Abstract

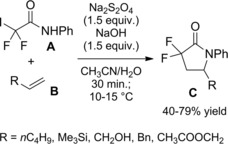

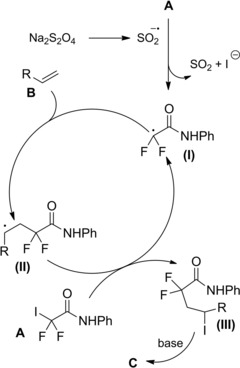

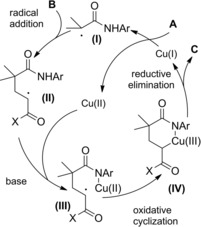

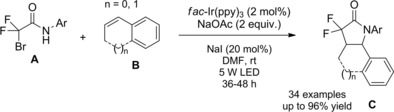

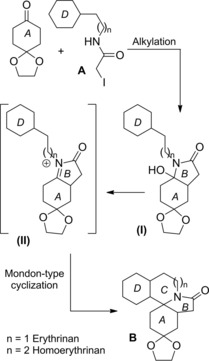

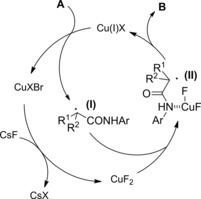

The aim of this review is to highlight the rich chemistry of α‐haloamides originally mainly used to discover new C−N, C−O and C−S bond forming reactions, and later widely employed in C−C cross‐coupling reactions with C(sp3), C(sp2) and C(sp) coupling partners. Radical‐mediated transformations of α‐haloamides bearing a suitable located unsaturated bond has proven to be a straightforward alternative to access diverse cyclic compounds by means of either radical initiators, transition metal redox catalysis or visible light photoredox catalysis. On the other hand, cycloadditions with α‐halohydroxamate‐based azaoxyallyl cations have garnered significant attention. Moreover, in view of the important role in life and materials science of difluoroalkylated compounds, a wide range of catalysts has been developed for the efficient incorporation of difluoroacetamido moieties into activated as well as unactivated substrates.

Keywords: amides, electrochemistry, photocatalysis, radical reactions, reaction mechanisms

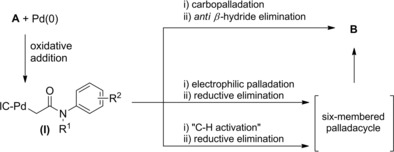

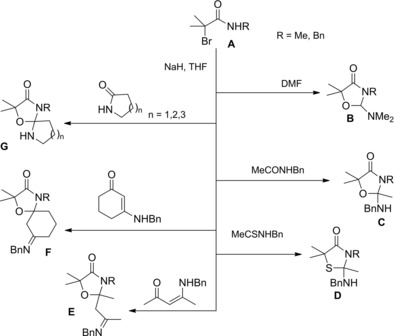

What can α‐haloamides do? The α‐haloamide functional group is an efficient platform for a lot of transformations. Its framework, surprisingly rich of chemically “touchable” atoms, has been used for α‐aminations, radical cyclizations to β‐ and γ‐lactams, intra‐ and intermolecular transition metal catalyzed α‐alkylations, α‐alkenylations, α‐alkynylations, α‐arylations, as well as a three‐atom unit for heterocyclic formation.

1. Introduction

α‐Halocarbonyl compounds are useful synthetic intermediates in a number of widely different organic transformations. Among them, α‐haloamides have been attracting increasing attention in view of their high reactivity as building blocks for the preparation of a variety of intermediates for the synthesis of biologically active molecules and pharmaceuticals. These compounds are used as starting materials for the preparation of a myriad of compounds including α‐,1 β‐ and γ‐lactams,2 dioxopiperazines,3a–3b 2,5‐dioxopyrrolidines,4 oxazolidinones,5a–5f thiazolidin‐4‐ones,5b tetramic acids,6a–6b glycoside amides,7 and peptidomimetics.8a–8g

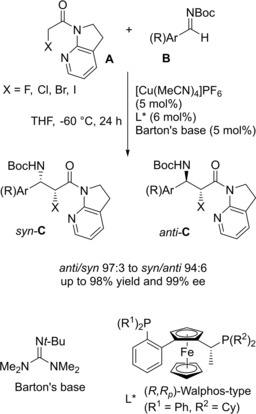

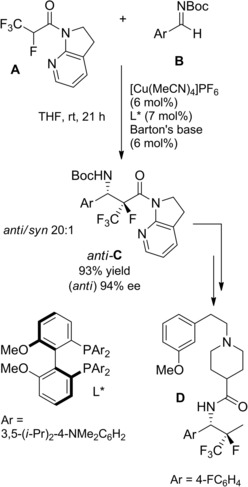

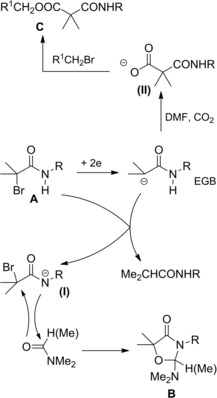

Thus, halogen substitution by a variety of nitrogen and oxygen nucleophiles allows the synthesis of aminoamides and alkoxyamides respectively, the site‐selective substitution of the bromine with O‐nucleophiles being promoted by silver oxide.9 Notably, the C−X bond polarization can be inverted by electroreduction generating enolates useful for the formation of a new C−C bond,10 while α‐halo‐7‐azaindoline amides behaving as halogen‐bearing enolate precursors take part to catalytic asymmetric Mannich‐Type reaction affording compounds with halogens on a stereogenic carbon.11

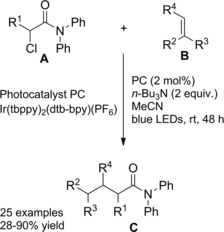

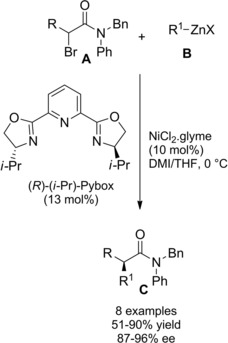

A variety of α‐chloro amides bearing a suitable located double bond has been utilized as convenient substrate for atom transfer radical cyclization.12a–12b The formation of cyclic systems by carbon‐carbon bond formation by the use of free radical cyclization protocols, originally mediated by organostannane or organosilane reagents (e. g. Bu3SnH or HSi(SiMe3)3), has been later more conveniently performed using copper complexes13 or visible light photoredox catalysis.14 Moreover, the development of transition metal‐catalyzed cross‐coupling reactions as C−C bond forming reactions between an organic electrophile and an organometallic reagents further expanded the synthetic usefulness of α‐haloamides. Notably, the potential of using transition metal‐catalyzed C−C bond formation to prepare enantioenriched molecules was immediately recognized by the synthetic chemistry community and α‐haloamides have been widely employed as organic electrophiles. In 2005, Fisher and Fu15 described the Ni‐catalyzed Negishi cross‐coupling of racemic α‐bromo amides with organozinc reagents in the presence of the chiral ligand (i‐Pr)‐Pybox as an exceptionally useful method to obtain enantiopure α‐chiral amides.

At present, information about the synthesis and the chemistry of α‐halogenated amides are just scattered throughout literature, if one excludes a minireview article published by Comesse et al.16 while this manuscript was under peer review process.

The aim of this survey is to focus new attention on the broad potential of the α‐haloamides as versatile synthons in organic synthesis; the number of papers dealing with the chemistry of α‐haloamides has been partitioned within different Sections giving the rightful emphasis to the reaction mechanisms.

A brief introduction is in Section 1.; methods for their preparations in racemic as well as in enantio‐enriched forms have been summarized in Section 2. The collected papers showcase a multivalent nature for the alpha‐carbon (αC), de facto α‐haloamides can act as suitable electrophiles for carbon‐ or heteroatom‐centered nucleophiles in reactions proceeding with displacement of the α‐halogen atom. Alternatively, the latter can be abstracted from the αC under reductive conditions, the single electron transfer process giving the corresponding carbon‐centered radical as the highly reactive species. On the other hand, the αC can turn to a nucleophile center both by removal of a proton under basic conditions or as a result of a two‐electron transfer process coming with removal of the α‐halogen. That is why most of chemical reactions occurs at this crucial site of the α‐haloamide substrates.

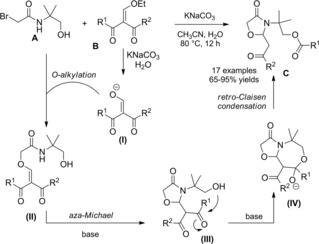

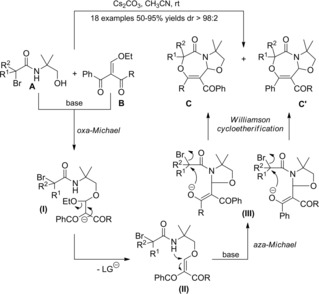

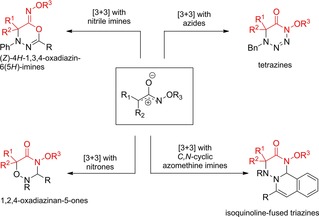

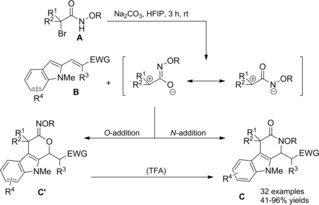

Our choice has been grouping articles according to the nature of the bond generated by the various reaction. Thus, Section 3. is dedicated to base‐promoted conversions of α‐haloamides into aziridinones, unusual bidentate electrophiles. Processes for α‐aminations are collected in Section 4., whereas processes for αC−C bond formation found accommodation in Sections 5–10, substantially ordered according to both the hybridization of the carbon atom that results connected to αC and the nature of processes involved in C−C bond construction. Collected in Section 11. is the copious number of papers dealing with reactions occurring simultaneously at the αC and N/O atoms where α‐haloamides act as three‐atom units for concise synthesis of heterocycles. Eventually, Section 12. is dedicated to synthetic processes not properly suited for inclusion in previous Sections.

For the sake of clarity the caption of each Scheme includes both the reference number and the Section to which the paper refers. In the text, as well as in the Schemes, bold capital letters denote reagents and products, reacting α‐haloamides being A. Synthetic intermediates and pivotal species in catalytic cycles are designated by Roman numerals.

2. Preparations

2.1. Preparation of Achiral and Chiral Racemic α‐halo Amides

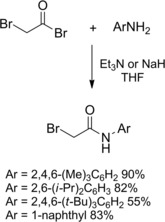

The classical approach to the synthesis of α‐halo amides involves substitution at the carbonyl group of an α‐haloacetyl halide (acyl halide or ester) with a nucleophilic amine (Scheme 1). Such processes suffer the low reactivity displayed by sterically hindered or electron‐poor amines. The reaction of aniline derivatives and α‐bromoacetyl bromide in the presence of Et3N afforded the desired products in moderate to good yields (80‐90 %) however, NaH was required for reacting the 2,4,6‐tri‐tert‐butylaniline, the expected amide being formed in 55 % yield.17a–17c

Scheme 1.

Preparation of N‐aryl‐2‐bromoacetamides (ref. [17a–c] – Section 2.1).

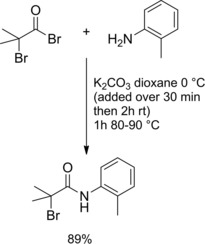

Recently,18 the 2‐bromo‐2‐methyl‐N‐o‐tolylpropanamide was prepared in good yield reacting o‐toluidine with 2‐bromo‐2‐methylpropanoyl bromide in boiling dioxane in the presence of K2CO3 (Scheme 2).

Scheme 2.

Preparation of 2‐bromo‐2‐methyl‐N‐o‐tolylpropanamide (ref. [18] – Section 2.1).

A variety of functionalized α‐chloroamides has been obtained by reaction between chloroacetyl chloride and mono‐ or bis‐aliphatic or aromatic amines in water under basic or neutral conditions.19

Interestingly, chloroacetyl chlorides reacted with N‐benzylidene imines in the presence of stoichiometric triethylamine to give high yields of 3‐chloro‐β‐lactams (Scheme 3)20 which were promptly dehalogenated by electroreduction in the presence of proton donors. Alternatively, electroreduction in the presence of electrophiles such as Ac2O or CO2 gave functionally 3‐substituted β‐lactams.21a–21b

Scheme 3.

Preparation of 3‐chloro‐β‐lactams (ref. [20] – Section 2.1).

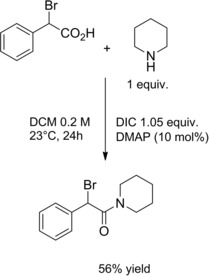

α‐Bromo amides can also be synthesized from the corresponding α‐bromo acid using N,N’‐diisopropylcarbodiimide (DIC) for the coupling with amines (Scheme 4.)22

Scheme 4.

Amidation of α‐bromo acid using DIC (ref. [22] – Sction 2.1).

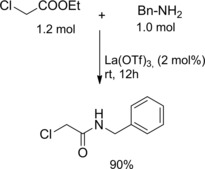

The intrinsic reactivity of ethyl chloroacetate could be altered in the presence of 2 mol% of La(OTf)3, the reaction with benzylamine providing the expected α‐chloroacetamide in 90 % yield (Scheme 5).23

Scheme 5.

Amidation of ethyl chloroacetate using La(OTf)3 (ref. [23] – Section 2.1).

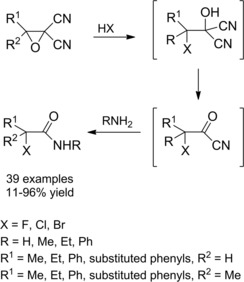

Alternatively, α‐halo amides are formed in good to moderate yields in a one‐pot multistep reaction between a variety of α,α‐dicyano epoxides (monosubstituted alkyl, aryl; disubstituted alkyl‐aryl) and amines (primary alkyl, aryl, amino esters, amino amides) in the presence of hydrohalides (Scheme 6).24

Scheme 6.

Preparation of α‐haloamides from dicyano epoxides (ref. [24] – Section 2.1).

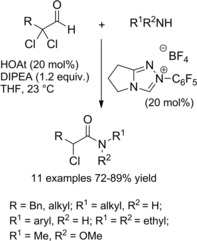

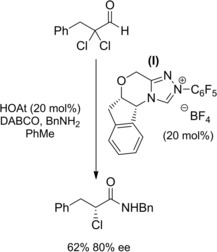

In 2007, Vora and Rovis25a–25b reported the amidation of aldehydes with an α‐reducible centre using catalytic amounts (20 mol%) of N‐heterocyclic carbenes (NHCs) in conjunction with 1‐hydroxy‐7‐azabenzotriazole (HOAt) as the co‐catalyst (20 mol%) (Scheme 7).

