Abstract

Following a request from the European Commission, EFSA was asked to deliver a scientific opinion on the safety and efficacy of zinc chelates of lysine and glutamic acid (Zinc‐LG) as a nutritional feed additive for all animal species. The EFSA Panel on Additives and Products or Substances used in Animal Feed (FEEDAP) Panel concludes that, owing to safety considerations, the simultaneous use of both feed and water supplemented with Zinc‐LG should be avoided. Zinc‐LG is safe for chickens for fattening; this conclusion can be extrapolated to all animal species/categories provided that the maximum authorised levels in the EU for total zinc in feed are not exceeded. No increases in the zinc content of animal tissues and products are expected from the use of Zinc‐LG in animal nutrition. There is no indication that the toxicity of Zinc‐LG is essentially different from that described for inorganic divalent zinc. The use of Zinc‐LG in animal nutrition is of no concern for consumer safety provided that the maximum authorised total zinc levels in feed are respected. Owing to its zinc content, the handling of the additive poses a risk to users by inhalation. The additive is considered as a skin and respiratory sensitiser; it is non‐irritant to eye and to skin. Zinc‐LG is intended to be a substitute for other authorised zinc additives and will not further increase the environmental burden of zinc; therefore, the FEEDAP Panel considers that the use of the additive in animal nutrition would not pose an additional risk for the environment. Zinc‐LG is a source of bioavailable zinc, comparable to the standard inorganic zinc source, and therefore, the additive is efficacious in meeting the birds zinc requirements; this conclusion can be extrapolated to all animal species/categories. The FEEDAP Panel posed a recommendation concerning the description of the additive.

Keywords: nutritional additives, compounds of trace elements, zinc chelates of lysine and glutamic acid, ProPath Zn, safety, efficacy

1. Introduction

1.1. Background and Terms of Reference

Regulation (EC) No 1831/20031 establishes the rules governing the Community authorisation of additives for use in animal nutrition. In particular, Article 4(1) of that Regulation lays down that any person seeking authorisation for a feed additive or for a new use of a feed additive shall submit an application in accordance with Article 7.

The European Commission received a request from Zinpro Animal Nutrition (Europe), Inc.2 for authorisation of the product zinc chelates of lysine and glutamic acid, when used as a feed additive for all animal species (category: nutritional additives; functional group: compounds of trace elements).

According to Article 7(1) of Regulation (EC) No 1831/2003, the Commission forwarded the application to the European Food Safety Authority (EFSA) as an application under Article 4(1) (authorisation of a feed additive or new use of a feed additive). The particulars and documents in support of the application were considered valid by EFSA as of 22 February 2018.

According to Article 8 of Regulation (EC) No 1831/2003, EFSA, after verifying the particulars and documents submitted by the applicant, shall undertake an assessment in order to determine whether the feed additive complies with the conditions laid down in Article 5. EFSA shall deliver an opinion on the safety for the target animals, consumer, user and the environment and on the efficacy of the product zinc chelates of lysine and glutamic acid, when used under the proposed conditions of use (see Section 3.1.5).

1.2. Additional information

The additive, zinc chelates of lysine and glutamic acid, is intended to be used as a source of zinc in all animal species. The additive has not been previously authorised as a feed additive in the European Union (EU).

The applicant holds a patent on the zinc chelates of lysine and glutamic acid, with the title ‘Mixed amino acid metal salt complexes’.3

2. Data and methodologies

2.1. Data

The present assessment is based on data submitted by the applicant in the form of a technical dossier4 in support of the authorisation request for the use of zinc chelates of lysine and glutamic acid as a feed additive.

The FEEDAP Panel used the data provided by the applicant together with data from other sources, such as previous risk assessments by EFSA or other expert bodies, peer‐reviewed scientific papers and other scientific reports, to deliver the present output.

EFSA has verified the European Union Reference Laboratory (EURL) report as it relates to the methods used for the control of the zinc chelates of lysine and glutamic acid in animal feed. The Executive Summary of the EURL report can be found in Annex A.5

2.2. Methodologies

The approach followed by the FEEDAP Panel to assess the safety and the efficacy of zinc chelates of lysine and glutamic acid is in line with the principles laid down in Regulation (EC) No 429/2008 and the relevant guidance documents: Guidance on nutritional additives (EFSA FEEDAP Panel, 2012a), Technical guidance: Tolerance and efficacy studies in target animals (EFSA FEEDAP Panel, 2011), Technical Guidance for assessing the safety of feed additives for the environment (EFSA, 2008), Guidance for the preparation of dossiers for additives already authorised for use in food (EFSA FEEDAP Panel, 2012b), Guidance for establishing the safety of additives for the consumer (EFSA FEEDAP Panel, 2012c) and Guidance on studies concerning the safety of use of the additive for users/workers (EFSA FEEDAP Panel, 2012d).

