Abstract

Following a request from the European Commission, the EFSA Panel on Contaminants in the Food Chain (CONTAM) provided a scientific opinion on the assessment of a decontamination process of fish meal. It consisted of extraction of the fish oil, filtration and adsorption with activated carbon, and replacement with decontaminated fish oil in order to reduce the amount of dioxins (polychlorinated dibenzo‐p‐dioxins (PCDDs) and polychlorinated dibenzofurans (PCDFs)), and dioxin‐like (DL‐) and non‐dioxin‐like (NDL‐) polychlorinated biphenyls (PCBs). All feed decontamination processes must comply with the acceptability criteria specified in the Commission Regulation (EU) 2015/786. Data provided by the feed business operator were assessed for efficacy of the process and to demonstrate that the process did not adversely affect the characteristics and the nature of the product. The process was effective in removing PCDD/Fs (97%) and DL‐ and NDL‐PCBs (93%). The fish meal produced complied with EU regulations for these contaminants. The Panel considered that the reference to information available in published literature was a pragmatic approach to demonstrate that the replacement of fish oil and the use of activated carbon to adsorb these contaminants does not lead to any detrimental changes in the nature of the fish meal. However, it was noted that the process could deplete some beneficial constituents (e.g. oil‐soluble vitamins). Information was provided to demonstrate the safe disposal of the waste material. The CONTAM Panel concluded that on the basis of the information submitted by the feed business operator the proposed decontamination process to remove dioxins (PCDD/Fs) and PCBs from the fish meal by oil extraction followed by replacement with decontaminated fish oil, was compliant with the acceptability criteria provided for in Commission Regulation (EU) 2015/786 of 19 May 2015.

Keywords: decontamination process, dioxins, PCDD/Fs, PCBs, fish oil, fish meal, physical filtration

1. Introduction

1.1. Background and Terms of Reference as provided by the requestor

1.1.1. Background

Directive 2002/32/EC of the European Parliament and of the Council of 7 May 2002 on undesirable substances in animal feed1 provides that the use of products intended for animal feed which contain levels of undesirable substances exceeding the maximum levels laid down in Annex I of that Directive is prohibited.

Directive 2002/32/EC provides also that Member States are to ensure that measures are taken to guarantee the correct application of any acceptable detoxification process on products intended for animal feed and the conformity of those detoxified products with the provisions of Annex I of that Directive. In order to ensure a uniform assessment across the European Union of the acceptability of detoxification processes, acceptability criteria for detoxification processes have been established at Union level by Commission Regulation (EU) 2015/786 of 19 May 2015 defining acceptability criteria for detoxification processes applied to products intended for animal feed as provided for in Directive 2002/32/EC of the European Parliament and of the Council.

The acceptability criteria for detoxification processes established by the Regulation shall ensure that the detoxified feed does not endanger animal and public health and the environment and that the characteristics of the feed are not adversely altered by the detoxification process. The Regulation furthermore provides that the compliance of a detoxification process with those criteria shall be scientifically assessed by the European Food Safety Authority (EFSA) on a request from the Commission.

The Commission has received the following application referring to a detoxification process for assessment by EFSA of compliance with the acceptability criteria:

| Feed to be decontaminated | Process | Contaminants of concern |

|---|---|---|

| Fish meal | Extraction of oil followed by replacement with decontaminated fish oil (physical filtration) | Dioxins and PCBs |

1.1.2. Terms of Reference

In accordance with Art. 29 (1) of Regulation (EC) No 178/2002, the European Commission asks the European Food Safety Authority for an assessment of this detoxification process for compliance with the acceptability criteria provided for in Commission Regulation (EU) 2015/786 of 19 May 2015.

1.2. Interpretation of the Terms of Reference

EFSA received from the European Commission requests for scientific opinions on the assessment of applications referring to feed detoxification processes to be compliant with acceptability criteria specified in the Commission Regulation (EU) 2015/786 of 19 May 2015.2 In this context, the term detoxification is interpreted as either decontamination by removing the contaminants or by chemical or biological processes able to reduce the toxicity of the contaminants present.

