Abstract

Following a request from the European Commission, the Panel on Additives and Products or Substances used in Animal Feed (FEEDAP) was asked to deliver a scientific opinion on l‐tryptophan produced by fermentation using Escherichia coli KCCM 80152 when used as nutritional additive in feed and water for drinking for all animal species. The production strain and its recombinant DNA were not detected in the additive. l‐Tryptophan, manufactured by fermentation with E. coli KCCM 80152, does not give rise to any safety concern with regard to the genetic modification of the production strain. The use of l‐tryptophan produced using E. coli KCCM 80152 in supplementing feed to compensate for tryptophan deficiency in feedingstuffs is safe for non‐ruminant target species. Using unprotected forms of tryptophan in ruminants can be a risk. The use of l‐tryptophan produced by fermentation using E. coli KCCM 80152 in animal feed presents no concerns to consumers of animal products. Due to the content of endotoxins, the additive poses a risk for persons handling the additive when exposed by inhalation. The additive is not considered irritant for skin or eyes and is not considered a skin sensitiser. The additive under assessment is safe for the environment. The additive under assessment is regarded as an effective source of the amino acid l‐tryptophan for all non‐ruminant species. If l‐tryptophan is intended for use in ruminants, it should be protected from ruminal degradation.

Keywords: nutritional additive, amino acids, l‐tryptophan, safety, efficacy, Escherichia coli KCCM 80152

1. Introduction

1.1. Background and Terms of Reference

Regulation (EC) No 1831/20031 establishes the rules governing the Community authorisation of additives for use in animal nutrition. In particular, Article 4(1) of that Regulation lays down that any person seeking authorisation for a feed additive or for a new use of a feed additive shall submit an application in accordance with Article 7.

The European Commission received a request from CJ Europe GmbH2 for authorisation of the product l‐Tryptophan, produced using E. coli KCCM80152, when used as a feed additive for all animal species (category: nutritional additives; functional group: amino acids, their salts and analogues).

According to Article 7(1) of Regulation (EC) No 1831/2003, the Commission forwarded the application to the European Food Safety Authority (EFSA) as an application under Article 4(1) (authorisation of a feed additive or new use of a feed additive). The particulars and documents in support of the application were considered valid by EFSA as of 21 February 2018.

According to Article 8 of Regulation (EC) No 1831/2003, EFSA, after verifying the particulars and documents submitted by the applicant, shall undertake an assessment in order to determine whether the feed additive complies with the conditions laid down in Article 5. EFSA shall deliver an opinion on the safety for the target animals, consumer, user and the environment and on the efficacy of the product l‐Tryptophan produced by fermentation with E. coli KCCM80152, when used as nutritional additive in feed and water for drinking for all animal species under the proposed conditions of use (see Section 3.1.4).

1.2. Additional information

l‐Tryptophan (minimum content of 98% on dry matter basis) produced by fermentation with six strains of E. coli (KCCM 11132P, DSM 25084, FERM BP‐11200, FERM BP‐11354, CGMCC 7.59 or CGMCC 3667) is currently authorised as a nutritional feed additive for use in all animal species.3 The product under assessment, l‐tryptophan produced by E. coli KCCM 80152, has not been previously authorised as feed additive in the European Union (EU).

l‐Tryptophan is authorised for use in food,4 cosmetics5 and as a veterinary medicinal product.6 , 7

l‐Tryptophan is described in the European Pharmacopoeia (2017), monograph 01/2017:1272.

The EFSA Panel on Additives and Products or Substances used in Animal Feed published several opinions on the safety and efficacy of l‐tryptophan produced by different strains of E. coli for all animal species (EFSA FEEDAP Panel, 2013, 2014a,b, 2015a,b, 2016a,b, 2017a,b, 2019a,b).

The Panel on Dietetic Products, Nutrition and Allergies (NDA) of EFSA issued a scientific opinion on the substantiation of health claims related to l‐tryptophan (EFSA NDA Panel, 2011). The Panel on Nutrition, Dietetic Products, Novel Food and Allergy of the Norwegian Scientific Committee for Food Safety (VKM) published an opinion on histidine, methionine, S‐adenosylmethionine and tryptophan added to foods and drinks and in food supplements (VKM, 2013) and another on l‐tryptophan in food supplements and energy drinks (VKM, 2016) and concluded that doses ≥ 250 mg/day may represent a risk of adverse health effects for children, adolescents and adults.

2. Data and methodologies

2.1. Data

The present assessment is based on data submitted by the applicant in the form of a technical dossier8 in support of the authorisation request for the use of l‐tryptophan produced by fermentation using E. coli KCCM 80152 as additive for feed and water for drinking in all animal species.

The FEEDAP Panel used the data provided by the applicant together with data from other sources, such as previous risk assessments by EFSA or other expert bodies, peer‐reviewed scientific papers, other scientific reports and experts’ knowledge, to deliver the present output.

EFSA has verified the European Union Reference Laboratory (EURL) report as it relates to the methods used for the control of the l‐Tryptophan produced by fermentation with E. coli K12 KCCM 80152 in animal feed. The Executive Summary of the EURL report can be found in Annex A.9

2.2. Methodologies

The approach followed by the FEEDAP Panel to assess the safety and the efficacy of l‐tryptophan produced by fermentation with E. coli KCCM 80152 is in line with the principles laid down in Regulation (EC) No 429/2008 and the relevant guidance documents: Guidance on nutritional additives (EFSA FEEDAP Panel, 2012a), Tolerance and efficacy studies in target animals (EFSA FEEDAP Panel, 2011), Technical Guidance for assessing the safety of feed additives for the environment (EFSA, 2008a), Guidance for establishing the safety of additives for the consumer (EFSA FEEDAP Panel, 2012b), Guidance on studies concerning the safety of use of the additive for users/workers (EFSA FEEDAP Panel, 2012c), Technical Guidance: Microbial studies (EFSA, 2008b), Guidance on microorganisms used as feed additive or as production organisms (EFSA FEEDAP Panel, 2018).

3. Assessment

l‐Tryptophan minimum 98% produced by fermentation using E. coli KCCM 80152 is intended to be used as a nutritional feed additive under the functional group ‘amino acids, their salts and analogues’ in feed and water for drinking for all animal species.

3.1. Characterisation

3.1.1. Characterisation of the production organism

■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■

The susceptibility of the production strain to all antibiotics recommended by EFSA for E. coli in the 2012 guidance (EFSA FEEDAP Panel, 2012d) was assayed by broth microdilution. ■■■■■■■■■■

3.1.1.1. Information relating to the genetic modification

Characteristics of the recipient or parental microorganism

The recipient strain is E. coli KCCM 11132P, which was derived from E. coli K‐12 W3110 by classical mutagenesis and genetic modification. E. coli KCCM 11132P ■■■■■ This strain has been previously characterised by the FEEDAP Panel in a previous opinion (EFSA FEEDAP Panel, 2015b), and did not raise safety concerns.

