Abstract

According to Article 12 of Regulation (EC) No 396/2005, EFSA has reviewed the maximum residue levels (MRLs) currently established at European level for the pesticide active substance profoxydim. To assess the occurrence of profoxydim residues in plants, processed commodities, rotational crops and livestock, EFSA considered the conclusions derived in the framework of Directive 91/414/EEC as well as the European authorisations reported by Member States (including the supporting residues data). Based on the assessment of the available data, MRL proposals were derived and a consumer risk assessment was carried out. Albeit, all information required by the regulatory framework was present and a risk for consumers was not identified, a risk management decision may still be taken regarding the residue definition for enforcement.

Keywords: profoxydim, MRL review, Regulation (EC) No 396/2005, consumer risk assessment, herbicide

Summary

Profoxydim was included in Annex I to Directive 91/414/EEC on 1 August 2011 by Commission Implementing Regulation (EU) No 706/2011 and has been deemed to be approved under Regulation (EC) No 1107/2009, in accordance with Commission Implementing Regulation (EU) No 540/2011, as amended by Commission Implementing Regulation (EU) No 541/2011. As profoxydim was approved after the entry into force of Regulation (EC) No 396/2005 on 2 September 2008, the European Food Safety Authority (EFSA) is required to provide a reasoned opinion on the review of the existing maximum residue levels (MRLs) for that active substance in compliance with Article 12(1) of the aforementioned regulation. To collect the relevant pesticide residues data, EFSA asked Spain, the designated rapporteur Member State (RMS), to complete the Pesticide Residues Overview File (PROFile) and to prepare a supporting evaluation report. The PROFile and evaluation report provided by the RMS were made available to the Member States. A request for additional information was addressed to the Member States in the framework of a completeness check period, which was initiated by EFSA on 2 October 2017 and finalised on 1 December 2017. After having considered all the information provided, EFSA prepared a completeness check report which was made available to Member States on 5 February 2018.

Based on the conclusions derived in the framework of Directive 91/414/EEC and the additional information provided by the RMS and Member States, EFSA prepared in February 2018 a draft‐reasoned opinion, which was circulated to Member States for consultation via a written procedure. Comments received by 13 April 2018 were considered during the finalisation of this reasoned opinion. The following conclusions are derived.

The nature of residues of profoxydim was investigated in primary crops (cereals) and rotational crops (root and tuber vegetables, leafy vegetables, pulses and oilseeds, and cereals). In light of the results of the metabolism study, profoxydim is rapidly and intensively metabolised in primary crops. The parent compound is not detected, but a variety of metabolites having in common the thiopyranylcyclohexenone substructure were identified. The confined rotational crop study showed that significant residues are not expected in succeeding crops. The residue definition for enforcement and risk assessment was set as the sum of profoxydim and all metabolites containing the thiopyranylcyclohexenone moiety (with all three oxidation states of sulfur) expressed as profoxydim (determined as BH 625‐23). This residue definition can be enforced in both rice grain and straw, with a limit of quantification (LOQ) of 0.05 mg/kg. The proposed residue definition is limited to cereal crops.

The available residue trials were sufficient to derive MRL proposals as well as risk assessment values for rice grain (the only food commodity under assessment). A tentative MRL was also derived for rice straw in view of the envisaged need to set MRLs in feed items. As it is not expected that residue levels in rice grain exceed the LOQ and the chronic exposure is foreseen to be far below the 10% of the acceptable daily intake (ADI), no further investigation on the nature and magnitude of residues in processed commodities were required.

Profoxydim is authorised for use on rice (grain and straw) that might be fed to livestock. The dietary burden values calculated for all groups of livestock did not trigger the threshold value of 0.1 mg/kg dry matter (DM). Therefore, further investigations of residues in livestock are not required. Alike, setting of MRLs in animal commodities is not needed.

Chronic and acute consumer exposure resulting from the authorised uses reported in the framework of this review was calculated using revision 2 of the EFSA Pesticide Residues Intake model (PRIMo). The highest chronic exposure represented 0.8% of the ADI (PT, general population) and the highest acute exposure amounted to 1.3% of the acute reference dose (ARfD) (rice).

Background

Regulation (EC) No 396/20051 (hereinafter referred to as ‘the Regulation’) establishes the rules governing the setting and the review of pesticide maximum residue levels (MRLs) at European level. Article 12(1) of that Regulation stipulates that the European Food Safety Authority (EFSA) shall provide within 12 months from the date of the inclusion or non‐inclusion of an active substance in Annex I to Directive 91/414/EEC2 a reasoned opinion on the review of the existing MRLs for that active substance. As profoxydim was included in Annex I to Council Directive 91/414/EEC on 1 August 2011 by means of Commission Implementing Regulation (EU) No 706/20113 and has been deemed to be approved under Regulation (EC) No 1107/20094, in accordance with Commission Implementing Regulation (EU) No 540/20115, as amended by Commission Implementing Regulation (EU) No 541/20116, EFSA initiated the review of all existing MRLs for that active substance.

According to the legal provisions, EFSA shall base its reasoned opinion in particular on the relevant assessment report prepared under Directive 91/414/EEC. It should be noted, however, that, in the framework of Directive 91/414/EEC, only a few representative uses are evaluated, whereas MRLs set out in Regulation (EC) No 396/2005 should accommodate all uses authorised within the European Union (EU), and uses authorised in third countries that have a significant impact on international trade. The information included in the assessment report prepared under Directive 91/414/EEC is therefore insufficient for the assessment of all existing MRLs for a given active substance.

To gain an overview of the pesticide residues data that have been considered for the setting of the existing MRLs, EFSA developed the Pesticide Residues Overview File (PROFile). The PROFile is an inventory of all pesticide residues data relevant to the risk assessment and MRL setting for a given active substance. This includes data on:

the nature and magnitude of residues in primary crops;

the nature and magnitude of residues in processed commodities;

the nature and magnitude of residues in rotational crops;

the nature and magnitude of residues in livestock commodities;

the analytical methods for enforcement of the proposed MRLs.

Spain, the designated rapporteur Member State (RMS) in the framework of Directive 91/414/EEC, was asked to complete the PROFile for profoxydim and to prepare a supporting evaluation report (Spain, 2017a). The PROFile and the supporting evaluation report were submitted to EFSA on 29 May 2014 and 15 July 2017, respectively, and made available to the Member States. A request for additional information was addressed to the Member States in the framework of a completeness check period which was initiated by EFSA on 2 October 2017 and finalised on 1 December 2017. Additional evaluation reports were submitted by Spain and the European Union Reference Laboratories (EURLs) for Pesticide Residues (EURL, 2017; Spain, 2017b) and, after having considered all the information provided by the RMS and the EURLs for Pesticide Residues, EFSA prepared a completeness check report which was made available to all Member States on 5 February 2018. No further clarifications were sought from Member States.

Based on the conclusions derived in the framework of Directive 91/414/EEC, and the additional information provided by the RMS and the EURLs Reference Laboratories for Pesticide Residues, EFSA prepared in February 2018 a draft‐reasoned opinion, which was submitted to Member States for commenting via a written procedure. All comments received by 13 April 2018 were considered by EFSA during the finalisation of the reasoned opinion.