Scheme 7.

Preparation of α‐chloroamides using the NHC/HOAt system (ref. [25a] – Section 2.1).

In fact, by utilizing 2,2‐dichloro‐3‐phenyl propanal as the redox substrate, a variety of secondary and tertiary α‐chloro amides could be prepared in good yields.

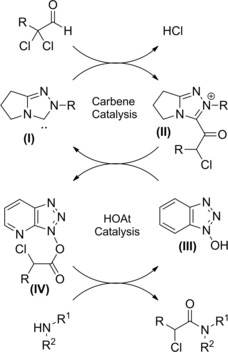

It was hypothesized that the nucleophilic carbene (I) adds to the aldehyde generating the acyl azolium intermediate (II) which transferring the acyl moiety to HOAt (III) gives the activated carboxylate intermediate (IV). The latter, following nucleophilic attack by the amine provides the amide and regenerates the co‐catalyst (III) (Scheme 8).

Scheme 8.

Mechanistic hypothesis for the NHC/HOAt‐promoted amidation of aldehydes with an α‐reducible centre (ref. [25a‐b] – Section 2.1).

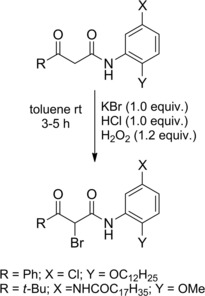

β‐Carbonyl‐α‐bromoamides could be prepared in quantitative yields by chemoselective monobromination of the corresponding active methylene compounds using potassium bromide, hydrochloric acid and 30 % hydrogen peroxide in toluene (Scheme 9).26

Scheme 9.

Preparation of α‐bromoamides via monobromination of β‐ketoamides (ref. [26] – Section 2.1).

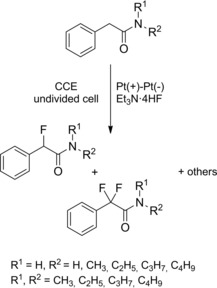

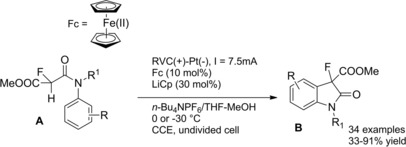

The introduction of fluorine atoms at the α‐position of amides deserves special attention because it may lead to unprecedented or modified biological properties of the target molecule. Noel and co‐workers first exploited organic electrochemistry as an environmentally friendly method for achieving the α‐fluorination of N‐alkyl and N,N‐dialkyl phenylacetamides.27 Specifically, it was observed that under potentiostatic conditions the electrolysis led to predominantly side chain fluorination at the active methylene group, while nuclear fluorination was predominant under galvanostatic conditions (Scheme 10).

Scheme 10.

Anodic fluorination of phenylacetamides under CCE conditions (ref. [27] – Section 2.1).

It was also observed that the fluorination of N,N‐dialkyl phenylacetamides produced variety of products when compared to N‐alkyl phenylacetamides. Importantly, the solvent‐free anodic fluorination proceeded smoothly using Et3N ⋅ 4HF as the fluorinating ionic liquid medium in an undivided cell equipped with two platinum electrodes under current constant electrolysis (CCE) conditions.

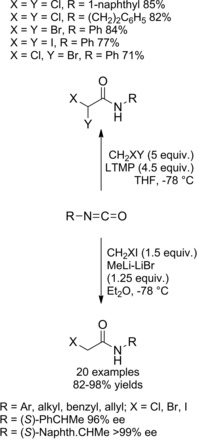

Pace et al. introduced an efficient strategy to prepare a diverse array of α‐halo and α,α‐dihaloacetamides based on the reaction of widely available isocyanates with monohalolithium and dihalolithium carbenoids (Scheme 11).28a–28b

Scheme 11.

Preparation of α‐halo and α,α‐dihaloacetamides via homologation of isocyanates with lithium carbenoids (ref. [28a–b] – Section 2.1).

While monohalolithium carbenoids could be prepared by a smooth lithium‐iodine exchange, the preparation of the corresponding dihalo compounds proved to be highly dependent on the base used to realize the deprotonation, with lithium 2,2,6,6‐tetramethylpiperidine (LTMP) emerging as optimal. Notably, chloro‐, bromo‐ and iodomethyllithiums reacted equally to give the corresponding α‐haloamides in high yields. Moreover, halo‐acetamides with chiral frameworks on the amide nitrogen atom could be easily achieved using chiral isocyanates as starting materials.28b

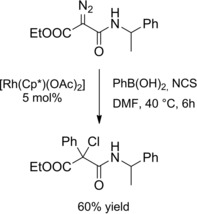

A diazoacetate bearing an amide group acted as an effective acceptor‐acceptor substrate in a chloroarylation reaction with phenyl boronicacid and N‐chlorosuccinimide (NCS) (Scheme 12).29

Scheme 12.

Synthesis of an α‐chloroamide by Rh(III)‐catalyzed cascade difunctionalization of an α‐diazocarbonyl compound (ref. [29] – Section 2.1).

The arylation/chlorination cascade reaction occurred in the presence of a [RhIII(Cp*)]‐catalyst. Principal steps in the catalytic cycle should be the formation of an arylrhodium(III) complex that evolves to an arylrhodium‐carbene complex by reaction with the diazocarbonyl compound. Then, a migratory insertion reaction should produce a rhodium(III)‐diketonate which coordinates NCS. Eventually, nucleophilic displacemnent of the N−Cl group by the diketonate ligand affords the α‐chloroamide with a quaternary stereocenter.

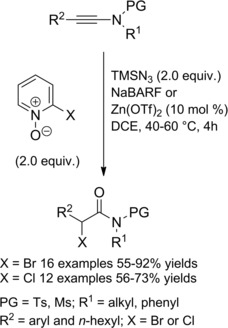

Ts‐ or Ms‐protected ynamides underwent Lewis acid‐catalyzed transformation into α‐halo amides through an alkyne oxidation‐halogenation tandem process with 2‐halopyridine N‐oxide (2 equiv.) serving both as the oxidant and the halogen source (Scheme 13).30a–30b

Scheme 13.

Preparation of α‐haloamides via ynamides oxidation‐halogenation tandem process (ref. [30a‐b] – Section 2.1).

The reaction occurred in few hours (DCE at 40–60 °C) in the presence of TMSN3 (2 equiv.) and the Lewis acid (10 mol%). Either Zn(OTf)2 or NaBARF (sodium tetrakis[3,5‐bis(trifluoromethyl)phenyl]borate) could be effective catalysts for activating the ynamides substrates to the nucleophilic attack of 2‐halopyridine N‐oxides, the ancillary event in the proposed reaction mechanism.

Thus, various aryl‐ substituted ynamides were converted in good to excellent yields both to α‐bromo and α‐chloro amides by employing 2‐bromo‐ and 2‐chloropyridine N‐oxide respectively. Moreover, albeit less efficiently, the protocol could also be applied to an alkyl‐substituted ynamide.

2.2. Preparation of Chiral Non‐Racemic α‐halo Amides

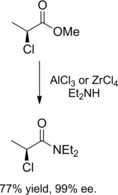

From chiral sources: The acyl nucleophilic substitution reaction between methyl (S)‐(‐)‐2‐chloropropionate and diethylamine performed in the presence of a Lewis acid (AlCl3 or ZrCl4) allowed the preparation of the corresponding (S)‐(+)‐N,N‐diethyl‐2‐chloropropionamide in high chemical (77 %) and optical (99 %) yield (Scheme 14).31

Scheme 14.

Methyl 2‐(S)‐chloropropionate as the chiral source (ref. [31] – Section 2.2).

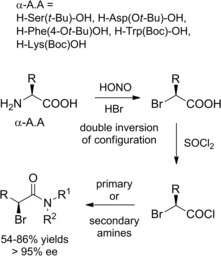

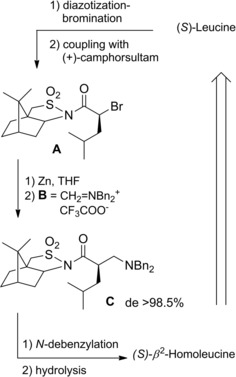

2‐(S)‐Bromoamides could be prepared by amidation reaction of the corresponding 2‐(S)‐bromoacyl chloride in turn easily prepared from natural amino acids (α‐A.A) through diazotization‐halogenation and SOCl2‐mediated carboxy‐activation (Scheme 15).32 As the one‐pot two step process replacing the primary amino group for bromine atom occurred through vicinal carboxyl group assistance, the resulting 2‐bromoacids as well as the corresponding amides were produced with retention of configuration.

Scheme 15.

Natural amino acids as the chiral sources (ref. [32] – Section 2.2).

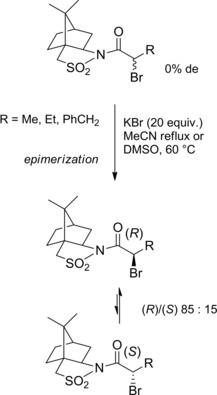

Using chiral auxiliaries: In 1995 Ward and co‐workers33 found out that diastereomeric α‐bromoamides derived from the Oppolzer's (−)‐camphorsultam34 underwent epimerization when treated with KBr (20 equiv.) in polar aprotic solvents (Scheme 16). De facto, the diastereomeric excess (de) increased from 0 to 70 % after 1 hr in refluxing MeCN (or DMSO at 60 °C). Specifically, the (R)‐isomers with the bromine located on the less hindered face were the preferred diastereomers.

Scheme 16.

Bromide anion promoted epimerization of α‐bromoamides incorporating the Oppolzer's camphorsultam chiral auxiliary (ref. [33] – Section 2.2).

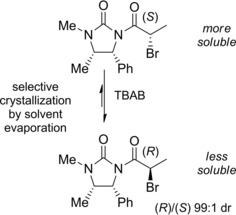

Interestingly, the diastereomeric population could also be controlled by favoring the conversion of the more soluble diastereomer to the less soluble one (Scheme 17). Caddick and Jenkins35 reported the crystallization‐induced dynamic resolution (CIDR) of α‐bromoacyl imidazolidinone where tetrabutylammoniumbromide (TBAB) was involved in the halogenated stereogenic center epimerization.

Scheme 17.

CIDR of the α‐bromopropanamide incorporating an imidazolidinone chiral auxiliary under TBAB epimerization conditions (ref. [35] – Section 2.2).

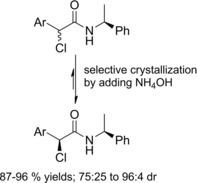

Park and co‐workers36 discovered that (S)‐1‐phenylethylamine was an effective chiral auxiliary for the higly stereoselective CIDR of α‐chloro‐α‐aryl acetamides (Scheme 18).

Scheme 18.

CIDR of α‐chloro‐α‐aryl acetamides incorporating the (S)‐1‐phenylethylamine chiral auxiliary under base‐catalyzed epimerization conditions (ref. [36] – Section 2.2).

Thus, the everyday (for 7 days) addition of NH4OH to the (αRS)‐diastereomeric mixtures in THF led the (αS)‐diastereomers to selectively crystallize. Notably, the chlorinated (S)‐stereogenic center was configurationally stable in the absence of base.

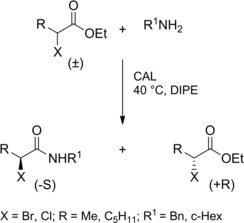

Using enzymes as chiral catalysts: Optically enriched α‐haloamides with concomitant enrichment of the starting α‐haloesters could be efficiently obtained using lipases as catalysts, Candida Antartica lipase (CAL) in anhydrous diisopropyl ether (DIPE) being the best choice for this approach (Scheme 19).37

Scheme 19.

Preparation of enantio‐enriched α‐haloamides using CAL (ref. [37] – Section 2.2).

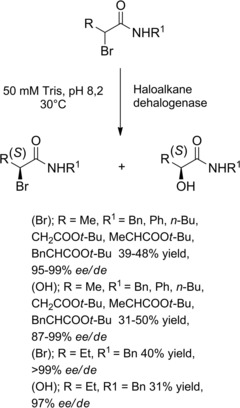

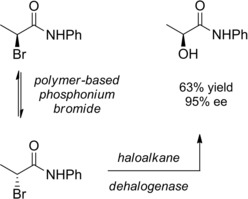

Haloalkane dehalogenases from five sources were heterologously expressed in Escherichia coli, isolated, and tested for their ability to achieve kinetic resolution of fourteen racemic α‐bromoamides with different α‐C and N substituents.38 Seven of these compounds could be converted with a high enantioselectivity (E value>200). In all cases, the (R)‐α‐bromoamides were the preferred substrates in the nucleophilic substitution reaction providing the (S)‐α‐hydroxyamides (Scheme 20). Conversions on a preparative scale with a catalytic amount of enzyme (enzyme:substrate ratio less 1 : 50 w/w) were all completed within 17–46 h and optically pure α‐bromoamides and α‐hydroxyamides were isolated with good yields.

Scheme 20.

Preparation of enantio‐enriched α‐bromoamides using haloalkane dehalogenase (ref. [38] – Section 2.2).

Interestingly, by combining the haloalkane dehalogenase‐mediated enantioselective kinetic resolution with the bromide anion‐promoted epimerization of the halogenated stereogenic center, Janssen and co‐workers39 established a process for a dynamic kinetic resolution (DKR) of racemic N‐phenyl‐2‐bromopropionamide (Scheme 21). A polymer‐based phosphonium bromide in the form of a finely powdered water‐insoluble solid was entrusted with the rapid (αS) to (αR) conversion of the α‐bromoamide while the haloalkane dehalogenase catalyzed the enantioselective bromine substitution. In the overall the DKR provided the N‐phenyl‐2‐(S)‐hydroxypropionamide in 63 % yield and 95 % ee (or 78 % yield and 88 % ee).

Scheme 21.

DKR of the N‐phenyl‐α‐bromopropionamide (ref. [39] – Section 2.2).

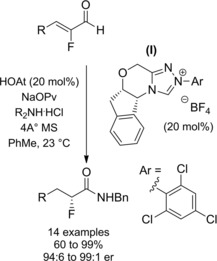

Using non‐ezymatic chiral catalysts: Vora and Rovis in their NHC‐redox amidation of α‐reducible aldehydes (Scheme 7, Section 2.1.)25a–25b reported a single asymmetric reaction. Precisely, the N‐benzyl‐2(R)‐chloro‐3‐phenyl propanamide was prepared reacting 2,2‐dichloro‐3‐phenyl propanal with benzylamine by using the chiral triazolium (I) as the NHC‐precatalyst (Scheme 22). Later on, they found that α‐fluoro‐α,β‐unsaturated aldehydes were a lot more gratifying substrates (Scheme 23).40 In fact, the NHC‐redox amidation protocol worked well in the conversion of α‐fluoroenals into enantioenriched α‐fluoroamides. The optimized conditions entailed reacting α‐fluoroenals with amine hydrochloride salts in toluene using the organocatlyst system composed of the chiral triazolium precatalyst (I) and the HOAt co‐catalyst. Excellent yields and selectivities were achieved provided that sodium pivalate (NaOPv) was the base; the presence of 4 A° molecular sieves was also important in order to preclude hydration.

