Abstract

The present opinion deals with the re‐evaluation of konjac (E 425), comprising konjac gum (E 425 i) and konjac glucomannan (E 425 ii) when used as food additives. Following the conceptual framework for the risk assessment of certain food additives re‐evaluated under Commission Regulation (EU) No 257/2010, the Panel considered that current use of konjac (E 425) was limited in all food categories to maximum permitted level (MPL) of 10 g/kg, and that the calculated indicative refined exposure assessment for all population groups was below 0.1 mg/kg body weight (bw) per day for the general population (mean and high level). Konjac gum and konjac glucomannan were unlikely to be absorbed intact and were significantly fermented by intestinal microbiota. The available database on toxicological studies was considered limited, however, no relevant adverse effects were seen in rats and dogs in 90‐day feeding studies according to the SCF, the no‐observed‐effect level (NOEL) in rats being 1,250 mg konjac glucomannan/kg bw per day. Konjac gum and konjac glucomannan were of no concern with respect to the genotoxicity. After a daily dosage of 3,000 mg in adults for 12 weeks, several individuals experienced abdominal discomfort including diarrhoea or constipation. The Panel concluded that there was no need for a numerical acceptable daily intake (ADI) and that there was no safety concern for the general population at the refined exposure assessment for the reported uses of konjac gum (E 425 i) and konjac glucomannan (E 425 ii) as food additives under the current conditions of use of 10 g/kg. The Panel agreed with the conclusions of the SCF (1997) that the uses of konjac (E 425) as an additive at the levels up to 10 g/kg in food are acceptable, provided that the total intake from all sources stays below 3 g/day.

Keywords: konjac gum (E 425 i), konjac glucomannan (E 425 ii), konjac mannan, CAS Registry number 37220‐17‐0, food additives

Summary

The present opinion deals with the re‐evaluation of konjac (E 425), comprising konjac gum (E 425 i) and konjac glucomannan (E 425 ii) when used as food additives.

In the European Union (EU), konjac gum (E 425 i) and konjac glucomannan (E 425 ii) have been evaluated by the Scientific Committee for Food in 1996 (SCF, 1997), who could not establish an acceptable daily intake (ADI) for both of the substances. The SCF considered that ‘the uses of konjac gum (E 425 i) and konjac glucomannan (E 425 ii) as additives at the intended levels up to 10 g/kg in food are acceptable, provided that the total intake from all sources did not exceed 3 g/day'. Konjac flour (INS 425) was evaluated by the Joint FAO/WHO Expert Committee on Food Additives (JECFA) in 1993 and 1996 (JECFA, 1993, 1996). In 1993, the Committee allocated a temporary ADI ‘not specified’ for konjac flour. In 1996, an ADI ‘not specified’ was allocated.

The Panel noted that toxicological studies with an alginate‐konjac‐xanthan polysaccharide complex, called PGX, were available for its evaluation as novel food by the EFSA Panel on Dietetic Products, Nutrition and Allergies (EFSA NDA Panel, 2017). The EFSA Panel on Food Additives and Nutrient Sources added to Food (EFSA ANS Panel) did not consider results of these studies in its re‐evaluation of the individual substance konjac glucomannan (E 425 ii). It is not possible to conclude to what extent are the reported effects attributable to one of the individual components of the complex. The physicochemical properties of the individual components might also have changed during the manufacturing process of PGX.

Konjac gum (E 425 i) and konjac glucomannan (E 425 ii) are authorised as food additives in the EU in accordance with Annex II and Annex III to Regulation (EU) No 1333/2008 on food additives and specific purity criteria have been defined in the Commission Regulation (EU) No 231/2012. According to this Regulation, there are distinct specifications for konjac gum (E 425 i) and konjac glucomannan (E 425 ii). JECFA has one specification for konjac flour (INS 425). Konjac gum (E 425 i) and konjac glucomannan (E 425 ii) are distinguished by their grade of purity. The JECFA specification for konjac flour (INS 425) covers both EU specifications.

According to Commission Regulation (EU) No 231/2012, both konjac gum (E 425 i) and konjac glucomannan (E 425 ii) are defined as water soluble hydrocolloid obtained from konjac flour. Konjac gum is obtained by aqueous extraction, while konjac glucomannan is obtained by washing with water‐containing ethanol. In the Regulation, konjac flour is defined as the unpurified raw product from the tuber of the perennial plant Amorphophallus konjac.

The in vitro degradation and the in vivo digestibility of konjac glucomannan in animals demonstrated that this compound would not be absorbed intact or hydrolysed by digestive enzymes.

Konjac glucomannan and konjac flour can be regarded as non‐toxic based on the results of acute oral toxicity studies.

No relevant studies on short‐term and subchronic toxicity for konjac gum and konjac glucomannan are available. However, additional studies on nutritional effects are described; no relevant substance‐induced adverse effects were observed.

Based on the data available, the Panel noted that there is no concern with respect to the genotoxicity of konjac flour.

No relevant studies on chronic toxicity and carcinogenicity for konjac gum (E 425 i) and konjac glucomannan (E 425 ii) were available. The Panel noted that no adverse effects were observed in rats in a long‐term feeding trial over 18 months with 1% refined konjac meal in diet, and in mice receiving 10% of konjac glucomannan with the diet for 10 months.

No reproductive toxicity studies were available. The Panel considered that the developmental toxicity studies of Burger et al. (1992) as referred to by JECFA (1993) in cats and of Sun Tan et al. (2015) in sows were both limited and not sufficient for the evaluation of the developmental toxicity of konjac gum (E 425 i) and konjac glucomannan (E 425 ii).

From both human and animal data, the Panel considered that there was no indication for concern for immunotoxicity or allergenicity with konjac gum (E 425 i) and konjac glucomannan (E 425 ii) used as food additives.

In human studies, gastrointestinal discomfort (i.e. laxative effects, flatulence, full stomach, feeling of hungry and abdominal distension) has been reported in several clinical human studies included in two meta‐analyses. In a relevant study, a dosage of 3 g konjac glucomannan (divided in three times 1 g)/person per day corresponding to 33 mg/kg body weight (bw) per day based on mean body weight of approximately 90 kg, for 12 weeks, was associated with gastrointestinal effects (diarrhoea or constipation).

Konjac (E 425) is authorised in a wide range of foods. The Panel did not identify brand loyalty to a specific food category and therefore the Panel considered that the non‐brand‐loyal scenario covering the general population was the most appropriate and realistic scenario for risk characterisation because it is assumed that the population would probably be exposed long‐term to the food additive present at the mean reported use in processed food.

Very few reported use levels were made available to the European Food Safety Authority (EFSA). Only three food categories out of 67 were taken into account in the refined scenario. Thus the two refined exposure estimates (brand‐loyal consumer scenario and non‐brand‐loyal scenario) are similarly low (below 0.1 mg/kg bw per day in any scenario and population).

According to the conceptual framework for the risk assessment of certain food additives re‐evaluated under Commission Regulation (EU) No 257/2010 (EFSA ANS Panel, 2014) and given that:

current use of konjac (E 425) was limited in all food categories to maximum permitted level (MPL) of 10 g/kg;

an indicative refined exposure assessment has been calculated: for all population groups, it was below 0.1 mg/kg bw per day for the general population (mean and high level);

konjac gum and konjac glucomannan were unlikely to be absorbed intact and were significantly fermented by intestinal microbiota;

the available database on toxicological studies was considered limited, however no relevant adverse effects were seen in rats and dogs in 90‐day feeding studies according to the SCF, and the no‐observed‐effect level (NOEL) in rats was 1,250 mg konjac glucomannan/kg bw per day;

konjac gum and konjac glucomannan would be of no concern with respect to the genotoxicity;

after a daily dosage of 3,000 mg in adults (corresponding to 33 mg/kg bw based on mean body weight of approximately 90 kg) for 12 weeks, several individuals experienced abdominal discomfort including diarrhoea or constipation,

the Panel concluded that there was no need for a numerical ADI and that there was no safety concern for the general population at the refined exposure assessment for the reported uses of konjac gum (E 425 i) and konjac glucomannan (E 425 ii) as food additives under the current conditions of use at level of 10 g/kg.

The Panel agreed with the conclusions of the SCF (1997) that the uses of konjac (E 425), comprising konjac gum (E 425 i) and konjac glucomannan (E 425 ii), as an additive at the levels up to 10 g/kg in food are acceptable, provided that the total intake from all sources does stay below 3 g/day.

The Panel recommended that the European Commission considers harmonising the microbiological specifications for polysaccharidic thickening agents, such as gums, and to include criteria for total aerobic microbial count (TAMC) and total combined yeasts and moulds count (TYMC) into the EU specifications of konjac gum (E 425 i) and konjac glucomannan (E 425 ii).

Although the Panel realised that the exposure to these additives is rather low, the Panel recommended that the European Commission considers revising the current limits for the toxic elements (lead and arsenic) in the EU specification for konjac gum (E 425 i) and konjac glucomannan (E 425 ii).