The evaluation report submitted by the RMS (Spain, 2017a) and the evaluation reports submitted by the RMS and the EURLs (EURL, 2017; Spain, 2017b) are considered as supporting documents to this reasoned opinion and, thus, are made publicly available.

In addition, key supporting documents to this reasoned opinion are the completeness check report (EFSA, 2018a) and the Member States consultation report (EFSA, 2018b). These reports are developed to address all issues raised in the course of the review, from the initial completeness check to the reasoned opinion. Also, the chronic and acute exposure calculations for all crops reported in the framework of this review performed using the EFSA Pesticide Residues Intake Model (PRIMo) (excel file) and the PROFile are key supporting documents and made publicly available as background documents to this reasoned opinion. Furthermore, a screenshot of the report sheet of the PRIMo is presented in Appendix C.

Terms of Reference

According to Article 12 of Regulation (EC) No 396/2005, EFSA shall provide a reasoned opinion on:

the inclusion of the active substance in Annex IV to the Regulation, when appropriate;

the necessity of setting new MRLs for the active substance or deleting/modifying existing MRLs set out in Annex II or III of the Regulation;

the inclusion of the recommended MRLs in Annex II or III to the Regulation;

the setting of specific processing factors as referred to in Article 20(2) of the Regulation.

The active substance and its use pattern

Profoxydim is the ISO common name for (5RS)‐2‐{(1EZ)‐N‐[(2RS)‐2‐(4‐chlorophenoxy)propoxy]butanimidoyl}‐3‐hydroxy‐5‐[(3RS)‐thian‐3‐yl]cyclohex‐2‐en‐1‐one (IUPAC).

Profoxydim is used as a herbicide. It is an inhibitor of the acetyl coenzyme A carboxylase activity in the chloroplasts of susceptible grass weed species. The inhibition initiates a wide ranging cascade of physiological consequences, such as the prevention of fatty acid biosynthesis and thus of triglyceride and phospholipid formation. Profoxydim acts as a contact grass herbicide and is translocated in the plant both acropetally and basipetally.

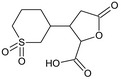

The chemical structure of the active substance and its main metabolites are reported in Appendix F.

Profoxydim was evaluated in the framework of Directive 91/414/EEC with Spain designated as RMS. The representative use supported for the peer review process was post‐emergence outdoor application on rice. Following the peer review, a decision on inclusion of the active substance in Annex I to Directive 91/414/EEC was published by means of Commission Implementing Regulation (EU) No 706/2011, which entered into force on 1 August 2011. According to Regulation (EU) No 540/2011, as amended by Commission Implementing Regulation (EU) No 541/2011, profoxydim is deemed to have been approved under Regulation (EC) No 1107/2009. This approval is restricted to uses as herbicide in rice only. As EFSA was not yet involved in the peer review of profoxydim, an EFSA Conclusion on this active substance is not available.

The EU MRLs for profoxydim are established in Annex IIIA of Regulation (EC) No 396/2005, as amended by Commission Regulation (EC) No 839/20087. Codex maximum residue limits (CXLs) for profoxydim are not available. There are no MRL changes occurred since the entry into force of the Regulation mentioned above.

For the purpose of this MRL review, the critical uses of profoxydim currently authorised within the EU have been collected by the RMS and reported in the PROFile. The details of the authorised good agricultural practices (GAPs) for profoxydim are given in Appendix A. The RMS did not report any use authorised in third countries that might have a significant impact on international trade.

Assessment

EFSA has based its assessment on the PROFile submitted by the RMS, the evaluation report accompanying the PROFile (Spain, 2017a), the draft assessment report (DAR) and its addenda prepared under Council Directive 91/414/EEC (Spain, 2001, 2002, 2006), the review report on profoxydim (European Commission, 2011), as well as the evaluation reports submitted during the completeness check (EURL, 2017; Spain, 2017b). The assessment is performed in accordance with the legal provisions of the uniform principles for evaluation and authorisation of plant protection products as set out in Commission Regulation (EU) No 546/20118 and the currently applicable guidance documents relevant for the consumer risk assessment of pesticide residues (European Commission, 1997a–1997b, 1997c, 1997d, 1997e, 1997f, 1997g, 2000, 2010a,b, 2017 and OECD, 2011, 2013).

More detailed information on the available data and on the conclusions derived by EFSA can be retrieved from the list of end points reported in Appendix B.

1. Residues in plants

1.1. Nature of residues and methods of analysis in plants

1.1.1. Nature of residues in primary crops

The metabolism of profoxydim was investigated following foliar application in rice plants. In the experimental studies, a 1:1 labelled mixture of [cyclohexenone‐4(6)‐ 14C]‐profoxydim and [phenyl‐U‐14C]‐profoxydim was used at the representative dose rate (200 g.a.s/ha) and twofold the said rate (2 × 200 g.a.s/ha).

In rice, profoxydim is rapidly and extensively metabolised by oxidation reactions, ether cleavage and desalkoxylation of the side chain. The parent compound was not detected in any of the samples (plant, grain, husks or straw) at any sampling stage. At 0 days after treatment (DAT) in whole plant, the sulfhoxide BH 625‐1 and its isomer were the main metabolites, accounting for 26–45%, and 11–12% total radioactive residue (TRR), respectively. The latter reinforces the postulation of rapid metabolism via oxidation of the parent compound.

In grain (124 DAT), at the 2 × 1N dosing rate, TRRs accounted for 0.043 (cyclohexenone labelled) to 0.235 mg eq/kg (phenyl labelled). Up to eight individual metabolites were identified, none of them at values ˃ 0.01 mg/kg (0.1–3% TRR). It should be stressed that a large proportion of the radioactivity (42.5–62.1% TRR) in grain remained unextracted, being more important for the phenyl‐ than for cyclohexenone‐labelled form. In both cases, the major proportion of this unextracted radioactivity was found to be associated with protein and carbohydrates. On the other hand, in straw (124 DAT, 2 × 1N), 94.3–97.5% TRR was extracted, and the residues amounted to 2.41–3.35 mg/kg. For the cyclohexenone label, metabolites 625M27, 625M30 and 625M28 represented the most prominent TRR, accounting for 18.2, 13.2 and 12.2%, respectively. All the three metabolites share the common moiety thiopyranylcyclohexenone. In the case of the phenyl label, radioactivity exceeding 10% was reached by the carboxylic acid BH 625‐22 (12.0% TRR, 0.289 mg/kg) and the disaccharide derivative 625M34 (11.2% TRR, 0.270 mg/kg).

1.1.2. Nature of residues in rotational crops

Rice can be grown in rotation with other crops. According to soil degradation studies performed in a laboratory at 20°C, under aerobic conditions, and evaluated in the framework of Directive 91/414/EEC, DT90 values of profoxydim ranged between 2 and 41 days, which are lower than the trigger value of 100 days (European Commission, 2011). However, DT90 values of the main soil metabolites, namely BH 625‐1 and BH 625‐10, were reported to be 185–374 and 239–318 days, respectively. Therefore, an investigation of residues in rotational crops was required.

