Abstract

Ever since their introduction, nickel–titanium (NiTi) alloys have continued to revolutionize the field of endodontics. They have considerable advantages over the conventional stainless steel file in terms of mechanical properties. However, despite of their superior mechanical properties, NiTi alloys still pose some risk of fracture. Consequently, there has been considerable research conducted to investigate the mechanisms behind the occurrence of these procedural errors. Since the last decade, different proprietary processing procedures have been introduced to further improve the mechanical properties of NiTi alloys. These treatments include thermal, mechanical, electropolishing, and recently introduced electric discharge machining. The main purpose of these treatments is to impart a more martensitic phase into the files at normal body temperature, so that the maximum advantage of flexibility can be obtained. These heat-treated instruments also possess improved cyclic fatigue resistance when compared to conventional NiTi alloys. NiTi alloys can be subclassified as the instruments mainly containing austenitic phase (conventional NiTi, M-wire, R-phase), and those containing martensitic phase (controlled memory wire, ProTaper Gold, and Vortex Blue). Instruments based on austenitic alloys possess superelastic properties due to the stress-induced martensitic transformation. Contrary to this, martensitic alloys can easily be deformed due to phase transformation, and they can demonstrate the shape memory effect when heated. This review discusses the different phase transformations and heat treatments that the NiTi instruments undergo.

Keywords: Austenite phase, controlled memory, martensite phase, nickel–titanium (NiTi) alloys, R-phase, thermo-mechanical treatment

HIGHLIGHTS.

Nickel–titanium (NiTi) wires have gained a special place in commercial applications in dentistry because of their shape memory effect, biocompatibility, and corrosion resistance.

When stress is placed on a NiTi wire, the austenite form is converted to the martensite (stress-induced martensite) form, which can accommodate greater stress without increasing the strain.

This review discusses different phase transformations and heat treatments the NiTi instruments undergo.

It also discusses the different types of newly introduced file systems and their clinical implications.

INTRODUCTION

The introduction of nickel–titanium (NiTi) alloys in the late 1980s led to a revolution in endodontics as these files were shown to have considerable advantages over stainless steel (SS) files, especially in relation to the safety of instrumentation (1). NiTi files were able to overcome the issue of rigidity and low resistance to cyclic fatigue associated with stainless steel instruments. Other than the advantage of increased flexibility and shorter treatment time, NiTi wires also resulted in fewer procedural errors such as zipping, ledges, or transportation due to their superelasticity, compared with SS files (1, 2).

NiTi wires have gained a special commercial applications in dentistry because of their shape memory effect, and corrosion resistance. These properties of the alloy occur as a result of transition from the austenite to martensite form. This transformation requires “twinning,” which is a reversible atomic process that divides the lattice into two symmetric parts at an angle and allows reduction of strain during the transformation phase (3).

Phase Transformations

The NiTi alloys used for manufacturing of the endodontic instruments contain approximately 56% (wt) of nickel and 44% (wt) of titanium. (4) However, even a 0.1% change in the composition of these alloys can result in a 10°C change in the transformation temperature, which can subsequently affect the mechanical characteristics of these alloys (5). At room temperature, these alloys are in the austenite form, which is a body-centered cubic structure (6). On cooling, the austenite form becomes a monoclinic structure called martensite (Fig. 1) because of a classic linear thermal contraction.

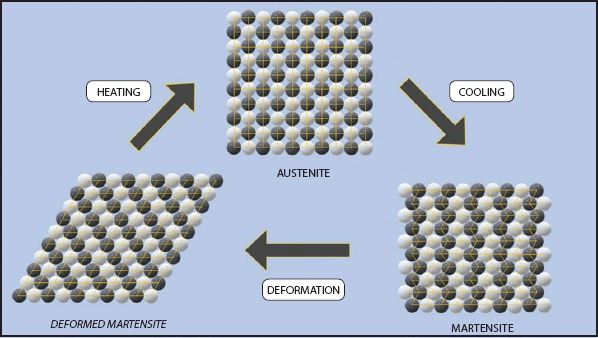

Figure 1.

Martensitic transformation: Pseudoplastic behavior of NiTi is based on austenite and martensite crystal configurations, which depend on temperature

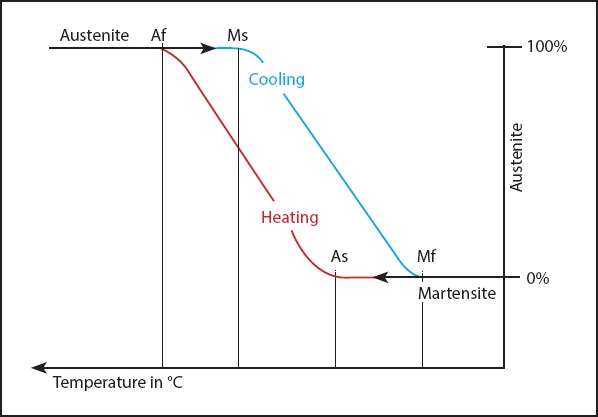

On further cooling down to Ms, that is, “Martensite Start” temperature, the contraction accelerates (7). However, when it is further cooled, the contraction rate becomes linear again until a certain point, that is, the “Martensite Finish” (Mf), indicating the point where the proportion of martensite phase in the alloy reaches 100%. Reheating this martensite phase will eventually reverse the process and yield an austenite form (Fig. 2). An intermediate phase, that is, the R-phase, or “Rhombohedral phase”, occurs on cooling before the martensitic transformation is complete (8).

Figure 2.

Temperature hysteresis in NiTi alloys. (As) austenite start temperature; (Af) austenite finish temperature; (Ms) martensite start temperature; (Mf) martensite finish temperature

When the external stresses are placed on a NiTi wire, the austenite form is converted to martensite (stress-induced martensite) form, which can accommodate greater stress without increasing the strain (up to 8%). As a result, a NiTi file has transformational elasticity, also known as superelasticity, or the ability to return to its original shape after being deformed (9). The stress-induced martensitic state is not stable at room temperature, so an immediate retransformation from the martensitic to the austenite phase occurs once the stress is released. This leads to a spring-back of the endodontic instrument to the original shape when it is removed from the canal (10).

