Abstract

The EFSA Panel on Food Additives and Nutrient Sources added to Food (ANS) provides a scientific opinion re‐evaluating the safety of propane‐1,2‐diol (E 1520) when used as a food additive. In 1996, the Scientific Committee on Food (SCF) established an acceptable daily intake (ADI) of 25 mg/kg body weight (bw) per day for propane‐1,2‐diol. Propane‐1,2‐diol is readily absorbed from the gastrointestinal and is expected to be widely distributed to organs and tissues. The major route of metabolism is oxidation to lactic acid and pyruvic acid. At high concentrations, free propane‐1,2‐diol is excreted in the urine. No treatment‐related effects were observed in subchronic toxicity studies. The available data did not raise concern with respect to genotoxicity. Haematological changes suggestive of an increased red blood cell destruction with a compensatory increased rate of haematopoiesis were observed at the highest dose level (5,000 mg/kg bw per day) in a 2‐year study in dogs. No adverse effects were reported in a 2‐year chronic study in rats with propane‐1,2‐diol (up to 2,500 mg/kg bw per day). The SCF used this study to derive the ADI. No adverse effects were observed in the available reproductive and developmental toxicity studies. Propane‐1,2‐diol (E 1520) is authorised according to Annex III in some food additives, food flavourings, enzymes and nutrients and it is then carried over to the final food. Dietary exposure to E 1520 was assessed based on the use levels and analytical data. The Panel considered that for the food categories for which information was available, the exposure was likely to be overestimated. Considering the toxicity database, the Panel concluded that there was no reason to revise the current ADI of 25 mg/kg bw per day. The Panel also concluded that the mean and the high exposure levels (P95) of the brand‐loyal refined exposure scenario did not exceed the ADI in any of the population groups from the use of propane‐1,2‐diol (E 1520) at the reported use levels and analytical results.

Keywords: propane‐1,2‐diol; propylene glycol; E 1520; CAS No 57‐55‐6; food additive

Summary

Propane‐1,2‐diol (E 1520) is authorised as a food additive in the European Union (EU) according to Regulation (EC) No 1333/2008 on food additives and specific purity criteria have been defined in the Commission Regulation (EU) No 231/2012.

In 1996, the Scientific Committee on Food (SCF) established an acceptable daily intake (ADI) of 25 mg/kg body weight (bw) per day for propane‐1,2‐diol.

In 1973, the Joint FAO/WHO Expert Committee on Food Additives (JECFA) allocated an ADI of 0–25 mg/kg bw for propane‐1,2‐diol and in 2001 evaluated propane‐1,2‐diol as a food flavouring; however, the Committee did not finalise the evaluation as it wanted confirmation that the substance is actually used as food flavouring. The Panel noted that propane‐1,2‐diol is not authorised as a flavouring substance in the EU according to Regulation 1334/2008.

Propane‐1,2‐diol is readily absorbed from the gastrointestinal tract in experimental animals and in humans and is expected to be widely distributed to organs and tissues. The major route of metabolism is oxidation to lactic acid and pyruvic acid. An alternative route of metabolism of propane‐1,2‐diol to lactic acid is via phosphorylated glycol. At high concentrations, free propane‐1,2‐diol is excreted in the urine as the elimination of propane‐1,2‐diol from the body is saturated at dose levels higher than 20,000 mg/day in humans. The renal clearance in young infants up to the age of approximately 3 months appeared to be much lower than in adults.

The acute oral toxicity of propane‐1,2‐diol was low.

No treatment‐related effects were observed in subchronic toxicity studies in which 1,000 mg propane‐1,2‐diol/kg bw per day was administered by gavage to mice, rats, dogs and monkeys for 92–97 days.

The Panel considered that the available data did not raise concern with respect to genotoxicity of propane‐1,2‐diol.

Except for haematological changes suggestive of an increased red blood cell destruction with a compensatory increased rate of haematopoiesis at the highest dose level (5,000 mg/kg bw per day), no adverse effects were observed in a 2‐year study in dogs administered propane‐1,2‐diol in the diet (2,000 or 5,000 mg/kg bw per day). No adverse effects, including neoplastic findings, were reported in a chronic study in rats administered propane‐1,2‐diol in the diet (up to 2,500 mg/kg bw per day) for 2 years. The SCF and JECFA used the study in rats to derive an ADI of 25 mg/kg bw per day using an uncertainty factor of 100.

No adverse effects were observed in the available reproductive and developmental toxicity studies.

Propane‐1,2‐diol (E 1520) is authorised according to Annex III in some food additives, food flavourings, enzymes and nutrients and it is then carried over to the final food. Dietary exposure to the food additive was assessed based on data received by both industry (use levels) and Member States (analytical data). In the refined exposure assessment scenario, 20 food categories were taken into account. Because propane‐1,2‐diol (E 1520) is authorised only according to Annex III, its labelling is not mandatory, therefore, the Panel considered that the list of uses of this food additive from the Mintel's Global New Products Database (GNPD) was likely not exhaustive.

The exposure assessment was hampered by several uncertainties; overall the Panel considered that for the food categories for which information was available, the exposure was likely to be overestimated. The Panel considered that the brand‐loyal scenario covering the general population was the most appropriate scenario for risk characterisation of E 1520 assuming that the population is likely to be exposed long‐term to the food additive present at the maximum reported use in foods belonging to the food category ‘Flavoured drinks’ and at the mean reported use/analytical data in foods belonging to the other food categories. The highest high level of exposure (P95) to propane‐1,2‐diol (E 1520) according to this scenario was estimated at 23.3 mg/kg bw per day in children.

The Panel also noted that propane‐1,2‐diol could be formed from metabolism of other food additives (e.g. E 405, E 477). In this opinion, a combined exposure assessment was not performed.

Considering the overall toxicity database, the Panel concluded that there was no reason to revise the current ADI of 25 mg/kg bw per day for propane‐1,2‐diol (E 1520).

The Panel also concluded that the mean and the high exposure levels (P95) of the brand‐loyal refined exposure scenario did not exceed the ADI in any of the population groups from the use of propane‐1,2‐diol (E 1520) as a food additive at the reported use levels and analytical results.

The Panel recommended that:

the European Commission considers lowering the current maximum limits for lead in the EU specification for propane‐1,2‐diol (E 1520) in order to ensure that propane‐1,2‐diol (E 1520) as food additives will not be a significant source of exposure to this toxic element in food.

the European Commission considers inclusion of maximum limits for propylene oxide, mono‐ and di‐ethylene glycol and propylene carbonate in the EU specifications for propane‐1,2‐diol (E 1520).

the need for a combined exposure assessment to propane‐1,2‐diol from E 1520 and from other food additives from which propane‐1,2‐diol is formed through metabolism should be considered.

1. Introduction

The present opinion document deals with the re‐evaluation of propane‐1,2‐diol (E 1520) when used as a food additive.

1.1. Background and Terms of Reference as provided by the European Commission

1.1.1. Background

Regulation (EC) No 1333/20081 of the European Parliament and of the Council on food additives requires that food additives are subject to a safety evaluation by the European Food Safety Authority (EFSA) before they are permitted for use in the European Union. In addition, it is foreseen that food additives must be kept under continuous observation and must be re‐evaluated by EFSA.

For this purpose, a programme for the re‐evaluation of food additives that were already permitted in the European Union before 20 January 2009 has been set up under the Regulation (EU) No 257/20102. This Regulation also foresees that food additives are re‐evaluated whenever necessary in light of changing conditions of use and new scientific information. For efficiency and practical purposes, the re‐evaluation should, as far as possible, be conducted by group of food additives according to the main functional class to which they belong.

The order of priorities for the re‐evaluation of the currently approved food additives should be set on the basis of the following criteria: the time since the last evaluation of a food additive by the Scientific Committee on Food (SCF) or by EFSA, the availability of new scientific evidence, the extent of use of a food additive in food and the human exposure to the food additive taking also into account the outcome of the Report from the Commission on Dietary Food Additive Intake in the EU3 of 2001. The report ‘Food additives in Europe 20004’ submitted by the Nordic Council of Ministers to the Commission, provides additional information for the prioritisation of additives for re‐evaluation. As colours were among the first additives to be evaluated, these food additives should be re‐evaluated with a highest priority.

In 2003, the Commission already requested EFSA to start a systematic re‐evaluation of authorised food additives. However, as a result of adoption of Regulation (EU) 257/2010 the 2003 Terms of References are replaced by those below.

1.1.2. Terms of Reference

The Commission asks EFSA to re‐evaluate the safety of food additives already permitted in the Union before 2009 and to issue scientific opinions on these additives, taking especially into account the priorities, procedures and deadlines that are enshrined in the Regulation (EU) No 257/2010 of 25 march 2010 setting up a programme for the re‐evaluation of approved food additives in accordance with the Regulation (EC) No 1333/2008 of the European Parliament and of the Council on food additives.

1.2. Information on existing authorisations and evaluations

Propane‐1,2‐diol (E 1520) is an authorised food additive in the EU according to Annex III of Regulation (EC) No 1333/2008 and specific purity criteria have been defined in the Commission Regulation (EU) No 231/20125.

