min. The coagulated material was transferred to a wooden form (10.0 × 10.0 × 8.0 cm) lined with muslin cloth and drained for 1 h under a pressure of 20 g/cm2.

Determination of tofu yield

The yield of tofu was expressed as in previous methods with some modifications (Zhu et al. 2016). The yield (g) is the weight of tofu obtained from 800 mL of soymilk.

WHC of tofu

Approximately 6 g (Wt) of each tofu sample was removed from the central portion according to Cao and Zhu with some modification (Cao et al. 2017; Zhu et al. 2016). The tofu sample was centrifuged at 7000 g for 20 min at 4 °C. Supernatants were discarded, and residual liquids were carefully removed with dry filter paper. The removed water was weighed (Wr), and water-holding capacity was calculated according to the equation below:

Texture measurement

Tofu samples were cut into 1 cm × 1 cm × 1 cm cubes using a razor and analysed on a TAXT texture analyser (Stable MicroSystem, TAXT Plus, UK) according to Cao with some modification (Cao et al. 2017). The samples were compressed twice to 50% deformation using a P/36R probe, with trigger force 5 g, pre-test speed 5.0 mm/s, test speed 1.0 mm/s, and post-test speed 1.0 mm/s. Hardness, springiness, cohesiveness, and gumminess were determined.

Sensory evaluation

According to Wang et al. with some modification (Wang et al. 2013), five volunteers who are majoring in food were recruited as the sensory panel and did the sensory evaluation for fermented tofu samples. Morphology (flatness, smoothness, uniformity), colour (yellow, white, uniform), taste (salty, sapid, soft, astringent, delicate, acid, rough), flavour (bean flavour, sweetness, bitterness, fermented flavour) and acceptability (hardness, flavour, taste, colour, quality) were chosen as evaluated values for different tofu samples. A scale of 1–5 was used for tofu rating: morphology (1: very uneven 5: very flat), colour (1: very yellow, 5: very white), taste (1: quite rough, 5: very smooth), flavour (1: extremely bitter, 5: very sweet), and acceptability (1: very unacceptable, 5: extremely acceptable).

Scanning electron microscopy

Samples were prepared as described by Zhu with some modifications (Zhu et al. 2016). The tofu sample was cut into strips (2 mm × 2 mm × 5 mm) with a double-sided blade, fixed by 2.5% glutaraldehyde (pH 6.8) at 4 °C for 1.5 h, and rinsed with 0.1 M pH 6.8 phosphate buffer. The tofu samples were then dehydrated with 50%, 70%, 90% ethanol (10 min each); 100% ethanol (three times, 10 min each); 100% ethanol: tert-butanol = 1:1; pure t-butanol once (15 min). The sample was freeze-dried, and the surface of the sample was coated by spraying with powdered gold. The sample was then placed under a scanning electron microscope (5 kV) to observe its microstructure.

Flavour analysis

Analysis of volatile compounds of fermented tofu was modified according to the method reported by Vannini et al. (2008). The sample (3 g) was equilibrated at 60 °C for 10 min. The SPME fibres were exposed to each sample for 40 min, and the fibres were finally inserted into the injection port of the gas chromatograph for 3 min for sample desorption. A Chrompack DB 5 MS capillary column (30-m length, 0.25-mm internal diameter) was used (Chrompack, Middelburg, The Netherlands). GC/MS detection was performed using an Agilent 7890 gas chromatograph (Agilent Technologies, Palo Alto, CA) connected to an Agilent 5975C mass selective detector operating in electron ionization mode (ionization voltage, 70 eV).

Data analysis

Experiments were performed in triplicate, and data were collected in triplicate and evaluated using SPSS (ver. 20.0, IBM software, Chicago, USA). Differences among group means were considered significant at P < 0.05.

Results and discussion

Yield and WHC of tofu

WHC reflects the ability of a gel to effectively immobilize water within its matrices (Wu et al. 2009), which could reflect the spatial structure of the protein gel (Wu et al. 2014).