A stress-induced change without permanent deformation for up to 8% strain is possible in NiTi alloys, as opposed to 1% in stainless steel (11). On releasing the stress, the martensite form reverts back to the original shape, that is, the austenite form (12).

Superelasticity

NiTi alloys show the phenomenon of superelasticity where the stress remains constant, despite the increase in strain up till a certain range. Their superelastic property is caused by the austenite transforming into the martensite form. The strain remains constant during this transformation until the whole NiTi mass has converted to the martensite form, which would indicate that the superelasticity phase has ended (13). If deformation is continued beyond this point, the stress/strain curve will take the shape of classic relationship as the potential of the crystals in the structure to absorb strain is exhausted (8). However, if the plastic deformation limit is not reached, the deformation will remain reversible.

Fracture mechanisms

NiTi instruments possess a risk of separation or fracture during use because of torsional or cyclic fatigue (14). Distortion of rotary NiTi files is often not visible without magnification. Consequently, these instruments can fracture without any warning signs as opposed to SS instruments where distortion can be perceived easily (15). Cyclic fatigue occurs due to the instrument rotating in a curved canal and generating repetitive tension/compression cycles that eventually lead to metal fatigue (16), whereas torsional fatigue is a result of different parts of the file rotating at different speeds. Clinically, torsional fatigue is the result of the instrument tip binding to the canal dentin, whereas the shank continues to rotate, creating a torque that results in torsional fracture (17). Torsional fatigue resistance is basically how much a file can twist before fracturing. This property is desirable during the use in a narrow and constricted canal where torsional load would be high during use.

Manufacturers are constantly trying to develop changes in NiTi rotary systems to improve the mechanical properties of these instruments, especially the fatigue resistance. One of the changes incorporated was heat treatment of these alloys, which produced instruments with superior mechanical properties (18). Other methods used produced instruments with different cross-sectional designs, or incorporated new manufacturing processes (19).

Thermal treatments

Thermal treatments aim to affect the transition temperatures of the NiTi alloys and subsequently modify the fatigue resistance, whether it is torsional or cyclic fatigue (20). A proprietary thermal treatment is applied to the alloy during the R-phase when it undergoes martensite transformation. This heat treatment maintains a crystallographic structure and apparently gives these files a higher fracture resistance and increased flexibility (21). Recently, manufacturers have developed NiTi superelastic alloys with a special heat treatment so that these NiTi alloys have a stable martensite phase in different clinical conditions. There are kinds of heat-treated NiTi alloys available: M-wire, R-phase, and CM wire.

The M-wire was introduced in 2007, and is essentially a thermally processed NiTi alloy that is stable at body temperature. It was developed via thermo-mechanical processing and contains three crystalline phases: deformed and micro-twinned martensite, R-phase, and austenite (6). The presence of the martensite phase improves the fatigue resistance of the file, but at the expense of hardness, which prompts the need for different surface treatments (22). Examples of M-wire files in market are ProFile GT series, Vortex files, ProTaper Next, Reciproc, and WaveOne. Literature reports a significantly improved cyclic fatigue resistance of M-wire, for example, ProTaper Next in comparison with conventional NiTi instruments. However, many studies show no difference in cyclic fatigue of M-wire and conventional NiTi files (23-26).

The other crystalline phase, that is, the R-phase (pre-martensitic) occurs along a very narrow temperature range on the heating or cooling curve between martensitic and austenitic forms. These instruments have increased resistance to cyclic fatigue along with greater flexibility than conventional NiTi files (27). An example is the twisted file (TF), which is manufactured using the twisting method. The basic austenite phase is transformed into the R-phase by heating and cooling. Serial heating and cooling would convert the twisted R-phase back to the austenite crystalline phase, which would become superelastic while stressed. This treatment can result in increased cyclic fatigue resistance of TF (11). However, literature reports that the R-phase instrument has a lower torsional strength than conventional NiTi files (28-31).

CM wires were introduced in 2010. They have a lower nickel content (52% wt.), as compared to other NiTi files. To incorporate extreme flexibility, these files undergo special thermo-mechanical treatment that also improves the shape memory effect of these files. Consequently, they do not have the rebound effect after unloading, and their original shape is restored after heat application or autoclaving procedure. Clinically, this incurs the benefit of pre-bending this file before placing in a curved canal, especially with patients with limited mouth opening. The CM wire has a stable martensite phase because the austenite finishing temperature is above the working temperature. This implies that thermally processed controlled memory alloys would mostly or totally be in the martensite phase at body temperature (32) (Fig. 3). CM instruments also have increased resistance to cyclic fatigue (300%–800% more fatigue resistant) because of their unique manufacturing process as they do not rebound to their original shape (33). However, they have one major drawback of increased tendency of permanent plastic deformation during use. Due to this weakness, these instruments are recommended for single use only (34). Some commercial brands of CM files include Hyflex CM, Thypoon Infinite Flex NiTi Files, V-Taper 2H, and Hyflex electrical discharge machining (EDM).

Figure 3.

Comparison of austenitic (ProTaper Next) and martensitic NiTi files (CM wire). (a) The austenitic NiTi file cannot be bent at room temperature; (b) The martensitic file can be bent at room temperature

Surface treatments

When electric current is used to deposit metallic ions on one of the electrodes, the process is called electroplating. Any electrochemical process that would aim to reduce the surface irregularities of a material is known as electropolishing (8). Physical vapor deposition is a process whereby NiTi instruments are coated with a thin layer of titanium nitride. This results in an improved cutting efficiency and corrosion resistance without affecting the superelasticity of these instruments (35).