Characteristics of the donor organism

■■■■■

■■■■■■■■■■■■■■■

Description of the genetic modification process

■■■■■■■■■■■■■■■

■■■■■

3.1.2. Manufacturing process

The dossier contains information on the production process■■■■■16

■■■■■■■■■■

3.1.3. Characterisation of the additive

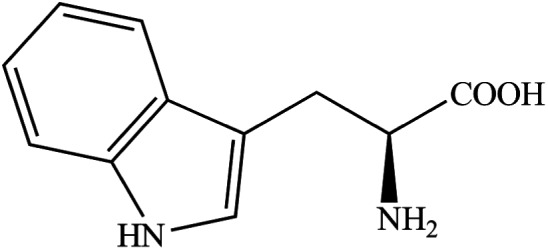

l‐Tryptophan (International Union of Pure and Applied Chemistry (IUPAC) name: (2S)‐2‐amino‐3‐(1H‐indol‐3‐yl) propanoic acid; synonyms: (S)‐α‐amino‐1‐H‐indole‐3‐propanoic acid, l‐α‐aminoindole‐3‐propionic acid, l‐α‐amino‐3‐indolepropionic acid, 2‐amino‐3‐indolylpropanoic acid, l‐β‐3‐indolylalanine) has the Chemical Abstracts Service (CAS) No 73‐22‐3 and European Inventory of Existing Commercial Chemical Substances (EINECS) No 200‐795‐6. The chemical formula is C11H12N2O2, the molecular weight is 204.23 g/mol. The structural formula is given in Figure 1.

Figure 1.

Structural formula of l‐tryptophan

The l‐tryptophan content of the product is specified as ≥ 98%, the other components being water ≤ 1%, and crude ash ≤ 1%.18

The analysis of five batches of l‐tryptophan showed an average content of tryptophan of 98.8% on as is basis (range 98.5–99.4%) and moisture was 0.1%.19 On a dry matter basis, the amount of tryptophan was, on average, 98.9% (range 98.6–99.5%).

The applicant provided additional data on five batches of the additive to determine the amount of identified matter in the additive.20 On as is basis, the amount of identified material was 99.0%. Tryptophan was analysed by an unspecified High Performance Liquid Chromatography (HPLC) method.

The specific optical rotation of three batches of the final product was measured by the European Pharmacopeia method. Analytical values ranged from −30.5° to −31.2°,21 which is within the range described in the European Pharmacopoeia (−30° to −33°) for this amino acid and confirms the identity of the l‐enantiomer.22

3.1.3.1. Impurities

Five batches of the final product were analysed for heavy metals (lead, cadmium and mercury) and arsenic.23 Lead and arsenic were below the limit of detection (LOD), mercury ranged from below LOD to 0.023 mg/kg and cadmium from below LOD to 0.21 mg/kg. Copper ranged from 2.1 to 5.4 mg/kg and zinc ranged from below LOD to 10.4 mg/kg.

Analysis of microbial contamination of the final product (five batches) indicated that Salmonella spp. (in 25‐g samples) was absent whereas total bacterial count, E. coli, yeasts and filamentous fungi were < 103 CFU/g.24

Mycotoxins were analysed in five batches of the final product.25 Aflatoxins (not specified) ranged from below LOD to 0.2 μg/kg. Ochratoxin A, zearalenone and deoxinivalenol had concentrations below LOD (except one batch that had 6 μg ochratoxin A/kg).

Dioxins (polychlorinated dibenzodioxins (PCDDs) and polychlorinated dibenzofurans (PCDFs)) and dioxin‐like polychlorinated biphenyls (PCBs) were analysed in five batches of the final product. Dioxins (WHO‐PCDD/F‐TEQ) ranged from 0.16 to 0.33 ng/kg and the sum of dioxins and dioxin like PCBs (WHO‐PCDD/F‐PCB‐TEQ) ranged from 0.30 to 0.58 ng/kg.26

The endotoxin activity (three batches analysed by European Pharmacopoeia method) ranged from 0.36 to 0.40 IU/mg.27

1,1′‐Ethylidene‐bis‐l‐tryptophan (EBT) and 1‐methyl‐1,2,3,4‐tetrahydro‐beta‐carboline‐3‐carboxylic acid (MTCA), present in a specific brand of l‐tryptophan produced by fermentation, were implicated in the eosinophilia–myalgia syndrome outbreak that occurred in humans in New Mexico in 1989 (Hertzman et al., 1990). The concentrations of EBT and MTCA were analysed in three batches of the final product (EurPh method 2.2.29) and were below the LOD in all three batches.28 The maximum permitted content of EBT (impurity A) and the sum of all other impurities (B‐L, including MTCA), in l‐tryptophan, as specified by the European Pharmacopoeia (2010), is 10 mg/kg and 390 mg/kg, respectively.

■■■■■■■■■■ Positive controls were included.

■■■■■■■■■■■■■■■

3.1.3.2. Physical characteristics

The product under assessment is a solid pale brownish odourless powder. Bulk density ranged from 350 to 500 kg/m3.31 Its water solubility is 10.6 g/L at 20°C.32 The hydrogen potential (pH) ranged from 6.2 to 6.8.33

The particle size distribution (three batches analysed by sieving) showed that the percentages of particles having a diameter below 88 μm were 73, 75 and 77% (w/w), respectively.34

The dusting potential was analysed (Stauber–Heubach method) in three batches of the product under assessment. The results ranged from 1.97 to 6.66 g/m3.35

3.1.3.3. Stability and homogeneity

The applicant submitted a study on the shelf‐life of the additive and a study on the stability of the additive in water for drinking performed with the additive under assessment. The rest of the stability studies (shelf‐life at room temperature, stability in premixtures and in feedingstuffs and capacity to distribute homogeneously in premixtures and in pelleted feed) were performed with l‐tryptophan produced by different E. coli strains (KCCM 80135 or KCCM 11132P) from the same producer (EFSA FEEDAP Panel, 2015b, 2019c).36 As the production strains share a common lineage (E. coli K12 derivatives), the manufacturing process is the same and the product characteristics are very similar, the FEEDAP Panel considers that the stability and homogeneity studies performed with l‐tryptophan of the other two production strains are indicative of the stability of the product under assessment. No information was available on the stability of the additive during feed processing.

The shelf‐life of three batches of the additive under assessment was tested at 25 ± 2°C and at 40 ± 2°C when packed in double polyethylene bags for 6 months.37 No losses were observed. No losses were observed in three batches produced by another strain (KCCM 11132P) stored at 25°C up to 3 years.