The SCF evaluated several times propane‐1,2‐diol as a food additive (SCF, 1978, 1996, 1997), as a solvent in food (SCF, 1981, 1996, 1997), as monomers and additives for food contact plastics (SCF, 1999). The Committee in its evaluation in 1981 concluded that there were sufficient data available, including long‐term studies in rats and dogs, to establish an acceptable daily intake (ADI), and they agreed with the ADI of 0–25 mg/kg body weight (bw) established by the Joint FAO/WHO Expert Committee on Food Additives (JECFA, 1974). In its evaluation in 1993 of propane‐1,2‐diol as a food additive, the SCF noted an uncertainty with regard to potential mutagenic effects at the germ cell level, which led the Committee to make the ADI temporary (but keeping the figure of 25 mg/kg bw per day) (SCF, 1996). In 1996, the SCF evaluated new genotoxicity studies and although they did not entirely correspond to the SCF's request the Committee concluded nevertheless that the ADI of 25 mg/kg bw per day could be reassigned to propane‐1,2‐diol (SCF, 1997).

In 1973, JECFA allocated an ADI of 0–25 mg/kg bw based on the level in rat and dog causing no toxicological effect of 2,500 mg/kg bw and using an uncertainty factor of 100 (JECFA, 1974). In 2001, JECFA evaluated propane‐1,2‐diol as a food flavouring; however, the Committee did not finalise the evaluation as it wanted confirmation that the substance is actually used as food flavouring (JECFA, 2002a,b). The Panel noted that propane‐1,2‐diol is not authorised as a flavouring substance in the EU according to Regulation 1334/2008.

Propane‐1,2‐diol (Ref. No 23740 and 81840) is included in the Union list of authorised substances that may be intentionally used in the manufacture of plastic layers in plastic materials and articles (Annex I to Commission Regulation (EU) No 10/20116).

The Scientific Committee for Animal Nutrition (SCAN) expressed a provisional opinion on the use of propane‐1,2‐diol as a preservative in animal feed on the health of cats because of claims that when the additive is fed to cats over a prolonged period of time, erythrocytes may develop oxidative damage to the haemoglobin, Heinz body formation and, possibly, reduced resistance to oxidative stress. The Committee concluded provisionally that there was no immediate need to suspend the use of the substance in feed for cats (SCAN, 1991).

The EFSA Panel on Contaminants in the Food Chain (CONTAM) evaluated a list of substances, including propylene glycol, in the Annex to Commission Directive 96/3/EC as acceptable previous cargoes for edible fats and concluded that those would not be of health concern as previous cargoes (EFSA CONTAM Panel, 2011).

The EFSA Panel on Biological Hazards (BIOHAZ) and the Panel on Food Contact Materials, Enzymes, Flavourings and Processing Aids (CEF) evaluated the safety and efficacy of a product, containing propane‐1,2‐diol as a carrier, used for the removal of microbial surface contamination of raw poultry products. Both Panels concluded that the potential exposure to propane‐1,2‐diol was several orders of magnitude below the ADI and thus not of toxicological concern (EFSA BIOHAZ Panel and CEF Panel, 2012).

A working group established by the Nordic Council of Ministers concluded that there was no need to re‐evaluate propane‐1,2‐diol (E 1520), but a survey to estimate the likely exposure to the substance was recommended. This recommendation was based on the fact that Danish control examinations revealed levels of up to 28 g/kg in cakes (TemaNord, 2002).

The European Agency for the Evaluation of Medicinal Products (EMA) has evaluated the use of propane‐1,2‐diol as a pharmacological active substance for animal uses and found it acceptable for ‘all food producing species with no special conditions of use’ (EMA, 1996).

The Committee for Medicinal Products for Human Use (CHMP) considered the procedure under Article 5(3) of Regulation (EC) No 726/2004 on the excipient, propylene glycol in medicines for children as per questions posed (EMA, 2014a). In the final document, EMA concluded ‘Nevertheless, clinical data showed that in children from the age of 5 years and adult patients, up to 500 mg/kg/day of propylene glycol could generally be considered safe. In the absence of compelling data this safety threshold is decreased to 50 mg/kg/day in children less than 5 years old, and even to 1 mg/kg/day in pre‐term and term neonates due to known immaturity of both metabolic and renal clearances of propylene glycol in these populations’ (EMA, 2014b).

Propane‐1,2‐diol is permitted in cosmetic products (European Commission database – CosIng7).

2. Data and methodologies

2.1. Data

The Panel was not provided with a newly submitted dossier. EFSA launched public calls for data,8 , 9 to collect relevant information from interested parties.

The Panel based its assessment on information submitted to EFSA following the public calls for data, information from previous evaluations and additional available literature up to February 2018. Attempts were made at retrieving relevant original study reports on which previous evaluations or reviews were based, however not always these were available to the Panel.

Food consumption data from the EFSA Comprehensive European Food Consumption Database (Comprehensive Database10) was used to estimate the dietary exposure to propane‐1,2‐diol (E 1520).

The Mintel's Global New Products Database (GNPD) was used to verify the use of propane‐1,2‐diol (E 1520) in food products. Mintel's GNPD is an online database that contains the compulsory ingredient information present on the label of food products.

2.2. Methodologies

This opinion was formulated following the principles described in the EFSA Guidance on transparency with regard to scientific aspects of risk assessment (EFSA Scientific Committee, 2009) and following the relevant existing Guidances from the EFSA Scientific Committee.

The ANS Panel assessed the safety of propane‐1,2‐diol (E 1520) as a food additive in line with the principles laid down in Regulation (EU) 257/2010 and the relevant guidance documents: Guidance on submission for food additive evaluations by the SCF (2001).

When the test substance was administered in the feed or in the drinking water, but doses were not explicitly reported by the authors as mg/kg bw per day based on actual feed or water consumption, the daily intake was calculated by the Panel using the relevant default values as indicated in the EFSA Scientific Committee Guidance document (EFSA Scientific Committee, 2012) for studies in rodents or, in the case of other animal species, by JECFA (2000). In these cases, the daily intake is expressed as ‘equivalent’.

For this evaluation, the Panel used 1.036 g/cm3 (INRS, 2010) as a density for propane‐1,2‐diol.

Dietary exposure to propane‐1,2‐diol (E 1520) from its use as a food additive was estimated combining food consumption data available within the EFSA Comprehensive Database with the reported use levels and analytical data submitted to EFSA following a call for data. Different scenarios were used to calculate exposure (see Section 3.3.1). Uncertainties on the exposure assessment were identified and discussed.

3. Assessment

3.1. Technical data

3.1.1. Identity of the substance

Propane‐1,2‐diol (E 1520) has as chemical formula C3H8O2 and a molecular weight 76.10 g/mol. The substance exists under different enantiomeric forms. Table 1 shows the structural formulae and chemical registry numbers of these different forms.

Table 1.

Structural formulae of enantiomers and registry numbers of propane‐1,2‐diol

| Name | Structural formula | CAS registry numbera | EC (EINECS) numbera |

|---|---|---|---|

| (R)‐(−)‐1,2‐Propanediol |

|

4254‐14‐2 | 610‐038‐5 |

| (S)‐(+)‐1,2‐Propanediol |

|

4254‐15‐3 | 610‐030‐0 |

| (R,S)‐1,2‐propanediol |

|

57‐55‐6 | 200‐338‐0 |

CAS: Chemical Abstracts Service; EINECS: European Inventory of Existing Chemical Substances.

EC inventory available online: https://echa.europa.eu/information-on-chemicals/ec-inventory

According to Commission Regulation (EU) No 231/2012, the propane‐1,2‐diol (E 1520) has the EINECS Number 200‐338‐0. According to the EC inventory, the EINECS number indicated in the EU specifications for E 1520 refers to CAS 57‐55‐6 that corresponds to (R,S)‐1,2‐propanediol (Scifinder,11 online). The Panel noted that the authorisation of the racemic ((R,S)‐1,2‐propanediol) is not clearly stated in the EU specifications.

Synonyms: propylene glycol; α‐propylene glycol; 1,2‐dihydroxypropane; methyl ethylene glycol.

According to Commission Regulation (EU) No 231/2012, propane‐1,2‐diol (E 1520) is described as a clear, colourless, hygroscopic, viscous liquid. It is soluble in water, ethanol and acetone.

Propane‐1,2‐diol has a melting point of −60°C, a boiling point of 186–190°C and the partition coefficient (octanol/water) (log Pow) is −0.912 (CEFIC, 2012 (Documentation provided to EFSA n. 2)).

3.1.2. Specifications

The specifications for propane‐1,2‐diol (E 1520) as defined in the Commission Regulation (EU) No 231/2012 and by JECFA (2006) are listed in Table 2.

Table 2.