Recently introduced NiTi file systems

BT-RaCe (FKG Dentaire) is a new file system introduced in 2013, derived from conventional austenite NiTi. These files have characteristic uniform triangular cross section and a blunt tip design called the booster tip. They undergo a surface electrochemical treatment that increases the resistance to cyclic fatigue (36). The booster tip is claimed to reduce the occurrence of deviation and transportation. This specialized tip is the unique feature of the BT-RaCe system that allows it to track canal curvatures with less stress and increased safety. Burklein et al. compared root canal preparations using the ProTaper Next and BT-RaCe systems and found no significant differences between them in canal transportation and straightening. The triangular cross section design has the tendency to make the instrument more flexible than other cross section designs (21, 37).

Hyflex CM (Coltène/Whaledent) is a NiTi rotary system that was first manufactured in 2011, and it is the first thermo-mechanically treated NiTi endodontic alloy. NiTi files made up of CM wire do not have superelastic properties, neither at room temperature nor at body temperature in comparison to conventional NiTi files (22). The austenite finish temperature of Hyflex CM is 47–55°C, which is above the intracanal temperature (38). These files are reported to have a 300% times higher resistance to cyclic fatigue than conventional NiTi systems (38-41). This system tends to reduce the canal straightening effect due to its controlled memory effect. Studies have confirmed the reduced canal straightening of Hyflex CM when compared to other file systems (39, 40, 42). Instruments based on the CM wire also have an increased flexibility compared to M-wire and other conventional NiTi instruments (43-46). They also have increased cutting efficiency in lateral action compared to conventional NiTi systems, in spite of having greater flexibility (47, 48).

All these characteristics of Hyflex CM are attributed to the greater proportion of the martensitic component in the alloy (39, 40). The files of this system consists of various cross-sectional designs and tapers, that is, triangular (sizes 25,.08 taper and 20,.06 taper) and quadrangular (sizes 20,.04 taper, 25,.04 taper, 30,.04 taper, and 40,.04 taper) (49).

The Hyflex EDM (Coltène-Whaledent) file system introduced in 2016 is considered as an evolution of the Hyflex CM, as Hyflex EDM is produced with CM alloy and uses the EDM technology. EDM is a recognized noncontact machining process that allows a precise quantity of material removed via pulsed electric discharge. (50) Work pieces are machined in the EDM manufacturing process by generating a potential between a work piece and a tool. The sparks produced in this process cause the surface layer of the material to melt and evaporate (51). This creates a unique surface of new NiTi files and provides them with excellent mechanical properties by giving the instruments a rough and hard surface and increasing their cutting efficiency (52, 53). The transformation temperatures of Hyflex EDM are found to be higher compared to Hyflex CM. According to the X-ray diffraction analysis, Hyflex EDM consists of martensite and substantial amounts of R-phase, whereas Hyflex CM has a mixture of martensite and austenite phases (54). The lack of austenitic phase in Hyflex EDM could be due to its raised austenitic start temperature (as ~42°C) that prevents the formation of austenite at room or body temperature (38, 54). Hyflex EDM still has a higher hardness than conventional CM wires, despite absence of or reduced austenitic phase, thus substantiating the hardening effect of EDM (54). Hyflex EDM exhibits a significantly increased cyclic fatigue resistance in comparison to Hyflex CM, M-wire based instruments, and conventional NiTi systems (19, 43, 54-57). This system also tends to create centered canal preparations, hence respecting the original root canal anatomy (49, 58, 59). Currently, there is no evidence regarding the superiority of Hyflex EDM cutting efficiency. This system is composed of three instruments used in a sequence: one for coronal (size 25,12 taper) enlargement; one for glide path (size 10,.05 taper); and last one for canal shaping. The file for canal shaping has a variable taper, 0.25 mm tip with a taper 0.08 for the initial 4 mm, which decreases to 0.04 toward the midpoint. Hyflex EDM also has different cross section designs along its length, having a quadrangular cross section at the starting point, rectangular at the middle, and becoming triangular at the coronal part. A speed of 500 rpm with a torque of 2.5 N/cm is recommended for this system (19, 59).

Vortex Blue and Protaper Gold (Dentsply) were first introduced in 2011 as ProFile Vortex Blue. These files are manufactured through a complex heating–cooling proprietary treatment resulting in a visible titanium oxide layer on the surface, which imparts a blue colour to the alloy. They are now available as two gold and two blue heat-treated systems. Two of them are used in reciprocating motion (Reciproc Blue, VDW; WaveOne Gold), and other two are used in rotary motion (ProFile Vortex Blue; ProTaper Gold) (60). These systems can be deformed and hence also display controlled memory effect (61). They differ from CM wire systems as they are ground before they undergo the post-machining heat treatment (44). The austenite finish temperature of Vortex Blue was found to be around body temperature (38°C) whereas the martensitic start temperature is around 31°C. Despite having lower transformation temperatures, these systems contain a greater amount of stable martensite than M-wire, thus increasing the softness and ductility of the alloy (62). ProTaper Gold has a transformation temperature well above the body temperature, leading to mainly martensitic or R-phase under clinical conditions (63). The flexibility and fatigue resistance of all Blue heat-treated and Gold instruments was found to be high as compared with the conventional NiTi and M-wire instruments (56, 61-70). All Gold and Blue heat-treated systems produce well-centered canal preparations in especially severely curved canals (58, 71, 72).