1. Introduction

The present opinion deals with the re‐evaluation of konjac (E 425), comprising konjac gum (E 425 i) and konjac glucomannan (E 425 ii) when used as food additives.

1.1. Background and Terms of Reference as provided by the European Commission

1.1.1. Background

Regulation (EC) No 1333/20081 of the European Parliament and of the Council on food additives requires that food additives are subject to a safety evaluation by the European Food Safety Authority (EFSA) before they are permitted for use in the European Union (EU). In addition, it is foreseen that food additives must be kept under continuous observation and must be re‐evaluated by EFSA.

For this purpose, a programme for the re‐evaluation of food additives that were already permitted in the EU before 20 January 2009 has been set up under the Regulation (EU) No 257/20102. This Regulation also foresees that food additives are re‐evaluated whenever necessary in light of changing conditions of use and new scientific information. For efficiency and practical purposes, the re‐evaluation should, as far as possible, be conducted by group of food additives according to the main functional class to which they belong.

The order of priorities for the re‐evaluation of the currently approved food additives should be set on the basis of the following criteria: the time since the last evaluation of a food additive by the Scientific Committee on Food (SCF) or by EFSA, the availability of new scientific evidence, the extent of use of a food additive in food and the human exposure to the food additive taking also into account the outcome of the Report from the Commission on Dietary Food Additive Intake in the EU3 of 2001. The report ‘Food additives in Europe 20004’ submitted by the Nordic Council of Ministers to the Commission, provides additional information for the prioritisation of additives for re‐evaluation. As colours were among the first additives to be evaluated, these food additives should be re‐evaluated with a highest priority.

In 2003, the Commission already requested EFSA to start a systematic re‐evaluation of authorised food additives. However, as a result of adoption of Regulation (EU) 257/2010, the 2003 Terms of References are replaced by those below.

1.1.2. Terms of Reference

The Commission asks EFSA to re‐evaluate the safety of food additives already permitted in the Union before 2009 and to issue scientific opinions on these additives, taking especially into account the priorities, procedures and deadlines that are enshrined in the Regulation (EU) No 257/2010 of 25 March 2010 setting up a programme for the re‐evaluation of approved food additives in accordance with the Regulation (EC) No 1333/2008 of the European Parliament and of the Council on food additives.

1.1.3. Interpretation of the Terms of Reference

This re‐evaluation refers exclusively to the uses of konjac gum (E 425 i) and konjac glucomannan (E 425 ii) as food additives in food, including food supplements, and does not include a safety assessment of other uses of konjac gum and konjac glucomannan (E 425 ii) as described in Section 3.4.3.

1.2. Information on existing evaluations and authorisations

Konjac gum (E 425 i) and konjac glucomannan (E 425 ii)5 are authorised as food additives in the EU in accordance with Annex II and Annex III to Regulation (EC) No 1333/2008 on food additives and specific purity criteria have been defined in the Commission Regulation (EU) No 231/20126.

In the EU, konjac gum (E 425 i) and konjac glucomannan (E 425 ii) have been evaluated by the SCF in 1996 (SCF, 1997), who could not establish an acceptable daily intake (ADI) for both the substances. For konjac gum (E 425 i), the SCF (1997) noted ‘Adequate subchronic and long‐term feeding studies with this material are lacking and a no‐observed‐effect level cannot be derived. In addition, it has not been clarified to what extent the main component glucomannan is digested in the human intestine'. For konjac glucomannan (425 ii), the SCF noted that ‘it was tested adequately in 90‐day feeding studies with rats and beagle dogs. These studies did not reveal any relevant toxic effects and a no‐observed‐effect level of 2.5% glucomannan in the diet can be derived, corresponding to 1.25 g/kg body weight per day. However, a long‐term toxicity/carcinogenicity study is lacking and only gene mutation tests in bacteria were performed with a negative result. In addition, it has not been clarified to what extent the glucomannan is digested in the human intestine’. On the other hand, the SCF concluded, that ‘the existing data (including genotoxicity studies with konjac glucomannan (E 425 ii) as well as human experience did not give reason for concern. Konjac materials have a long history as traditional food in Far East countries. Apart from diarrhoea, abdominal pain and an effect on vitamin absorption after ingestion of high doses, no adverse effects of oral ingestion have been reported in humans’. The SCF considered therefore that ‘the uses of konjac gum (E 425 i) and konjac glucomannan (E 425 ii) as additives at the intended levels up to 1% in food are acceptable, provided that the total intake from all sources did not exceed 3 g/day. This upper limit should be taken into account when setting the conditions of use. The SCF noted that directive 95/2/EC included a footnote in relation to similar products which points out that these substances should not be used to produce dehydrated foodstuffs intended to rehydrate on ingestion’. The SCF considered that a similar remark would be applicable to konjac gum (E 425 i) and konjac glucomannan (E 425 ii).

Konjac flour (INS 425) was evaluated by the Joint FAO/WHO Expert Committee on Food Additives (JECFA) in 1993 and 1996 (JECFA, 1993, 1996). In 1993, the Committee allocated a temporary ADI ‘not specified’ for konjac flour.7 In 1996, an ADI ‘not specified’ was allocated. The evaluation was based on laboratory animal data the ‘available toxicological data from human studies, the long history of use of konjac as a food in China and Japan, and estimates of konjac flour consumption from traditional and anticipated food additive uses. The Committee stressed that its evaluation applies only to the use of konjac flour as a food additive’.

Konjac gum and konjac glucomannan have been also reviewed by the Nordic Council of Ministers (TemaNord, 2002), who concluded that for both substances there is no evidence of any toxic effect, taking into account the long history of safe use in Far Eastern countries. In the review by TemaNord, however, attention was drawn to the effects elicited by these substances on the gastrointestinal tract (diarrhoea, flatulence and slight abdominal pain) and to the fact that it would be prudent to restrict their total daily intake. For konjac gum and konjac glucomannan, the present restrictions in use should ensure that. For konjac glucomannan, the use is restricted to 10 g/kg, which should ensure compliance.

Against the background, that there have been fatal accidents, mainly in children and a few in elderly persons, in various countries inside and outside the EU, resulting from asphyxiation following the ingestion of jelly mini‐cups confectionery containing the additive E 425, the use of this additive in jelly confectionery was prohibited in the EU, by the Directive 2003/52/EC of 18 June 2003 amending Directive 95/2/EC as regards the conditions of use for a food additive E 425 konjac, because of the choking hazard.

In 2009, the EFSA Panel on Dietetic Products, Nutrition and Allergies (EFSA NDA Panel, 2009) prepared a scientific opinion on the scientific substantiation of health claims in relation to glucomannan (konjac mannan) and the maintenance of normal blood cholesterol concentrations. On the basis of the data available, the Panel concluded that ‘a cause and effect relationship has been established between the consumption of glucomannan and the reduction of blood cholesterol concentrations. In order to bear the claim, a food should provide at least 4 g/day of glucomannan in one or more servings. The target population is the general population’.

In 2010, the EFSA NDA Panel (2010) prepared another scientific opinion on the scientific substantiation of health claims in relation to glucomannan (konjac mannan) and reduction of body weight, reduction of post‐prandial glycaemic responses, maintenance of normal blood glucose concentrations, maintenance of normal (fasting) blood concentrations of triglycerides, maintenance of normal blood cholesterol concentrations, maintenance of normal bowel function and decreasing potentially pathogenic gastrointestinal microorganisms. The EFSA NDA Panel concluded that a cause and effect relationship has been established between the consumption of glucomannan and the maintenance of normal blood cholesterol concentrations and the reduction of body weight. In order to obtain the claimed effect of reduction of body weight, ‘at least 3 g of glucomannan should be consumed daily in three doses of at least 1 g each, together with 1–2 glasses of water before meals, in the context of an energy‐restricted diet. The target population is overweight adults’. A cause and effect relationship has not been established between the consumption of glucomannan and the other claimed effects.

The conditions and restrictions of use for the health claims for glucomannan (konjac mannan) to contribute to weight loss and to the maintenance of normal blood cholesterol concentrations are authorised by the Commission Regulation (EU) No 432/2012.