This scientific opinion assesses the physical decontamination process of fish meal contaminated with organic lipophilic components (e.g. dioxins), in which contaminated fish oil is removed and detoxified by means of adsorption with activated carbon. The decontaminated oil is then added back to the fish meal. With this approach levels of dioxins (polychlorinated dibenzo‐p‐dioxins (PCDDs) and polychlorinated dibenzofurans (PCDFs)), dioxin‐like and non‐dioxin‐like polychlorinated biphenyls (DL‐ and NDL‐PCBs) are reduced in the processed fish meal.

The EFSA Scientific Panel on Contaminants in the Food Chain (CONTAM Panel) concluded that the Terms of Reference provided by the European Commission were clear and that the opinion for the assessment of this physical decontamination process should mainly focus on data in order to:

enable the assessment of the efficacy of the process to remove the contaminants from the feed batches to ensure compliance with the requirements of Directive 2002/32/EC, and

demonstrate that the decontamination process does not adversely affect the characteristics and the nature of the feed.

Information concerning the safe disposal of the removed part of the feed was also considered.

1.3. Additional information

The feed business operator has provided the European Commission with information referring to the proposed decontamination process and its effectiveness as laid down in Directive 2002/32/EC.

2. Data and methodologies

2.1. Data

The feed business operator has submitted information in support of its claim regarding the efficacy of the decontamination process of fish meal from PCDD/Fs and DL‐and NDL‐PCBs through the removal of contaminated oil and the replacement with decontaminated fish oil. During the process, fish oil is decontaminated by adsorption with activated carbon and physical filtration to lower the amount of PCDD/Fs and PCBs. These documents provided included information on the decontamination process, on control steps and on analytical data (certificates of analysis).

The CONTAM Panel based its assessment on the information provided (see Section ‘Documentation provided to EFSA’) to address the Terms of Reference.

2.2. Methodologies

The CONTAM Panel evaluated the acceptability of the proposed decontamination process as requested by the relevant regulations, specifically Directive 2002/32/EC and Commission Regulation (EU) 2015/786 and their Annexes. The assessment is conducted in line with the principles described in the EFSA guidance on transparency in the scientific aspects of risk assessment (EFSA, 2009) and following the relevant existing guidance from the EFSA Scientific Committee, as appropriate.

3. Assessment

3.1. Method of analysis

The feed business operator has submitted information on the analysis for PCDD/F and DL‐ and NDL‐PCBs performed by an accredited laboratory (Eurofins GfA Lab Service GmbH (Hamburg), Germany, through Eurofins Scientific Finland Oy, Raisio – Finland).

The analytical laboratory followed provisions of Commission Regulation (EU) No 709/2014 of 20 June 2014 amending Regulation (EC) No 152/2009 as regards the determination of the levels of PCDD/Fs and DL‐ and NDL‐PCBs.3

3.2. Decontamination process

The feed business operator has submitted sufficient information to assess the operation, including data on levels of PCDD/Fs and DL‐ and NDL‐PCBs, and a scheme describing the decontamination process of the fish meal.

The removal of PCDD/Fs and DL‐ and NDL‐PCBs from fish meal by extraction of the oil is reported to be a simple and effective method (Baron et al., 2007). PCDD/Fs and PCBs are removed from the extracted oil through adsorption on activated carbon from liquid media. The adsorption process is well known for PCDD/Fs and DL‐PCBs and evidence of its efficacy is available in the scientific literature (Eppe et al., 2005; Maes et al., 2005; Oterhals et al., 2007). The effectiveness of the procedure may vary depending on different factors such as the medium to be decontaminated, the level of impurity and its composition in terms of congener profile, and the use of specific activated carbon.