Max-Wire (Martensite-Austenite-electropolish-fileX), recently introduced by FKG Dentaire, is the first endodontic file system that combines both the shape memory effect and superelasticity in a single system in clinical applications. The two available marketed instruments of Max-Wire are XP-endo Shaper and XP-endo Finisher (both FKG Dentaire). These files are relatively straight in their martensitic phase at room temperature, which changes to curved shape due to phase transformation to the austenitic phase when exposed to intracanal temperature. Hence, it possesses the shape memory effect when inserted into the canal (martensite state to austenite state) and exhibits superelasticity during canal preparation. The curved shape of these files enables them to adapt very well to canal irregularities (60). Studies have reported significantly increased cyclic fatigue resistance of XP-endo Shaper compared to Hyflex CM, Vortex Blue, and iRaCe (73, 74). However, they had less torsional resistance compared to Vortex Blue (74, 75)

2Shape File System (MicroMega) is a new generation file system produced with a proprietary heat treatment (T-wire), which aims to enhance both the flexibility and cyclic fatigue resistance by 40% in comparison to One Shape (53, 76). This system has the latest generation of cross section with triple helix, two main cutting edges, and one secondary cutting edge, which make a perfect compromise between cutting efficiency and debris removal. 2Shape rotary file system consists of two files: a TS1 (25/.04) and TS2 (25/.06) (77).

One Curve (MicroMega) is a single file NiTi rotary system introduced in 2017, based on one single file for shaping root canal (78). One Curve file system is produced with a C-wire heat treatment technology. As claimed by the manufacturer, this instrument has a controlled memory and thus the ability to pre-bend, which enhances the shaping of root canal (79). The One Curve file has a variable cross section for a better centering ability and cutting efficiency (79). The cyclic fatigue resistance of One Curve file is reported to be 2.4 times higher when compared to OneShape system (80).

The composition, alloy, properties, and recommended use of these new systems are summarized in Table 1.

TABLE 1.

Composition, properties, and recommended use of different NiTi systems

| NiTi System | Alloy | Composition | Properties | Recommended use |

|---|---|---|---|---|

| Hyflex CM | CM wire | Martensite with different amounts of austenite and R-phase | • No superelasticity • High resistance to cyclic fatigue • Increased flexibility |

• Severely curved canals • Bypassing ledges |

| Hyflex EDM | CM wire; EDM technology | No austenite phase | • Increased cutting efficiency • Increased cyclic fatigue resistance |

• Straighter canals • Used in combination with Hyflex CM in severely curved canals |

| BT-RaCe | Conventional NiTi | Austenite-Electropolished | • Triangular cross section • Booster tip |

• Conservative instrumentation of all types of canals • Original canal shape maintained |

| Vortex Blue and ProTaper Gold | M-wire | Martensite TiO2 layer on surface | • Shape memory • Super elasticity • Increased cyclic fatigue resistance |

• Severely curved canals • Bypassing ledges |

| XP-endo Shaper | Max-Wire | • High resistance to cyclic fatigue | • Complex root canal morphology | |

| XP-endo Finisher | • Superelasticity • Shape memory |

|||

| 2Shape | T-wire | • Asymmetric cross section • Additional cutting edges |

• Complex root canal morphology | |

| One Curve | C wire | • Increased flexibility • Better cyclic fatigue resistance |

• Complex root canal morphology |

CONCLUSION

With emerging technology, we see endodontics being swept away in the latest wave of technization. There is plethora of different systems available, and a large number of studies have focused on various physical and chemical aspects of NiTi files. Various proprietary methods and treatments have been introduced to enhance the cutting ability and file design. Files with the austenite phase have super elastic properties and are recommended to be used in straight or mildly curved canals, whereas those instruments composed of the martensite phase possess high flexibility along with increased resistance to cyclic fatigue and are recommended to be used while preparing canals with complex curvatures. Heat-treated and controlled memory NiTi alloys are being used widely nowadays as reflected by the current literature. These newer designs have increased flexibility and reduced shape memory property. When used clinically, these instruments can better penetrate the entrance of the canals as they can be pre-bent to maintain the flexed shape.

While we are riding the wave, let us not forget that an experienced endodontist is the foremost formula for success, whereas the material being used is only a secondary factor. Prudent use of contemporary devices along with the basics of anatomy will lead to a predictable higher quality of root canal treatment on a broader basis, thus helping to preserve more teeth for a greater number of years.

Footnotes

Conflict of interest: The authors declared no conflict of interest.

Ethics Committee Approval: As this is a secondary study, it doesn’t require ERC approval.

Peer-review: Externally peer-reviewed.

Financial Disclosure: The authors declared no financial support.

Authorship contributions: Concept – S.T.; Design – K.Z.; Supervision – F.U.; Funding - None; Materials - None; Data collection &/or processing – S.T., K.Z.; Analysis and/or interpretation – S.T., K.Z.; Literature search – S.T., K.Z.; Writing – None; Critical Review – F.U.

REFERENCES

- 1.Walia HM, Brantley WA, Gerstein H. An initial investigation of the bending and torsional properties of Nitinol root canal files. J Endod. 1988;14(7):346–51. doi: 10.1016/s0099-2399(88)80196-1. [DOI] [PubMed] [Google Scholar]

- 2.Liu SB, Fan B, Cheung GS, Peng B, Fan MW, Gutmann JL, et al. Cleaning effectiveness and shaping ability of rotary ProTaper compared with rotary GT and manual K-Flexofile. Am J Dent. 2006;19(6):353–8. [PubMed] [Google Scholar]

- 3.Wayman CM, Ōtsuka K. Shape memory materials. Cambridge University Press; 1998. [Google Scholar]

- 4.Mohammadi Z, Soltani MK, Shalavi S, Asgary S. A Review of the Various Surface Treatments of NiTi Instruments. Iran Endod J. 2014;9(4):235–40. [PMC free article] [PubMed] [Google Scholar]

- 5.Yoneyama T, Miyazaki S. Shape memory alloys for biomedical applications. Cambridge: Boca Raton Woodhead Pub, CRC Press; 2009. [Google Scholar]

- 6.Ye J, Gao Y. Metallurgical characterization of M-Wire nickel-titanium shape memory alloy used for endodontic rotary instruments during low-cycle fatigue. J Endod. 2012;38(1):105–7. doi: 10.1016/j.joen.2011.09.028. [DOI] [PubMed] [Google Scholar]