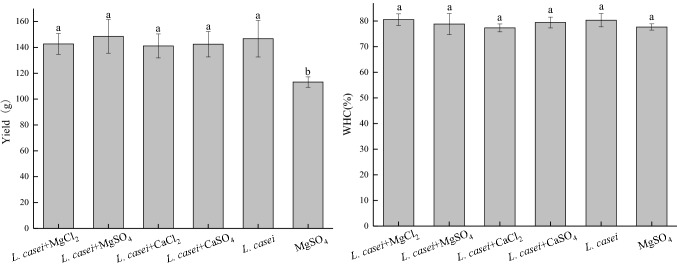

The results of yield and WHC of tofu made from different coagulants are presented in Fig. 2. The yield of tofu condensed with MgSO4 alone was significantly lower than the yield of the other groups, which was 113.18 g. There was no significant difference in the yield between the groups of tofu fermented with L. casei, and the value ranged from 141.19 to 148.56 g. The results showed that fermentation by L. casei could increase the yield of tofu. The lower yield of MgSO4 tofu may be due to the rapid solidification of the magnesium salt, resulting in a larger and uneven gel network, retaining less moisture. There was no significant difference in the WHC of tofu with different coagulants, and the value range of WHC was 77.32–80.52%. The higher WHC of magnesium sulfate may be the reason that the yield of tofu is lower, and the water that is not easily lost is retained in the structure. Different salt coagulants had no significant influence on the yield and WHC of fermented tofu. Generally, the enhancement in gel strength and homogeneity can improve the WHC (Wang et al. 2017). The yield of tofu increased by fermentation indicates that the slow release of lactic acid neutralizes the negative surface charge on soy protein particles and allows protein network structure formation through non-covalent bonding. In the process of forming a network structure, the network structure could continuously maintain water molecules, thereby increasing the yield and WHC of the tofu (Li et al. 2017). The slow fermentation of LAB greatly improved the yield of tofu, so the effect on the gelation of tofu is greater than salt coagulum.

Fig. 2.

Yield and WHC of fermented tofu prepared with different coagulants. Different letters are significantly different (P < 0.05)

Textural properties of tofu

The texture results for tofu prepared by the combination of L. casei and salt coagulant are summarized in Table 1.

Table 1.

Texture characteristics of fermented tofu made with different coagulants

| Coagulants | L. casei + MgCl2 | L. casei + MgSO4 | L. casei + CaCl2 | L. casei + CaSO4 | L. casei | MgSO4 |

|---|---|---|---|---|---|---|

| Hardness (g) | 410.87 ± 41.52a | 394.72 ± 34.59a | 377.41 ± 25.68ab | 331.34 ± 19.26c | 347.67 ± 34.14bc | 378.11 ± 40.68ab |

| Springiness (mm) | 0.953 ± 0.032b | 1.076 ± 0.290ab | 0.906 ± 0.032b | 0.904 ± 0.020b | 0.988 ± 0.003b | 1.271 ± 0.436a |

| Cohesiveness | 0.637 ± 0.099c | 0.722 ± 0.025b | 0.639 ± 0.036c | 0.673 ± 0.034bc | 0.710 ± 0.058b | 0.800 ± 0.009a |

| Gumminess (g) | 260.32 ± 30.07abc | 285.12 ± 28.29ab | 258.57 ± 42.19a | 222.82 ± 14.39c | 246.35 ± 26.68bc | 298.84 ± 52.91a |

| Chewiness (g) | 248.49 ± 32.10b | 305.19 ± 76.48a | 217.96 ± 12.17b | 201.26 ± 11.43b | 243.57 ± 26.78b | 319.62 ± 73.04a |

a–cMeans in a same line with different letters are significantly different (P < 0.05). Variation of the mean represents standard deviation of triplicate for each measurement

The tofu from magnesium salt had the highest hardness. The hardness of the tofu using MgCl2 as a coagulant after L. casei fermentation was up to 410.87 g, which was significantly higher than the hardness of other groups. The higher hardness value for MgCl2 coagulated tofu samples was probably due to the quicker coagulation, which induced an intense interaction between soy protein and magnesium ions, thus creating a more compact tofu structure (Prabhakaran et al. 2006). There was no significant difference in the hardness between L. casei + MgSO4 and MgSO4 tofu, indicating that the salt coagulant is closely related to the hardness of tofu. The hardness of CaSO4 is lower than the hardness of the magnesium salt sample. Wang et al. confirmed that the aggregation rate of MgCl2 and MgSO4 was faster than the aggregation rate of CaSO4 (Wang et al. 2019). The hardness of CaCl2 is greater than the hardness of CaSO4, probably because the chloride salt had a faster rate for coagulating soybean proteins than the sulfate salt, which is consistent with the study by Li et al. (2017), L. casei fermentation causes the protein to undergo acid-induced gelation first, then heat completes the gelation more fully, and finally the gel formation is completed by combining with salt.

