Abstract

The present opinion deals with the re‐evaluation of propane‐1,2‐diol alginate (E 405) when used as a food additive. The Panel noted that absorption, distribution, metabolism and excretion (ADME) data on propane‐1,2‐diol alginate gave evidence for the hydrolysis of this additive into propane‐1,2‐diol and alginic acid. These two compounds have been recently re‐evaluated for their safety of use as food additives (EFSA ANS Panel, 2017, 2018). Consequently, the Panel considered in this opinion the major toxicokinetic and toxicological data of these two hydrolytic derivatives. No adverse effects were reported in subacute and subchronic dietary studies with propane‐1,2‐diol alginate. The available data did not indicate a genotoxic concern for propane‐1,2‐diol alginate (E 405) when used as a food additive. Propane‐1,2‐diol alginate, alginic acid and propane‐1,2‐diol were not of concern with respect to carcinogenicity. The Panel considered that any adverse effect of propane‐1,2‐diol alginate would be due to propane‐1,2‐diol. Therefore, the acceptable daily intake (ADI) of the food additive E 405 is determined by the amount of free propane‐1,2‐diol and the propane‐1,2‐diol released from the food additive after hydrolysis. According to the EU specification, the concentration of free and bound propane‐1,2‐diol amounts to a maximum of 45% on a weight basis. On the worst‐case assumption that 100% of propane‐1,2‐diol would be systemically available and considering the ADI for propane‐1,2‐diol of 25 mg/kg body weight (bw) per day, the Panel allocated an ADI of 55 mg/kg bw per day for propane‐1,2‐diol alginate. The Panel concluded that exposure estimates did not exceed the ADI in any of the population groups from the use of propane‐1,2‐diol alginate (E 405) as a food additive. Therefore, the Panel concluded that there is no safety concern at the authorised use levels.

Keywords: propylene glycol alginate, propane‐1, 2‐diol alginate, (E 405), alginic acid, propane‐1, 2‐diol, food additive

Summary

The present opinion deals with the re‐evaluation of propane‐1,2‐diol alginate (E 405) when used as a food additive.

Propane‐1,2‐diol alginate (E 405) is authorised as a food additive in the European Union (EU) in accordance with Annex II and Annex III to Regulation (EC) No 1333/2008 on food additives and specific purity criteria have been defined in the Commission Regulation (EU) No 231/20121.

Propane‐1,2‐diol alginate was previously evaluated by the Scientific Committee for Food (SCF) and the Joint FAO/WHO Expert Committee on Food Additives (JECFA), both bodies considering that the acceptable daily intake (ADI) for propane‐1,2‐diol alginate should be limited only by the amount of free propane‐1,2‐diol and propane‐1,2‐diol esterified with alginic acid, hydrolysed after oral exposure and released (JECFA, 1993; SCF, 1994). While the SCF established for propane‐1,2‐diol alginate an ADI of 25 mg/kg body weight (bw) per day, expressed as propane‐1,2‐diol, JECFA allocated an ADI of 70 mg propane‐1,2‐diol alginate/kg bw per day.2

Propane‐1,2‐diol alginate as defined by Commission Regulation (EU) No 231/2012 is the ester of alginic acid with propane‐1,2‐diol. It varies in composition according to its degree of esterification and the percentage of free and neutralised carboxyl groups in the molecule.

In vitro experiments have shown that propane‐1,2‐diol alginate is partially hydrolysed by simulated gastric and intestinal juices to propane‐1,2‐diol and alginic acid. In vivo studies using autoradiography gave also evidence for a partial but not complete hydrolysis to propane‐1,2‐diol and alginic acid. According to previous EFSA assessments of these two hydrolytic moieties, propane‐1,2‐diol is absorbed and its metabolites would enter the normal energy‐forming pathways. However, together with any non‐hydrolysed material, the alginate moiety is not absorbed and excreted in the faeces, confirming the data previously provided in the assessment on the safety of alginic acid and its salts (EFSA ANS Panel, 2017). The Panel noted that absorption, distribution, metabolism and excretion (ADME) data on propane‐1,2‐diol alginate gave evidence for the hydrolysis of this additive into propane‐1,2‐diol and alginic acid. These two compounds have been recently re‐evaluated for their safety of use as food additives E 400 and E 1520 (EFSA ANS Panel, 2017, 2018). Consequently, the Panel considered in this opinion the major toxicokinetic and toxicological data of these two hydrolytic derivatives.

The acute toxicity of propane‐1,2‐diol alginate, alginic acid and its salts, and propane‐1,2‐diol was considered to be low.

Although various subacute and subchronic dietary studies with propane‐1,2‐diol alginate in laboratory animals were available to the Panel, several of these studies were of limited relevance for risk assessment due to the low numbers of animals per group and/or limited reporting. None of these studies demonstrated adverse effects.

Propane‐1,2‐diol alginate was tested in several in vitro assays (point mutation in bacteria, chromosomal aberrations in mammalian cells) and in vivo (host‐mediated assay, dominant lethal and bone marrow chromosome aberration in rat) that, despite some limitations, did not reveal any genotoxic effect. In addition, alginic acid and propane‐1,2‐diol, the two hydrolytic metabolites of propane‐1,2‐diol alginate, were considered by EFSA of no genotoxic concern (EFSA ANS Panel, 2017, 2018). The Panel therefore noted that the available data did not indicate a genotoxic concern for propane‐1,2‐diol alginate (E 405) when used as a food additive.

Propane‐1,2‐diol alginate, alginic acid and propane‐1,2‐diol were not of concern with respect to carcinogenicity. No adverse effects, including neoplastic findings, were reported in a 2‐year study in rats administered 2,500 mg propane‐1,2‐diol/kg bw per day for 2 years (Gaunt et al., 1972). The SCF and JECFA used the study in rats to establish an ADI of 25 mg propane‐1,2‐diol/kg bw per day using an uncertainty factor of 100, the Panel agreed with this ADI (EFSA ANS Panel, 2018).

In limited two‐ or three‐generation reproductive toxicity studies with propane‐1,2‐diol alginate and alginate, no adverse effects were reported up to 2,500 mg/kg bw per day. In prenatal developmental toxicity studies with propane‐1,2–diol alginate in rats, hamsters and rabbits, no developmental effects were observed up to the highest dose tested (~ 700–800 mg propane–1,2‐diol alginate/kg bw per day). No prenatal developmental toxicity studies were available for alginates. Propane‐1,2‐diol induced no treatment‐related effects in two reproductive toxicity studies (mice and rats) and six developmental studies in mice, rats, hamsters and rabbits, no treatment‐related effects were observed at the highest doses tested (1,000 mg propane‐1,2‐diol/kg bw per day and higher).

The Panel considered that any adverse effect of propane‐1,2‐diol alginate would be due to propane‐1,2‐diol. Therefore, the ADI of the food additive E 405 is determined by the amount of free propane‐1,2‐diol and the propane‐1,2‐diol released from the food additive after hydrolysis. According to the EU specification, the concentration of free and bound propane‐1,2–diol amounts to a maximum of 45% on a weight basis. On the worst‐case assumption that 100% of propane‐1,2‐diol (free and bound) would be systemically available and considering the ADI for propane‐1,2‐diol of 25 mg/kg bw per day, the Panel allocated an ADI of 55 mg/kg bw per day for propane‐1,2‐diol alginate (100/45 × 25).

Due to the discrepancies observed between the Mintel Global New Products Databases (GNPDs) and the reported use levels data, the Panel considered that the reported use levels for the refined exposure assessment scenarios are not covering sufficiently the present use of the additive. As a matter of fact, the Panel noted that use levels were reported for only one food category (‘FC 14.1.2 Beer and malt beverages’) out of the 21 in which propane‐1,2‐diol alginate (E 405) is authorised.

Thus, considering that (1) this food category does not cover the uses identified in the Mintel's GNPD, (2) this food category is not relevant to estimate the exposure to the food additive for the younger population groups, (3) use levels were reported only for niche products of beer, (4) low percentage (< 1%) of beers are labelled with the additive according to the Mintel's GNPD, the Panel decided not to perform refined exposure scenarios. Only the regulatory maximum level exposure assessment scenario is presented in the current assessment. As this scenario is not considering the consumption of food supplements and foods for special medical purposes (FSMP), the possible additional exposure from their consumption was also investigated.

Estimates of exposure assessment scenarios did not exceeded the ADI of 55 mg/kg bw per day for propane‐1,2‐diol alginate (E 405) for any population groups.

The Panel considered that the uncertainties identified would, in general, result in an overestimation of the exposure to propane‐1,2‐diol alginate (E 405) from its use as a food additive according to Annex II to Regulation (EC) No 1333/2008 in the regulatory maximum level exposure scenario (Section 3.4.1).

The Panel noted that food categories which may contain propane‐1,2‐diol alginate (E 405) due to carry‐over (Annex III, Part 1) were not considered in any of the current exposure assessment scenarios.

The Panel noted that propane‐1,2‐diol available from propane‐1,2‐diol alginate (E 405) would add to the exposure to the food additive propane‐1,2‐diol (E 1520) previously re‐evaluated by the Panel (EFSA ANS Panel, 2018).