A rotational crop study was reported in the DAR (Spain, 2001). Profoxydim was applied onto bare soil as a 1:1 mixture of both labelled forms at a dose rate of 2 × 200 g a.s./ha. Carrots, lettuce, wheat and bean were sown in the treated soil 30 days after application. Total radioactive residues were found to be below 0.01 mg/kg in the edible parts of succeeding crops. The highest TRR was observed in wheat straw at 124 days replanting interval, extractable radioactive residue: 0.05 mg/kg, and remaining radioactive residue: 0.07 mg/kg.

Based on the available data, it can be concluded that the investigated application of profoxydim shall not give rise to residues in succeeding crops. Hence, additional studies with longer plant back intervals for soil aging (120, 365 days) would not be required.

1.1.3. Nature of residues in processed commodities

Studies investigating the effect of industrial and/or household processing on the nature of the residues are not available. Nonetheless, considering that residues of profoxydim exceeding 0.05 mg/kg are not expected in treated grains nor chronic exposure exceeds the 10% of the acceptable daily intake (ADI) (see also Sections 1.2.1 and 3), it is concluded that processing studies are not needed.

1.1.4. Methods of analysis in plants

In light of the variety of metabolites identified, a common moiety residue analytical method BASF Method Nr. D 9612/1 was regarded as being the most suitable for residue analysis and enforcement purposes in rice grain and straw. The basis for the method is that the cyclohexenone ring of profoxydim and its metabolites is oxidised to the corresponding glutaric acid, which is subsequently methylated to form the corresponding glutaric acid dimethyl‐ester. Determination is achieved by gas chromatography coupled to mass spectrometry (GC‐MS). The limit of quantification (LOQ) of the method was reported to be 0.05 mg/kg (Spain, 2017a). An interlaboratory validation method confirming the findings of the primary method was submitted in the DAR (Spain, 2001).

During the completeness check, the EURLs provided a QuEChERS analytical method based on liquid chromatography and tandem mass spectrometry detection (LC‐MS/MS) for the enforcement of profoxydim, as parent compound only, with a LOQ of 0.005 mg/kg in dry commodities (EURL, 2017). This method only covers the parent compound.

1.1.5. Stability of residues in plants

During the completeness check, the RMS provided a study on the potential degradation of residues during the storage of the residue trials samples. The storage stability of profoxydim (BAS 625‐Li) and the metabolites 625M28 and 625M27 was demonstrated for a period of 24 months at −20°C in rice grain and straw (Spain, 2017b). During the completeness check, the RMS confirmed that both BAS 625‐Li and BAS 625H refer to profoxydim parent compound (EFSA, 2018a).

1.1.6. Proposed residue definitions

Bearing in mind the metabolism studies carried out with rice and two different radiolabels, profoxydim is quickly and extensively metabolised in rice plants, originating a variety of metabolites, none of them present at significant levels. Moreover, according to the rotational crop study, total residues in succeeding crops did not exceed 0.01 mg/kg, either. Nevertheless, the most prominent residues have in common the moiety of the thiopyranylcyclohexenone with the three states of oxidation of sulfur. In view of this, the residue definition for enforcement and risk assessment was set as the sum of profoxydim and all metabolites containing the thiopyranylcyclohexenone moiety (with all three oxidation states of sulfur), expressed as profoxydim (determined as BH 625‐23). This residue definition can be enforced in both rice grain and straw, with a LOQ of 0.05 mg/kg.

It is noteworthy to mention that, according to the RMS, the common moiety given in the residue definition may also come from other herbicides, such as cycloxydim. The latter is a limitation in terms of specificity of the proposed residue definition for enforcement. Depending on the specificity of the common moiety thiopyranylcyclohexenone to profoxydim, risk managers may consider a more restrictive residue definition (e.g. parent compound only). However, it is highlighted that parent compound only is not a good marker for enforcement as it is extensively degraded in plants. In order to assist risk managers in the decision process, RMS shall provide further detailed information on the other possible sources of the common moiety thiopyranylcyclohexenone.

In addition, EFSA emphasises that the above studies do not investigate the possible impact of plant metabolism on the isomer ratio of profoxydim and further investigation on this matter would in principle be required. Since guidance on the consideration of isomer ratios in the consumer risk assessment is not yet available, EFSA recommends that this issue is reconsidered when such guidance is available.

1.2. Magnitude of residues in plants

1.2.1. Magnitude of residues in primary crops

To assess the magnitude of profoxydim residues resulting from the reported GAPs, EFSA considered all residue trials reported by the RMS in its evaluation report (Spain, 2017a). All residue trial samples considered in this framework were stored in compliance with the demonstrated storage conditions (EFSA, 2018a). Decline of residues during storage of the trial samples is therefore not expected.

The number of residue trials and extrapolations was evaluated in accordance with the European guidelines on comparability, extrapolation, group tolerances and data requirements for setting MRLs (European Commission, 2017).

The available residue trials are sufficient to derive MRL and risk assessment values for the two commodities under consideration (rice, both grain and straw). It is noted that the critical GAP reported for rice is not expected to lead to significant residue levels in grain. This is confirmed by 10 residue field trials conducted in Southern Europe (SEU), according to GAP and in line with good laboratory practice (GLP). Hence, MRL and risk assessment values can be set at the enforcement LOQ for rice grain, and 0.2 mg/kg for rice straw.

1.2.2. Magnitude of residues in rotational crops

The confined metabolism studies allowed to conclude that neither profoxydim nor its metabolism products are expected in rotational crops grown on soil previously treated with profoxydim (see Section 1.1.2). No further studies are required.

1.2.3. Magnitude of residues in processed commodities

There are no studies available on the magnitude of residues in processed commodities of rice. These data are not required in this review (see also Section 1.1.3).

1.2.4. Proposed MRLs

The available data are considered sufficient to derive MRL proposals as well as risk assessment values for rice grain (the only food commodity under assessment). A tentative MRL was also derived for rice straw in view of the future need to set MRLs in feed items.

2. Residues in livestock

Profoxydim is authorised for use on rice grain and rice straw that might be fed to livestock. Livestock dietary burden calculations were therefore performed for different groups of livestock according to OECD guidance (OECD, 2013), which has now also been agreed upon at European level. The input values for all relevant commodities are summarised in Appendix D. It shall be stressed that the default concentration factor usually considered for rice, bran/pollard was not taken into account in the calculation since residues foreseen in rice grain are expected to remain below the LOQ (see Section 1.2.1). The calculated dietary burdens for all groups of livestock were found to be below the trigger value of 0.1 mg/kg dry matter (DM), further investigation of residues as well as the setting of MRLs in commodities of animal origin is thus unnecessary.