Specifications for propane‐1,2‐diol (E 1520) according to Commission Regulation (EU) No 231/2012 and JECFA (2006)

| Commission Regulation (EU) No 231/2012 | JECFA (2006) | |

|---|---|---|

| Assay | Content not less than 99.5% on the anhydrous basis | Not less than 99.5% on the anhydrous basis |

| Description | Clear, colourless, hygroscopic, viscous liquid | Clear, colourless, hygroscopic, viscous liquid |

| Identification | ||

| Solubility | Soluble in water, ethanol and acetone | Soluble in water, ethanol and acetone |

| Specific gravity (20°C/20°C) | 1.035–1.040 | 1.035–1.040 |

| Refractive index | [n]D 20: 1.431–1.433 | – |

| Infrared absorption | – | The infrared spectrum of a potassium bromide dispersion of the sample corresponds with the infrared spectrum below [in the specifications] |

| Purity | ||

| Distillation | 99.5% of the product distils between 185°C and 189°C. The remaining 0.5% consists mainly of dimers and traces of trimers from propane‐1,2‐diol | 99% v/v distils between 185‐ and 189°C |

| Water | Not more than 1.0% (Karl Fischer method) | Not more than 1.0% (Karl Fischer) |

| Sulphated ash | Not more than 0.07% | Not more than 0.07% |

| Free acid | – | Add 3–6 drops of phenol red TS to 50 mL water, then add 0.1N sodium hydroxide until solution remains red for 30 s. To this solution, add about 50 g of the sample accurately weighed. Titrate with 0.01N sodium hydroxide until the original red colour returns and remains for 15 s. Not more than 1.67 mL of 0.01N sodium hydroxide are consumed by a sample of 50.0 g |

| Lead | Not more than 2 mg/kg | Not more than 2 mg/kg |

The Panel noted that, according to the EU specifications for propane‐1,2‐diol (E 1520), lead, as an impurity, is accepted up to a concentration of 2 mg/kg. Contamination at this level could have a significant impact on the exposure already close to the health‐based guidance value or benchmark doses (lower confidence limits) established by EFSA (EFSA CONTAM Panel, 2010, 2012).

According to the literature (Fowles et al., 2013) and to the information on the manufacturing process (see Section 3.1.3), some by products (mono‐ and di‐ethylene glycol) might be formed next to residual propylene oxide used as a starting material. The Panel noted that there are not maximum limits for propylene oxide and mono‐ and di‐ethylene glycol in the EU specifications for propane‐1,2‐diol (E 1520).

According to information from the literature (Holtbruegge et al. (2015), see Section 3.1.3), propane‐1,2‐diol, which is intended to be used as a food additive, can be manufactured by using as a raw material propylene carbonate, which may not be completely removed from the final product, propane‐1,2‐diol. The Panel noted that no maximum limits for propylene carbonate are set in EU specifications for E 1520.

3.1.3. Manufacturing process

According to industry, propane‐1,2‐diol is made from propylene oxide by reaction with water. The resulting mixture consisting of mono‐, di‐ and tri‐glycols is distilled to obtain purified propane‐1,2‐diol. The product is in accordance with the requirements for the European Pharmacopoeia for use as a pharmaceutical excipient, and for use in food, feed and personal care applications. The production process does not utilise catalysts or solvents and the final product does not contain any additive (e.g. stabilisers, antioxidants) (CEFIC, 2012 (Documentation provided to EFSA n. 2)).

Holtbruegge et al. (2015) proposed an optimisation of the production method of high purity propane‐1,2‐diol, patented by Buchanan et al. (2002), which is intended for various uses, including the use as a food additive. After a transesterification of propylene carbonate with methanol, where sodium methoxide is used as a catalyst, a membrane‐assisted reactive separation process is proposed. According to this method, propane‐1,2‐diol is collected together with non‐reacted propylene carbonate and subsequently the two solvents are separated via distillation.

In the literature other methods for manufacturing of propane‐1,2‐diol are reported or proposed, based on

a liquid‐phase high pressure reaction (600 atmospheres) of synthetic gas in the presence of a rhodium cluster complex (ASTDR, 1997),

an hydrogenolysis of glycerol by using various catalysts like: copper, nickel or noble metals (Bozga et al., 2011), highly active copper/magnesia (magnesium oxide) catalysts (Pudi et al., 2015) or a copper/zinc/magnesia catalyst (Mondal et al., 2017), chromium oxide, or ruthenium or platinum/tungsten catalysts (Kutz et al., 2017),

via fermentation of deoxy sugars (i.e. rhamnose) or other substrates by using Clostridia, Enterobacteriaceae or yeasts (Tanaka et al., 2017; Kutz et al. (2017)).

The Panel noted that none of these methods is suitable for the production of the food additive E 1520, without further purification steps, as they yield propane‐1,2‐diol having a lower purity than required in the EU specifications for E 1520.

3.1.4. Methods of analysis in food

An analytical enzymatic method for the determination of propane‐1,2‐diol in commercial food is available (Hamano et al., 1984). The method is based on the extraction of propane‐1,2‐diol from the food with deionised water followed by its oxidation by propylene glycol dehydrogenase from Microcyclus eburneus. During this step, oxidised nicotinamide adenine dinucleotide (NAD+) is reduced to NADH and the absorbance of the solution is measured at 340 nm. Recoveries ranged from 85% up to 99%. The limit of detection (LOD) was equal to 2 mg/kg.

A gas chromatographic method with flame ionisation detection method is also available for the determination of propane‐1,2‐diol in beer, after extraction with ethyl acetate. The recovery rate of the method was reported to be 88% and the LOD 0.73 mg/L (Williamson and Iverson, 1993).

Tandem mass spectrometry method has been used for identification of propane‐1,2‐diol in fish. The sample was homogenised with methanol. No performance criteria of the method were given (Matusik et al., 1993).

A titrimetric analytical method for the determination of propane‐1,2‐diol in vanilla extract was also described (AOAC, 2000). This method is only applicable when the vanilla extract contains high amounts of the food additive.

Sagadykova et al. (2017) described a method for the determination of propane‐1,2‐diol in wines using gas chromatography–mass spectrometry (GC/MS). According to this method, a solid‐phase microextraction of the semi‐volatile constituents of wine prior to the final injection to the GC–MS apparatus is applied. A standard addition is used to skip the estimation of recovery rates and the LOD is 2 mg/L. A similar approach for the determination of propane‐1,2‐diol in cheese was proposed by Badertscher et al. (2017) where an esterification with phenyl boronic acid preceded the injection into GC–MS. The LOD in this case was reported to be below 1 mg/kg.

A high‐performance liquid chromatography (HPLC) method for the determination of propane‐1,2‐diol in spirits was proposed by Tanaka et al. (2017). In this case, the Cu(II) ions of the mobile phase enable the determination of the substance via an UV‐detector (at 250 nm) with a LOD of 0.1 mL/L.

3.1.5. Stability of the substance, and reaction and fate in food

According to the information provided by industry, propane‐1,2‐diol is hygroscopic and sensitive to sunlight, air, oxidising agents, acids, bases and high temperatures. Partial oxidation in the presence of oxygen may lead to the formation of aldehydes, ketones, acids and dioxolanes. When stored outside in transparent plastic containers, the rate of degradation increases with temperature, the presence of metals and/or exposure to sun (UV) light. It has been shown that no aldehydes, ketones, acids and dioxolanes were formed from propane‐1,2‐diol in a stability test over 2 years when kept out of sunlight and kept at a temperature not exceeding 40°C (CEFIC, 2012 (Documentation provided to EFSA n. 2)). Hence, according to industry, it is generally recommended to store the product in approved, closed containers at temperatures not exceeding 40°C.

According to industry (CEFIC, 2012 (Documentation provided to EFSA n. 2)), the stability of propane‐1,2‐diol as such is representative for the stability of the substance in food because there is no interaction of the substance with food components.

The Panel noted that, as propane‐1,2‐diol may be used in a variety of food, which can also be heat‐treated and/or stored in daylight, it is expected that the substance partially degrades.

3.2. Authorised uses and use levels

Propane‐1,2‐diol (E 1520) is not authorised to be added directly to food according to Annex II to Regulation (EC) No 1333/2008 on food additives. Maximum levels of propane‐1,2‐diol (E 1520) in final foods (via carry‐over from food improving agents or nutrients) have been defined only in Annex III to Regulation (EC) No 1333/2008 on food additives, as amended.

According to Annex III, Part 1 of Regulation (EC) No 1333/2008, propane‐1,2‐diol (E 1520) is authorised as a carrier in food additives (colours, emulsifiers and anti‐oxidants), with a maximum level of 1,000 mg/kg in final food. It is also authorised from all sources in foodstuffs up to 3,000 mg/kg (individually or in combination with triethyl citrate (E 1505), glyceryl diacetate (E 1517) and glyceryl triacetate (E 1518)); in the case of beverages, with the exception of cream liqueurs, the maximum level of E 1520 is 1,000 mg/L from all sources.

According to Annex III, Part 3, propane‐1,2‐diol (E 1520) is authorised as a food additive, only as a carrier, in food enzymes, at the maximum level of 500 g/kg in enzyme preparation and with a maximum level from all sources in foodstuffs of 3,000 mg/kg (individually or in combination with E 1505, E 1517 and E 1518). In the case of beverages, with the exception of cream liqueurs, the maximum level of E 1520 is 1,000 mg/L from all sources.

In addition, according to Annex III, Part 4, propane‐1,2‐diol (E 1520) is authorised in all flavourings individually or in combination with E 1505, E 1517 and E 1518 at the maximum level of 3,000 mg/kg from all sources in foodstuffs as consumed, or as reconstituted according to the instructions of the manufacturers. In the case of beverages, with the exception of cream liqueurs, the maximum level of E 1520 is 1,000 mg/L from all sources.