3. Assessment

The additive under assessment is ‘Zinc chelates of lysine and glutamic acid’ (trade name: ProPath Zn). The additive corresponds to the active compound. As abbreviation, the short name of Zinc‐LG will be used throughout this opinion to refer to the additive under assessment. It is intended to be used in feed (either mashed or pelleted form) and water (via complementary feed) as a nutritional additive (functional group compounds of trace elements) – source of zinc, for all animal species and categories.6

3.1. Characterisation

3.1.1. Characterisation of the compound

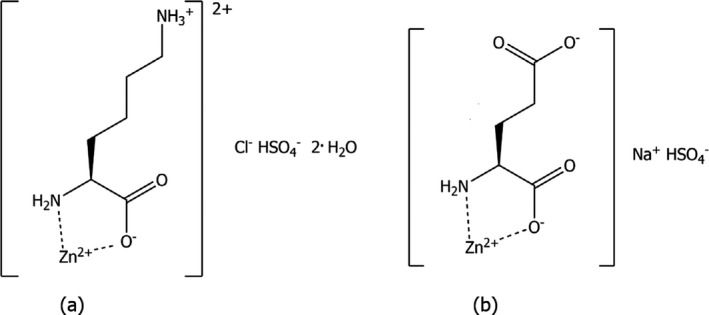

The active substance is divalent zinc in the form of chelates of lysine and glutamic acid in a mixture 1:1.7 The chemical names according to International Union of Pure and Applied Chemistry (IUPAC) are zinc‐2,6‐diaminohexanoic acid and zinc‐2‐aminopentanedioic acid. The compounds are not identified by the Chemical Abstracts Service (CAS) number. The chemical formulas of the two compounds are C6H19ClN2O8SZn and C5H8NNaO8SZn, respectively. The structural formulas are shown in Figure 1 and the corresponding molecular weights are of 380.12 g/mol for the zinc chelate of lysine and 330.55 g/mol for zinc chelate of glutamic acid. The theoretical content of zinc in is 17.2% and 18.8%, respectively.8

Figure 1.

Structural formulas of zinc chelates of lysine (a) and glutamic acid (b)

Five batches of the product were analysed for zinc, lysine, glutamic acid, chloride and sulfur. The average contents were: zinc was about 17.6% (17.3–17.8), lysine 20.1% (19.8–20.5), glutamic acid 22.1% (21.3–22.7), chloride 5.5% (5.4–5.6), sulfur 8.8% (8.6–9.0) and water 2.7% (2.4–2.9).9 The remaining composition was not identified but it can be assumed to be represented by the other components of the counter ions (hydrogen and oxygen from HSO4 – and sodium). The FEEDAP Panel notes that about a further 2% of the additive might be unidentified.

Five batches were analysed for undesirable substances. Levels of heavy metals (cadmium Cd, lead Pb and mercury Hg), arsenic (As) and fluorine (F) were provided8 (As: < 0.19–0.35 mg/kg, Cd: 2.39–3.73 mg/kg, Pb: < 0.2 mg/kg, Hg: < 0.01–0.03 mg/kg and F: 24.2–25.1 mg/kg).10 The levels of dioxins (polychlorinated dibenzofurans (PCDF) and polychlorinated dibenzo(p)dioxins (PCDD)) and the sum of dioxins and dioxin‐like polychlorinated biphenyls (PCBs) were 0.022–0.034 ng WHO‐PCDD/F‐TEQ/kg and 0.024–0.04 ng WHO‐PCDD/F‐PCB‐TEQ/kg, respectively. The concentrations of the undesirable substances analysed comply with those set in Directive 2002/32/EC for compounds of trace elements or, if not mentioned in the Directive, do not represent a concern.11 Nickel was analysed in three batches of the additive and the values reported were in the range of 1.26–1.35 mg/kg.12

Analysis of three batches (aged 12–13 months) confirmed that the product is not a potential source of microbial contamination. Counts of Enterobacteriaceae and Escherichia coli were below the limit of quantification (LOQ) (< 10 cfu/g) and Salmonella was not detected in 25 g. Levels of aflatoxin B1 and ochratoxin A analysed in three batches were below the LOQ (< 0.1 μg/kg).13

The additive is a solid product, soluble in water, with a melting point of 197°C. The bulk density tested in three batches is 0.446 g/cm3.14

Dusting potential was analysed in three batches by the Stauber–Heubach method (five measurements of each batch). The values reported were in the range of 1.3–3.6 g/m3. The same batches were submitted for analysis of the particle size by laser diffraction. The results (v/v) showed on average 26.7% (range 26.2–27.7%), 66.8% (range 63.5–70.2%) and 81.5% (range 78.7–84.4%) for particles < 10 μm, < 50 μm and < 100 μm, respectively.15 Zinc in the dust was provided with analysis of three batches with an average of 12.2% (range 10.4–13.6).12

3.1.2. Manufacturing process

■■■■■

■■■■■■■■■■■■■■■

3.1.3. Stability and homogeneity

For compounds of trace elements (including chelates), stability studies are generally not required.

Two stability studies to determine the shelf‐life of the additive, each with one batch stored at 25°C/60% relative humidity (RH) (ambient conditions) and at 40°C/70% RH (environmental chamber conditions) were performed.21 After 24 months, the zinc content was stable (no losses) under ambient conditions and decreased from 17.7 to 17.2% (3.0%) under environmental chamber conditions; the total lysine/glutamic acid content decreased from 38.5 to 38.2 (0.8%) under ambient conditions and was stable under environmental chamber conditions.

A stability study of the additive in premixtures, mash feed and pellet feed measuring zinc content was provided.22 After 6 months of storage, no losses of zinc were reported in the premixture or the mash feed and a recovery of 93.9% was identified for pelleted feed. The content of choline chloride in the premixture was 5%.23

The capacity of the additive to homogeneously distribute in premixtures and complete feed (mash and pelleted) for chickens for fattening was investigated, analysing the zinc content in 10 subsamples each.22 The coefficient of variation (CV) of the zinc concentration in the two premixtures tested (mean zinc content: 23,721 and 20,466 mg/kg) was 3.3% and 5.1%. The CV of the mash feed (mean zinc content: 137 mg/kg) was 6.1%, that of the same feed after pelleting (mean zinc content: 146 mg/kg) was 5.8%.22

3.1.4. Physico‐chemical incompatibilities or interactions

No incompatibilities are expected due to the nature of the product.