Propane‐1,2‐diol may be released from propane‐1,2‐diol alginate (E 405) at a maximum of 45% according to the EU specification. Based on this, and considering the highest P95 exposure level observed, the highest exposure to propane‐1,2‐diol was calculated to be:

in the regulatory maximum level exposure assessment scenario 17.8 mg/kg bw per day of propane‐1,2‐diol in toddlers (released from 39.6 mg/kg bw per day of propane‐1,2‐diol alginate (E 405));

in the regulatory maximum level exposure assessment scenario considering also the consumption of FSMPs, 21.1 mg/kg bw propane‐1,2‐diol per day in infants (released from 46.8 mg/kg bw per day of propane‐1,2‐diol alginate (E 405)).

Considering the overall metabolic and toxicity database, the Panel confirmed the previously established ADI for propane‐1,2‐diol alginate (E 405) of 25 mg/kg bw per day expressed as propane‐1,2‐diol. This corresponds to an ADI for propane‐1,2‐diol alginate (E 405) of 55 mg/kg bw per day, based on the concentration of free and bound propane‐1,2‐diol amounting to a maximum of 45%.

The Panel concluded that exposure estimates did not exceed the ADI in any of the population groups from the use of propane‐1,2‐diol alginate (E 405) as a food additive. Therefore, the Panel concluded that there is no safety concern at the authorised use levels.

The Panel recommended the European Commission to consider:

revising the maximum limits for the impurities of toxic elements (lead, mercury, cadmium and arsenic) in the EU specification for propane‐1,2‐diol alginate (E 405) in order to ensure that propane‐1,2‐diol alginate (E 405) as a food additive will not be a significant source of exposure to these toxic elements in food;

the inclusion of maximum limits for propylene oxide, mono‐ and diethylene glycol, and propylene carbonate in the EU specifications for propane‐1,2‐diol alginate (E 405);

the collection of more data on usage and use levels of propane‐1,2‐diol alginate (E 405) in order to perform a more realistic exposure assessment.

1. Introduction

The present opinion deals with the re‐evaluation of propane‐1,2‐diol alginate (E 405) when used as a food additive.

1.1. Background and Terms of Reference as provided by the European Commission

1.1.1. Background

Regulation (EC) No 1333/20083 of the European Parliament and of the Council on food additives requires that food additives are subject to a safety evaluation by the European Food Safety Authority (EFSA) before they are permitted for use in the European Union. In addition, it is foreseen that food additives must be kept under continuous observation and must be re‐evaluated by EFSA.

For this purpose, a programme for the re‐evaluation of food additives that were already permitted in the European Union before 20 January 2009 has been set up under the Regulation (EU) No 257/20104. This Regulation also foresees that food additives are re‐evaluated whenever necessary in light of changing conditions of use and new scientific information. For efficiency and practical purposes, the re‐evaluation should, as far as possible, be conducted by a group of food additives according to the main functional class to which they belong.

The order of priorities for the re‐evaluation of the currently approved food additives should be set on the basis of the following criteria: the time since the last evaluation of a food additive by the Scientific Committee on Food (SCF) or by EFSA, the availability of new scientific evidence, the extent of use of a food additive in food and the human exposure to the food additive taking also into account the outcome of the Report from the Commission on Dietary Food Additive Intake in the EU5 of 2001. The report ‘Food additives in Europe 2000’6 submitted by the Nordic Council of Ministers to the Commission, provides additional information for the prioritisation of additives for re‐evaluation. As colours were among the first additives to be evaluated, these food additives should be re‐evaluated with a highest priority.

In 2003, the Commission already requested EFSA to start a systematic re‐evaluation of authorised food additives. However, as a result of adoption of Regulation (EU) 257/2010 the 2003 Terms of References are replaced by those below.

1.1.2. Terms of Reference

The Commission asks the EFSA to re‐evaluate the safety of food additives already permitted in the Union before 2009 and to issue scientific opinions on these additives, taking especially into account the priorities, procedures and deadlines that are enshrined in the Regulation (EU) No 257/2010 of 25 March 2010 setting up a programme for the re‐evaluation of approved food additives in accordance with the Regulation (EC) No 1333/2008 of the European Parliament and of the Council on food additives.

1.1.3. Interpretation of Terms of Reference

This re‐evaluation refers exclusively to the uses of propane‐1,2‐diol alginate (E 405) as a food additive in food, including food supplements, and does not include a safety assessment of other uses of propane‐1,2‐diol l alginate (as described in Section 3.4.2). The Panel noted that the term propylene glycol alginate (PGA) is frequently used as a synonym for propane‐1,2‐diol alginate.

1.2. Information on existing evaluations and authorisations

Propane‐1,2‐diol alginate (E 405) is authorised as a food additive in the EU in accordance with Annex II and Annex III to Regulation (EC) No 1333/2008 on food additives and specific purity criteria have been defined in the Commission Regulation (EU) No 231/20127.

In the EU, propane‐1,2‐diol alginate (E 405) has been evaluated by the Scientific Committee for Food (SCF) in 1994 (SCF, 1994), who allocated for propane‐1,2‐diol alginate an acceptable daily intake (ADI) of 25 mg/kg body weight (bw) expressed as propane‐1,2‐diol.8 No toxicological data were specified. The SCF recommended a re‐evaluation of propane‐1,2‐diol which was performed in 1996 (SCF, 1997) and an ADI of 25 mg/kg bw per day was assigned. In 2018, the EFSA ANS Panel performed a re‐evaluation of propane‐1,2‐diol and derived an ADI of 25 mg/kg bw per day based on a chronic toxicity study in rats in which a NOAEL of 2,500 mg/kg bw per day was identified and using a safety factor of 100. In 2017, the EFSA Panel on Food Additives and Nutrient Sources added to Food (EFSA ANS Panel, 2017) re‐evaluated the safety of alginic acid and its sodium, potassium, ammonium and calcium salts (E 400–E 404) when used as food additives. The Panel concluded that ‘there was no need for a numerical ADI for alginic acid and its salts (E 400, E 401, E 402, E 403 and E 404)’.

Propane‐1,2‐diol alginate (E 405) was evaluated by the Joint FAO/WHO Expert Committee on Food Additives (JECFA) in 1993 (JECFA, 1993) who concluded that the ADI for propane‐1,2‐diol alginate is limited only by the amount of free propane‐1,2‐diol and propane‐1,2‐diol esterified with alginic acid, hydrolysed after oral exposure and released. Propane‐1,2‐diol alginate contains totally up to 36% propane‐1,2‐diol.9 On the assumption that all of the esterified propane‐1,2‐diol is hydrolysed, and ‘taking into account the ADI of 0–25 mg/kg by for propylene glycol, the Committee allocated an ADI of 0–70 mg/kg bw (100/36 x 25) to propylene glycol alginate’. The Committee stated that new toxicological studies are available for propane‐1,2‐diol but these data were not evaluated A re‐evaluation of propane‐1,2‐diol was recommended by JECFA. The ADI for propane‐1,2‐diol alginate should be reconsidered thereafter. In 1973, JECFA evaluated propane‐1,2‐diol E 1520) as a food additive and allocated an ADI of 0–25 mg/kg bw based on the level in rat and dog causing no toxicological effect of 2,500 mg/kg bw and using an uncertainty factor of 100 (JECFA, 1974). In 2001, JECFA evaluated propane‐1,2‐diol as a food flavouring; however, the Committee did not finalise the evaluation since it seeked confirmation that the substance was actually used as food flavouring (JECFA, 2002a,b). The Panel noted that propane‐1,2‐diol is not authorised as a flavouring substance in the EU according to Regulation 1334/2008.

Propane‐1,2‐diol alginate (E 405) has also been reviewed by the Nordic Council of Ministers (TemaNord, 2002a,b). It was concluded that the database is sufficient for evaluation of health hazard although most data are old.

Propane‐1,2‐diol alginate (E 405) belongs to the group of food additives that were found in jelly minicups, which were suspended in 2004 by the European Commission from being to be placed on the market and for import (Commission Decision 2004/37/EC; EC, 2004), following the measures taken and information provided by the different Member States. Jelly minicups are defined as ‘jelly confectionery of a firm consistence, contained in semi‐rigid minicups or minicapsules, intended to be ingested in a single bite by exerting pressure on the minicups or minicapsule to project the confectionery into the mouth.’

In 2004, the EFSA Panel on Food Additives, Flavourings, Processing Aids and Materials in Contact with Food (EFSA AFC Panel, 2004) prepared a scientific opinion on a request from the European Commission related to the use of certain food additives derived from seaweed or non‐seaweed origin, including propane‐1,2‐diol alginate (E 405) in jelly minicups. The AFC Panel concluded that any of these gel‐forming additives or of any other type that gave rise to a confectionery product of a similar size, with similar physical and/or physicochemical properties and that could be ingested in the same way as the jelly minicups, would give rise to a risk for choking (EC, 2004). The use of these additives in jelly minicups is not authorised in the EU.10

In 2006, the EFSA AFC Panel prepared a scientific opinion on the use of formaldehyde as a preservative during the manufacture and preparation of food additives; the Panel estimated that exposure to gelling additives such as alginates containing residual formaldehyde at the levels of 50 mg/kg of additive would be of no safety concern (EFSA, 2006). Maximum limits (not more than 50 mg/kg) are established in the current EC Regulation for formaldehyde in several thickening food additives from algae origin including alginic acid and its salts (E 400–E 404) (EU Regulation No 231/2012).