The stability of three batches l‐tryptophan produced by another strain (E. coli KCCM 80135) in a vitamin mineral premixture (containing 4% choline chloride) at a supplementation rate of 0.5% was tested at 25 ± 2°C for 6 months. The premixture was packed in aluminium vacuum bags. The losses observed ranged from 0.4 to 2.2% after the 6‐month period.38 (VDLUFA method)

The stability of three batches of l‐tryptophan produced by another strain (E. coli KCCM 80135) in a complete feed for chickens for fattening (mash feed based on maize, soybean meal and wheat), at a supplementation rate of 0.4%, was tested after storage at 25 ± 2°C in aluminium vacuum bags for 3 months. After the 3‐month period, the observed losses ranged from 0.5 to 4.6%.39

The capacity of l‐tryptophan produced by another strain (E. coli KCCM 80135) to distribute homogeneously in the premixture described above was studied by analysing 10 subsamples. The coefficient of variation (CV) was 5.7%.40

The capacity of l‐tryptophan produced by another strain (E. coli KCCM 80135) to distribute homogeneously in a pelleted complete feed for chickens for fattening when supplemented at 0.2% was studied analysing 10 subsamples. After mixing, the complete feed was preconditioned using water steam at ≤ 72°C, pelleted at 81°C, dried at 60–65°C and then cooled for 10 min to 23°C. The CV was 2.9%.41 No measurement was performed between mixing and preconditioning (stability during feed processing).

The stability of the additive under assessment in water for drinking (three batches) was measured at a concentration of 0.5 g/L when stored at 25 and 40°C for 48 h. Losses were < 1% in both cases.42

3.1.3.4. Physico‐chemical incompatibilities

No physico‐chemical incompatibilities in feed are expected with other additives, medical products or feed materials.

3.1.4. Conditions of use

It is proposed that l‐tryptophan will be used in feeds to achieve an adequate amino acid profile and to meet the l‐tryptophan requirements for all animal species. It can be added directly to feedingstuffs/complementary feedingstuffs or via premixtures. The additive is also proposed for use in water for drinking. No inclusion levels have been proposed as the requirements, in quantitative terms, depend on the species, the physiological state of the animal, the performance level, the environmental conditions and the amino acid composition of the unsupplemented diet.

3.2. Safety

3.2.1. Safety of the genetic modification

The recipient organism E. coli KCCM 11132P is considered to be safe. The production strain KCCM 80152 contains ■■■■■ This trait does not raise safety concern.

The production strain and its recombinant DNA were not detected in the additive. The product l‐tryptophan, manufactured by fermentation with E. coli KCCM 80152, does not give rise to any safety concern with regard to the genetic modification of the production strain.

3.2.2. Safety for the target species

Tolerance studies are not normally required for highly purified amino acids. Such tolerance studies with a certain indispensable amino acid will inevitably result in amino acid imbalances, with depression of feed intake and hence impaired performance and increased nitrogen excretion. This is also the case for the product under application which contains on average 98.9% l‐tryptophan and 1% unidentified material on a dry matter basis. The endotoxin activity ranged from 0.36 to 0.40 IU/mg. These values are negligible compared with ca. 1,000 IU/mg commonly found in feedingstuffs (Cort et al., 1990). Therefore, at the usual conditions of use of the additive in feed, the endotoxins added by the additive would be insignificant compared to the background in feed.

The l‐tryptophan requirements of the target animal species and the safety of the use of this essential amino acid in non‐ruminant and ruminant nutrition were summarised in previous opinions of the EFSA FEEDAP Panel (2013, 2015a).

Given the high purity of the product, the FEEDAP Panel considers that the use of l‐tryptophan produced with E. coli KCCM 80152 is safe for non‐ruminant target species when used to supplement the diet in appropriate amounts. The FEEDAP Panel reiterates (2015a) that ruminal metabolism of unprotected l‐tryptophan may result in the production of toxic quantities of 3‐methylindole (skatole), which causes pulmonary disease (fog fever; emphysema) in cattle and goats. Consequently, using unprotected forms of tryptophan in ruminants can be a risk.

The FEEDAP Panel recommended in a previous statement that amino acids, their salts and analogues should generally not be used in water for drinking because of the risk of imbalances and for hygiene reasons (EFSA FEEDAP Panel, 2010).

3.2.2.1. Conclusions on safety for the target species

The use of l‐tryptophan produced using E. coli KCCM 80152 in supplementing feed to compensate for tryptophan deficiency in feedingstuffs is safe for non‐ruminant target species. Using unprotected forms of tryptophan in ruminants can be a risk.

The FEEDAP Panel has concerns on the safety of the simultaneous oral administration of l‐tryptophan via water for drinking and feed.

3.2.3. Safety for the consumer

The absorption and metabolic fate of l‐tryptophan were described in a previous opinion (EFSA FEEDAP Panel, 2013).

The amino acid l‐tryptophan supplemented to feed will be incorporated into proteins of tissues and/or products of animal origin and any of their potential excess will be metabolised and excreted. Therefore, the composition of tissues and products of animal origin will not be affected by the use of l‐tryptophan in animal nutrition.

The product under assessment is produced by fermentation. Concerns for the consumer would derive not from the amino acid itself, which will be incorporated into proteins, but from possible residues from fermentation. Considering that (1) the product originating from E. coli KCCM 80152 is highly purified (average 98.9% l‐tryptophan and 1% unidentified material on a dry matter basis) and (2) the concentrations of EBT and MTCA are < 3 mg/kg additive, no additional toxicological data are required.

3.2.3.1. Conclusions on safety for the consumer

The use of l‐tryptophan produced by fermentation with E. coli KCCM 80152 in animal nutrition raises no safety concerns for consumers of animal products.

3.2.4. Safety for the user

The applicant provided an acute inhalation toxicity test, an eye irritation test, a skin irritation test and a dermal sensitisation test performed with l‐tryptophan produced by a different production strain (E. coli KCCM 11132P or E. coli KCCM 80135).43 As the purity and physical characteristics of the test item are very similar to the ones of the product under assessment, the production process is the same and the strains share a common lineage, the FEEDAP Panel considers that the results of the toxicological studies performed with l‐tryptophan originating from those two E. coli strains can be used to support the safety for the user of l‐tryptophan produced with E. coli KCCM 80152.

3.2.4.1. Effects on the respiratory system

The additive contains about 74–77% of particles have a diameter < 88 μm and there is indirect evidence that the dusting potential is up 6.7 g/m3 (see Section 3.1.3).

In an acute inhalation toxicity study in accordance with the Organisation for Economic Co‐operation and Development (OECD) Guideline 403,44 a group of 10 RccHan™:WIST strain rats (five males and five females) were exposed to a concentration of 5.1 mg l‐tryptophan (98.5% purity)/l air for 4 h (nose only exposure system). The signs observed (decreased/increased respiratory rate, hunched posture, piloerection and wet fur) disappeared on day 4 after exposure. No mortality occurred and no macroscopic lesions were observed at the necropsy. The 4 h LC50 for acute inhalation toxicity is considered to be > 5.1 mg/L.