Scheme 22.

Preparation of the enantio‐enriched N‐benzyl‐2‐chloro‐3‐phenyl propanamide using the chiral NHC‐precursor (I) in the redox amidation (ref. [25a–b] – Section 2.2).

Scheme 23.

Preparation of enantio‐enriched α‐fluoroamides using the chiral NHC‐precursor (I) in the redox amidation (ref. [40] – Section 2.2).

The method showed to tolerate functional groups such as esters, silyl ethers, and carbamates providing a variety of secondary and tertiary α‐fluorinated amides including Weinreb amide derivatives.

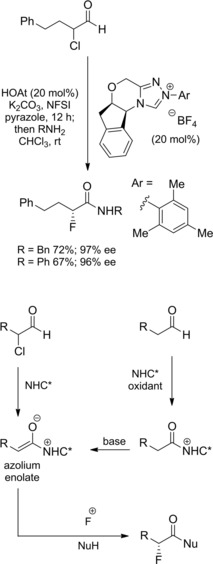

In 2015 Sun and co‐workers41 reported the N‐fluorobenzenesulfonimide (NFSI) mediated asymmetric α‐fluorination of azolium enolates resulting from the addition of the Bode NHC catalyst onto the carbonyl group of α‐chloro aldehydes (Scheme 24). Indeed, various nucleophiles (NuH) including amines participated to the reaction with azolium enolates and NFSI. A suitable combination of precatalyst, oxidant, base, fluorination reagent and the additive pyrazole (as an acyl transfer reagent), converted racemic 4‐phenyl‐2‐chloro butanal and amines (aniline and benzyl amine) into the corresponding highly enantioenriched α‐fluoro amides. Notably, simple aliphatic aldehydes were suitable substrates too, with NFSI acting both as the oxidant and the fluorine source (bottom of Scheme 24).

Scheme 24.

NFSI‐mediated asymmetric α‐fluorination of azolium enolates derived from the Bode NHC catalyst (ref. [41] – Section 2.2).

3. Aziridinones Ring‐Forming/Ring‐Opening Processes

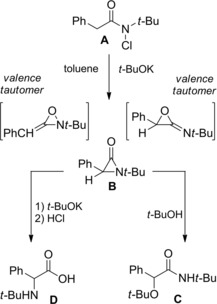

Interest in α‐lactams dates back to 1962 when Baumgarten42a–42b first isolated and characterized the 1‐t‐butyl‐3‐phenylaziridinone B resulting from the base (t‐BuOK) mediated dehydrochlorination of N‐chloro‐N‐t‐butyl phenylacetamide A (Scheme 25). The physical data, together with the dual mode of ring cleavage following attack with O‐nuclephiles, supported the α‐lactam structure even though the alternative structures (valence tautomers) could not be ruled out.

Scheme 25.

Baumgarten's preparation of aziridinone B and ring cleavage reactions with O‐nucleophiles (ref. [42a–b] – Section 3).

Specifically, while the recrystallized α‐lactam appeared to be a quite stable compound when kept dry in the freezer, it promptly reacted with t‐BuOH providing N‐t‐Bu‐2‐t‐BuO‐phenylacetamide C as well as with t‐BuOK/t‐BuOH affording N‐t‐Bu phenylglycine D after acid hydrolysis.

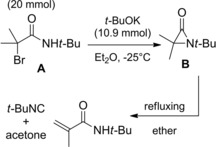

Later, Sheehan and Lengyel43 reported the synthesis of 1‐t‐butyl‐3,3‐dimethylaziridinone B by t‐BuOK (10.9 mmol) mediated dehydrobromination of N‐t‐Bu 2‐bromo‐2‐methylpropanamide A (20 mmol) in Et2O at −25 °C (Scheme 26).

Scheme 26.

Preparation of aziridinone B by Sheehan and Lengyel (ref. [43] – Section 3).

The α‐lactam decomposed into N‐t‐butylmethacrylamide and smaller amounts of t‐butylisonitrile and acetone following a short reflux period in ether. Even more unstable resulted α‐lactams with less encumbered N‐substituents.

Scrimin and co‐workers44 found convenient to carry out the dehydrohalogenation reaction by treatment of the α‐haloamide substrates with potassium hydroxide in benzene or toluene in the presence of 18‐crown‐6 ether as a phase‐transfer catalyst.

In 2002, a further improvement has been described making use of sodium hydride in dichloromethane in the presence of 15‐crown‐5 ether at room temperature.45

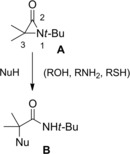

Sheehan and Lengyel43 underlined a dichotomous outcome for the reactions between nucleophilic species with the electrophilic α‐lactam (aziridinone) A, the latter either as an isolated compound (Scheme 27) or a putative transient intermediate in the reaction medium (Scheme 28). Specifically, the aziridinone A reacted with nonionic nucleophiles (e. g., alcohol, amine, thiol) at room temperature affording N‐t‐Bu 2‐substituted‐isobutyramides B (Scheme 27).

Scheme 27.

Ring opening reactions of the isolated aziridinone A with nonionic nucleophiles (ref. [43] – Section 3).

Scheme 28.

Ring opening reactions of the putative aziridinone B with the tert‐butoxy anion (ref. [43] – Section 3).

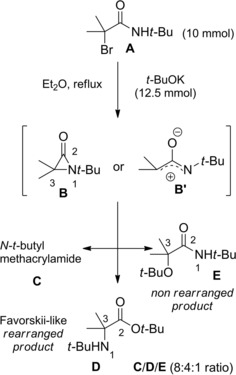

On the other hand, the dehydrobromination of the starting α‐bromoamide A (10 mmol) performed with t‐BuOK (12.5 mmol) in diethyl ether at reflux, returned the N‐t‐butylmethacrylamide C, the t‐Bu 2‐t‐butylamino‐2‐methyl propanoate D, and the N‐t‐Bu 2‐t‐BuO‐isobutyramide E in 8 : 4 : 1 ratio (Scheme 28). The formation of the isomeric products D and E was rationalized in terms of the acyl‐nitrogen cleavage and the alkyl‐nitrogen cleavage respectively of the in situ formed α‐lactam B when attacked by the tert‐butoxy anion.

Thus, the preferential nucleophilic attack at C2 with 2–1 sigma bond heterolysis provided the Favorskii‐like “rearranged product” D whereas attack at C3 with 3–1 sigma bond heterolysis yielded the “non‐rearranged product” E.

As an alternative mechanism explaining the dual reactivity of α‐lactams toward nucleophiles it was advanced the involvement of a highly reactive aza‐oxyallylic cation B’ (Scheme 28). However, a set of experiments by Hoffman and co‐workers46 using enantiopure α‐lactams established that attack at the C‐2 position consistently produced an amino acid derivative with retention in stereochemistry, while attack at the C‐3 position produced an amide with inversion in stereochemistry. The latter finding ruled out the intermediacy of a planar aza‐oxyallylic cation intermediate, which would instead result in product racemization.

Despite numerous theoretical and mechanistic studies tried enlightening the outcome in nucleophilic aziridinone ring opening reaction, it remained difficult to predict whether nucleophilic attack would be favoured at the C‐2 or C‐3 position of the α‐lactam.47

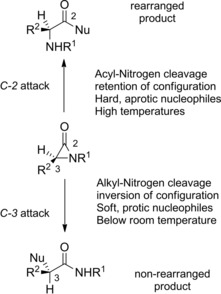

Summing up, protic or ‘‘soft’’ nucleophiles reacting below approximately room temperature produce the “non‐rearranged products”. Conversely, aprotic or ‘‘hard’’ nucleophiles at elevated temperatures afford the “rearranged products” (Scheme 29).

Scheme 29.

Dichotomous outcome for the aziridinones ring opening reactions (ref. [47] – Section 3).

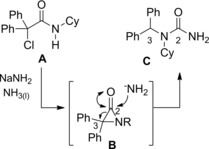

To complete the scenario D'Angeli and co‐workers in 196448 disclosed a rearrangement reaction competing with the Favorskii‐like one, occurring when the N‐cyclohexyl‐α‐chloro‐α,α‐diphenylacetamide A reacted with NaNH2 in liquid ammonia. They reported that the reaction furnished the N1‐cyclohexyl‐N1‐benzhydrylurea C as the predominant product (Scheme 30). Its formation plausibly deriving via C2−C3 sigma bond heterolysis of the incipient α‐lactam B in turn formed by base mediate dehydrochlorination of the starting α‐chloroamide. Importantly, the unusual aziridinone ring‐opening reaction occurred, provided that two phenyl substituents were present at the halogenated α‐carbon atom of the amide.

Scheme 30.

Unusual aziridinone ring opening reaction (ref. [48] – Section 3).

4. α‐Amination of α‐Haloamides

α‐Amino amides are a class of organic compounds exhibiting a variety of biological activity that makes them potential candidates for drug development and discovery. These compounds represent the smallest subunit of naturally occurring peptides and proteins; they have also been used as building blocks for the synthesis of different heterocycles and ligands for the metal‐catalysts.

Replacement of the α‐halogen atom by nitrogen nucleophiles in the presence of inorganic or organic bases is among the available methods for the synthesis of α‐amino amides using α‐chloro, α‐bromo and α‐iodoamides as starting materials. Lidocaine (15.7 g) has been recently produced by Ley and co‐workers under flow conditions within two working days (85 % overall yield).49 The second reaction of the two‐step synthesis consisted of the diethylamine alkylation with 2‐chloro‐N‐(2,6‐dimethylphenyl)acetamide in the presence of Et3N. Optimized conditions featured DMF as the solvent, a reactor temperature of 99 °C, residence time of 17.8 min, and 3.9 equiv. of amine to chloroacetamide.

2‐(Alkylamino)acetamides have been prepared by reaction of 2‐chloro‐N,N‐dimethylacetamide with amines and β‐aminoalcohols in the presence of sodium bicarbonate or triethylamine in benzene at reflux50 while potassium bicarbonate in refluxing acetonitrile has been used when 2‐bromoacetamide was the substrate.51

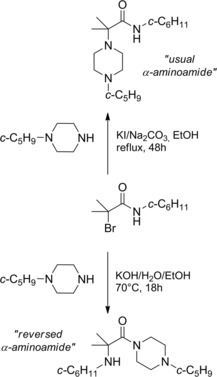

The reaction of 2‐bromo‐N‐cyclohexyl‐2‐methylpropanamide with 1‐cyclopentylpiperazine in the presence of solid sodium carbonate/potassium iodide in ethanol at reflux produced the “usual α‐aminoamide”. However, changing the reaction conditions to aqueous potassium hydroxide in ethanol at 50–70 °C led to the formation of a Favorskii‐like rearranged product: the “reversed α‐aminoamide” (Scheme 31).52

Scheme 31.

Dual reactivity for 2‐bromo‐N‐cyclohexyl‐2‐methylpropanamide toward 1‐cyclopentylpiperazine in the presence of inorganic bases (ref. [52] – Section 4).

In spite of several examples in literature showing a dual reactivity for the α‐haloamides intercepting amine nucleophiles,52, 53a–53b exclusive formation of “usual α‐aminoamides” has been observed by Guziec and Torres,54 Lai,55 and Scrimin and co‐workers.56 Tested reaction conditions entailed treating the α‐haloamide substrates in neat amine with powdered NaOH at 0–5 °C or their dropwise addition to amines in NaH/THF at room temperature. Additionally, the NaOH/H2O/DCM/TBAB biphasic system was also effective to produce “usual α‐aminoamides”.

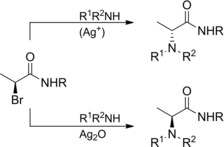

The chemistry of α‐bromoamides toward bromine substitution by a variety of nucleophiles (primary, secondary and tertiary amines, carboxylic acids, alcohols, saccharides, aminoacids) has been deeply investigated by D'Angeli and co‐workers57 and summarized in a short review.58 Interestingly, they found that (S)‐2‐bromopropanamides reacted with amine nucleophiles either in the presence of soluble Ag(I) salts or insoluble Ag2O as promoters (Scheme 32).

Scheme 32.

Stereospecific bromine replacement by amine nucleophiles in the presence of soluble Ag(I) salts or insoluble Ag2O (ref. [57] – Section 4).

In particular, the first ones afforded (R)‐2‐aminopropanamides, whereas substitution products with retention of configuration were formed by employing Ag2O. In the latter case, an early stage formation of aziridine‐lactams from the α‐bromo secondary amides was postulated as the pivotal step.57

The effectiveness of stoichiometric silver oxide in promoting direct functionalization of encumbered alkyl bromides including α‐tert‐alkyl bromides of primary, secondary and tertiary amides with O‐, N‐, and C‐nucleophiles was later improved by Vachal and co‐workers.59 Indeed, they were able to increase both the reaction rate and selectivity performing the substitution reaction in MeCN/H2O (95 : 5). The glad finding was explained assuming that the presence of water as a co‐solvent favors a tight association of all reaction partners in the bond‐forming event of the reaction coordinate.

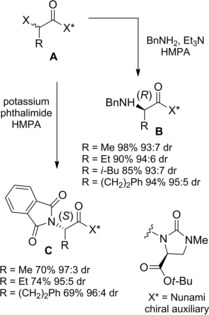

Alternatively, stereoselectivity in asymmetric nucleophilic halogen substitution could be achieved using chiral α‐haloamides equipped with a chiral auxiliary so as one of the two α‐epimers could react faster than the other one, due to the difference in diastereomeric transistion state energies.60 Moreover, suitable DKR processes have been developed by ensuring a fast diastereoisomer conversion could take place in situ. A variety of chiral amines have been used as chiral auxiliaries for the DKR of α‐haloamides. Nunami et al. succeeded in efficient DKR of (αRS)‐epimers A incorporating the chiral auxiliary t‐butyl (4S)‐1‐methyl‐2‐oxoimidazolidin‐4‐carboxylate (Scheme 33).61

Scheme 33.

DKR of α‐haloamides A incorporating the Nunami chiral auxiliary in reactions with nitrogen nucleophiles under base‐catalyzed epimerization conditions (ref. [61] – Section 4).