In 2017, the EFSA NDA Panel published a scientific opinion on an alginate‐konjac‐xanthan polysaccharide complex (PGX) in the framework of Regulation (EC) No 258/97 (EFSA NDA Panel, 2017). PGX is produced by mixing konjac glucomannan, xanthan gum and sodium alginate in a specific ratio, claimed proprietary and confidential, and then processing them by a proprietary process involving heat. Based on studies comparing different physicochemical parameters for PGX and the three individual substances, the applicant claimed that PGX is a ‘novel complex’ rather than a mixture of the three substances. The maximum daily intake of PGX from fortified foods and food supplements recommended by the applicant was 15 g/person. From a 13‐week study in Sprague–Dawley rats, which received a diet containing 0%, 1.25%, 2.5% or 5% of PGX, the EFSA NDA Panel derived a no‐observed‐adverse effect level (NOAEL) of 2.5% PGX in the diet equivalent to 1.8 g/kg body weight (bw) per day. This was based on statistically significant increases in serum activities of alanine transaminase (ALT) and aspartate transaminase (AST) in females in the high‐dose group. Considering the highest mean and 95th percentile anticipated daily intake of PGX from fortified foods, the EFSA NDA Panel derived margins of exposure (MoE) of 12 and 6. The MoE derived by the EFSA NDA Panel for PGX consumed as food supplements was 9. The EFSA NDA Panel concluded that the safety of PGX as novel food for the intended uses and use levels as proposed by the applicant has not been established.

2. Data and methodologies

2.1. Data

The EFSA Panel on Food Additives and Nutrient Sources added to Food (EFSA ANS Panel) was not provided with a newly submitted dossier. EFSA launched public calls for data,8 , 9 , 10 and, if relevant, contacted other scientific risk assessment bodies to collect relevant information from interested parties.

The Panel based its assessment on information submitted to EFSA following the public calls for data, information from previous evaluations and additional available literature up to the last Working Group meeting before the adoption of the opinion.11 Attempts were made at retrieving relevant original study reports on which previous evaluations or reviews were based, however not always these were available to the Panel.

The EFSA Comprehensive European Food Consumption Database (Comprehensive Database12) was used to estimate the dietary exposure.

The Mintel's Global New Products Database (GNPD) is an online resource listing food products and compulsory ingredient information that should be included in labelling. This database was used to verify the use of konjac gum (E 425 i) and konjac glucomannan (E 425 ii) in food products.

2.2. Methodologies

This opinion was formulated following the principles described in the EFSA Guidance on transparency in the scientific aspects of risk assessment (EFSA Scientific Committee, 2009) and following the relevant existing Guidances from the EFSA Scientific Committee.

The ANS Panel assessed the safety of konjac gum (E 425 i) and konjac glucomannan (E 425 ii) as food additives in line with the principles laid down in Regulation (EU) 257/2010 and in the relevant guidance documents: Guidance on submission for food additive evaluations by the SCF (2001) and taking into consideration the Guidance for submission for food additive evaluations in 2012 (EFSA ANS Panel, 2012).

When the test substances were administered in the feed or in the drinking water, but doses were not explicitly reported by the authors as mg/kg bw per day based on actual feed or water consumption, the daily intake was calculated by the Panel using the relevant default values as indicated in the EFSA Scientific Committee (2012) for studies in rodents or, in the case of other animal species, by JECFA (2000). In these cases, the daily intake is expressed as ‘equivalent to’. When in human studies in adults (aged above 18 years) the dose of the test substance administered was reported in mg/person per day, the dose in mg/kg bw per day was calculated by the Panel using a body weight of 70 kg as default for the adult population as described in the EFSA Scientific Committee Guidance document (EFSA Scientific Committee, 2012).

Dietary exposure to konjac gum (E 425 i) and konjac glucomannan (E 425 ii) from their use as food additives was estimated combining the food consumption data available within the EFSA Comprehensive European Food Consumption Database with the maximum permitted levels (MPLs) and/or reported use levels and analytical data submitted to EFSA following a call for data. Different exposure scenarios were calculated (see Section 3.4.1). Uncertainties on the exposure assessment were identified and discussed with regard to their impact on the final exposure calculation.

In the context of this re‐evaluation, the Panel followed the conceptual framework for the risk assessment of certain food additives re‐evaluated under Commission Regulation (EC) No 257/2010 (EFSA ANS Panel, 2014).

3. Assessment

3.1. Technical data

3.1.1. Identity of the substances

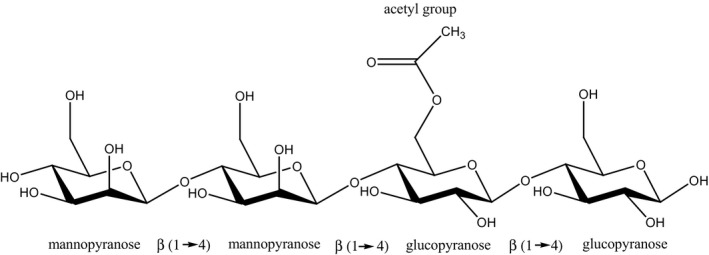

According to Commission Regulation (EU) No 231/201213, both konjac gum (E 425 i) and konjac glucomannan (E 425 ii) are defined as water‐soluble hydrocolloid obtained from konjac flour. Konjac gum is obtained by aqueous extraction, while konjac glucomannan is obtained by washing with water‐containing ethanol. In the Regulation, konjac flour is defined as the unpurified raw product from the root of the perennial plant Amorphophallus konjac. Its main component is a high‐molecular‐weight polysaccharide glucomannan which consists of d‐mannose and d‐glucose units at a molar ratio of 1.6:1.0, connected by β(1‐4)‐glycosidic bonds. Further in the definition of glucomannan from konjac gum is stated that shorter side chains are attached through β(1‐3)‐glycosidic bonds, and acetyl groups occur at random at a ratio of about 1 group per 9–19 sugar units, while in the definition of konjac glucomannan it is said that branching occur at about each 50th or 60th unit and that about each 19th sugar residue is acetylated.

The CAS registry number 37220‐17‐0 and the EINECS No 253‐404‐6 correspond to konjac mannan, a term that covers for both konjac gum and konjac glucomannan. Konjac gum (E 425 i) and konjac glucomannan (E 425 ii) are distinguished in the definition regarding the main components (≥ 75% carbohydrate vs ≥ 95% total dietary fibre on a dry weight basis) and in molecular weight.

According to Commission Regulation (EU) No 231/2012, the average molecular weight of the polysaccharide in konjac gum is in the range of 200,000–2,000,000 and in konjac glucomannan 500,000–2,000,000. The Panel noted that the indication of the molecular weight is covering a larger range down to 200,000 for konjac gum as compared to konjac glucomannan.

Concerning impurities, konjac gum and konjac glucomannan differ in the maximum permitted content of proteins (N × 5.7) (≤ 3% vs ≤ 1.5%), starch (≤ 3% vs ≤ 1.5%), inorganic substances (total ash) (≤ 5% vs ≤ 2%) and contaminants such as lead (≤ 2% vs ≤ 1%), as well as in physical properties such as solubility and viscosity in 1% solution.

The glucomannan from konjac gum and from konjac glucomannan is composed of linear chains of (1→4)‐linked mannopyranose and glucopyranose units with varying amounts of acetyl groups. The degree of acetyl groups distribution in the konjac gum is reported to be at a ratio of about 1 group per 9–19 sugar units (Takigami, 2000; Nishinari and Gao, 2007; Parry, 2010; Commission Regulation (EU) No 231/1012). The degree of acetyl groups distribution in the konjac glucomannan is reported to be lower at about 19th sugar residue (Commission Regulation (EU) No 231/1012). Regarding the konjac gum, according to Katsuraya et al. (2003) and Nishinari and Gao (2007), shorter polysaccharide side‐chains are attached to the C6 of glucosyl units of the backbone, while according to Takigami (2000) and Commission Regulation (EU) No 231/2012, branching point is at the position 3.

The structural formula of the repeating unit of konjac glucomannan is presented in Figure 1.

Figure 1.

Structural formula of the repeating unit of konjac glucomannan

According to Commission Regulation (EU) No 231/2012, konjac gum (E 425 i) is a white to cream to light tan powder, while konjac glucomannan (E 425 ii) is a white to slightly brownish fine particle size, free flowing and odourless powder. Both konjac gum and konjac glucomannan are dispersible in hot or cold water forming a highly viscous solution. Solubility increases with heat and speed of agitation. pH values of the solutions of konjac gum and glucomannan are in the ranges of 4.0–7.0 and 5.0–7.0, respectively. Depending on purity, they absorb water up to 200 times of their weight. The glucomannan forms viscous, pseudoplastic dispersions. Viscosity of 1% solutions at 35°C were estimated to be in the range between 13.5 and 18.0 mPa·s (Takigami, 2000; BeMiller, 2008; Parry, 2010). An important property of konjac gum, konjac glucomannan and konjac flour in water is the physicochemical interaction with xanthan gum, k‐carrageenan and agar causing a synergistic increase in viscosity (Tako, 1992; Akesowan, 2002; Liang et al., 2011).

The Panel noted that in cases, where konjac gum (E 425 i) and konjac glucomannan (E 425 ii) is added in combination with other gums, such as xanthan gum (E 415), agar (E 406) or carrageenan (E 407), the synergistic increase in viscosity has to be taken into consideration.