The endotoxin activity in the additive was up to 0.40 IU/mg. The scenario used to estimate the exposure of persons handling the additive to endotoxins in the dust, based on the EFSA Guidance on user safety (EFSA FEEDAP Panel, 2012b) is described in the Appendix A. The health‐based recommended threshold for the quantity of inhaled endotoxins per working day is 900 IU, derived from provisional occupational exposure limits given by the Dutch Expert Committee on Occupational Safety (DECOS) (Health Council of the Netherlands, 2010) and the UK Health and Safety Executive (HSE, 2013). Based upon the calculation of the potential endotoxin content in dust, the inhalation exposure could be up to 1,479 endotoxin IU per working day, indicating thus an inhalation exposure to endotoxins for persons handling the additive.

3.2.4.2. Effects on skin and eyes

In an in vitro bovine corneal opacity and permeability (BCOP) assay (method B.47 of Commission Regulation (EC) No 440/2008), 0.75 mL of a concentration of 20% l‐tryptophan (w/v, 98.7% purity) in sodium chloride (0.9% solution) was applied to incubated adult cattle corneas for 4 h.45 Negative (sodium chloride solution 0.9%) and positive control (imidazole 20% solution in sodium chloride 0.9%) items were tested concurrently. The two endpoints measured, decreased light transmission through the cornea (opacity) and increased passage of sodium fluorescein dye through the cornea (permeability) were combined in an empirically derived formula to obtain an in vitro irritancy score (IVIS). As the IVIS score for the test item was ≤ 3, no classification is required. The controls performed as expected.

In an in vitro skin irritation study using reconstructed human epidermis model (EPISKIN™) in accordance with OECD Guideline 439, 10 mg of l‐tryptophan (98.7% purity) was applied (triplicate tissues) topically on the epidermal surface for 15 min, rinsed and followed by a post‐exposure incubation period of 42 h.46 Potential cytotoxicity of the test item was measured by the colorimetric 3‐(4,5‐dimethylthiazol‐2‐yl)‐2,5‐diphenyltetrazolium bromide (MTT) reduction assay and compared with negative (10 μL of Dulbecco's phosphate‐buffered saline solution) or positive (10 μL of sodium lauryl sulphate 5% w/v) controls. The relative mean viability of the test item treated tissues was 110% after 42 h post exposure incubation period. The controls performed as expected. The test item was considered not irritant for the skin.

In an in vivo skin sensitisation study (local lymph node assay in mouse) in accordance with OECD Guideline 429, l‐tryptophan (98.5% purity) caused no signs of toxicity, visual local skin irritation or irritation indicated by an ≥ 25% increase in mean ear thickness.47 Consequently, the additive was classified as non‐skin sensitiser.

3.2.4.3. Conclusions on safety for the user

From an acute toxicity inhalation study, there are no indications that the product under assessment is toxic by inhalation. Nevertheless, the persons handling the additive may be exposed to endotoxins by inhalation. The additive is not considered irritant for skin or eyes and is not considered a skin sensitiser.

3.2.5. Safety for the environment

The amino acid l‐tryptophan is a physiological and natural component of animals and plants. When given to animals, it is not excreted as such, but as urea/uric acid, indole‐related compounds and carbon dioxide. The use of the product l‐tryptophan in animal nutrition would not lead to any localised increase in the concentration in the environment. It is concluded that the use of the product under assessment, produced by E. coli KCCM 80152 as a feed additive does not represent a risk to the environment.

The production strain E. coli KCCM 80152 and its recombinant DNA were not detected in the final product. The product does not pose any environmental safety concern associated with the genetic modification of the production strain.

3.3. Efficacy

Efficacy studies are not required for amino acids naturally occurring in the proteins of plants and animals. The nutritional role of the amino acid l‐tryptophan is well established in the scientific literature. The additive feed grade l‐tryptophan is regarded as an effective source of the amino acid l‐tryptophan.

Overdosing of supplemental l‐tryptophan may increase skatole and indole in the hind gut resulting in boar taint of pork (Zamaratskaia and Squires, 2008).

The efficacy of this essential amino acid in non‐ruminant and ruminant nutrition was summarised in a previous opinion of the EFSA FEEDAP Panel (2014b). The FEEDAP Panel reiterates that, if the product l‐tryptophan is used in ruminants, it should be protected from ruminal degradation.

3.4. Post‐market monitoring

The FEEDAP Panel considers that there is no need for specific requirements for a post‐market monitoring plan other than those established in the Feed Hygiene Regulation48 and Good Manufacturing Practice.

4. Conclusions

The production strain and its recombinant DNA were not detected in the additive. l‐Tryptophan, manufactured by fermentation with E. coli KCCM 80152, does not give rise to any safety concern with regard to the genetic modification of the production strain.

The use of l‐tryptophan produced using E. coli KCCM 80152 in supplementing feed to compensate for tryptophan deficiency in feedingstuffs is safe for non‐ruminant target species. Using unprotected forms of tryptophan in ruminants can be a risk.

The use of l‐tryptophan produced by fermentation using E. coli KCCM 80152 in animal feed presents no concerns to consumers of animal products.

Due to the content of endotoxins, the additive poses a risk for persons handling the additive when exposed by inhalation. The additive is not considered irritant for skin or eyes and is not considered a skin sensitiser.

The additive under assessment is safe for the environment.

The additive under assessment is regarded as an effective source of the amino acid l‐tryptophan for all non‐ruminant species. If l‐tryptophan is intended for use in ruminants, it should be protected from ruminal degradation.

5. Recommendations

It is recommended that the specification of the additive complies with the European Pharmacopeia with regard to l‐tryptophan impurities.

Chronology

| Date | Event |

|---|---|

| 29/9/2017 | Dossier received by EFSA. Feed grade l‐tryptophan produced with Escherichia coli K12 KCCM 80152. Submitted by CJ Europe GmbH |

| 5/10/2017 | Reception mandate from the European Commission |

| 21/2/2018 | Application validated by EFSA – Start of the scientific assessment |

| 26/4/2018 | Request of supplementary information to the applicant in line with Article 8(1)(2) of Regulation (EC) No 1831/2003 – Scientific assessment suspended. Issues: characterisation of the additive, stability, characterisation of the production strain and of the genetic modification process |

| 21/5/2018 | Comments received from Member States |

| 18/5/2018 | Reception of the Evaluation report of the European Union Reference Laboratory for Feed Additives |

| 4/7/2018 | Reception of supplementary information from the applicant ‐ Scientific assessment re‐started |

| 9/10/2018 | Request of supplementary information to the applicant in line with Article 8(1)(2) of Regulation (EC) No 1831/2003 – Scientific assessment suspended Issues: Characterisation of the production strain |

| 18/10/2018 | Reception of supplementary information from the applicant – Scientific assessment re‐started |

| 30/10/2018 | Request of supplementary information to the applicant in line with Article 8(1)(2) of Regulation (EC) No 1831/2003 – Scientific assessment suspended Issues: Characterisation of the additive |

| 6/12/2018 | Reception of supplementary information from the applicant ‐ Scientific assessment re‐started |

| 14/12/2018 | Request of supplementary information to the applicant in line with Article 8(1)(2) of Regulation (EC) No 1831/2003 – Scientific assessment suspended Issues: Characterisation of the additive |

| 6/3/2019 | Reception of supplementary information from the applicant – Scientific assessment re‐started |

| 3/4/2019 | Opinion adopted by the FEEDAP Panel. End of the Scientific assessment |