3.1.5. Conditions of use

Zinc‐LG is intended to be used in all types of feed (supplementation of feed should be done via premixture) or water (via complementary feed) for all animal species. It should be used up to a maximum total zinc content of 200 mg/kg complete feed (pets), 180 mg/kg complete feed (salmonids and milk replacers), 150 mg/kg complete feed (piglets, sows, rabbits and all fish other than salmonids) and 120 mg/kg complete feed (other species and categories).12

The applicant proposed half of the dose in feed for use in water for drinking.12

3.2. Safety

The additive is a mixture of zinc chelate of lysine and zinc chelate of glutamic acid. The additive will introduce only a minor fraction of the amino acids, lysine and glutamic acid, which contributes negligibly to the intake of the animals. The sources of amino acids are already authorised and have been assessed by EFSA as feed additives (EFSA FEEDAP Panel, 2014, 2015a). Therefore, no relevance for the safety assessment is foreseen for the amino acids delivered by the additive.

The use in water for drinking of several zinc compounds was discussed in depth in a previous opinion of the FEEDAP Panel (EFSA FEEDAP Panel, 2015b), concluding that the simultaneous use of both feed and water supplemented with zinc should be avoided. The FEEDAP Panel retains this conclusion as applicable also to Zinc‐LG and reiterates its previous statement that compounds of trace elements should generally not be used in water for drinking (EFSA FEEDAP Panel, 2010).

3.2.1. Safety for the target species

Where a feed additive application is made as a nutritional additive for all animal species, tolerance data may be limited to one species. The maximum tolerable levels for zinc have been reviewed by the FEEDAP Panel in previous opinions (e.g. EFSA FEEDAP Panel, 2015b).

3.2.1.1. Tolerance study

The applicant provided a tolerance study with Zinc‐LG in chickens for fattening with duration of 35 days.24

A total of 840 chickens for fattening (male, Ross 308) were randomly allocated to seven treatments. and six replicates. Birds were housed in 42 pens with 20 birds per pen (six replicate pens per treatment).

The treatments consisted of a control without added zinc (T1) an inorganic zinc source (zinc sulfate) in three dosses (standard – 80 (T2), maximum recommended – 150 (T3) and tolerance – 440 (T4) mg total zinc per kg of feed) and an organic zinc source (Zinc‐LG) in three doses (standard – 80 (T5), maximum recommended – 150 (T6) and tolerance – 440 (T7) mg total zinc per kg of feed) (see Table 1). The FEEDAP Panel identified that the ‘maximum recommended dose’ is slightly higher than the maximum current authorise total zinc in feed (120 mg Zn/kg complete feed) and corresponds to the formerly authorised total maximum concentration of zinc in feed; under this respect, the Panel notes that the experimental diets were produced close to the date in which the new legislation (Commission Implementing Regulation (EU) 2016/1095 of 6 July 2016) entered into force.

Table 1.

Description of the seven treatment groups

| Treatment | Source | Added Zinc mg/kg | Total Zinc mg/kg (Intended) | Total Zinc mg/kg (Analysed) | |

|---|---|---|---|---|---|

| Starter | Grower | ||||

| T1 | Nonea | 0 | 40 | 39 | 40 |

| T2 | Zinc sulfate | 40 | 80 | 79 | 82 |

| T3 | 110 | 150b | 138 | 149 | |

| T4 | 400 | 440 | 414 | 465 | |

| T5 | Zinc‐LG | 40 | 80 | 77 | 85 |

| T6 | 110 | 150b | 168 | 159 | |

| T7 | 400 | 440 | 453 | 447 | |

Since the background zinc concentration of the basal diets was 34 and 30 mg Zn/kg, these diets were supplemented with zinc sulfate to achieve a total of 40 mg Zn/kg basal diet. The control diet was used in the rest of the treatments.

The current maximum authorised dose for zinc (total) in feed is 120 mg/kg chicken feed.

All chickens were fed a basal mashed feed (starter/grower). The diets were mainly composed of wheat, maize and soybean meal and contained as a starter (days 1–21) 216.9 g/kg crude protein and 12.3 MJ/kg of apparent metabolizable energy (AME) and as a grower (days 22–35) 193.0 g/kg crude protein and 12.7 MJ/kg AME.

Mortality and general health were monitored throughout the study. Performance was assessed at day 1 (only body weight), and days 21 and 35 by measuring feed intake and body weight and calculating feed to gain ratio (F/G). At the study termination (day 35), a total of 84 birds (2 birds/pen) were killed and blood samples were taken for analysis of haematology25 and biochemistry26; during this procedure also tissue and organ samples were taken for residue study (see Section 3.2.2.1).

Data were subjected to analysis of variance (ANOVA); when a significant difference was detected, treatment means were compared with Fisher's least significant difference test. The pen was considered as the statistical unit for the performance parameters, whilst the individual animal was the statistical unit for haematology and biochemical parameters.

Mortality was 2.7% in the overall study and was not linked to any treatment; this mortality rate is in line with industry standards for Ross 308. Performance parameters did not evidence significant differences between treatments (average among treatments: body weight = 2.623 kg; total feed intake = 3.664 kg/bird; F/G = 1.397) (Table 2).