Although not required, studies investigating the nature of profoxydim residues in commodities of animal origin were assessed by the RMS and reported in the framework of Directive 91/414/EEC (Spain, 2001). The reported metabolism studies comprise one study performed with lactating goats and one with laying hens using both radiolabelled forms, i.e. 14C‐cyclohexenone and ‐phenyl, of the test substance profoxydim. Lactating goats were dosed at 50N and 1400N rates compared to the maximum dietary burden calculated for sheep. In the low‐dose group, the radioactivity was rapidly and almost completely extracted (82.3% of the total dose). Products from mainly two key metabolic transformations were observed, on the cyclohexenone side of the molecule: oxidation of the thioether to the corresponding sulfoxide and sulfone and cleavage of the oxime ether bond. Cleavage of the phenyl ether bond was observed on the phenyl portion. The major part of the residue was found in liver (0.31–0.43 mg eq/kg) and kidney (0.13–0.15 mg eq/kg). Up to six metabolites were identified, but only the parent compound and the corresponding sulfoxide (BH 625‐1 and isomer) exceeded 0.05 mg eq/kg. More precisely, the parent accounted for 0.053 mg eq/kg (17.1% TRR) and 0.086 mg eq/kg (19.9% TRR) for the cyclohexenone and phenyl label, respectively in liver. With respect to BH 625‐1 and isomer, they were found to be 0.050 mg eq/kg (39% TRR) in kidney and 0.069 mg eq/kg (22.2% TRR) in liver for the cyclohexenone label, and 0.082 mg eq/kg (55% TRR) in kidney and 0.085 mg eq/kg (19.8% TRR) in liver for the phenyl side.

Laying hens were dosed with both radiolabelled forms of the test substance at 225N and 300N rates compared to the maximum dietary burden calculated for poultry (broiler). The same metabolic pathway as in ruminants was proposed for poultry. Alike, radioactivity was rapidly and almost completely excreted (82.9–86% of total dose). The most part of the residue was found in liver (0.12–0.14 mg eq/kg) and egg yolk (0.05–0.094 mg eq/kg). Seven metabolites were identified, being the parent and its sulfoxide (BH 625‐1 and isomer) the most prominent ones. It shall be underlined that none of the metabolites exceeded 0.05 mg/kg.

Considering the current dietary burden calculations, a residue definition for enforcement and risk assessment in livestock is not needed, neither proposed. Since significant percentages of parent compound and metabolite BH 625‐1 (and isomer) were not present in all matrices, these two analytes may not be sufficient markers for enforcement purposes in case the dietary burden would be triggered in the future. However, the common moiety thiopyranylcyclohexenone was present in all edible tissues. Furthermore, a GC‐MS method determining this common moiety as BH 625‐23 is currently available, with a LOQ of 0.005 mg/kg for eggs, muscle, fat, kidney and liver, and 0.01 mg/kg for milk.

Livestock feeding studies were not performed in the assessment and they are not required in this review.

3. Consumer risk assessment

Chronic and acute exposure calculations for all crops reported in the framework of this review were performed using revision 2 of the EFSA PRIMo (EFSA, 2007). Input values for the exposure calculations were derived in compliance with the decision tree reported in Appendix E. Hence, for rice grain (the only food commodity under assessment) where MRL and risk assessment values could be derived by EFSA in the framework of this review, input values were derived according to the internationally agreed methodologies (FAO, 2009). All input values included in the exposure calculations are summarised in Appendix D.

The calculated exposure values were compared with the toxicological reference value for profoxydim, derived by the European Commission, (2011) under Directive 91/414/EEC. The highest chronic exposure was calculated for Portuguese general population, representing 0.8% of the ADI, and the highest acute exposure was calculated for rice, representing 1.3% of the acute reference dose (ARfD). Based on these calculations, EFSA concludes that the use of profoxydim on rice is acceptable with regard to consumer exposure.

It should be mentioned that the ratio of the four isomers was not defined in the mixture nor was further information reported in the toxicological studies (Spain, 2001). Therefore, in the event that higher toxicity would be attributed to one particular isomer, the above calculations may need to be reconsidered. However, considering the large margin of safety shown in the aforementioned calculations, this is not expected to affect the outcome of the risk assessment. Therefore, further information on the mixture of the four constituent isomers tested in the toxicological studies is deemed desirable (minor deficiency).

EFSA emphasises that the above assessment does not consider the possible impact of plant metabolism on the isomer ratio of profoxydim and further investigation on this matter would in principle be required. Since guidance on the consideration of isomer ratios in the consumer risk assessment is not yet available, EFSA recommends that this issue is reconsidered when such guidance is available.

Conclusions

The nature of residues of profoxydim was investigated in primary crops (cereals) and rotational crops (root and tuber vegetables, leafy vegetables, pulses and oilseeds and cereals). In light of the results of the metabolism study, profoxydim is rapidly and intensively metabolised in primary crops. The parent compound is not detected, but a variety of metabolites having in common the thiopyranylcyclohexenone substructure were identified. The confined rotational crop study showed that significant residues are not expected in succeeding crops. The residue definition for enforcement and risk assessment was set as the sum of profoxydim and all metabolites containing the thiopyranylcyclohexenone moiety (with all three oxidation states of sulfur), expressed as profoxydim (determined as BH 625‐23). This residue definition can be enforced in both rice grain and straw, with a LOQ of 0.05 mg/kg. The proposed residue definition is limited to cereal crops.

The available residue trials were sufficient to derive MRL proposals as well as risk assessment values for rice grain (the only food commodity under assessment). A tentative MRL was also derived for rice straw in view of the envisaged need to set MRLs in feed items. As it is not expected that residue levels in rice grain exceed the LOQ and the chronic exposure is foreseen to be far below the 10% of the ADI, no further investigation on the nature and magnitude of residues in processed commodities was required.

Profoxydim is authorised for use on rice (grain and straw) that might be fed to livestock. The dietary burden values calculated for all groups of livestock did not trigger the threshold value of 0.1 mg/kg DM. Therefore, further investigations of residues in livestock are not required. Alike, setting of MRLs in animal commodities is not needed.

Chronic and acute consumer exposure resulting from the authorised uses reported in the framework of this review was calculated using revision 2 of the EFSA PRIMo. The highest chronic exposure represented 0.8% of the ADI (PT, general population) and the highest acute exposure amounted to 1.3% of the ARfD (rice).

Recommendations

MRL recommendations were derived in compliance with the decision tree reported in Appendix E of the reasoned opinion (see Table 1). The MRL value derived for the only food commodity under evaluation (rice grain) is sufficiently supported by data and is therefore proposed for inclusion in Annex II to the Regulation. However, a risk management decision may still be taken on the residue definition for enforcement. It was noted that the proposed residue definition including a common moiety may not be specific to profoxydim. Therefore, the RMS is kindly asked to provide the following clarification:

To specify which are the other possible sources of the common moiety thiopyranylcyclohexenone.

Table 1.

Summary table

| Code number | Commodity | Existing EU MRL (mg/kg) | Outcome of the review | |

|---|---|---|---|---|

| MRL (mg/kg) | Comment | |||

|

Enforcement residue definition (existing): profoxydim Enforcement residue definition (proposed): sum of profoxydim and all metabolites containing the thiopyranylcyclohexenone moiety (with all three oxidation states of sulfur), expressed as profoxydim (determined as BH 625‐23) | ||||

| 0500060 | Rice grain | 0.05a | 0.05a | Further consideration neededb |

| – | Other commodities of plant and animal origin | See Regulation (EC) No 839/2008 | – | Further consideration neededc |

MRL: maximum residue level.

Indicates that the MRL is set at the limit of quantification.

MRL is derived from a GAP evaluated at EU level, which is fully supported by data and for which no risk to consumers is identified; no CXL is available (combination G–I in Appendix E); however, the proposed residue definition may not be specific to profoxydim.

There are no relevant authorisations or import tolerances reported at EU level; no CXL is available. Either a specific LOQ or the default MRL of 0.01 mg/kg may be considered (combination A–I in Appendix E).