Interestingly, the chiral auxiliary served to prepare both enantiomers B and C of the amino acid derivatives simply by shifting from benzylamine to the Gabriel reagent (potassium phthalimide) as nitrogen nucleophile in the stereospecific amination processes. The DKR processes occurring at room temperature in the polar solvent hexamethylphosphoramide (HMPA) gave high levels of stereocontrol under base‐catalyzed epimerization conditions. As the chiral auxiliary could be easily removed without racemization (BnOLi/THF) the process established a facile access to a range of optically active L‐ and D‐α‐amino acid derivatives.62a–62b

It is notable that the Nunami chiral auxiliary was also effective in the stereoselective alkylation of α‐bromo amides with malonic ester enolates, the DKR processes leading to carbon‐carbon bond formation.8f

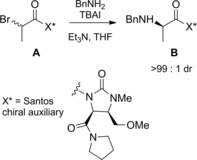

Caddick and co‐workers introduced the (4R,5S)‐1,5‐dimethyl‐4‐phenylimidazolidin‐2‐one as the suitable chiral environment for efficient stereo‐differentiation of chiral α‐bromo amides A in halogen substitution reaction with a variety of nitrogen, sulfur and carbon nucleophiles (Scheme 34).63

Scheme 34.

DKR of α‐haloamide A incorporating the Caddick chiral auxiliary in reactions with carbon and heteroatom nucleophiles using TBAI as the epimerizing agent (ref. [63] – Section 4).

Thus, high levels of selectivity were observed by using TBAI as the epimerizing agent. Interestingly, the SN2 reactions occurred with an unusual dichotomy of diastereoselection whereby a metalated nucleophile afforded mainly the (αS)‐epimeric product C whereas H‐bonding amine nucleophiles gave the (αR)‐epimeric product B; disappointing levels of stereo‐differentiation were achieved with sulfur nucleophiles. Importantly, both the coupling and the removal of the ephedrine‐derived chiral auxiliary required mild conditions.

Theoretical rationalization of the collected experimental results from the literature led Santos et al.64 to design a new imidazolidinone‐based chiral auxiliary effective for the DKR of diastereomeric 2‐bromopropanamides reacting with benzylamine (Scheme 35). The halogen substitution reaction onto amide A, conducted in the presence of TBAI and Et3N, provided the α‐aminated compound B in 92 % yield with >99 : 1 dr.

Scheme 35.

Santos chiral auxiliary effective for the DKR of diastereomeric 2‐bromopropanamides reacting with benzylamine using TBAI as the epimerizing agent (ref. [64] – Section 4).

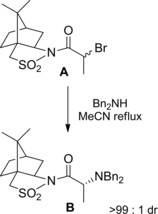

Ward et al. obtained brilliant results using Oppolzer's chiral (−)‐camphorsultam, the aminated (αR)‐epimer B being formed as the single diastereomer in quantitative yield when an (αRS) diastereomeric mixture of the α‐bromo amide A reacted with dibenzylamine in refluxing acetonitrile (Scheme 36).65

Scheme 36.

DKR of α‐bromoamide A incorporating the Oppolzer chiral auxiliary reacting with dibenzylamine under base‐catalyzed epimerization conditions (ref. [65] – Section 4).).

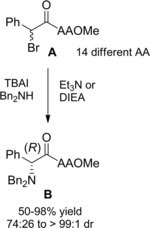

Asymmetric nucleophilic substitution reactions between dibenzylamine and α‐bromoamides A derived from L‐amino acids provided di‐ and tripeptide analogues B incorporating optically pure N‐protected (αR)‐unnatural amino acids in up to 95 % yield and >99 : 1 dr.8e, 8g The actual pathway for the asymmetric process in which the chiral information of an amino acid precursor is efficiently transferred to the new C−N bond formation at α‐halo carbon center, is a dynamic kinetic resolution requiring the TBAI/DIEA couple for the fast epimerization of the substrate (Scheme 37).

Scheme 37.

DKR of α‐bromoamides A derived from L‐amino acids reacting with dibenzylamine under TBAI/DIEA epimerization conditions (ref. [8e, 8g] – Section 4).

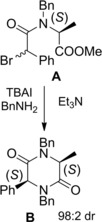

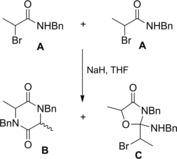

Instead, none or disappointing levels of stereo‐differentiation (51 : 49 to 77 : 23 dr) were achieved using benzylamine. However, the less sterically demanding amine nucleophile reacted with the N‐Bn α‐bromo phenylacetyl L‐AlaOMe A affording the 2(S),5(S)‐disubstituted diketopiperazine B with 98 : 2 dr (Scheme 38). Thus, the switching from secondary to tertiary amides (N‐Bn derivatives) favored the (αS)‐selectivity in the αC−N bond forming step.3b

Scheme 38.

DKR of N‐Bn α‐bromoamide A reacting with benzylamine under TBAI epimerization conditions (ref. [3b] – Section 4).

In the following three examples, a copper catalyst is entrusted with the replacement of the α‐halogen atom by nitrogen nucleophiles.

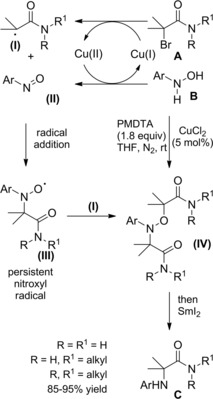

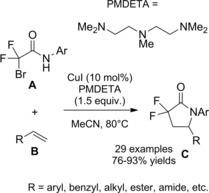

A general method for the construction of α‐amino carbonyl compounds containing sterically hindered aniline moiety is based on reaction of α‐bromocarbonyl substrates (amides in this context) with phenylhydroxylamine using CuCl2/PMDTA as the optimal catalyst system (PMDTA=pentamethyldiethylenetriamine) (Scheme 39).66

Scheme 39.

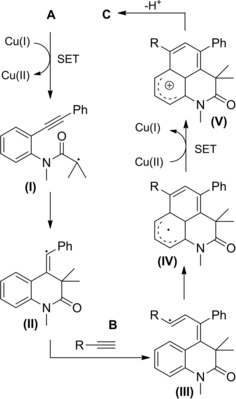

Copper‐catalyzed α‐amination of α‐bromoamides using phenylhydroxylamine (ref. [66] – Section 4).

The process results copper‐catalyzed as a Cu(I) single electron transfer (SET) to the α‐bromoamide A matches the N‐aryl hydroxylamine B oxidation that is in turn a Cu(II)‐mediated step. It has been proposed that the nitroso compound (II), formed in the Cu(II)‐mediated oxidation step, intercepts the α‐radicalamide (I) in turn formed in the Cu(I) SET‐step. The resulting nitroxyl radical (III) then captures a second radical species (I) giving the N−O adduct (IV) which undergoes Sm‐mediated reduction to the sterically hindered α‐anilinoamides C.

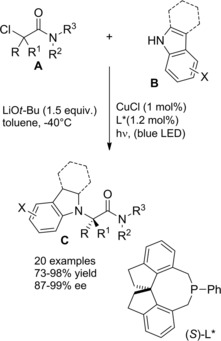

Fu and co‐workers established an elegant and convenient way for reacting racemic tertiary alkyl α‐chloroamides A with either carbazoles and indoles nucleophiles B (Scheme 40).67

Scheme 40.

Asymmetric copper‐catalyzed C−N cross‐couplings induced by visible light (ref. [67] – Section 4).

Specifically, it was found that irradiation of the partners at −40 °C for 16 hours in the presence of CuCl, a chiral phosphine (L*), and lithium tert‐buthoxide (LiOt−Bu) generated the aimed C−N cross‐coupling products C featuring fully substituted stereocenters with good to excellent enantioselectivity. Notably, the enantioconvergent process transforming the racemic starting material into a single product enantiomer required a copper‐based chiral photocatalyst derived from commercially available components. As a possible mechanism, the irradiation of a copper‐nucleophile complex (I) leads to an excited‐state (II) that adds oxidatively to C−Cl bond of the α‐haloamide A (Scheme 41).

Scheme 41.

Mechanistic hypothesis for the copper‐catalyzed C−N cross‐couplings induced by visible light (ref. [67] – Section 4).

The resulting Cu(III)‐complex (III) delivers the cross‐coupled product C via a reductive elimination step. In such a way, the Cu(I)‐catalyst (IV) is restored for the subsequent ligand substitution with the nitrogen nucleophile giving (I).

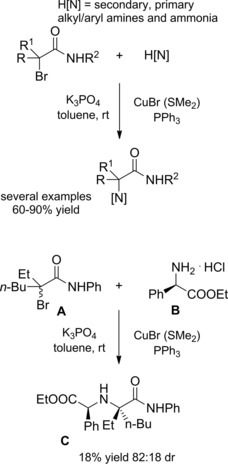

A year later Nishikata et al. reported their achievements of a copper‐catalyzed amination of hindered tertiary alkyl α‐bromoamides with either amines or ammonia (top Scheme 42).68

Scheme 42.

Copper‐catalyzed amination of hindered tertiary alkyl α‐bromoamides with either amines or ammonia (ref. [68] – Section 4).

Importantly, the method allowed for the facile preparation of congested and highly functionalized α‐aminoamides through C−N bond formation at room temperature with no overalkylation detectable when using ammonia. Interestingly, the chiral racemic α‐bromoamide A coupled with (R)‐phenylglycine ethyl ester B affording the corresponding aminated product C with a chiral quaternary carbon center with high diastereoselectivity (dr=82 : 18) (bottom Scheme 42). In addition, substrates possessing two different NH2 groups reacted chemoselectively (the aromatic amine undergoing preferential alkylation over the aliphatic one) and a primary amine was a better nucleophile with respect to a secondary one. Although β‐hydride elimination from an α‐bromoamide was problematic, it was found that the presence of PPh3 inhibited the undesired side reaction. On the basis of a serie of control experiments, the authors advanced a reaction mechanism overlapping the one proposed by Fu and co‐workers67 for the asymmetric copper‐catalyzed C−N cross‐couplings induced by visible light.

5. Intramolecular α‐Alkylation of α‐Haloamides: Syntheses of β‐Lactams

Variously decorated azetidin‐2‐ones are endowed with important biomedical activities. Moreover, enantiopure β‐lactams are versatile chiral intermediates in organic synthesis reason why, a great deal of work has been devoted to the development of efficient synthetic approaches to their preparation in a stereocontrolled fashion.

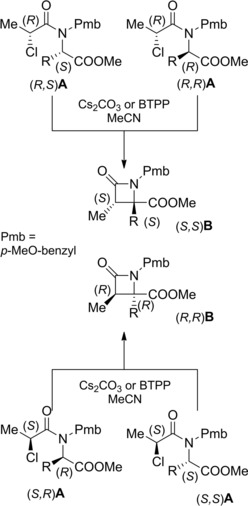

In‐depth studies by González‐Muñiz and co‐workers69a–69e esthablished that α‐haloamides derived from α‐amino acids were convenient precursors for acceding to this key structural motif in non‐racemic form. Thus, the simple base‐promoted (Cs2CO3 in MeCN) cyclization of some N‐benzyl‐N‐chloroacetyl amino acids provided the expected 1,4,4‐trisubstituted azetidin‐2‐ones in good yields and with ee up to 58 %. The moderate enantioselectivities during the 4‐exo‐tet cyclization process could be explained appealing to the memory of chirality phenomenon.70a–70d Intriguingly, the chirality of the α‐amino acid stereogenic center, missed upon proton abstraction is on the other hand transferred (partly in this case) to the final compound without using any external chiral source.

The same research group71 reported that the hydrogen‐bonding organocatalyst TADDOL along with the phosphazene base (tert‐butylimino)tris(pyrrolidino)phosphorane (BTPP), was a helpful additive to enhance memory of chirality while transforming α‐chloroamides A into the amino acid derived β‐lactams B (top Scheme 43). Surprisingly, the TADDOL additive was effective regardless of its configuration and enantiopurity. The degree of the selectivity improvement in favor of the (S)‐product was dependent on the nature of the amino acid aromatic side chain [Δee due to TADDOL: 36 % for Phe and Tyr, 8 % for Trp(Boc)] (bottom Scheme 43).

Scheme 43.

β‐Lactams via 4‐exo‐tet cyclization of α‐chloroamides derived from α‐amino acids in the presence of BTTP and TADDOL additives to enhance memory of chirality (ref. [71] – Section 5).

The base‐promoted 4‐exo‐tet‐cyclization strategy was also applied to enantiomerically pure N‐benzyl‐N‐chloropropanoyl amino acid derivatives A in order to accede to valuable chiral 1,3,4,4‐tetrasubstituted β‐lactams B (Scheme 44).72

Scheme 44.

Diastereo‐ and enantioselective 4‐exo‐tet cyclization of α‐chloroamides derived from α‐amino acids (ref. [72] – Section 5).

Intriguingly, a diastereo‐ and enantioselective process yielded exclusively 3,4‐cis β‐lactam derivatives regardless of the absolute configuration of the α‐amino acid center, a stereochemical outcome de facto abolishing the memory of chirality phenomenon.

In fact, asymmetric construction of the quaternary stereogenic center was entirely dependent upon configuration of the 2‐chloropropionyl moiety.

Theoretical calculations on the transition states explained the high stereoselectivity of the process and prompted the authors to extend the protocol to the preparation of a 1,3,4‐trisubstituted 2‐azetidinone, a Gly‐derived β‐lactam, in enantiomeric pure form.73

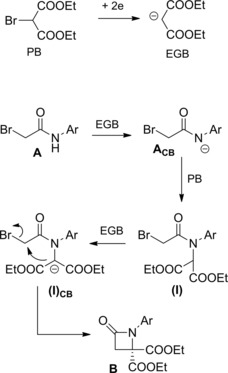

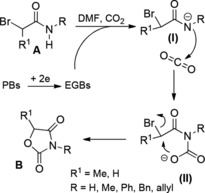

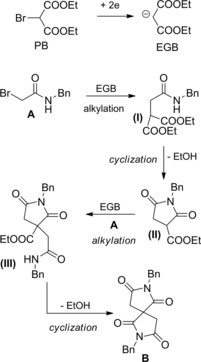

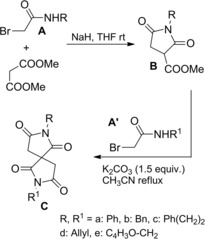

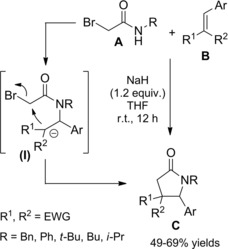

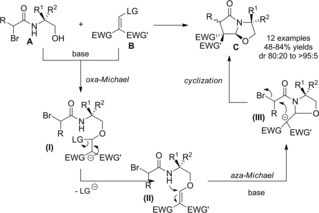

β‐Lactams B were prepared in moderate yields by an electrochemical process where the electrogenerated base (EGB) diethyl malonate anion reacted with α‐haloacetanilides A (Scheme 45).74a–74b

Scheme 45.