Table 2.

Effect of Zinc‐LG on performance parameters in chickens for fattening after 35 days

| Treatment | Zinc‐intended (mg/kg diet) | Body weight (kg) | Feed intake (total kg/bird) | F/G |

|---|---|---|---|---|

| Control | 40 | 2.628 | 3.701 | 1.409 |

| Zinc sulfate | 80 | 2.608 | 3.646 | 1.398 |

| 150 | 2.665 | 3.729 | 1.399 | |

| 440 | 2.633 | 3.682 | 1.398 | |

| Zinc‐LG | 80 | 2.622 | 3.654 | 1.393 |

| 150 | 2.583 | 3.598 | 1.394 | |

| 440 | 2.625 | 3.635 | 1.385 |

F/G: feed to gain ratio.

The haematological parameters did not show significant treatment‐related effects. Only the biochemistry parameter glucose was significantly affected by treatment but did not indicate a dose‐dependent relation with the zinc level or source in feed. The glucose levels identified in all groups are higher than published values (Adekunle and Omoh, 2014); the reason could be the occurrence of stress in animals before sampling.

Necropsy did not show clinical findings that were related to zinc source or dose level.

The tolerance study indicates that Zinc‐LG is safe up to 440 mg Zn/kg feed; a margin of safety of at least 3 can be derived in chickens for fattening.

The additive will introduce only a minor fraction of the amino acids, lysine and glutamic acid, which contributes negligibly to the intake of the animals; no relevance for target animals' safety is foreseen.

3.2.1.2. Conclusions on safety for the target species

Based on a tolerance study, the FEEDAP Panel concludes that the additive is safe for chickens for fattening. This conclusion can be extrapolated to all animal species and categories provided that the maximum authorised levels in the EU for total zinc in feed are not exceeded.

3.2.2. Safety for the consumer

The sources used for both amino acids are authorised in the EU and their safety have been established. Therefore, the FEEDAP Panel retains that only zinc is of interest concerning the consumer safety.

3.2.2.1. Deposition study

The applicant submitted a study on tolerance of chickens for fattening (see Section 3.2.1.1). This study provided data on zinc deposition in tissues and organs (breast muscle, skin‐fat, kidney, liver, and bone (tibia) samples) on chickens for fattening fed the Zinc‐LG. Samples were taken at day 36 after necropsy, from a total of 84 birds (12 birds/treatment).

There were no statistically significant differences between treatments for zinc levels of edible tissues and tibia, indicating that no significant deposition of zinc occurred at the relevant tested supplementation levels, up to the maximum levels authorised in feed (Table 3).27

Table 3.

Analytical results of zinc content in edible tissues and tibia (results in fresh matter)

| Treatment | Source | Zn in feed mg/kga | Skin and Fat mg/kg | Muscle mg/kg | Liver mg/kg | Kidney mg/kg | Tibia mg/kg |

|---|---|---|---|---|---|---|---|

| T1 | None | 40 | 9.3 | 7.8 | 24.0 | 19.0 | 84.8 |

| T2 | Zinc sulfate | 80 | 10.0 | 7.7 | 24.0 | 18.4 | 90.8 |

| T3 | 150 | 9.8 | 7.7 | 23.9 | 19.1 | 93.2 | |

| T5 | Zinc‐LG | 80 | 9.8 | 8.4 | 24.3 | 18.8 | 91.8 |

| T6 | 150 | 9.5 | 7.8 | 25.1 | 19.2 | 96.2 |

Confirmed by analysis.

3.2.2.2. Toxicology of zinc

The toxicological properties of zinc have been extensively described by the Scientific Committee on Food (SCF) (EC, 2003), by Sandstead (2015) and in EFSA FEEDAP opinions (e.g. 2012, 2015); no substantial differences between inorganic and organic zinc compounds are expected concerning zinc toxicity. Depressed copper uptake with associated copper deficiency is the most sensitive and well‐characterised effect of chronic excess of zinc intake in humans and animals. Accordingly, a tolerable upper intake level (UL) for zinc of 25 mg/day in adults is derived from a human no observed adverse effect level (NOAEL) of 50 mg/day in adults for altered copper status and an uncertainty factor of 2 to allow for observed variability within the general population (EC, 2003).

3.2.2.3. Assessment of consumer safety

The FEEDAP Panel has summarised, in several opinions (see, e.g. EFSA FEEDAP Panel, 2015b and references herein), the zinc intake of the European population and the possible contribution of zinc supplementation of animal feeds. In all consumer groups, tissues and products of animal origin contributed to about 40–50% of total zinc intake. In its previously adopted opinion on the potential reduction of the currently authorised maximum zinc content in complete feed, the FEEDAP Panel concluded that the newly proposed reduced maximum zinc levels would not, essentially, influence consumer exposure (EFSA FEEDAP Panel, 2014). There is no indication that the current intake levels in the European population, which already include food commodities from zinc‐supplemented animals, may be higher than the UL (EFSA NDA Panel, 2014).

Based on study on chickens for fattening, the supplementation with Zinc‐LG up to the maximum level of total zinc in feedingstuffs permitted in the EU is unlikely to increase zinc deposition in edible tissues. Therefore, the FEEDAP Panel considers that the use of Zinc‐LG as a nutritional additive would not significantly influence consumer exposure.