The Committee for Medicinal Products for Human Use (CHMP) considered the procedure under Article 5(3) of Regulation (EC) No 726/2004 on the excipient, propane‐1,2‐diol in medicines for children as per questions posed (EMA, 2014b). In the final document (Questions & answers on propane‐1,2‐diol and esters in the context of the revision of the guideline on ‘Excipients in the label and package leaflet of medicinal products for human use’ (CPMP/463/00 Rev. 1, November 2014), the European Medicines Agency (EMA) concluded ‘Nevertheless, clinical data showed that in children from the age of 5 years and adult patients, up to 500 mg/kg per day of propane‐1,2‐diol could generally be considered safe. In the absence of compelling data this safety threshold is decreased to 50 mg/kg per day in children less than 5 years old, and even to 1 mg/kg per day in pre‐term and term neonates due to known immaturity of both metabolic and renal clearances of propane‐1,2‐diol in these populations’.

2. Data and methodologies

2.1. Data

The Panel was not provided with a newly submitted dossier. EFSA launched public calls for data,11 , 12 , 13 to collect relevant information from interested parties.

The Panel based its assessment on information submitted to EFSA following the public calls for data, information from previous evaluations and additional available literature up to the last Working Group meeting before the adoption of the opinion.14 Attempts were made at retrieving relevant original study reports on which previous evaluations or reviews were based, however not always these were available to the Panel.

The EFSA Comprehensive European Food Consumption Database (Comprehensive Database15) was used to estimate the dietary exposure.

The Mintel's Global New Products Database (GNPD) is an online database which was used for checking the labelling of products containing propane‐1,2‐diol alginate (E 405) within the EU's food products as the GNPD shows the compulsory ingredient information presented in the labelling of products.

2.2. Methodologies

This opinion was formulated following the principles described in the EFSA Guidance on transparency in the scientific aspects of risk assessment (EFSA Scientific Committee, 2009) and following the relevant existing Guidances from the EFSA Scientific Committee.

The ANS Panel assessed the safety of propane‐1,2‐diol alginate (E 405) as a food additive in line with the principles laid down in Regulation (EU) 257/2010 and in the relevant guidance document: Guidance on submission for food additive evaluations by the Scientific Committee on Food (SCF, 2001) and taking into consideration the Guidance for submission for food additive evaluations in 2012 (EFSA ANS Panel, 2012).

When the test substance was administered in the feed or in the drinking water, but doses were not explicitly reported by the authors as mg/kg bw per day based on actual feed or water consumption, the daily intake was calculated by the Panel using the relevant default values as indicated in the EFSA Scientific Committee Guidance document (EFSA Scientific Committee, 2012) for studies in rodents or, in the case of other animal species, by JECFA (2000). In these cases, the daily intake is expressed as equivalent. When in human studies in adults (aged above 18 years) the dose of the test substance administered was reported in mg/person per day, the dose in mg/kg bw per day was calculated by the Panel using a body weight of 70 kg as default for the adult population as described in the EFSA Scientific Committee Guidance document (EFSA Scientific Committee, 2012).

Dietary exposure to propane‐1,2‐diol alginate (E 405) from its use as a food additive was estimated combining food consumption data available within the EFSA Comprehensive European Food Consumption Database with the maximum permitted levels (MPLs). Different exposure scenarios were calculated (see Section 3.4.1). Uncertainties on the exposure assessment were identified and discussed.

In the context of this re‐evaluation, the Panel considered the conceptual framework for the risk assessment of certain food additives re‐evaluated under Commission Regulation (EC) No 257/2010 (EFSA ANS Panel, 2014).

3. Assessment

3.1. Technical data

3.1.1. Identity of the substances

Propane‐1,2‐diol alginate

Propane‐1,2‐diol alginate as defined by Commission Regulation (EU) No 231/2012 is the ester of alginic acid with propane‐1,2‐diol. It varies in composition according to its degree of esterification and the percentage of free and neutralised carboxyl groups in the molecule.

The substance has the CAS No 9005‐37‐2; the EINECS number is not available. The substance is also known by several synonyms such as hydroxypropyl alginate, 1,2‐propane diol ester of alginic acid and propylene glycol alginate.

Two isomers of the esterification are generally possible. Propane‐1,2‐diol alginate consists of 2‐hydroxypropyl alginate although lesser quantities of the structural isomer 1‐hydroxymethylethyl alginate may be present (Steiner and McNeely, 1951).

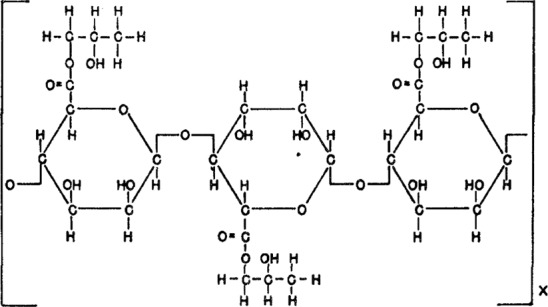

The structural formula of propane‐1,2‐diol alginate is presented in Figure 1.

Figure 1.

Structural formula of propane‐1,2‐diol alginate (Steiner and McNeely, 1951)

The Panel noted that the propane‐1,2‐diol group contains an asymmetric carbon (C2) atom. As the ester is synthesised by reaction of propylene oxide, two stereoisomers should be formed. On request of EFSA, one of the interested parties replied that the manufacturers of the food additive do not control the stereochemical configuration of the reaction product as this is not a requirement for propane‐1,2‐diol alginate in the EU specifications.

According to Commission Regulation (EU) No 231/2012 and JECFA specifications monograph (JECFA, 2006), the molecular formula of propane‐1,2‐diol alginate is (C9H14O7)n (esterified) and the typical average molecular weight of propane‐1,2‐diol alginate ranges from 10,000 to 600,000. According to JECFA (2006), the theoretical molecular weight of the structural unit is 234.21.

Aqueous solutions of propane‐1,2‐diol alginate are highly viscous at low concentrations, which is characteristic for alginates (Steiner and McNeely, 1951). Viscosity of propane‐1,2‐diol alginate solutions is a function of the degree of polymerisation, the degree of esterification and the presence of polyvalent metal ions like Ca2+. Typically, viscosity is in the range 25–500 mPa·s for a 1% solution and degrees of esterification from about 50% to about 90%. Generally, viscosity is increased by polyvalent metal ions. Propane‐1,2‐diol alginate with less than 60% esterification will react with calcium ions to give enhanced viscosity, while highly esterified propane‐1,2‐diol alginate is not affected by the presence of calcium ions (CRC, 1990; Voragen et al., 2012).

3.1.2. Specifications

The specifications for propane‐1,2‐diol alginate (E 405) as defined in the Commission Regulation (EU) No 231/2012 and by JECFA (2006) are listed in Table 1.

Table 1.

Specifications for propane‐1,2‐diol alginate (E 405) according to Commission Regulation (EU) No 231/2012 and JECFA (2006)

| Commission Regulation (EU) No 231/2012 | JECFA (2006) | |

|---|---|---|

| Definition | Propane‐1,2‐diol ester of alginic acid; varies in composition according to its degree of esterification and the percentage of free and neutralised carboxyl groups in the molecule | Propylene glycol alginate is an ester of alginic acid in which some of the carboxyl groups are esterified with propylene glycol, some neutralised with an appropriate alkali and some remain free |

| Assay | Yields, on the anhydrous basis, not less than 16% and not more than 20% of carbon dioxide | Yields, on the dried basis, not less than 16% and not more than 20% of carbon dioxide (CO2) |

| Description | Nearly odourless, white to yellowish brown fibrous or granular powder | White to yellowish brown filamentous, grainy, granular or powdered forms |

| Identification | ||

| Test for 1,2‐propanediol | Passes test (after hydrolysis) | – |

| Test for alginic acid | Passes test (after hydrolysis) | – |

| Solubility | – | Soluble in water giving a viscous, colloidal solution; soluble in up to 60% aqueous ethanol depending upon degree of esterification |

| Precipitate formation with sulfuric acid | – | To 10 mL of a 1% solution of the sample add 1 mL of sodium hydroxide TS. Heat in a boiling water bath for about 5 min, cool and add 1 mL of dilute sulfuric acid TS. A gelatinous precipitate is formed |

| Precipitate formation with lead acetate | – | To 5 mL of a 1% solution of the sample add 1 mL of lead acetate. A gelatinous precipitate is formed |

| Purity | ||

| Loss on drying | Not more than 20% (105°C, 4 h) | Not more than 20% (105°, 4 h) |

| Total propane‐1,2‐diol content | Not less than 15% and not more than 45% | Not less than 15% and not more than 45% |

| Free propane‐1,2‐diol content | Not more than 15% | Not more than 15% |

| Water‐insoluble matter | Not more than 2% on the anhydrous basis | Not more than 2% on the dried basis |