In addition, according to Annex III, Part 5, Section A of Regulation (EC) No 1333/2008, propane‐1,2‐diol (E 1520) is authorised as a carrier only, in all nutrients (except nutrients intended to be used in foodstuffs for infants and young children listed in point 13.1 of Part E of Annex II) at maximum level of 1,000 mg/kg in final food and with a maximum level for E 1518 and E 1520 from all sources in foodstuffs of 3,000 mg/kg (individually or in combination with E 1505 and E 1517). In the case of beverages, with the exception of cream liqueurs, the maximum level of E 1520 is 1,000 mg/L from all sources.

3.3. Exposure data

3.3.1. Reported use levels or data on analytical levels of propane‐1,2‐diol

Most food additives in the EU are authorised at a specific maximum permitted level (MPL). However, a food additive may be used at a lower level than the MPL. Therefore, information on actual use levels is required for performing a more realistic exposure assessment.

In the framework of Regulation (EC) No 1333/2008 on food additives and of Commission Regulation (EU) No 257/2010 regarding the re‐evaluation of approved food additives, EFSA issued a public call12 for occurrence data (usage level and/or concentration data) on propane‐1,2‐diol (E 1520). In response to this call, occurrence data on propane‐1,2‐diol (E 1520) were submitted to EFSA by both industry and Member States.

Summarised data on reported use levels in foods provided by industry

Industry provided EFSA with data on use levels (n = 548) of propane‐1,2‐diol (E 1520) in foods for 22 food categories. The provided use levels were submitted by FoodDrinkEurope (FDE), the International Chewing Gum Association (ICGA), Specialised Nutrition Europe (SNE), KRÜGER GmbH & Co and Spanish Association of Postharvest Services and Processes (AGRUPOST). The majority of the submitted data (n = 521) were for the food category ‘Edible ices’ (FC 03).

The Panel noted that two use levels referred to niche products. These products belonged to the food categories ‘Decorations, coatings and fillings’ (FC 05.4) and ‘Dietary foods for special medical purposes’ (FC 13.2). These use level were not considered in the exposure assessment. For FC 05.4, a use level referring to a widely used product was available, whereas FC 13.2 was not included in the exposure assessment (see Section 3.3.3).

The Panel considered that the reported use levels refer to the level of propane‐1,2‐diol (E 1520) in final food from all sources in foodstuffs (as a carrier from food additives, enzymes, flavouring and all nutrients).

Appendix A provides data on the use levels of propane‐1,2‐diol (E 1520) in foods as reported by industry.

Summarised data on analytical results in food submitted by Member States

In total, 162 analytical results were reported to EFSA by four countries: the Czech Republic (n = 7), Germany (n = 72), Denmark (n = 73) and Ireland (n = 10). These data were mainly for flavourings or essence and pastries and cakes covering four food categories. Foods were sampled between 2000 and 2016, and the majority of them (98%) were analysed the year that they were collected.

Around half of the analytical results on propane‐1,2‐diol (E 1520) were left‐censored: either not quantified (< limit of quantification (LOQ)) in 62 samples, or not detected (< LOD) in 25 samples.

Complete information on the methods of analysis (e.g. validation) was not made available to EFSA, but all samples were derived from accredited laboratories.

The Panel noted that eight analytical results were obtained via suspect sampling and were therefore excluded from the exposure assessment.

In order to include recent analytical data in the exposure assessment, only samples sampled in the last 10 years were included. Samples collected before 2008 (n = 39) were therefore also excluded from further analysis.

Overall, 115 analytical results were reported for propane‐1,2‐diol (E 1520) in four food categories and in flavourings.

Appendix B shows the analytical results of propane‐1,2‐diol (E 1520) in foods as reported by Member States.

The Panel noted that the analytical data reported by Member States showed the presence of propane‐1,2‐diol in three food categories for which no uses have been reported by the food manufacturers out of the four food categories for which data were reported. This may relate to the fact that E 1520 is not directly added to the food by the manufacturers, but carried over via uses of food ingredients, such as some food additives, food flavourings, enzymes and nutrients.

3.3.2. Summarised data extracted from the Mintel's Global New Products Database

The Mintel's GNPD is an online database that monitors new introductions of packaged goods in the market worldwide. It contains information of over 2.5 million food and beverage products of which more than 900,000 are or have been available on the European food market. The Mintel's GNPD started covering EU's food markets in 1996; currently, it contains data from 20 out of its 28 Member‐States and Norway.13

For the purpose of this Scientific Opinion, the Mintel's GNPD14 was used for checking the labelling of food and beverage products and food supplements for propane‐1,2‐diol (E 1520) within the EU's food market as the database contains the compulsory ingredient information on the label.

As mentioned before, propane‐1,2‐diol (E 1520) is authorised according to Annex III in some food additives, food flavourings, enzymes and nutrients and it is then carried over to the final food. According to legislation, the labelling of food additives used as such is not mandatory. Despite this, propane‐1,2‐diol (E 1520) was labelled on 278 products between January 2013 and January 2018 (456 products on any date) according to the Mintel's GNPD.

The products labelled with the food additive were mainly cakes, pastries and sweet goods, and baking ingredients and mixes.

Appendix C lists the percentage of the food products labelled with propane‐1,2‐diol (E 1520) out of the total number of food products per food sub‐category according to the Mintel's GNPD food classification. The percentages ranged from less than 0.1% in many food sub‐categories to 1.2% in the Mintel's GNPD food subcategory ‘Frozen desserts’. The average percentage of foods labelled to contain propane‐1,2‐diol (E 1520) was 0.1%. However, since the labelling of propane‐1,2‐diol (E 1520) is not mandatory, the information about the use of this food additive from the Mintel's GNPD is very likely not exhaustive. However, the data received from industry seem to be in agreement with the foods labelled with propane‐1,2‐diol (E 1520) according to the Mintel's GNPD.

3.3.3. Food consumption data used for exposure assessment

EFSA Comprehensive European Food Consumption Database

Since 2010, the EFSA Comprehensive European Food Consumption Database (Comprehensive Database) has been populated with national data on food consumption at a detailed level. Competent authorities in the European countries provide EFSA with data on the level of food consumption by the individual consumer from the most recent national dietary survey in their country (cf. Guidance of EFSA on the ‘Use of the EFSA Comprehensive European Food Consumption Database in Exposure Assessment’ (EFSA, 2011a). Consumption surveys added in the Comprehensive database in 2015 were also taken into account in this assessment.15

The food consumption data gathered by EFSA were collected by different methodologies and thus direct country‐to‐country comparisons should be interpreted with caution. Depending on the food category and the level of detail used for exposure calculations, uncertainties could be introduced owing to possible subjects’ underreporting, and/or misreporting of the consumption amounts. Nevertheless, the EFSA Comprehensive Database includes the currently best available food consumption data across Europe.

Food consumption data from the following population groups were used for the exposure assessment: infants, toddlers, children, adolescents, adults, and the elderly. For the present assessment, food consumption data were available from 33 dietary surveys carried out in 19 European countries (Table 3).

Table 3.

Population groups considered for the exposure estimates of propane‐1,2‐diol (E 1520)

| Population | Age range | Countries with food consumption surveys covering more than 1 day |

|---|---|---|

| Infants | From more than 12 weeks up to and including 11 months of age | Bulgaria, Denmark, Finland, Germany, Italy, UK |

| Toddlersa | From 12 months up to and including 35 months of age | Belgium, Bulgaria, Denmark, Finland, Germany, Italy, Netherlands, Spain, UK |

| Childrenb | From 36 months up to and including 9 years of age | Austria, Belgium, Bulgaria, Czech Republic, Denmark, Finland, France, Germany, Greece, Italy, Latvia, Netherlands, Spain, Sweden, UK |

| Adolescents | From 10 years up to and including 17 years of age | Austria, Belgium, Cyprus, Czech Republic, Denmark, Finland, France, Germany, Italy, Latvia, Netherlands, Spain, Sweden, UK |

| Adults | From 18 years up to and including 64 years of age | Austria, Belgium, Czech Republic, Denmark, Finland, France, Germany, Hungary, Ireland, Italy, Latvia, Netherlands, Romania, Spain, Sweden, UK |

| The elderlyb | From 65 years of age and older | Austria, Belgium, Denmark, Finland, France, Germany, Hungary, Ireland, Italy, Romania, Netherlands, Sweden, UK |

The term ‘toddlers’ in the EFSA Comprehensive Database corresponds to ‘young children’ in Regulations (EC) No 1333/2008 and (EU) No 609/2013.

The terms ‘children’ and ‘the elderly’ correspond, respectively, to ‘other children’ and the merge of ‘elderly’ and ‘very elderly’ in the Guidance of EFSA on the ‘Use of the EFSA Comprehensive European Food Consumption Database in Exposure Assessment’ (EFSA, 2011a).

Consumption records were codified according to the FoodEx classification system (EFSA, 2011b). Nomenclature from the FoodEx classification system has been linked to the food categorisation system (FCS) as presented in Annex II of Regulation (EC) No 1333/2008, part D to perform exposure estimates. In practice, the FoodEx food codes were matched to the FCS food categories.