Pending on this information, an alternative and more restrictive residue definition (e.g. parent compound only) may be considered by risk managers. However, it is highlighted that parent compound only is not a good marker for enforcement as it is rapidly and extensively degraded in plants.

A minor deficiency was also identified in the assessment, but it is not expected to have an impact either on the validity of the MRL derived or the national authorisations. The following information is considered desirable:

Further information on the isomer ratio in the profoxydim mixture should be provided. Also, in the event that a specific isomer ratio was administered to conduct the toxicological studies, the composition of this mixture should be documented.

Abbreviations

- a.i.

active ingredient

- a.s.

active substance

- ADI

acceptable daily intake

- ARfD

acute reference dose

- BBCH

growth stages of mono‐ and dicotyledonous plants

- bw

body weight

- CF

conversion factor for enforcement residue definition to risk assessment residue definition

- CXL

codex maximum residue limit

- DAR

draft assessment report

- DAT

days after treatment

- DM

dry matter

- DT90

period required for 90% dissipation (define method of estimation)

- EC

emulsifiable concentrate

- EC

European Commission

- EURLs

European Union Reference Laboratories for Pesticide Residues (former CRLs)

- FAO

Food and Agriculture Organization of the United Nations

- GAP

Good Agricultural Practice

- GC‐MS

gas chromatography with mass spectrometry

- GLP

Good Laboratory Practice

- HR

highest residue

- IEDI

international estimated daily intake

- IESTI

international estimated short‐term intake

- ILV

independent laboratory validation

- ISO

International Organisation for Standardization

- IUPAC

International Union of Pure and Applied Chemistry

- LC–MS/MS

liquid chromatography with tandem mass spectrometry

- LOQ

limit of quantification

- Mo

monitoring

- MRL

maximum residue level

- MS

mass spectrometry detector

- MS/MS

tandem mass spectrometry detector

- NEU

northern European Union

- OECD

Organisation for Economic Co‐operation and Development

- PBI

plant back interval

- PF

processing factor

- PHI

preharvest interval

- PRIMo

(EFSA) Pesticide Residues Intake Model

- PROFile

(EFSA) Pesticide Residues Overview File

- QuEChERS

Quick, Easy, Cheap, Effective, Rugged, and Safe (analytical method)

- RD

residue definition

- RMS

rapporteur Member State

- SANCO

Directorate‐General for Health and Consumers

- SEU

southern European Union

- SMILES

simplified molecular‐input line‐entry system

- STMR

supervised trials median residue

- TRR

total radioactive residue

- WHO

World Health Organization

Appendix A – Summary of authorised uses considered for the review of MRLs

1.

| Critical outdoor GAPs for Northern Europe | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Crop | Region | Outdoor/Indoor | Member state or country | Pest controlled | Formulation | Application | PHI or waiting period (days) | Comments | ||||||||||||

| Common name | Scientific name | Type | Content | Method | Growth stage | Number | Interval (days) | Rate | ||||||||||||

| Conc. | Unit | From BBCH | Until BBCH | Min. | Max. | Min. | Max. | Min. | Max. | Unit | ||||||||||

| Rice | Oryza sativa | SEU | Outdoor | IT, ES | Echinocloa crus‐galli, Panicum dichotomiflorum | EC | 200.0 | g/L | Foliar treatment ‐ spraying | 14 | 29 | 1 | 80.00 | 200.00 | g a.i./ha | n.a. |

Application conditions: BBCH 14: 80 g a.i./ha BBCH 21–23: 100 g a.i./ha BBCH 23‐29: 200 g a.i./ha Mixing with adjuvant recommended (0,25‐0,3%) |

|||

GAP: Good Agricultural Practice; BBCH: growth stages of mono‐ and dicotyledonous plants; PHI: preharvest interval; NEU: northern European Union; SEU: southern European Union; a.i.: active ingredient.

Appendix B – List of end points

B.1. Residues in plants

B.1.1. Nature of residues and methods of analysis in plants

B.1.1.1. Metabolism studies, methods of analysis and residue definitions in plants

| Primary crops (available studies) | Crop groups | Crop(s) | Application(s) | Sampling (DAT) |

|---|---|---|---|---|

| Cereals/grass crops | Rice | Foliar treatment at BBCH 30, 200 g a.s./ha |

Green matter: 0 Whole plant: 66 Grain and straw: 124 |

|

| Rice | Foliar treatment from BBCH 30, 2 × 200 g a.s./ha |

Green matter: 0 Whole plant: 66 Grain and straw: 124 |

||

| Source: Spain, 2001.All studies were performed using phenyl‐ and cyclohexenone‐radiolabelled profoxydim. | ||||

| Rotational crops(available studies) | Crop groups | Crop(s) | Application(s) |

PBI (DAT) |

| Root/tuber crops | Carrot | Bare soil application, 2 × 200 g a.s./ha | 30 | |

| Leafy crops | Lettuce | Bare soil application, 2 × 200 g a.s./ha | 30 | |

| Cereal (small grain) | Wheat | Bare soil application, 2 × 200 g a.s./ha | 30 | |

| Pulses and oilseeds | Bean | Bare soil application, 2 × 200 g a.s./ha | 30 | |

| Source: Spain, 2001.All studies were performed using phenyl‐ and cyclohexenone‐radiolabelled profoxydim. | ||||

| Processed commodities(hydrolysis study) | Conditions | Investigated? | ||

| Pasteurisation (20 min, 90°C, pH 4) | No | |||

| Baking, brewing and boiling (60 min, 100°C, pH 5) | No | |||

| Sterilisation (20 min, 120°C, pH 6) | No | |||

| Not investigated and not required. | ||||

| Can a general residue definition be proposed for primary crops? | No |

| Rotational crop and primary crop metabolism similar? | Yes |

| Residue pattern in processed commodities similar to residue pattern in raw commodities? | Not triggered |

| Plant residue definition for monitoring (RD‐Mo) | Cereals only: sum of profoxydim and all metabolites containing the thiopyranylcyclohexenone moiety (with all three oxidation states of sulfur) expressed as profoxydim (determined as BH 625‐23) |

| Plant residue definition for risk assessment (RD‐RA) | Cereals only: sum of profoxydim and all metabolites containing the thiopyranylcyclohexenone moiety (with all three oxidation states of sulfur) expressed as profoxydim (determined as BH 625‐23) |

| Conversion factor (monitoring to risk assessment) | Not relevant |

| Methods of analysis for monitoring of residues (analytical technique, crop groups, LOQs) | Rice grains:

|

a.i.: active ingredient; DAT: days after treatment; PBI: plant back interval; GC‐MS: gas chromatography with mass spectrometry; LC–MS/MS: liquid chromatography with tandem mass spectrometry; LOQ: limit of quantification; ILV: independent laboratory validation.