| Formaldehyde | Not more than 50 mg/kg | – |

| Arsenic | Not more than 3 mg/kg | Not more than 3 mg/kg |

| Lead | Not more than 5 mg/kg |

Not more than 5 mg/kg Determine using an atomic absorption technique appropriate to the specified level |

| Mercury | Not more than 1 mg/kg | – |

| Cadmium | Not more than 1 mg/kg | – |

| Total plate count | Not more than 5,000 colonies per gram |

Not more than 5,000 colonies per gram Initially prepare a 10−1 dilution by adding a 50 g sample to 450 mL of Butterfield's phosphate buffered dilution water and homogenising in a high speed blender |

| Yeast and moulds | Not more than 500 colonies per gram | Not more than 500 colonies per gram |

| E. coli | Absent in 5 g | Negative by test |

| Salmonella spp. | Absent in 10 g | Negative by test |

The safety of use of formaldehyde as a processing aid during the storage and manufacturing of thickening agents from algae origin was evaluated by the EFSA (2006) and it was concluded that exposure to gelling additives such as alginic acid and its salts containing residual formaldehyde at the levels of 50 mg/kg of additive would be of no safety concern. The Panel noted that maximum limits (not more than 50 mg/kg) are established in the current EC Regulation for formaldehyde in alginic acid (E 400) and its salts (E 401–E 404) (EU No 231/2012). According to information gathered by the Panel, it is not clear if formaldehyde continues to be used for those needs by some manufacturers, whilst other manufacturers report not using it anymore (EFSA, 2006; Documentation provided to EFSA n. 14).

Formaldehyde has also been shown to be a natural component of most marine algae including brown seaweeds. The levels detected in seaweeds used for alginate extraction were 14 mg/kg for Laminaria digitata, 17 mg/kg for Fucus serratus and 23 mg/kg for Ascophyllum nodosum (Yang et al., 1998). Most of this formaldehyde is expected to be eliminated by drying during the manufacturing process of alginic acid and its salts.

A single‐laboratory validated colorimetric method has been developed for measuring residual formaldehyde in alginate products (Farrell, 2007; Documentation provided to EFSA n. 14). The estimated limit of detection (LOD) and limit of quantification (LOQ) for the method were 0.7 and 2.3 mg/kg, respectively. Residual formaldehyde levels in the five tested alginate products were in the range of 2–3 mg/kg. According to the author, this indicated that the chemical and heat treatments involved in the manufacturing process were efficient at removing formaldehyde from the product.

The Panel considered that it could be appropriate to define in the specifications for propane‐1,2‐diol alginate (E 405) a suitable validated analytical method of appropriate accuracy for the determination of formaldehyde.

Because of the polysaccharidic nature of this compound, it can be a substrate of microbiological contamination during storage. This has been demonstrated recently by the mycotoxin contaminations of gums (Zhang et al., 2014). The Panel noted that the differences in the microbiological criteria for propane‐1,2‐diol alginate between the specifications given by the EU Regulation and those given by JECFA are not decisive.

Pesticides are not used, nor needed in the production of seaweeds and according to industry (Documentation provided to EFSA n. 13), available analytical data did not show the presence of pesticides.

The Panel noted that, according to the EU specifications for propane‐1,2‐diol alginate (E 405) impurities of the toxic elements arsenic, cadmium, lead and mercury are accepted up to concentrations of 3, 1, 5 and 1 mg/kg, respectively. Contamination at such levels could have a significant impact on the exposure to these elements, for which the exposures already are close to the health‐based guidance values or benchmark doses (lower Confidence Limits) established by EFSA (EFSA CONTAM Panel, 2009a,b, 2010, 2012a, 2012b c 2014).

3.1.3. Manufacturing process

Propane‐1,2‐diol alginate is prepared by treatment of partially neutralised alginic acid with propylene oxide (Voragen et al., 2012). The esterification of the carboxylic acid group of alginic acid takes place slowly at room temperature but considerably faster at a slightly elevated temperature with an upper limit of approximately 75°C. The reaction is carried out in equipment suitable for operation under moderate pressure (Steiner and McNeely, 1951).

3.1.4. Methods of analysis in food

A method for the quantitative analysis of propane‐1,2‐diol alginate in beer has been reported by Diepenmaat‐Wolters et al. (1997). The polysaccharide is precipitated from beer using 70% alcohol. The propane‐1,2‐diol residues are saponified with ammonium hydroxide, and then subsequently hydrolysed with methanolic HCl and trifluoroacetic acid. The resulting free guluronic and mannuronic acid can be analysed by high‐performance anion‐exchange chromatography (HPAEC). Propane‐1,2‐diol alginate concentrations of > 10 mg/L can be determined quantitatively, below this level only qualitative detection is obtained. Recovery from spiked beers was found to be 60%.

3.1.5. Stability of the substance, and reaction and fate in food

As a result of the blocking of large fraction of the carboxyl groups with a propane‐1,2‐diol alginate ester, the alginate ester is soluble in acid solutions that will precipitate sodium alginate as alginic acid. In addition to acid resistance, propane‐1,2‐diol alginate has an improved resistance to precipitation by calcium and other metal salts. At alkaline pH, propane‐1,2‐diol alginate is gradually hydrolysed to propane‐1,2‐diol and alginate ion (Steiner and McNeely, 1951). Propane‐1,2‐diol alginate is by a factor of 104–105 more instable against alkaline hydrolysis, compared to the unsubstituted alginate (Draget, 2000).

3.2. Authorised uses and use levels

Maximum levels of propane‐1,2‐diol alginate (E 405) have been defined in Annex II to Regulation (EC) No 1333/200816 on food additives, as amended. These levels are defined by the Panel as ‘maximum permitted levels’ (MPLs) in this document.

Table 2 summarises food categories that are permitted to contain propane‐1,2‐diol alginate (E 405) and the corresponding MPLs as set by Annex II to Regulation (EC) No 1333/2008.

Table 2.

MPLs of propane‐1,2‐diol alginate (E 405) in foods according to the Annex II to Regulation (EC) No 1333/2008

| Food category number | Food category name | E‐number | Restrictions/exception | MPL (mg/L or mg/kg as appropriate) |

|---|---|---|---|---|

| 02.2.2 | Other fat and oil emulsions including spreads as defined by Council Regulation (EC) No 1234/2007 and liquid emulsions | E 405 | 3,000 | |

| 03 | Edible ices | E 405 | Only water‐based edible ices | 3,000 |

| 04.2.4.1 | Fruit and vegetable preparations excluding compote | E 405 | 5,000 | |

| 05.2 | Other confectionery including breath freshening microsweets | E 405 | Only sugar confectionary | 1,500 |

| 05.3 | Chewing gum | E 405 | 5,000 | |

| 05.4 | Decorations, coatings and fillings, except fruit‐based fillings covered by category 4.2.4 | E 405 | 1,500 | |

| Only fillings, toppings and coatings for fine bakery wares and desserts | 5,000 | |||

| 07.2 | Fine bakery wares | E 405 | 2,000 | |

| 12.6 | Sauces | E 405 | 8,000 | |

| 13.1.5.1 | Dietary foods for infants for special medical purposes and special formulae for infants | E 405 | From 12 months onwards in specialised diets intended for young children who have cow's milk intolerance or inborn errors of metabolism | 200 |

| 13.1.5.2 | Dietary foods for babies and young children for special medical purposes as defined in Directive 1999/21/EC | E 405 | From 12 months onwards in specialised diets intended for young children who have cow's milk intolerance or inborn errors of metabolism | 200 |

| 13.2 | Dietary foods for special medical purposes defined in Directive 1999/21/EC (excluding products from food category 13.1.5) | E 405 | 1,200 | |

| 13.3 | Dietary foods for weight control diets intended to replace total daily food intake or an individual meal (the whole or part of the total daily diet) | E 405 | 1,200 | |

| 14.1.4 | Flavoured drinks | E 405 | 300 | |

| 14.2.1 | Beer and malt beverages | E 405 | 100 | |

| 14.2.3 | Cider and perry | E 405 | Excluding cidre bouché | 100 |

| 14.2.6 | Spirit drinks as defined in Regulation (EC) No 110/2008 | E 405 | Only emulsified liqueurs | 10,000 |

| 14.2.8 | Other alcoholic drinks including mixtures of alcoholic drinks with non‐alcoholic drinks and spirits with less than 15% of alcohol (14.2.8) | E 405 | Only in fermented grape must‐based drinks | 100 |

| 15.1 | Potato‐, cereal‐, flour‐ or starch‐based snacks | E 405 | Only cereal‐ and potato‐based snacks | 3,000 |

| 17.1a | Food supplements supplied in a solid form including capsules and tablets and similar forms, excluding chewable forms | E 405 | 1,000 | |

| 17.2a | Food supplements supplied in a liquid form | E 405 | 1,000 | |

| 17.3a | Food supplements supplied in a syrup‐type or chewable form | E 405 | 1,000 |

MPL: maximum permitted level.

17 refers to food supplements as defined in Directive 2002/46/EC of the European Parliament and of the Council excluding food supplements for infants and young children.