3.2.1. Description of the process

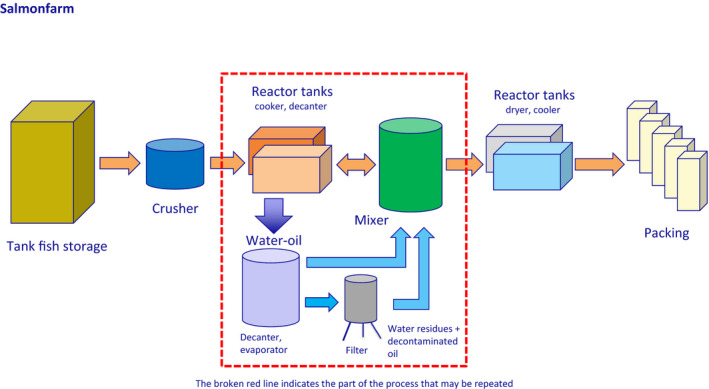

A multistep process (Figure 1) was described for the removal of the water‐oil fraction from the raw material, which was exchanged with the decontaminated fish oil in order to decrease the levels of organic lipophilic components in the final product. After passing through a crusher, the material is heated to allow the separation of oil and water from the solid material. The water–oil mixture continues into two separators, resulting in the separation of aqueous soluble materials from the oil. The water is evaporated and the residual proteinaceous material is returned to the fish meal. The oil is filtered through activated carbon in order to decontaminate it, and it is then added back to residual material, resulting in reduced levels of PCDD/Fs and PCBs in the fish meal. Parts of this process may be repeated in order to further decrease the level of contamination in the reconstituted final product. After drying, the material is cooled, ground and packed. The fish meal is only marketed after analysis for PCDD/Fs and PCBs confirm regulatory compliance.

Figure 1.

Schematic diagram of the process used by the feed business operator

The filters are changed when the results from analysis for PCDD/Fs and PCBs increase. The used active carbon is removed and transported immediately to a specialised waste company for disposal.

3.2.2. Efficacy of the process

The feed business operator has provided analytical records referring to a total of five batches of fish meal that underwent the decontamination process and for which laboratory analyses were performed during the last quarter of 2017. Levels of PCDD/Fs and DL‐ and NDL‐PCBs for each sample were measured. Individual data from these batches with relative reductions are reported in Tables 1 and 2.

Table 1.

Levels of PCDD/Fs and DL‐PCBs in the samples of fish meal before and after the decontamination process

| Fish meal | PCDD/Fs | DL‐PCBs | ||||||

|---|---|---|---|---|---|---|---|---|

| Before process | After process | Reduction (%) | Average reduction (%) | Before process | After process | Reduction (%) | Average reduction (%) | |

| Batch A | 16 | 0.394 | 97.5 | 96.7 | 9.40 | 0.484 | 94.9 | 92.7 |

| Batch B | 13.9 | 0.373 | 97.3 | 7.64 | 0.485 | 93.7 | ||

| Batch C | 14.9 | 0.0649 | 99.6 | 8.96 | 0.572 | 93.6 | ||

| Batch D | 8.69 | 0.508 | 94.2 | 5.73 | 0.708 | 87.7 | ||

| Batch E | 15.4 | 0.625 | 96.0 | 8.77 | 0.826 | 90.6 | ||

PCDD/F: polychlorinated dibenzo‐p‐dioxins and polychlorinated dibenzofurans; DL‐PCB: dioxin‐like polychlorinated biphenyls.

Values expressed in ng WHO2005‐TEQ/kg.

Table 2.

Levels of the sum of PCDD/Fs and DL‐PCBs, and NDL‐PCBs in the samples of fish meal before and after the decontamination process

| Fish meal | Sum of PCDD/Fs and DL‐PCBs | NDL‐PCBs | ||||||

|---|---|---|---|---|---|---|---|---|

| Before process | After process | Reduction (%) | Average reduction (%) | Before process | After process | Reduction (%) | Average reduction (%) | |

| Batch A | 25.4 | 0.878 | 96.5 | 95.2 | 92.2 | 4.94 | 94.7 | 93.3 |

| Batch B | 21.6 | 0.858 | 96.0 | 90.0 | 6.09 | 93.2 | ||

| Batch C | 23.9 | 0.673 | 97.2 | 87.9 | 5.36 | 93.9 | ||

| Batch D | 14.4 | 1.22 | 91.5 | 62.1 | 6.95 | 88.8 | ||

| Batch E | 24.2 | 1.45 | 94.0 | 92.9 | 7.52 | 91.9 | ||

PCDD/F: polychlorinated dibenzo‐p‐dioxins and polychlorinated dibenzofurans; DL‐PCB: dioxin‐like polychlorinated biphenyls; NDL‐PCB: non‐dioxin‐like polychlorinated biphenyls.