Electrochemical process converting α‐bromoamides and diethyl bromomalonate into β‐lactams (ref. [74a–b] – Section 5).

The formal insertion of a malonate framework into the amide skeleton could be rationalized in terms of halide displacement by an internal carbon centered nucleophile leading to C3−C4 β‐lactam bond formation. Presumably, diethyl bromomalonate acted both as a probase (PB) and an alkylating agent.

Thus, N‐alkylation of the α‐haloamide conjugated base ACB with the PB formed N‐bis(ethoxycarbonyl)methylhaloacetanilides (I) which provided azetidin‐2‐ones B prior deprotonation to (I)CB and the ensuing intramolecular alkylation reaction.

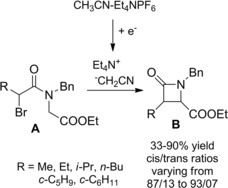

13 years later a simple diastereoselective electrosynthesis of cis‐3‐alkyl‐1‐benzyl‐4‐ethoxycarbonyl‐β‐lactams B was reported by the same research group (Scheme 46).75a–75b The process entailed the 4‐exo‐tet‐cyclization of N‐(ethoxycarbonyl)methyl‐N‐benzyl‐2‐bromoalkylcarboxamides A with cyanomethyl anion acting as EGB.

Scheme 46.

Diastereoselective electrosynthesis of β‐lactams B via 4‐exo‐tet cyclization of α‐bromoamides A (ref. [75a–b] – Section 5).

Indeed, galvanostatic cathodic reduction of a solution of acetonitrile and tetraethylammonium hexafluorophospate (Et4NPF6) (supporting electrolyte) conducted at room temperature and under a nitrogen atmosphere, provided tetraalkylammonium cyanomethyl anion. The latter, acting as a naked anion turned out to be a very reactive EGB.

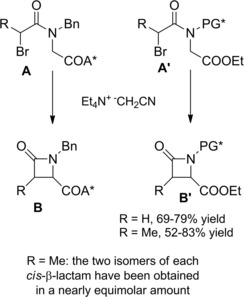

The above strategy could be successfully extended to a variety of α‐bromoamides bearing a chiral auxiliary or chiral protective groups paving the way to an easy, high‐yielding, and stereocontrolled synthesis of chiral cis‐β‐lactams (Scheme 47).76

Scheme 47.

Stereocontrolled electrosynthesis of cis‐β‐lactams via 4‐exo‐tet cyclization of α‐bromoamides incorporating chiral auxiliaries or N‐protective groups (ref. [76] – Section 5).

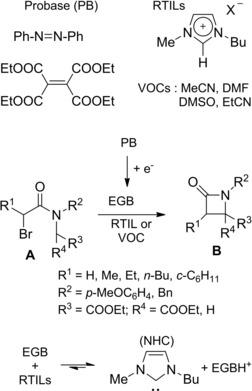

The electrochemically induced cyclization of bromoamides to β‐lactams also occurred in room‐temperature ionic liquids (RTILs) (Scheme 48).77 The eco‐friendly process avoided the use of volatile organic solvents (VOCs) and supporting electrolytes, affording the desired β‐lactams in good to elevated yields via C3−C4 bond formation. The reaction protocol entailed the addition of the haloamide A to an electrolyzed solution of probases (PB) azobenzene or tetraethyl ethenetetracarboxylate in the RTIL (1‐butyl‐3‐methylimidazolium exafluorophospate). Cyclization to the corresponding β‐lactams B did take place via initial deprotonation at C4 by the EGB followed by intramolecular SN reaction.

Scheme 48.

EGB/NHC‐promoted 4‐exo‐tet cyclization of α‐bromoamides in imidazolium‐based RTILs (ref. [77] – Section 5).

Thus, in accord to the reaction pathway, the reactivity of the bromoamides resulted affected mainly by the acidity of the proton at C4 and secondarily by the nature of the substituents on N and C3 atoms. As the N‐heterocyclic carbene (NHC) is a weaker base than the EGB, a proton‐exchange reaction between the EGB and the imidazolium cation was conjectured possible (bottom Scheme 48).

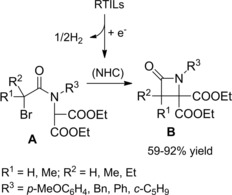

The “non‐innocent” nature of imidazolium‐based RTILs was then established succeeding in the azetidin‐2‐one synthesis just by exposure of α‐bromo amides to NHCs in situ formed by cathodic cleavage of the C2/hydrogen bond of RTILs.78 Indeed, the electrogenerated NHC acted as a basic promotor of the cyclization of bromo amides to β‐lactams (Scheme 49).

Scheme 49.

Electrogenerated NHC as basic promotor for the 4‐exo‐tet cyclization of α‐bromoamides (ref. [78] – Section 5).

Owing to the high chemoselectivity, mild reaction conditions and the elimination of toxic and harmful chemicals, electrochemical processes are of great interest. We confide that convenient devices standardized for both in batch and flow electrosynthesis which are nowadays commercially available, will direct even more synthetic chemists to contemplate electrochemical methods for acceding designed compounds also in a large‐scale production.

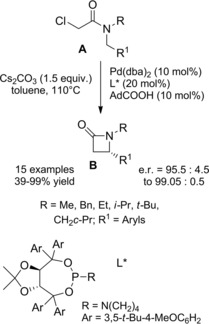

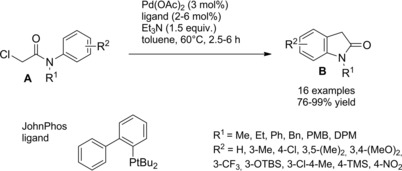

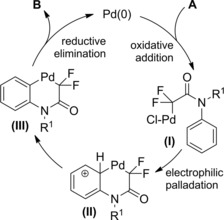

In 2014 Cramer and co‐workers79 disclosed an intriguing Pd(0)‐catalyzed synthesis of β‐lactams B from readily accessible N‐benzyl tertiary chloroacetamides A (Scheme 50). To work well the reaction required tertiary amide functional group with bulky and branched substituents on the amide nitrogen atom, the methyl group being not suitable. Undesired nucleophilic substitution at the α‐chloro position of the chloro amide by the carboxylate co‐catalyst, as well as aryl C(sp 2)‐H functionalization, were mitigated via co‐catalyst and ligand structure optimization.

Scheme 50.

Pd(0)‐catalyzed synthesis of β‐lactams B from N‐benzyl tertiary chloroacetamides A (ref. [79] – Section 5).

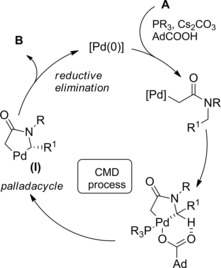

It was proposed that a concerted metallated deprotonative (CMD) process, with activation of chloroacetamides at their benzylic C−H bond, was involved in the formation of a five‐membered palladacycle (I) (Scheme 51). The latter intermediate underwent a strain‐building reductive elimination to the four‐membered ring of the β‐lactam B. In this step the challenging C(sp 3)−C(sp 3) bond formation goes with the regeneration of the active Pd(0) species. Notably, in the presence of a chiral ligand (a bulky TADDOL‐derived phosphoramidite) in combination with AdCOOH (adamantyl carboxylic acid) the process resulted in an asymmetric C−H functionalization.

Scheme 51.

Mechanistic hypothesis for the Pd(0)‐catalyzed synthesis of β‐lactams from N‐benzyl tertiary chloroacetamides (ref. [79] – Section 5).

Thus, the enantiodiscriminating CMD‐step provided β‐lactams B in excellent yields and enantioselectivities (up to 99 % ee). The preferred absolute configuration of the chiral carbon was (S) as established by X‐ray crystallographic analysis. Intriguingly, when tertiary N‐cyclopropyl chloroacetamides A were the substrates, the palladium‐mediated enantiodiscriminating CMD‐process, proceeding with the Taddol phosphonite ligand L* and 1‐adamantane carboxylic acid cooperation, provided homo‐chiral (R,R‐configurated when R1=H) cyclopropane‐fused γ‐lactams B (Scheme 52).80

Scheme 52.

Pd(0)‐catalyzed synthesis of cyclopropane‐fused γ‐lactams B from N‐cyclopropyl chloroacetamides A (ref. [80] – Section 5).

A reductive elimination process onto a six‐membered palladacycle was advanced as the pivotal step forging enantioselectively the pyrrolidine ring through C(sp 3)−C(sp 3) bond formation. To note, the enantioselective process was found to be not limited to the use of cyclopropanes as source of activatable C−H bonds.

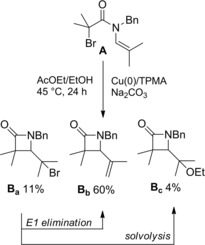

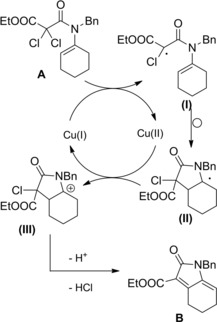

In 2016 Clark and co‐workers2 reported a fruitful method for achieving four‐membered lactams based on a Cu(0) (copper wire)‐mediated stereoelectronically favored81 4‐exo‐trig ring closure of the unsaturated α‐bromo amide A (Scheme 53).

Scheme 53.

Cu(0)‐mediated 4‐exo‐trig ring closure of the α‐bromo enamide (ref. [2] – Section 5).

The cyclization reaction performed in the presence of the ligand complex tris(2‐pyridylmethyl)amine) (TPMA) and the base Na2CO3 afforded the β‐lactam derivatives Ba‐c with compound Bb arising from E1 elimination of the labile tertiary bromide functional group of Ba, and Bc by solvolysis of the corresponding tertiary cation intermediate.

6. Intramolecular α‐Alkylation of α‐Haloamides: Syntheses of γ‐Lactams

6.1. γ‐Lactams via 5‐exo‐trig Radical Cyclization

Organotin hydrides have been widely employed as radical reducing agents to convert unsaturated organohalides to various carbocycles or heterocycles. In this context haloamides provided with internal olefin group played a privileged role as useful precursors of electrophilic carboradicals undergoing cyclization to a wide range of pyrrolidin‐2‐ones.

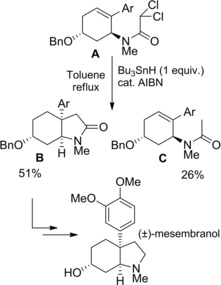

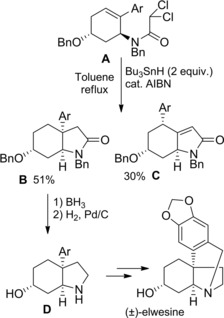

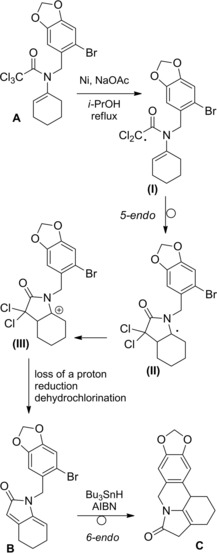

In 1991 Ikeda and Ishibashi's research group82 reported the stereoselective syntheses of the Sceletium alkaloid (±)‐mesembranol (Scheme 54) and the Amaryllidaceae alkaloid (±)‐elwesine (scheme 55) through processes whose featuring step is a tributyltin hydride (Bu3SnH) mediated radical cyclization. Thus, dichloroacetamide A, following exposure to the action of Bu3SnH (1 equiv.) and a catalytic amount of azobis(isobutyronitrile) (AIBN) in boiling toluene, provided the expected cis‐3a‐aryloctahydroindolones B in 51 % yield along with product C (26 %), the latter resulting by the carbamoyl radical intermediate reduction. The lactam B was converted to (±)‐mesembranol according to an already described protocol.83

Scheme 54.

Synthesis of the Sceletium alkaloid (±)‐mesembranol by Bu3SnH‐mediated radical cyclization of the unsaturated dichloroacetamide A (ref. [82] – Section 6.1).

Scheme 55.

Synthesis of the Amaryllidaceae alkaloid (±)‐elwesine by Bu3SnH‐mediated radical cyclization of the unsaturated dichloroacetamide A (ref. [84] – Section 6.1).

On the other hand, dichloroacetamide A treated with 2 molar equiv. of Bu3SnH gave lactam B in 51 % yield along with the rearrangement product C (30 % yield) (Scheme 55). The former compound reduced with borane and deprotected by hydrogenolysis gave the amine D which was an advanced intermediate along the synthesis of the alkaloid (±)‐elwesine.84

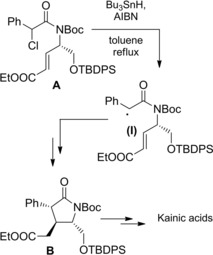

As a further example, classical synthetic targets such as the kainic acid family were obtained from tri‐substituted pyrrolidin‐2‐ones B in turn derived by Bu3SnH mediated cyclization of suitable α‐chloroamides A incorporating a α,β‐unsaturated ester moiety (Scheme 56).85a–85b

Scheme 56.

Synthesis of the Kainic acids by Bu3SnH‐mediated radical cyclization of the unsaturated chloroamide A (ref. [85a–b] – Section 6.1).

Atom transfer radical cyclizations (ATRC) represent a popular synthetic tool for the simultaneous formation of a C−C and C−X bond across an alkene or alkyne. They are de facto non‐reductive alternatives to organotin hydrides in mediating radical cyclization reactions in organic synthesis.

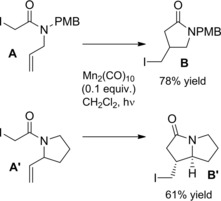

Homolitic Mn−Mn bond cleavage of dimanganese decacarbonyl [Mn2(CO)10], achieved by heating or photolysis, generates the manganese pentacarbonyl radical which can form carbon‐centered radical by halogen‐atom abstraction from suitable organic substrates. Thus, photolysis of iodide A with 0.1 equivalents of dimanganese decacarbonyl afforded pyrrolidinone B via iodine‐atom transfer 5‐exo‐trig cyclization (Scheme 57).86 Similarly the ATRC of A′ was the salient step in an enantioselective synthesis of the pyrrolizidine alkaloid (−)‐trachelanthramidine (Scheme 57).

Scheme 57.

Dimanganese decacarbonyl promoted ATRC (ref. [86] – Section 6.1).