3.2.2.4. Conclusions on safety for the consumer

No increases in the zinc content of animal tissues and products are expected from the use of Zinc‐LG in animal nutrition. There is no indication that the toxicity of Zinc‐LG is essentially different from that described for inorganic divalent zinc. The FEEDAP Panel concludes that the use of Zinc‐LG in animal nutrition is of no concern for consumer safety provided that the maximum authorised total zinc levels in feed are respected.

3.2.3. Safety for the user

3.2.3.1. Effects on the respiratory system

No specific studies were provided by the applicant regarding the toxicity of the additive on the respiratory system.

The highest dusting potential of the additive was 3.6 g/m3 and the zinc maximum concentration in the dust was 13.61% (see Section 3.1.1). Thus, it can be calculated that a maximum concentration of 490 mg Zn/m3 could be released by the dust when handling the additive. Considering that the respirable and the thoracic fractions amounted up to 27.69% and 70.19%, respectively (see Section 3.1.1), based on a conservative approach, it could be estimated that respirable zinc from dust would be about 194 mg/m3, assuming that the dust consists only of particles ≤ 50 μm and its respirable fraction about 39.5% (27.7 of 70.2). Considering the zinc threshold limit value (TLV) of 2 mg/m3 (ACGIH, 2003), the TLV is exceeded by about two orders of magnitude. Owing the zinc content of the additive, the FEEDAP Panel considers that handling of the additive, poses a risk to users by inhalation.

The nickel maximum content of the additive was 1.35 mg/kg. The dusting potential of the product amounted up to 3.6 g/m3, corresponding to about 0.005 mg Ni/m3, which is below the occupational exposure limit (OEL) for the inhalable fraction of water‐soluble nickel (0.01 mg Ni/m3; EC, 2011). However, due to the presence of nickel in the additive, it should be considered as a respiratory sensitiser.

3.2.3.2. Effects on the eyes and skin

The applicant presented two in vivo acute irritation studies in rabbits according OECD guidelines No. 404 and No. 405, respectively, for skin28 and eye.28 Under the experimental conditions adopted, the additive was found to be non‐irritant for the skin and for the eye of the rabbit.

The nickel content of the additive is up to 1.35 mg/kg; given its well‐known sensitisation potential (EC, 2011) and in the absence of skin sensitisation studies the additive is classified as a skin sensitiser.29

3.2.3.3. Conclusions on safety for the user

Owing to the zinc content of Zinc‐LG, the handling of the additive poses a risk to users by inhalation. The additive is considered as a skin and respiratory sensitiser. It is non‐irritant to eye and to skin.

3.2.4. Safety for the environment

The additive under assessment, Zinc‐LG, is intended to be a substitute for other authorised zinc additives and will not further increase the environmental burden of zinc. Therefore, the FEEDAP Panel considers that the use of the additive in animal nutrition would not pose an additional risk for the environment.

3.3. Efficacy

For demonstration of the efficacy of nutritional additives, one study in a single animal species or category, including laboratory animals, is considered sufficient (EFSA FEEDAP Panel, 2012a).

3.3.1. Study in chickens for fattening

The applicant provided a combined tolerance/efficacy study in chickens for fattening30 (see Sections 3.2.1.1 and 3.2.2.1). The experimental groups in the study are shown in Table 1. In this trial, zinc concentration in edible tissues/organs and tibias was measured (Table 3).

Animals receiving the Zinc‐LG supplemented diets up to the maximum authorised total zinc in feed showed no differences in zinc deposition in edible tissues/organs and tibia compared to those in the control group or the zinc sulfate at comparable levels of zinc supplementation in diets. This lack of difference among all the experimental groups (both Zinc‐LG and inorganic zinc) with the control group may be explained by the already adequate zinc concentration in the diet of that group (40 mg Zn/kg feed).

3.3.2. Conclusions on efficacy for the target species

Based on the deposition of zinc in tibia as well as in other tissues/organs in chickens for fattening, the FEEDAP Panel concludes that the additive is a source of bioavailable zinc, comparable to the standard inorganic zinc source, and therefore, the additive is efficacious in meeting the birds zinc requirements. This conclusion can be extrapolated to all animal species and categories.

3.4. Post‐market monitoring

The FEEDAP Panel considers that there is no need for specific requirements for a post‐market monitoring plan other than those established in the Feed Hygiene Regulation31 and Good Manufacturing Practice.

4. Conclusions

The FEEDAP Panel concludes that, owing to safety considerations, the simultaneous use of both feed and water supplemented with Zinc‐LG should be avoided.

Based on a tolerance study, the FEEDAP Panel concludes that the additive is safe for chickens for fattening. This conclusion can be extrapolated to all animal species and categories provided that the maximum authorised levels in the EU for total zinc in feed are not exceeded.

No increases in the zinc content of animal tissues and products are expected from the use of Zinc‐LG in animal nutrition. There is no indication that the toxicity of Zinc‐LG is essentially different from that described for inorganic divalent zinc. The FEEDAP Panel concludes that the use of Zinc‐LG in animal nutrition is of no concern for consumer safety provided that the maximum authorised total zinc levels in feed are respected.

Owing to the zinc content of Zinc‐LG, the handling of the additive poses a risk to users by inhalation. The additive is considered as a skin and respiratory sensitiser. It is non‐irritant to eye and to skin.

The additive under assessment, Zinc‐LG, is intended to be a substitute for other authorised zinc additives and will not further increase the environmental burden of zinc. Therefore, the FEEDAP Panel considers that the use of the additive in animal nutrition would not pose an additional risk for the environment.