Infrared (IR), 1H‐ and 13C‐nuclear magnetic resonance (NMR) spectra of konjac glucomannan are available (Takigami, 2000; Crescenzi et al., 2002; Katsuraya et al., 2003). Ultraviolet/visual (UV/VIS) and mass spectra (MS) were not identified in the literature searches in Toxline, Medline, and SciFinder.

Synonyms for konjac glucomannan are konjac mannan or glucomannan (Merck Index, 2006). However, according to JECFA (2006), konjac flour is known under the synonyms konjac mannan, konjac, konnyaku and INS No 425 (JECFA, 2006), whereas Martindale gives konjac flour and konjak mannan as synonyms for glucomannan (Martindale, 2017). The Panel noted that the use of the terms ‘konjac glucomannan’, ‘konjac mannan’ and ‘konjac flour’ in literature is not always specific and it is ambiguous. According to the EU Regulation, konjac flour is not a synonym for the food additive konjac (E 425) comprising konjac gum (E 425 i) and konjac glucomannan (E 425 ii). In this opinion, the term used by the authors of the cited studies is used.5

The Panel noted that according to the EU specifications, konjac gum (E 425 i) and konjac glucomannan (E 425 ii) originated from the plant A. konjac, while according to the JECFA specification konjac flour may also derived from other species from Amorphophallus (see Section 3.1.2).

Upon request of the Panel for information on the particle size distribution, data were provided by industry (Documentation provided to EFSA n.9) regarding the particle size of konjac gum when used as food additive. According to the submitted results of batch analysis by laser diffraction of 100 mesh commercial konjac gum (E 425 i), samples showed a mean particle size of 102.3 μm with a standard deviation of 0.08 μm. The smallest particles detected were 6.61 μm meaning no particles were found in the 0–100 nm range. According to IFAC (Documentation provided to EFSA n.9), ‘It should be noted that when used in food applications, all konjac powder particles are dissolved into solution, making mean particle size powder data meaningless with respect to the nanoscale’.

The Panel noted that the differences between the konjac gum (E 425 i) and the konjac glucomannan (E 425 ii) are based on molecular weight distributions, different degrees of acetylation and different contents of impurity in the konjac gum, leading to different physicochemical properties. This might be due to the use of different solvents to prepare the food additives.

3.1.2. Specifications

Specifications have been defined in Commission Regulation (EU) No 231/1012 and by JECFA (2006). The available specifications are listed in Table 1.

Table 1.

Commission Regulation (EU) No 231/1012 and JECFA (2006) specifications for konjac gum (E 425 i), konjac Glucomannan (E 425 ii) and konjac Flour (INS 425)

| Commission Regulation (EU) No 231/2012 konjac gum (E 425 i) | Commission Regulation (EU) No 231/2012 konjac glucomannan (E 425 ii) | JECFA (2006) konjac Flour (INS 425) | |

|---|---|---|---|

| Definition | Konjac gum is a water‐soluble hydrocolloid obtained from the konjac flour by aqueous extraction. Konjac flour is the unpurified raw product from the root of the perennial plant Amorphophallus konjac. The main component of konjac gum is the water‐soluble high‐molecular‐weight polysaccharide glucomannan, which consists of d‐mannose and d‐glucose units at a molar ratio of 1,6:1,0, connected by β(1‐4)‐glycosidic bonds. Shorter side chains are attached through β(1‐3)‐glycosidic bonds, and acetyl groups occur at random at a ratio of about 1 group per 9–19 sugar units | Konjac glucomannan is a water‐soluble hydrocolloid obtained from konjac flour by washing with water‐containing ethanol. Konjac flour is the unpurified raw product from the tuber of the perennial plant Amorphophallus konjac. The main component is the water‐soluble high‐molecular‐weight polysaccharide glucomannan, which consists of d‐mannose and d‐glucose units at a molar ratio of 1,6:1,0, connected by β(1‐4)‐glycosidic bonds with a branch at about each 50th or 60th unit. About each 19th sugar residue is acetylated | The hydrocolloidal polysaccharide obtained from the tubers of various species of Amorphophallus; principal component is a high‐molecular‐weight, slightly branched, non‐ionic glucomannan consisting of mannose and glucose, connected by β‐1,4 linkages, at a respective molar ratio of approximately 1.6‐4:1; acetyl groups along the glucomannan back‐bone contribute to solubility properties and are located, on average, every 9–19 sugar units |

| Molecular weight | The main component, glucomannan, has an average molecular weight of 200,000–2,000,000 | 500,000–2,000,000 | The main component, glucomannan, has an average molecular weight of 200,000–2,000,000 |

| Assay | Not less than 75% carbohydrate | Total dietary fibre: not less than 95% on a dry weight basis |

Not less than 75% carbohydrate The remainder, after subtracting from 100% the sum of the percentages of total ash, loss on drying and protein, represents the percentage of carbohydrate (glucomannans) in the sample |

| Description | A white to cream to light tan powder | White to slightly brownish fine particle size, free flowing and odourless powder | White or cream to light tan powder |

| Identification | |||

| Solubility | Dispersible in hot or cold water forming a highly viscous solution with a pH between 4.0 and 7.0 | Dispersible in hot or cold water forming a highly viscous solution with a pH between 5.0 and 7.0. Solubility is increased by heat and mechanical agitation |

Dispersible in hot or cold water forming a highly viscous solution with a pH between 4.0 and 7.0 Solubility is increased by heat and mechanical agitation. Addition of mild alkali to the solution results in the formation of a heat‐stable gel that resists melting, even under extended heating conditions |

| Gel formation | Add 5 mL of a 4% sodium borate solution to a 1% solution of the sample in a test tube, and shake vigorously. A gel forms | – | Add 5 mL of a 4% sodium borate solution to a 1% solution of the sample in a test tube, and shake vigorously. A gel forms |

| Formation of heat‐stable gel | Prepare a 2% solution of the sample by heating it in a boiling water bath for 30 min, with continuous agitation and then cooling the solution to room temperature. For each gram of the sample used to prepare 30 g of the 2% solution, add 1 mL of 10% potassium carbonate solution to the fully hydrated sample at ambient temperature. Heat the mixture in a water bath to 85°C, and maintain for 2 h without agitation. Under these conditions, a thermally stable gel is formed | Prepare a 2% solution of the sample by heating it in a boiling water bath for 30 min, with continuous agitation and then cooling the solution to room temperature. For each gram of the sample used to prepare 30 g of the 2% solution, add 1 mL of 10% potassium carbonate solution to the fully hydrated sample at ambient temperature. Heat the mixture in a water bath to 85°C, and maintain for 2 h without agitation. Under these conditions a thermally stable gel is formed | Prepare a 2% solution of the sample by heating it in a boiling water bath for 30 min, with continuous agitation and then cooling the solution to room temperature. For each gram of the sample used to prepare the 2% solution, add 1 mL of 10% potassium carbonate solution to the fully hydrated sample at ambient temperature. Heat the mixture in a water bath to 85°, and maintain for 2 h without agitation. Under these conditions, a thermally stable gel is formed. Related hydrocolloids such as guar gum and locust bean gum do not form thermally stable gels and are negative by this test |

| Purity | |||

| Loss on drying | Not more than 12 % (105°C, 5 h) | Not more than 8% (105°C, 3 h) | Not more than 15% (105°, 5 h) |

| Starch | Not more than 3% | Not more than 1% | – |

| Protein | Not more than 3% (N × 5.7) |

Not more than 1.5% (N × 5.7) Determine nitrogen by the Kjeldahl method. The percentage of nitrogen in the sample multiplied by 5.7 gives the percent of protein in the sample |

Not more than 8% Proceed as directed under Nitrogen Determination (Kjeldahl method). The percentage of nitrogen in the sample multiplied by 5.7 gives the percent of protein in the sample |

| Viscosity (1% solution) | Not less than 3 kg/m·s at 25°C | Not less than 20 kg/m s at 25°C | – |

| Ether‐soluble material | Not more than 0.1% | Not more than 0.5% | – |

| Sulphite (as SO2) | – | Not more than 4 mg/kg | – |

| Chloride | – | Not more than 0.02% | – |

| 50% Alcohol‐soluble material | – | Not more than 2.0% | – |

| Total ash | Not more than 5.0% (800°C, 3–4 h) | Not more than 2.0% (800°C, 3–4 h) | Not more than 5% (800°, 3–4 h) |

| Arsenic | Not more than 3 mg/kg | – | – |

| Lead | Not more than 2 mg/kg | Not more than 1 mg/kg |

Not more than 2 mg/kg Determine using an atomic absorption technique appropriate to the specified level. The selection of sample size and method of sample preparation may be based on the principles of the method described in Volume 4, ‘Instrumental Methods’ |

| Microbiological criteria | |||

| Salmonella spp. | Absent in 12.5 g | Absent in 12.5 g | – |

| Escherichia coli | Absent in 5 g | Absent in 5 g | – |

In Commission Regulation (EU) No 231/1012, there are distinct specifications for konjac gum (E 425 i) and konjac glucomannan (E 425 ii). JECFA has one specification for konjac flour (INS 425). Konjac gum (E 425 i) and konjac glucomannan (E 425 ii) are distinguished by their grade of purity. The JECFA specification for konjac flour (INS 425) covers both EU specifications.