According to Annex III, Part 1, of Regulation (EC) No 1333/2008 propane‐1,2‐diol alginate (E 405) is also authorised as carrier in all food additives with a maximum level at quantum satis (QS).

3.3. Exposure data

3.3.1. Reported use levels or data on analytical levels of propane‐1,2‐diol alginate (E 405)

Most food additives in the EU are authorised at a specific MPL. However, a food additive may be used at a lower level than the MPL. Therefore, information on actual use levels is required for performing a more realistic exposure assessment.

In the framework of Regulation (EC) No 1333/2008 on food additives and of Commission Regulation (EU) No 257/2010 regarding the re‐evaluation of approved food additives, EFSA issued public calls17 , 18 for occurrence data (usage level and/or concentration data) on propane‐1,2‐diol alginate (E 405).

In response to the first call, Marinalg International provided some information (Documentation provided to EFSA n. 3) on the use of propane‐1,2‐diol alginate (E 405) in foods.

In addition, in response to the public call of year 2015, information on the actual use levels of propane‐1,2‐diol alginate (E 405) in foods was made available to EFSA by industry. No analytical data on the concentration of propane‐1,2‐diol alginate (E 405) in foods were made available by the Member States.

Summarised data on reported use levels in foods provided by industry

Industry provided EFSA with data on use levels (n = 12) of propane‐1,2‐diol alginate (E 405) in foods for 3 out of the 21 food categories in which propane‐1,2‐diol alginate (E 405) is authorised.

Updated information on the actual use levels of propane‐1,2‐diol alginate (E 405) in foods was made available to EFSA by FoodDrinkEurope (FDE) (Documentation provided to EFSA n. 16) and Marinalg International (Marinalg) (Documentation provided to EFSA n. 17).

The Panel noted that Marinalg (which submitted three use levels) is not directly using gums in food products but is a food additive producer. Use levels reported by food additive producers are not considered at the same level as those provided by food industry. Food additive producers might recommend use levels to the food industry but the final levels might, ultimately, be different. Therefore, unless food additive producers confirm that the recommended levels are used by food industry, they are not considered in the refined exposure scenarios. Data from food additive producers will only be used in the maximum level exposure assessment scenario in case of QS authorisation when no data are available from food industry. In this way, the most complete exposure estimates are calculated. In the current assessment, all food categories are authorised with a numerical MPL, and maximum reported use levels of Marinalg equalled the MPLs.

The Panel noted that the remaining nine use levels on beer and malt beverages referred to niche products. Since no other use levels were available from food industry, the Panel decided not to carry out refined assessment, as the available dataset was considered insufficient to provide a solid basis for it.

Appendix A provides data on the use levels of propane‐1,2‐diol alginate (E 405) in foods as reported by industry.

3.3.2. Summarised data extracted from the Mintel's Global New Products Database

The Mintel's GNPD is an online database which monitors new introductions of packaged goods in the market worldwide. It contains information of over 2.5 million food and beverage products of which more than 1,000,000 are or have been available on the European food market. Mintel started covering EU's food markets in 1996, currently having 20 out of its 28 member countries and Norway presented in the Mintel GNPD.19

For the purpose of this Scientific Opinion, the Mintel's GNPD20 was used for checking the labelling of food and beverages products and food supplements for propane‐1,2‐diol alginate (E 405) within the EU's food market as the database contains the compulsory ingredient information on the label.

According to the Mintel's GNPD, propane‐1,2‐diol alginate (E 405) was labelled on 226 products mainly of ‘Beer’, ‘Dairy Based Ice Cream & Frozen Yogurt’ and ‘Table Sauces’ between January 2013 and January 2018.

Appendix B lists the number and percentage of the food products labelled with propane‐1,2‐diol alginate (E 405) out of the total number of food products per food subcategories according to the Mintel's GNPD food classification. The percentages ranged from less than 0.1% in many food subcategories to 1.5% in Mintel's GNPD food sub‐category ‘Water Based Ice Lollies, Pops & Sorbets’. The average percentage of foods labelled to contain propane‐1,2‐diol alginate (E 405) was 0.13%.

The Panel noted that propane‐1,2‐diol alginate (E 405) was listed as ingredient in 11 food products of the Mintel's GNPD subcategories ‘Fish Products’, ‘Instant Noodles’, ‘Meal Kits’, ‘Chocolate Tablets’, ‘Pasta’ where it is not authorised as such.

3.3.3. Food consumption data used for exposure assessment

EFSA Comprehensive European Food Consumption Database

Since 2010, the EFSA Comprehensive European Food Consumption Database (Comprehensive Database) has been populated with national data on food consumption at a detailed level. Competent authorities in the European countries provide EFSA with data on the level of food consumption by the individual consumer from the most recent national dietary survey in their country (cf. Guidance of EFSA on the ‘Use of the EFSA Comprehensive European Food Consumption Database in Exposure Assessment’ (EFSA, 2011a). Consumption surveys added in the Comprehensive database in 2015 were also taken into account in this assessment.15

The food consumption data gathered by EFSA were collected by different methodologies and thus direct country‐to‐country comparisons should be interpreted with caution. Depending on the food category and the level of detail used for exposure calculations, uncertainties could be introduced owing to possible subjects’ underreporting and/or misreporting of the consumption amounts. Nevertheless, the EFSA Comprehensive Database includes the currently best available food consumption data across Europe.

Food consumption data from the following population groups: infants, toddlers, children, adolescents, adults and the elderly were used for the exposure assessment. For the present assessment, food consumption data were available from 33 different dietary surveys carried out in 19 European countries (Table 3).

Table 3.

Population groups considered for the exposure estimates of propane‐1,2‐diol alginate (E 405)

| Population | Age range | Countries with food consumption surveys covering more than 1 day |

|---|---|---|

| Infants | From more than 12 weeks up to and including 11 months of age | Bulgaria, Denmark, Finland, Germany, Italy, UK |

| Toddlersa | From 12 months up to and including 35 months of age | Belgium, Bulgaria, Denmark, Finland, Germany, Italy, Netherlands, Spain, UK |

| Childrenb | From 36 months up to and including 9 years of age | Austria, Belgium, Bulgaria, Czech Republic, Denmark, Finland, France, Germany, Greece, Italy, Latvia, Netherlands, Spain, Sweden, UK |

| Adolescents | From 10 years up to and including 17 years of age | Austria, Belgium, Cyprus, Czech Republic, Denmark, Finland, France, Germany, Italy, Latvia, Netherlands, Spain, Sweden, UK |

| Adults | From 18 years up to and including 64 years of age | Austria, Belgium, Czech Republic, Denmark, Finland, France, Germany, Hungary, Ireland, Italy, Latvia, Netherlands, Romania, Spain, Sweden, UK |

| The elderlyb | From 65 years of age and older | Austria, Belgium, Denmark, Finland, France, Germany, Hungary, Ireland, Italy, Romania, Netherlands, Sweden, UK |

The term ‘toddlers’ in the EFSA Comprehensive Database corresponds to ‘young children’ in Regulations (EC) No 1333/2008 and (EU) No 609/2013.

The terms ‘children’ and ‘the elderly’ correspond, respectively, to ‘other children’ and the merge of ‘elderly’ and ‘very elderly’ in the Guidance of EFSA on the ‘Use of the EFSA Comprehensive European Food Consumption Database in Exposure Assessment’ (EFSA, 2011a).

Consumption records were codified according to the FoodEx classification system (EFSA, 2011b). Nomenclature from the FoodEx classification system has been linked to the food categorisation system (FCS) as presented in Annex II of Regulation (EC) No 1333/2008, part D, to perform exposure estimates. In practice, the FoodEx food codes were matched to the FCS food categories.

Food categories considered for the exposure assessment of propane‐1,2‐diol alginate (E 405)

The food categories in which the use of propane‐1,2‐diol alginate (E 405) is authorised were selected from the nomenclature of the EFSA Comprehensive Database (FoodEx classification system), at the most detailed level possible (up to FoodEx Level 4) (EFSA, 2011b).

Some food categories or their restrictions/exceptions are not referenced in the EFSA Comprehensive Database. For the following food categories, the restrictions/exceptions which apply to the use of propane‐1,2‐diol alginate (E 405) could not be taken into account, and therefore the whole food category was considered in the exposure assessment. This applies to five food categories (three of them considered in the MPL scenario, while FCs 13.1.5.1 and 13.1.5.2 are taken into account in the calculations concerning foods for special medical purposes (FSMPs)) (Appendix C) and may have resulted in an overestimation of the exposure:

5.4 Decorations, coatings and fillings, except fruit‐based fillings covered by category 4.2.4. In this food category the additive is authorised with an MPL of 1,500 mg/kg in general, but for ‘only fillings, toppings and coatings for fine bakery wares and desserts’ has an MPL of 5,000 mg/kg. As these products cannot be clearly distinguished in the Comprehensive Database, in order to be conservative, an MPL of 5,000 mg/kg was applied for the whole category.

13.1.5.1 Dietary foods for infants for special medical purposes and special formulae for infants and 13.1.5.2 Dietary foods for babies and young children for special medical purposes as defined in Directive 1999/21/EC, ‘from 12 months onwards in specialised diets intended for young children who have cow's milk intolerance or inborn errors of metabolism’. The restriction could not be taken into account and the whole food categories were considered.