To note, the trapping of the intermediate cyclic primary radical with TEMPO has proved to be an effective method for the preparation of cyclic hydroxylamines B from α‐haloamides A (Scheme 58).86

Scheme 58.

5‐exo‐trig cyclization of A with Mn2(CO)10 in the presence of TEMPO (ref. [86] – Section 6.1).

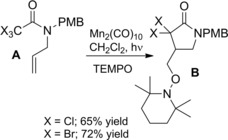

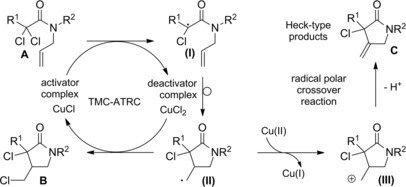

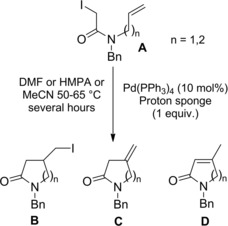

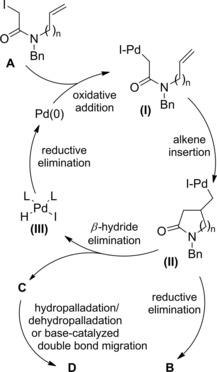

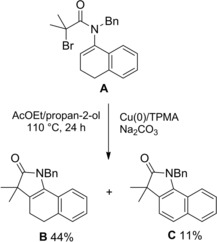

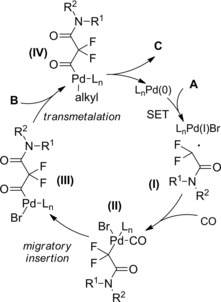

In transition‐metal‐catalyzed atom‐transfer radical cyclizations (TMC‐ATRC) it is a redox catalyst (typically a complex of copper or ruthenium) which is entrusted with the generation of carbon‐centered radicals. In this context, N‐allyl α‐haloamides A are de facto converted into γ‐lactams B through intramolecular addition of the C−X bond (X=Cl, Br, I) across the tethered olefin group (Scheme 59).

Scheme 59.

Transition‐metal‐catalysed atom‐transfer radical cyclization and radical‐polar crossover reaction–Section 6.1

The reaction mechanism features three basic steps: I) the transition‐metal‐catalyst (TMC‐ activator complex) increases its oxidation state by one abstracting a halogen atom from the amide substrate to give the TMC‐deactivator complex; II) the so formed N‐allyl‐carbamoyl methyl radical (I) cyclizes through a regioselective 5‐exo intramolecular attack onto the C=C bond; III) the new formed radical intermediate (II) is quenched by halogen transfer from the TMC‐deactivator complex. In the last step, the halogenated lactam B is formed while the transition‐metal‐catalyst complex is restored in the reduced state (TMC‐activator complex).

As a side reaction, the combination of two radicals leads to the TMC‐deactivator complex accumulation and to a decrease in catalytic rate.

Alternatively, in a radical‐polar crossover reaction, radical (II) oxidation by the TMC‐deactivator complex generates a carbenium ion (III) which is converted into Heck‐type products C through loss of a proton from the adjacent atom (Scheme 59). The radical oxidation step occurs with the TMC‐activator complex restoration. Ultimately, radical‐polar crossover reactions lead to replace the halogen atom of α‐haloamides with an alkenyl goup. Therefore, papers dealing with the topic are commented in the specific Section 8.

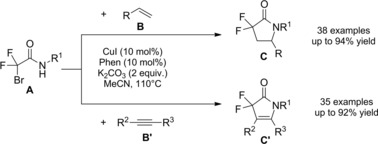

A variety of N‐allyl‐α‐haloamides has been successfully used as 5‐exo‐trig cyclization substrates to yield lactam scaffolds and different catalytic systems have been developed over 40 years. [Cu(I)87a–87k and Ru(II)87g, 88a–88m].

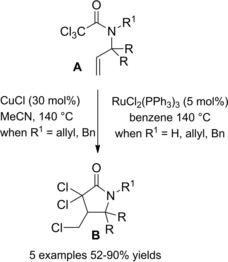

Nagashima and co‐workers prepared γ‐butyrolactams via copper or ruthenium‐catalyzed cyclization of N‐allyl trichloroacetamides A (Scheme 60). While RuCl2(PPh3)3 was an effective catalyst both for secondary and tertiary unsaturated amides, CuCl gave higher yields with the tertiary ones. The carbon‐carbon bond forming reactions, performed in sealed tubes at 140 °C, furnished regioselectively the α,α,γ‐trichloro‐γ‐lactams B, no δ‐lactams being usually detectable.89 The products could be transformed into various nitrogen‐heterocycles through selective dechlorination steps with Bu3SnH.90

Scheme 60.

TMC 5‐exo‐trig ATRC (ref. [89] – Section 6.1).

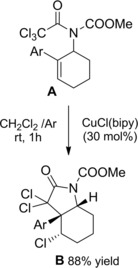

The introduction of electron‐withdrawing groups to the nitrogen atom of the amide substrates together with the use of the CuX(bipy)‐catalyst (bipy=bipyridine) in dichloroethane led the cyclization processes to occur under mild conditions.91a–91b As a relevant application, the TMC‐ATRC of trichloroacetamide A gave easy access to cis‐3a‐aryloctahydroindole derivatives B which could be converted to racemic mesembrane and crinane alkaloids (Scheme 61).

Scheme 61.

CuCl(bipy)‐promoted ATRC of trichloacetamide A (ref. [91a–b] – Section 6.1).

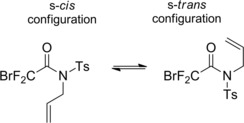

The Nagashima research group applied its efficient ATRC strategy to various N‐allyl‐N‐tosylhalodifluoroacetamides.92 They established the role of the N‐tosyl group was to lower the rotational barriers of the fluorinated amides leading to facile access of the rotamer favorable for the cyclization, namely that arranging CF2‐X and allyl group in the s‐cis configuration (Scheme 62).

Scheme 62.

N‐allyl‐N‐tosylbromodifluoroacetamide rotamers (ref. [92] – Section 6.1).

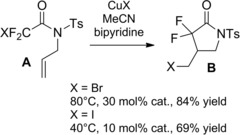

Thus, α,α‐difluoro‐γ‐halo‐γ‐lactam derivatives B were achieved in good to high yields using CuX(bipy) catalysts, the reactivity of the halodifluoroacetamides A decreasing in the order I>Br≫Cl (Scheme 63). Interestingly, the 5‐exo‐trig cyclisation onto N‐allyliodoamide substrates could be triggered by fluorescent light at room temperature with the aid of catalytic amount of either PPh3 or Pd(PPh3)4 in THF.

Scheme 63.

CuX(bipy)‐promoted ATRC of halodifluoroacetamides A (ref. [92] – Section 6.1).

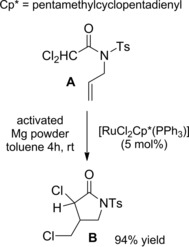

N‐Allyl‐N‐tosyldichloroacetamides were less reactive substrates for the ATRC process and when standard catalysts, such as CuCl(bipy) or RuCl2(PPh3)3 were used then high reaction temperatures and/or high catalyst loadings were required.93 However, the cyclization of these reticent substrates has been later reported by Severin and co‐workers94 by using 5 mol% of the air‐stable Ru(III)‐complex [RuCl2Cp*‐(PPh3)] as a pre‐catalyst (Cp*=pentamethylcyclopentadienyl), in combination with Mg(0) in a “supplemental activator and regenerating agent” (SARA)‐ATRC (Scheme 64).2

Scheme 64.

(SARA)‐ATRC of dichloroacetamide A promoted by [RuCl2Cp*−(PPh3)] in combination with Mg(0) (ref. [94] – Section 6.1).

In fact, the zero‐oxidation‐state Mg was the co‐catalyst committed with the in situ generation and re‐generation of the catalytically active ruthenium(II) species (activator complex) by reduction of ruthenium(III) species. The combined catalytic species converted dichloroacetamide A into the γ‐lactam derivative B with efficiency paralleling the one of the air and moisture sensitive methoxy‐bridged dimer [{RuCp*(OMe)}2] used in combination with pyridine as an activating ligand.

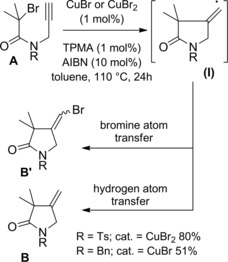

Clark and Wilson found AIBN (10 mol%) was an effective SARA additive in their copper mediated ATRC of N‐allyl tertiary and secondary alkyl bromoacetamides.95 The relatively slow 5‐exo‐trig cyclization reactions could be mediated both by CuBr or the more oxidatively stable CuBr2 (1 mol%) in conjunction with the TPMA ligand (1 mol%). Either heating at 50 °C in CH2Cl2 or at 110 °C in toluene furnished the atom transfer cyclized products in excellent yields without the need of an inert atmosphere.

Auto‐tandem catalysis is an atom‐economical and environmentally benign synthetic method involving two or more mechanistically distinct reactions promoted by a single catalyst only.

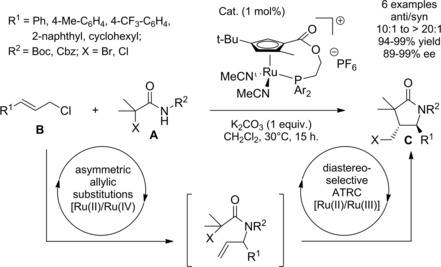

In 2013 Onitsuka and co‐workers96 disclosed an asymmetric auto‐tandem reaction catalyzed by a planar‐chiral cyclopentadienyl‐ruthenium complex able to promote both the allylic amidation and the ATRC (Scheme 65).

Scheme 65.

Asymmetric auto‐tandem allylic amidation/atom‐transfer radical cyclization catalyzed by a planar‐chiral cyclopentadienyl‐ruthenium complex (ref. [96] – Section 6.1).

In detail, the first reaction involved a [Ru(II)/Ru(IV)]‐cycle whereas the second one proceeded by a [Ru(II)/Ru(III)]‐cycle.

Thus, a sequential regio‐, enantio‐, and diastereoselective reaction of α‐haloamide derivatives A (including an α‐dichoroamide) with allylic chlorides B provided synthetically useful γ‐lactams C with multiple stereogenic centers through one‐pot sequential allylic amidation/atom‐transfer radical cyclization.

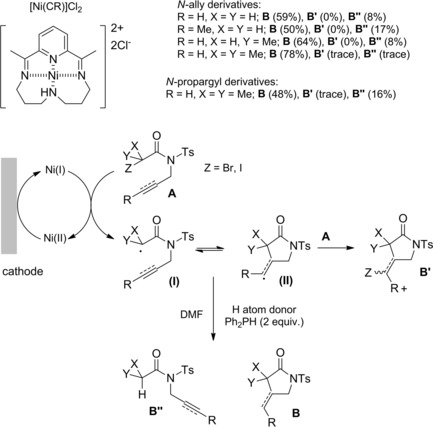

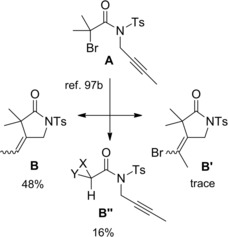

Interestingly, the concept of generating and re‐generating the active catalytic species in ATRC processes94 was also fulfilled electrochemically. Ozaki et al. studied the indirect electroreduction of N‐allyl and N‐propargyl‐α‐haloamides A by electrogenerated Ni(I) complexes in DMF or CH3CN containing a supporting electrolyte (Et4NClO4).97a–97b The electrochemical radical‐type cyclizations proceeding at room temperature required Ni(II) complexes which underwent reduction at a graphite electrode (Scheme 66). As single‐electron‐transfer catalyst the so formed Ni(I) species, reduced the haloamide substrates A to the corresponding carbamoyl radicals (I) which afforded the expected γ‐lactams via radical intermediate (II) in turn generated through a 5‐exo‐trig cyclization process.

Scheme 66.

Radical‐type cyclization of α‐haloamides A by electrogenerated Ni(I) complexes (ref. [97a–b] – Section 6.1).

To close the cycle, the formed Ni(II) returned to the active Ni(I) through cathodic electroreduction. Notably, the method converted into cyclized products B, B′, substrates that tended to yield only the simple reduction products B′′ in attempted tin hydride‐mediated cyclizations. Moreover, the selective formation of halogenated and non‐halogenated pyrrolidinones could be achieved making use of the difference in the ability of the solvent to donate a hydrogen atom to the cyclic carbon‐centered radicals.

Later, Medeiros and co‐workers obtained better results in terms of yields and selectivities by conducting the electrosyntheses in “green” solvents such as EtOH and EtOH‐H2O mixtures.98

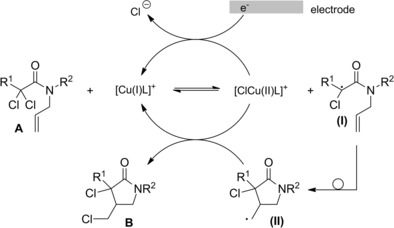

More recently, a copper‐catalyzed electrochemically mediated atom transfer radical cyclization (eATRC) of A has been developed as an easy and clean method allowing the synthesis of dichlorinated γ‐lactams B through the intermediacy of the radical species (I) and (II).99

In detail, the electrosynthesis conducted in acetonitrile used the [Cu(II)TPMA] catalyst which was activated and continuously regenerated to its active copper(I) form by reduction at a platinum (Pt) electrode (Scheme 67).

Scheme 67.

Copper‐catalyzed electrochemically mediated atom transfer radical cyclization of A (ref. [99] – Section 6.1).

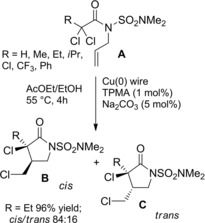

The previously discussed (Scheme 53, Section 5.) Clark's method2 for achieving four‐membered lactams was also efficient to promote 5‐exo‐trig ATRC of unsaturated α‐halogeno amides. Thus, the Cu(0)/TPMA catalyst‐system converted dimethylsulfamoyl‐N‐protected‐N‐allyl carboxamides A into cis/trans mixture of five‐membered lactams B and C in good to excellent yield (Scheme 68). Precisely, the thermodynamically more stable and synthetically useful cis‐γ‐lactams B were the prevailing diastereomers. As a key feature the Cu(0) acted as a supplementary activator and reducing agent in a SARA‐ATRC process. To note, the Cu(0)/TPMA catalyst‐system gave disappointing results when tested using N‐propargyl‐N‐tosyl‐α‐bromoisobutanamide as a suitable substrate for the corresponding 5‐exo‐dig ATRC process.

Scheme 68.

(SARA)‐ATRC of dichloroamides A promoted by Cu(0)/TPMA catalyst‐system (ref. [2] – Section 6.1).