The Panel noted that in the definition of konjac gum the organ of origin should be named tuber instead of root.14

Because of both the botanical origin and the polysaccharidic nature of gums, they can be a substrate of microbiological contamination and of field and storage fungal development. The latter has been recently demonstrated by the mycotoxin contaminations of gums (Zhang et al., 2014). The Panel noted that the microbiological specifications for polysaccharidic thickening agents, such as gums, should be harmonised and that for konjac gum (E 425 i) and konjac glucomannan (E 425 ii) criteria for total aerobic microbial count (TAMC) and total combined yeasts and moulds count (TYMC) should be included into the EU specifications as it is the case for other polysaccharidic thickening agents (e.g. alginic acids and its salts (E 400–E 404), agar (E 406), carrageenan (E 407), processed eucheuma seaweed (E 407a), xanthan gum (E 415), gellan gum (E 418)).

In view of the botanical origin of konjac gum and konjac glucomannan, furthermore limitations of possible contamination with pesticides should be considered.

According to the EU and JECFA specifications, konjac flour and konjac gum should contain not less than 75% carbohydrate and according to EU specifications konjac glucomannan should contain not less than 95% total dietary fibre on a dry weight basis. The Panel noted that, while JECFA expressed the carbohydrate content (glucomannans) by subtracting the sum of the percentages of total ash, loss on drying and protein from 100%, no information on the method of assay for carbohydrate and total dietary fibre are provided in the EU specifications.

The Panel noted that, according to the EU specifications for konjac gum (E 425 i) and konjac glucomannan (E 425 ii), impurities of the toxic elements arsenic and lead are accepted up concentrations of 3 and 2 mg/kg, respectively. Contamination at such levels could have a significant impact on the exposure to these metals, for which the exposures already are close to the health‐based guidance values or benchmark doses (lower confidence limits) established by the EFSA (EFSA CONTAM Panel, 2009, 2010, 2012, 2014). The Panel noted that no limits for cadmium and mercury are defined in the EU specifications.

3.1.3. Manufacturing process

According to Commission Regulation (EU) No 231/1012, konjac gum (E 425 i) and konjac glucomannan (E 425 ii) are prepared from konjac flour. Konjac flour is the unpurified raw product from the root of the perennial plant A. konjac.15 In contrast, according to the JECFA (2006) specification, konjac flour (INS 425) may be produced from various species of Amorphophallus, which is a genus comprising around 150 species (Parry, 2010).

Amorphophallus is cultivated mainly in Japan and China. Two‐year‐old konjac tubers are washed, sliced into thin chips which are dried and then pulverised by dry or wet milling. The glucomannan content in commercial konjac flours is about 70–90% of the dry matter (Takigami, 2000; Parry, 2010).

According to Commission Regulation (EU) No 231/1012, konjac gum (E 425 i) is obtained from konjac flour by aqueous extraction. According to the information provided by one of the manufacturers, the flour is washed with alcohol (isopropanol or ethanol) in the manufacturing process (Documentation provided to EFSA n.2).

Konjac glucomannan (E 425 ii) is obtained from konjac flour by washing with water‐containing ethanol. By this washing procedure, microfine powders remaining on the surface and impurities trapped inside the konjac particles are removed (Takigami, 2000).

3.1.4. Methods of analysis in food

Only one analytical method for the quantification of konjac glucomannan in foods was identified in the literature search in Toxline, Medline and SciFinder. Hurley et al. (2010) developed an enzyme‐linked immunosorbent assay (ELISA) for quantification of the additive in gum mixtures and in confectionary. For the test, a polyclonal antibody obtained from sheep was used. The ELISA was found to be specific for konjac glucomannan and sensitive, with a detection limit of 0.1 mg/L.

Methods for the determination of other polysaccharide gums in food were published. Although these methods were not validated for konjac, they should also be applicable for konjac glucomannan.

Different polysaccharides (locust bean gum, guar gum, gum arabic, tragacanth, arabinogalactan, carrageenan, furcellaran, agar, xanthan) were analysed quantitatively in dairy products (Glueck and Thier, 1980). The polysaccharides are extracted from foodstuff, and then fat, starch, milk proteins and carbohydrates are removed by extraction or degradation. The resulting polysaccharide fraction is analysed by gas chromatography after hydrolysis with trifluoroacetic acid, derivatisation of the resulting monosaccharides with hydroxylamine hydrochloride and acetic acid anhydride to form the aldonitrilacetate derivatives. The polysaccharides can be qualitatively identified by their characteristic monosaccharide pattern, and quantified via the single monosaccharide peaks. In the case of konjac glucomannan, glucose and mannose should be identified as hydrolysis products. For the polysaccharides, recoveries of 80–90% were obtained when adding 0.05% of the thickeners to skim milk or 1–2% to mixtures of ice cream or pudding constituents (Glueck and Thier, 1980). In a later investigation, the analytical procedure was improved by Preuss and Thier (1983). Changes in the separation of interfering substances (fats, proteins and starch) allowed the quantitative determination of polysaccharide gums in a variety of foods like blancmange powder, glaze, fruit ice and cream cheese. Recoveries for most of the thickeners and gums are about 60–85% with a coefficient of variation of 2–8%.

For the qualitative test of gums in mayonnaise and French dressing, the AOAC Official Method 937.12 is reported by the Association of Official Agricultural Chemists (AOAC, now AOAC International) (AOAC, 2002). The gums are precipitated from the food sample, hydrolysed to monosaccharides which are qualitatively identified. This method is not applicable in presence of starch. A similar method (AOAC Official Method 935.61) for qualitative determination of gums in salad dressing based on a precipitation reaction is applicable in presence of starch (AOAC, 2002). Both methods are usable for determination of the sum of different gums used in foodstuff.

3.1.5. Stability of the substance, and reaction and fate in food

Glucomannan starts to decompose around 250°C, decomposition is complete at 350°C. Viscosity is affected at temperatures above 80°C, especially in acidic media. Konjac glucomannan is degraded by enzymes such as β‐d‐glucanase and β‐d‐mannanase; therefore, food preservative should be used to prevent fermentation by air‐borne microorganisms (Parry, 2010).

3.2. Authorised uses and use levels

Maximum levels of konjac (E 425), comprising konjac gum (E 425 i) and konjac glucomannan (E 425 ii), have been defined in Annex II to Regulation (EC) No 1333/200815 on food additives, as amended. In this document, these levels are named MPLs.

Currently, konjac gum (E 425 i) and konjac glucomannan (E 425 ii) are authorised food additives in the EU included in Group I at the MPL of 10 g/kg individually or in combination. Table 2 summarises foods that are permitted to contain konjac (E 425), comprising konjac gum (E 425 i) and konjac glucomannan (E 425 ii) and the corresponding MPLs as set by Annex II to Regulation (EC) No 1333/2008.

Table 2.

MPLs of konjac (E 425), comprising konjac gum (E 425 i) and konjac glucomannan (E 425 ii) in foods according to the Annex II to Regulation (EC) No 1333/2008

| Food category number | Food category name | Restrictions/exception | MPL (g/L or g/kg) |

|---|---|---|---|

| 01.3 | Unflavoured fermented milk products, heat‐treated after fermentation | 10 g/kg, individually or in combination | |

| 01.4 | Flavoured fermented milk products including heat treated products | 10 g/kg, individually or in combination | |

| 01.6.3 | Other creams | 10 g/kg, individually or in combination | |

| 01.7.1 | Unripened cheese excluding products falling in category 16 | Except mozzarella | 10 g/kg, individually or in combination |

| 01.7.5 | Processed cheese | 10 g/kg, individually or in combination | |

| 01.7.6 | Cheese products excluding products falling in category 16 | 10 g/kg, individually or in combination | |

| 01.8 | Dairy analogues including beverage whiteners | 10 g/kg, individually or in combination | |

| 02.2.2 | Other fat and oil emulsions including spreads as defined by Council Regulation (EC) No 1234/2007 and liquid emulsions | 10 g/kg, individually or in combination | |

| 02.3 | Vegetable oil pan spray | 10 g/kg, individually or in combination | |

| 03 | Edible ices | 10 g/kg, individually or in combination | |

| 04.2.1 | Dried fruit and vegetables | 10 g/kg, individually or in combination | |

| 04.2.2 | Fruit and vegetables in vinegar, oil, or brine | 10 g/kg, individually or in combination | |

| 04.2.4.1 | Fruit and vegetable preparations excluding compote | 10 g/kg, individually or in combination | |

| 04.2.5.4 | Nut butters and nut spreads | 10 g/kg, individually or in combination | |

| 04.2.6 | Processed potato products | 10 g/kg, individually or in combination | |

| 05.1 | Cocoa and Chocolate products as covered by Directive 2000/36/EC | Only energy‐reduced or with no added sugars | 10 g/kg, individually or in combination |

| 05.2 | Other confectionery including breath freshening microsweets |

May not be used in jelly mini‐cups, defined, for the purpose of this Regulation, as jelly confectionery of a firm consistence, contained in semi rigid mini‐cups or mini‐ capsules, intended to be ingested in a single bite by exerting pressure on the mini‐ cups or mini‐capsule to project the confectionery into the mouth E 425 may not be used in jelly confectionery |