Food categories considered for the exposure assessment of propane‐1,2‐diol (E 1520)

As described in Section 3.2, propane‐1,2‐diol (E 1520) is not authorised to be added directly into foods (no authorisation according to Annex II to Regulation No 1333/2008). Propane‐1,2‐diol (E 1520) is only authorised in some food additives (colours, emulsifiers and antioxidants) or enzymes, flavourings and nutrients. As a result of this authorisation, the majority of foods and beverages, within a diet could contain propane‐1,2‐diol (E 1520) via carry over. However, the available data received suggested that only a few products out of the whole number of products on the European market contained propane‐1,2‐diol (E 1520).

A regulatory maximum level exposure assessment scenario could be calculated by attributing to all foods and cream liqueurs the MPL of 3,000 mg/kg and to beverages, except cream liqueurs, the MPL of 1,000 mg/kg. However, this scenario would be very uncertain and would result in an unrealistically high estimate of the exposure. Thus, the Panel considered that a regulatory maximum level exposure assessment scenario would not provide useful information about the exposure to propane‐1,2‐diol (E 1520) and decided to perform only a refined exposure assessment scenario.

In the refined exposure assessment scenario, only food categories for which data were made available to EFSA (either from industry or from Member States), and for which consumption data were available were included in the exposure assessment. The food categories, which were taken into account, are described below (in ascending order of the FCS codes):

01.7.1 Unripened cheese excluding products falling in category 16,

01.8 Dairy analogues, including beverages whiteners,

03 Edible ices,

04.1 Unprocessed fruits and vegetables,16

04.2.6 Processed potato products,

05.1 Cocoa and chocolate products as covered by Directive 2000/36/EC,

05.2 Other confectionary including breath freshening microsweets,

05.3 Chewing gum,

05.4 Decorations, coatings and fillings, except fruit‐based fillings covered by category 4.2.4,

07.2 Fine bakery wares,

12.2.2 Seasonings and condiments,

12.5 Soups and broths,

12.6 Sauces,

14.1.4 Flavoured drinks,

14.1.5.2 Coffee, coffee and chicory extracts, tea, herbal‐ and fruit‐infusions; coffee substitutes, coffee mixes and mixes for ‘hot beverages’, Other than coffee, coffee extracts

14.2.2 Wine and other products defined by Reg (EC) No 1234/2007, and alcohol‐free counterparts,

14.2.6 Spirits drinks as defined in Reg (EC) No 110/2008, except cream liqueurs,

14.2.6 Spirits drinks as defined in Reg (EC) No 110/2008, only cream liqueurs,

15.1 Potato‐,cereal‐, flour‐ or starch‐based snacks,

16 Desserts,

17.1 Food supplements supplied in a solid form including capsules and tablets and similar forms, excluding chewable forms,

17.3 Food supplements supplied in a syrup‐type or chewable form.

For three food categories, use levels were provided by industry but could not be taken into account in the exposure assessment: FC 01.7.6 Cheese products, FC 13.2 Dietary foods for special medical purposes, and FC 18 processed foods not covered by categories 1 to 17. For FC 01.7.6, no consumption data were available in the EFSA Comprehensive database. The eating occasions belonging to FCs 13.2 (and 13.3) and 18 have been reclassified under food categories in accordance to their main ingredient, as food items belonging to these food categories may be very diverse and, in addition, for FCs 13.2 and 13.3, there is very limited information on their consumption. The reported use levels of E 1520 for FCs 13.2 and 18 (Appendix A) were not considered in the exposure assessment.

Additionally, industry provided use levels for FCs 17.1 and 17.3: food supplements in solid, syrup‐type or chewable form. In the EFSA Comprehensive database, no information is provided on the form of food supplements ingested. In the exposure assessment, all food supplements (including FC 17.2, food supplements in liquid form) were therefore considered together.

The Panel noted that analytical data were provided on both artificial and natural flavourings (Appendix B). To take these data into account in an exposure assessment, information on the levels of these flavourings in each flavoured food as well as a list of flavoured foods would be needed. As this information was not available, conservative assumptions would be needed to include these flavourings in the exposure assessment, which would result in unrealistically high estimates of exposure. The Panel decided therefore not to use these data in the current exposure assessment of propane‐1,2‐diol (E 1520). However, the Panel considered that the reported use levels and the available analytical data on propane‐1,2‐diol (E 1520), included its use in flavouring preparations.

For the refined scenario, 20 food categories were taken into account. The exposure to propane‐1,2‐diol (E 1520) via the ingestion of food supplements was assessed via a separate exposure scenario and included the same food categories as the refined scenario as well as the three food supplement food categories (Appendix B).

3.4. Exposure estimates

3.4.1. Exposure to propane‐1,2‐diol (E 1520) from its use as a food additive

The Panel estimated the chronic dietary exposure to propane‐1,2‐diol (E 1520) for the following population groups: infants, toddlers, children, adolescents, adults and the elderly. Dietary exposure to propane‐1,2‐diol (E 1520) was calculated by multiplying concentrations of propane‐1,2‐diol (E 1520) per food category (Appendix D) with their respective consumption amount per kilogram body weight for each individual in the Comprehensive Database. The exposure per food category was subsequently added to derive an individual total exposure per day. These exposure estimates were averaged over the number of survey days, resulting in an individual average exposure per day for the survey period. Dietary surveys with only one day per subject were excluded as they were considered as not adequate to assess repeated exposure.

This was carried out for all individuals per survey and per population group, resulting in distributions of individual exposure per survey and population group (Table 3). Based on these distributions, the mean and the 95th percentile of exposure were calculated per survey and per population group. The 95th percentile of exposure was only calculated for those population groups with a sufficiently large sample size (EFSA, 2011a). Therefore, in the present assessment, the 95th percentile of exposure for infants from Italy and for toddlers from Belgium, Italy and Spain was not estimated.

As described above, a regulatory exposure scenario was not estimated in the current opinion. Thus, solely a refined exposure assessment scenario to propane‐1,2‐diol (E 1520) was carried out by the Panel based on reported use levels and analytical data. This scenario does not consider the consumption of food supplements. This source of exposure was covered in an additional scenario (food supplements consumers only scenario).

Refined exposure assessment scenario

The refined exposure assessment scenario of propane‐1,2‐diol (E 1520) was based on use levels reported by food industry and analytical results reported by Member States. This exposure scenario can consider only food categories for which these data were available to the Panel.

Appendix D summarises the concentration levels of propane‐1,2‐diol (E 1520) used in the refined exposure assessment scenario. Based on the available data set, the Panel calculated two refined exposure estimates based on two model populations:

-

The brand‐loyal consumer scenario: It was assumed that a consumer is exposed long‐term to propane‐1,2‐diol (E 1520) present at the maximum reported use/P95 of analytical level for one food category. This exposure estimate is calculated as follows:

-

1

– Combining food consumption with the maximum of the reported use levels or the 95th percentile of the analytical results, whichever was highest or available, for the main contributing food category at the individual level.

-

2

– Using the mean of the typical reported use levels or the mean of analytical results, whichever was highest or available, for the remaining food categories.

-

1

The non‐brand‐loyal consumer scenario: It was assumed that a consumer is exposed long‐term to propane‐1,2‐diol (E 1520) present at the mean reported use/analytical levels in food. This exposure estimate is calculated using the mean of the typical reported use levels or the mean of analytical results for all food categories.

In the two refined exposure assessment scenarios, the concentration levels considered by the Panel were extracted from the whole dataset (i.e. reported use levels and analytical results). To consider left‐censored analytical data (i.e. analytical results < LOD or < LOQ), the substitution method as recommended in the ‘Principles and Methods for the Risk Assessment of Chemicals in Food’ (WHO, 2009) and the EFSA scientific report ‘Management of left‐censored data in dietary exposure assessment of chemical substances’ (EFSA, 2010) was used. In the present opinion, analytical data below LOD or LOQ were assigned half of LOD or LOQ, respectively (middle bound (MB)). Subsequently, per food category, the mean or median, whichever is highest, MB concentration was calculated.

Appendix D summarised the concentration levels of propane‐1,2‐diol (E 1520) used in the refined exposure scenarios.

Food supplement consumers only exposure assessment scenario

Use levels for propane‐1,2‐diol (E 1520) were reported by food industry for FC 17: Food supplements as defined in Directive 2002/46/EC excluding food supplements for infants and young children. As exposure via food supplements may deviate largely from that via food, and the number of food supplement consumers may be low depending on populations and surveys, an extra exposure scenario was calculated in order to reflect additional exposure to propane‐1,2‐diol (E 1520) from food supplements compared to exposure to propane‐1,2‐diol (E 1520) excluding these sources. This scenario was estimated assuming that consumers of food supplements were exposed to propane‐1,2‐diol (E 1520) present at the maximum reported use levels in food supplements on a daily basis. For the remaining food categories (20 categories), the mean/median of the typical reported use levels or analytical results was used.

As FC 17 does not consider food supplements for infants and toddlers as defined in the legislation, exposure to propane‐1,2‐diol (E 1520) from food supplements were not estimated for these two population groups.

This scenario included 23 food categories (Appendix D).