B.1.1.2. Stability of residues in plants

| Plant products (available studies) | Category | Commodity | T (°C) | Stability (Months/years) |

|---|---|---|---|---|

| Dry commodity | Rice grain | −20 | 24 | |

| Other matrices | Rice straw | −20 | 24 | |

| Source: Spain (2017b)Study performed spiking matrices with profoxydim, 625M28 (BH 517‐1) and 625M27 (BH 625‐27) | ||||

B.1.2. Magnitude of residues in plants

B.1.2.1. Summary of residues data from the supervised residue trials

| Crop | Region/indoorb | Residue levels observed in the supervised residue trials relevant to the supported GAPs (mg/kg) |

Recommendations/comments (OECD calculations) |

MRL proposals (mg/kg) |

HR (mg/kg)c |

STMR (mg/kg)d |

|---|---|---|---|---|---|---|

| Rice grains | SEU | 10 × < 0.05 | Trials compliant with GAP (Spain, 2001) | 0.05a | < 0.05 | < 0.05 |

| Rice straw | SEU | 7 × < 0.05; 0.07; 0.14 |

Trials compliant with GAP (Spain, 2001). OECD = 0.18 |

0.2 | 0.14 | 0.05 |

GAP: Good Agricultural Practice; OECD: Organisation for Economic Co‐operation and Development; MRL: maximum residue level.

Indicates that the MRL is proposed at the limit of quantification.

NEU: Outdoor trials conducted in northern Europe, SEU: Outdoor trials conducted in southern Europe, Indoor: indoor EU trials or Country code: if non‐EU trials.

Highest residue.

Supervised trials median residue.

B.1.2.2. Residues in succeeding crops

|

Confined rotational crop study (quantitative aspect) |

Residues in edible part of succeeding crops (root and green vegetables, beans and cereals) destined for human consumption are not expected to be present above the LOQ. |

| Field rotational crop study | Not required |

B.1.2.3. Processing factors

Processing studies of rice grains to polished rice are not necessary.

B.2. Residues in livestock

| Relevant groups | Dietary burden expressed in | Most critical dieta | Most critical commoditya |

Trigger exceeded (Y/N) |

|||

|---|---|---|---|---|---|---|---|

| mg/kg bw per day | mg/kg DM | ||||||

| Med. | Max. | Med. | Max. | ||||

|

Cattle (all diets) |

0.0005 | 0.0007 | 0.01 | 0.02 | Cattle (dairy) | Rice, straw | No |

|

Cattle (dairy only) |

0.0005 | 0.0007 | 0.01 | 0.02 | Cattle (dairy) | Rice, straw | No |

|

Sheep (all diets) |

0.0009 | 0.0014 | 0.02 | 0.03 | Sheep (lamb) | Rice, straw | No |

|

Sheep (ewe only) |

0.0007 | 0.0011 | 0.02 | 0.03 | Sheep (ram/ewe) | Rice, straw | No |

|

Swine (all diets) |

0.0001 | 0.0001 | 0.01 | 0.01 | Swine (breeding) | Rice, bran/pollard | No |

|

Poultry (all diets) |

0.0004 | 0.0004 | 0.01 | 0.01 | Poultry (broiler) | Rice, bran/pollard | No |

|

Poultry (layer only) |

0.0002 | 0.0002 | 0.00 | 0.00 | Poultry (layer) | Rice, bran/pollard | No |

DM: dry matter.

Calculated for the maximum dietary burden.

B.2.1. Nature of residues and methods of analysis in livestock

B.2.1.1. Metabolism studies, methods of analysis and residue definitions in livestock

|

Livestock (available studies) |

Animal |

Dose (mg/kg bw per day) |

Duration (days) |

N rate/comment |

|---|---|---|---|---|

| Laying hen | 0.09 | 8 | 225N/compared to the maximum dietary burden calculated for poultry (broiler) | |

| 0.12 | 8 | 300N/compared to the maximum dietary burden calculated for poultry (broiler) | ||

| Lactating goat | 0.07 | 6 | 50N/compared to the maximum dietary burden calculated for sheep | |

| 2 | 6 | 1400N/compared to the maximum dietary burden calculated for sheep | ||

| Source: Spain, 2001All studies were performed using phenyl‐ and cyclohexenone‐radiolabelled profoxidim | ||||

| Time needed to reach a plateau concentration in milk and eggs (days) |

Milk: 3–5 days Eggs: 2 days |

| Metabolism in rat and ruminant similar (Yes/No) | Yes |

| Animal residue definition for monitoring (RD‐Mo) | Not triggered |

| Animal residue definition for risk assessment (RD‐RA) | Not triggered |

| Conversion factor (monitoring to risk assessment) | Not applicable |

| Fat soluble residues (Yes/No) | Not applicable |

|

Methods of analysis for monitoring of residues (analytical technique, crop groups, LOQs) |

Eggs, muscle, fat, kidney and liver:

Milk:

|

Bw: body weight; GC‐MS: gas chromatography with mass spectrometry; LOQ: limit of quantification.

B.2.1.2. Stability of residues in livestock

| Animal products (available studies) | Animal | Commodity | T (°C) | Stability (Months/years) |

|---|---|---|---|---|

| – | – | – | – | |

| Not available and not required | ||||

B.2.2. Magnitude of residues in livestock

B.2.2.1. Summary of the residue data from livestock feeding studies

| Animal commodity |

Residues at the closest feeding level (mg/kg) |

Estimated value at 1N | MRL proposal (mg/kg) | CF | ||

|---|---|---|---|---|---|---|

| Mean | Highest | STMR (mg/kg) | HR (mg/kg) | |||

| Cattle (all diets) – Not triggered according to dietary burden calculations | ||||||

| Cattle (dairy only) – Not triggered according to dietary burden calculations | ||||||

| Sheep (all diets) – Not triggered according to dietary burden calculations | ||||||

| Sheep (dairy only) – Not triggered according to dietary burden calculations | ||||||

| Swine – Not triggered according to dietary burden calculations | ||||||

| Poultry (all diets) – Not triggered according to dietary burden calculations | ||||||

| Poultry (layer only) – Not triggered according to dietary burden calculations | ||||||

CF: conversion factor; HR: highest residue; MRL: Median residue level; STMR: supervised trials median residue.

B.3. Consumer risk assessment

| ADI | 0.005 mg/kg bw per day (European Commission, 2011) |

| Highest IEDI, according to EFSA PRIMo | 0.8% ADI (PT, general population) |

| Assumptions made for the calculations |

The calculation is based on the median residue levels in the raw rice grain. The contributions of commodities where no GAP was reported in the framework of this review, were not included in the calculation |

| ARfD | 0.05 mg/kg bw (European Commission, 2011) |

| Highest IESTI, according to EFSA PRIMo | 1.3% ARfD (rice) |

| Assumptions made for the calculations | The calculation is based on the highest residue levels in the raw rice grain |

ADI: acceptable daily intake; bw: body weight; IEDI: international estimated daily intake; PRIMo: (EFSA) Pesticide Residues Intake Model; WHO: World Health Organization; ARfD: acute reference dose; IESTI: international estimated short‐term intake.

B.4. Proposed MRLs

| Code number | Commodity | Existing EU MRL (mg/kg) | Outcome of the review | |

|---|---|---|---|---|

| MRL (mg/kg) | Comment | |||

|

Enforcement residue definition (existing): profoxydim Enforcement residue definition (proposed): sum of profoxydim and all metabolites containing the thiopyranylcyclohexenone moiety (with all three oxidation states of sulfur), expressed as profoxydim (determined as BH 625‐23) | ||||

| 0500060 | Rice grain | 0.05a | 0.05a | Further consideration neededb |

| – | Other commodities of plant and animal origin | See Regulation (EC) No 839/2008 | – | Further consideration neededc |

EU MRL: European Union maximum residue level.