Abbreviations

- BCOP

bovine corneal opacity and permeability

- CAS

Chemical Abstracts Service

- CFU

colony‐forming unit

- CV

coefficient of variation

- EBT

1′‐Ethylidene‐bis‐l‐tryptophan

- EURL

European Union Reference Laboratory

- FCC

Food Chemical Codex

- HPLC

High Performance Liquid Chromatography

- LOD

limit of detection

- MTCA

1‐methyl‐1,2,3,4‐tetrahydro‐beta‐carboline‐3‐carboxylic acid

- NDA

Dietetic Products, Nutrition and Allergies

- PCDDs

polychlorinated dibenzodioxins

- PCDFs

polychlorinated dibenzofurans

- VKM

Norwegian Scientific Committee for Food Safety

- WHO

World Health Organization

Appendix A – Safety for the user

1.

The effects of endotoxin inhalation and the exposure limits have been described in a previous opinion (EFSA FEEDAP Panel, 2015a,b).

Calculation of maximum acceptable levels of exposure from feed additives

The probable exposure time according to EFSA guidance (EFSA FEEDAP Panel, 2012b) for additives added in premixtures assumes a maximum of 40 periods of exposure per day, each comprising 20 s = 40 × 20 = 800 s/day. With an uncertainty factor of 2, maximum inhalation exposure would occur for 2 × 800 = 1,600 s = 0.444 h/day. Again, assuming a respiration volume of 1.25 m3/h, the inhalation volume providing exposure to potentially endotoxin‐containing dust would be 0.444 × 1.25 = 0.556 m3/day. This volume should contain no more than 900 IU endotoxin, so the dust formed from the product should contain no more than 900/0.556 = 1,619 IU/m3.

Calculation of endotoxin content of dust

Two key measurements are required to evaluate the potential respiratory hazard associated with the endotoxin content of the product (the dusting potential of the product, expressed in g/m3, and the endotoxin activity of the dust, determined by the Limulus amoebocyte lysate assay (expressed in IU/g)). If data for the dust are not available, the content of endotoxins of the product can be taken instead. If the content of endotoxins of the relevant additive is a IU/g and the dusting potential is b g/m3, then the content of endotoxins of the dust, c IU/m3, is obtained by simple multiplication, a × b. This resulting value is further used for calculation of the potential inhalatory exposure of users to endotoxins from the additive under assessment (Table A.1) (EFSA FEEDAP Panel, 2012b).

Table A.1.

Estimation of user exposure to endotoxins from the additive l‐tryptophan produced by Escherichia coli KCCM 80152, including consideration of using a filter mask FF P2 or FF P3 as a preventative measure

| Calculation | identifier | Description | Amount | Source |

|---|---|---|---|---|

| a | Endotoxin content IU/g product | 400 | Technical dossier | |

| b | Dusting potential (g/m3) | 6.657 | Technical dossier | |

| a × b | c | Endotoxin content in the air (IU/m3) | 2,662.8 | |

| d | No of premixture batches made/working day | 40 | EFSA Guidance on user safety (EFSA FEEDAP Panel, 2012b) | |

| e | Time of exposure (s) per production of one batch | 20 | EFSA Guidance on user safety (EFSA FEEDAP Panel, 2012b) | |

| d × e | f | Total duration of daily exposure/worker (s) | 800 | |

| g | Uncertainty factor | 2 | EFSA Guidance on user safety (EFSA FEEDAP Panel, 2012b) | |

| f × g | h | Refined total duration of daily exposure/worker (s) | 1,600 | |

| h/3,600 | i | Refined total duration of daily exposure (h) | 0.44 | |

| j | Inhaled air (m3) per 8‐h working day | 10 | EFSA Guidance on user safety (EFSA FEEDAP Panel, 2012b) | |

| j/8 × i | k | Inhaled air during exposure (m3) | 0.56 | |

| c × k | l | Endotoxin inhaled (IU) during exposure per 8‐h working day | 1,479 | |

| m | Health‐based recommended exposure limit of endotoxin (IU/m3) per 8‐h working day | 90 | Health Council of the Netherlands, 2010 | |

| m × j | n | Health‐based recommended exposure limit of total endotoxin exposure (IU) per 8‐h working day | 900 | |

| l/10 | Endotoxins inhaled (IU) per 8‐h working day reduced by filter mask FF P2 (reduction factor 10) | 148 | ||

| l/20 | Endotoxins inhaled (IU) per 8‐h working day reduced by filter mask FF P3 (reduction factor 20) | 74 |

Annex A – Executive summary of the European Union Reference Laboratory for Feed Additives on the Methods of Analysis for l‐tryptophan produced by Escherichia coli K12 KCCM 80152

1.

In the current application, authorisation is sought under Article 4(1) for l‐ tryptophan produced by Escherichia coli K12 KCCM 80152, under the category/functional group 3(c) ‘nutritional additives’/‘amino acids, their salts and analogues’, according to Annex I of Regulation (EC) No 1831/2003. Authorisation is sought for all animal species. l‐ tryptophan is already authorised as feed additive under Commission Implementing Regulation (EU) 2017/873. According to the Applicant, the product has a minimum purity of 98% and it is intended to be mixed either in premixtures or added directly to feedingstuffs or water for drinking. However, the Applicant did not propose a minimum or maximum l‐ tryptophan content in feedingstuffs.

For the quantification of l‐ tryptophan in the feed additive, premixtures, feedingstuffs and water, the Applicant submitted a single‐laboratory validated analytical method based on High Performance Liquid Chromatography (HPLC) with photometric detection. However, based on the data provided, the European Union Reference Laboratory (EURL) cannot recommend this method for official control. The EURL previously evaluated and recommended (i) the ring‐trial validated

EN ISO 13904:2016 method based on HPLC with fluorescence detection (HPLC‐FLD) for the quantification of l‐ tryptophan in feed additive and premixtures (containing more than 2% of tryptophan); and (ii) the ring‐trial validated Community method based on HPLC‐FLD for the quantification of l‐ tryptophan in feedingstuffs. Based on the performance characteristics available, the EURL recommends for official control these two ring‐trial validated methods to quantify tryptophan in the feed additive, premixtures and/or feedingstuffs. In addition, the EURL identified the “l‐tryptophan monograph” of the Food Chemical Codex (FCC) for the identification of the feed additive. Furthermore, in the frame of the stability studies, the Applicant presented experimental data obtained analysing tryptophan in water with the VDLUFA official method based on HPLC‐FLD dedicated for the determination of tryptophan in feed. The results presented are considered sufficient to demonstrate the suitability of the method for the analysis of the amino acid in water. Hence, the EURL recommends for official control this method to quantify tryptophan in water.