Based on the deposition of zinc in tibia as well as in other tissues/organs in chickens for fattening, the FEEDAP Panel concludes that the additive is a source of bioavailable zinc, comparable to the standard inorganic zinc source, and therefore, the additive is efficacious in meeting the birds zinc requirements. This conclusion can be extrapolated to all animal species and categories.

5. Recommendations

The FEEDAP Panel recommends to include the sources of lysine and glutamic acid (including the production strain(s), where applicable) in the description of the additive. The content of lysine and glutamic acid in the additive should be also indicated in the description of the product.

Documentation provided to EFSA/Chronology

| Date | Event |

|---|---|

| 21/12/2017 | Dossier received by EFSA. Zinc chelates of lysine and glutamic acid for all animal species. Submitted by Zinpro Animal Nutrition (Europe), Inc. |

| 11/01/2018 | Reception mandate from the European Commission |

| 22/02/2018 | Application validated by EFSA – Start of the scientific assessment |

| 03/05/2018 | Request of supplementary information to the applicant in line with Article 8(1)(2) of Regulation (EC) No 1831/2003 – Scientific assessment suspended. Issues: characterisation, safety for target species, safety for the consumers and safety for the user |

| 22/05/2018 | Comments received from Member States |

| 21/06/2018 | Request of supplementary information to the applicant in line with Article 8(1)(2) of Regulation (EC) No 1831/2003 (Addendum) – Scientific assessment suspended. Issue: characterisation |

| 22/08/2018 | Reception of supplementary information from the applicant ‐ Scientific assessment re‐started |

| 17/12/2018 | Spontaneous submission of information by the applicant. Issue: characterisation |

| 24/01/2019 | Request of supplementary information to the applicant in line with Article 8(1)(2) of Regulation (EC) No 1831/2003 – Scientific assessment suspended Issue: characterisation |

| 07/03/2019 | Clarification teleconference during risk assessment with the applicant according to the “EFSA's Catalogue of support initiatives during the life‐cycle of applications for regulated products” |

| 14/03/2019 | Reception of supplementary information from the applicant – Scientific assessment re‐started |

| 02/07/2017 | Opinion adopted by the FEEDAP Panel. End of the Scientific assessment |

Abbreviations

- AME

apparent metabolizable energy

- ANOVA

analysis of variance

- CAS

Chemical Abstracts Service

- cfu

colony forming unit

- CV

coefficient of variation

- EURL

European Union Reference Laboratory

- F/G

feed to gain ratio

- FEEDAP

EFSA Panel on Additives and Products or Substances used in Animal Feed

- HPLC

high‐performance liquid chromatography

- ICP‐AES

inductively coupled plasma atomic emission spectrometry

- IUPAC

International Union of Pure and Applied Chemistry

- LOQ

limit of quantification

- NOAEL

no observed adverse effect level

- OEL

occupational exposure limit

- PCB

polychlorinated biphenyl

- PCDD

polychlorinated dibenzo(p)dioxins

- PCDF

polychlorinated dibenzofurans

- RH

relative humidity

- RSDr

relative standard deviations for repeatability

- SCF

Scientific Committee on Food

- TEQ

toxic equivalent

- TLV

threshold limit value

- UL

tolerable upper intake level

- WHO

World Health Organization

Annex A – Executive Summary of the Evaluation Report of the European Union Reference Laboratory for Feed Additives on the Method(s) of Analysis for zinc chelates of lysine and glutamic acid

1.

In the current application authorisation is sought under Article 4(1) for zinc chelates of lysine and glutamic acid under the category/functional group (3b) ‘nutritional additives’/’compounds of trace elements’, according to the classification system of Annex I of Regulation (EC) No 1831/2003. Specifically, authorisation is sought for the use of the feed additive for all categories and species.

Zinc chelates of lysine and glutamic acid is a solid preparation with a minimum content of 17% (w/w) of zinc, 19% (w/w) of lysine and 19% (w/w) of glutamic acid.

The feed additive is intended to be incorporated into premixtures and feedingstuffs. In addition, the maximum levels of total zinc in the feedingstuffs, ranging from 120 to 200 mg/kg depending on the animal species/category, are established by Regulation (EU) 2016/1095.

For the quantification of total zinc in the feed additive, premixtures and feedingstuffs the Applicant submitted the two internationally recognised ring‐trial validated CEN methods based on inductively coupled plasma atomic emission spectrometry (ICP‐AES): EN 15510 and EN 15621. These two methods together with the Community method based on atomic absorption spectrometry, which was further ring‐trial validated by the UK Food Standards Agency (FSA), were previously evaluated and recommended by the EURL in the frame of the Zinc group dossier.

In addition, the EURL is aware of two ring‐trial validated methods, namely: ISO 6869 based on atomic absorption spectrometry (AAS) and EN 17053 based on inductively coupled plasma mass spectrometry (ICP‐MS).

Based on the acceptable method performance characteristics available, the EURL recommends for official control the five ring‐trial validated methods: (i) EN 15621 and ISO 6869 for the quantification of total zinc in the feed additive, premixtures and feedingstuffs; (ii) EN 15510 and EN 17053 for the quantification of total zinc in premixtures and feedingstuffs; and (iii) the Community method (Commission Regulation (EC) No 152/2009 – Annex IV‐C) for the quantification of total zinc in feedingstuffs.