Sensory evaluation

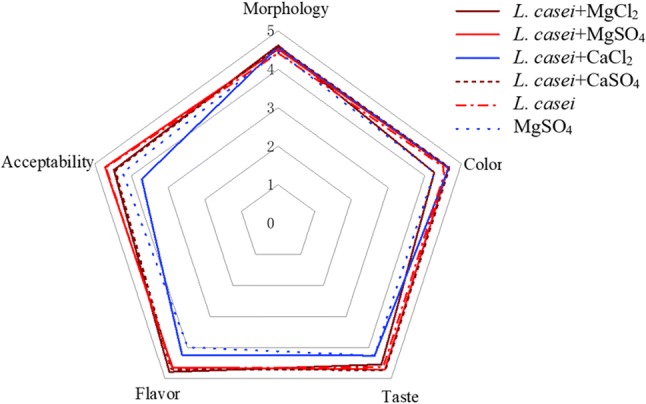

Sensory evaluations of six kinds of fresh tofu prepared with different coagulants were performed, and the results are shown in Fig. 3 and Table 2.

Fig. 3.

Sensory evaluation score of fresh tofu coagulated with different coagulants

Table 2.

Sensory characteristics of fermented tofu made with different coagulants

| Coagulants | L. casei + MgCl2 | L. casei + MgSO4 | L. casei + CaCl2 | L. casei + CaSO4 | L. casei | MgSO4 |

|---|---|---|---|---|---|---|

| Morphology | 4.62 ± 0.16a | 4.52 ± 0.36ab | 4.58 ± 0.22a | 4.60 ± 0.19a | 4.24 ± 0.18b | 4.46 ± 0.05ab |

| Color | 4.26 ± 0.51bc | 4.64 ± 0.23a | 4.66 ± 0.15a | 4.68 ± 0.08a | 4.58 ± 0.22ab | 4.18 ± 0.13b |

| Taste | 4.56 ± 0.38abc | 4.72 ± 0.22a | 4.26 ± 0.33bc | 4.74 ± 0.18a | 4.64 ± 0.37ab | 4.20 ± 0.07c |

| Flavour | 4.8 ± 0.45a | 4.66 ± 0.27ab | 4.24 ± 0.50bc | 4.72 ± 0.13a | 4.68 ± 0.34ab | 3.86 ± 0.13c |

| Acceptability | 4.48 ± 0.44ab | 4.72 ± 0.22a | 3.72 ± 1.11b | 4.44 ± 0.42ab | 4.7 ± 0.41a | 4.14 ± 0.13ab |

| Total | 22.72 ± 1.31a | 23.26 ± 1.23a | 21.06 ± 1.69b | 23.18 ± 0.81a | 22.84 ± 1.41a | 20.84 ± 0.18b |

a–cMeans in a same line with different letters are significantly different (P < 0.05). Variation of the mean represents standard deviation of triplicate for each measurement

As shown in Fig. 3 and Table 2, the structure of tofu fermented by L. casei only was relatively loose, and the morphology value was lower than the morphology value of other groups. There was no significant difference between the other groups of tofu, indicating that the salt coagulant is beneficial for hardness of tofu. The colour values of L. casei + MgCl2 and MgSO4 were significantly lower than the colour values of the other four groups, probably due to the darker colour of tofu caused by MgCl2, and the colour value of the other groups of fermented tofu had a better performance, indicating that the quality of fermented tofu was generally good. L. casei + CaCl2 had lower flavour and taste values, probably because it produced a bitter taste. The flavour and taste value of magnesium sulfate are significantly lower than the flavour and taste value of the other groups except L. casei + CaCl2, indicating that the fermentation could give a better flavour to tofu, because fermented soymilk produced aromas that consumers prefer (Blagden and Gilliland 2005; Donkor et al. 2007). The results of sensory evaluation showed that the production of fermented tofu by LAB combined with salt coagulant can be accepted as a new type of tofu, except with CaCl2 + L. casei.