14.2.3 Cider and perry, ‘excluding cidre bouché’. Restriction could not be taken into account as this specific information is not included in the Comprehensive Database. Thus, the whole food category was taken into account.

14.2.8 Other alcoholic drinks including mixtures of alcoholic drinks with non‐alcoholic drinks and spirits with less than 15% of alcohol (14.2.8), ‘only in fermented grape must‐based drinks’. Restriction could not be taken into account as this specific information is not included in the Comprehensive Database. The whole food category was taken into account.

For the FCs 17.1/17.2/17.3 Food supplements, in solid, liquid, syrup‐type or chewable form, the form cannot be differentiated and the same level was applied to the whole FC 17.

Propane‐1,2‐diol alginate (E 405) is also allowed in FCs 13.2 and 13.3. Food items under FCs 13.2, 13.3 consumed by population groups‐children, adolescents, adults and the elderly‐ may be very diverse and, in addition, there is very limited information on their consumption. Therefore, eating occasions belonging to the FCs 13.2, 13.3 were reclassified under food categories in accordance to their main component.

The MPLs available for FCs 13.2 and 13.3 were not considered for the exposure assessment.

Considering that the FC 18 (Processed foods not covered by categories 1 to 17, excluding foods for infants and young children) is extremely unspecific (e.g. composite foods), processed foods, prepared or composite dishes belonging to the FC 18 were reclassified under food categories in accordance to their main component.

The Panel considered the data received insufficient to carry out refined exposure scenarios therefore, only the regulatory maximum level exposure scenario was performed including 14 food categories in the present exposure assessment to propane‐1,2‐diol alginate (E 405). As this scenario is not considering the consumption of food supplements and FSMP, the possible additional exposure from their consumption was also investigated. (Appendix C).

3.4. Exposure estimates

3.4.1. Exposure to propane‐1,2‐diol alginate (E 405) from its use as a food additive

The Panel estimated the chronic dietary exposure to propane‐1,2‐diol alginate (E 405) for the following population groups: infants; toddlers, children, adolescents, adults and the elderly. Dietary exposure to propane‐1,2‐diol alginate (E 405) was calculated by multiplying MPLs of propane‐1,2‐diol alginate (E 405) per food category (Appendix C) with their respective consumption amount per kilogram body weight for each individual in the Comprehensive Database. The exposure per food category was subsequently added to derive an individual total exposure per day. These exposure estimates were averaged over the number of survey days, resulting in an individual average exposure per day for the survey period. Dietary surveys with only 1 day per subject were excluded as they are considered as not adequate to assess repeated exposure.

This was carried out for all individuals per survey and per population group, resulting in distributions of individual exposure per survey and population group (Table 3). On the basis of these distributions, the mean and 95th percentile of exposure were calculated per survey and per population group. The 95th percentile of exposure was only calculated for those population groups with a sufficiently large sample size (EFSA, 2011a). Therefore, in the present assessment, the 95th percentile of exposure for infants from Italy and for toddlers from Belgium, Italy and Spain were not estimated.

Exposure assessment to propane‐1,2‐diol alginate (E 405) was carried out by the ANS Panel based on the MPLs as set down in the EU legislation, defined as the regulatory maximum level exposure assessment scenario.

Regulatory maximum level exposure assessment scenario does not consider the consumption of food supplements and FSMP. However, the possible exposure from their consumption was also investigated using their MPLs in addition to the food categories considered in the regulatory maximum level exposure assessment scenario.

Regarding the food supplements, dietary exposure was estimated only for the four older population groups as food supplements for infants and young children are excluded from FC 17.

A possible additional exposure from the use of propane‐1,2‐diol alginate (E 405) as carrier in all food additives in accordance with Annex III to Regulation (EC) No 1333/2008 (Part 1) was not considered in any of the exposure assessment scenarios.

Regulatory maximum level exposure assessment scenario

The regulatory maximum level exposure assessment scenario is based on the MPLs as set in Annex II to Regulation (EC) No 1333/2008. For propane‐1,2‐diol alginate (E 405), the MPLs used in the assessment are listed in Table 2 (Appendix C).

The Panel considers the exposure estimates derived following this scenario as the most conservative since it is assumed that that the population will be exposed to the food additive present in food at the MPL over a longer period of time.

Dietary exposure to propane‐1,2‐diol alginate (E 405)

Table 4 summarises the estimated exposure to propane‐1,2‐diol alginate (E 405) from its use as a food additive in six population groups (Table 3) according to the regulatory maximum level exposure assessment scenario. Detailed results per population group and survey are presented in Appendix D.

Table 4.

Summary of dietary exposure to propane‐1,2‐diol alginate (E 405) from its use as food additive in the regulatory maximum level exposure assessment scenario in six population groups (minimum–maximum across the dietary surveys in mg/kg bw per day)

| Infants | Toddlers | Children | Adolescents | Adults | The elderly | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (12 weeks–11 months) | (12–35 months) | (3–9 years) | (10–17 years) | (18–64 years) | (≥ 65 years) | |||||||

| Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | |

| Mean | 0.5 | 8.5 | 3.6 | 19.0 | 6.0 | 18.9 | 3.5 | 13.2 | 1.8 | 8.2 | 1.3 | 6.0 |

| P95th | 7.4 | 35.1 | 11.7 | 39.6 | 13.9 | 38.2 | 7.6 | 27.7 | 4.9 | 21.8 | 3.2 | 14.5 |

From the regulatory maximum level exposure assessment scenario, the mean exposure to propane‐1,2‐diol alginate (E 405) from its use as a food additive ranged from 0.5 mg/kg bw per day in infants to 19.0 mg/kg bw per day in toddlers. The 95th percentile of exposure to propane‐1,2‐diol alginate (E 405) ranged from 3.2 mg/kg bw per day in elderly to 39.6 mg/kg bw per day in toddlers.

Taking into account, for consumers only, also the exposure from food supplements with the MPLs of the corresponding categories (FCs 17.1, 17.2, 17.3), added to categories considered for the regulatory maximum level exposure assessment scenario, the highest mean and 95th percentile exposure was estimated in children, with levels of 29.1 mg/kg bw per day and 38.1 mg/kg bw per day respectively.

Taking into account the consumption of foods for special medical purposes for the whole population of infants and toddlers based on MPLs of the corresponding categories (FCs 13.1.5.1, 13.1.5.2) and added to food categories considered for the regulatory maximum level exposure assessment scenario, the highest mean exposure was estimated in toddlers, with 21.4 mg/kg bw per day while the highest 95th percentile exposure was estimated in infants with a level of 46.8 mg/kg bw per day.

Main food categories contributing to exposure to propane‐1,2‐diol alginate (E 405) in the regulatory maximum level exposure assessment scenario

From the regulatory maximum level exposure assessment scenario, the main contributing food categories to the total mean exposure estimates for every population groups were fine bakery wares and sauces. In addition, for infants, processed fruits and vegetables (FC 4.2.4.1 Fruit and vegetable preparation excluding compote) contributed significantly, while for toddlers, children, adolescents and adults, flavoured drinks are considered as an important source of exposure. In the elderly group, fat and oil emulsions are contributing significantly as well. (Appendix E).

Uncertainty analysis

Uncertainties in the exposure assessment of propane‐1,2‐diol alginate (E 405) have been discussed above. In accordance with the guidance provided in the EFSA opinion related to uncertainties in dietary exposure assessment (EFSA, 2007), the following sources of uncertainties have been considered and summarised in Table 5.

Table 5.

Qualitative evaluation of influence of uncertainties on the dietary exposure estimate

| Sources of uncertainties | Directiona |

|---|---|

| Consumption data: different methodologies/representativeness/underreporting/misreporting/no portion size standard | +/– |

| Use of data from food consumption surveys covering only a few days to estimate high percentiles (95th) long‐term (chronic) exposure | + |

|

Concentration data:

|

+ |

| Foods which may contain the food additive according to Annex III to Regulation (EC) No 1333/2008 not taken into account | – |

|

Regulatory maximum level exposure assessment scenario:

|

+ + |

+, uncertainty with potential to cause overestimation of exposure; –, uncertainty with potential to cause underestimation of exposure.

For all scenarios, propane‐1,2‐diol alginate (E 405) present in foods as carry‐over (Annex III to Regulation No 1333/2008) was not considered which would also lead to an underestimation of exposure to propane‐1,2‐diol alginate (E 405).

Overall, the Panel considered that the uncertainties identified indicated an overestimation of the exposure to propane‐1,2‐diol alginate (E 405) as a food additive according to Annex II, in European countries considered in the EFSA European Comprehensive database in the regulatory maximum level exposure scenario.

Based on the Mintel's GNPD information, the Panel noted that propane‐1,2‐diol alginate (E 405) may not be used in all food categories in which it is authorised, as confectionary, chewing gums, cider and perry, spirits drinks are not listed in the Mintel GNPD's. In many other food categories, only few food products are labelled with the food additive (such as other fat and oil emulsions, snacks, etc. (Appendix B)).