- 7.Aoki T, Okafor IC, Watanabe I, Hattori M, Oda Y, Okabe T. Mechanical properties of cast Ti-6Al-4V-XCu alloys. J Oral Rehabil. 2004;31(11):1109–14. doi: 10.1111/j.1365-2842.2004.01347.x. [DOI] [PubMed] [Google Scholar]

- 8.Ounsi HF, Nassif W, Grandini S, Salameh Z, Neelakantan P, Anil S. Evolution of Nickel-titanium Alloys in Endodontics. J Contemp Dent Pract. 2017;18(11):1090–6. doi: 10.5005/jp-journals-10024-2181. [DOI] [PubMed] [Google Scholar]

- 9.Zhou H, Peng B, Zheng YF. An overview of the mechanical properties of nickel–titanium endodontic instruments. Endod Topics. 2013;29(1):42–54. [Google Scholar]

- 10.Viana AC, Chaves Craveiro de Melo M, Guiomar de Azevedo Bahia M, Lopes Buono VT. Relationship between flexibility and physical, chemical, and geometric characteristics of rotary nickel-titanium instruments. Oral Surg Oral Med Oral Pathol Oral Radiol Endod. 2010;110(4):527–33. doi: 10.1016/j.tripleo.2010.05.006. [DOI] [PubMed] [Google Scholar]

- 11.Shen Y, Zhou HM, Zheng YF, Peng B, Haapasalo M. Current challenges and concepts of the thermomechanical treatment of nickel-titanium instruments. J Endod. 2013;39(2):163–72. doi: 10.1016/j.joen.2012.11.005. [DOI] [PubMed] [Google Scholar]

- 12.Otsuka K, Ren X. Physical metallurgy of Ti–Ni-based shape memory alloys. Prog Mater Sci. 2005;50(5):511–678. [Google Scholar]

- 13.Thompson SA. An overview of nickel-titanium alloys used in dentistry. Int Endod J. 2000;33(4):297–310. doi: 10.1046/j.1365-2591.2000.00339.x. [DOI] [PubMed] [Google Scholar]

- 14.Kim JY, Cheung GS, Park SH, Ko DC, Kim JW, Kim HC. Effect from cyclic fatigue of nickel-titanium rotary files on torsional resistance. J Endod. 2012;38(4):527–30. doi: 10.1016/j.joen.2011.12.018. [DOI] [PubMed] [Google Scholar]

- 15.Parashos P, Gordon I, Messer HH. Factors influencing defects of rotary nickel-titanium endodontic instruments afterclinical use. J Endod. 2004;30(10):722–5. doi: 10.1097/01.don.0000129963.42882.c9. [DOI] [PubMed] [Google Scholar]

- 16.Sattapan B, Nervo GJ, Palamara JE, Messer HH. Defects in rotary nickel-titanium files after clinical use. J Endod. 2000;26(3):161–5. doi: 10.1097/00004770-200003000-00008. [DOI] [PubMed] [Google Scholar]

- 17.Peters OA, Barbakow F. Dynamic torque and apical forces of ProFile.04 rotary instruments during preparation of curved canals. Int Endod J. 2002;35(4):379–89. doi: 10.1046/j.0143-2885.2001.00494.x. [DOI] [PubMed] [Google Scholar]

- 18.Bulem ÜK, Kececi AD, Guldas HE. Experimental evaluation of cyclic fatigue resistance of four different nickel-titanium instruments after immersion in sodium hypochlorite and/or sterilization. J Appl Oral Sci. 2013;21(6):505–10. doi: 10.1590/1679-775720130083. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 19.Pedullà E, Lo Savio F, Boninelli S, Plotino G, Grande NM, La Rosa G, et al. Torsional and Cyclic Fatigue Resistance of a New Nickel-Titanium Instrument Manufactured by Electrical Discharge Machining. J Endod. 2016;42(1):156–9. doi: 10.1016/j.joen.2015.10.004. [DOI] [PubMed] [Google Scholar]

- 20.McCormick P, Liu Y. Thermodynamic analysis of the martensitic transformation in NiTi—II. Effect of transformation cycling. Acta Metallurgica et Materialia. 1994;42(7):2407–13. [Google Scholar]

- 21.Kim HC, Yum J, Hur B, Cheung GS. Cyclic fatigue and fracture characteristics of ground and twisted nickel-titanium rotaryfiles. J Endod. 2010;36(1):147–52. doi: 10.1016/j.joen.2009.09.037. [DOI] [PubMed] [Google Scholar]

- 22.Zhou HM, Shen Y, Zheng W, Li L, Zheng YF, Haapasalo M. Mechanical properties of controlled memory and superelastic nickel-titanium wires used in the manufacture of rotary endodontic instruments. J Endod. 2012;38(11):1535–40. doi: 10.1016/j.joen.2012.07.006. [DOI] [PubMed] [Google Scholar]

- 23.Alapati SB, Brantley WA, Iijima M, Clark WA, Kovarik L, Buie C, et al. Metallurgical characterization of a new nickel-titanium wire for rotary endodontic instruments. J Endod. 2009;35(11):1589–93. doi: 10.1016/j.joen.2009.08.004. [DOI] [PubMed] [Google Scholar]

- 24.Ruiz-Sánchez C, Faus-Matoses V, Alegre-Domingo T, Faus-Matoses I, Faus-Llácer VJ. An in vitro cyclic fatigue resistance comparison of conventional and new generation nickel-titanium rotary files. J Clin Exp Dent. 2018;10(8):e805–9. doi: 10.4317/jced.55091. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 25.Gambarini G, Grande NM, Plotino G, Somma F, Garala M, De Luca M, et al. Fatigue resistance of engine-driven rotary nickel-titanium instruments produced by new manufacturing methods. J Endod. 2008;34(8):1003–5. doi: 10.1016/j.joen.2008.05.007. [DOI] [PubMed] [Google Scholar]

- 26.Pérez-Higueras JJ, Arias A, de la Macorra JC, Peters OA. Differences in cyclic fatigue resistance between ProTaper Next and ProTaper Universal instruments at different levels. J Endod. 2014;40(9):1477–81. doi: 10.1016/j.joen.2014.02.025. [DOI] [PubMed] [Google Scholar]