For the quantification of lysine and glutamic acid in the feed additive the Applicant submitted the ring‐trial validated EN ISO 13903 method based on ion exchange chromatography coupled with post‐column derivatisation and photometric detection (IEC‐VIS). This standard method is equivalent to the experimental protocol described in the Community method designed for the determination of free (synthetic and natural) and of total (peptide‐bound and free) amino acids including lysine and glutamic acid, using an amino acid analyser or a high‐performance liquid chromatography (HPLC) equipment. This method does not distinguish between the salts and the amino acid enantiomers.

The Applicant applied the above mentioned IEC‐VIS method for analysis of five batches of the feed additive with an average content of 20% (w/w) for lysine and 22% (w/w) for glutamic acid. Relative standard deviations for repeatability (RSDr) of 1.2% and 2.2%, respectively, were obtained. This is in agreement with the precision values reported in the frame of the two ring‐trial validation studies.

Based on the performance characteristics available, the EURL recommends for official control the method based on IEC‐VIS to quantify lysine and glutamic acid in the feed additive.

Further testing or validation of the methods to be performed through the consortium of National Reference Laboratories as specified by Article 10 (Commission Regulation (EC) No 378/2005, as last amended by Regulation (EU) 2015/1761) is not considered necessary.

Suggested citation: EFSA Panel on Additives and Products or Substances used in Animal Feed (FEEDAP) , Bampidis V, Azimonti G, Bastos ML, Christensen H, Dusemund B, Kouba M, Kos Durjava M, López‐Alonso M, López Puente S, Marcon F, Mayo B, Pechová A, Petkova M, Sanz Y, Villa RE, Woutersen R, Cubadda F, Flachowsky G, Mantovani A, López‐Gálvez G and Ramos F, 2019. Scientific Opinion on the safety and efficacy of zinc chelates of lysine and glutamic acid as feed additive for all animal species. EFSA Journal 2019;17(7):5782, 14 pp. 10.2903/j.efsa.2019.5782

Requestor: European Commission

Question number: EFSA‐Q‐2018‐00012

Panel members: Giovanna Azimonti, Vasileios Bampidis, Maria de Lourdes Bastos, Henrik Christensen, Birgit Dusemund, Maryline Kouba, Mojca Kos Durjava, Marta López‐Alonso, Secundino López Puente, Francesca Marcon, Baltasar Mayo, Alena Pechová, Mariana Petkova, Fernando Ramos, Yolanda Sanz, Roberto Edoardo Villa and Ruud Woutersen.

Acknowledgements: The EFSA FEEDAP Panel (EFSA Panel on Additives and Products or Substances used in Animal Feed) wishes to thank the following for the support provided to this scientific output (in alphabetical order of the last name): Jaume Galobart, Orsolya Holczknecht, Niovi Kordali and Paola Manini.

Legal notice: Relevant information or parts of this scientific output have been blackened in accordance with the European Commission decision on the confidentiality requests formulated by the applicant. A previous, provisional version of this output which had been made publicly available pending the adoption of the decision has been replaced by this version. The full output has been shared with the European Commission, EU Member States and the applicant.

Adopted: 2 July 2019

Amended: 16 January 2020

Notes

Regulation (EC) No 1831/2003 of the European Parliament and of the Council of 22 September 2003 on additives for use in animal nutrition. OJ L 268, 18.10.2003, p. 29.

Zinpro Animal Nutrition (Europe), Inc. Akkerdistel 2E. 5831 PJ. Boxmeer. The Netherlands.

Technical Dossier/Section II/Annex II‐37. Patent Number: US20120315372A1. Available online: https://patents.google.com/patent/US20120315372

FEED dossier reference: FAD‐2017‐0072.

The full report is available on the EURL website: https://ec.europa.eu/jrc/sites/jrcsh/files/finrep-fad-2017-0072-zn-lys-glu.pdf

Technical dossier/Section II/2.5.1.

Technical Dossier Supplementary Information.

Technical Dossier/Spontaneous Information.

Technical Dossier/Section II/Annex II‐1 to II‐15.

Values preceded by the sign ‘<’ mean the LOQ.

Directive 2002/32/EC of the European Parliament and of the Council of 7 May 2002 on undesirable substances in animal feed. OJ L 140, 30.5.2002, p. 10.

Technical Dossier/Supplementary information.

Technical dossier/Section II/2.1.4.

Technical dossier/ Annex II‐36.

Technical Dossier/Section II/Annex II‐36.

■■■■■

■■■■■

■■■■■

■■■■■

■■■■■

Technical Dossier/Section II/Annex II‐41 and Annex II‐42.

Technical dossier/Section II/Annex II‐43.

Technical dossier/Section II/Annex II‐43. Technical Dossier/Supplementary Information and Spontaneous information.

Technical Dossier/Section III/Annex III_3_1.

Haemoglobin, packed cell volume, white blood cell count, red blood cell count, mean corpuscular haemoglobin concentration, mean corpuscular volume.

Alkaline phosphatase, alanine aminotransferase, aspartate aminotransferase, creatine phosphokinase, glutamate dehydrogenase, gamma glutamyl transferase, lactate dehydrogenase, albumin, total protein, urea, creatinine, bilirubin, phosphate, triglycerides, Ca, albumin/globulin ratio, Na, K, Cl, glucose.

At higher levels that the maximum authorised in feed (treatments T4 and T7, see Table 1; total of 440 mg Zn/kg feed) higher deposition was observed in liver, kidney and tibia for both sources compared to the control.

Technical dossier/Section III/Annex_III_3_2.

Technical Dossier/Supplementary Information/August 2018.

Technical Dossier/Section IV/Annex_IV_4_1.