Dietary exposure to propane‐1,2‐diol (E 1520)

Table 4 summarises the estimated exposure to propane‐1,2‐diol (E 1520) from its use as a food additive in six population groups (Table 3), according to the different exposure scenarios. Detailed results per population group and survey are presented in Appendix E.

Table 4.

Summary of dietary exposure to propane‐1,2‐diol (E 1520) from its use as a food additive in the refined exposure scenario in six population groups (minimum–maximum across the dietary surveys in mg/kg bw per day)

| Infants (12 weeks–11 months) | Toddlers (12–35 months) | Children (3–9 years) | Adolescents (10–17 years) | Adults (18–64 years) | The elderly (≥ 65 years) | |

|---|---|---|---|---|---|---|

| Refined estimated exposure assessment scenario | ||||||

| Brand‐loyal scenario | ||||||

| Mean | 0.2–3.1 | 1.0–11.6 | 3.4–10.5 | 1.8–7.0 | 1.0–3.6 | 0.8–3.0 |

| 95th percentile | 0.4–12.4 | 3.3–21.8 | 7.7–23.3 | 4.4–15.2 | 2.9–9.5 | 2.0–7.3 |

| Non‐brand‐loyal scenario | ||||||

| Mean | 0.1–1.5 | 0.4–8.4 | 1.8–7.8 | 1.3–5.3 | 0.7–2.4 | 0.5–1.2 |

| 95th percentile | 0.3–5.7 | 1.2–16.4 | 5.4–15.3 | 3.8–10.7 | 1.8–6.6 | 1.3–2.9 |

In the brand‐loyal scenario of the refined estimated exposure scenario, the mean exposure to propane‐1,2‐diol (E 1520) from its use as a food additive ranged from 0.2 mg/kg bw per day in infants to 11.6 mg/kg bw per day in toddlers. The high exposure to propane‐1,2‐diol (E 1520) ranged from 0.4 mg/kg bw per day in infants to 23.3 mg/kg bw per day in children.

In the non‐brand‐loyal scenario, mean exposure to propane‐1,2‐diol (E 1520) from its use as a food additive ranged from 0.1 mg/kg bw per day in infants to 8.4 mg/kg bw per day in toddlers. The 95th percentile of exposure to propane‐1,2‐diol (E 1520) ranged from 0.3 mg/kg bw per day in infants to 16.4 mg/kg bw per day in toddlers.

The main contributing food categories from the refined estimated exposure scenarios, both brand‐loyal and non‐brand‐loyal scenario were unprocessed fruit and vegetables and fine bakery wares for infants; for all the other population groups, main contributing food categories were fine bakery wares and flavoured drinks (Appendix F).

In the food supplements consumers only scenario, mean exposure to propane‐1,2‐diol (E 1520) from its use as a food additive ranged from 0.7 mg/kg bw per day for the elderly to 10.9 mg/kg bw per day for children. The 95th percentile of exposure to propane‐1,2‐diol (E 1520) ranged between 1.7 mg/kg bw per day for the elderly to 14.2 mg/kg bw per day for children.

Uncertainty analysis

Uncertainties in the exposure assessment of propane‐1,2‐diol (E 1520) have been discussed above. In accordance with the guidance provided in the EFSA opinion related to uncertainties in dietary exposure assessment (EFSA, 2007), the following sources of uncertainties have been considered and summarised in Table 5.

Table 5.

Qualitative evaluation of influence of uncertainties on the dietary exposure estimate

| Sources of uncertainties | Directiona |

|---|---|

| Consumption data: different methodologies/representativeness/underreporting/misreporting/no portion size standard | +/– |

| Use of data from food consumption surveys covering only a few days to estimate high percentiles (95th) long‐term (chronic) exposure | + |

| Correspondence of reported use levels and analytical data to the food items in the EFSA Comprehensive Database: uncertainties to which types of food the levels refer | +/– |

| Uncertainty in possible national differences in use levels of food categories | +/– |

Concentration data:

|

+ +/– – |

Food categories selected for the exposure assessment:

|

– +/– |

Refined exposure assessment scenario:

|

+/– +/– |

MS: Member State; FC: food category; LOD: limit of detection; LOQ: limit of quantification.

+, uncertainty with potential to cause overestimation of exposure; –, uncertainty with potential to cause underestimation of exposure.

Propane‐1,2‐diol (E 1520) is only authorised as carrier according to Annex III to Regulation No 1333/2008, and therefore has the potential to be present in the majority of the food and beverage products.

Use levels of the food additive were made available by industry for 22 food categories. Member States provided analytical data on four food categories and flavourings.

The Panel noted that according to the Mintel's GNPD, propane‐1,2‐diol (E 1520) was labelled in less than 300 food products in the last 5 years. For five food subcategories that included foods that were labelled with propane‐1,2‐diol (E 1520) according to the Mintel's classification (Appendix C), no data (reported use levels or analytical data) were provided to EFSA and these food categories were therefore not taken into account in the exposure assessment (Cider, Bread & Bread Products, Poultry Products, Spoonable Yogurt and Fish Products). However, the number of foods labelled with the food additive within these food sub‐categories was very small: maximally 5 (Appendix C). On the other hand, some foods for which data were provided were not found to be labelled in the Mintel's GNPD (cheese products). Furthermore, the percentage of foods per food sub‐category labelled to contain propane‐1,2‐diol (E 1520) was maximally 1.2% (Appendix C), as opposed to the assumption of 100% labelled of the foods belonging to an authorised food category in the exposure assessment. Given that propane‐1,2‐diol (E 1520) is authorised only according to Annex III and industry is not obliged to label the additive, information from the Mintel's GNPD is uncertain.

It should also be noted that the use of MB LOD/LOQ values (half of LOD or LOQ) in the exposure assessment (Section 3.3.1) may have resulted in either an overestimation, where propane‐1,2‐diol (E 1520) was not present, or underestimation, where the concentration was between the MB and LOQ/LOD value, but the analytical method was not able to detect or quantify it. The Panel however estimated that the possible under/overestimation would have been minor as only for three food categories, analytical data were used in the refined exposure assessment scenario.

The Panel considered that based on the data that could be used in the refined exposure assessment scenario (food categories for which information was available) the uncertainties identified would result in an overestimation of the exposure to propane‐1,2‐diol (E 1520) from its use as a food additive, according to Annex III, in European countries considered in the EFSA European database.

3.4.2. Exposure via other sources

Propane‐1,2‐diol is also used in cosmetic products. Propane‐1,2‐diol is used as humectant, solvent and preservative in a wide range of medicinal products (EMA, 2014a).

Lactobacillus parabuchneri, one of the most frequent representatives of lactobacilli present in cheese, and the closely related Lactobacillus buchneri were found to be produced propane‐1,2‐diol in cheese (Badertscher et al., 2017).

Quantification of exposure via these sources was not precisely known and therefore could not be taken into account in this opinion.

The Panel noted that propane‐1,2‐diol could be formed from metabolism of other food additives (e.g. E 405, E 477). In this opinion, a combined exposure assessment was not performed.

3.5. Biological and Toxicological data

Even though it was not specifically indicated, the Panel considered that the propane‐1,2‐diol tested in the biological and toxicological studies considered for this opinion would appear to be in the racemic form.

3.5.1. Absorption, distribution, metabolism and excretion

Animals

Rats

The absorption of propane‐1,2‐diol was investigated by injection of 10 mL/kg bw of a 10% propane‐1,2‐diol solution (1,031 mg/kg bw) into intestinal loops (15 cm long), the stomach and the colon, in several animal species (van Winkle, 1941a). A total number of 72 rats, 16 rabbits and 48 cats were used for the experiments. Absorption of propane‐1,2‐diol was reported to be identical in rabbits and cats showing a very rapid absorption within 30 min from jejunum followed by duodenum, colon, and stomach. Propane‐1,2‐diol was reported to be absorbed more rapidly in rats where a complete absorption from the jejunum occurred within 20–30 min, whereas in rabbits and cats the absorption from jejunum was 91% after 1 h. In cats, absorption of propane‐1,2‐diol from the jejunum was found to be dose‐dependent (after injection of a 5%, 10%, 50% or 100% solution). At the lowest dose (5%), 66.4% propane‐1,2‐diol was absorbed, whereas 49.4% was absorbed at the highest dose (100%). After 1 h, similar absorption levels for propane‐1,2‐diol (88.2–95.2%) were noted at all doses.

In the same publication, the renal excretion of propane‐1,2‐diol was described in rats. For this investigation, groups of five rats were given 5%, 10%, 15% or 20% propane‐1,2‐diol in the drinking water for 1 week (equivalent to 6,216, 12,432, 18,648 or 24,864 mg propane‐1,2‐diol/kg bw per day); thereafter, the propane‐1,2‐diol solutions were replaced by water (van Winkle, 1941a). After a normal fluid balance was obtained, the propane‐1,2‐diol treatment was repeated. Measurement of the propylene concentration in the urine showed that, regardless of the concentration of propane‐1,2‐diol in the drinking water, about one‐third of the amount ingested was excreted unchanged in the urine; the remaining two‐thirds were, according to the authors, metabolised in the body.