- 27.Ha JH, Kim SK, Cohenca N, Kim HC. Effect of R-phase heat treatment on torsional resistance and cyclic fatigue fracture. J Endod. 2013;39(3):389–93. doi: 10.1016/j.joen.2012.11.028. [DOI] [PubMed] [Google Scholar]

- 28.Yum J, Cheung GS, Park JK, Hur B, Kim HC. Torsional strength and toughness of nickel-titanium rotary files. J Endod. 2011;37(3):382–6. doi: 10.1016/j.joen.2010.11.028. [DOI] [PubMed] [Google Scholar]

- 29.Park SY, Cheung GS, Yum J, Hur B, Park JK, Kim HC. Dynamic torsional resistance of nickel-titanium rotary instruments. J Endod. 2010;36(7):1200–4. doi: 10.1016/j.joen.2010.02.016. [DOI] [PubMed] [Google Scholar]

- 30.King JB, Roberts HW, Bergeron BE, Mayerchak MJ. The effect of autoclaving on torsional moment of two nickel-titanium endodontic files. Int Endod J. 2012;45(2):156–61. doi: 10.1111/j.1365-2591.2011.01958.x. [DOI] [PubMed] [Google Scholar]

- 31.Casper RB, Roberts HW, Roberts MD, Himel VT, Bergeron BE. Comparison of autoclaving effects on torsional deformation and fracture resistance of three innovative endodontic file systems. J Endod. 2011;37(11):1572–5. doi: 10.1016/j.joen.2011.07.008. [DOI] [PubMed] [Google Scholar]

- 32.Metzger Z, Teperovich E, Zary R, Cohen R, Hof R. The self-adjusting file (SAF). Part 1:respecting the root canal anatomy-a new concept of endodontic files and its implementation. J Endod. 2010;36(4):679–90. doi: 10.1016/j.joen.2009.12.036. [DOI] [PubMed] [Google Scholar]

- 33.Shen Y, Qian W, Abtin H, Gao Y, Haapasalo M. Fatigue testing of controlled memory wire nickel-titanium rotary instruments. J Endod. 2011;37(7):997–1001. doi: 10.1016/j.joen.2011.03.023. [DOI] [PubMed] [Google Scholar]

- 34.Peters OA, Gluskin AK, Weiss RA, Han JT. An in vitro assessment of the physical properties of novel Hyflex nickel-titanium rotary instruments. Int Endod J. 2012;45(11):1027–34. doi: 10.1111/j.1365-2591.2012.02067.x. [DOI] [PubMed] [Google Scholar]

- 35.Schäfer E. Effect of physical vapor deposition on cutting efficiency of nickel-titanium files. J Endod. 2002;28(12):800–2. doi: 10.1097/00004770-200212000-00002. [DOI] [PubMed] [Google Scholar]

- 36.Lopes HP, Elias CN, Vieira VT, Moreira EJ, Marques RV, de Oliveira JC, et al. Effects of electropolishing surface treatment on the cyclic fatigue resistance of BioRace nickel-titanium rotary instruments. J Endod. 2010;36(10):1653–7. doi: 10.1016/j.joen.2010.06.026. [DOI] [PubMed] [Google Scholar]

- 37.Zhang EW, Cheung GS, Zheng YF. Influence of cross-sectional design and dimension on mechanical behavior of nickel-titanium instruments under torsion and bending:a numerical analysis. J Endod. 2010;36(8):1394–8. doi: 10.1016/j.joen.2010.04.017. [DOI] [PubMed] [Google Scholar]

- 38.Shen Y, Zhou HM, Zheng YF, Campbell L, Peng B, Haapasalo M. Metallurgical characterization of controlled memory wire nickel-titanium rotary instruments. J Endod. 2011;37(11):1566–71. doi: 10.1016/j.joen.2011.08.005. [DOI] [PubMed] [Google Scholar]

- 39.Marceliano-Alves MF, Sousa-Neto MD, Fidel SR, Steier L, Robinson JP, Pécora JD, et al. Shaping ability of single-file reciprocating and heat-treated multifile rotary systems:a micro-CT study. Int Endod J. 2015;48(12):1129–36. doi: 10.1111/iej.12412. [DOI] [PubMed] [Google Scholar]

- 40.Saber SE, Nagy MM, Schäfer E. Comparative evaluation of the shaping ability of ProTaper Next, iRaCe and Hyflex CM rotary NiTi files in severely curved root canals. Int Endod J. 2015;48(2):131–6. doi: 10.1111/iej.12291. [DOI] [PubMed] [Google Scholar]

- 41.Plotino G, Testarelli L, Al-Sudani D, Pongione G, Grande NM, Gambarini G. Fatigue resistance of rotary instruments manufactured using different nickel-titanium alloys:a comparative study. Odontology. 2014;102(1):31–5. doi: 10.1007/s10266-012-0088-8. [DOI] [PubMed] [Google Scholar]

- 42.Bürklein S, Börjes L, Schäfer E. Comparison of preparation of curved root canals with Hyflex CM and Revo-S rotary nickel-titanium instruments. Int Endod J. 2014;47(5):470–6. doi: 10.1111/iej.12171. [DOI] [PubMed] [Google Scholar]

- 43.Goo HJ, Kwak SW, Ha JH, Pedullà E, Kim HC. Mechanical Properties of Various Heat-treated Nickel-titanium Rotary Instruments. J Endod. 2017;43(11):1872–7. doi: 10.1016/j.joen.2017.05.025. [DOI] [PubMed] [Google Scholar]

- 44.Pereira ÉS, Viana AC, Buono VT, Peters OA, Bahia MG. Behavior of nickel-titanium instruments manufactured with different thermal treatments. J Endod. 2015;41(1):67–71. doi: 10.1016/j.joen.2014.06.005. [DOI] [PubMed] [Google Scholar]