The main uncertainty identified by the Panel raised from the unavailability of use levels for many of the 21 food categories for which propane‐1,2‐diol alginate (E 405) is authorised as a food additive.

The Panel noted that use levels were reported on niche products of one food category listed in the Mintel GNPD. ‘Beer’ is the main food category labelled with propane‐1,2‐diol alginate (E 405), as it represented approximately 30% of the food products labelled with propane‐1,2‐diol alginate (E 405) with however only a few percentage of beers labelled with the food additive (less than 1%). Thus, the Panel considered that these uncertainties were too large to enable to propose an accurate refined exposure assessment of propane‐1,2‐diol alginate (E 405) as a food additive.

Exposure to propane‐1,2‐diol from propane‐1,2‐diol alginate (E 405)

The Panel noted that propane‐1,2‐diol available from propane‐1,2‐diol alginate (E 405) would add to the exposure to the food additive propane‐1,2‐diol (E 1520) previously re‐evaluated by the Panel (EFSA ANS Panel, 2018).

The total maximum content of propane‐1,2‐diol in propane‐1,2‐diol alginate (E 405) amounts up to a maximum of 45% by weight according to the EU specification. The Panel considered a maximum release of 45% as a worst case on which exposure was estimated.

Based on the highest P95 exposure level observed in the regulatory maximum level exposure assessment scenario for propane‐1,2‐diol alginate (E 405) (39.6 mg/kg bw per day for toddlers), the highest exposure to propane‐1,2‐diol was calculated to be 17.8 mg/kg bw per day.

For infants in the regulatory maximum level exposure assessment scenario considering also the consumption of FSMPs, the highest P95 exposure to propane‐1,2‐diol alginate (E 405) was 46.8 mg/kg bw per day, an exposure of 21.1 mg propane‐1,2‐diol/kg bw per day was calculated.

Overall, the Panel considered that accurate exposure assessment for propane‐1,2‐diol released from propane‐1,2‐diol alginate was hampered by the same uncertainties as mentioned above.

3.4.2. Exposure via other uses

3.4.2.1. Pharmaceutical uses

Information on pharmaceutical uses was obtained by searches of the literature, the websites of national competent authorities for medicinal products and publicly available SmPC (summary of product characteristics) on the nationally available authorised products indicated to EFSA by the EMA communication (Documentation provided to EFSA, n. 15).

Propane‐1,2‐diol alginate is also used as an excipient in medicinal products authorised in centralised procedures as seen from the answer of EMA. The documented daily dosage is approximately 63 mg/day for adults.

Propane‐1,2‐diol alginate is used as suspending and thickening agents but also as a stabiliser for oil‐in‐water emulsions and as binding and disintegrating agents in pharmaceutical industry (Martindale, 2014).

There are no data available indicating the use of propane‐1,2‐diol alginate as an active ingredient in medicinal products.

Nevertheless alginates are known to be given as an active ingredient, sometimes formulated in combination with carbonates and other antacids (aluminium hydroxide), in the management of gastroesophageal reflux disease (GERD). Alginic acid or its salts react with gastric acid to form a viscous gel acting as a mechanical barrier to reduce reflux of gastric content (Mandel et al., 2000; Kapadia and Mane, 2007; Martindale, 2014; Reimer et al., 2016).

Propane‐1,2‐diol is used as humectant, solvent and preservative in a wide range of medicinal products (EMA, 2014a).

As no data were available to the Panel, exposure to propane‐1,2‐diol alginate via medicinal products were not considered in this opinion.

3.5. Biological and toxicological data

The Panel also considered in this opinion the major toxicokinetic and toxicological data on alginic acid and propane‐1,2‐diol, the two hydrolytic derivatives of propane‐1,2‐diol alginate. These two compounds have been recently re‐evaluated for their safety of use as food additives E 400 and E 1520 (EFSA ANS Panel, 2017, 2018).

3.5.1. Absorption, distribution, metabolism and excretion (ADME)

The Panel noted that certain high‐molecular‐weight dietary polysaccharides could be partially broken down by the microbiota in the large intestine of humans. In addition to intermediate metabolites such as lactic, acrylic or fumaric acids, the main end products of this colonic anaerobic digestive process are short‐chain fatty acids (SCFA), such as acetic, propionic and butyric acids, that are absorbed from the colon (Cummings and Englyst, 1987).

3.5.1.1. Propane‐1,2‐diol alginate (E 405)

3.5.1.1.1. In vitro studies

As reported by JECFA (1993), ‘in vitro hydrolysis studies with propylene glycol alginate in simulated gastric juice and simulated intestinal juice showed no hydrolysis in simulated gastric juice, while intestinal juice hydrolyzed 25% in 4 h, 65% in 12 h and 80% in 24 h’ (McNeely and Shepherd, 1966, unpublished report).

3.5.1.1.2. In vivo study

The absorption, distribution throughout the body tissues and excretion of propane‐1,2‐diol alginate were followed in mice after oral administration, using the technique of whole‐body autoradiography (Sharratt and Dearn, 1972). The authors used two different samples of propane‐1,2‐diol alginate. One labelled with 14C in the alginate moiety was prepared from seaweed of Laminaria hyperborean cultivated in sea‐water containing 14C‐carbonate. The other 14C‐labelled in the propane‐1,2‐diol was prepared by esterification of alginic acid from Ascophyllum nodosum with 14C‐labelled propylene oxide.

In case of radiolabelling on alginate, CF1 mice (n = 8; 3–4 weeks old; no data about sex) received an oral dose of approximately 5,000 mg/kg bw propane‐1,2‐diol alginate (as a 10% aqueous solution). One mouse was killed every 1, 2, 4, 6 or 8 h and 1, 3 or 5 days after gavage.

A similar experiment was performed with radiolabelled propane‐1,2‐diol alginate on propane‐1,2‐diol; 7 mice received a dose of approximately 1,000 mg/kg bw and one mouse was killed every 2, 4, 6 or 8 h and 1, 3 or 5 days after gavage. All animals were sectioned (100‐μm thick sections) for whole body autoradiography. The sections were in contact with X‐ray film for 6 or 60 days prior to film processing.

When propane‐1,2‐diol alginate labelled on the alginate moiety was given to mice, the autoradiographs indicated that the whole radioactivity (100%) was confined to the contents of the gastrointestinal tract at all times whereas no radioactivity was detected in other organs. Five days after the oral administration, nearly complete excretion of radioactivity was observed and only traces were present in the rectum.

When propane‐1,2‐diol alginate labelled on propane‐1,2‐diol moiety was administered, the radioactivity was absorbed to some extent, distributed rapidly over the whole body, particularly concentrated in the liver and was completely removed from all tissues in 3–4 days. The Panel calculated that the part of radioactivity present in extra digestive tissues would represent approximately 25% of the administered radioactivity. The unabsorbed or non‐hydrolysed portion was excreted in the faeces within 3 days.

According to the authors, while hydrolysis of propane‐1,2‐diol alginate to propane‐1,2‐diol and alginate was only partial at a dose of 1,000 mg/kg bw in mice, the hydrolysis is likely to be more complete at lower levels, such as those likely to be ingested by humans.

3.5.1.2. Alginic acid and derived salts (E 400–E 404)

In its previous assessment of the safety of alginic acid and its salts (EFSA ANS Panel, 2017), the ANS Panel considered that the in vitro degradation and the in vivo studies demonstrated that the biological fate of alginic acid and its salts was similar. Alginic acid and its salts would not be absorbed intact regardless of the form administered; they would not be metabolised by enzymes present in the gastrointestinal tract. However, considering in vitro studies using alginic acid, they could be partially fermented during their passage through the large intestine by the action of the intestinal microbiota. The rate of hydrolysis in the gastrointestinal tract in humans is unknown, but it is expected that the limited extent of hydrolysis of alginic acid and its salts would lead to the production of fermentation products such as SCFAs. Based on the available knowledge on the role of SCFA as end products of the fermentation of dietary fibres by the anaerobic intestinal microbiota (Topping and Clifton, 2001; Den Besten et al., 2013), the Panel considered that their potential formation as fermentation products from alginic acid and its salts did not raise a safety concern.

3.5.1.3. Propane‐1,2‐diol (E 1520)

As reported in its previous evaluation of propane‐1,2‐diol (EFSA ANS Panel, 2018), the ANS Panel considered that this compound is readily absorbed from the gastrointestinal tract in experimental animals and in humans and is expected to be widely distributed to organs and tissues. The major route of metabolism is oxidation to lactic acid and pyruvic acid. An alternative route of metabolism of propane‐1,2‐diol to lactic acid is via phosphorylated glycol. Lactate is mainly metabolised via the citric acid cycle and excreted as carbon dioxide via exhalation. At high concentrations, free propane‐1,2‐diol is excreted in the urine as the metabolism of propane‐1,2‐diol is saturated at dose levels higher than 20,000 mg/day in humans. The Panel noted that ADME data on the hydrolysis product propane‐1,2‐diol are presented in the OECD evaluation (2001). Absorption of orally applied propane‐1,2‐diol and its removal from the body follows first order kinetics. Clearance from blood in humans is rapid, with a mean half‐life of 2 h. Absorbed propane‐1,2‐diol is readily converted into lactic acid and pyruvic acid and enters the general metabolic pool.