Microstructure of tofu

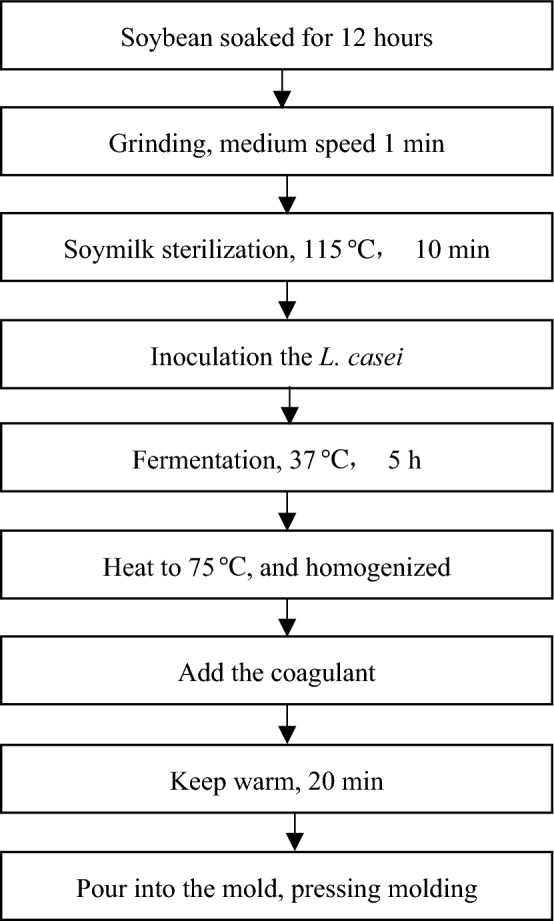

Microstructure is an important indicator for evaluating the quality of tofu. Scanning electron micrographs of tofu condensed with different salt coagulants are shown in Fig. 4.

Fig. 4.

SEM micrographs of tofu prepared with different coagulants. a L. casei + MgCl2, b L. casei + MgSO4, c L. casei + CaCl2, d L. casei + CaSO4, e L. casei, f MgSO4. Scale bar = 3 μm

As shown in Fig. 4, the honeycomb structure of fermented tofu using different coagulants can be seen. Fermentation by L. casei is a slow acid production process, and the gelatine particle rearrangement time is prolonged, resulting in a more uniform texture of the tofu gel (Grygorczyk and Corredig 2013). The network of the microstructure of fermented tofu was relatively dense, with relatively uniform distribution of small pores. As shown in the SEM image, the fermented tofu prepared by L. casei combined with MgCl2 had the finest and most uniform pores and has a hard texture, possibly because the acid produced by L. casei induced first coagulation of the protein to slow down the MgCl2 coagulation of the protein, so that the gel forms a smooth and uniform network structure. Saio studied the relationship between the structure and texture of the tofu gel and concluded that the gel network density and protein aggregate size affect the gel texture (Saio 1979). The gel network structure of tofu made with MgSO4 is relatively loose and rough, probably due to the rapid aggregation leading to the formation of large and coarse protein aggregates (Wang et al. 2019). Li et al. found that traditional tofu usually had a coarse and loose gel network structure (Li et al. 2014). Therefore, fermentation makes the gel structure of tofu more uniform and improves the quality characteristics of tofu.

Flavour analysis

The main volatile compounds of tofu were hexanal, 1-hexanol, 1-octene-3-ol, and dipentylfuran, which are considered to be degradation products of polyunsaturated fatty acids. The main volatile compounds, respectively, present herbal flavour, sour taste, green notes of mushrooms and grasses, and bean and green notes (Shi et al. 2015). Among these compounds, hexanal is one of the most commonly used flavour compounds, with a lower threshold and higher content in tofu, which is the fragrance component of soymilk (Wilkens and Lin. 1970). 2-Pentylfuran and 1-octene-3-ol are the main aroma active ingredients of soymilk and play a key role in the characteristic flavour of soymilk (Dan et al. 2018; Zhang et al. 2018).

Thirty-eight volatile compounds were identified in fermented tofu, including 6 esters, 8 alcohols, 3 acids, 2 ketones, 13 olefins, and 6 other compounds. In L. casei + MgSO4 tofu, 10 flavour compounds were detected, of which hexanal accounted for 7.21%, 1-hexanol accounted for 20.90%, 1-octene-3 alcohol accounted for 13.05%, and 2-pentylfuran accounted for 13.14%. These compounds together accounted for 54.29%. Among the five type of fermented tofu, the maximum relative content of the four main flavour compounds was L. casei + MgSO4. This result was consistent with the results of sensory analysis: L. casei + MgSO4 had the highest sensory value. The highest relative content of hexanal, hexanol and 1-octene-3 alcohol was L. casei + MgSO4 tofu. The highest relative content of dipentylfuran was L. casei + CaCl2 tofu (Table 3).