Indicates that the MRL is set at the limit of quantification.

MRL is derived from a GAP evaluated at EU level, which is fully supported by data and for which no risk to consumers is identified; no CXL is available (combination G‐I in Appendix E); however, the proposed residue definition may not be specific to profoxydim.

There are no relevant authorisations or import tolerances reported at EU level; no CXL is available. Either a specific LOQ or the default MRL of 0.01 mg/kg may be considered (combination A‐I in Appendix E).

Appendix C – Pesticide Residue Intake Model (PRIMo)

1.

Appendix D – Input values for the exposure calculations

D.1. Livestock dietary burden calculations

| Feed commodity | Median dietary burden | Maximum dietary burden | ||

|---|---|---|---|---|

| Input value (mg/kg) | Comment | Input value (mg/kg) | Comment | |

| Rice, bran/pollard | 0.05a | STMRa | 0.05a | STMRa |

| Rice, straw | 0.05a | STMR | 0.14 | HR |

STMR: supervised trials median residue; HR: highest residue; PF: processing factor.

Indicates that the input value is proposed at the limit of quantification.

For rice bran, no default processing factor was applied because profoxydim is applied early in the growing season and residues are expected to be below the LOQ. Concentration of residues in these commodities is therefore not expected.

D.2. Consumer risk assessment

| Commodity | Chronic risk assessment | Acute risk assessment | ||

|---|---|---|---|---|

| Input value (mg/kg) | Comment | Input value (mg/kg) | Comment | |

| Rice, grain | 0.05a | STMR | 0.05a | HR |

STMR: supervised trials median residue.

Indicates that the input value is proposed at the limit of quantification.

Appendix E – Decision tree for deriving MRL recommendations

1.

Appendix F – Used compound codes

1.

| Code/trivial name | IUPAC name/SMILES notation/InChiKeya | Structural formulab |

|---|---|---|

| Profoxydim (BAS 625H) |

(5RS)‐2‐{(1EZ)‐N‐[(2RS)‐2‐(4‐chlorophenoxy)propoxy]butanimidoyl}‐3‐hydroxy‐5‐[(3RS)‐thian‐3‐yl]cyclohex‐2‐en‐1‐one Clc1ccc(cc1)OC(C)CO\N=C(/CCC)C=2C(=O)CC(CC=2O)C3CCCSC3 KRQUFUKTQHISJB‐UHFFFAOYSA‐N |

|

| BAS 625‐Li |

lithium (5RS)‐2‐{(1EZ)‐N‐[(2RS)‐2‐(4‐chlorophenoxy)propoxy]butanimidoyl}‐3‐oxo‐5‐[(3RS)‐thian‐3‐yl]cyclohex‐1‐en‐1‐olate [Li+].Clc1ccc(cc1)OC(C)CO\N=C(/CCC)C=2C(=O)CC(CC=2[O‐])C3CCCSC3 LRGTYGSKTGIXOL‐UHFFFAOYSA‐M |

|

| BH 625‐1 and isomer |

(3RS)‐3‐[(1RS)‐4‐{(1EZ)‐N‐[(2RS)‐2‐(4‐chlorophenoxy)propoxy]butanimidoyl}‐3‐hydroxy‐5‐oxocyclohex‐3‐en‐1‐yl]‐1λ4‐thian‐1‐one O=S1CCCC(C1)C3CC(=O)C(C(\CCC)=N\OCC(C)Oc2ccc(Cl)cc2)=C(O)C3 AJYSITMZKMUSQF‐UHFFFAOYSA‐N |

|

| BH 625‐27 = 625M27 carboxylic acid derivative |

3‐[(3RS)‐1‐oxo‐1λ4‐thian‐3‐yl]pentanedioic acid O=S1CCCC(C1)C(CC(=O)O)CC(=O)O DVZHDNBXUJHHIV‐UHFFFAOYSA‐N |

|

| BH 625‐30 = 625M30carboxylic acid derivative |

(2RS,3RS)‐3‐[(3RS)‐1,1‐dioxo‐1λ6‐thian‐3‐yl]‐5‐oxooxolane‐2‐carboxylic acid O=S1(=O)CCCC(C1)C2CC(=O)OC2C(=O)O VCRCXRJKPGIJEV‐UHFFFAOYSA‐N |

|

| BH 517‐1 = 625M28carboxylic acid derivative |

3‐[(3RS)‐1,1‐dioxo‐1λ6‐thian‐3‐yl]pentanedioic acid O=S1(=O)CCCC(C1)C(CC(=O)O)CC(=O)O ZQTHHTAJXROHTN‐UHFFFAOYSA‐N |

|

| BH 625‐22 |

(2RS)‐2‐(4‐chlorophenoxy)propanoic acid Clc1ccc(OC(C)C(=O)O)cc1 DKHJWWRYTONYHB‐UHFFFAOYSA‐N |

|

| BH 625‐10 |

(6RS)‐6‐[(3S)‐1‐oxo‐1λ4‐thian‐3‐yl]‐2‐propyl‐6,7‐dihydro‐1,3‐benzoxazol‐4(5H)‐one O=S1CCCC(C1)C2CC(=O)c3nc(CCC)oc3C2 JITWEXSKOFSQCI‐UHFFFAOYSA‐N |

|

| BH 625‐23 |

dimethyl 3‐[(3RS)‐1,1‐dioxo‐1λ6‐thian‐3‐yl]pentanedioate O=S1(=O)CCCC(C1)C(CC(=O)OC)CC(=O)OC YZVQGYPSQUKGQX‐UHFFFAOYSA‐N |

|

SMILES: simplified molecular‐input line‐entry system

Bold: the compound name in bold has been used in this document.

ACD/Name 2015 ACD/Labs 2015 Release (File version N20E41, Build 75170, 19 December 2014).

ACD/ChemSketch 2015 ACD/Labs 2015 Release (File version C10H41, Build 75059, 17 December 2014).

Suggested citation: EFSA (European Food Safety Authority) , Brancato A, Brocca D, Carrasco Cabrera L, De Lentdecker C, Ferreira L, Greco L, Jarrah S, Kardassi D, Leuschner R, Lythgo C, Medina P, Miron I, Molnar T, Nougadere A, Pedersen R, Reich H, Sacchi A, Santos M, Stanek A, Sturma J, Tarazona J, Theobald A, Vagenende B and Villamar‐Bouza L, 2018. Reasoned opinion on the review of the existing maximum residue levels for profoxydim according to Article 12 of Regulation (EC) No 396/2005. EFSA Journal 2018;16(5):5282, 27 pp. 10.2903/j.efsa.2018.5282

Requestor: European Commission

Question number: EFSA‐Q‐2011‐00172

Acknowledgement: EFSA wishes to thank the rapporteur Member State, Spain, for the preparatory work on this scientific output.

Approved: 24 April 2018

Notes

Regulation (EC) No 396/2005 of the European Parliament and of the Council of 23 February 2005 on maximum residue levels of pesticides in or on food and feed of plant and animal origin and amending Council Directive 91/414/EEC. OJ L 70, 16.3.2005, p. 1–16.