Further testing or validation of the methods to be performed through the consortium of National Reference Laboratories as specified by Article 10 (Commission Regulation (EC) No 378/2005, as last amended by Regulation (EU) 2015/1761) is not considered necessary.

Suggested citation: EFSA Panel on Additives and Products or Substances used in Animal Feed (FEEDAP) , Bampidis V, Azimonti G, Bastos ML, Christensen H, Dusemund B, Kouba M, Kos Durjava M, López‐Alonso M, López Puente S, Marcon F, Mayo B, Pechová A, Petkova M, Sanz Y, Villa RE, Woutersen R, Costa L, Dierick N, Flachowsky G, Glandorf B, Herman L, Mantovani A, Saarela M, Wallace RJ, Anguita M, Tarrés‐Call J and Ramos F, 2019. Scientific Opinion on the safety and efficacy of l‐tryptophan produced by fermentation with Escherichia coli KCCM 80152 for all animal species. EFSA Journal 2019;17(5):5695, 16 pp. 10.2903/j.efsa.2019.5695

Requestor: European Commission

Question number: EFSA‐Q‐2017‐00693

Panel members: Giovanna Azimonti, Vasileios Bampidis, Maria de Lourdes Bastos, Henrik Christensen, Birgit Dusemund, Maryline Kouba, Mojca Kos Durjava, Marta López‐Alonso, Secundino López Puente, Francesca Marcon, Baltasar Mayo, Alena Pechová, Mariana Petkova, Fernando Ramos, Yolanda Sanz, Roberto Edoardo Villa and Ruud Woutersen.

Acknowledgements: The Panel wishes to thank the following for the support provided to this scientific output: Jaume Galobart, Matteo Innocenti and Orsolya Holczknecht.

Legal notice: Relevant information or parts of this scientific output have been blackened in accordance with the European Commission decision on the confidentiality requests formulated by the applicant. The full output has been shared with the European Commission, EU Member States and the applicant.

Adopted: 3 April 2019

Notes

Regulation (EC) No 1831/2003 of the European Parliament and of the Council of 22 September 2003 on additives for use in animal nutrition. OJ L 268, 18.10.2003, p. 29.

CJ Europe GmbH, Ober der Roeth 4, 65824 Schwalbach am Taunus, Germany.

Commission implementing regulation (EU) 2017/873 of 22 May 2017 concerning the authorisation of l‐tryptophan produced by Escherichia coli as feed additive for all animal species. OJ L 134, 23.5.2017, p. 14.

Regulation (EU) No 609/2013 of the European Parliament and of the Council of 12 June 2013 on food intended for infants and young children, food for special medical purposes and total diet replacement for weight control and repealing Council Directive 92/52/EEC, Commission Directives 96/8/EC, 1999/21/EC, 2006/125/EC and 2006/141/EC, Directive 2009/39/EC of the European Parliament and of the Council and Commission Regulations (EC) No 41/2009 and (EC) No 953/2009, OJ L 181, 29.6.2013, p. 35.

Commission Decision of 9 February 2006 amending Decision 96/335/EC establishing an inventory and a common nomenclature of ingredients employed in cosmetic products. OJ L 97, 5.4.2006, p. 1–528.

Commission Regulation (EU) No 37/2010 of 22 December 2009 on pharmacologically active substances and their classification regarding maximum residue limits in foodstuffs of animal origin. OJ L 15, 20.1.2010, p. 1.

Regulation (EC) No 470/2009 of the European Parliament and of the Council of 6 May 2009 laying down Community procedures for the establishment of residue limits of pharmacologically active substances in foodstuffs of animal origin, repealing Council Regulation (EEC) No 2377/90 and amending Directive 2001/82/EC of the European Parliament and of the Council and Regulation (EC) No 726/2004 of the European Parliament and of the Council. OL L 152, 16.6.2009, p. 11.

FEED dossier reference: FAD‐2017‐0052.

The full report is available on the EURL website: https://ec.europa.eu/jrc/sites/jrcsh/files/finrep-fad-2017-0052-tryptophan.pdf

■■■■■

■■■■■

■■■■■

■■■■■

■■■■■

■■■■■

Technical dossier/Section II.2.3.1.

■■■■■

Technical dossier/Section II.1.3 and Table II.1.3a.

Technical dossier/Section II/Annex II.1.6. Tryptophan determined by analytical method VDLUFA 4.11.2.

Technical dossier/Section II/Annex II.1.4 and supplementary information July 2018/SIN CJ Trp 80152.

Technical dossier/Supplementary information December 2018/Annex SIN 1.

European Pharmacopoeia monograph 1/2015:1272.

Technical dossier/Section II/Annex II.1.6. LOD in mg/kg were 0.01 for mercury, 0.1 for cadmium, 0.2 for zinc and 1 for lead and arsenic.

Technical dossier/Section II/Annex II.1.5.

Technical dossier/Section II/Annex II.1.5. LOD (in µg/kg) was 0.1 for aflatoxins, 5 for ochratoxin A, 17 for zearalenone and 134 for deoxynivalenol.

Technical dossier/Section II/Annex II.1.6.

Technical dossier/Supplementary information July 2018/Annex SIN 01.

Technical dossier/Section II/Annexes II.1.8 and Supplementary information July 2018/Annex SIN 02, LOD was 3 mg/kg.

■■■■■

■■■■■

Technical dossier/Section II/Annex II.3.1.

Technical dossier/Section II.1.5.

Technical dossier/Section II/Annex II.1.3.

Technical dossier/Section II.1.5, table II.1.5a and annex II.1.8.

Technical dossier/Supplementary information December 2018/Annex SIN 2.

Technical dossier/Supplementary information July 2018/SIN CJ L‐trp 80152.

Technical dossier/Section II/Annex II.4.2.

Technical dossier/Section II/Annex II.4.3.

Technical dossier/Section II/Annex II.4.4.

Technical dossier/Section II/Annex II.4.7.

Technical dossier/Section II/Annex II.4.6.

Tehcnical dossier/Section II/Annex II.4.5.

Technical dossier/Supplementary information July 2018/SIN CJ L‐try 18152/Answer to question 1.

Technical dossier/Seciton III/Annex III.3a.

Technical dossier/Section III/Annex III.3.3.

Technical dossier/Section III/Annex III.3.4.

Technical dossier/Section III/Annex III.3.5.

Regulation (EC) No 183/2005 of the European Parliament and of the Council of 12 January 2005 laying down requirements for feed hygiene. OJ L 35, 8.2.2005, p. 1.