Values expressed in ng WHO2005‐TEQ/kg (PCDD/Fs and DL‐PCBs) or μg/kg (NDL‐PCBs).

Data from the five batches showed that the decontamination process decreased the sum of the concentration of PCDD/Fs and DL‐PCBs (ng WHO2005‐TEQ/kg, expressed as ‘toxic equivalent’) by approximately 95% and specifically for PCDD/Fs by approximately 97%. For NDL‐PCBs, the decrease is approximately 93%.

Directive 2002/32/EC of the European Parliament and of the Council of 7 May 2002 on undesirable substances in animal feed and its updates sets action thresholds and maximum levels. Action thresholds are intended to keep the presence of specific undesirable substances in products intended for animal feed as low as possible in order to reduce their presence in the food chain. Where such action thresholds are exceeded, investigations must be carried out to identify the sources of the undesirable substances and steps taken to reduce or eliminate such sources. As shown in Table 3, the action threshold for fish and derived products for dioxins (sum of PCDDs and PCDFs) is 0.75 ng WHO2005‐TEQ/kg and the maximum level is 1.25 ng WHO2005‐TEQ/kg while the maximum limit for the sum of PCDD/Fs and DL‐PCBs is 4.0 ng WHO2005‐TEQ/kg and for NDL‐PCBs 30 μg/kg.

Table 3.

Action thresholds and maximum levels PCDD/Fs, DL‐PCBs and NDL‐PCBs in fish products (with exception of fish oil) according to Directive 2002/32/EC and its amendments

| Contaminant | Action thresholds | Maximum levels |

|---|---|---|

| PCDD/Fs | 0.75 | 1.25 |

| DL‐PCBs | 2.0 | – |

| Sum of above | – | 4.0 |

| NDL‐PCBs | – | 30.0 |

PCDD/F: polychlorinated dibenzo‐p‐dioxins and polychlorinated dibenzofurans; DL‐PCB: dioxin‐like polychlorinated biphenyls; NDL‐PCB: non‐dioxin‐like polychlorinated biphenyls; –: not set in regulation.

Values expressed in ng WHO2005‐TEQ/kg (PCDD/Fs and DL‐PCBs) or μg/kg (NDL‐PCBs); moisture content of 12%.

The CONTAM Panel noted that analytical results from two decontaminated fish oil batches were also provided. Both are well below the maximum levels for PCDD/Fs and the sum of PCDD/Fs and DL‐PCBs.

3.3. Characteristics and nature of the fish meal

Characteristics and nature of the fish meal from decontaminated batches were partially described, but were limited to moisture, crude fat and crude protein content (%) for the final product (the five batches analysed for dioxin content). The following ranges for moisture, fat and protein, respectively, were noted: 6.3–8.5%, 12.3–14.3% and 71.6–73.4%. Therefore, a full and direct comparison of the same batches before and after the decontamination by means of evaluation of the fatty acids profile and other key characteristics was not feasible.

3.4. Disposal of the removed materials and filters

The feed business operator submitted information about the company specialising in hazardous waste used for safe disposal of the waste filter materials. As soon as the performance of the filter starts to decline, the activated carbon contained in the filter is replaced.

3.5. Discussion

The CONTAM Panel assessed the information made available in the documents submitted by the feed business operator and was of the view that sufficient information was available to make an assessment of the proposed decontamination process for PCDD/Fs and DL‐ and NDL‐PCBs from fish meal.

A description of the process with its filtration steps was provided together with a process chart for fish meal and oil decontamination. The Panel also considered that a good general knowledge for decontamination of fish oil exists and was of the view that a clear picture of the proposed process and its performances was available.

The data enabled the CONTAM Panel to assess the quality of the analysis performed and to evaluate the efficacy of the decontamination process. The proposed process appears to be effective in reducing PCDD/Fs an PCBs from the fish product, achieving high percentages of decontamination. The concentrations of PCDD/Fs and DL‐ and NDL‐PCBs still in the feed after the decontamination process complied with the levels reported in the Annex I of Directive 2002/32/EC, falling below the legal limits including the action thresholds.