10 g/kg, individually or in combination |

| 05.3 | Chewing gum | 10 g/kg, individually or in combination | |

| 05.4 | Decorations, coatings and fillings, except fruit‐based fillings covered by category 4.2.4 | 10 g/kg, individually or in combination | |

| 06.2.2 | Starches | 10 g/kg, individually or in combination | |

| 06.3 | Breakfast cereals | 10 g/kg, individually or in combination | |

| 06.4.2 | Dry pasta | Only gluten free and/or pasta intended for hypoproteic diets in accordence with Directive 2009/39/EC | 10 g/kg, individually or in combination |

| 06.4.4 | Potato gnocchi | Except fresh refrigerated potato gnocchi | 10 g/kg, individually or in combination |

| 06.4.5 | Fillings of stuffed pasta (ravioli and similar) | 10 g/kg, individually or in combination | |

| 06.5 | Noodles | 10 g/kg, individually or in combination | |

| 06.6 | Batters | 10 g/kg, individually or in combination | |

| 06.7 | Pre‐cooked or processed cereals | 10 g/kg, individually or in combination | |

| 07.1 | Bread and rolls | except products in 7.1.1 and 7.1.2 | 10 g/kg, individually or in combination |

| 07.2 | Fine bakery wares | 10 g/kg, individually or in combination | |

| 08.3.1 | Non‐heat treated processed meat | 10 g/kg, individually or in combination | |

| 08.3.2 | Heat‐treated processed meat | Except foie gras, foie gras entier, blocs de foie gras, Libamáj, libamáj egészben, libamáj tömbben | 10 g/kg, individually or in combination |

| 08.3.3 | Casings and coatings and decorations for meat | 10 g/kg, individually or in combination | |

| 09.2 | Processed fish and fishery products including molluscs and crustaceans | 10 g/kg, individually or in combination | |

| 09.3 | Fish roe | Only processed fish roe | 10 g/kg, individually or in combination |

| 10.2 | Processed eggs and egg products | 10 g/kg, individually or in combination | |

| 11.2 | Other sugars and syrups | 10 g/kg, individually or in combination | |

| 12.1.2 | Salt substitutes | 10 g/kg, individually or in combination | |

| 12.2.2 | Seasonings and condiments | 10 g/kg, individually or in combination | |

| 12.3 | Vinegars | 10 g/kg, individually or in combination | |

| 12.4 | Mustard | 10 g/kg, individually or in combination | |

| 12.5 | Soups and broths | 10 g/kg, individually or in combination | |

| 12.6 | Sauces | 10 g/kg, individually or in combination | |

| 12.7 | Salads and savoury‐based sandwich spreads | 10 g/kg, individually or in combination | |

| 12.8 | Yeast and yeast products | 10 g/kg, individually or in combination | |

| 12.9 | Protein products excluding products covered in category 1.8 | 10 g/kg, individually or in combination | |

| 13.2 | Dietary foods for special medical purposes defined in Directive 1999/21/EC (excluding products from food category 13.1.5) | 10 g/kg, individually or in combination | |

| 13.3 | Dietary foods for weight control diets intended to replace total daily food intake or an individual meal (the whole or part of the total daily diet) | 10 g/kg, individually or in combination | |

| 13.4 | Foods suitable for people intolerant to gluten as defined by Regulation (EC) No 41/2009 | Including dry pasta | 10 g/kg, individually or in combination |

| 14.1.2 | Fruit juices as defined by Directive 2001/112/EC and vegetable juices | Only vegetable juices | 10 g/kg, individually or in combination |

| 14.1.3 | Fruit nectars as defined by Directive 2001/112/EC and vegetable nectars and similar products | Only vegetable nectars | 10 g/kg, individually or in combination |

| 14.1.4 | Flavoured drinks | 10 g/kg, individually or in combination | |

| 14.1.5.2 | Other | Excluding unflavoured leaf tea; including flavoured instant coffee | 10 g/kg, individually or in combination |

| 14.2.3 | Cider and perry | 10 g/kg, individually or in combination | |

| 14.2.4 | Fruit wine and made wine | 10 g/kg, individually or in combination | |

| 14.2.5 | Mead | 10 g/kg, individually or in combination | |

| 14.2.6 | Spirit drinks as defined in Regulation (EC) No 110/2008 | Except whisky or whiskey | 10 g/kg, individually or in combination |

| 14.2.7.1 | Aromatised wines | 10 g/kg, individually or in combination | |

| 14.2.7.2 | Aromatised wine‐based drinks | 10 g/kg, individually or in combination | |

| 14.2.7.3 | Aromatised wine‐product cocktails | 10 g/kg, individually or in combination | |

| 14.2.8 | Other alcoholic drinks including mixtures of alcoholic drinks with non‐alcoholic drinks and spirits with less than 15% of alcohol and | 10 g/kg, individually or in combination | |

| 15.1 | Potato‐, cereal‐, flour‐ or starch‐based snacks | 10 g/kg, individually or in combination | |

| 15.2 | Processed nuts | 10 g/kg, individually or in combination | |

| 16 | Desserts excluding products covered in category 1, 3 and 4 | 10 g/kg, individually or in combination | |

| 17.1a | Food supplements supplied in a solid form including capsules and tablets and similar forms, excluding chewable forms | 10 g/kg, individually or in combination | |

| 17.2a | Food supplements supplied in a liquid form | 10 g/kg, individually or in combination | |

| 17.3a | Food supplements supplied in a syrup‐type or chewable form | 10 g/kg, individually or in combination | |

| 18 | Processed foods not covered by categories 1–17 excluding foods for infants and young children | 10 g/kg, individually or in combination |

MPL: maximum permitted level.

FCS 17 refers to food supplements as defined in Directive 2002/46/EC of the European Parliament and of the Council excluding food supplements for infants and young children.

According to Annex III, Part 1 of Regulation (EC) No 1333/2008, konjac (E 425) is authorised as a carrier in all food additives at quantum satis (QS).

According to Annex III, Part 4 of Regulation (EC) No 1333/2008, konjac (E 425) is authorised as a food additive including as a carrier in all flavourings at QS.

The Regulation (EC) No 1333/2008 stipulates that konjac (E 425), comprising konjac gum (E 425 i) and konjac glucomannan (E 425 ii), as a food additive, belonging to group I, is not authorised for the uses to produce dehydrated foods intended to rehydrate on ingestion, in jelly mini‐cups and in jelly confectionery.

The Panel noted that these restrictions have to be seen against the background of human cases of fatal accidents, resulting from asphyxiation following the ingestion of jelly mini‐cups confectionery containing the additive (EFSA, 2004) and of severe adverse effects, such as oesophageal obstruction after oral intake of the additive in the form of tablets without enough liquid (Fung, 1984; Henry et al., 1986; Vanderbeek et al., 2007).

3.3. Exposure data

3.3.1. Reported use levels or data on analytical levels of konjac gum (E 425 i) and konjac glucomannan (E 425 ii)

Most food additives in the EU are authorised at a specific MPL. However, a food additive may be used at a lower level than the MPL. Therefore, information on actual use levels is required for performing a more realistic exposure assessment, especially for those food additives for which no MPL is set and which are authorised according to QS.

In the framework of Regulation (EC) No 1333/2008 on food additives and of Commission Regulation (EU) No 257/2010 regarding the re‐evaluation of approved food additives, EFSA issued public calls,16 , 17 for occurrence data (usage level and/or concentration data) on konjac gum (E 425 i) and konjac glucomannan (E 425 ii). In response to this public call, updated information on the actual use levels of konjac gum (E 425 i) and konjac glucomannan (E 425 ii) in foods was made available to EFSA by industry. No analytical data on the concentration of konjac gum (E 425 i) and konjac glucomannan (E 425 ii) in foods were made available by the Member States.

3.3.1.1. Summarised data on reported use levels in foods provided by industry

Industry provided EFSA with data on use levels (n = 85) of konjac (E 425) in foods for 44 out of the 67 food categories in which konjac (E 425) is authorised.

Updated information on the actual use levels of konjac (E 425) in foods was made available to EFSA by Association for International Promotion of Gums (AIPG, Documentation provided to EFSA n.4), EUROGUM A/S (Documentation provided to EFSA n.6), Fabricante Embutidos del centro SA (España) (EMCESA, Documentation provided to EFSA n.7), FoodDrinkEurope (FDE, Documentation provided to EFSA n.3) and International Food Additives Council (IFAC, Documentation provided to EFSA n.5).