The kinetics of propane‐1,2‐diol elimination and metabolism in vivo have been investigated in rats (Morshed et al., 1988). Male Wistar rats (6 animals/group) were given a single oral dose of propane‐1,2‐diol administered as an aqueous solution at concentrations of 4.83, 9.66, 19.32, 38.64 and 77.28 mmol/kg bw. The time required to reach the maximum concentration of propane‐1,2‐diol in blood was linearly related to the dose (10, 20, 30, 60 and 90 min, respectively). The rate of elimination of propane‐1,2‐diol from the blood was found to be a first‐order process. The plot of the observed elimination velocity vs the propane‐1,2‐diol doses indicated that the elimination of propane‐1,2‐diol from the body was saturated at the higher dose levels. Likewise, a linear increase in the urinary excretion of propane‐1,2‐diol was observed for increasing doses (24‐h urine samples) with only 1/5 of the administered dose of propane‐1,2‐diol being excreted within the 24‐h period. According to the authors, the maximal metabolising capacity in rats of 0.63 g/kg bw per hour was equivalent to 1.06 kg/day for an average 70‐kg human.

Rabbits

Rabbits (2 animals) showed increased excretion of glucuronic acid in the urine (22% and 100%, respectively, at 48 h after dosing) following administration of a single dose of 2.3 mL propane‐1,2‐diol/kg bw (2.383 mg/kg bw) by oral gavage, indicating, according to the authors, that propane‐1,2‐diol was conjugated to glucuronic acid and that the conjugate was excreted in the urine (Fellows et al., 1947).

The blood concentration of propane‐1,2‐diol in New Zealand White rabbits (four animals) reached its maximum level 1 h after administration by gavage of 28.4% propane‐1,2‐diol (38.66 mmol/kg bw, equal to 2,942 mg) as an aqueous solution (Morshed et al., 1991a).

Cats

Plasma levels of propane‐1,2‐diol were determined in two cats fed a 12% propane‐1,2‐diol diet (equal to 1,600 mg/kg bw per day) (Christopher et al., 1989a). Plasma levels of propane‐1,2‐diol at 19.1 and 8.4 mM/L were reported at day 24 after introduction of the propane‐1,2‐diol diet.

Dogs

A dose of 2, 8 or 12 mL/kg bw (2,072, 8,288 and 12,432 mg/kg bw) of propane‐1,2‐diol was administered per dog (Lehman and Newman, 1937). For investigating absorption, the dose was given by stomach tube as a 50% solution (v/v) in warm tap water. The dog dosed with 2,072 mg/kg bw, received the same dose intravenously in addition to the oral dose. The dog dosed with 8,288 mg/kg bw was a second time treated with the same dose, now under pentobarbital anaesthesia. A dose of 6 mL (6,216 mg/kg bw) was given into the in situ isolated stomach from an untreated dog. The maximum blood propane‐1,2‐diol level was observed 30 min after administration of 2 mL/kg bw and 2–4 h after administration of 8 or 12 mL/kg bw. Forty‐eight hours after administration, 12% of the total dose was excreted in the urine at 2 mL/kg bw and 39% at 8 mL/kg bw; after administration of 12 mL/kg bw, 36% of the total dose was excreted in the urine after 24 h. As the blood concentration time profile was nearly identical in the dog dosed with 2,072 mg/kg bw orally and intravenously, the author concluded that the absorption was rapid and nearly complete. As the maximum blood concentration in the dog in which a dose of 6,216 mg/kg bw was given into the isolated stomach was at the same level as in the blood of the dog having received 2,072 mg/kg bw, the authors concluded that the absorption by the stomach was low. The Panel agreed with the interpretation of the results.

Plasma levels of propane‐1,2‐diol were determined in female dogs as a function of time after a single dose of 5,000 mg/kg bw (Weil et al., 1971). Peak values were reached at 6–8 h after dosing and levels at 12 h after dosing were approximately half those at 8 h.

Humans

Absorption of propane‐1,2‐diol in human was found to be slower than in dog, as illustrated by an experiment in which three human subjects were given a single oral dose of 1 mL propane‐1,2‐diol/kg bw (1,036 mg/kg bw) (68, −75 mL/subject) (Hanzlik et al., 1939a). The highest concentration of propane‐1,2‐diol measured in blood was reached after 30 min and persisted for approximately 4 h before they began to decline, indicating, according to the authors, ‘a delayed absorption keeping pace with the elimination of propane‐1,2‐diol from the body’. Blood concentrations varied considerably between individuals. About 20–25% was eliminated in the urine within 10 h.

The pharmacokinetic profile of the substance was examined in a multiple oral‐dosing study by Yu et al. (1985). Propane‐1,2‐diol was the solvent for the anti‐epileptic drug phenytoin given to outpatients of a neurological clinic. With the phenytoin, the patients received 20.7 g propane‐1,2‐diol three times daily for a minimum of 3 days (n = 16) or 41.4 g propane‐1,2‐diol twice daily for a period of 3 days (n = 6). Propane‐1,2‐diol was rapidly absorbed from the gastrointestinal tract with maximum plasma concentrations obtained within 1 h of dosing. The average serum half‐life of propane‐1,2‐diol was calculated to be 3.8 h (20.7 g, 3 times daily) and 4.1 h (41.4 g, 2 times daily), respectively. The average apparent total body clearance was approximately 0.1 L/kg per hour. However, a significant variability in clearance rate among individuals was observed. The apparent volume of distribution was approximately 0.5 L/kg.

In a study with intravenous administration of propane‐1,2‐diol (doses between 5.1 and 21 g/day) to 6 patients, the mean clearance was 0.41 L/h per kg bw, and the volume of distribution 0.8 L/kg bw (Speth et al., 1987). The difference in apparent clearance and apparent volume of distribution after oral dosing as compared to intravenous dosing might be explained by the bioavailability but also by a saturated excretion.

A population pharmacokinetic analysis of propane‐1‐2‐diol was done on 372 plasma samples taken from infants (1–11 samples per patient) between 20 min and 20.5 h after intravenous administration of a drug: paracetamol (34), phenobarbital (25) and phenobarbital plus paracetamol (3), which was dissolved in propane‐1‐2‐diol (De Cock et al., 2013). Sixty‐two preterm and term infants were involved in the study, with a gestational age between 24 and 41 weeks at birth and an age between 1 and 82 days, weighing 630–3,980 g. The population value for the clearance was 0.0849 L/h, which is extremely lower than the value for adults (8.64–23.4 L/h per 1.73 m2; Speth et al., 1987). Variability in clearance was explained by body weight at birth. Volume of distribution was dependent on the current body weight. For example, the volume of distribution of a neonate of 1 kg (0.23–0.40 L) was very different compared with a neonate of 4 kg (1.69–3 L).

In a further analysis of their data, De Cock et al. (2014) found out that renal elimination increased from 15% of total clearance after the first dose to 25% of the total clearance, one day later by an unknown mechanism. Compared to the renal clearance in adults which is 45% of the total clearance renal clearance in newborn infants was low, indicating the not yet fully maturated renal function at this age.

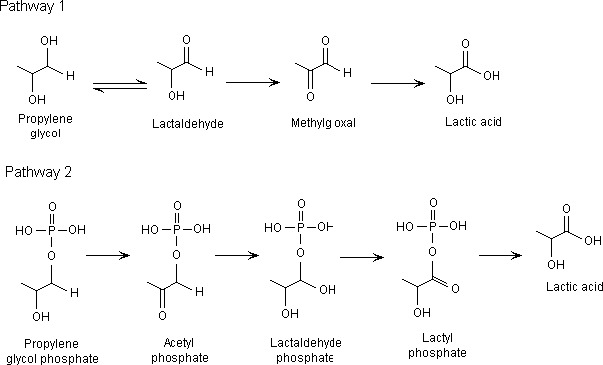

The metabolism of propane‐1,2‐diol has been reviewed by different authors (Ruddick, 1972; LaKind et al., 1999) (Figure 1).

Figure 1.

Metabolism of propane‐1,2‐diol in mammals (re‐produced from Ruddick (1972))

Overall, propane‐1,2‐diol is readily absorbed from the gastrointestinal tract in experimental animals and in humans and is expected to be widely distributed to organs and tissues. The major route of metabolism is oxidation to lactic acid and pyruvic acid. An alternative route of metabolism of propane‐1,2‐diol to lactic acid is via phosphorylated glycol. Lactate may be metabolised via the citric acid cycle and excreted as carbon dioxide via exhalation. At high concentrations, free propane‐1,2‐diol is excreted in the urine as the metabolism of propane‐1,2‐diol is saturated at dose levels higher than 20,000 mg/day in humans (Yu et al., 1985). The Panel noted that in premature infants and infants in the first weeks of life the clearance of propane‐1,2‐diol was extremely low (De Cock et al., 2014).

3.5.2. Acute toxicity

3.5.2.1.

Mice

Groups of 10–20 mice were fasted overnight (18 h before treatment) before administration of a single dose of 20.0, 22.5, 25.0 or 30.0 mL propane‐1,2‐diol/kg bw by stomach tube (Laug et al., 1939). The LD50 value was calculated to be 23.9 mL propane‐1,2‐diol/kg bw (24,760 mg/kg bw).

Groups of at least four mice received a single oral dose of propane‐1,2‐diol (six dose levels, not specified) (Latven and Molitor, 1939). The LD50 value was calculated to be 22.0 mL propane‐1,2‐diol/kg bw (22,792 mg/kg bw).