6.2. γ‐Lactams via 5‐endo‐trig Radical Cyclization

General and productive synthetic protocols achieving γ‐lactams have also been developed looking at the alternative 5‐endo‐trig cyclization of αC‐centered radicals generated from N‐vinyl‐α‐haloamides, otherwise named α‐haloenamides.100a–100e In 2001, this topic has been authoritatively reviewed by Pearsons101 while more recently a short review on the radical cyclization of trichloroacetamides to lactams has appeared in the literature.102 For sake of completenesss we will report here only significative classical examples as well as the uncovered most recent findings.

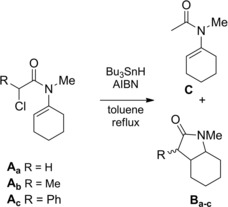

Ikeda, Ishibashi, and co‐workers were the first to show that a variety of halo‐enamides under free‐radical reducing conditions (Bu3SnH) cyclized in a “disfavored” 5‐endo‐trig manner to give five‐membered lactams with high degree of efficiency (Scheme 69).103a–103b However, some exceptions (α‐bromo amides bearing sulfur and/or aryl substituent(s) at the terminus of the N‐vinylic bond) where β‐lactams resulted from preferential 4‐exo‐trig cyclization were also described.104a–104b

Scheme 69.

5‐endo‐trig radical cyclization of α‐ haloenamides under free‐radical reducing conditions (ref. [103a–b] – Section 6.2).

When a boiling solution of Aa in toluene was treated with 1.1 equiv. of Bu3SnH in the presence of a catalytic amount of azobisisobutyronitrile (AIBN), the octahydroindol‐3‐one Ba was obtained in 63 % yield along with the reduction product C (8 %).

The cyclizations of Ab and Ac occurred more cleanly to give the corresponding lactams Bb (3α‐Me : 3β‐Me=6 : 1) and Bc (3α‐Ph : 3β‐Ph=2 : 3) in 73 and 75 % yields, respectively (Scheme 69).

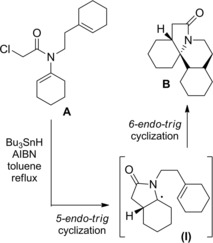

The 5‐endo‐trig radical cyclization of the α‐halo amides A generated the radical intermediate (I) from which the tetracyclic perhydroerythrinane skeleton B was built up via a successive 6‐endo‐trig cyclization onto the N‐tethered olefin group (Scheme 70).105

Scheme 70.

Radical cascade process providing the tetracyclic perhydroerythrinane skeleton B (ref. [105] – Section 6.2).

A similar radical cascade process providing the tricyclic indolizidinone B entailed an initial 5‐endo cyclization onto the dehydroamino ester group of A to generate the α‐amino ester radical (I) which in turn underwent a 6‐endo cyclization onto the N‐tethered cyclohexene moiety (Scheme 71).106a–106b

Scheme 71.

Radical cascade process providing the tricyclic indolizidinone B (ref. [106a–b] – Section 6.2).

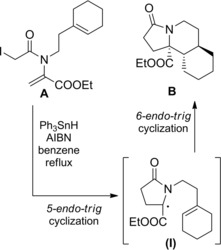

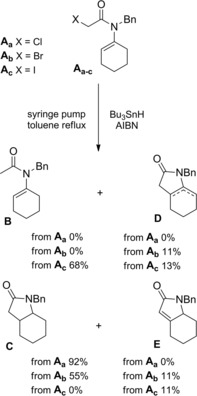

Ishibashi and co‐workers107 made unusual observations in comparing radical cyclizations of α‐chloro‐, α‐bromo‐, and α‐iodoenamide Aa‐c which were precursors of the same radical species (Scheme 72).

Scheme 72.

5‐endo‐trig radical cyclization of α‐haloenamides Aa‐c: comparison between α‐Cl, α‐Br, and α‐I substrates (ref. [107] – Section 6.2).

Slow syringe pump addition of Bu3SnH to α‐haloenamides at reflux in toluene provided a mixture of the expected cyclized/reduced product C along with cyclized/non‐reduced products D and E and directly reduced (non‐cyclized) product B in very different ratio. Surprisingly, the α‐iodoenamide was by far the poorest performer of the three.

Later, Curran and co‐workers108 established that the ability of the α‐iodoenamide Ac to provide cyclized products could be largely restored, with cyclized/reduced ratio up to >99 : 1, by adding K2CO3 as a base. Therefore, α‐chloroenamide Aa and α‐iodoenamide Ac behaved as complementary precursors, with chloride Aa giving largely cyclized/reduced product C and iodide Ac giving largely cyclized/non‐reduced products D and E.

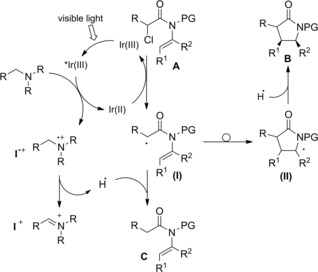

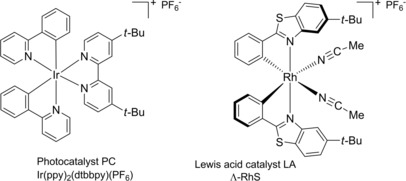

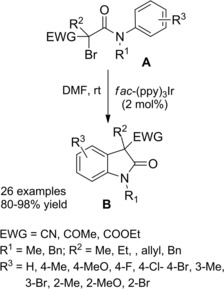

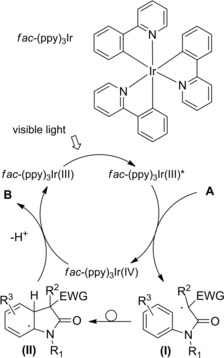

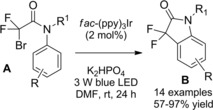

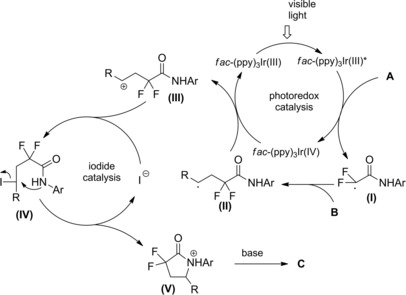

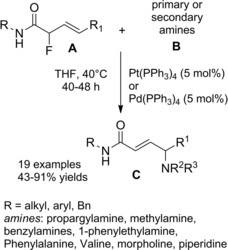

In 2016 Rueping and co‐workers14 described the first intramolecular version of their previously established method exploiting the electron‐rich Ir‐complex [Ir(tbppy)2(dtb‐bpy)PF6] to catalyze the photoredox intermolecular radical addition of α‐chloro amides onto alkenes (Scheme 78, Section 7.1.). Thus, the visible light mediated 5‐endo‐trig cyclization of α‐chloroenamides A led to the synthesis of valuable substituted γ‐lactams B (Scheme 73). The mild and tin‐free method requiring tributylamine to mediate the C−Cl bond single‐electron reduction generally proceeded in moderate to good yields with a broad range of substrates with different substitution patterns. Remarkably, in almost all cases, only one diastereoisomer was formed.

Scheme 78.

Visible light mediated reductive radical addition of the chloroamides A onto olefins B with [Ir(tbppy)2(dtb‐bpy)PF6] catalyst (ref. [112] – Section 7.1).

Scheme 73.

Visible light mediated 5‐endo‐trig cyclization of α‐chloroenamides A with [Ir(tbppy)2(dtb‐bpy)PF6] catalyst (ref. [14] – Section 6.2)

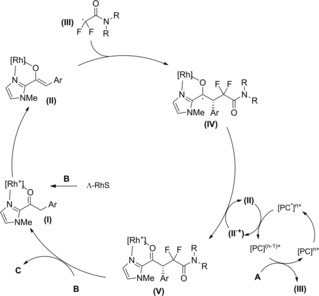

Regarding the photoreductive reaction mechanism (Scheme 74), it was assumed that irradiation with visible light triggers the photoredox catalytic cycle of Ir(III), whose stable and long‐lived excited state *Ir(III) acts as an oxidant towards trialkylamines generating the aminium radical cation I..+ The so formed Ir(II) can reduce the α‐chloroenamide A to the α‐carbonyl radical (I) which can partition between the directly reduced product C and the 5‐endo cyclized product B via the radical intermediate (II).

Scheme 74.

Mechanistic hypothesis for the photoreductive reaction mechanism (ref. [14] – Section 6.2).

7. Intermolecular α‐Alkylation of α‐Haloamides

7.1. From αC(Hal) to αC(Alk)

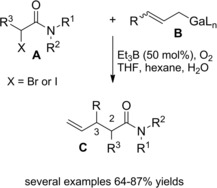

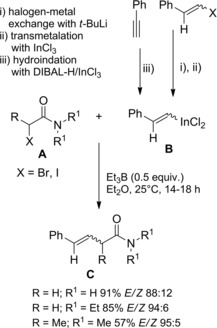

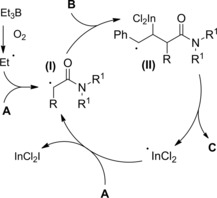

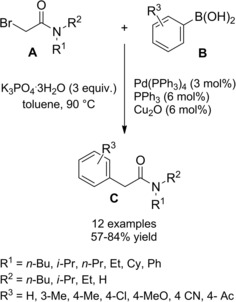

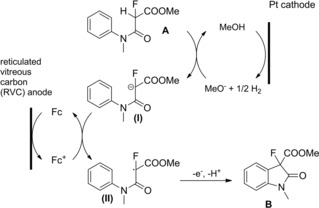

Oshima and co‐workers109 found that allylic gallium reagents gave cross‐coupling reactions with α‐iodo (or bromo) carbonyl compounds in the presence of triethylborane (Et3B) and oxygen. In particular, α‐haloamides A smoothly reacted with B (3 equiv.) at room temperature furnishing 4,5‐unsaturated amides C via C2−C3 bond formation (Scheme 75). An ethyl radical, formed in situ by Et3B oxidation, was assumed as the reactive species triggering the coupling reaction.

Scheme 75.

Cross‐coupling reactions of α‐haloamides with allylic gallium reagents in the presence of Et3B and oxygen (ref. [109] – Section 7.1).

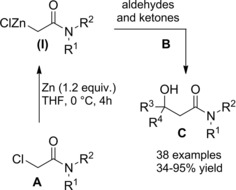

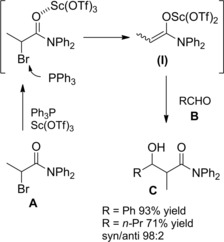

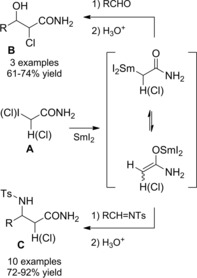

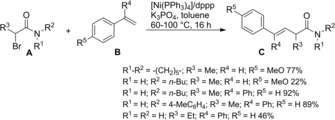

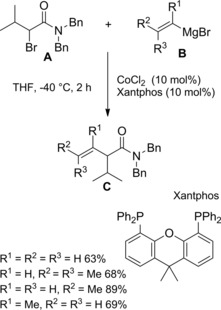

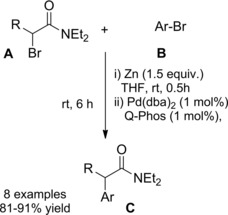

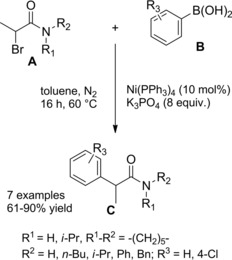

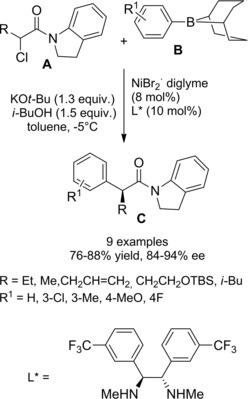

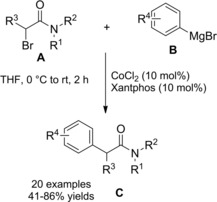

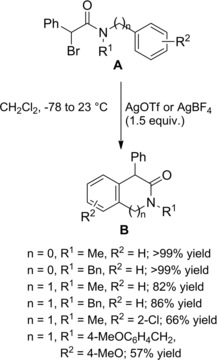

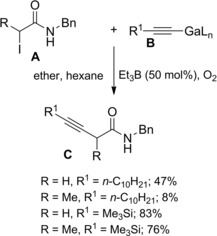

Cross‐coupling racemic secondary alkyl α‐bromoamides A with freshly prepared organozinc reagents B in the presence of the catalyst system consisting of NiCl2 .glyme and (R)‐(i‐Pr)‐Pybox ligand, paved the way to a stereoconvergent synthesis of chiral amides C (Scheme 76).15, 110

Scheme 76.

Asymmetric Negishi cross‐coupling reaction of α‐haloamides A with organozinc reagents B (ref. [15, 110] – Section 7.1).

The asymmetric Negishi reaction conducted in a solvent mixture of 1,3‐dimethyl‐2‐imidazolidinone (DMI) and THF at 0 °C well tolerated organozinc reagents with a variety of functional groups, such as olefins, ethers, imides, and nitriles. Notably, simple reduction of the resulting α‐chiral amides with LiAlH4 furnished the corresponding chiral non‐racemic primary alcohols in good yields.

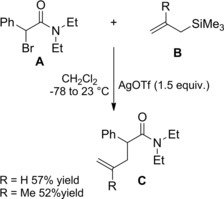

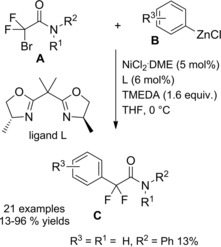

Silver‐promoted ionization of α‐bromo amides has been conveniently used as source of unexpectedly stabile carbocations which gave rise to α‐alkylated amides by intercepting carbon‐based nucleophiles (Scheme 77). Thus, allyl‐ and methallyltrimethylsilane B took part to Ag(I)‐promoted carbon‐carbon bond forming reactions with α‐bromoamide A producing the corresponding allylated products C in moderate yields.111 To note, α‐bromo amides lacking the carbocation‐stabilizing aryl group didn't take part in α‐alkylation reactions.

Scheme 77.

Ag(I)‐promoted carbon‐carbon bond forming reactions between α‐bromoamide A and allyl silanes B (ref. [111] – Section 7.1).