The Panel noted that some data providers (e.g. AIPG, Eurogums A/S, IFAC) are not food industry using gums in their food products but food additive producers. Usage levels reported by food additive producers are not considered at the same level as those provided by food industry. The ANS Panel considered that food additive producers might recommend usage levels to the food industry but the final levels might, ultimately, be different. Therefore, unless food additive producers confirm that the recommended levels are used by food industry, they are not considered in the refined exposure scenario.

For instance, for Eurogum A/S (Documentation provided to EFSA n.6), ‘all the submitted data are theoretical amounts suggested or recommended’; they are ‘based on their own technical know‐how regarding adequate/recommended levels of use in different food applications’. Eurogums A/S provided three identical levels on meat products. These levels were not considered in the current estimates (Documentation provided to EFSA n.6).

Appendix A provides data on the use levels of konjac (E 425) in foods as reported by industry.

3.3.2. Summarised data extracted from the Mintel's Global New Products Database

The Mintel's GNPD is an online database which monitors product introductions in consumer packaged goods markets worldwide. It contains information of over 2 million food and beverage products of which more than 900,000 are or have been available on the European food market. Mintel started covering EU's food markets in 1996, currently having 20 out of its 28 member countries and Norway presented in the Mintel GNPD.18

For the purpose of this Scientific Opinion, the Mintel GNPD19 was used for checking the labelling of products containing konjac gum (E 425 i) and konjac glucomannan (E 425 ii) within the EU's food products as the Mintel GNPD shows the compulsory ingredient information presented in the labelling of products.

According to Mintel, konjac gum (E 425 i) and konjac glucomannan (E 425 ii) is labelled on around 300 products of pastas, noodles, prepared meals, meat products. Around 250 products were found to be published in this database between 2012 and 201721 out of which few drinks (n = 11). Some of the foods ingredients mention ‘konjac flour’ without referring to any food additive characteristics (e.g. E‐number or function in food such as a gelling agent).

Appendix B presents the percentage of the food products labelled with konjac (E 425) between 2012 and 2017, out of the total number of food products per food subcategories according to the Mintel food classification.

3.3.3. Food consumption data used for exposure assessment

3.3.3.1. EFSA Comprehensive European Food Consumption Database

Since 2010, the EFSA Comprehensive European Food Consumption Database (Comprehensive Database) has been populated with national data on food consumption at a detailed level. Competent authorities in the European countries provide EFSA with data on the level of food consumption by the individual consumer from the most recent national dietary survey in their country (cf. Guidance of EFSA on the ‘Use of the EFSA Comprehensive European Food Consumption Database in Exposure Assessment’ (EFSA, 2011a). New consumption surveys recently20 added in the Comprehensive database were also taken into account in this assessment.12

The food consumption data gathered by EFSA were collected by different methodologies and thus direct country‐to‐country comparisons should be interpreted with caution. Depending on the food category and the level of detail used for exposure calculations, uncertainties could be introduced owing to possible subjects’ underreporting and/or misreporting of the consumption amounts. Nevertheless, the EFSA Comprehensive Database represents the best available source of food consumption data across Europe at present.

Food consumption data from the following population groups: infants, toddlers, children, adolescents, adults and the elderly were used for the exposure assessment. For the present assessment, food consumption data were available from 33 different dietary surveys carried out in 19 European countries (Table 3).

Table 3.

Population groups considered for the exposure estimates of konjac gum (E 425 i) and konjac glucomannan (E 425 ii)

| Population | Age range | Countries with food consumption surveys covering more than 1 day |

|---|---|---|

| Infants | From more than 12 weeks up to and including 11 months of age | Bulgaria, Denmark, Finland, Germany, Italy, UK |

| Toddlers | From 12 months up to and including 35 months of age | Belgium, Bulgaria, Denmark, Finland, Germany, Italy, Netherlands, Spain, UK |

| Childrena | From 36 months up to and including 9 years of age | Austria, Belgium, Bulgaria, Czech Republic, Denmark, Finland, France, Germany, Greece, Italy, Latvia, Netherlands, Spain, Sweden, UK |

| Adolescents | From 10 years up to and including 17 years of age | Austria, Belgium, Cyprus, Czech Republic, Denmark, Finland, France, Germany, Italy, Latvia, Spain, Sweden, UK |

| Adults | From 18 years up to and including 64 years of age | Austria, Belgium, Czech Republic, Denmark, Finland, France, Germany, Hungary, Ireland, Italy, Latvia, Netherlands, Romania, Spain, Sweden, UK |

| The elderlya | From 65 years of age and older | Austria, Belgium, Denmark, Finland, France, Germany, Hungary, Ireland, Italy, Romania, Sweden, UK |

The terms ‘children’ and ‘the elderly’ correspond, respectively, to ‘other children’ and the merge of ‘elderly’ and ‘very elderly’ in the Guidance of EFSA on the ‘Use of the EFSA Comprehensive European Food Consumption Database in Exposure Assessment’ (EFSA, 2011a).

Consumption records were codified according to the FoodEx classification system (EFSA, 2011b). Nomenclature from the FoodEx classification system has been linked to the Food Classification System (FCS) as presented in Annex II of Regulation (EC) No 1333/2008, part D, to perform exposure estimates. In practice, FoodEx food codes were matched to the FCS food categories.

3.3.3.2. Food categories selected for the exposure assessment of konjac gum (E 425 i) and konjac glucomannan (E 425 ii)

The food categories in which the use of konjac gum (E 425 i) and konjac glucomannan (E 425 ii) is authorised were selected from the nomenclature of the EFSA Comprehensive Database (FoodEx classification system), at the most detailed level possible (up to FoodEx Level 4) (EFSA, 2011b).

Some food categories are not referenced in the EFSA Comprehensive Database and could therefore not be taken into account in the present estimate. This was the case for nine food categories and may result in an underestimation of the exposure. The food categories which were not taken into account are described below (in ascending order of the FCS codes):

06.4.4 Gnocchi;

06.6 Noodles;

06.7 Pre‐cooked or processed cereals;

08.3.3 Casings and coatings and decorations for meat;

12.1.1 Salt substitutes;

13.2 Dietary foods for special medical purposes defined in Directive 1999/21/EC (excluding products from food category 13.1.5);

13.3 Dietary foods for weight control diets intended to replace total daily food intake or an individual meal (the whole or part of the total daily diet);

13.4 Foods suitable for people intolerant to gluten as defined by Regulation (EC) No 41/2009;

14.1.3 Fruit nectars as defined by Directive 2001/112/EC and vegetable nectars and similar products, only vegetable nectars.

The following food subcategories cannot be differentiated from the whole food category and therefore the whole food category was considered in the exposure assessment. This applies to two food categories (Appendix D) and may result in an overestimation of the exposure:

01.6.3 Other creams

17.1/17.2/17.3 Food supplements, in solid, liquid, syrup‐type or chewable form.

For the remaining food categories, the refinements considering the restrictions/exceptions as set in Annex II to Regulation No 1333/2008 were applied. Overall, for the regulatory maximum level exposure scenario, nine food categories were not taken into account because no consumption data are available, thus 58 food categories were included. For the refined exposure assessment scenario, only three food categories were taken into account because either no concentration data were provided to EFSA either the data provided were from food additives producers. (Appendix B).

3.4. Exposure estimates

3.4.1. Exposure to konjac gum (E 425 i) and konjac glucomannan (E 425 ii) from their use as food additives

The Panel estimated chronic exposure for the following population groups: infants; toddlers, children, adolescents, adults and the elderly. Dietary exposure to konjac (E 425) was calculated by multiplying konjac (E 425) concentrations for each food category (Appendix C) with their respective consumption amount per kilogram of body weight for each individual in the Comprehensive Database. The exposure per food category was subsequently added to derive an individual total exposure per day. These exposure estimates were averaged over the number of survey days, resulting in an individual average exposure per day for the survey period. Dietary surveys with only one day per subject were excluded as they are considered as not adequate to assess repeated exposure.

This was carried out for all individuals per survey and per population group, resulting in distributions of individual exposure per survey and population group (Table 3). Based on these distributions, the mean and 95th percentile of exposure were calculated per survey for the total population and per population group. High percentile exposure was only calculated for those population groups where the sample size was sufficiently large to allow calculation of the 95th percentile of exposure (EFSA, 2011a). Therefore, in the present assessment, high levels of exposure for infants from Italy and for toddlers from Belgium, Italy and Spain were not included.

Exposure assessment to konjac (E 425) was carried out by the ANS Panel based on: (1) MPLs as set down in the EU legislation (defined as the regulatory maximum level exposure assessment scenario); and (2) reported use levels (defined as the refined exposure assessment scenario). These two scenarios are discussed in detail below.