Rats

A single dosage of 26,000, 31,200 or 36,400 mg propane‐1,2‐diol/kg bw was administered orally to groups of rats (5 animals/group) (Weatherby and Haag, 1938). The LD50 value was calculated to be 33,500 mg/kg bw.

Groups of 9–10 rats were fasted overnight (18 h before treatment) before administration of a single dose of 15.0, 17.5, 17.6, 18.6, 20.0, 21.4, 22.5, 22.6 or 25.0 mL propane‐1,2‐diol/kg bw by stomach tube (Laug et al., 1939). The LD50 value was calculated to be 21.0 mL propane‐1,2‐diol/kg bw (21,756 mg/kg bw).

Rats received a single dose of propane‐1,2‐diol (diluted in water) by stomach tube. In most cases, 10 rats/group were used and the maximal dosage was 50,000 mg propane‐1,2‐diol/kg bw (Smyth et al., 1941). The LD50 value was calculated to be 26,380 mg propane‐1,2‐diol/kg bw.

Groups of five female rats received a single dose by gavage of 18.2, 27.7, 31.6, 50.4 or 57.2 mL propane‐1,2‐diol/kg bw (Thomas et al., 1949). The LD50 value was reported to be 28 mL propane‐1,2‐diol/kg bw (29,008 mg/kg bw).

Groups of female F344 rats (5/groups) received a single oral dose of propane‐1,2‐diol by gavage. The LD50 value was reported to be 22,800 mg/kg bw (Clark et al., 1979). Acute haemorrhagic enteritis together with adrenocortical haemorrhage and widespread lymphocyte depletion were observed at 23,500 mg propane‐1,2‐diol/kg bw.

Guinea pigs

Groups of 10 guinea pigs were fasted overnight (18 h before treatment) before administration of a single dose of 15.0, 17.5, 20.0 or 22.5 mL propane‐1,2‐diol/kg bw by stomach tube (Laug et al., 1939). The LD50 value was calculated to be 18.9 mL propane‐1,2‐diol/kg bw (19,580 mg/kg bw).

A single dose of propane‐1,2‐diol diluted in water was administered to guinea pigs by stomach tube. In most cases, 10 animals/group were used and the maximal dosage was 50,000 mg propane‐1,2‐diol/kg bw (Smyth et al., 1941). The LD50 value was calculated to be 18,350 mg/kg bw).

Rabbits

Groups of rabbits (2–9/group) were dosed with 15,750, 18,900, 19,950 or 21,000 mg propane‐1,2‐diol/kg bw (Braun and Cartland, 1936). Deaths occurred within 18–36 h post‐treatment and the minimum lethal dose (MLD) of propane‐1,2‐diol was estimated to 20,000 mg propane‐1,2‐diol/kg bw.

Overall, the acute toxicity for propanediol‐1,2‐diol was low.

3.5.3. Short‐term and subchronic toxicity

3.5.3.1.

Mice

A group of CD1 mice (10 animals/sex) was given 1,000 mg propane‐1,2‐diol/kg bw per day dissolved in distilled water by gavage for 92–93 days (Thackaberry et al., 2010). The study was performed in accordance with the OECD guideline No 408 (limit test) and in compliance with good laboratory practice (GLP). The control group was administered by gavage 20 mg/kg bw per day in distilled water of hydroxypropyl methylcellulose. No differences in clinical observations, body weights, food consumption, ophthalmology, electrocardiograms, clinical pathology (blood and urine) or absolute and relative organ weights were found between the propane‐1,2‐diol group and the control group. No macroscopic or histopathologic changes in any organs (full section) were observed compared to controls.

Rats

The effect of continuous administration of propane‐1,2‐diol in the drinking water was studied by Seidenfeld and Hanzlik (1932). Groups of 5 rats (sex not specified) were given 1%, 2%, 5%, 10%, 25% or 50% solutions of propane‐1,2‐diol in water for 140 days (equal to 1,600, 3,680, 7,700 or 13,200 mg/kg bw per day for the 1%, 2%, 5% or 10% group, respectively). The majority of rats receiving 25 or 50% propane‐1,2‐diol died by the end of day 6 or day 9, respectively; the animals showed an average weight loss of 10–20 g/rat and the fluid intake was less than 0.5 mL/rat. No significant changes in growth and body weight were found in animals given 1%, 2%, 5% or 10% propane‐1,2‐diol solution, and no significant pathological changes in the kidneys, heart, spleen and liver were observed.

In a subchronic toxicity study, a group of six female rats was given a concentration of 3.58% propane‐1,2‐diol (equivalent to 2,890 mg/kg bw per day) via the drinking water for 11 weeks (Holck, 1937). During the experiment, one rat died (week 10). According to the authors, by the end of the study, a significant weight loss was observed for one rat and the remaining rats were beginning to lose weight.

The toxicity of propane‐1,2‐diol was studies in white growing rats by administration of the substance in the drinking water (Weatherby and Haag, 1938). Groups of five male rats at weaning age received concentrations of 0%, 0.1%, 0.3%, 1%, 3% or 10% propane‐1,2‐diol in their drinking water for 100 days. Food and drink were allowed ad libitum. According to the authors, rats receiving 10% propane‐1,2‐diol in their drinking water consumed from 9,600 to 15,800 mg propane‐1,2‐diol/kg bw per day. During the first 10 days of the experiment, a decrease in weight gain together with poor physical conditions was observed for rats receiving 10% propane‐1,2‐diol compared to the other groups. After this period, the animals seemed to recover and increase in weight in the same way as the control group. Two animals from the 10% propane‐1,2‐diol group and one animal from the 1% propane‐1,2‐diol group died before study termination. No different microscopic changes were found in organs for any of the groups receiving propane‐1,2‐diol when compared to the control group.

In rats (5 animals, sex not specified) given daily 10 mL propane‐1,2‐diol/kg bw (10,360 mg/kg bw per day) by gavage for 15 weeks, no effect on the growth rate was observed compared to control rats (van Winkle, 1941b).

Hanzlik et al. (1939a) investigated the toxicity of propane‐1,2‐diol in young growing rats in a continued consumption study and in a paired feeding experiment. In the continued consumption study, rats (5 rats/group) were fed for 24 weeks on a diet where 25%, 50%, 75% or 100% of the carbohydrate in the diet was replaced with propane‐1,2‐diol. The group fed a carbohydrate‐free, 100% propane‐1,2‐diol‐substituted diet showed no weight gain and all rats died within about a month from study initiation. Rats receiving a 75% propane‐1,2‐diol diet showed significant reduced food intake and impaired growth rate; all rats died within 14 weeks after study initiation. A reduced growth rate and decreased food consumption was observed for groups given diets containing 25% or 50% propane‐1,2‐diol (equal to 8,288 or 31,200 mg propane‐1,2‐diol/kg bw per day) though it was most pronounced at the beginning of the study; no mortality occurred within 20 weeks. According to the authors, the reduced initial growth rate observed in groups fed propane‐1,2‐diol diets may be caused by a distaste of the diet due to the propane‐1,2‐diol content. To test this hypothesis, a paired feeding experiment was performed where groups of 6 rats were fed a 25% carbohydrate reduced diet for 5 months. During this period, rats were dosed daily by gavage with propane‐1,2‐diol (equal to 12.8% of total food intake the previous day, or 25% carbohydrate substitution) or water (control). Rats administered propane‐1,2‐diol increased significantly in body weight compared to controls, which, according to the authors is due to a higher calorie intake from propane‐1,2‐diol and showed the lack of any toxic effect of propane‐1,2‐diol.

In a study by van Winkle and Newman (1941), paired‐fed rats (5 rats/group) received propane‐1,2‐diol or water (control) daily by stomach tube for 127–163 days. Rats dosed with propane‐1,2‐diol were kept on a 25% reduced carbohydrate diet and dosed with a caloric equivalent amount of propane‐1,2‐diol (total propane‐1,2‐diol intake ranged from 92.4 to 135.4 mg). Propane‐1,2‐diol dosed rats were found to grow more rapidly and showed an increased weight gain compared to the controls. In addition, propane‐1,2‐diol was found to increase the concentration of liver glycogen with 2–7 times (van Winkle and Newman, 1941).

Administration of 5% or 10% propane‐1,2‐diol (equivalent to 6,250 and 12,500 mg/kg bw per day) in the drinking water to 10 male rats for 5 weeks resulted in significantly decreased red blood cell count (8–11%) (Vaille et al., 1971). A dose‐related increase in the liver weight (relative/absolute 20/11% or 37/27%) and in blood glucose (39% or 78%) was reported in the 5% or 10% group respectively. No histopathological (liver, spleen, kidneys, heart, pancreas, adrenal glands) changes were observed. The Panel noted that the administered doses were high, the highest one being half of the LD50 value.

When CD rats (15/sex per group) were fed a diet containing 50,000 mg propane‐1,2‐diol/kg diet (equivalent to 4,500 mg/kg bw per day) for 15 weeks, no effects on serum and urine parameters, haematology or organ weights (brain, heart, liver, spleen, kidneys, adrenals, gonads, and pituitary) were noted (Gaunt et al., 1972). No abnormalities were seen at necropsy.