- 45.Pongione G, Pompa G, Milana V, Di Carlo S, Giansiracusa A, Nicolini E, et al. Flexibility and resistance to cyclic fatigue of endodontic instruments made with different nickel-titanium alloys:a comparative test. Ann Stomatol (Roma) 2012;3(3-4):119–22. [PMC free article] [PubMed] [Google Scholar]

- 46.Testarelli L, Plotino G, Al-Sudani D, Vincenzi V, Giansiracusa A, Grande NM, et al. Bending properties of a new nickel-titanium alloy with a lower percent by weight of nickel. J Endod. 2011;37(9):1293–5. doi: 10.1016/j.joen.2011.05.023. [DOI] [PubMed] [Google Scholar]

- 47.Morgental RD, Vier-Pelisser FV, Kopper PM, de Figueiredo JA, Peters OA. Cutting efficiency of conventional and martensitic nickel-titanium instruments for coronal flaring. J Endod. 2013;39(12):1634–8. doi: 10.1016/j.joen.2013.08.016. [DOI] [PubMed] [Google Scholar]

- 48.Peters OA, Morgental RD, Schulze KA, Paqué F, Kopper PM, Vier-Pelisser FV. Determining cutting efficiency of nickel-titanium coronal flaring instruments used in lateral action. Int Endod J. 2014;47(6):505–13. doi: 10.1111/iej.12177. [DOI] [PubMed] [Google Scholar]

- 49.Pinheiro SR, Alcalde MP, Vivacqua-Gomes N, Bramante CM, Vivan RR, Duarte MAH, et al. Evaluation of apical transportation and centring ability of five thermally treated NiTi rotary systems. Int Endod J. 2018;51(6):705–13. doi: 10.1111/iej.12881. [DOI] [PubMed] [Google Scholar]

- 50.Daneshmand S, Kahrizi EF, Abedi E, Abdolhosseini MM. Influence of machining parameters on electro discharge machining of NiTi shape memory alloys. Int J Electrochem Sci. 2013;8(3):3095–104. [Google Scholar]

- 51.Bojorquez B, Marloth R, Es-Said O. Formation of a crater in the workpiece on an electrical discharge machine. Engineering Failure Analysis. 2002;9(1):93–7. [Google Scholar]

- 52.Haapasalo M, Shen Y. Evolution of nickel–titanium instruments:from past to future. Endod Topics. 2013;29(1):3–17. [Google Scholar]

- 53.Özyürek T, Gündoğar M, Uslu G, Yılmaz K, Staffoli S, Nm G, et al. Cyclic fatigue resistances of Hyflex EDM, WaveOne gold, Reciproc blue and 2shape NiTi rotary files in different artificial canals. Odontology. 2018;106(4):408–13. doi: 10.1007/s10266-018-0340-y. [DOI] [PubMed] [Google Scholar]

- 54.Iacono F, Pirani C, Generali L, Bolelli G, Sassatelli P, Lusvarghi L, et al. Structural analysis of HyFlex EDM instruments. Int Endod J. 2017;50(3):303–13. doi: 10.1111/iej.12620. [DOI] [PubMed] [Google Scholar]

- 55.Gündoğar M, Özyürek T. Cyclic Fatigue Resistance of OneShape, HyFlex EDM, WaveOne Gold, and ReciprocBlue Nickel-titanium Instruments. J Endod. 2017;43(7):1192–6. doi: 10.1016/j.joen.2017.03.009. [DOI] [PubMed] [Google Scholar]

- 56.Kaval ME, Capar ID, Ertas H. Evaluation of the cyclic fatigue and torsional resistance of novel nickel-titanium rotary files with various alloy properties. J Endod. 2016;42(12):1840–3. doi: 10.1016/j.joen.2016.07.015. [DOI] [PubMed] [Google Scholar]

- 57.Pirani C, Iacono F, Generali L, Sassatelli P, Nucci C, Lusvarghi L, et al. HyFlex EDM:superficial features, metallurgical analysis and fatigue resistance of innovative electro discharge machined NiTi rotary instruments. Int Endod J. 2016;49(5):483–93. doi: 10.1111/iej.12470. [DOI] [PubMed] [Google Scholar]

- 58.Özyürek T, Yılmaz K, Uslu G. Shaping Ability of Reciproc, WaveOne GOLD, and HyFlex EDM Single-file Systems in Simulated S-shaped Canals. J Endod. 2017;43(5):805–9. doi: 10.1016/j.joen.2016.12.010. [DOI] [PubMed] [Google Scholar]

- 59.Venino PM, Citterio CL, Pellegatta A, Ciccarelli M, Maddalone M. A Micro-computed Tomography Evaluation of the Shaping Ability of Two Nickel-titaniumInstruments, HyFlex EDM and ProTaper Next. J Endod. 2017;43(4):628–32. doi: 10.1016/j.joen.2016.11.022. [DOI] [PubMed] [Google Scholar]

- 60.Zupanc J, Vahdat-Pajouh N, Schäfer E. New thermomechanically treated NiTi alloys - a review. Int Endod J. 2018;51(10):1088–103. doi: 10.1111/iej.12924. [DOI] [PubMed] [Google Scholar]

- 61.Plotino G, Grande NM, Cotti E, Testarelli L, Gambarini G. Blue treatment enhances cyclic fatigue resistance of vortex nickel-titanium rotary files. J Endod. 2014;40(9):1451–3. doi: 10.1016/j.joen.2014.02.020. [DOI] [PubMed] [Google Scholar]

- 62.Shen Y, Zhou H, Coil JM, Aljazaeri B, Buttar R, Wang Z, et al. ProFile Vortex and Vortex Blue Nickel-Titanium Rotary Instruments after Clinical Use. J Endod. 2015;41(6):937–42. doi: 10.1016/j.joen.2015.02.003. [DOI] [PubMed] [Google Scholar]