References

- Cort N, Fredriksson G, Kindahl H, Edqvist LE and Rylander R, 1990. A clinical and endocrine study on the effect of orally administered bacterial endotoxin in adult pigs and goats. Journal of Veterinary Medicine Series A, 37, 130–137. [DOI] [PubMed] [Google Scholar]

- EFSA (European Food Safety Authority), 2008a. Technical Guidance of the Scientific Panel on Additives and Products or Substances used in Animal Feed (FEEDAP) for assessing the safety of feed additives for the environment. EFSA Journal 2008;6(10):842, 28 pp. 10.2903/j.efsa.2008.842 [DOI] [Google Scholar]

- EFSA (European Food Safety Authority), 2008b. Technical guidance: Microbial studies. EFSA Journal 2008;6(10):836, 3 pp. 10.2903/j.efsa.2008.836 [DOI] [Google Scholar]

- EFSA FEEDAP Panel (EFSA Panel on Additives and Products or Substances used in Animal Feed) , 2010. Scientific opinion on the use of feed additives authorised/applied for use in feed when supplied via water. EFSA Journal 2010;8(12):1956, 9 pp. 10.2903/j.efsa.2010.1956. Available online: http://www.efsa.europa.eu/efsajournal [DOI] [Google Scholar]

- EFSA FEEDAP Panel (EFSA Panel on Additives and Products or Substances used in Animal Feed), 2011. Technical guidance: Tolerance and efficacy studies in target animals. EFSA Journal 2011;9(5):2175, 15 pp. 10.2903/j.efsa.2011.2175 [DOI] [Google Scholar]

- EFSA FEEDAP Panel (EFSA Panel on Additives and Products or Substances used in Animal Feed), 2012a. Guidance for the preparation of dossiers for nutritional additives. EFSA Journal 2012;10(1):2535, 14 pp. 10.2903/j.efsa.2012.2535 [DOI] [Google Scholar]

- EFSA FEEDAP Panel (EFSA Panel on Additives and Products or Substances used in Animal Feed), 2012b. Guidance for establishing the safety of additives for the consumer. EFSA Journal 2012;10(1):2537, 12 pp. 10.2903/j.efsa.2012.2537 [DOI] [Google Scholar]

- EFSA FEEDAP Panel (EFSA Panel on Additives and Products or Substances used in Animal Feed), 2012c. Guidance on studies concerning the safety of use of the additive for users/workers. EFSA Journal 2012;10(1):2539, 5 pp. 10.2903/j.efsa.2012.2539 [DOI] [Google Scholar]

- EFSA FEEDAP Panel (EFSA Panel on Additives and Products or Substances used in Animal Feed), 2012d. Guidance on the assessment of bacterial susceptibility to antimicrobials of human and veterinary importance. EFSA Journal 2012;10(6):2740, 10 pp. 10.2903/j.efsa.2012.2740 [DOI] [Google Scholar]

- EFSA FEEDAP Panel (EFSA Panel on Additives and Products or Substances used in Animal Feed), 2013. Scientific opinion on the safety and efficacy of L‐tryptophan produced by Escherichia coli (FERM BP‐11200) for all animal species based on a dossier submitted by Ajinomoto Eurolysine SAS. EFSA Journal 2013;11(10):3368, 2 pp. 10.2903/j.efsa.2013.3368 [DOI] [Google Scholar]

- EFSA FEEDAP Panel (EFSA Panel on Additives and Products or Substances used in Animal Feed), 2014a. Scientific Opinion on the safety and efficacy of L‐tryptophan produced by Escherichia coli (FERM BP‐11354) for all animal species, based on a dossier submitted by Ajinomoto Eurolysine S.A.S. EFSA Journal 2014;12(10):3826, 13 pp. 10.2903/j.efsa.2014.3826 [DOI] [Google Scholar]

- EFSA FEEDAP Panel (EFSA Panel on Additives and Products or Substances used in Animal Feed), 2014b. Scientific Opinion on the safety and efficacy of L‐tryptophan technically pure produced by fermentation with Escherichia coli for all animal species, based on a dossier submitted by HELM AG on behalf of Global Bio‐Chem Technology. EFSA Journal 2014;12(5):3673, 2 pp. 10.2903/j.efsa.2014.3673 [DOI] [Google Scholar]

- EFSA FEEDAP Panel (EFSA Panel on Additives and Products or Substances used in Animal Feed), 2015a. Scientific Opinion on the safety and efficacy of L‐tryptophan produced by Escherichia coli CGMCC 7.59 for all animal species based on a dossier submitted by HELM AG on behalf of Meihua Holdings Co. Ltd. EFSA Journal 2015;13(2):4015, 17 pp. 10.2903/j.efsa.2015.4015 [DOI] [Google Scholar]

- EFSA FEEDAP Panel (EFSA Panel on Additives and Products or Substances used in Animal Feed), 2015b. Scientific Opinion on the safety and efficacy of L‐tryptophan, technically pure, produced by Escherichia coli strains DSM 25084, KCCM 11132P or SARI12091203 for all animal species based on a dossier submitted by AMAC EEIG. EFSA Journal 2015;13(9):4238, 29 pp. 10.2903/j.efsa.2015.4238 [DOI] [Google Scholar]

- EFSA FEEDAP Panel (EFSA Panel on Additives and Products or Substances used in Animal Feed), 2016a. Scientific opinion on the safety of L‐tryptophan produced by fermentation using Escherichia coli CGMCC 3667, for all animal species based on a dossier submitted by GBT Europe GmbH. EFSA Journal 2016;14(1):4343, 13 pp. 10.2903/j.efsa.2016.4343 [DOI] [Google Scholar]

- EFSA FEEDAP Panel (EFSA Panel on Additives and Products or Substances used in Animal Feed), 2016b. Scientific opinion on the safety of L‐tryptophan produced by fermentation with Escherichia coli CGMCC 7.59 for all animal species based on a dossier submitted by Feedway Europe NV. EFSA Journal 2016;14(5):4444, 9 pp. 10.2903/j.efsa.2016.4444 [DOI] [Google Scholar]

- EFSA FEEDAP Panel (EFSA Panel on Additives and Products or Substances used in Animal Feed), Rychen G, Aquilina G, Azimont i G, Bampidis V, Bastos ML, Bories G, Chesson A, Cocconcelli PS, Flachowsky G, Gropp J, Kolar B, Kouba M, López‐Alonso M, López Puente S, Mantovani A, Mayo B, Ramos F, Saarela M, Villa RE, Wester P, Costa LG, Dierick N and Wallace RJ, 2017a. Scientific opinion on the safety of L‐tryptophan technically pure, produced by fermentation with Escherichia coli strains DSM 25084, KCCM 11132P and SARI12091203 for all animal species based on a dossier submitted by FEFANA Asbl. EFSA Journal 2017;15(2):4712, 11 pp. 10.2903/j.efsa.2017.4712 [DOI] [PMC free article] [PubMed] [Google Scholar]