Regulation (EC) No 183/2005 of the European Parliament and of the Council of 12 January 2005 laying down requirements for feed hygiene. OJ L 35, 8.2.2005, p. 1.

References

- ACGIH (American Conference of Governmental Industrial Hygienists), 2003. Available online: https://www.osha.gov/dts/chemicalsampling/data/CH_277000.html

- Adekunle AR and Omoh OS, 2014. Haematological traits and serum chemistry of broiler chicken fed bread waste based diets. Journal of Animal Health and Production, 2, 51–54. [Google Scholar]

- EC (European Commission), 2003. Opinion of the Scientific Committee on Food on the tolerable upper intake level of zinc. Available online: https://ec.europa.eu/food/sites/food/files/safety/docs/sci-com_scf_out177_en.pdf

- EC (European Commission), 2011. Recommendation from the Scientific Committee on Occupational Exposure Limits (SCOEL) for nickel and inorganic nickel compounds. Employment, Social Affairs and Inclusion. SCOEL/SUM/85, June 2011. Available online: http://ec.europa.eu/social/BlobServlet?docId=3803&langId=en

- EFSA (European Food Safety Authority), 2008. Technical Guidance of the Scientific Panel on Additives and Products or Substances used in Animal Feed (FEEDAP) for assessing the safety of feed additives for the environment. EFSA Journal 2008;6(10):842, 28 pp. 10.2903/j.efsa.2008.842 [DOI] [Google Scholar]

- EFSA FEEDAP Panel (EFSA Panel on Additives and Products or Substances Used in Animal Feed), 2010. Scientific Opinion on the use of feed additives authorised/applied for use in feed when supplied via water. EFSA Journal 2010;8(12):1956, 9 pp. 10.2903/j.efsa.2010.1956 [DOI] [Google Scholar]

- EFSA FEEDAP Panel (EFSA Panel on Additives and Products or Substances used in Animal Feed), 2011. Technical guidance: Tolerance and efficacy studies in target animals. EFSA Journal 2011;9(5):2175, 15 pp. 10.2903/j.efsa.2011.2175 [DOI] [Google Scholar]

- EFSA FEEDAP Panel (EFSA Panel on Additives and Products or Substances used in Animal Feed), 2012a. Guidance for the preparation of dossiers for nutritional additives. EFSA Journal 2012;10(1):2535, 14 pp. 10.2903/j.efsa.2012.2535 [DOI] [Google Scholar]

- EFSA FEEDAP Panel (EFSA Panel on Additives and Products or Substances used in Animal Feed), 2012b. Guidance for the preparation of dossiers for additives already authorised for use in food. EFSA Journal 2012;10(1):2538, 4 pp. 10.2903/j.efsa.2012.2538 [DOI] [Google Scholar]

- EFSA FEEDAP Panel (EFSA Panel on Additives and Products or Substances used in Animal Feed), 2012c. Guidance for establishing the safety of additives for the consumer. EFSA Journal 2012;10(1):2537, 12 pp. 10.2903/j.efsa.2012.2537 [DOI] [Google Scholar]

- EFSA FEEDAP Panel (EFSA Panel on Additives and Products or Substances used in Animal Feed), 2012d. Guidance on studies concerning the safety of use of the additive for users/workers. EFSA Journal 2012;10(1):2539, 5 pp. 10.2903/j.efsa.2012.2539 [DOI] [Google Scholar]

- EFSA FEEDAP Panel (EFSA Panel on Additives and Products or Substances used in Animal Feed), 2014. Scientific Opinion on the safety and efficacy of the use of amino acids (chemical group 34) when used as flavourings for all animal species. EFSA Journal 2014;12(5):3670, 19 pp. 10.2903/j.efsa.2014.3670 [DOI] [Google Scholar]

- EFSA FEEDAP Panel (EFSA Panel on Additives and Products or Substances used in Animal Feed), 2015a. Scientific Opinion on the safety and efficacy of l‐lysine monohydrochloride, technically pure, produced with Escherichia coli CGMCC 3705 and l‐lysine sulphate produced with Corynebacterium glutamicum CGMCC 3704 for all animal species, based on a dossier submitted by HELM AG. EFSA Journal 2015;13(7):4156, 25 pp. 10.2903/j.efsa.2015.4156 [DOI] [Google Scholar]

- EFSA FEEDAP Panel (EFSA Panel on Additives and Products or Substances used in Animal Feed), 2015b. Scientific Opinion on the safety and efficacy of zinc compounds (E6) as feed additives for all animal species (zinc acetate, dihydrate; zinc chloride, anhydrous; zinc oxide; zinc sulphate, heptahydrate; zinc sulphate, monohydrate; zinc chelate of amino acids, hydrate; zinc chelate of glycine, hydrate), based on a dossier submitted by FEFANA asbl. EFSA Journal 2015;13(4):4058, 46 pp. 10.2903/j.efsa.2015.4058 [DOI] [Google Scholar]

- EFSA NDA Panel (EFSA Panel on Dietetic Products, Nutrition and Allergies), 2014. Scientific Opinion on Dietary Reference Values for zinc. EFSA Journal 2014;12(10):3844, 76 pp. 10.2903/j.efsa.2014.3844 [DOI] [Google Scholar]

- Sandstead HH, 2015. Zinc. Chapter 61 In: Nordberg et al. (eds.). Handbook on the Toxicology of Metals. 4th Edition. Academic Press Publications; UK: pp. 1369–1385. [Google Scholar]