Council Directive 91/414/EEC of 15 July 1991 concerning the placing of plant protection products on the market. OJ L 230, 19.8.1991, p. 1–32. Repealed by Regulation (EC) No 1107/2009.

Commission Implementing Regulation (EU) No 706/2011 of 20 July 2011 approving the active substance profoxydim, in accordance with Regulation (EC) No 1107/2009 of the European Parliament and of the Council concerning the placing of plant protection products on the market, and amending the Annex to Commission Implementing Regulation (EU) No 540/2011. OJ L 190, 21.7.2011, p. 50–53.

Regulation (EC) No 1107/2009 of the European Parliament and of the Council of 21 October 2009 concerning the placing of plant protection products on the market and repealing Council Directives 79/117/EEC and 91/414/EEC. OJ L 309, 24.11.2009, p. 1–50.

Commission Implementing Regulation (EU) No 540/2011 of 25 May 2011 implementing Regulation (EC) No 1107/2009 of the European Parliament and of the Council as regards the list of approved active substances. OJ L 153, 11.6.2011, p. 1–186.

Commission Implementing Regulation (EU) No 541/2011 of 1 June 2011 amending Implementing Regulation (EU) No 540/2011 implementing Regulation (EC) No 1107/2009 of the European Parliament and of the Council as regards the list of approved active substances. OJ L 153, 11.6.2011, p. 187–188.

Commission Regulation (EC) No 839/2008 of 31 July 2008 amending Regulation (EC) No 396/2005 of the European Parliament and of the Council as regards Annexes II, III and IV on maximum residue levels of pesticides in or on certain products. OJ L 234, 30.8.2008, p. 1–216.

Commission Regulation (EU) No 546/2011 of 10 June 2011 implementing Regulation (EC) No 1107/2009 of the European Parliament and of the Council as regards uniform principles for evaluation and authorisation of plant protection products. OJ L 155, 11.06.2011, p. 127–175.

References

- EFSA (European Food Safety Authority), 2007. Reasoned opinion on the potential chronic and acute risk to consumers’ health arising from proposed temporary EU MRLs. EFSA Journal 2007;5(3):32r, 1141 pp. 10.2903/j.efsa.2007.32r [DOI] [Google Scholar]

- EFSA (European Food Safety Authority), 2018a. Completeness check report on the review of the existing MRLs of profoxydim prepared by EFSA in the framework of Article 12 of Regulation (EC) No 396/2005, 2 February 2018. Available online: www.efsa.europa.eu

- EFSA (European Food Safety Authority), 2018b. Member States consultation report on the review of the existing MRLs of profoxydim prepared by EFSA in the framework of Article 12 of Regulation (EC) No 396/2005, 20 April 2018. Available online: www.efsa.europa.eu

- EURL (European Union Reference Laboratories for Pesticide Residues), 2017. Evaluation report prepared under Article 12 of Regulation (EC) No 396/2005. Analytical methods validated by the EURLs and overall capability of official laboratories to be considered for the review of the existing MRLs for profoxydim, 30 November 2017. Available online: www.efsa.europa.eu

- European Commission , 1997a. Appendix A. Metabolism and distribution in plants. 7028/IV/95‐rev., 22 July 1996.

- European Commission , 1997b. Appendix B. General recommendations for the design, preparation and realization of residue trials. Annex 2. Classification of (minor) crops not listed in the Appendix of Council Directive 90/642/EEC. 7029/VI/95‐rev. 6, 22 July 1997.

- European Commission , 1997c. Appendix C. Testing of plant protection products in rotational crops. 7524/VI/95‐rev. 2, 22 July 1997.

- European Commission , 1997d. Appendix E. Processing studies. 7035/VI/95‐rev. 5, 22 July 1997.

- European Commission , 1997e. Appendix F. Metabolism and distribution in domestic animals. 7030/VI/95‐rev. 3, 22 July 1997.

- European Commission , 1997f.Appendix H. Storage stability of residue samples. 7032/VI/95‐rev. 5, 22 July 1997.

- European Commission , 1997g. Appendix I. Calculation of maximum residue level and safety intervals.7039/VI/95 22 July 1997. As amended by the document: classes to be used for the setting of EU pesticide maximum residue levels (MRLs). SANCO 10634/2010, finalised in the Standing Committee on the Food Chain and Animal Health at its meeting of 23–24 March 2010.

- European Commission , 2000. Residue analytical methods. For pre‐registration data requirement for Annex II (part A, section 4) and Annex III (part A, section 5 of Directive 91/414. SANCO/3029/99‐rev. 4.

- European Commission , 2010a. Classes to be used for the setting of EU pesticide Maximum Residue Levels (MRLs). SANCO 10634/2010‐rev. 0, Finalised in the Standing Committee on the Food Chain and Animal Health at its meeting of 23–24 March 2010.

- European Commission , 2010b. Residue analytical methods. For post‐registration control. SANCO/825/00‐rev. 8.1, 16 November 2010.

- European Commission , 2011. Review report for the active substance profoxydim. Finalised in the Standing Committee on the Food Chain and Animal Health at its meeting on 17 June 2011 in view of the approval of profoxydim as active substance in accordance with Regulation (EC) No 1107/2009. SANCO/11198/2011‐Final, 17 June 2011.

- European Commission , 2017. Appendix D. Guidelines on comparability, extrapolation, group tolerances and data requirements for setting MRLs. 7525/VI/95‐rev.10.3, June 2017.

- FAO (Food and Agriculture Organization of the United Nations), 2009. Submission and evaluation of pesticide residues data for the estimation of Maximum Residue Levels in food and feed. Pesticide Residues. 2nd Ed. FAO Plant Production and Protection Paper 197, 264 pp.

- OECD (Organisation for Economic Co‐operation and Development), 2011. OECD MRL calculator: spreadsheet for single data set and spreadsheet for multiple data set, 2 March 2011. In: Pesticide Publications/Publications on Pesticide Residues. Available online: http://www.oecd.org

- OECD (Organisation for Economic Co‐operation and Development), 2013. Guidance document on residues in livestock. In: Series on Pesticides No 73. ENV/JM/MONO(2013)8, 04 September 2013.

- Spain , 2001. Draft assessment report on the active substance BAS 625H (profoxydim) prepared by the rapporteur Member State Spain in the framework of Council Directive 91/414/EEC, March 2001.

- Spain , 2002. Addendum to the draft assessment report on the active substance BAS 625H (profoxydim) prepared by the rapporteur Member State Spain in the framework of Council Directive 91/414/EEC, B7 – Residue data, September 2002.

- Spain , 2006. Addendum to the draft assessment report on the active substance BAS 625H (profoxydim) prepared by the rapporteur Member State Spain in the framework of Council Directive 91/414/EEC, B7 – Residue data, November 2006.

- Spain , 2017a. Evaluation report prepared under Article 12.1 of Regulation (EC) No 396/2005. Review of the existing MRLs for profoxydim, 15 July 2017. Available online: www.efsa.europa.eu

- Spain , 2017b. Evaluation report prepared under Article 12.1 of Regulation (EC) No 396/2005. Review of the existing MRLs for profoxydim, 16 November 2017. Available online: www.efsa.europa.eu