Table 3.

Relative content of flavour compounds of tofu made from different coagulants

| Volatile compound | Chemical formula | Relative content (%) | ||||

|---|---|---|---|---|---|---|

| L. casei + MgCl2 | L. casei + MgSO4 | L. casei + CaCl2 | L. casei + CaSO4 | L. casei | ||

| 2-Pentylfuran | C9H14O | 14.70 ± 0.40b | 13.14 ± 0.22c | 16.63 ± 0.10a | 13.53 ± 0.18c | 16.56 ± 0.20a |

| Hexanal | C6H12O | 7.06 ± 0.11a | 7.21 ± 0.13a | 6.32 ± 0.14b | 7.01 ± 0.17a | 6.48 ± 0.15b |

| 1-Hexanol | C6H14O | 16.98 ± 0.18b | 20.90 ± 0.97a | 20.48 ± 0.57a | 16.73 ± 0.28b | 15.51 ± 0.16c |

| 1-Octen-3-ol | C8H16O | 10.05 ± 0.29c | 13.05 ± 0.31a | 7.91 ± 0.28e | 11.60 ± 0.54b | 9.22 ± 0.26d |

a–eMeans in a same line with different letters are significantly different (P < 0.05). Variation of the mean represents standard deviation of triplicate for each measurement

The other volatile compounds of tofu made with L. casei + MgCl2 were cyclodecyl alcohol (4.76%), l-alanine, and methyl ester (2.00%). Additional flavour substances of tofu prepared with L. casei + MgSO4 were mainly hexyl formate (0.21%) and triisopropyl isopropylate (2.16%). Other volatile compound sources for tofu with L. casei + CaCl2 were 1-decen-3-ol (5.37%), and tofu made with L. casei + CaSO4 was mainly limonene (0.558%). 3-Cyclohepten-1-one and 1-butanol could be detected simultaneously in fermented tofu manufactured with L. casei + MgCl2 and L. casei + CaSO4. The difference in the volatile flavour content of fermented tofu may be due to the difference in the use of coagulants and the loss of some flavour substances in the processing. The difference from other fermented soybean products may be related to different strains and the changes in the manufacturing process (Blagden and Gilliland 2005).

Conclusions

Fermented tofu prepared by combining L. casei with salt coagulants was studied. There was no significant difference in the yield (141.19–148.56 g) between the groups of tofu prepared by L. casei and salt coagulants, but the yields were higher than the yields of the group of tofus condensed with MgSO4 alone (113.18 g). No significant difference in the WHC (77.32–80.52%) of tofu with different coagulants was found. Fermentation by L. casei could increase the hardness of tofu and produce a dense structure. The tofu sensory value of L. casei + MgSO4 was higher than the tofu sensory value of L. casei and MgSO4 separately. The content of the main flavour compounds in L. casei + MgSO4 tofu was highest. Salt coagulants have a greater contribution to the texture and quality of fermented tofu. Therefore, LAB fermentation combined with salt coagulants could be used as a new method to improve the quality of tofu. However, the formation mechanism of fermented tofu with LAB and the role of metabolites are still unclear and need to be studied further.

Acknowledgements

This study was supported by the National Key Research and Development Program of China, (Nos. 2018YFD0400500, 2018YFD0400503) and the “Academic backbone” Project of Northeast Agricultural University (No. 18XG28).

Abbreviations

- WHC

Water-holding capacity

- L. casei

Lactobacillus casei

- L. plantarum

Lactobacillus plantarum

- LAB

Lactic acid bacteria

Compliance with ethical standards

Conflict of interest

The authors declare no competing financial interest.

References

- Blagden TD, Gilliland SE. Reduction of levels of volatile components associated with the “beany” flavor in soymilk by lactobacilli and streptococci. J Food Sci. 2005;70(3):M186–M189. doi: 10.1111/j.1365-2621.2005.tb07148.x. [DOI] [Google Scholar]

- Cao FH, Li XJ, Luo SZ, Mu DD, Zhong XY, Jiang ST, Zheng Z, Zhao YY. Effects of organic acid coagulants on the physical properties of and chemical interactions in tofu. LWT Food Sci Technol. 2017;85:58–65. doi: 10.1016/j.lwt.2017.07.005. [DOI] [Google Scholar]