It was stated by the business operator that each final product batch is released only after analytical control to verify regulatory compliance for PCDD/Fs and PCBs.

The CONTAM Panel concluded that by adopting the process described in this application, it is possible to meet the current EU requirements for quality of fish meal with respect to these contaminants after exchange for decontaminated fish oil. This assessment is based on the assumption that the levels of PCDD/Fs and PCBs in untreated fish meal would be within the range of the tested batches.

Although insufficient experimental evidence was available for the maintained characteristics of the treated fish meal, the CONTAM Panel was of the view that in principle the use of lipid extraction followed by replacement with decontaminated fish oil should not result in any detrimental changes in the quality of the fish meal as long as it was reconstituted with decontaminated fish oil with otherwise similar composition. This view is supported by information from literature (Baron et al., 2007). It is possible that the decontaminated oil used to reconstitute the fish meal could be depleted of some beneficial constituents (e.g. lipid‐soluble vitamins).

The feed business operator reported that as soon as the performance of the filters used to decontaminate the fish oil starts to decline, the activated carbon contained in the filter is replaced. It is also reported that exhausted filters are properly disposed through a specific waste company.

The CONTAM Panel noted that it is the responsibility of Member States to ensure that measures are taken to guarantee the correct application of any acceptable decontamination process on products intended for animal feed, and the conformity of those decontaminated products with the provisions included in the Commission Regulation (EU) 2015/786 and its Annexes. No copy of the authorisation from the national authority for the establishment to carry out the decontamination process was provided.

3.6. Uncertainty analysis

According to the interpretation of the Terms of Reference, the assessment of a physical decontamination process should mainly focus on the evaluation of the efficacy of the process to remove the contaminants and on the evidence that the characteristics and the nature of the final product are not adversely affected.

Efficacy of the process: the removal of PCDD/Fs and DL‐ and NDL‐PCBs from fishmeal by extraction of the oil is reported to be a simple and effective method. PCDD/Fs and PCBs are removed from extracted oil through adsorption on activated carbon. The method used to decontaminate the fish oil is based on a well‐established approach that has been described in the scientific literature. There is little uncertainty in the fact that the process will be effective in removing certain contaminants from the product; however, the specific composition of the starting material will influence the efficacy of the process. In addition, there are some remaining uncertainties that may arise from the operation of the process, such as the effectiveness in removing water/oil from the raw material to allow a sufficient reduction of PCDD/F and PCB levels.

Characteristics of the product: characteristics and nature of the fish meal from decontaminated batches were only partially described, and therefore some uncertainty on the impact of the process on the characteristics of the final product remains. While it is possible that the process can remove some beneficial constituents from the fish oil (e.g. lipophilic vitamins), there is little chance that hazardous substances are introduced into the final product.

4. Conclusions

In relation to the Terms of Reference, the CONTAM Panel concluded:

on the basis of the information submitted by the feed business operator the proposed decontamination process is effective in reducing PCDD/Fs and DL‐ and NDL‐PCBs in the product by means of fish oil extraction followed by replacement with decontaminated fish oil;

there is no evidence that the decontamination process leads to detrimental changes in the nutritional composition of the fish meal; however, it is possible that the process could deplete some beneficial constituents (e.g. vitamins);

the decontamination process to remove PCDD/Fs and DL‐ and NDL‐PCBs from the fish meal, was assessed to be compliant with the acceptability criteria provided for in Commission Regulation (EU) 2015/786 of 19 May 2015.

Documentation provided to EFSA

Information provided by Salmonfarm Oy ‐ Finland to support the effectiveness of a detoxification procedure using physical filtration to remove unwanted substances from fish oil; June 2016.

Additional information submitted by Salmonfarm Oy ‐ Finland in response to requests from the EFSA CONTAM Panel; July and December 2017.