These scenarios do not consider the consumption of food supplements (FC 17.1, FC 17.2 and FC 17.3) which are covered in an additional specific exposure scenario detailed below (food supplements consumers only scenario).

Certain foods for special medical purposes (FSMP) consumed in population groups of children, adolescents, adults and the elderly may be very diverse; they cannot be considered because of very limited information on consumption. Eating occasions belonging to the food categories 13.2, 13.3 and 13.4 were therefore reclassified under food categories in accordance to their main component.

Considering that the food category 18 (Processed foods not covered by categories 1 to 17, excluding foods for infants and young children) is extremely unspecific (e.g. composite foods), processed foods, prepared or composite dishes belonging to the food category 18 were reclassified under food categories in accordance to their main component. Therefore, FC 18 is not taken into account as contributor to the total exposure estimates.

3.4.1.1. Regulatory maximum level exposure assessment scenario

The regulatory maximum level exposure assessment scenario is based on the MPLs as set in Annex II to Regulation (EC) No 1333/2008 and listed in Table 2.

A possible additional exposure from the use of konjac (E 425) as a food additive in food flavourings in accordance with Annex III to Regulation (EC) No 1333/2008 (Part 4) was not considered in the regulatory maximum level exposure assessment scenario. Despite this, the Panel considers the exposure estimates derived following this scenario as the most conservative as it is assumed that the population group will be exposed to konjac (E 425) present in food at MPL over a longer period of time.

3.4.1.2. Refined exposure assessment scenario

The refined exposure assessment scenario is based on use levels reported by industry. This exposure scenario can consider only food categories for which the above data were available to the Panel.

Appendix C summarises the concentration levels of konjac (E 425) used in the refined exposure assessment scenario. Based on the available data set, the Panel calculated two refined exposure estimates based on different model populations:

-

The brand‐loyal consumer scenario: It was assumed that a consumer is exposed long term to konjac (E 425) present at the maximum reported use level for one food category. This exposure estimate is calculated as follows:

-

1

— Combining food consumption with the maximum of the reported use levels for the main contributing food category at the individual level.

-

2

— Using the mean of the typical reported use levels for the remaining food categories.

-

1

The non‐brand‐loyal consumer scenario: It was assumed that a consumer is exposed long term to konjac (E 425) present at the mean reported use level in food. This exposure estimate is calculated using the mean of the typical reported use levels for all food categories.

3.4.1.3. Specific exposure assessment scenario

-

‘Food supplement consumers only’ scenario: Konjac (E 425) is authorised in the food categories 17.1, 17.2 and 17.3 Food supplements as defined in Directive 2002/46/EC excluding food supplements for infants and young children. As exposure via food supplements may deviate largely from the one via food, and that the number of food supplement consumers may be low depending on populations and surveys, an additional scenario was calculated in order to reflect additional exposure to food additives from food supplements compared to exposure to food additives excluding these sources. This scenario will be estimated as follow:

-

1

— Consumers only of food supplements will be assumed to be exposed to a food additive present at the MPL on a daily basis via consumption of food supplements (as no data from food industry are available for food supplements).

-

2

— For the remaining food categories (3/67 categories), the mean of the typical reported use levels is used.

-

1

As food categories 17.1, 17.2 and 17.3 do not consider food supplements for infants and toddlers as defined in the legislation, exposure to konjac (E 425) from food supplements are not estimated for these two population groups.

3.4.1.4. Dietary exposure to konjac (E 425)

Table 4 summarises the estimated exposure to konjac (E 425) from their use as food additives in six population groups (Table 3) according to the different exposure scenario's (Section 3.4.1). Detailed results per population group and survey are presented in Appendix D.

Table 4.

Summary of anticipated exposure to konjac (E 425) from their use as food additives in the maximum level exposure assessment scenario and in the refined exposure scenarios, in six population groups (minimum–maximum across the dietary surveys in mg/kg bw per day)

| Infants (12 weeks–11 months) | Toddlers (12–35 months) | Children (3–9 years) | Adolescents (10–17 years) | Adults (18–64 years) | The elderly (≥ 65 years) | |

|---|---|---|---|---|---|---|

| Regulatory maximum level exposure assessment scenario | ||||||

| Mean | 40.7–244.6 | 122.6–521.6 | 116.8–412.5 | 76.2–280.8 | 47.8–193.6 | 42.1–170.5 |

| 95th percentile | 95.3–793.3 | 299.7–842.1 | 241.7–705.5 | 153.0–477.9 | 105.2–375.9 | 90.9–299.5 |

| Refined estimated exposure assessment scenario | ||||||

| Brand‐loyal scenario | ||||||

| Mean | 0.001–0.007 | 0.006–0.030 | 0.009–0.034 | 0.004–0.022 | 0.004–0.014 | 0.003–0.011 |

| 95th percentile | 0.006–0.028 | 0.024–0.059 | 0.025–0.064 | 0.013–0.048 | 0.011–0.031 | 0.009–0.023 |

| Non‐brand‐loyal scenario | ||||||

| Mean | < 0.001–0.004 | 0.003–0.015 | 0.005–0.033 | 0.002–0.022 | 0.002–0.008 | 0.002–0.006 |

| 95th percentile | 0.003–0.015 | 0.013–0.044 | 0.013–0.063 | 0.007–0.048 | 0.006–0.024 | 0.005–0.016 |

From the regulatory maximum level exposure assessment scenario, mean exposure konjac (E 425) from its use as a food additive ranged from 40.7 mg/kg bw per day in infants to 521.6 mg/kg bw per day in toddlers. The 95th percentile of exposure to konjac (E 425) ranged from 90.9 mg/kg bw per day for the elderly to 842.1 mg/kg bw per day in toddlers.

From the refined estimated exposure, in both the brand‐loyal and non‐brand‐loyal scenario, mean and high exposure to konjac (E 425) from its use as a food additive was below 0.1 mg/kg bw per day.

For the food supplements consumers only, in the regulatory maximum level exposure assessment scenario, mean exposure to konjac (E 425) from its use as a food additive ranged from 0.002 mg/kg bw per day for the elderly to 0.033 mg/kg bw per day for children. The 95th percentile of exposure ranged from 0.007 for the elderly mg/kg bw/day to 0.064 mg/kg bw per day for children.

3.4.1.5. Main food categories contributing to exposure to konjac (E 425) using the maximum level exposure assessment scenario

From the regulatory maximum level exposure assessment scenario, the main contributing food categories to the total mean exposure estimates for infants and toddlers were flavoured fermented milk products. For children and adolescents, the main contributing food categories were flavoured drinks, while, for adults, the main contributing food categories were bread and rolls and flavoured drinks and for the elderly, coffee, tea, herbal and fruit infusions, chicory and flavoured drinks (see Appendix E for more details).

3.4.1.6. Main food categories contributing to exposure to konjac (E 425) using the refined exposure assessment scenario

The main contributing food category from the refined estimated exposure scenario, brand‐loyal and non‐brand‐loyal scenario were meat products, this is due to the low number of data available for the food categories (see Appendix E for more details). The second food category was yeast and yeast products.

Appendix E can be found in the online version of this output (‘Supporting information’ section): https://doi.org/10.2903/j.efsa.2017.4864.

3.4.1.7. Uncertainty analysis

Uncertainties in the exposure assessment of konjac (E 425) have been discussed above. In accordance with the guidance provided in the EFSA opinion related to uncertainties in dietary exposure assessment (EFSA, 2007), the following sources of uncertainties have been considered and summarised in Table 5.

Table 5.

Qualitative evaluation of influence of uncertainties on the dietary exposure estimate

| Sources of uncertainties | Directiona |

|---|---|

| Consumption data: different methodologies/representativeness/underreporting/misreporting/no portion size standard | +/– |

| Use of data from food consumption survey of a few days to estimate long‐term (chronic) exposure for high percentiles (95th percentile) | + |

| Correspondence of reported use levels and analytical data to the food items in the EFSA Comprehensive Food Consumption Database: uncertainties to which types of food the levels refer to | +/– |

| Uncertainty in possible national differences in use levels of food categories | +/– |

| Food categories selected for the exposure assessment: exclusion of food categories due to missing FoodEx linkage (n = 9/67 food categories) | – |

| Food categories selected for the exposure assessment: inclusion of food categories without considering the restriction/exception (n = 2/67 food categories) | + |

| The 3 food categories which were taken into account in the refined exposure assessment scenarios out of all authorised food categories (n = 67), corresponded to only 0.5 and 17% of the amount (g of foods by body weight) of food consumption documented in the EFSA Consumption Database | – |

| Food categories included in the exposure assessment: data not available for certain food categories which were excluded from the exposure estimates (only 3 food categories with available data) | – |

Regulatory maximum level exposure assessment scenario:

|

+ – – |

Refined exposure assessment scenarios:

|

+/– – – |

+, uncertainty with potential to cause over‐estimation of exposure; –, uncertainty with potential to cause underestimation of exposure.