- Dan T, Jin R, Ren W, Li T, Chen H, Sun T. Characteristics of milk fermented by Streptococcus thermophilus mga45-4 and the profiles of associated volatile compounds during fermentation and storage. Molecules. 2018;23(4):878. doi: 10.3390/molecules23040878. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Donkor ON, Henriksson A, Vasiljevic T, Shah NP. Rheological properties and sensory characteristics of set-type soy yogurt. J Agric Food Chem. 2007;55(24):9868–9876. doi: 10.1021/jf071050r. [DOI] [PubMed] [Google Scholar]

- Fung WY, Woo YP, Liong MT. Optimization of growth of Lactobacillus acidophilus FTCC 0291 and evaluation of growth characteristics in soy whey medium: a response surface methodology approach. J Agric Food Chem. 2008;56(17):7910–7918. doi: 10.1021/jf801567j. [DOI] [PubMed] [Google Scholar]

- Grygorczyk A, Corredig M. Acid induced gelation of soymilk, comparison between gels prepared with lactic acid bacteria and glucono-δ-lactone. Food Chem. 2013;141(3):1716–1721. doi: 10.1016/j.foodchem.2013.03.096. [DOI] [PubMed] [Google Scholar]

- He FJ, Chen JQ. Consumption of soybean, soy foods, soy isoflavones and breast cancer incidence: differences between Chinese women and women in western countries and possible mechanisms. Food Sci Hum Wellness. 2013;2(3–4):146–161. doi: 10.1016/j.fshw.2013.08.002. [DOI] [Google Scholar]

- Kao FJ, Su NW, Lee MH. Effect of calcium sulfate concentration in soymilk on the microstructure of firm tofu and the protein constitutions in tofu whey. J Agric Food Chem. 2003;51(21):6211–6216. doi: 10.1021/jf0342021. [DOI] [PubMed] [Google Scholar]

- Lee K-Y, Rahman MS, Kim A-N, Gul K, Kang S-W, Chun J, Kerr WL, Choi S-G. Quality characteristics and storage stability of low-fat tofu prepared with defatted soy flours treated by supercritical-CO2 and hexane. LWT. 2019;100:237–243. doi: 10.1016/j.lwt.2018.10.073. [DOI] [Google Scholar]

- Li H, Yan L, Wang J, Zhang Q, Zhou Q, Sun T, Chen W, Zhang H. Fermentation characteristics of six probiotic strains in soymilk. Ann Microbiol. 2012;62(4):1473–1483. doi: 10.1007/s13213-011-0401-8. [DOI] [Google Scholar]

- Li J, Cheng Y, Tatsumi E, Saito M, Yin L. The use of w/o/w controlled-release coagulants to improve the quality of bittern-solidified tofu. Food Hydrocolloids. 2014;35:627–635. doi: 10.1016/j.foodhyd.2013.08.002. [DOI] [Google Scholar]

- Li C, Rui X, Zhang Y, Cai F, Chen X, Jiang M. Production of tofu by lactic acid bacteria isolated from naturally fermented soy whey and evaluation of its quality. LWT Food Sci Technol. 2017;82:227–234. doi: 10.1016/j.lwt.2017.04.054. [DOI] [Google Scholar]

- Maki K, Tomoyo S, Mitsuru F. Metabolite profile of lactic acid-fermented soymilk. Food Nutr Sci. 2018;9:1327–1340. [Google Scholar]

- O’Toole DK. Soybean: soymilk, tofu, and okara. In: Wrigley CW, Corke H, Seetharaman K, Faubion J, editors. Encyclopedia of food grains. Amsterdam: Elsevier; 2016. pp. 134–143. [Google Scholar]

- Poudyal RL, Kobayashi R, Suzuki T, Watanabe M. Effect of different freezing and storage condition on the physical properties of protein coagulum (firm tofu) Int J Refrig. 2019;107:11–19. doi: 10.1016/j.ijrefrig.2019.07.022. [DOI] [Google Scholar]

- Prabhakaran MP, Perera CO, Valiyaveettil S. Effect of different coagulants on the isoflavone levels and physical properties of prepared firm tofu. Food Chem. 2006;99:492–499. doi: 10.1016/j.foodchem.2005.08.011. [DOI] [Google Scholar]