- 63.Duke F, Shen Y, Zhou H, Ruse ND, Wang ZJ, Hieawy A, et al. Cyclic Fatigue of ProFile Vortex and Vortex Blue Nickel-Titanium Files in Single and Double Curvatures. J Endod. 2015;41(10):1686–90. doi: 10.1016/j.joen.2015.06.012. [DOI] [PubMed] [Google Scholar]

- 64.Adıgüzel M, Capar ID. Comparison of Cyclic Fatigue Resistance of WaveOne and WaveOne Gold Small, Primary, and Large Instruments. J Endod. 2017;43(4):623–27. doi: 10.1016/j.joen.2016.11.021. [DOI] [PubMed] [Google Scholar]

- 65.De-Deus G, Silva EJ, Vieira VT, Belladonna FG, Elias CN, Plotino G, et al. Blue Thermomechanical Treatment Optimizes Fatigue Resistance and Flexibility of the Reciproc Files. J Endod. 2017;43(3):462–6. doi: 10.1016/j.joen.2016.10.039. [DOI] [PubMed] [Google Scholar]

- 66.Elnaghy AM, Elsaka SE. Mechanical properties of ProTaper Gold nickel-titanium rotary instruments. Int Endod J. 2016;49(11):1073–8. doi: 10.1111/iej.12557. [DOI] [PubMed] [Google Scholar]

- 67.Gao Y, Gutmann JL, Wilkinson K, Maxwell R, Ammon D. Evaluation of the impact of raw materials on the fatigue and mechanical properties of ProFile Vortex rotary instruments. J Endod. 2012;38(3):398–401. doi: 10.1016/j.joen.2011.11.004. [DOI] [PubMed] [Google Scholar]

- 68.Nguyen HH, Fong H, Paranjpe A, Flake NM, Johnson JD, Peters OA. Evaluation of the resistance to cyclic fatigue among ProTaper Next, ProTaper Universal, and Vortex Blue rotary instruments. J Endod. 2014;40(8):1190–3. doi: 10.1016/j.joen.2013.12.033. [DOI] [PubMed] [Google Scholar]

- 69.Uygun AD, Kol E, Topcu MK, Seckin F, Ersoy I, Tanriver M. Variations in cyclic fatigue resistance among ProTaper Gold, ProTaper Next and ProTaper Universal instruments at different levels. Int Endod J. 2016;49(5):494–9. doi: 10.1111/iej.12471. [DOI] [PubMed] [Google Scholar]

- 70.Özyürek T. Cyclic Fatigue Resistance of Reciproc, WaveOne, and WaveOne Gold Nickel-Titanium Instruments. J Endod. 2016;42(10):1536–9. doi: 10.1016/j.joen.2016.06.019. [DOI] [PubMed] [Google Scholar]

- 71.Duque JA, Vivan RR, Cavenago BC, Amoroso-Silva PA, Bernardes RA, Vasconcelos BC, et al. Influence of NiTi alloy on the root canal shaping capabilities of the ProTaper Universal and ProTaper Gold rotary instrument systems. J Appl Oral Sci. 2017;25(1):27–33. doi: 10.1590/1678-77572016-0230. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 72.Elnaghy AM, Elsaka SE. Shaping ability of ProTaper Gold and ProTaper Universal files by using cone-beamcomputed tomography. Indian J Dent Res. 2016;27(1):37–41. doi: 10.4103/0970-9290.179812. [DOI] [PubMed] [Google Scholar]

- 73.Elnaghy A, Elsaka S. Cyclic fatigue resistance of XP-endo Shaper compared with different nickel-titanium alloyinstruments. Clin Oral Investig. 2018;22(3):1433–7. doi: 10.1007/s00784-017-2245-5. [DOI] [PubMed] [Google Scholar]

- 74.Silva EJNL, Vieira VTL, Belladonna FG, Zuolo AS, Antunes HDS, Cavalcante DM, et al. Cyclic and Torsional Fatigue Resistance of XP-endo Shaper and TRUShape Instruments. J Endod. 2018;44(1):168–72. doi: 10.1016/j.joen.2017.08.033. [DOI] [PubMed] [Google Scholar]

- 75.Elnaghy AM, Elsaka SE. Torsional resistance of XP-endo Shaper at body temperature compared with several nickel-titanium rotary instruments. Int Endod J. 2018;51(5):572–6. doi: 10.1111/iej.12815. [DOI] [PubMed] [Google Scholar]

- 76.Uslu G, Özyürek T, Gündoğar M, Yılmaz K. Cyclic fatigue resistance of 2Shape, Twisted File and EndoSequence Xpress nickel-titanium rotary files at intracanal temperature. J Dent Res Dent Clin Dent Prospects. 2018;12(4):283–7. doi: 10.15171/joddd.2018.044. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 77.Micro-Mega. The 2Shape Brochure. [Accessed Jun 8, 2019]. Available at: http://micro-mega.com/wpcontent/uploads/2018/03/Brochure-2Shape-EN-1.pdf .

- 78.Elnaghy AM, Elsaka SE. Cyclic Fatigue Resistance of One Curve, 2Shape, ProFile Vortex, Vortex Blue, and RaCe Nickel-Titanium Rotary Instruments in Single and Double Curvature Canals. J Endod. 2018;44(11):1725–30. doi: 10.1016/j.joen.2018.07.023. [DOI] [PubMed] [Google Scholar]

- 79.Micro-Mega. The One Curve Brochure. [Accessed Jun 27, 2019]. Available at: http://micro-mega.com/wpcontent/uploads/2018/03/Brochure-One-Curve-EN-1.pdf .

- 80.Yılmaz K, Özyürek T, Uslu G. Comparision of Cyclic Fatigue Resistance of One Curve, Hyflex EDM, WaveOne Gold and Reciproc Blue Nickel-Titanium Rotary Files at Intra-canal Temperature. Cumhuriyet Dent J. 2019;22(1):42–7. [Google Scholar]