Abbreviations

- CONTAM Panel

EFSA Panel on Contaminants in the Food Chain

- DL‐PCBs

dioxin‐like polychlorinated biphenyls

- NDL‐PCBs

non‐dioxin‐like polychlorinated biphenyls

- PCBs

polychlorinated biphenyls

- PCDDs

polychlorinated dibenzo‐p‐dioxins

- PCDD/Fs

polychlorinated dibenzo‐p‐dioxins and polychlorinated dibenzofurans

- PCDFs

polychlorinated dibenzofurans

- TEQ

toxic equivalents

- WHO

World Health Organization

Suggested citation: EFSA CONTAM Panel (EFSA Panel on Contaminants in the Food Chain) , Knutsen HK, Alexander J, Barregård L, Bignami M, Brüschweiler B, Ceccatelli S, Cottrill B, Dinovi M, Edler L, Grasl‐Kraupp B, Hoogenboom LR, Nebbia CS, Oswald IP, Petersen A, Rose M, Roudot A‐C, Schwerdtle T, Vleminckx C, Vollmer G, Wallace H, Lundebye A‐K, Metzler M, Colombo P and Hogstrand C, 2018. Scientific Opinion on the assessment of a decontamination process for dioxins and PCBs from fish meal by replacement of fish oil. EFSA Journal 2018;16(2):5174, 10 pp. 10.2903/j.efsa.2018.5174

Requestor: European Commission

Question number: EFSA‐Q‐2016‐00797

Panel members: Jan Alexander, Lars Barregård, Margherita Bignami, Beat Brüschweiler, Sandra Ceccatelli, Bruce Cottrill, Michael Dinovi, Lutz Edler, Bettina Grasl‐Kraupp, Christer Hogstrand, Laurentius (Ron) Hoogenboom, Helle Katrine Knutsen, Carlo Stefano Nebbia, Isabelle P Oswald, Annette Petersen, Martin Rose, Alain‐Claude Roudot, Tanja Schwerdtle, Christiane Vleminckx, Günter Vollmer and Heather Wallace.

Adopted: 23 January 2018

Notes

Directive 2002/32/EC of the European Parliament and of the Council of 7 May 2002 on undesirable substances in animal feed. OJ L140, 30.5.2002, p. 10–22.

Commission Regulation (EU) 2015/786 of 19 May 2015 defining acceptability criteria for detoxification process applied to products intended for animal feed as provided for in Directive 2002/32/EC of the European Parliament and of the Council. OJ L 125, 21.5.2015, p. 10–14.

Commission Regulation (EU) No 709/2014 of 20 June 2014 amending Regulation (EC) No 152/2009 as regards the determination of the levels of dioxins and polychlorinated biphenyls. OJ L 188, 27.6.2014, p. 1–18.

References

- Baron C, Børresen T and Jacobsen C, 2007. Comparison of methods to reduce dioxin and polychlorinated biphenyls contents in fishmeal: extraction and enzymatic treatments. Journal of Agricultural and Food Chemistry, 55, 1620–1626. [DOI] [PubMed] [Google Scholar]

- EFSA (European Food Safety Authority), 2009. Guidance of the Scientific Committee on transparency in the scientific aspects of risk assessment carried out by EFSA. Part 2: general principles. EFSA Journal 2009;7(5):1051, 22 pp. 10.2903/j.efsa.2009.1051 [DOI] [Google Scholar]

- Eppe G, Carbonnelle S, Hellebosch L, De Meulenaer B, Vila Ayala J, De Greyt W, Verhé R, Goeyens L, Focant J and De Pauw E, 2005. Removal of PCDD/Fs and DL‐PCBs from fish oil by activated carbon. Compliance with European Legislation, Organohalogen Compounds, 67, 1412–1416. [Google Scholar]

- Maes J, De Meulenaer B, Van Heerswynghelsa P, De Greyta W, Eppec G, De Pauwc E and Huyghebaertb A, 2005. Removal of dioxins and PCB from fish oil by activated carbon and its influence on the nutritional quality of the oil. Journal of the American Oil Chemists’ Society, 82, 593–597. [Google Scholar]

- Oterhals Å, Solvang M, Nortvedt R and Berntssen MHG, 2007. Optimization of activated carbon‐based decontamination of fish oil by response surface methodology. European Journal of Lipid Science and Technology, 109, 691–705. [Google Scholar]