- Riciputi Y, Serrazanetti DI, Verardo V, Vannini L, Caboni MF, Lanciotti R. Effect of fermentation on the content of bioactive compounds in tofu-type products. J Funct Foods. 2016;27:131–139. doi: 10.1016/j.jff.2016.08.041. [DOI] [Google Scholar]

- Saio K. Tofu-relationships between texture and fine structure. Cereal Foods World. 1979;24:342–354. [Google Scholar]

- Serrazanetti DI, Ndagijimana M, Miserocchi C, Perillo L, Guerzoni ME. Fermented tofu: enhancement of keeping quality and sensorial properties. Food Control. 2013;34(2):336–346. doi: 10.1016/j.foodcont.2013.04.047. [DOI] [Google Scholar]

- Shi X, Li J, Wang S, Zhang L. Flavor characteristic analysis of soymilk prepared by different soybean cultivars and establishment of evaluation method of soybean cultivars suitable for soymilk processing. Food Chem. 2015;185:422–429. doi: 10.1016/j.foodchem.2015.04.011. [DOI] [PubMed] [Google Scholar]

- Vannini L, Patrignani F, Iucci L, Ndagijimana M, Vallicelli M, Lanciotti R, Guerzoni ME. Effect of a pre-treatment of milk with high pressure homogenization on yield as well as on microbiological, lipolytic and proteolytic patterns of “pecorino” cheese. Int J Food Microbiol. 2008;128(2):329–335. doi: 10.1016/j.ijfoodmicro.2008.09.018. [DOI] [PubMed] [Google Scholar]

- Wang JM, Lin QQ, Wang YY, Chen X. Research on soybean curd coagulated by lactic acid bacteria. Springerplus. 2013;2(1):250. doi: 10.1186/2193-1801-2-250. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Wang X, He Z, Zeng M, Qin F, Adhikari B, Chen J. Effects of the size and content of protein aggregates on the rheological and structural properties of soy protein isolate emulsion gels induced by CaSO4. Food Chem. 2017;221:130–138. doi: 10.1016/j.foodchem.2016.10.019. [DOI] [PubMed] [Google Scholar]

- Wang X, Luo K, Liu S, Adhikari B, Chen J. Improvement of gelation properties of soy protein isolate emulsion induced by calcium cooperated with magnesium. J Food Eng. 2019;244:32–39. doi: 10.1016/j.jfoodeng.2018.09.025. [DOI] [Google Scholar]

- Wilkens WF, Lin FM. Gas chromatographic and mass spectral analyses of soybean milk volatiles. J Agric Food Chem. 1970;18:333–336. doi: 10.1021/jf60169a003. [DOI] [Google Scholar]

- Wu M, Xiong YL, Chen J, Tang X, Zhou G. Rheological and microstructural properties of porcine myofibrillar protein–lipid emulsion composite gels. J Food Sci. 2009;74(4):E207–E217. doi: 10.1111/j.1750-3841.2009.01140.x. [DOI] [PubMed] [Google Scholar]

- Wu W, Hua YF, Lin QL. Effect of oxidative modification on thermal aggregation and gel properties of soy protein by malondialdehyde. J Food Sci Technol. 2014;51(3):485–493. doi: 10.1007/s13197-011-0533-7. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Yasin UA, Horo JT, Gebre BA. Physicochemical and sensory properties of tofu prepared from eight popular soybean [Glycine max (L.) Merrill] varieties in Ethiopia. Sci Afr. 2019 doi: 10.1016/j.sciaf.2019.e00179. [DOI] [Google Scholar]

- Zhang Q, Wang C, Li B, Li L, Lin D, Chen H, Liu Y, Li S, Qin W, Liu J, Liu W, Yang W. Research progress in tofu processing: from raw materials to processing conditions. Crit Rev Food Sci Nutr. 2016;58(9):1448–1467. doi: 10.1080/10408398.2016.1263823. [DOI] [PubMed] [Google Scholar]

- Zhang W, Liu X, Yang Z, Song H, Zhang Y, Jin Y. Effect of soaking and temperature process on the volatile compounds in soymilk made by soymilk maker. J Food Sci Technol. 2018;55(4):1591–1598. doi: 10.1007/s13197-018-3072-7. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Zhu Q, Wu F, Saito M, Tatsumi E, Yin L. Effect of magnesium salt concentration in water-in-oil emulsions on the physical properties and microstructure of tofu. Food Chem. 2016;201:197–204. doi: 10.1016/j.foodchem.2016.01.065. [DOI] [PubMed] [Google Scholar]