- EFSA FEEDAP Panel (EFSA Panel on Additiv es and Products or Substances used in Animal Feed), Rychen G, Aquilina G, Azimonti G, Bampidis V, Bastos ML, Bories G, Chesson A, Flachowsky G, Gropp J, Kolar B, Kouba M, López‐Alonso M, López Puente S, Mayo B, Ramos F, Saarela M, Villa RE, Wallace RJ, Wester P, Glandorf B, Herman L, Kärenlampi S, Aguilera J and Cocconcelli PS, 2017b. Scientific opinion on the safety of L‐tryptophan technically pure, produced by Escherichia coli CGMCC 3667, for all animal species based on a dossier submitted by GBT Europe GmbH. EFSA Journal 2017;15(3):4705, 7 pp. 10.2903/j.efsa.2017.4705 [DOI] [Google Scholar]

- EFSA FEEDAP Panel (EFSA Panel on Additives and Products or Substances used in Animal Feed), 2018. Rychen G, Aquilina G, Azimonti G, Bampidis V, Bastos ML, Bories G, Chesson A, Cocconcelli PS, Flachowsky G, Gropp J, Kolar B, Kouba M, Lopez‐Alonso M, Lopez Puente S, Mantovani A, Mayo B, Ramos F, Saarela M, Villa RE, Wallace RJ, Wester P, Glandorf B, Herman L, Karenlampi S, Aguilera J, Anguita M, Brozzi R and Galobart J, 2018. Guidance on the characterisation of microorganisms used as feed additives or as production organisms. EFSA Journal 2018;16(3):5206, 24 pp. 10.2903/j.efsa.2018.5206 [DOI] [PMC free article] [PubMed] [Google Scholar]

- EFSA FEEDAP Panel (EFSA Panel on Additives and Products or Substances used in Animal Feed), Bampidis V, Azimonti G, Bastos ML, Christensen H, Dusemund B, Kouba M, Kos Durjava M, Lopez‐Alonso M, Lopez Puente S, Marcon F, Mayo B, Pechova A, Petkova M, Sanz Y, Villa RE, Woutersen R, Costa L, Dierick N, Flachowsky G, Glandorf B, Herman L, Mantovani A, Saarela M, Wallace RJ, Anguita M, Tarres‐Call J and Ramos F, 2019a. Scientific Opinion on the safety and efficacy of L‐tryptophan produced by fermentation with Escherichia coli CGMCC 7.248 for all animal species. EFSA Journal 2019;17(2):5601, 16 pp. 10.2903/j.efsa.2019.5601 [DOI] [Google Scholar]

- EFSA FEEDAP Panel (EFSA Panel on Additives and Products or Substances used in Animal Feed), Bampidis V, Azimonti G, Bastos ML, Christensen H, Dusemund B, Kouba M, Kos Durjava M, Lopez‐Alonso M, Lopez Puente S, Marcon F, Mayo B, Pechova A, Petkova M, Sanz Y, Villa RE, Woutersen R, Costa L, Dierick N, Flachowsky G, Mantovani A, Wallace J, Tarres‐Call J and Ramos F, 2019b. Scientific Opinion on the safety and efficacy of L‐tryptophan produced with Escherichia coli CGMCC 11674 for all animal species. EFSA Journal 2019;17(3):5642, 17 pp. 10.2903/j.efsa.2019.5642 [DOI] [Google Scholar]

- EFSA FEEDAP Panel (EFSA Panel on Additives and Products or Substances used in Animal Feed), Bampidis V, Azimonti G, Bastos ML, Christensen H, Dusemund B, Kouba M, Kos Durjava M, Lopez‐Alonso M, Lopez Puente S, Marcon F, Mayo B, Pechova A, Petkova M, Sanz Y, Villa RE, Woutersen R, Costa L, Dierick N, Flachowsky G, Glandorf B, Herman L, Leng L, Mantovani A, Saarela M, Wallace RJ, Anguita M, Tarres‐Call J and Ramos F, 2019c. Scientific Opinion on the safety and efficacy of L‐tryptophan produced with Escherichia coli KCCM 80135 for all animal species. EFSA Journal 2019;17(4):5694, 21 pp. 10.2903/j.efsa.2019.5694 [DOI] [Google Scholar]

- EFSA GMO Panel (EFSA Panel on Genetically Modified Organisms), 2011. Scientific Opinion on Guidance on the risk assessment of genetically modified microorganisms and their products intended for food and feed use. EFSA Journal 2011;9(6):2193, 54 pp. 10.2903/j.efsa.2011.2193 [DOI] [Google Scholar]

- EFSA NDA Panel (Panel on Dietetic Products, Nutrition and Allergies), 2011. Scientific Opinion on the substantiation of health claims related to L‐tryptophan and maintenance of normal sleep (ID 596, 1671), enhancement of mood (ID 596), contribution to normal cognitive function (ID 596), and contribution to the maintenance or achievement of a normal body weight (ID 604) pursuant to Article 13(1) of Regulation (EC) No 1924/2006. EFSA Journal 2011;9(4):2073, 16 pp. 10.2903/j.efsa.2011.2073 [DOI] [Google Scholar]

- Health Council of the Netherlands , 2010. Endotoxins, 2010. Health‐based recommended occupational exposure limit. Publication No 2010/04OSH. Health Council of the Netherlands, The Hague, 100 pp. [Google Scholar]

- Hertzman PA, Blevins WL, Mayer J, Greenfield B, Ting M and Gleich GJ, 1990. Association of the eosinophilia‐myalgia syndrome with the ingestion of tryptophan. New England Journal of Medicine, 322, 869–873. [DOI] [PubMed] [Google Scholar]

- HSE (Health and Safety Executive), 2013. Occupational hygiene implications of processing waste at materials recycling facilities (MRFs). RR977 Research Report, HSE, London, UK, 41 pp. [Google Scholar]

- VKM , 2013. Risk assessment of Opinion of histidine, methionine, S‐adenosylmethionine and tryptophan. Opinion of the Panel on Nutrition, dietetic products, Novel Food an Allergy of the Norwegian Scientific Committee for Food Safety. ISBN: 978‐82‐8259‐079‐2, Oslo, Norway. [Google Scholar]

- VKM , 2016. Risk assessment of “other substances” – L‐tryptophan. Opinion of the Panel on Nutrition, dietetic products, Novel Food an Allergy of the Norwegian Scientific Committee for Food Safety. ISBN: 978‐82‐8259‐193‐5, Oslo, Norway. [Google Scholar]

- Zamaratskaia G and Squires E, 2008. Biochemical, nutritional and genetic effects on boar taint in entire male pigs. Animal, 2, 1–14. [DOI] [PubMed] [Google Scholar]