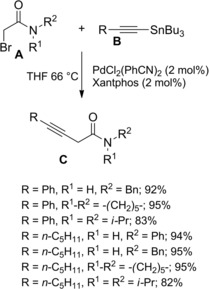

In 2014, Rueping and co‐workers112 established a tin‐free protocol to cross‐couple α‐chloro amides and alkenes where a regioselective photocatalyzed radical pathway produced α‐alkylated amides (Scheme 78). The reductive intermolecular radical addition process smoothly proceeded upon visible‐light irradiation of an acetonitrile solution of the chloroamides A and the olefins B (1 : 3 equiv. ratio) in the presence of tributylamine and the electron‐rich Ir catalyst [Ir(tbppy)2(dtb‐bpy)PF6]. The photoredox protocol being compatible with a broad spectrum of reagent partners served to achieve a series of alkylated amides C in good yields under mild conditions. With regard to the reaction mechanism it was advanced a photoredox catalytic cycle similar to the one previously described when discussing ref. [14] (Scheme 74, Section 6.2.).

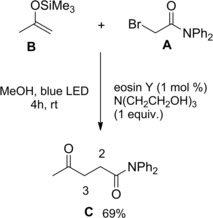

Yasuda and co‐workers reported a visible‐light‐induced radical coupling reaction of silyl enol ethers with α‐bromoketones, α‐bromoesters, and α‐bromoamides to give 1,4‐dicarbonyls.113 Thus, the reaction between the bromoacetamide A and trimethylsilyl propen‐2‐yl ether B led to the γ‐ketoamide C via C2−C3 bond formation (Scheme 79).

Scheme 79.

Visible‐light‐induced radical coupling reaction of silyl enol ethers B with α‐bromoamides A (ref. [113] – Section 7.1).

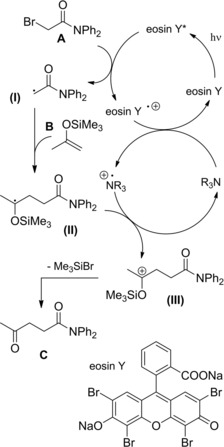

Interestingly, the inexpensive organic dye eosin Y together with triethanolamine (probably acting as a redox mediator in the eosin Y catalytic cycle) were an effective catalyst system to carry out the visible‐light‐induced, regioselective, non‐reductive radical addition process. In detail, a first SET from the photocatalyst to the α‐bromoamide generated the pivotal carbamoyl methyl radical (I) which, following addition onto the silyl enol ether B generated the siloxy‐substituted carbon radical (II) (Scheme 80). The latter, through a second SET‐step with the triethanolamine radical cation originated the siloxy‐substituted carbocation (III) from which the aimed γ‐ketoamide C resulted by bromide‐triggered trimethylsilyl group elimination.

Scheme 80.

Mechanistic hypothesis for the visible‐light‐induced, non‐reductive radical addition process (ref. [113] – Section 7.1).

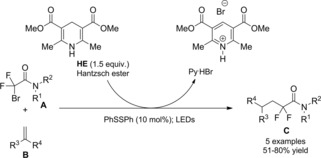

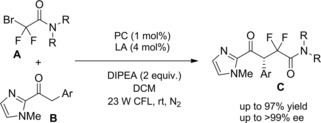

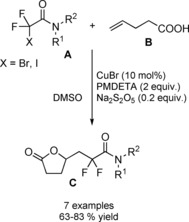

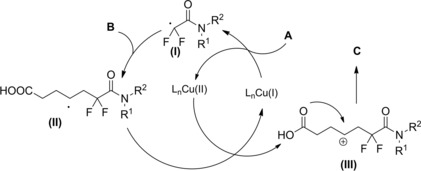

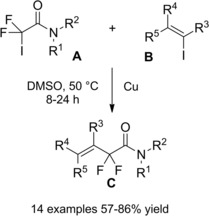

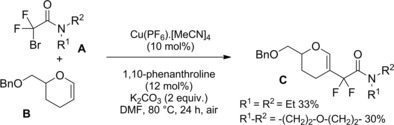

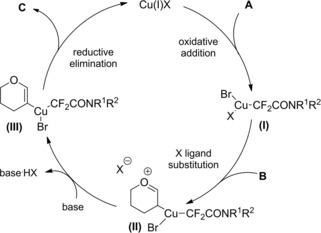

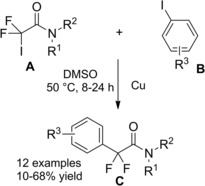

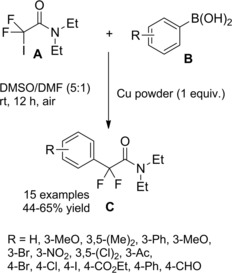

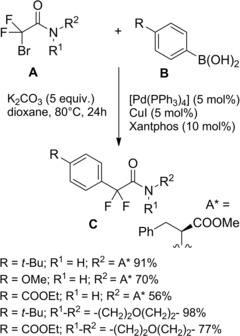

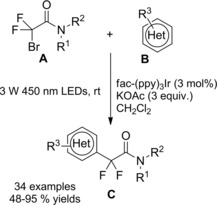

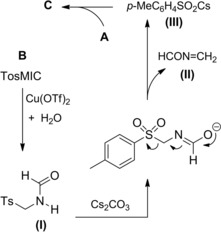

At almost the same time Cheng and co‐workers published their thiyl‐radical‐catalyzed photoreductive hydrodifluoroacetamidation of alkenes with Hantzsch ester.114 Irradiation of alkenes B and bromodifluoroacetamides A with blue light‐emitting diodes (LEDs) in acetonitrile at room temperature and in the presence of both the Hantzsch ester HE and diphenyldisulfide (Ph2S2) afforded hydrodifluoroacetamidation products C in moderate to good yields (Scheme 81). Terminal alkenes, cycloakenes, alkenes with heterocyclic moieties or alkenes bearing free as well as protected functional groups were, without distinction, good substrates for the hydrodifluoroacetamidation process. As regard the partners, tertiary, secondary and primary amides were well tolerated, the latter being inferior substrates.

Scheme 81.

Visible‐light‐induced hydrodifluoroacetamidation of alkenes with Hantzsch ester (ref. [114] – Section 7.1).

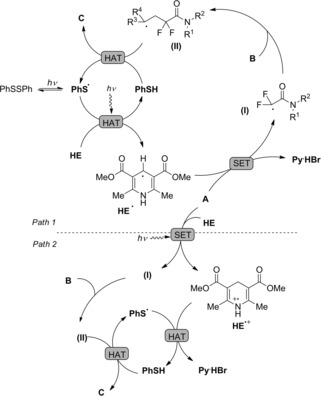

Mechanistic investigations showed that the photoreductive radical addition reaction involved the phenyl thiyl radical PhS . as the hydrogen atom transfer (HAT) and the multifunctional reagent HE as the hydrogen donor and electron donor (Scheme 82). In the presence of visible light, the diphenyldisulfide undergoes homolysis, giving PhS . entrusted with a hydrogen atom transfer (HAT) with the activated Hantzsch ester. Subsequent single electron transfer (SET) from the resulting Hantzsch ester radical HE . to α‐bromofluoroacetamide A generates the difluoroamide radical (I) together with the pyridinium derivative Py . HBr. Subsequent addition of (I) to the alkene B affords the radical intermediate (II) that, by way of a second HAT reaction involving thiophenol PhSH furnishes the difluoroalkylation product C and regenerates the phenyl thiyl radical.

Scheme 82.

Mechanistic hypothesis for the visible‐light‐induced hydrodifluoroacetamidation of alkenes with Hantzsch ester (ref. [114] – Section 7.1).

An alternative plausible reaction pathway starts with a SET reaction from the excited Hantzsch ester HE and bromodifluoroacetamide A giving the cationic radical HE .+ and amide radical (I) as intermediates.

At this stage, a HAT reaction between HE .+ and PhS . yields the pyridinium species Py . HBr together with PhSH. Eventually, the HAT between (II) and PhSH provides the hydrodifluoroacetamidation product C with recover of the thiyl radical species.

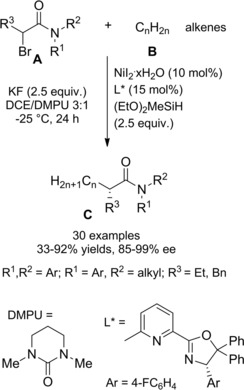

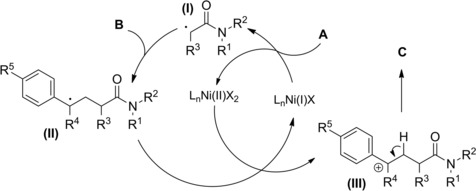

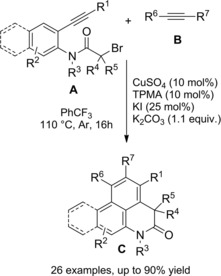

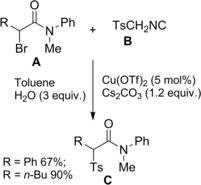

Zhou et al.115 disclosed a fruitful, mild process to achieve a range of chiral α‐alkylalkanoic amides C by way of a transition‐metal‐catalyzed cross‐coupling reaction of racemic α‐bromoamides A (1.5 equiv.) and olefins B (Scheme 83).

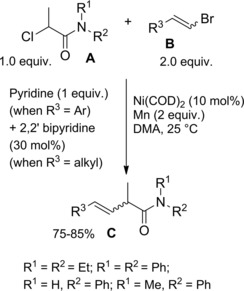

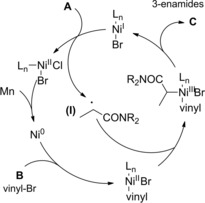

Scheme 83.

Ni‐catalyzed cross‐coupling reaction of racemic α‐bromoamides A and olefins B (ref. [115] – Section 7.1).

The method was versatile as either a variety of N‐aryl α‐bromoamides and alkenes with a diverse spectrum of functional groups were compatible. The enantioconvergent process using a Ni/Pyrox chiral catalyst provided enantioenriched compounds C with excellent terminal regioselectivity, regardless both of the starting position as well as of the number of substituents and of the geometry of the C=C bond in the olefinic substrates.

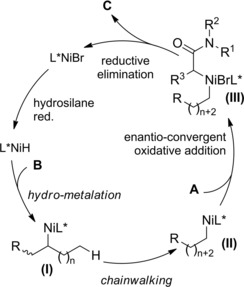

The reaction entailed a nickel‐hydride‐catalyzed alkene isomerization proceeding via hydrometalation‐chainwalking (Scheme 84). Thus, the first formed alkylnickel complex (I) is converted to the migrated alkylnickel complex (II) featuring the terminal C(sp3)‐H suitable activated for the alkylation process. The chiral ligand Pyrox bearing a methyl substituent at the C6‐position de facto promoted an asymmetric hydroalkylation reaction. Specifically, the stereochemical information generated after the oxidative addition of (II) onto the C−Br bond of the α‐haloamides A was retained in the products C in turn delivered by the Ni(III)‐complex (III) reductive elimination. Eventually, to close the catalytic circle, the L*NiH was regenerated in situ by reduction of L*NiBr with the hydrosilane reagent.

Scheme 84.

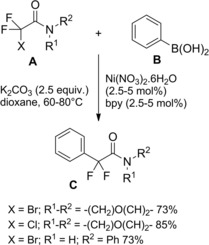

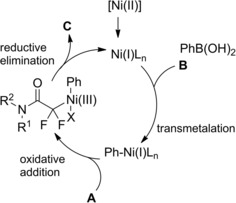

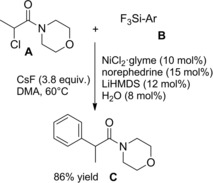

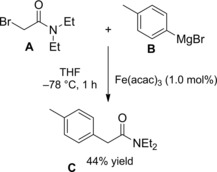

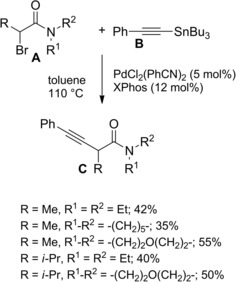

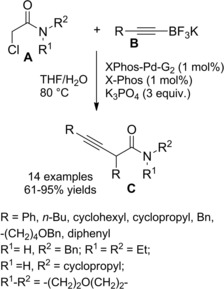

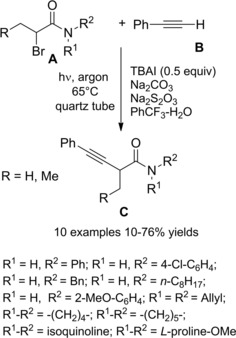

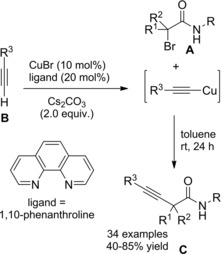

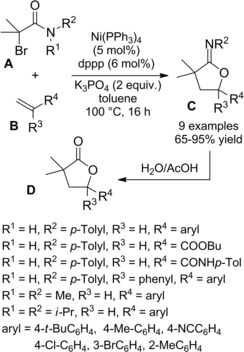

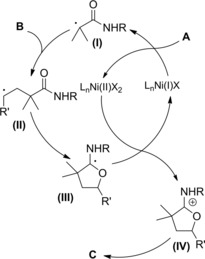

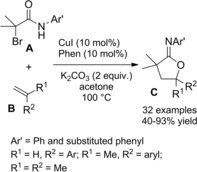

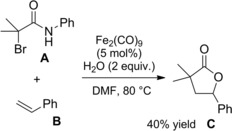

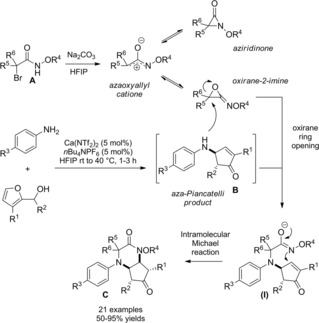

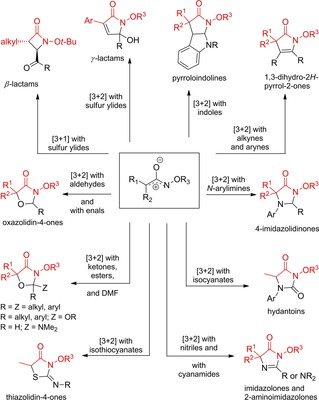

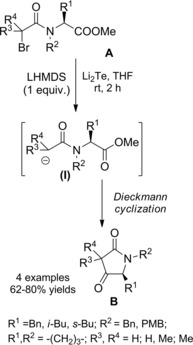

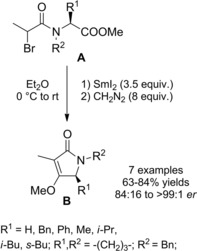

Mechanistic hypothesis for the Ni‐catalyzed cross‐coupling reaction of racemic α‐bromoamides A and olefins B (ref. [115] – Section 7.1).