Overall, in vitro experiments have shown that propane‐1,2‐diol alginate is partially hydrolysed by simulated gastric and intestinal juices to propane‐1,2‐diol and alginic acid. In vivo studies using autoradiography gave also evidence for a partial but not complete hydrolysis to propane‐1,2‐diol and alginic acid. According to previous EFSA assessment propane‐1,2‐diol is absorbed and its metabolites would enter the normal energy‐forming pathways. However, together with any non‐hydrolysed material, the alginate moiety was not absorbed intact but excreted in the faeces, confirming the data previously provided in the assessment on the safety of alginic acid and its salts (EFSA ANS Panel, 2017).

3.5.2. Acute toxicity

3.5.2.1. Propane‐1,2‐diol alginate (E 405)

Several acute toxicity studies were performed with propane‐1,2‐diol alginate. LD50s of propane‐1,2‐diol alginate were reported to be approximately 7,000 or 7,800 mg/kg bw in mice (Bailey et al., 1976; FDRL, 1976 as cited in JECFA, 1993) greater than 5,000 mg/kg (WRC, 1972; Documentation provided to EFSA n. 12), 7,200 mg/kg bw (FDRL, 1976; cited in JECFA, 1993) or greater than 10,000 mg/kg bw (Documentation provided to EFSA n. 4) in rats, approximately 7,000 mg/kg bw in hamsters (Bailey et al., 1976; FDRL, 1976 as cited in JECFA, 1993), and approximately 7,000 mg/kg bw or 7,600 mg/kg bw in rabbits (Bailey et al., 1976; FDRL, 1976 as cited in JECFA, 1993).

The Panel considered propane‐1,2‐diol alginate to be of low acute oral toxicity.

3.5.2.2. Alginic acid and derived salts (E 400–404)

The Panel considered alginic acid and its salts (E 400–E 404) of low acute oral toxicity (EFSA ANS Panel, 2017).

3.5.2.3. Propane‐1,2‐diol (E 1520)

The Panel considered that the data from acute toxicity studies in mice, rats, hamsters and rabbits indicated low acute toxicity of propanediol‐1,2‐diol (EFSA ANS Panel, 2018).

Overall, the Panel considered the acute toxicity of propane‐1,2‐diol alginate, alginic acid and propane‐1,2‐diol to be low.

3.5.3. Short‐term and subchronic toxicity

3.5.3.1. Propane‐1,2‐diol alginate (E 405)

Rats

No adverse effects (no further details) were observed in five male Sprague–Dawley rats gavaged with 5,000 mg propane‐1,2‐diol alginate/kg bw per day for 5 days (vehicle corn oil, origin not further specified). Data on control rats were not available (Documentation provided to EFSA n. 4).

In another study, two female rats per dose (strain not stated) received a diet containing 0% or 21.5% propane‐1,2‐diol alginate (not further specified) (equivalent to 0 or 21,500 mg/kg bw per day) for 4 weeks (no further details). In the treated rats, diarrhoea was noted. No effects were detected in histopathology of the liver, kidneys and intestine (no further data; MRCL, 1951; cited in JECFA, 1993). In a second study, four female rats per dose received 0 or 21.5% propane‐1,2‐diol alginate in the diet for 4 weeks followed by a 4‐week post‐exposure observation period. Treated rats showed diarrhoea and a slight decrease in body weight gain but appearance and behaviour were normal (no further data; MRCL, 1951; cited in JECFA, 1993). The Panel considered the relevance of these studies for risk assessment as limited due to the low number of animals per group, and limited number of parameters investigated, and that the only dose tested was very high.

In a study performed by Anderson et al. (1991), a group of 15 male rats (strain not stated) received 5% propane‐1,2‐diol alginate (not further specified) in the diet (5,000 mg/kg bw per day) for 30 days; the control was not specified. No clinical signs were observed. Ten treated rats had soft/‐ill formed faecal pellets in comparison to a stool of the controls. The standard urinalysis did not reveal any effects but necropsy showed distended ileum (n = 5), caecum (n = 15) and colon (n = 12) (no further data).

Guinea pigs

Guinea pigs (strain and sex not stated, n = 1–3/group) were fed 0%, 5%, 10%, 15% propane‐1,2‐diol alginate (Kelcoloid) in the diet (equivalent to 0, 2,000, 4,000 or 6,000 mg/kg bw per day, JECFA, 2000) for 26 weeks (Nilson and Wagner, 1951). Mortality occurred in controls and in the low‐dose group (2 guinea pigs died within 8 weeks in the control and 5% groups, respectively). No effects on body weight were reported after addition of vitamins. As the evaluation of this study was hampered by the insufficient reporting and low number of animals, the Panel considered the relevance of this study for risk assessment as limited.

Cats

In the same publication (Nilson and Wagner, 1951), a study in cats (strain, sex and number per group not stated) fed diets containing 0%, 5%, 10% or 15% of propane‐1,2‐diol alginate (Kelcoloid) for periods of varying duration (from 14 to 110 days) was described. The mean consumption of propane‐1,2‐diol alginate was reported to be from 5.0 to 15.8 g/animal per day depending on the dose level. Body weight loss was recorded for all cats on diet added propane‐1,2‐diol alginate. According to the authors this could be related to lower feed intake due to physical texture of the diet. The cats receiving ‘higher’ levels of propane‐1,2‐diol alginate (no information about the concentration) passed 2–3 stools of soft texture per day. There were no indications of toxicity and no findings, which could be attributed to treatment, were reported at necropsy and by histology. As the evaluation of this study was hampered by the insufficient reporting and low number of animals, the Panel considered the relevance of this study for risk assessment as limited.

Dogs

Groups of three male and three female Beagle Dogs received daily a diet containing 0%, 5%, or 15% propane‐1,2‐diol alginate (equal to 0, 1,000 or 3,000 mg/kg bw per day) for 12 months (WRC, 1959; Documentation provided to EFSA n. 11). Dogs were observed daily for clinical signs. The body weight was recorded once weekly. Haematology (parameters: haemoglobin, packed cell volume, white blood cell count, differential blood count) was performed at weeks –1, 0, 2, 6, 13, 26, 39 and 52, and clinical chemistry (parameters: urea nitrogen, alkaline phosphatase, glucose) at termination as well as urinalysis (parameters: sugar, albumin, microscopy, occult blood). Necropsy was performed and organ weights were measured (including liver, kidney, heart, spleen, testis, ovary, uterus, prostate, adrenals, thyroid gland). Organs and tissues were examined microscopically for histopathological changes (investigated organs: cerebrum, pons, midbrain, pituitary, heart, salivary gland, heart, liver, lung, kidney, spleen, pancreas, stomach, ileum, jejunum, duodenum, large bowel, testis, ovary, urinary bladder, prostate, uterus, lymph nodes). No clinical signs except soft stool consistency in the high‐dose group and no treatment‐related effects on feed consumption and body weight gain were noted. Haematology, clinical chemistry and urinalysis were within the normal limits. No treatment‐related effects were detected at necropsy and by microscopy. The Panel considered 3,000 mg/kg bw per day as the NOAEL, the highest dose tested.

3.5.3.2. Alginic acid and derived salts (E 400–404)

One short‐term toxicity study performed in rats with alginic acid up to 24,000 mg/kg bw per day, seven short‐term toxicity studies performed in rats with sodium alginate up to 12,000 mg/kg bw per day, one subchronic toxicity study performed in rats with sodium alginate up to 13,500 mg/kg bw per day and one subchronic study in dogs with sodium alginate up to 3,000 mg/kg bw per day were available. No adverse effects were observed. In the rat studies, the caecal enlargement described by the authors was considered by the Panel as an adaptive process related to the high doses tested (EFSA ANS Panel, 2017).

3.5.3.2.1. Propane‐1,2‐diol (E 1520)

No treatment‐related effects were observed in subchronic toxicity studies in which propane‐1,2‐diol was administered by gavage (1,000 mg/kg bw per day) to mice, rats, dogs and monkeys for 92–97 days (Thackaberry et al., 2010) (EFSA ANS Panel, 2018).

Overall, although various dietary studies with propane‐1,2‐diol alginate in laboratory animals were available to the Panel, several of these studies were of limited relevance for risk assessment due to the low numbers of animals per group and/or limited reporting. In these studies with dietary concentrations up to 25% of propane‐1,2‐diol alginate, loose stools were observed. Reliable studies comprised one short‐term toxicity study performed in rats with alginic acid up to 24,000 mg/kg bw per day, seven short‐term toxicity studies in rats with sodium alginate up to 12,000 mg/kg bw per day, one subchronic toxicity study performed in rats with sodium alginate up to 13,500 mg/kg bw per day and two subchronic studies in dogs, one with sodium alginate and another one with propane‐1,2‐diol both up to 3,000 mg/kg bw per day, and a subchronic study in monkeys exposed to 1,000 mg propane‐1,2‐diol/kg bw per day, the highest dose tested. None of these studies demonstrated adverse effects.

3.5.4. Genotoxicity

3.5.4.1. Propane‐1,2‐diol alginate (E 405)

3.5.4.1.1. In vitro studies